Experimental Investigation of Wavy-Lap Bonds with Natural Cotton Fabric Reinforcement under Cyclic Loading

Abstract

:1. Introduction

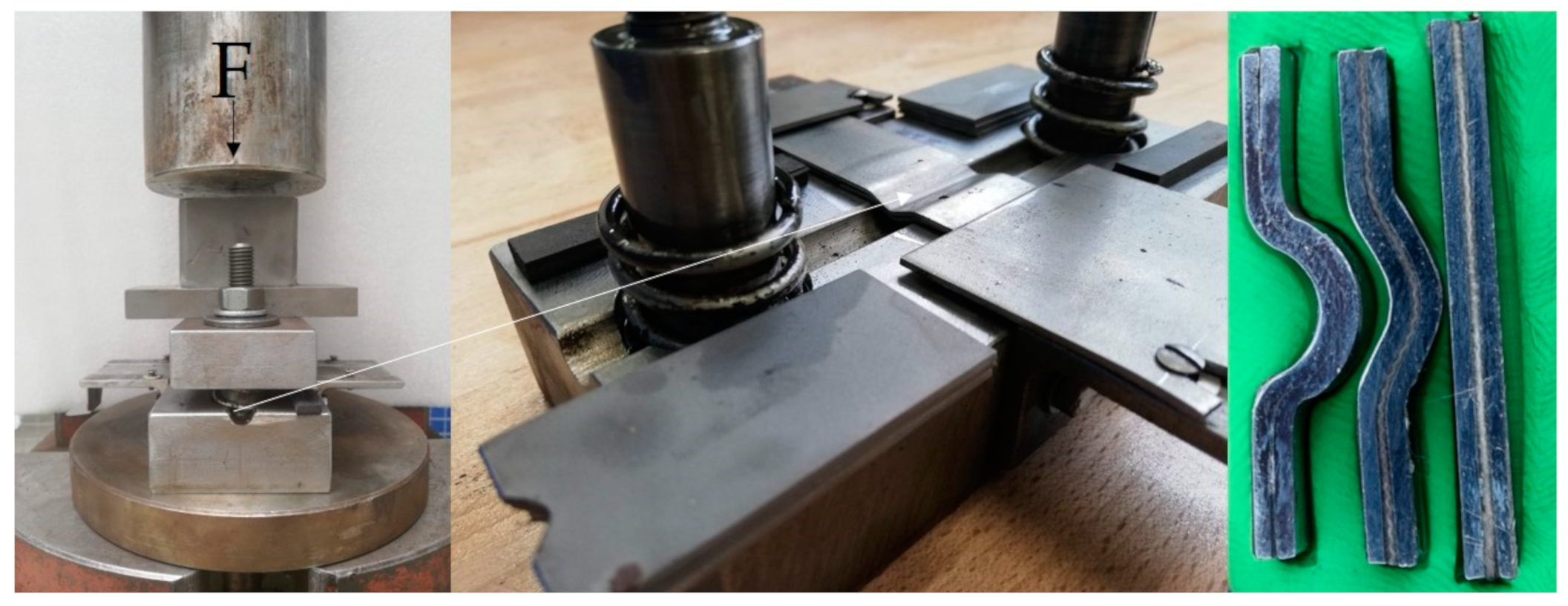

2. Materials and Methods

2.1. Materials

2.1.1. Bonded Material (Adherend)

2.1.2. Matrix and Reinforcement

- Soaking the fabrics in hot water (100 °C) for removal of starch;

- Rinsing with cold water for removal of residual impurity;

- Soaking the fabrics in 10% NaOH solution for 30 min. Distilled water was used to create the solution;

- Repeated washing of the alkali-treated fabrics with cold water;

- Drying the fabric in a laboratory oven at 105 °C temperature for 24 h [51].

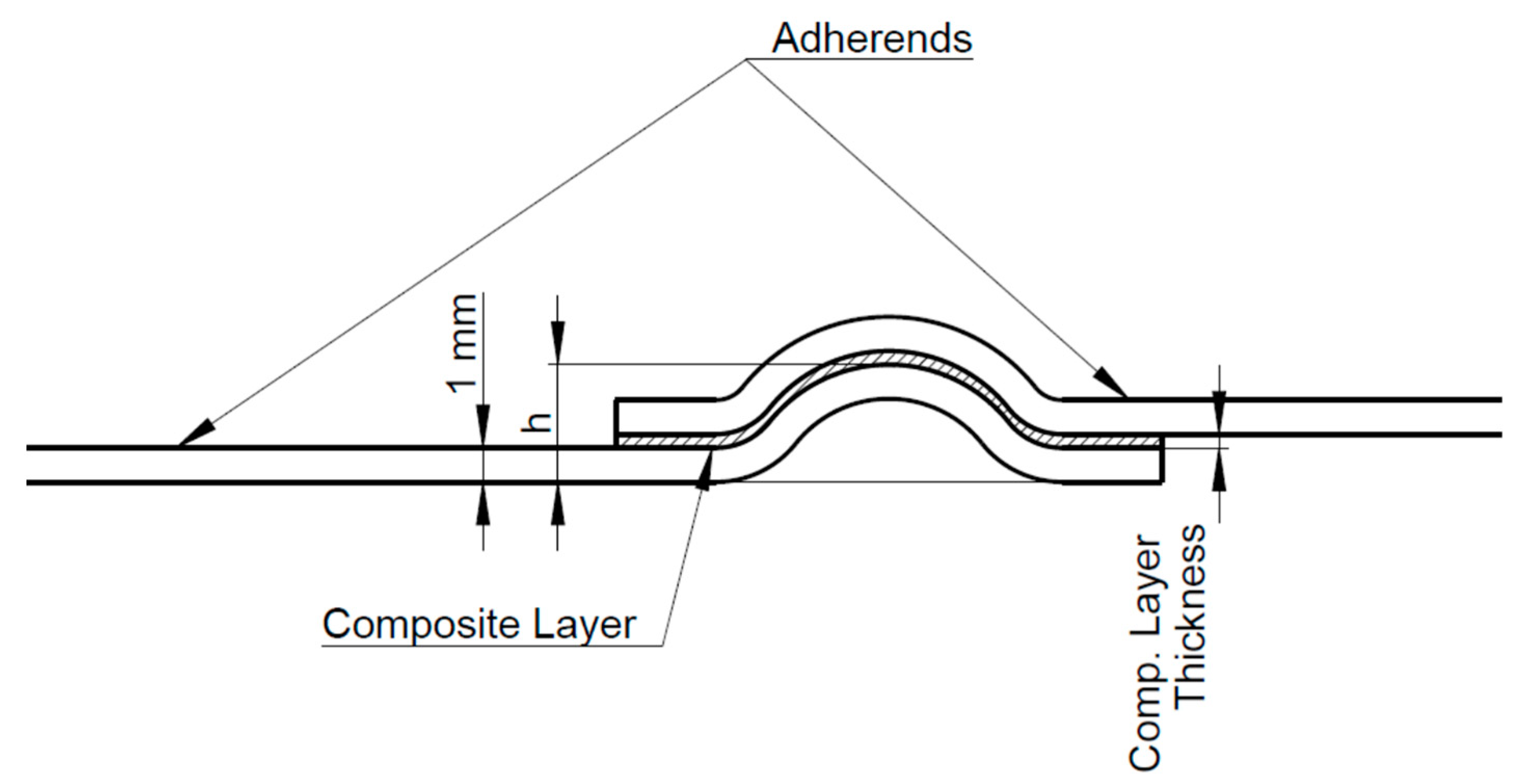

2.1.3. Preparation of Adhesive Bonds

2.2. Methods

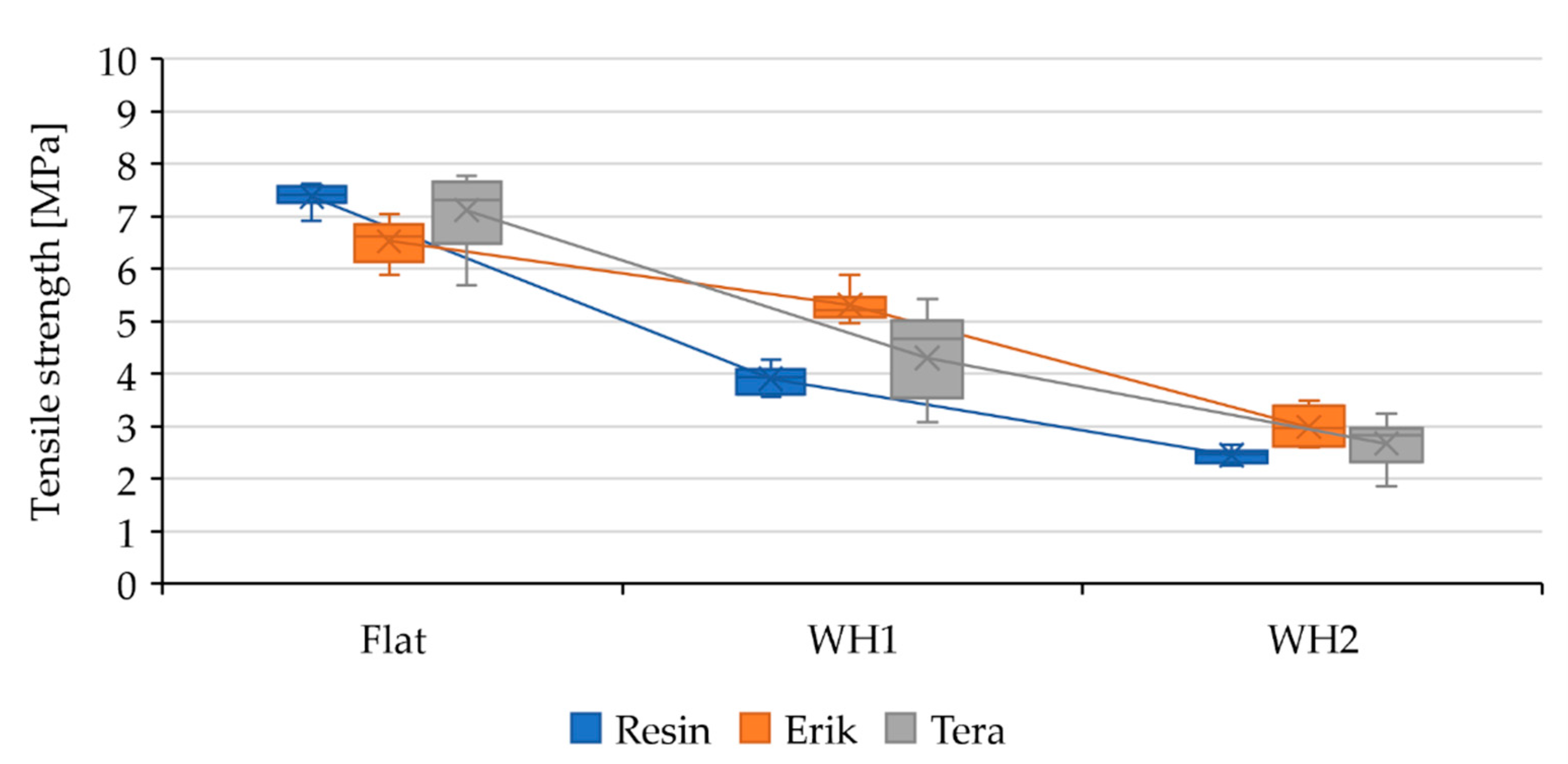

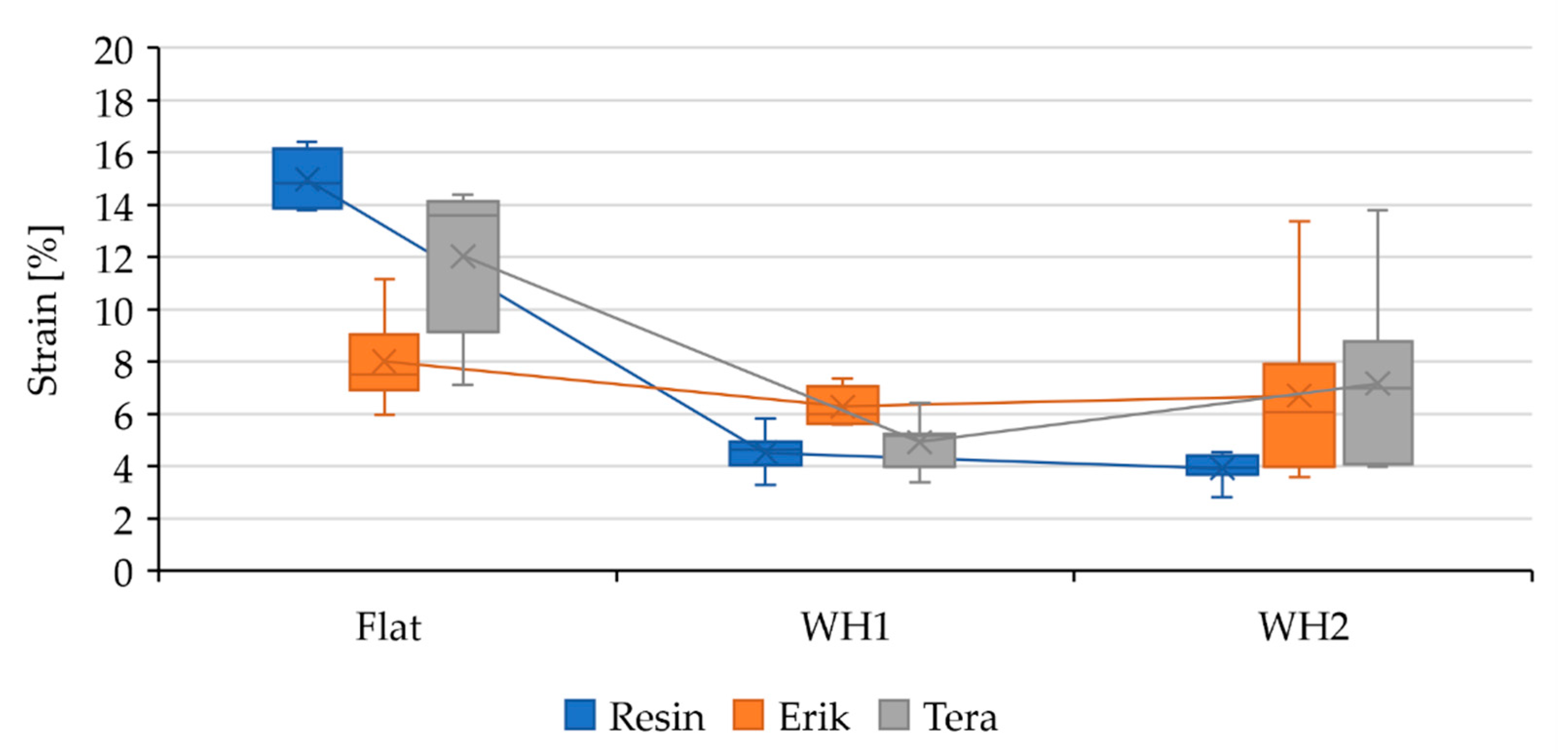

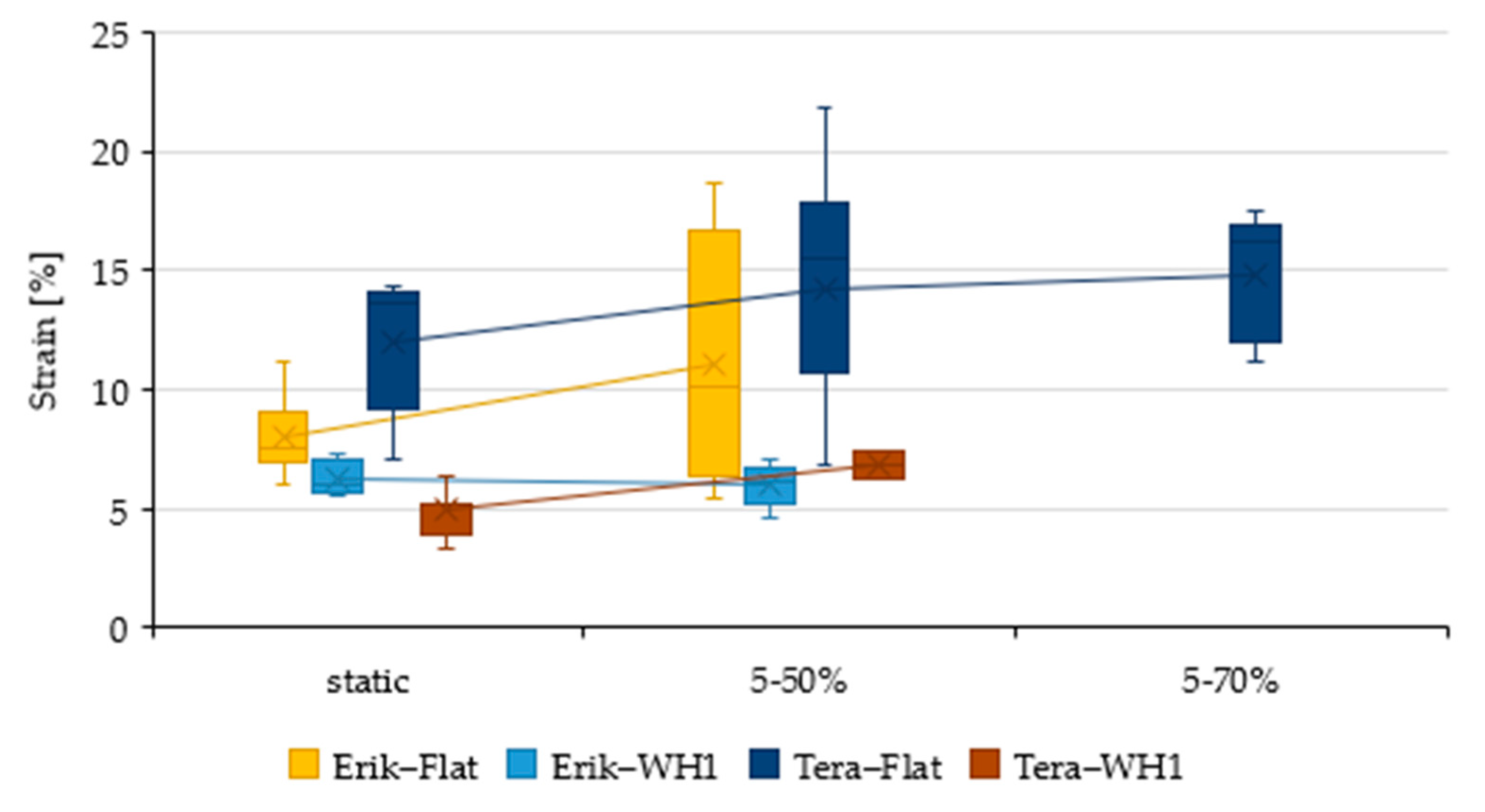

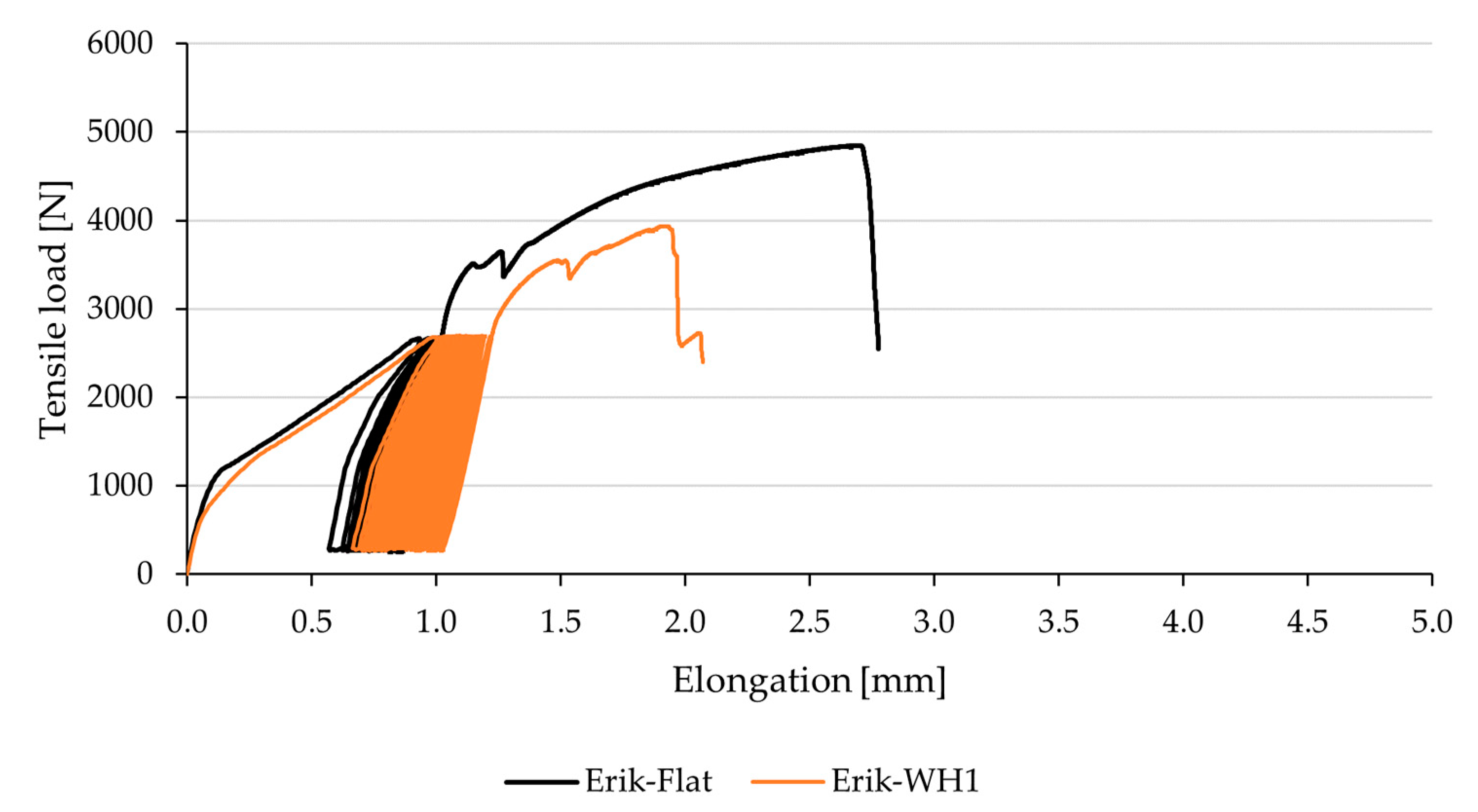

3. Results and Discussion

4. Conclusions

- Wave-shaped bonds WH1 and WH2 reduced the overall strength of the resin under static tests. For Resin-WH1, the strength decreased by 47% to 3.91 ± 0.23 MPa. For Resin-WH2, the strength decreased by 67% to 2.45 ± 0.13 MPa. Resin-Flat, WH1, and WH2 failed the cyclic tests.

- The reinforcing fabric has a positive effect on the mechanical performance of the adhesive bonds. The reinforcing fabrics Erik and Tera did not increase the overall strength of the bond but positively reduced the deformation of the bond and thus increased the elastic modulus and service life of the adhesive bonds under cyclic loading. Erik-Flat and Erik-WH1 passed the 5–50% (267–2674 N) cyclic tests. Tera-Flat and WH1 also passed the 5–50% (267–2674 N) cyclic test. Tera-Flat further passed the 5–70% (267–3743 N) cyclic test.

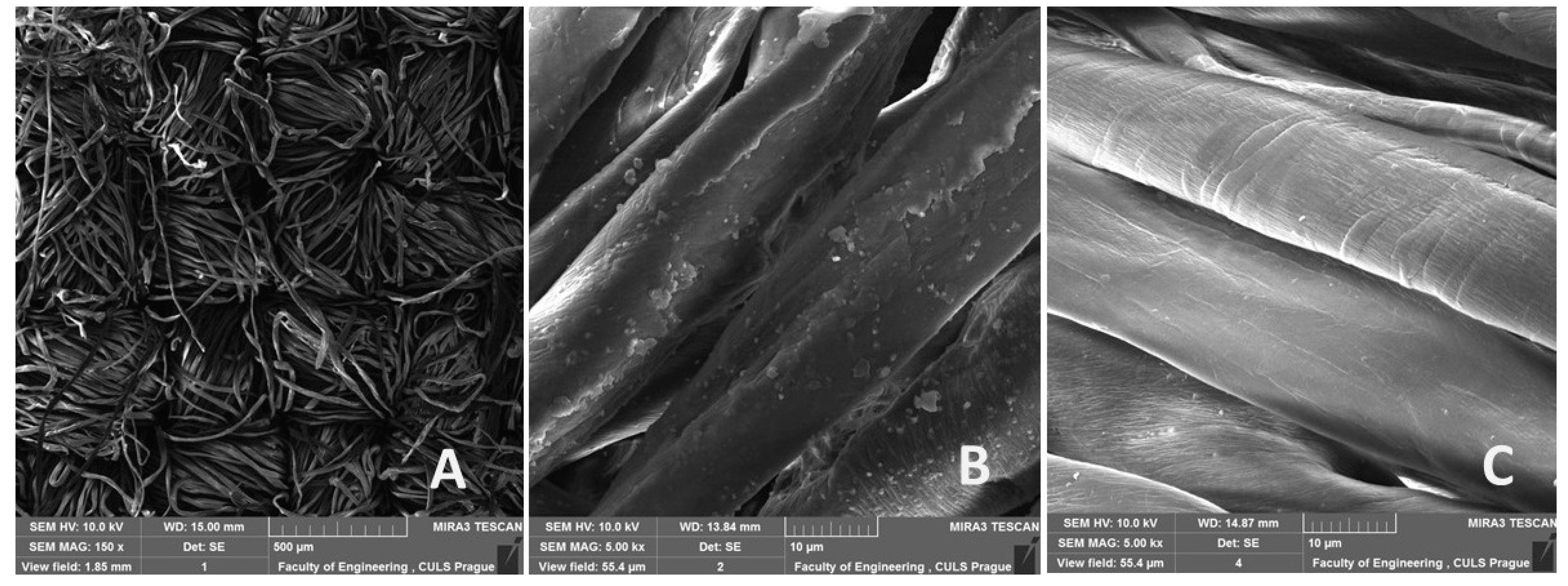

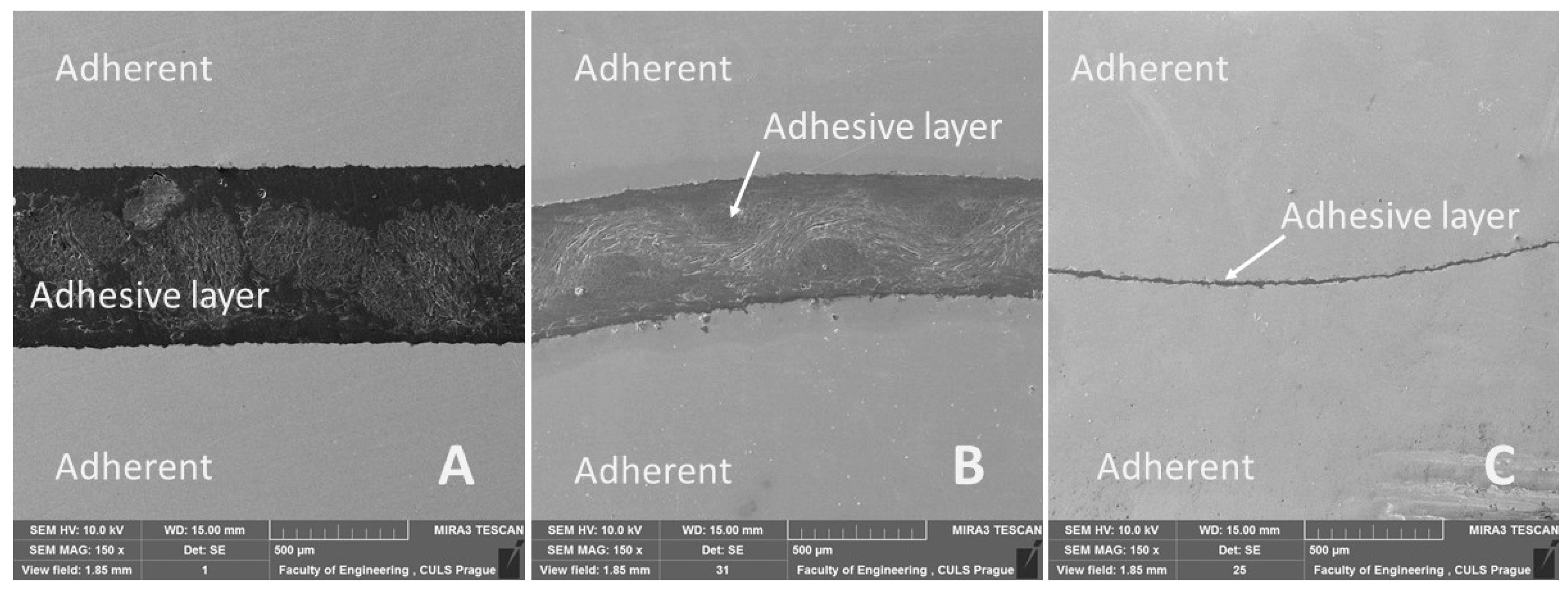

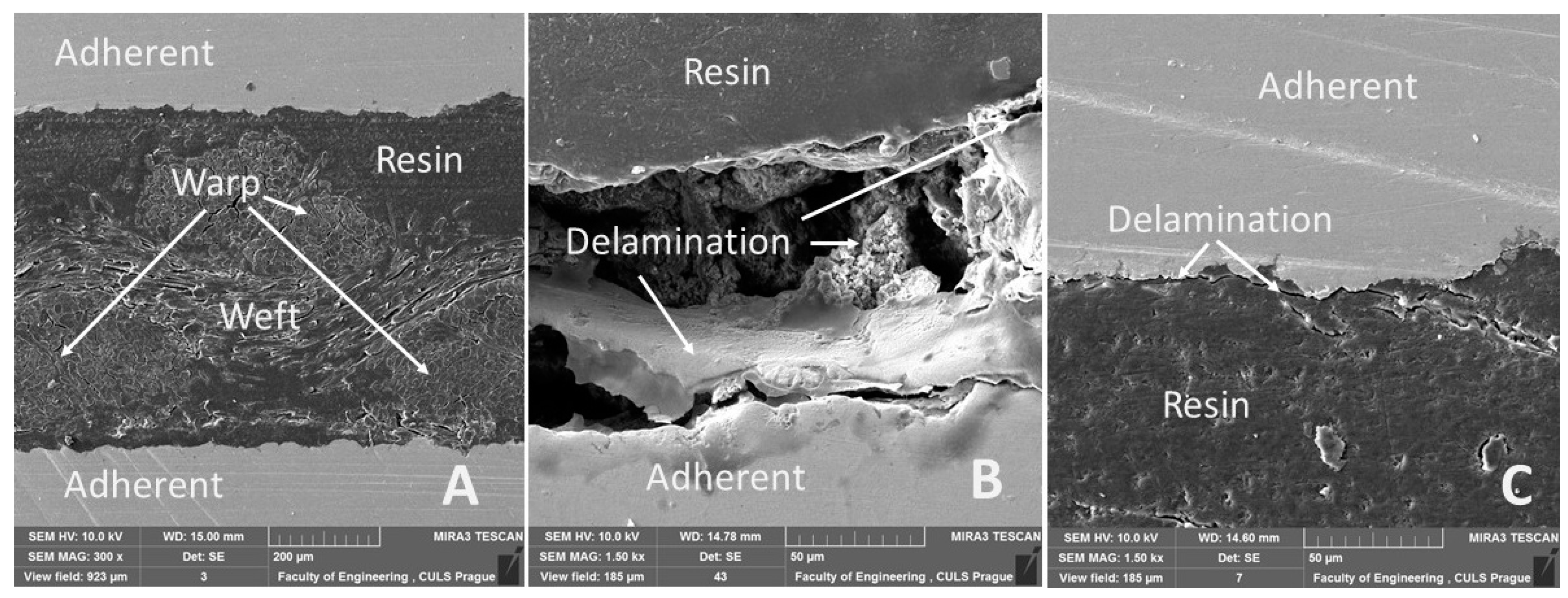

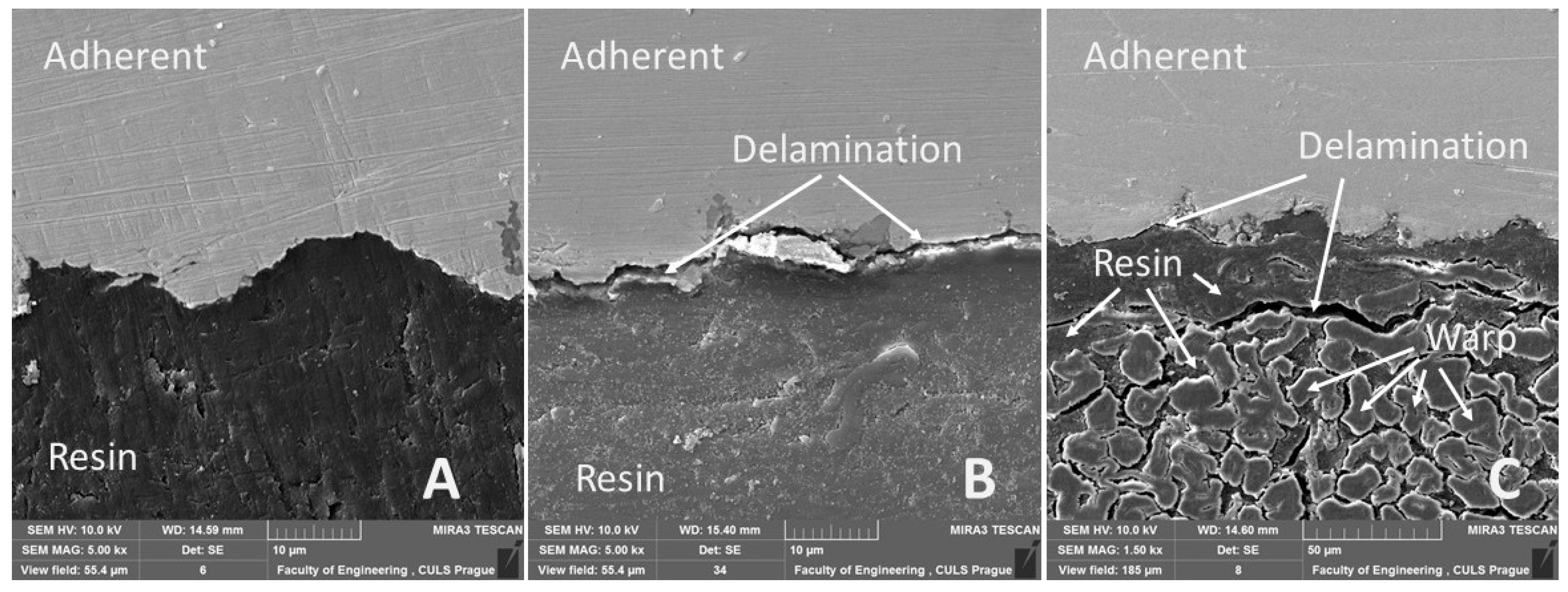

- SEM analysis showed a positive effect of alkali treatment (10% aqueous NaOH solution) on the fabric surface. The unwanted layers of lignin, oils, and fats were removed. The SEM analysis showed improved wettability of the reinforcing fabrics Erik and Tera due to the alkali treatment with 10% NaOH solution. The SEM analysis also showed the formation of micro-cracks with subsequent delamination due to cyclic loading at the adhesive/adherend interface and at the matrix/reinforcement interface.

- The results of this research demonstrate the ability of natural fabrics to act as reinforcement to increase the service life and safety of hybrid adhesive bonds under cyclic loading. Hybrid adhesive bonds create an interesting alternative in the design of adhesive bonding technology. The use of shaped design for the overlapped bonds is an interesting area that needs to be studied further.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barnes, T.; Pashby, I. Joining techniques for aluminium spaceframes used in automobiles: Part II—Adhesive bonding and mechanical fasteners. J. Mater. Process. Technol. 2000, 99, 72–79. [Google Scholar] [CrossRef]

- Preu, H.; Mengel, M. Experimental and theoretical study of a fast curing adhesive. Int. J. Adhes. Adhes. 2007, 27, 330–337. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Adams, R.D. Adhesive Bonding: Science, Technology and Applications; Woodhead Publishing: Abington Cambridge, UK, 2005; ISBN 9781855737419. [Google Scholar]

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology; CRS Press Taylor & Francis Group: Boca Raton, FL, USA, 2003; ISBN 0824709861. [Google Scholar]

- Müller, M.; Valášek, P. Composite adhesive bonds reinforced with microparticle filler based on egg shell waste. J. Phys. Conf. Ser. 2018, 1016, 12002. [Google Scholar] [CrossRef] [Green Version]

- Bahrami, B.; Ayatollahi, M.; Beigrezaee, M.; da Silva, L. Strength improvement in single lap adhesive joints by notching the adherends. Int. J. Adhes. Adhes. 2019, 95, 102401. [Google Scholar] [CrossRef]

- Stoeckel, F.; Konnerth, J.; Gindl-Altmutter, W. Mechanical properties of adhesives for bonding wood—A review. Int. J. Adhes. Adhes. 2013, 45, 32–41. [Google Scholar] [CrossRef]

- Kolář, V.; Tichý, M.; Müller, M.; Valášek, P.; Rudawska, A. Research on influence of cyclic degradation process on changes of structural adhesive bonds mechanical properties. Agron. Res. 2019, 17, 1062–1070. [Google Scholar] [CrossRef]

- Han, X.; Crocombe, A.; Anwar, S.N.R.; Hu, P. The strength prediction of adhesive single lap joints exposed to long term loading in a hostile environment. Int. J. Adhes. Adhes. 2014, 55, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Krolczyk, G.; Raos, P.; Legutko, S. Experimental analysis of surface roughness and surface texture of machined and fused deposition modelled parts. Teh. Vjesn. 2014, 21, 217–221. [Google Scholar]

- Nieslony, P.; Krolczyk, G.M.; Wojciechowski, S.; Chudy, R.; Zak, K.; Maruda, R.W. Surface quality and topographic inspection of variable compliance part after precise turning. Appl. Surf. Sci. 2018, 434, 91–101. [Google Scholar] [CrossRef]

- Rudawska, A. Selected aspects of the effect of mechanical treatment on surface roughness and adhesive joint strength of steel sheets. Int. J. Adhes. Adhes. 2014, 50, 235–243. [Google Scholar] [CrossRef]

- Bresson, G.; Jumel, J.; Shanahan, M.E.; Serin, P. Strength of adhesively bonded joints under mixed axial and shear loading. Int. J. Adhes. Adhes. 2012, 35, 27–35. [Google Scholar] [CrossRef]

- Mishra, R.; Militky, J.; Gupta, N.; Pachauri, R.; Behera, B. Modelling and simulation of earthquake resistant 3D woven textile structural concrete composites. Compos. Part B Eng. 2015, 81, 91–97. [Google Scholar] [CrossRef]

- Broughton, W.R.; Mera, R.; Hinopoulos, G. Cyclic Fatigue Testing of Adhesive Joints Test Method Assessment; NPL Report; National Physical Laboratory: Teddington, UK, 1999. [Google Scholar]

- Akrami, R.; Anjum, S.; Fotouhi, S.; Boaretto, J.; De Camargo, F.V.; Fotouhi, M. Investigating the effect of interface morphology in adhesively bonded composite wavy-lap joints. J. Compos. Sci. 2021, 5, 32. [Google Scholar] [CrossRef]

- Behera, B.K.; Pattanayak, A.K.; Mishra, R. Prediction of fabric drape behaviour using finite element method. J. Text. Eng. 2008, 54, 103–110. [Google Scholar] [CrossRef] [Green Version]

- Tichý, M.; Kolář, V.; Müller, M.; Mishra, R.K.; Šleger, V.; Hromasová, M. Quasi-static shear test of hybrid adhesive bonds based on treated cotton-epoxy resin layer. Polymers 2020, 12, 2945. [Google Scholar] [CrossRef]

- Boss, J.; Ganesh, V.; Lim, C.T. Modulus grading versus geometrical grading of composite adherends in single-lap bonded joints. Compos. Struct. 2003, 62, 113–121. [Google Scholar] [CrossRef]

- Da Silva, L.; Adams, R.D. Techniques to reduce the peel stresses in adhesive joints with composites. Int. J. Adhes. Adhes. 2007, 27, 227–235. [Google Scholar] [CrossRef]

- Zeng, Q.-G.; Sun, C.T. Novel design of a bonded lap joint. AIAA J. 2001, 39, 1991–1996. [Google Scholar] [CrossRef]

- Ávila, A.F.; Bueno, P.d.O. Stress analysis on a wavy-lap bonded joint for composites. Int. J. Adhes. Adhes. 2004, 24, 407–414. [Google Scholar] [CrossRef]

- Müller, M. Research on constructional shape of bond at connecting galvanized sheet of metal. Manuf. Technol. 2015, 15, 392–396. [Google Scholar] [CrossRef]

- Jaiswal, P.; Hirulkar, N.; Papadakis, L.; Jaiswal, R.R.; Joshi, N.B. Parametric study of non flat interface adhesively bonded joint. Mater. Today Proc. 2018, 5, 17654–17663. [Google Scholar] [CrossRef]

- Haghpanah, B.; Chiu, S.; Vaziri, A. Adhesively bonded lap joints with extreme interface geometry. Int. J. Adhes. Adhes. 2014, 48, 130–138. [Google Scholar] [CrossRef]

- Razavi, S.; Berto, F.; Peron, M.; Torgersen, J. Parametric study of adhesive joints with non-flat sinusoid interfaces. Theor. Appl. Fract. Mech. 2017, 93, 44–55. [Google Scholar] [CrossRef] [Green Version]

- Herrera-Franco, P.; Valadez-González, A. A study of the mechanical properties of short natural-fiber reinforced composites. Compos. Part B Eng. 2005, 36, 597–608. [Google Scholar] [CrossRef]

- Alkbir, M.F.; Sapuan, S.M.; Nuraini, A.A.; Ishak, M.R. Fibre properties and crashworthiness parameters of natural fibre-reinforced composite structure: A literature review. Compos. Struct. 2016, 148, 59–73. [Google Scholar] [CrossRef]

- Aziz, S.H.; Ansell, M.P. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 1—Polyester resin matrix. Compos. Sci. Technol. 2004, 64, 1219–1230. [Google Scholar] [CrossRef]

- Dalmay, P.; Smith, A.; Chotard, T.; Sahay-Turner, P.; Gloaguen, V.; Krausz, P. Properties of cellulosic fibre reinforced plaster: Influence of hemp or flax fibres on the properties of set gypsum. J. Mater. Sci. 2010, 45, 793–803. [Google Scholar] [CrossRef]

- Mishra, R.; Militky, J.; Baheti, V.; Huang, J.; Kale, B.; Venkataraman, M.; Bele, V.; Arumugam, V.; Zhu, G.; Wang, Y. The production, characterization and applications of nanoparticles in the textile industry. Text. Prog. 2014, 46, 133–226. [Google Scholar] [CrossRef]

- Petrásek, S.; Müller, M. Mechanical qualities of adhesive bonds reinforced with biological fabric treated by plasma. Agron. Res. 2017, 15, 1170–1181. [Google Scholar]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.; Olayo, R.; Herrera-Franco, P. Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites. Compos. Part B Eng. 1999, 30, 309–320. [Google Scholar] [CrossRef]

- Müller, M.; Valášek, P.; Kolář, V.; Šleger, V.; Gürdil, G.A.K.; Hromasová, M.; Hloch, S.; Moravec, J.; Pexa, M. Material utilization of cotton post-harvest line residues in polymeric composites. Polymers 2019, 11, 1106. [Google Scholar] [CrossRef] [Green Version]

- Valášek, P.; Müller, M.; Šleger, V.; Kolář, V.; Hromasová, M.; D’Amato, R.; Ruggiero, A. Influence of alkali treatment on the microstructure and mechanical properties of coir and abaca fibers. Materials 2021, 14, 2636. [Google Scholar] [CrossRef] [PubMed]

- Nam, T.H.; Ogihara, S.; Tung, N.H.; Kobayashi, S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly (butylene succinate) biodegradable composites. Compos. Part B Eng. 2011, 42, 1648–1656. [Google Scholar] [CrossRef]

- Fan, T.; Hu, R.; Zhao, Z.; Liu, Y.; Lu, M. Surface micro-dissolve method of imparting self-cleaning property to cotton fabrics in NaOH/urea aqueous solution. Appl. Surf. Sci. 2017, 400, 524–529. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Yu, P.; Salih, C.; Abousnina, R.; Heyer, T.; Schubel, P. Tensile fatigue behavior of polyester and vinyl ester based gfrp laminates—A comparative evaluation. Polymers 2021, 13, 386. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Peauril, J.; Salih, C.; Reddy, K.R.; Yu, P.; Schubel, P.; Heyer, T. Testing and modelling the fatigue behaviour of GFRP composites—Effect of stress level, stress concentration and frequency. Eng. Sci. Technol. Int. J. 2020, 23, 1223–1232. [Google Scholar] [CrossRef]

- Saraç, I.; Adin, H.; Temiz, Ş. Experimental determination of the static and fatigue strength of the adhesive joints bonded by epoxy adhesive including different particles. Compos. Part B Eng. 2018, 155, 92–103. [Google Scholar] [CrossRef]

- Hafiz, T.; Wahab, M.A.; Crocombe, A.; Smith, P. Mixed-mode fracture of adhesively bonded metallic joints under quasi-static loading. Eng. Fract. Mech. 2010, 77, 3434–3445. [Google Scholar] [CrossRef] [Green Version]

- Kelly, G. Quasi-static strength and fatigue life of hybrid (bonded/bolted) composite single-lap joints. Compos. Struct. 2006, 72, 119–129. [Google Scholar] [CrossRef]

- Šleger, V.; Müller, M. Quasi static tests of adhesive bonds of alloy AlCu4Mg. Manuf. Technol. 2015, 15, 694–698. [Google Scholar] [CrossRef]

- Kolář, V.; Müller, M.; Mishra, R.; Rudawska, A.; Šleger, V.; Tichý, M.; Hromasová, M.; Valášek, P. Quasi-static tests of hybrid adhesive bonds based on biological reinforcement in the form of eggshell microparticles. Polymers 2020, 12, 1391. [Google Scholar] [CrossRef]

- International Organization for Standardization. ČSN EN 1465—Adhesives—Determination of Tensile Lap-Shear Strength of Bonded Assemblies; Czech Standardization Institute: Prague, Czech Republic, 2009. [Google Scholar]

- DIN 17120 Grade St 37-3—Low Carbon Steel—Matmatch. Available online: https://matmatch.com/materials/minfm31305-din-17120-grade-st-37-3 (accessed on 13 May 2021).

- Rudawska, A.; Zaleski, K.; Miturska, I.; Skoczylas, A. Effect of the application of different surface treatment methods on the strength of titanium alloy sheet adhesive lap joints. Materials 2019, 12, 4173. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Svitap.cz. Available online: https://www.tkaniny-svitap.cz/kcfinder/upload/file/vzorkovnik.pdf (accessed on 19 May 2021).

- Boopathi, L.; Sampath, P.; Mylsamy, K. Investigation of physical, chemical and mechanical properties of raw and alkali treated Borassus fruit fiber. Compos. Part B Eng. 2012, 43, 3044–3052. [Google Scholar] [CrossRef]

- Bunsell, A.R. Handbook of Tensile Properties of Textile and Technical Fibres, 2nd ed.; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar]

- CHS-EPOXY 324 (EPOXY 1200) and Hardener P11. Available online: https://havel-composites.com/uploads/files/products/335/2bf05fdbe434cf27e38cd1554c43a9a4792aa4db.pdf (accessed on 19 May 2021).

- Kolář, V.; Müller, M.; Tichý, M.; Rudawska, A.; Hromasová, M. Influence of preformed adherent angle and reinforcing glass fibre on tensile strength of hybrid adhesive bond. Manuf. Technol. 2019, 19, 786–791. [Google Scholar] [CrossRef]

- You, M.; Li, Z.; Zheng, X.-L.; Yu, S.; Li, G.-Y.; Sun, D.-X. A numerical and experimental study of preformed angle in the lap zone on adhesively bonded steel single lap joint. Int. J. Adhes. Adhes. 2009, 29, 280–285. [Google Scholar] [CrossRef]

- Ávila, A.F.; Bueno, P.D.O. An experimental and numerical study on adhesive joints for composites. Compos. Struct. 2004, 64, 531–537. [Google Scholar] [CrossRef]

- Campilho, R.; de Moura, M.; Domingues, J. Numerical prediction on the tensile residual strength of repaired CFRP under different geometric changes. Int. J. Adhes. Adhes. 2009, 29, 195–205. [Google Scholar] [CrossRef]

- Müller, M.; Herák, D. Dimensioning of the bonded lap joint. Res. Agric. Eng. 2010, 56, 59–68. [Google Scholar] [CrossRef] [Green Version]

- Grant, L.; Adams, R.; da Silva, L.F. Experimental and numerical analysis of single-lap joints for the automotive industry. Int. J. Adhes. Adhes. 2009, 29, 405–413. [Google Scholar] [CrossRef]

- Tichý, M.; Kolář, V.; Muller, M.; Valasek, P. Quasi-static tests on polyurethane adhesive bonds reinforced by rubber powder. In Engineering for Rural Development; Latvia University of Life Sciences and Technologies: Jelgava, Latvia, 2019; Volume 18, pp. 1035–1041. [Google Scholar]

- Zavrtálek, J.; Müller, M.; Šléger, V. Low-cyclic fatigue test of adhesive bond reinforced with glass fibre fabric. Agron. Res. 2016, 14, 1138–1146. [Google Scholar]

- Symington, M.C.; Banks, W.M.; West, O.D.; Pethrick, R.A. Tensile testing of cellulose based natural fibers for structural composite applications. J. Compos. Mater. 2009, 43, 1083–1108. [Google Scholar] [CrossRef] [Green Version]

- Kalia, S.; Kaith, B.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites-A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Valasek, P.; Müller, M.; Šleger, V. Influence of plasma treatment on mechanical properties of cellulose-based fibres and their interfacial interaction in composite systems. BioResources 2017, 12, 5449–5461. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Miturska, I.; Rudawska, A.; Müller, M.; Hromasová, M. The Influence of mixing methods of epoxy composition ingredients on selected mechanical properties of modified epoxy construction materials. Materials 2021, 14, 411. [Google Scholar] [CrossRef]

- Miturska, I.; Rudawska, A.; Müller, M.; Valášek, P. The influence of modification with natural fillers on the mechanical properties of epoxy adhesive compositions after storage time. Materials 2020, 13, 291. [Google Scholar] [CrossRef] [Green Version]

- Rudawska, A. The effect of the salt water aging on the mechanical properties of epoxy adhesives compounds. Polymers 2020, 12, 843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ayatollahi, M.R.; Samari, M.; Razavi, S.M.J.; da Silva, L. Fatigue performance of adhesively bonded single lap joints with non-flat sinusoid interfaces. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1355–1363. [Google Scholar] [CrossRef]

- Da Silva, L.F.; Carbas, R.; Critchlow, G.; Figueiredo, M.; Brown, K. Effect of material, geometry, surface treatment and environment on the shear strength of single lap joints. Int. J. Adhes. Adhes. 2009, 29, 621–632. [Google Scholar] [CrossRef] [Green Version]

| Tensile Strength | 340–470 MPa |

|---|---|

| Yield strength | 225–235 MPa |

| Elastic modulus | 212 GPa |

| Elongation | 24% |

| C (%) | Mn (%) | P (%) | S (%) | Cu (%) | N (%) | Fe (%) |

|---|---|---|---|---|---|---|

| ≤0.19 | ≤1.50 | ≤0.04 | ≤0.04 | ≤0.60 | ≤0.014 | ≤99.55 |

| Fabric | Geometry | Areal Density | Warp-Way Strength (200 × 50 mm) | Weft-Way Strength (200 × 50 mm) |

|---|---|---|---|---|

| g × m−2 | N | N | ||

| Tera | Plain | 290 | 950 | 900 |

| Erik | Plain | 190 | 850 | 800 |

| Bond Type | Adherend Geometry (Shape) | Adhesive Layer Thickness (μm) | Characteristics |

|---|---|---|---|

| Resin | Flat | 33 ± 3 | Adhesive bonds with pure resin and flat shape, WH1 and WH2 |

| WH1 | |||

| WH2 | |||

| Erik | Flat | 432 ± 12 | Adhesive bonds with composite layer with Erik fabric and flat shape, WH1 and WH2 |

| WH1 | |||

| WH2 | |||

| Tera | Flat | 614 ± 9 | Adhesive bonds with composite layer with Tera fabric and flat shape, WH1 and WH2 |

| WH1 | |||

| WH2 |

| Adhesive Bond | Static Test | ||||||

|---|---|---|---|---|---|---|---|

| Tensile Strength | Strain | Modulus of Elasticity | |||||

| Shape | MPa | p-value | % | p-value | MPa | p-value | |

| Resin | Flat | 7.38 ± 0.22 | - | 14.30 ± 1.88 | - | 52.46 ± 6.65 | - |

| WH1 | 3.91 ± 0.23 | 0.01 | 4.51 ± 0.73 | 0.01 | 88.96 ± 16.02 | 0.01 | |

| WH2 | 2.45 ± 0.13 | 0.01 | 3.92 ± 0.54 | 0.01 | 63.67 ± 8.14 | 0.01 | |

| Erik | Flat | 6.53 ± 0.38 | 0.01 | 8.00 ± 1.59 | 0.01 | 83.68 ± 10.87 | 0.01 |

| WH1 | 5.31 ± 0.29 | 0.01 | 6.27 ± 0.65 | 0.01 | 85.18 ± 5.29 | 0.01 | |

| WH2 | 2.99 ± 0.33 | 0.01 | 6.69 ± 3.12 | 0.01 | 52.48 ± 17.16 | 0.50 | |

| Tera | Flat | 7.12 ± 0.74 | 0.22 | 12.03 ± 2.70 | 0.07 | 61.53 ± 10.43 | 0.06 |

| WH1 | 4.30 ± 0.83 | 0.01 | 4.92 ± 0.91 | 0.01 | 87.61 ± 7.91 | 0.01 | |

| WH2 | 2.67 ± 0.43 | 0.01 | 7.16 ± 3.14 | 0.01 | 44.99 ± 19.14 | 0.19 | |

| Adhesive Bond | Cyclic Test (5–50%) | Cyclic Test (5–70%) | |||||

|---|---|---|---|---|---|---|---|

| Tensile Strength | Strain | Finished Test Samples (1000 cycles) | Tensile Strength | Strain | Finished Test Samples (1000 cycles) | ||

| Shape | MPa | % | MPa | % | |||

| Resin | Flat | - | - | 0/7 | - | - | 0/7 |

| WH1 | - | - | 0/7 | - | - | 0/7 | |

| WH2 | - | - | 0/7 | - | - | 0/7 | |

| Erik | Flat | 7.13 ± 0.52 | 12.97 ± 4.06 | 7/7 | - | - | 3/7 |

| WH1 | 5.29 ± 0.32 | 5.99 ± 0.80 | 7/7 | - | - | 0/7 | |

| WH2 | - | - | 0/7 | - | - | 0/7 | |

| Tera | Flat | 7.45 ± 0.01 | 14.15 ± 2.82 | 7/7 | 7.49 ± 0.29 | 14.76 ± 2.41 | 7/7 |

| WH1 | 5.66 ± 0.40 | 6.79 ± 0.58 | 7/7 | - | - | 0/7 | |

| WH2 | - | - | 0/7 | - | - | 0/7 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolář, V.; Müller, M.; Tichý, M.; Mishra, R.K.; Hrabě, P.; Hanušová, K.; Hromasová, M. Experimental Investigation of Wavy-Lap Bonds with Natural Cotton Fabric Reinforcement under Cyclic Loading. Polymers 2021, 13, 2872. https://doi.org/10.3390/polym13172872

Kolář V, Müller M, Tichý M, Mishra RK, Hrabě P, Hanušová K, Hromasová M. Experimental Investigation of Wavy-Lap Bonds with Natural Cotton Fabric Reinforcement under Cyclic Loading. Polymers. 2021; 13(17):2872. https://doi.org/10.3390/polym13172872

Chicago/Turabian StyleKolář, Viktor, Miroslav Müller, Martin Tichý, Rajesh Kumar Mishra, Petr Hrabě, Kristýna Hanušová, and Monika Hromasová. 2021. "Experimental Investigation of Wavy-Lap Bonds with Natural Cotton Fabric Reinforcement under Cyclic Loading" Polymers 13, no. 17: 2872. https://doi.org/10.3390/polym13172872

APA StyleKolář, V., Müller, M., Tichý, M., Mishra, R. K., Hrabě, P., Hanušová, K., & Hromasová, M. (2021). Experimental Investigation of Wavy-Lap Bonds with Natural Cotton Fabric Reinforcement under Cyclic Loading. Polymers, 13(17), 2872. https://doi.org/10.3390/polym13172872