Finite Element Analysis of Gas Diffusion in Polymer Nanocomposite Systems Containing Rod-like Nanofillers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

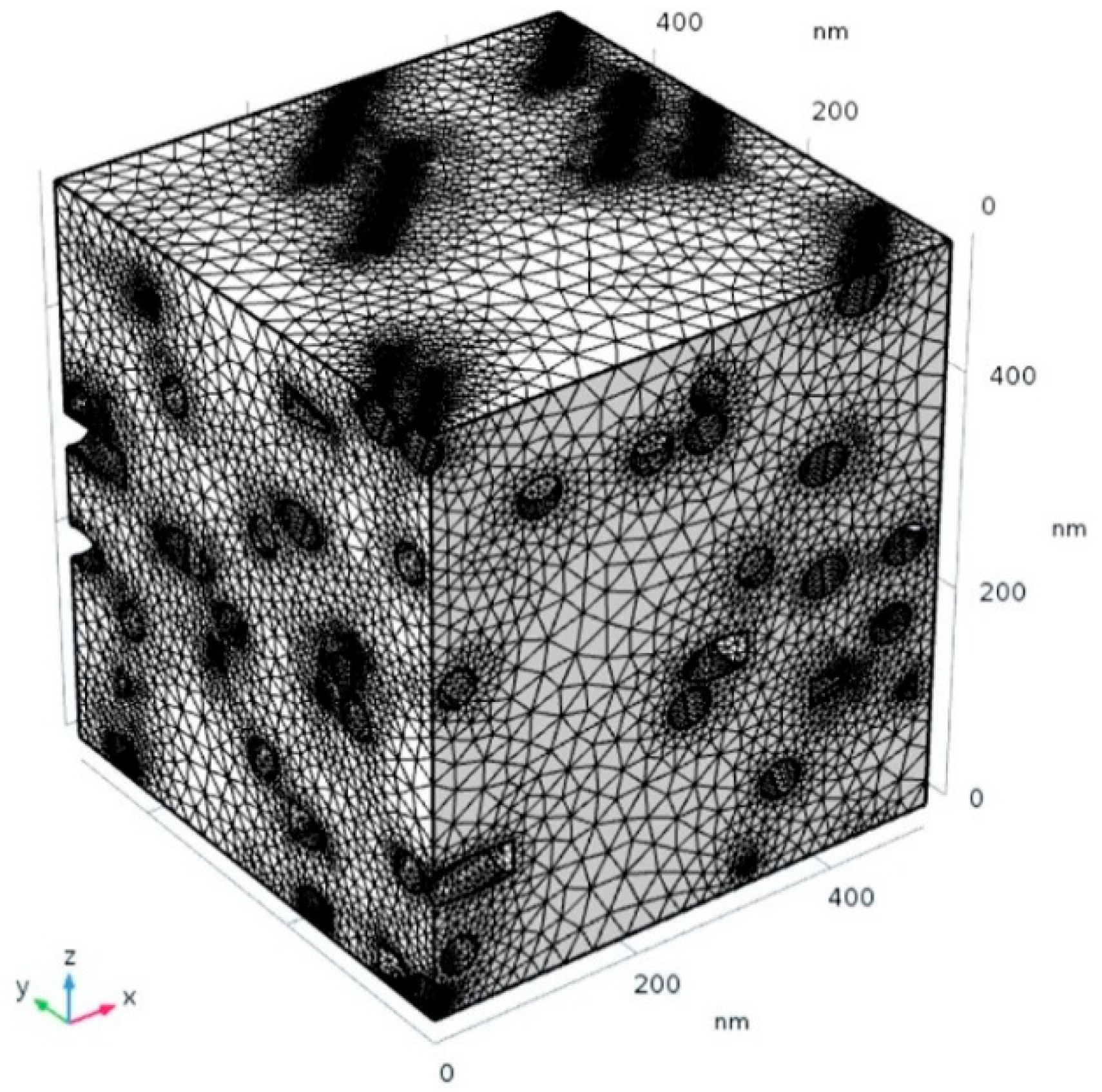

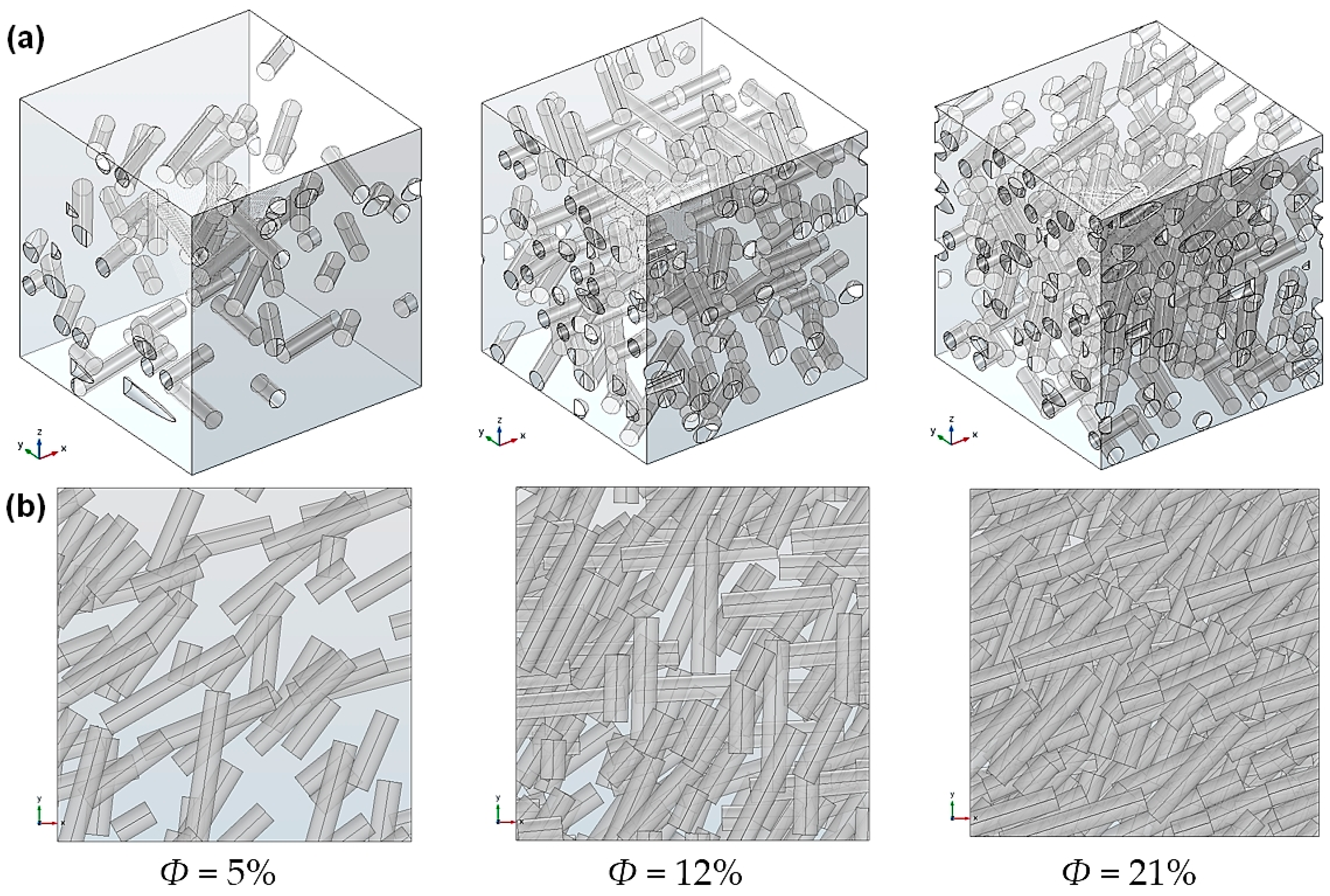

2.2. Geometry Modeling

2.3. Governing Equations and Boundary Conditions

2.4. Numerical Analysis

3. Results and Discussion

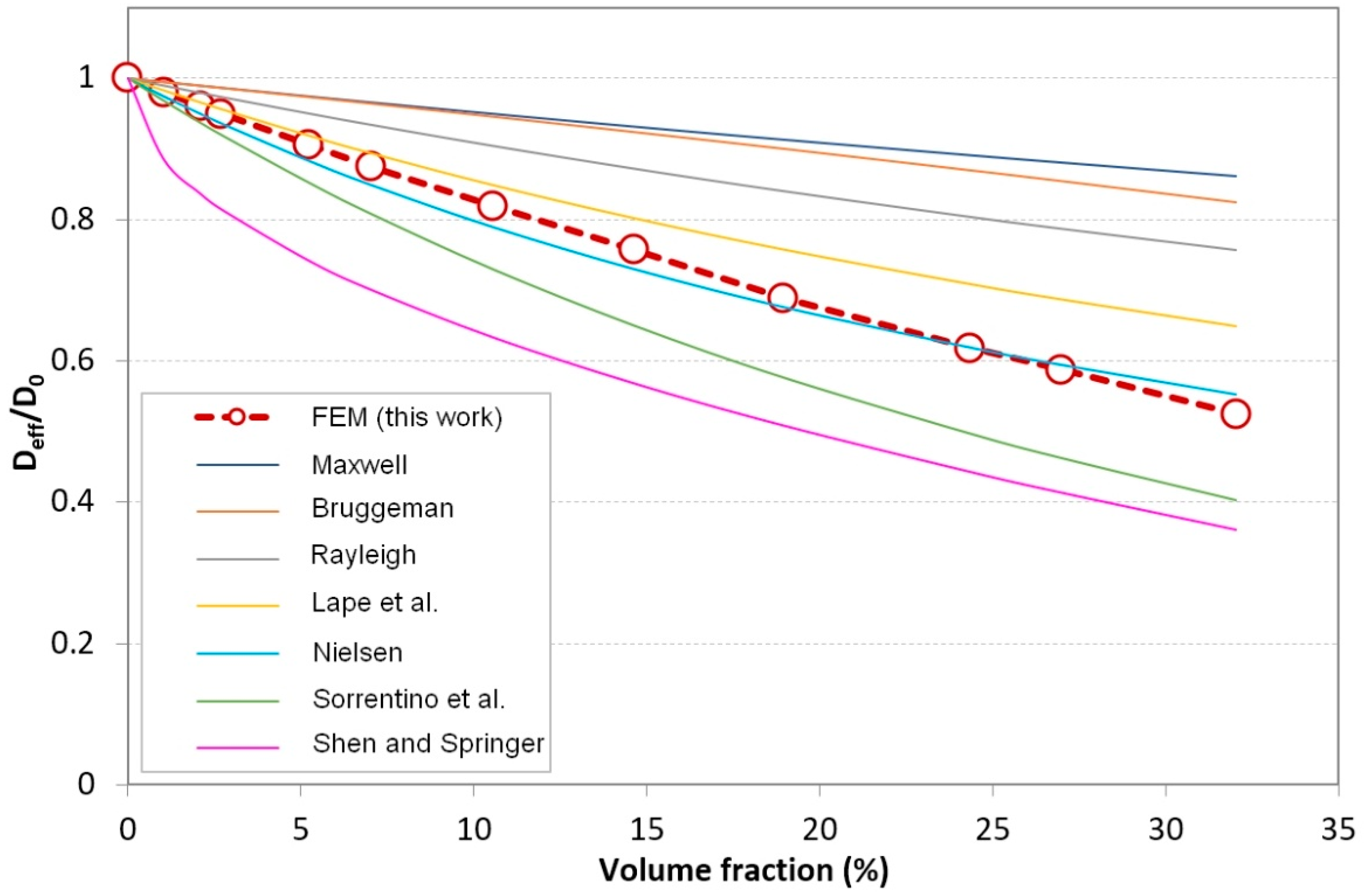

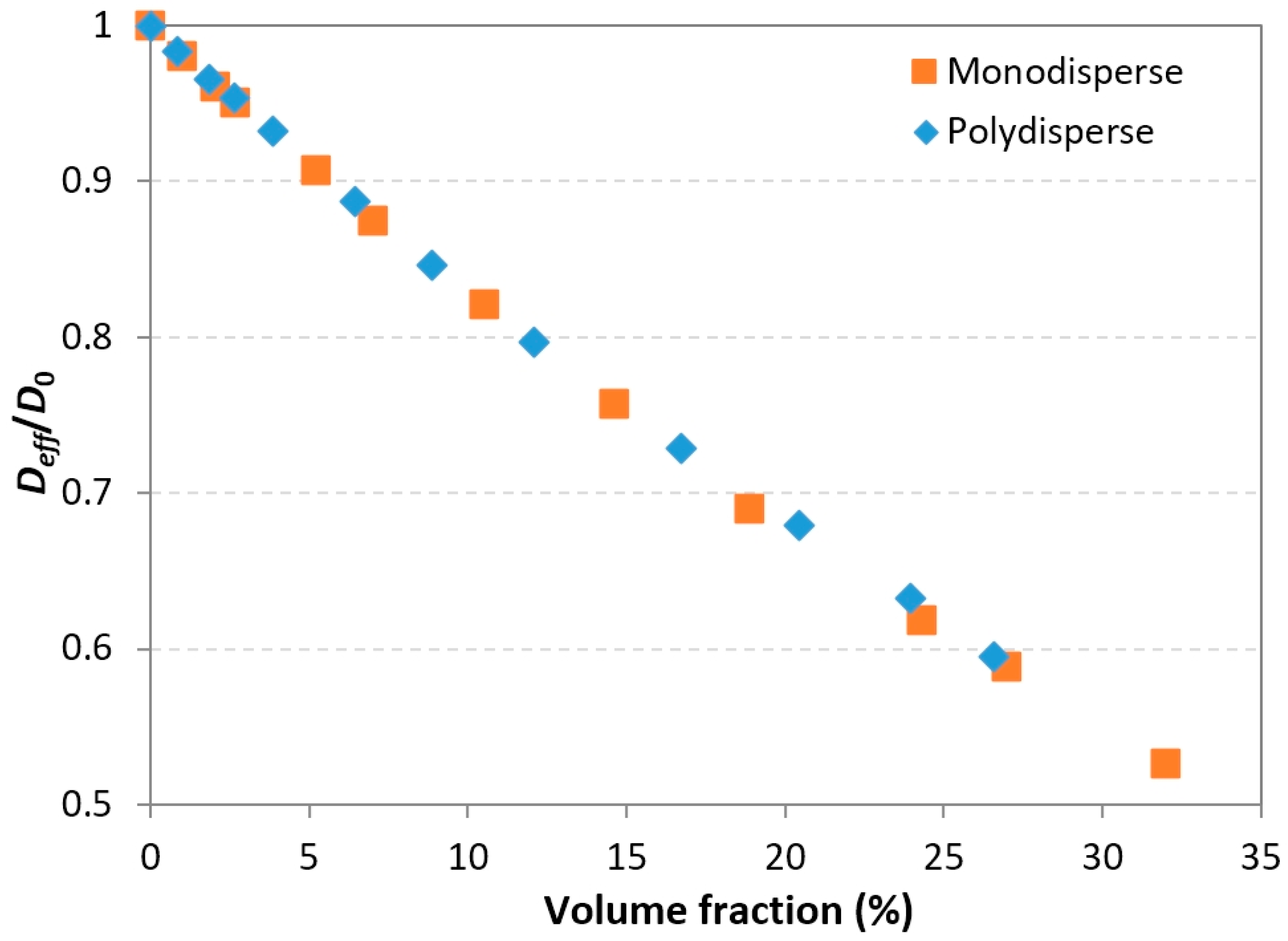

3.1. Effects of Filler Volume Fraction

- -

- The Nielsen model defines the aspect ratio as the ratio of the filler length to the filler width (adjusted to the rod diameter in the present case), meaning the aspect ratio value α = 5 should be used in the equation;

- -

- The model’s used by Sorrentino et al. [48] and Lape et al. [49] use an alternative aspect ratio definition, namely the ratio of the shorter dimension encountered in the diffusion direction to the filler thickness. For rods perpendicular to the diffusion direction, both parameters are adjusted to the rod diameter, meaning the aspect ratio value β = 1 should be considered in these models.

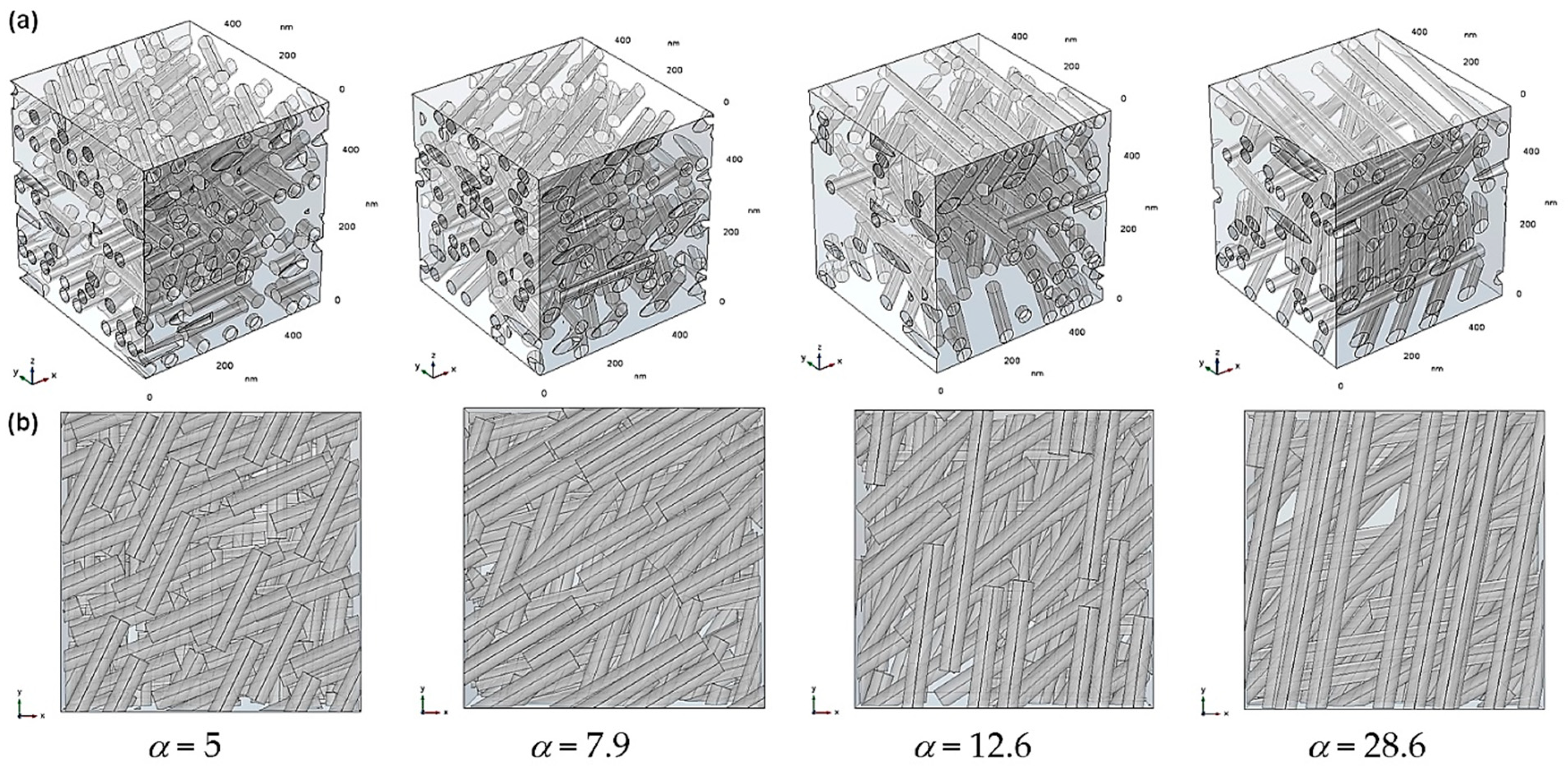

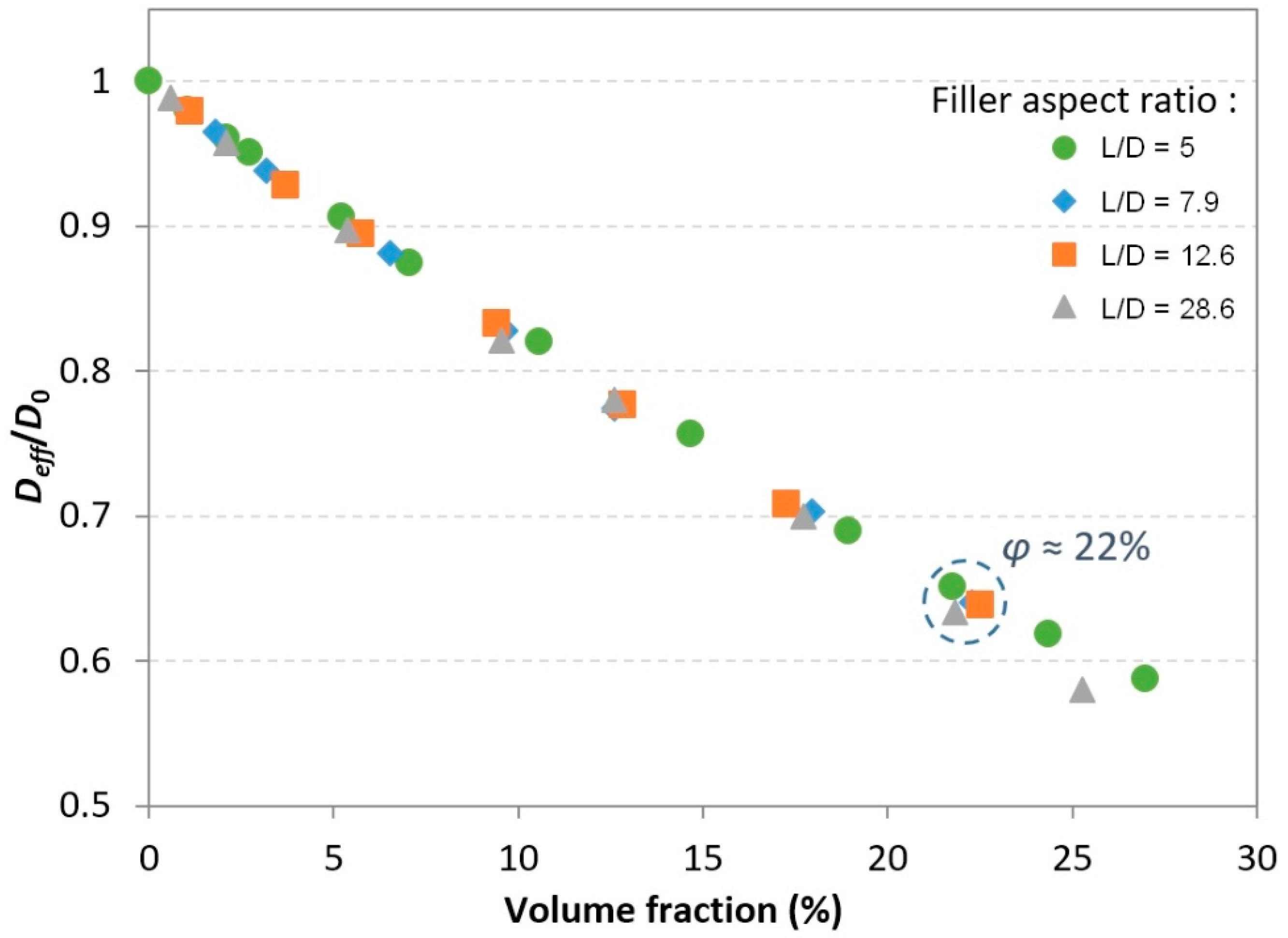

3.2. Effects of Filler Aspect Ratio and Polydispersity

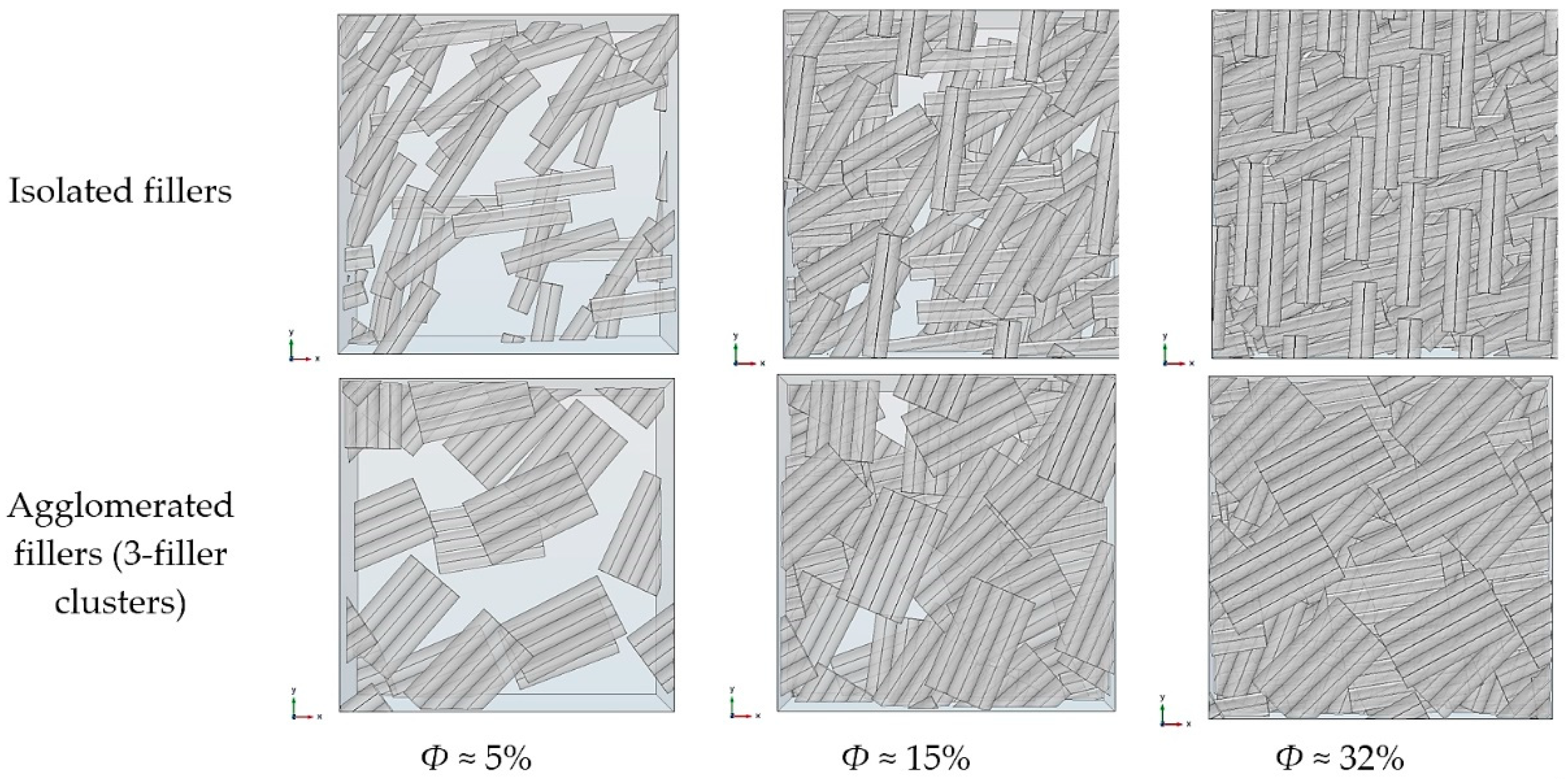

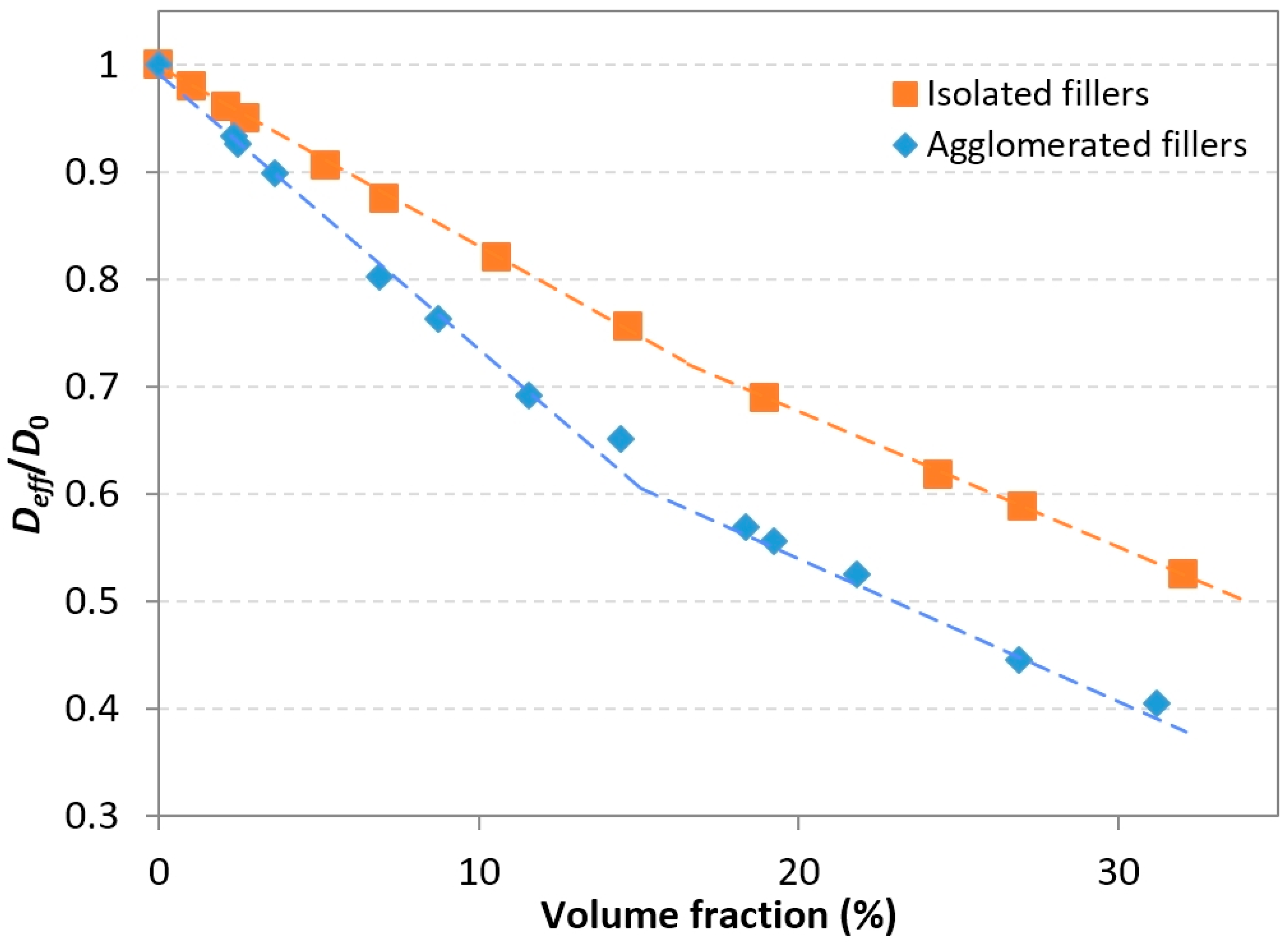

3.3. Effects of Filler Agglomeration

3.4. Effects of Filler–Matrix Interphase Properties

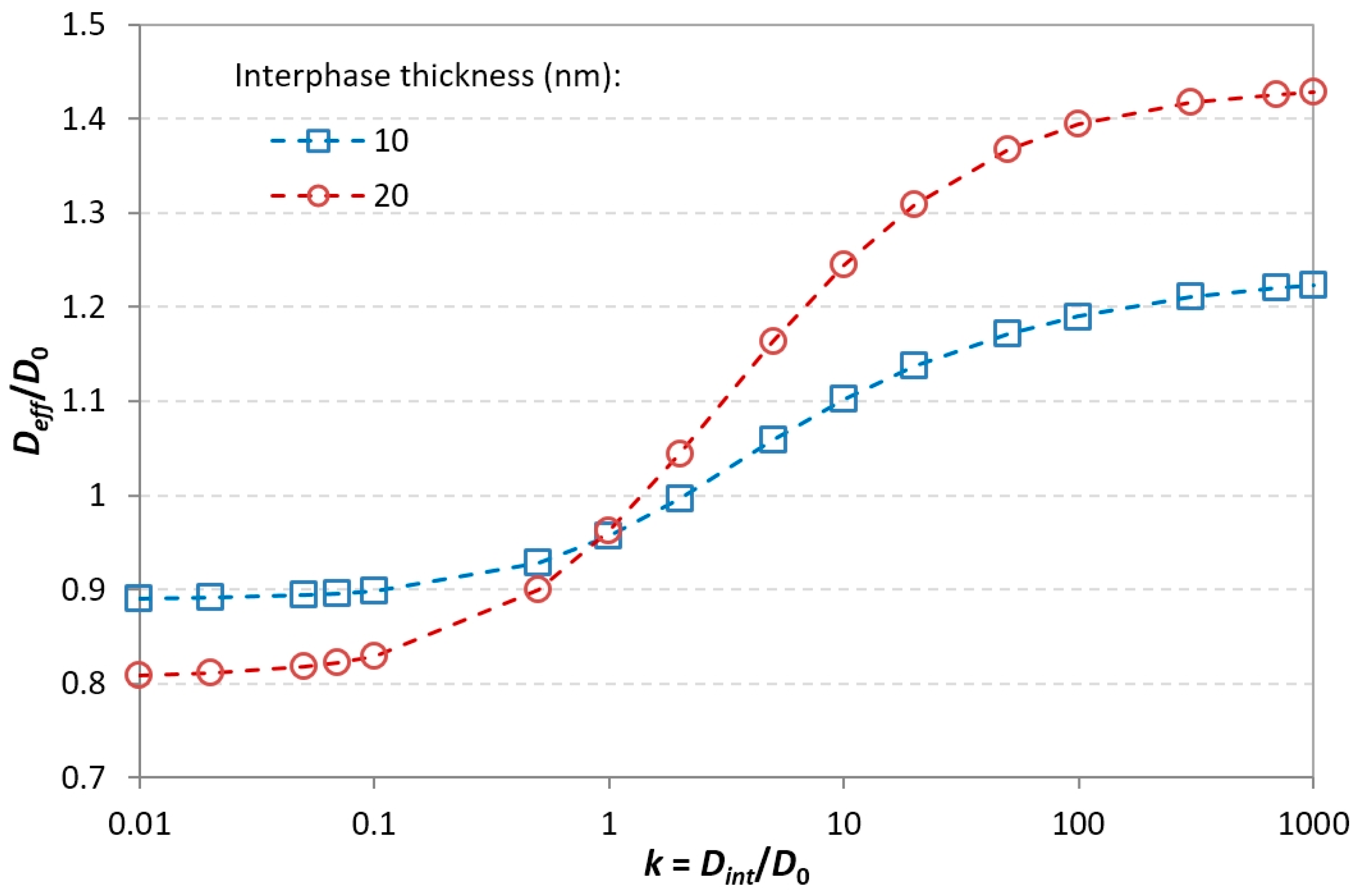

3.4.1. Effects of the Interphase Diffusivity

3.4.2. Effects of the Interphase Thickness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Giannakas, A.E.; Leontiou, A.A. Montmorillonite Composite Materials and Food Packaging. In Composites Materials for Food Packaging; Wiley Blackwell: Hoboken, NJ, USA, 2018; pp. 1–71. ISBN 9781119160243. [Google Scholar] [CrossRef]

- Kalendova, A.; Merinska, D.; Gerard, J.F.; Slouf, M. Polymer/clay nanocomposites and their gas barrier properties. Polym. Compos. 2013, 34, 1418–1424. [Google Scholar] [CrossRef]

- Passaglia, E.; Bertoldo, M.; Ceriegi, S.; Sulcis, R.; Narducci, P.; Conzatti, L. Oxygen and Water Vapor Barrier Properties of MMT Nanocomposites from Low Density Polyethylene or EPM with Grafted Succinic Groups. J. Nanosci. Nanotechnol. 2008, 8, 1690–1699. [Google Scholar] [CrossRef]

- Picard, E.; Vermogen, A.; Gérard, J.-F.; Espuche, E. Influence of the compatibilizer polarity and molar mass on the morphology and the gas barrier properties of polyethylene/clay nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 2593–2604. [Google Scholar] [CrossRef]

- Yu, J.; Buffet, J.-C.; O’Hare, D. Aspect Ratio Control of Layered Double Hydroxide Nanosheets and Their Application for High Oxygen Barrier Coating in Flexible Food Packaging. ACS Appl. Mater. Interfaces 2020, 12, 10973–10982. [Google Scholar] [CrossRef]

- Jia, L.; Ma, J.; Gao, D.; Lv, B. Layered Double Hydroxides/Polymer Nanocomposites. Prog. Chem. 2018, 30, 295–303. [Google Scholar] [CrossRef]

- Olivier, L.; Sabard, M.; Fulchiron, R.; Espuche, E.; David, L.; Guiu, A. Influence of α-ZrP fillers and process conditions on the morphology and the gas barrier properties of filled polyamide 6 films. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 1734–1746. [Google Scholar] [CrossRef]

- Nielsen, L.E. Models for the Permeability of Filled Polymer Systems. J. Macromol. Sci. Part A Chem. 1967, 1, 929–942. [Google Scholar] [CrossRef]

- Bharadwaj, R.K. Modeling the barrier properties of polymer-layered silicate nanocomposites. Macromolecules 2001, 34, 9189–9192. [Google Scholar] [CrossRef]

- Picard, E.; Vermogen, A.; Gérard, J.-F.; Espuche, E. Barrier properties of nylon 6-montmorillonite nanocomposite membranes prepared by melt blending: Influence of the clay content and dispersion state: Consequences on modelling. J. Memb. Sci. 2007, 292, 133–144. [Google Scholar] [CrossRef]

- Jiménez, A.; Peltzer, M.; Ruseckaite, R. Poly(Lactic acid) Science and Technology: Processing, Properties, Additives and Applications; Royal Society of Chemistry: Cambridge, UK, 2014; ISBN 978-1-84973-879-8. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed]

- Fiori, S. Industrial Uses of PLA. In Poly(Lactic acid) Science and Technology: Processing, Properties, Additives and Applications; Jiménez, A., Peltzer, M., Ruseckaite, R., Eds.; Royal Society of Chemistry: Cambridge, UK, 2014; pp. 315–333. [Google Scholar] [CrossRef]

- Rocca-Smith, J.R.; Pasquarelli, R.; Lagorce-Tachon, A.; Rousseau, J.; Fontaine, S.; Aguié-Béghin, V.; Debeaufort, F.; Karbowiak, T. Toward Sustainable PLA-Based Multilayer Complexes with Improved Barrier Properties. ACS Sustain. Chem. Eng. 2019, 7, 3759–3771. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Jonoobi, M.; Oladi, R.; Davoudpour, Y.; Oksman, K.; Dufresne, A.; Hamzeh, Y.; Davoodi, R. Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: A review. Cellulose 2015, 22, 935–969. [Google Scholar] [CrossRef]

- Rol, F.; Belgacem, M.N.; Gandini, A.; Bras, J. Recent advances in surface-modified cellulose nanofibrils. Prog. Polym. Sci. 2019, 88, 241–264. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef] [PubMed]

- Natterodt, J.C.; Petri-Fink, A.; Weder, C.; Zoppe, J.O. Cellulose nanocrystals: Surface modification, applications and opportunities at interfaces. CHIMIA Int. J. Chem. 2017, 71, 376–383. [Google Scholar] [CrossRef] [PubMed]

- Lin, N.; Huang, J.; Dufresne, A. Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: A review. Nanoscale 2012, 4, 3274–3294. [Google Scholar] [CrossRef] [PubMed]

- Hubbe, M.; Ferrer, A.; Tyagi, P.; Yin, Y.; Salas, C.; Pal, L.; Rojas, O.J. Nanocellulose in Thin Films, Coatings, and Plies for Packaging Applications: A Review. BioResources 2017, 12, 2143–2233. [Google Scholar] [CrossRef]

- Ferrer, A.; Pal, L.; Hubbe, M. Nanocellulose in packaging: Advances in barrier layer technologies. Ind. Crops Prod. 2017, 95, 574–582. [Google Scholar] [CrossRef]

- Kontturi, E.; Laaksonen, P.; Linder, M.B.; Nonappa; Gröschel, A.H.; Rojas, O.J.; Ikkala, O. Advanced Materials through Assembly of Nanocelluloses. Adv. Mater. 2018, 30, 1703779. [Google Scholar] [CrossRef]

- Bagheriasl, D.; Safdari, F.; Carreau, P.J.; Dubois, C.; Riedl, B. Development of cellulose nanocrystal-reinforced polylactide: A comparative study on different preparation methods. Polym. Compos. 2019, 40, E342–E349. [Google Scholar] [CrossRef]

- Muiruri, J.K.; Liu, S.; Teo, W.S.; Kong, J.; He, C. Highly Biodegradable and Tough Polylactic Acid–Cellulose Nanocrystal Composite. ACS Sustain. Chem. Eng. 2017, 5, 3929–3937. [Google Scholar] [CrossRef]

- Spinella, S.; Re, G.L.; Liu, B.; Dorgan, J.; Habibi, Y.; Leclère, P.; Raquez, J.-M.; Dubois, P.; Gross, R.A. Polylactide/cellulose nanocrystal nanocomposites: Efficient routes for nanofiber modification and effects of nanofiber chemistry on PLA reinforcement. Polymer 2015, 65, 9–17. [Google Scholar] [CrossRef]

- Tang, J.; Sisler, J.; Grishkewich, N.; Tam, K.C. Functionalization of cellulose nanocrystals for advanced applications. J. Colloid Interface Sci. 2017, 494, 397–409. [Google Scholar] [CrossRef] [PubMed]

- Wohlhauser, S.; Delepierre, G.; Labet, M.; Morandi, G.; Thielemans, W.; Weder, C.; Zoppe, J.O. Grafting Polymers from Cellulose Nanocrystals: Synthesis, Properties, and Applications. Macromolecules 2018, 51, 6157–6189. [Google Scholar] [CrossRef]

- Xu, X.; Liu, F.; Jiang, L.; Zhu, J.Y.; Haagenson, D.; Wiesenborn, D.P. Cellulose Nanocrystals vs. Cellulose Nanofibrils: A Comparative Study on Their Microstructures and Effects as Polymer Reinforcing Agents. ACS Appl. Mater. Interfaces 2013, 5, 2999–3009. [Google Scholar] [CrossRef]

- Fukuzumi, H.; Saito, T.; Iwamoto, S.; Kumamoto, Y.; Ohdaira, T.; Suzuki, R.; Isogai, A. Pore size determination of TEMPO-oxidized cellulose nanofibril films by positron annihilation lifetime spectroscopy. Biomacromolecules 2011, 12, 4057–4062. [Google Scholar] [CrossRef]

- Nuruddin, M.; Chowdhury, R.A.; Szeto, R.; Howarter, J.A.; Erk, K.A.; Szczepanski, C.R.; Youngblood, J.P. Structure–Property Relationship of Cellulose Nanocrystal–Polyvinyl Alcohol Thin Films for High Barrier Coating Applications. ACS Appl. Mater. Interfaces 2021, 13, 12472–12482. [Google Scholar] [CrossRef]

- Rader, C.; Weder, C.; Marti, R. Biobased Polyester-Amide/Cellulose Nanocrystal Nanocomposites for Food Packaging. Macromol. Mater. Eng. 2021, 306, 2000668. [Google Scholar] [CrossRef]

- Mondragon, G.; Peña-Rodriguez, C.; González, A.; Eceiza, A.; Arbelaiz, A. Bionanocomposites based on gelatin matrix and nanocellulose. Eur. Polym. J. 2015, 62, 1–9. [Google Scholar] [CrossRef]

- Bendahou, A.; Kaddami, H.; Espuche, E.; Gouanvé, F.; Dufresne, A. Synergism effect of montmorillonite and cellulose whiskers on the mechanical and barrier properties of natural rubber composites. Macromol. Mater. Eng. 2011, 296, 760–769. [Google Scholar] [CrossRef]

- Dhar, P.; Bhardwaj, U.; Kumar, A.; Katiyar, V. Poly (3-hydroxybutyrate)/cellulose nanocrystal films for food packaging applications: Barrier and migration studies. Polym. Eng. Sci. 2015, 55, 2388–2395. [Google Scholar] [CrossRef]

- Zid, S.; Zinet, M.; Espuche, E. Modeling diffusion mass transport in multiphase polymer systems for gas barrier applications: A review. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 621–639. [Google Scholar] [CrossRef]

- Barrer, R.M. Diffusion and Permeation in Heterogeneous Media. In Diffusion in Polymers; Park, G.S., Crank, J., Eds.; Academic Press: New York, NY, USA, 1968. [Google Scholar]

- Morel, F.; Espuche, E.; Bounor-Legaré, V.; Persynn, O.; Lacroix, M. Impact of coated calcium carbonate nanofillers and annealing treatments on the microstructure and gas barrier properties of poly(lactide) based nanocomposite films. J. Polym. Sci. Part. B Polym. Phys. 2016, 54, 649–658. [Google Scholar] [CrossRef]

- Picard, E.; Espuche, E.; Fulchiron, R. Effect of an organo-modified montmorillonite on PLA crystallization and gas barrier properties. Appl. Clay Sci. 2011, 53, 58–65. [Google Scholar] [CrossRef]

- Azzam, F. Assemblages Thermostimulables de Nanocristaux de Cellulose Décorés de Chaînes de Polymère. Ph.D. Thesis, Université de Grenoble, Grenoble, France, 2012. [Google Scholar]

- Zid, S.; Zinet, M.; Espuche, E. Numerical analysis of 3D mass diffusion in random (nano) composite systems: Effects of polydispersity and intercalation on barrier properties. J. Membr. Sci. 2019, 590, 117301. [Google Scholar] [CrossRef]

- Zid, S.; Zinet, M.; Espuche, E. 3D numerical analysis of mass diffusion in (nano) composites: The effect of the filler-matrix interphase on barrier properties. Model. Simul. Mater. Sci. Eng. 2020, 28, 075003. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism; Cambridge University Press: Cambridge, UK, 2010; Volume 9781108014, ISBN 9780511709333. [Google Scholar] [CrossRef]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann. Phys. 1935, 416, 636–664. [Google Scholar] [CrossRef]

- Rayleigh, L. LVI. On the influence of obstacles arranged in rectangular order upon the properties of a medium. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1892, 34, 481–502. [Google Scholar] [CrossRef]

- Shen, C.-H.; Springer, G.S. Moisture Absorption and Desorption of Composite Materials. J. Compos. Mater. 1976, 10, 2–20. [Google Scholar] [CrossRef]

- Cussler, E.L.; Hughes, S.E.; Ward, W.J.; Aris, R. Barrier membranes. J. Memb. Sci. 1988, 38, 161–174. [Google Scholar] [CrossRef]

- Sorrentino, A.; Tortora, M.; Vittoria, V. Diffusion behavior in polymer-clay nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 265–274. [Google Scholar] [CrossRef]

- Lape, N.K.; Nuxoll, E.E.; Cussler, E.L. Polydisperse flakes in barrier films. J. Memb. Sci. 2004, 236, 29–37. [Google Scholar] [CrossRef]

- Chen, X.; Papathanasiou, T.D. The transverse permeability of disordered fiber arrays: A statistical correlation in terms of the mean nearest interfiber spacing. Transp. Porous Media 2008, 71, 233–251. [Google Scholar] [CrossRef]

- Liang, C.-Y.; Uchytil, P.; Petrychkovych, R.; Lai, Y.C.; Friess, K.; Sipek, M.; Reddy, M.M.; Suen, S.Y. A comparison on gas separation between PES (polyethersulfone)/MMT (Na-montmorillonite) and PES/TiO2 mixed matrix membranes. In Proceedings of the Separation and Purification Technology; Elsevier: Amsterdam, The Netherlands, 2012; Volume 92, pp. 57–63. [Google Scholar] [CrossRef]

- Clémenson, S.; Léonard, D.; Sage, D.; David, L.; Espuche, E. Metal nanocomposite films prepared in Situ from PVA and silver nitrate. Study of the nanostructuration process and morphology as a function of the in Situ routes. J. Polym. Sci. Part. A Polym. Chem. 2008, 46, 2062–2071. [Google Scholar] [CrossRef]

- Picard, E.; Gauthier, H.; Gérard, J.-F.; Espuche, E. Influence of the intercalated cations on the surface energy of montmorillonites: Consequences for the morphology and gas barrier properties of polyethylene/montmorillonites nanocomposites. J. Colloid Interface Sci. 2007, 307, 364–376. [Google Scholar] [CrossRef]

- Dal Pont, K.; Gérard, J.-F.; Espuche, E. Modification of α-ZrP nanofillers by amines of different chain length: Consequences on the morphology and mechanical properties of styrene butadiene rubber based nanocomposites. Eur. Polym. J. 2012, 48, 217–227. [Google Scholar] [CrossRef]

- Morel, F.; Bounor-Legaré, V.; Espuche, E.; Persyn, O.; Lacroix, M. Surface modification of calcium carbonate nanofillers by fluoro- and alkyl-alkoxysilane: Consequences on the morphology, thermal stability and gas barrier properties of polyvinylidene fluoride nanocomposites. Eur. Polym. J. 2012, 48, 919–929. [Google Scholar] [CrossRef]

- Dal Pont, K.; Gérard, J.-F.; Espuche, E. Microstructure and properties of styrene-butadiene rubber based nanocomposites prepared from an aminosilane modified synthetic lamellar nanofiller. J. Polym. Sci. Part B Polym. Phys. 2013, 51, 1051–1059. [Google Scholar] [CrossRef]

- Pinnavaia, T.J. Intercalated clay catalysts. Science 1983, 220, 365–371. [Google Scholar] [CrossRef] [PubMed]

- Okada, A.; Usuki, A. The chemistry of polymer-clay hybrids. Mater. Sci. Eng. C 1995, 3, 109–115. [Google Scholar] [CrossRef]

- Giannelis, E.P. Polymer layered silicate nanocomposites. Adv. Mater. 1996, 8, 29–35. [Google Scholar] [CrossRef]

- Gain, O.; Espuche, E.; Pollet, E.; Alexandre, M.; Dubois, P. Gas barrier properties of poly(ε-caprolactone)/clay nanocomposites: Influence of the morphology and polymer/clay interactions. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 205–214. [Google Scholar] [CrossRef]

- Espuche, E.; David, L.; Rochas, C.; Afeld, J.L.; Compton, J.M.; Thompson, D.W.; Thompson, D.S.; Kranbuehl, D.E. In situ generation of nanoparticulate lanthanum(III) oxide-polyimide films: Characterization of nanoparticle formation and resulting polymer properties. Polymer 2005, 46, 6657–6665. [Google Scholar] [CrossRef]

- Picard, E.; Gérard, J.-F.; Espuche, E. Reinforcement of the Gas Barrier Properties of Polyethylene and Polyamide Through the Nanocomposite Approach: Key Factors and Limitations. Oil Gas. Sci. Technol. Rev. IFP Energ. Nouv. 2015, 70, 237–249. [Google Scholar] [CrossRef]

- Sabard, M.; Gouanvé, F.; Espuche, E.; Fulchiron, R.; Seytre, G.; Fillot, L.-A.; Trouillet-Fonti, L. Influence of montmorillonite and film processing conditions on the morphology of polyamide 6: Effect on ethanol and toluene barrier properties. J. Memb. Sci. 2014, 450, 487–498. [Google Scholar] [CrossRef]

- Waché, R.; Klopffer, M.-H.; Gonzalez, S. Characterization of Polymer Layered Silicate Nanocomposites by Rheology and Permeability Methods: Impact of the Interface Quality. Oil Gas. Sci. Technol. Rev. IFP Energ. Nouv. 2015, 70, 267–277. [Google Scholar] [CrossRef][Green Version]

- Suzuki, T.; Yamada, Y. Physical and gas transport properties of novel hyperbranched polyimide—Silica hybrid membranes. Polym. Bull. 2005, 53, 139–146. [Google Scholar] [CrossRef]

- Cornelius, C.J.; Marand, E. Hybrid silica-polyimide composite membranes: Gas transport properties. J. Membr. Sci. 2002, 202, 97–118. [Google Scholar] [CrossRef]

- Osman, M.A.; Mittal, V.; Morbidelli, M.; Suter, U.W. Polyurethane adhesive nanocomposites as gas permeation barrier. Macromolecules 2003, 36, 9851–9858. [Google Scholar] [CrossRef]

- Tenn, N.; Follain, N.; Soulestin, J.; Crétois, R.; Bourbigot, S.; Marais, S. Effect of nanoclay hydration on barrier properties of PLA/montmorillonite based nanocomposites. J. Phys. Chem. C 2013, 117, 12117–12135. [Google Scholar] [CrossRef]

- Minelli, M. Characterization and Modeling of the Barrier Properties in Nanostructured Systems. Ph.D. Thesis, University of Bologna, Bologna, Italy, 2009. [Google Scholar]

- Dutta, R.C.; Bhatia, S.K. Structure and Gas Transport at the Polymer—Zeolite Interface: Insights from Molecular Dynamics Simulations. ACS Appl. Mater. Interfaces 2018, 10, 5992–6005. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Z.; Jiang, J. Metal—organic framework/polymer mixed-matrix membranes for H2/CO2 separation: A fully atomistic simulation study. J. Phys. Chem. C 2012, 116, 19268–19277. [Google Scholar] [CrossRef]

- Semino, R.; Durholt, J.P.; Schmid, R.; Maurin, G. Multiscale modeling of the HKUST-1/polyvinyl alcohol) interface: From an atomistic to a coarse graining approach. J. Phys. Chem. C 2017, 121, 21491–21496. [Google Scholar] [CrossRef]

- Semino, R.; Ramsahye, N.A.; Ghoufi, A.; Maurin, G. Microscopic Model of the Metal-Organic Framework/Polymer Interface: A First Step toward Understanding the Compatibility in Mixed Matrix Membranes. ACS Appl. Mater. Interfaces 2016, 8, 809–819. [Google Scholar] [CrossRef] [PubMed]

- Benzaqui, M.; Semino, R.; Menguy, N.; Carn, F.; Kundu, T.; Guigner, J.-M.; McKeown, N.B.; Msayib, K.J.; Carta, M.; Malpass-Evans, R.; et al. Toward an Understanding of the Microstructure and Interfacial Properties of PIMs/ZIF-8 Mixed Matrix Membranes. ACS Appl. Mater. Interfaces 2016, 8, 27311–27321. [Google Scholar] [CrossRef] [PubMed]

- Mortazavi, B.; Bardon, J.; Ahzi, S. Interphase effect on the elastic and thermal conductivity response of polymer nanocomposite materials: 3D finite element study. Comput. Mater. Sci. 2013, 69, 100–106. [Google Scholar] [CrossRef]

- Amraei, J.; Jam, J.E.; Arab, B.; Firouz-Abadi, R.D. Effect of interphase zone on the overall elastic properties of nanoparticle-reinforced polymer nanocomposites. J. Compos. Mater. 2019, 53, 1261–1274. [Google Scholar] [CrossRef]

- Srivastava, A.; Kumar, D. A continuum model to study interphase effects on elastic properties of CNT/GS-nanocomposite. Mater. Res. Express 2017, 4, 025036. [Google Scholar] [CrossRef]

- Xu, W.; Zeng, Q.; Yu, A.; Paul, D.R. Determination of interphase thickness and mechanical properties of effective nanofillers in polymer nanocomposites by molecular dynamic simulation. In Proceedings of the Materials Science Forum; Trans Tech Publications Ltd.: Freinbach, Switzerland, 2010; Volume 654–656, pp. 1654–1657. [Google Scholar] [CrossRef]

| Model | Filler Shape | Distribution | Equation, | Ref. |

|---|---|---|---|---|

| Maxwell | Spheres | Regular | [43] | |

| Bruggeman | Spheres | Regular | [44] | |

| Rayleigh | Fibers | Regular | [45] | |

| Shen and Springer | Fibers | Regular | [46] | |

| Nielsen | Ribbons | Regular | [8] | |

| Sorrentino et al. | Ribbons | Random | [48] | |

| Lape et al. | Ribbons | Random | [49] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Htira, T.; Zid, S.; Zinet, M.; Espuche, E. Finite Element Analysis of Gas Diffusion in Polymer Nanocomposite Systems Containing Rod-like Nanofillers. Polymers 2021, 13, 2615. https://doi.org/10.3390/polym13162615

Htira T, Zid S, Zinet M, Espuche E. Finite Element Analysis of Gas Diffusion in Polymer Nanocomposite Systems Containing Rod-like Nanofillers. Polymers. 2021; 13(16):2615. https://doi.org/10.3390/polym13162615

Chicago/Turabian StyleHtira, Thouaiba, Sarra Zid, Matthieu Zinet, and Eliane Espuche. 2021. "Finite Element Analysis of Gas Diffusion in Polymer Nanocomposite Systems Containing Rod-like Nanofillers" Polymers 13, no. 16: 2615. https://doi.org/10.3390/polym13162615

APA StyleHtira, T., Zid, S., Zinet, M., & Espuche, E. (2021). Finite Element Analysis of Gas Diffusion in Polymer Nanocomposite Systems Containing Rod-like Nanofillers. Polymers, 13(16), 2615. https://doi.org/10.3390/polym13162615