Thermal, Physical and Mechanical Properties of Poly(Butylene Succinate)/Kenaf Core Fibers Composites Reinforced with Esterified Lignin

Abstract

1. Introduction

2. Materials and Methods

2.1. Esterification with Phthalic Anhydride Modification

2.2. Preparation and Formulation of Modified Lignin-Based Composites

2.3. Characterization of Surface Lignin Modification

2.3.1. Weight Percent Gain (WPG)

2.3.2. Fourier Transforms Infrared Spectroscopy (FTIR)

2.3.3. Dynamic Mechanical Analysis (DMA)

2.3.4. Thermal Conductivity Test

2.3.5. Physical Properties

Water Absorption Test

Density Determination of Material and Composite Sheet

2.3.6. Mechanical Properties

Tensile and Flexural Test

Impact Test

2.3.7. Morphological Analysis

3. Results & Discussion

3.1. Weight Percent Gain (WPG)

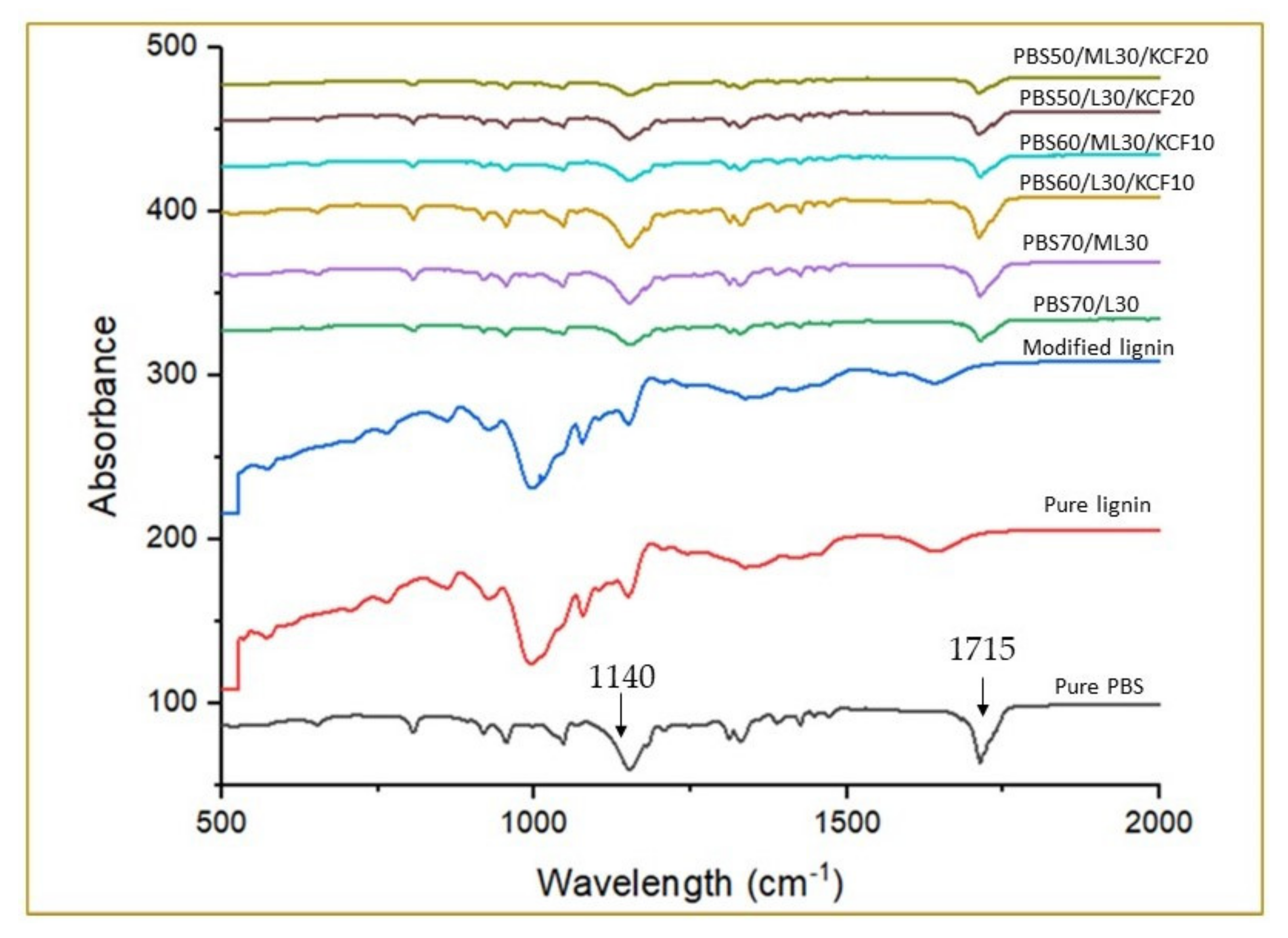

3.2. Fourier Transforms Infrared Spectroscopy (FTIR)

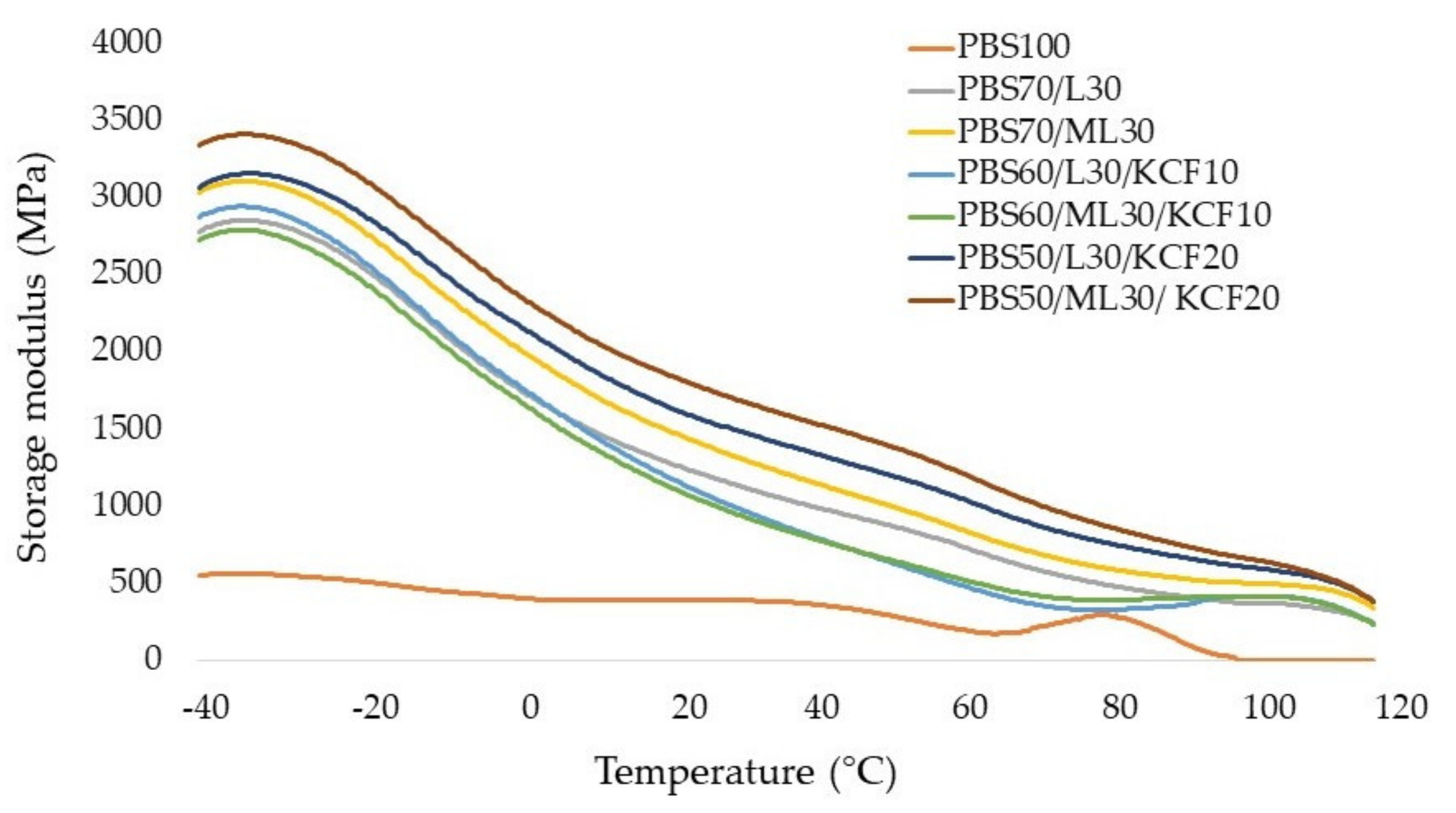

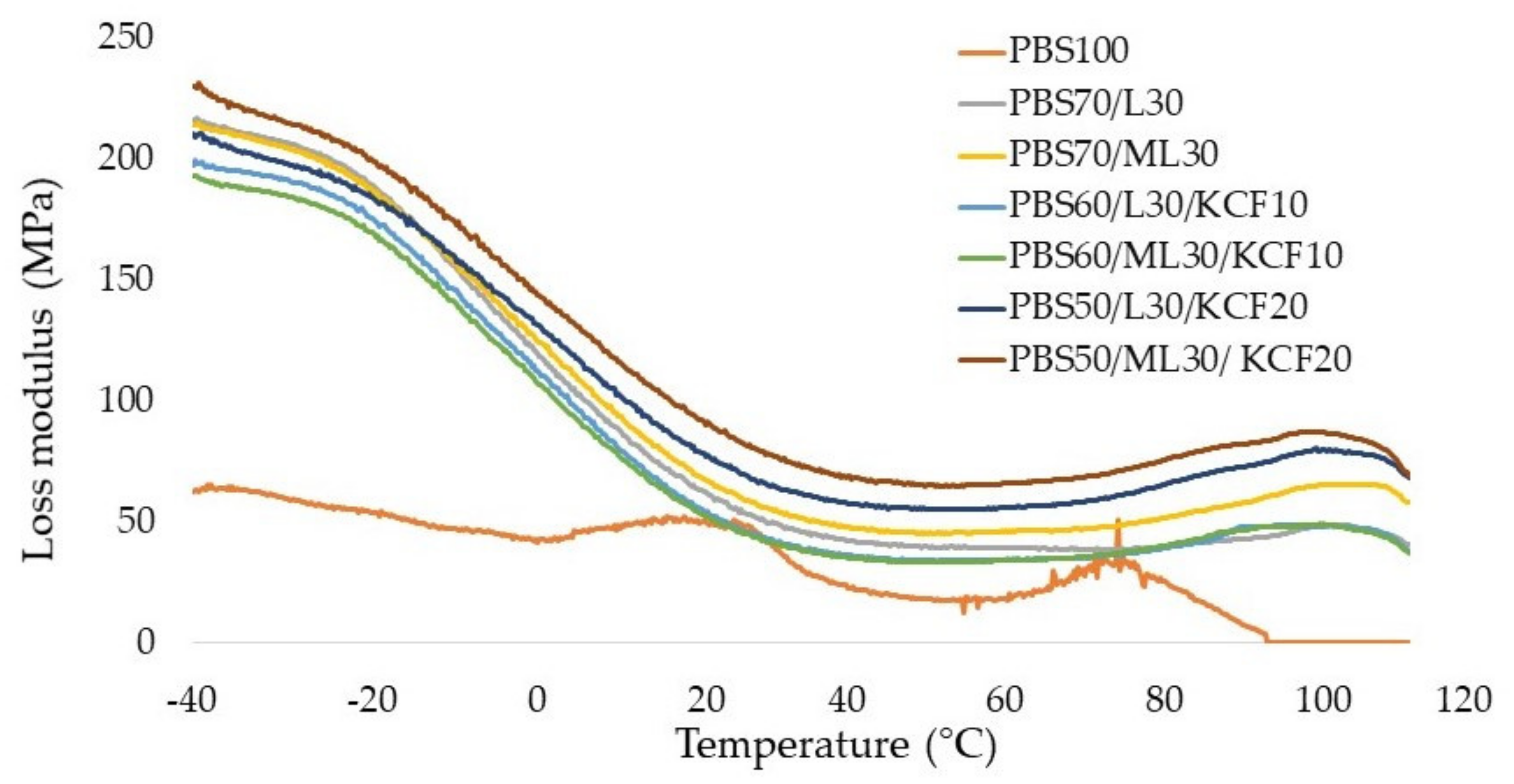

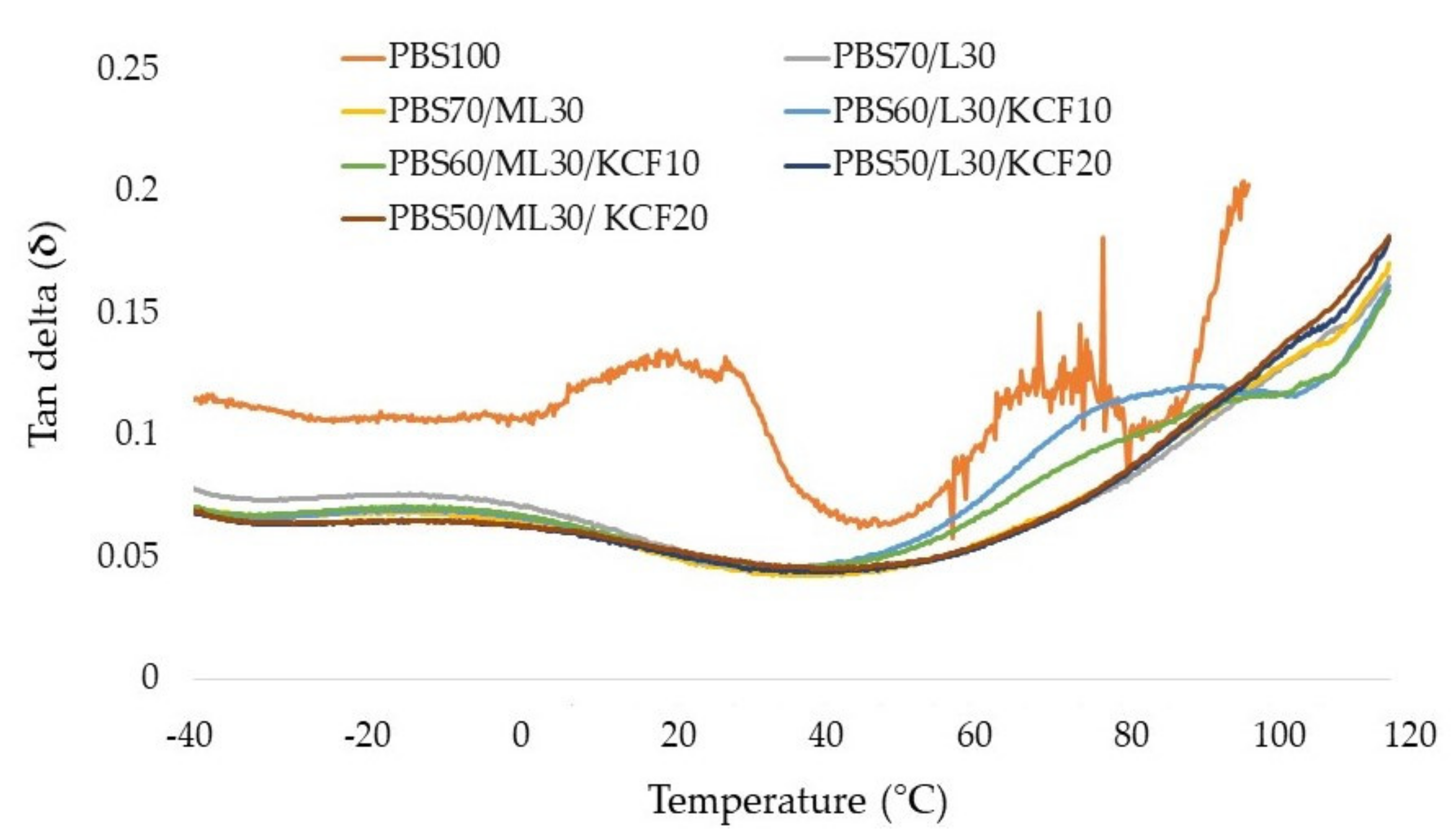

3.3. Dynamic Mechanical Analysis (DMA)

3.4. Physical Properties

3.4.1. Density

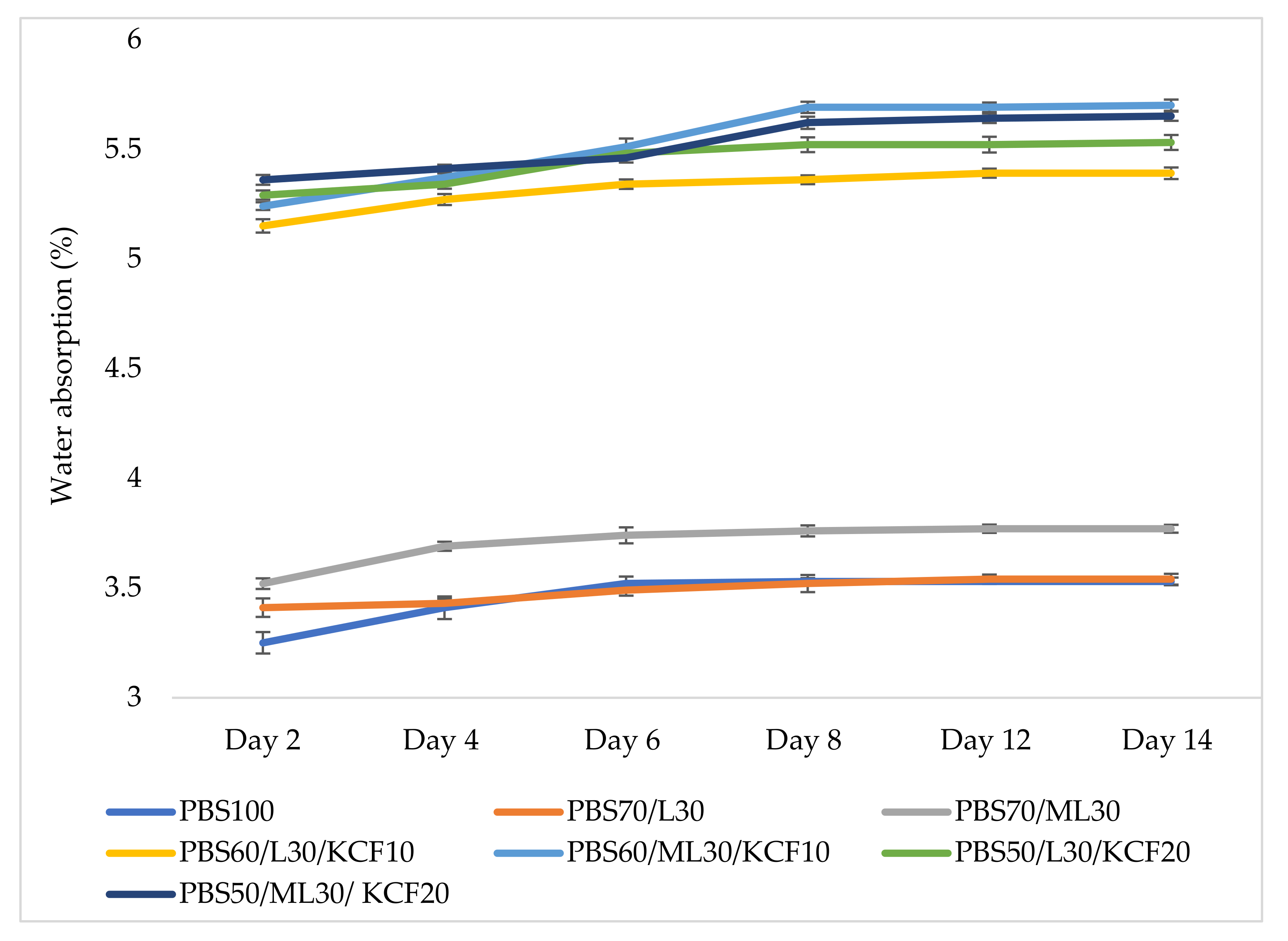

3.4.2. Water Absorption

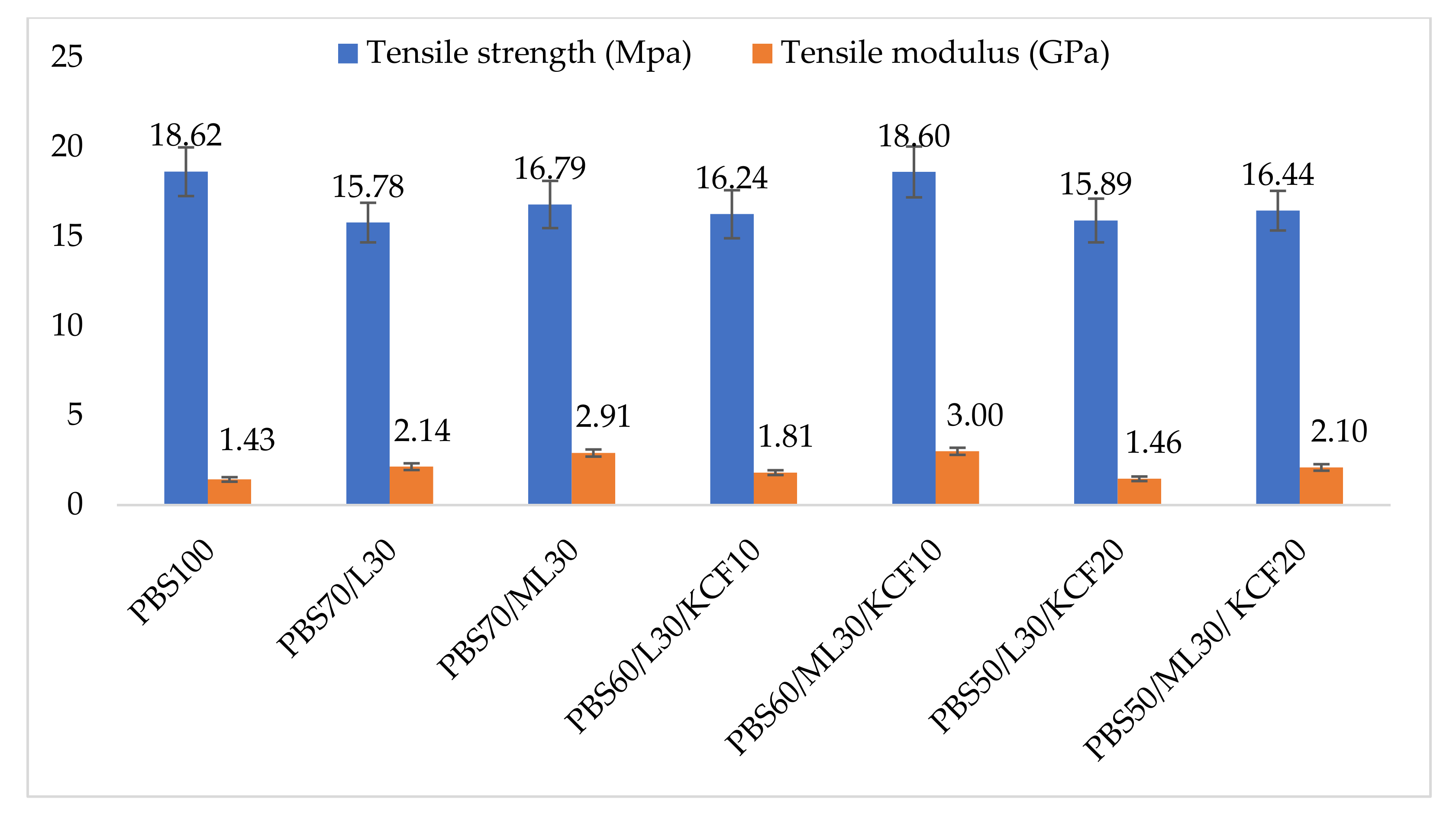

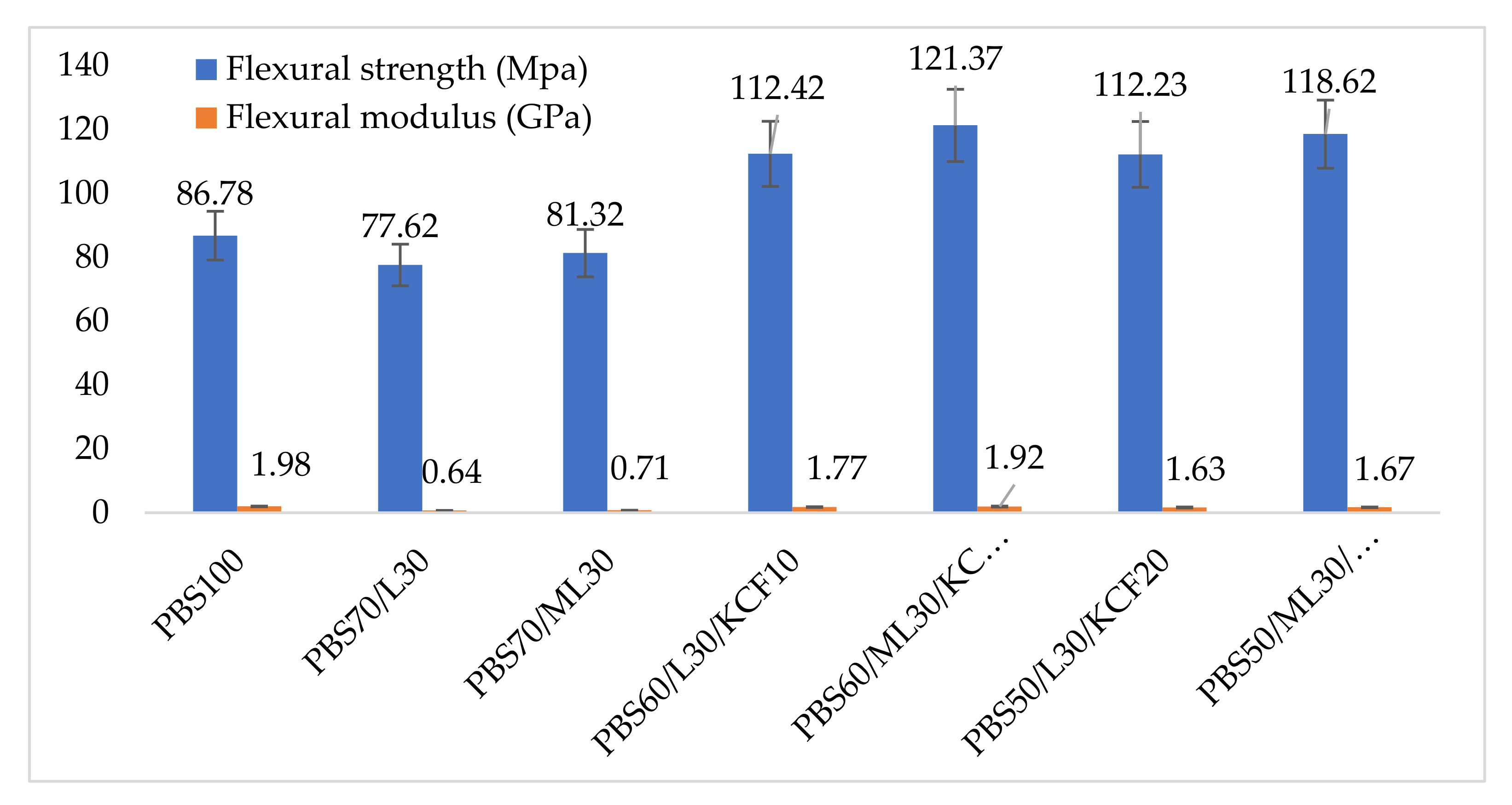

3.5. Mechanical Properties

3.6. Thermal Conductivity

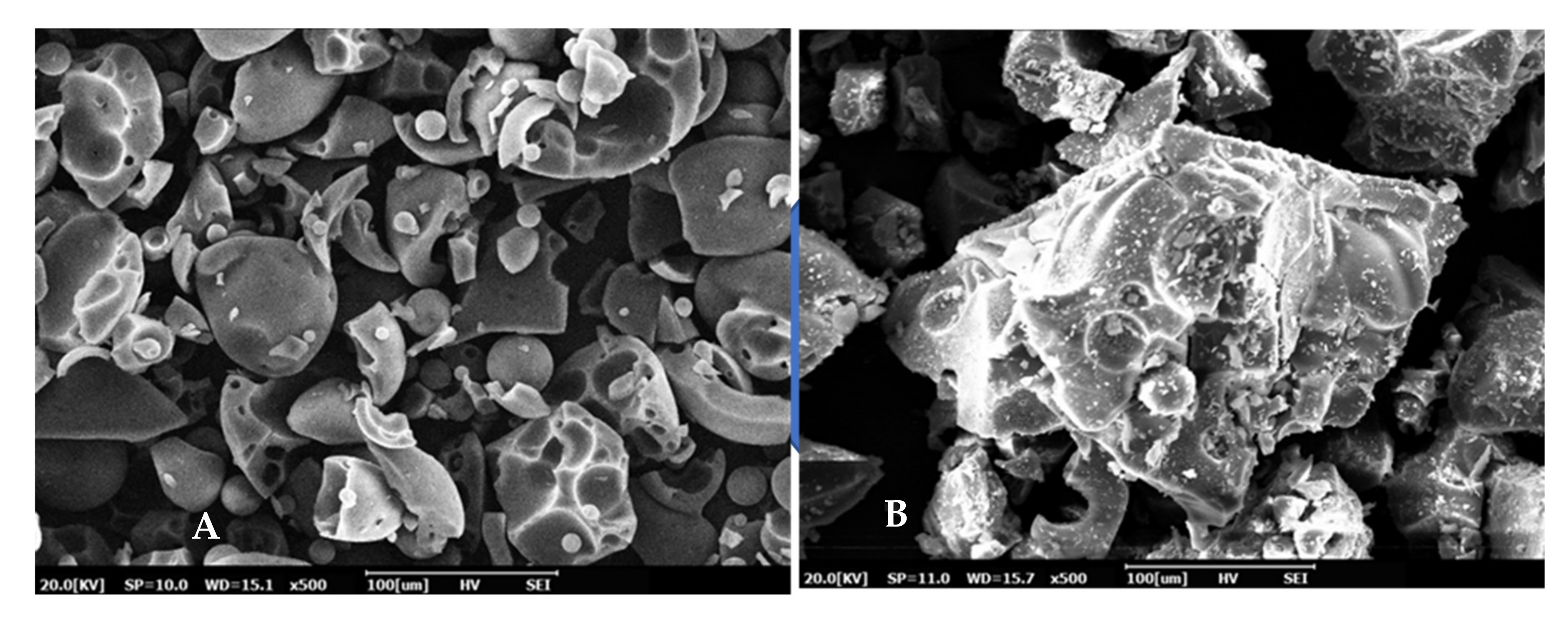

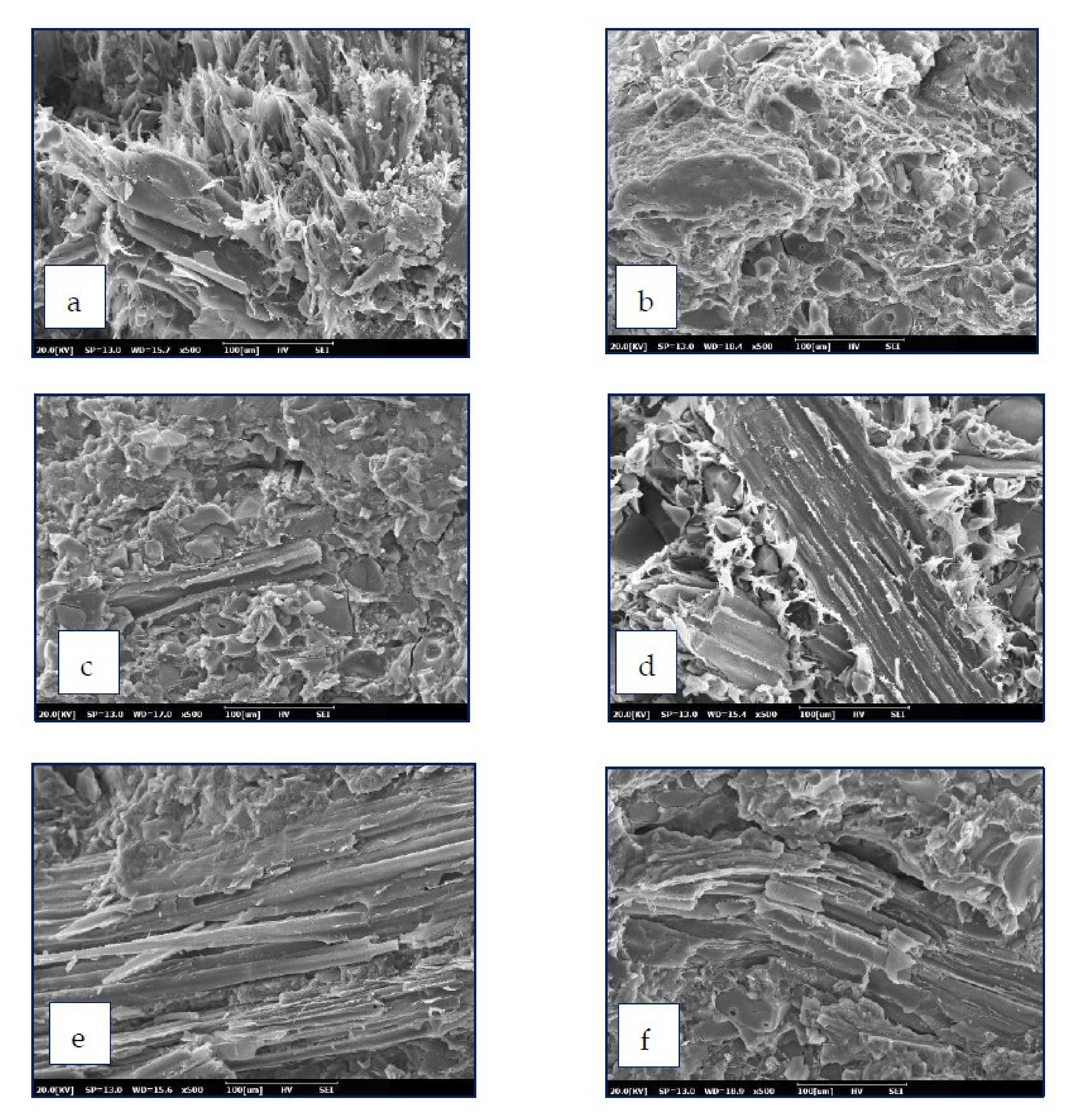

3.7. Morphology Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Dedication

References

- Ang, A.F.; Ashaari, Z.; Lee, S.H.; Tahir, P.M.; Halis, R. Lignin-based copolymer adhesives for composite wood panels—A review. Int. J. Adhes. Adhes. 2019, 95, 102408. [Google Scholar] [CrossRef]

- An, L.; Si, C.; Wang, G.; Choi, C.S.; Yu, Y.H.; Bae, J.H.; Lee, S.M.; Kim, Y.S. Efficient and green approach for the esterification of lignin with oleic acid using surfactant-combined microreactors in water. BioResources 2020, 15, 89–104. [Google Scholar]

- Orebom, A.; Di Francesco, D.; Shakari, P.; Samec, J.; Pierrou, C. Thermal and Mechanical Properties of Esterified Lignin in Various Polymer Blends. Molecules 2021, 26, 3219. [Google Scholar] [CrossRef] [PubMed]

- Kubo, S.; Kadla, J.F. Lignin-based Carbon Fibers: Effect of Synthetic Polymer Blending on Fiber Properties. J. Polym. Environ. 2005, 13, 97–105. [Google Scholar] [CrossRef]

- Abejón, R.; Pérez-Acebo, H.; Clavijo, L. Alternatives for Chemical and Biochemical Lignin Valorization: Hot Topics from a Bibliometric Analysis of the Research Published During the 2000–2016 Period. Processes 2018, 6, 98. [Google Scholar] [CrossRef]

- Saffian, H.A.; Talib, M.A.; Lee, S.H.; Tahir, P.M.; Lee, C.H.; Ariffin, H.; Asa’Ari, A.Z.M. Mechanical Strength, Thermal Conductivity and Electrical Breakdown of Kenaf Core Fiber/Lignin/Polypropylene Biocomposite. Polymers 2020, 12, 1833. [Google Scholar] [CrossRef]

- Ahmad Saffian, H.; Hyun-Joong, K.; Tahir, P.; Ibrahim, N.A.; Lee, S.H.; Lee, C.H. Effect of Lignin Modification on Properties of Kenaf Core Fiber Reinforced Poly(Butylene Succinate) Biocomposites. Materials 2019, 12, 4043. [Google Scholar] [CrossRef]

- Qu, J.-P.; Zhang, G.-Z.; Chen, H.-Z.; Yin, X.-C.; He, H.-Z. Solid conveying in vane extruder for polymer processing: Effects on pressure establishment. Polym. Eng. Sci. 2012, 52, 2147–2156. [Google Scholar] [CrossRef]

- Liu, H.Y.; Chen, F.Q.; Guo, R.B.; Zhang, G.; Qu, J. Effect of compatibilizer on the properties of PBS/lignin composites prepared via a vane extruder. J. Polym. Eng. 2015, 35, 829–837. [Google Scholar] [CrossRef]

- Huang, J.; Lu, X.; Zhang, N.; Yang, L.; Yan, M.; Liu, H.; Zhang, G.; Qu, J. Study on the properties of nano-TiO2/polybutylene succinate composites prepared by vane extruder. Polym. Compos. 2013, 35, 53–59. [Google Scholar] [CrossRef]

- Shih, Y.F.; Lee, W.C.; Jeng, R.J.; Huang, C.M. Water bamboo husk-reinforced poly (butylene succinate) biodegradable compo-sites. J. Appl. Polym. Sci. 2006, 99, 188–199. [Google Scholar] [CrossRef]

- Hassan, F.; Rozli, Z.; Mariyam, J.G.; Che Husna, A. Kenaf fiber composite in automotive industry. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 315–321. [Google Scholar] [CrossRef]

- Shahar, F.S.; Sultan, M.T.H.; Lee, S.H.; Jawaid, M.; Shah, A.U.M.; Safri, S.N.A.; Sivasankaran, P.N. A review on the orthotics and prosthetics and the potential of kenaf composites as alternative materials for ankle-foot orthosis. J. Mech. Behav. Biomed. Mater. 2019, 99, 169–185. [Google Scholar] [CrossRef] [PubMed]

- Ishak, M.R.; Leman, Z.; Sapuan, S.M.; Edeerozey, A.M.M.; Othman, I.S. Mechanical properties of kenaf bast and core fibre reinforced unsaturated polyester composites. IOP Conf. Ser. Mater. Sci. Eng. 2010, 11, 012006. [Google Scholar] [CrossRef]

- Ismail, H.; Hamid Abdullah, A.; Abu Bakar, A. Kenaf Core reinforced high-density polyethylene/soya powder composites: The effects of filler loading and compatibilizer. J. Reinf. Plast. Compos. 2010, 29, 2489–2497. [Google Scholar] [CrossRef]

- Feng, Y.; Shen, H.; Qu, J.; Liu, B.; He, H.; Han, L. Preparation and properties of PBS/sisal-fiber composites. Polym. Eng. Sci. 2010, 51, 474–481. [Google Scholar] [CrossRef]

- Kai, D.; Tan, M.J.; Chee, P.L.; Chua, Y.K.; Yap, Y.L.; Loh, X.J. Towards lignin-based functional materials in a sustainable world. Green Chem. 2016, 18, 1175–1200. [Google Scholar] [CrossRef]

- Thielemans, W.; Wool, R.P. Lignin Esters for Use in Unsaturated Thermosets: Lignin Modification and Solubility Modeling. Biomacromolecules 2005, 6, 1895–1905. [Google Scholar] [CrossRef]

- Yue, X.; Liu, P.; Ning, Y.; Xu, Y. Upgrading poly(butylene succinate)/wood fiber composites by esterified lignin. Compos. Interfaces 2016, 23, 873–885. [Google Scholar] [CrossRef]

- Chen, Y.; Stark, N.M.; Cai, Z.; Frihart, C.R.; Lorenz, L.F. and Ibach, R. E. Chemical modification of kraft lignin: Effect on chemical and thermal properties. BioResources 2014, 9, 5488–5500. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Hechenleitner, A.W.; Job, A.; Radovanocic, E.; Pineda, E.G. Thermal and photochemical stability of poly(vinyl alcohol)/modified lignin blends. Polym. Degrad. Stab. 2006, 91, 1192–1201. [Google Scholar] [CrossRef]

- Sailaja, R.; Deepthi, M. Mechanical and thermal properties of compatibilized composites of polyethylene and esterified lignin. Mater. Des. 2010, 31, 4369–4379. [Google Scholar] [CrossRef]

- Xiao, B.; Sun, X.F.; Sun, R.C. The chemical modification of lignin with succinic anhydride in aqueous systems. Polym. Degrad. Stab. 2001, 71, 223–231. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Ismail, H.; Ahmad, M.N.; Ariffin, A.; Hassan, K. The effect of various anhydride modifications on me-chanical properties and water absorption of oil palm empty fruit bunches reinforced polyester composites. Polym. Int. 2001, 50, 395–402. [Google Scholar] [CrossRef]

- Fox, S.C.; McDonald, A.G. Chemical and thermal characterization of three industrial lignins and their corresponding lignin esters. BioResources 2010, 5, 990–1009. [Google Scholar]

- Sahoo, S.; Misra, M.; Mohanty, A.K. Enhanced properties of lignin-based biodegradable polymer composites using injection moulding process. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1710–1718. [Google Scholar] [CrossRef]

- Lee, S.G.; Cho, D.; Park, W.H.; Han, S.O.; Drzal, L.T. Novel silk/poly(butylene succinate) biocomposites: The effect of short fibre content on their mechanical and thermal properties. Compos. Sci. Technol. 2005, 65, 647–657. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Rodrigue, D. Mechanical, rheological, morphological and water absorption properties of maleated polyethylene/hemp composites: Effect of ground tire rubber addition. Compos. Part B Eng. 2013, 51, 337–344. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.R. Dimensional stability of pineapple leaf fibre reinforced phenolic composites. In Proceedings of the 3rd Advanced Materials Conference 2016 (3rd AMC 2016), Kedah, Malaysia, 28–29 November 2016; p. 030016. [Google Scholar]

- Mariatti, M.; Jannah, M.; Abu Bakar, A.; Khalil, H.A. Properties of Banana and Pandanus Woven Fabric Reinforced Unsaturated Polyester Composites. J. Compos. Mater. 2008, 42, 931–941. [Google Scholar] [CrossRef]

- Ashori, A.; Sheshmani, S. Hybrid composites made from recycled materials: Moisture absorption and thickness swelling be-havior. Bioresour. Technol. 2010, 101, 4717–4720. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.H.; Kim, H.J.; Park, H.J.; Lee, B.J.; Hwang, T.S. Water absorption behavior and mechanical properties of lignocellulosic filler–polyolefin bio-composites. Compos. Struct. 2006, 72, 429–437. [Google Scholar] [CrossRef]

- Fabunmi, O.O.; Tabil, L.G.; Chang, P.R.; Panigrahi, S. Developing biodegradable plastics fromstarch. In Proceedings of the ASABE/CSBE North Central Intersectional Meeting, Las Vegas, NV, USA, 27–30 July 2003. [Google Scholar]

- Kim, H.-S.; Yang, H.-S.; Lee, B.; Hwang, T.S. Thermal properties of agro-flour-filled biodegradable polymer bio-composites. J. Therm. Anal. Calorim. 2005, 81, 299–306. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; Monteiro, S. Evaluation of Izod impact and bend properties of epoxy composites reinforced with mallow fibers. J. Mater. Res. Technol. 2020, 9, 373–382. [Google Scholar] [CrossRef]

- Kiae, M.; Kord, B.; Vaysi, R. Influence of residual lignin content on physical and mechanical properties of kraft pulp/pp composites. Maderas. Ciencia Tecnología 2014, 16, 495–503. [Google Scholar] [CrossRef][Green Version]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Karwa, R. One-Dimensional Steady State Heat Conduction. In Ignition and Wave Processes in Combustion of Solids; Springer Science and Business Media LLC: New York, NY, USA, 2017; pp. 7–116. [Google Scholar]

- Zhao, X.; Zhang, Y.; Yang, M.; Huang, Z.; Hu, H.; Huang, A.; Feng, Z. Acylation of Lignin with Different Acylating Agents by Mechanical Activation-Assisted Solid Phase Synthesis: Preparation and Properties. Polymer 2018, 10, 907. [Google Scholar] [CrossRef] [PubMed]

| Comosites | Code | PBS (%) | Lignin (%) | PMDI (%) | KCF (%) |

|---|---|---|---|---|---|

| PBS | PBS100 | 100 | 0 | 3 | 0 |

| PBS/Lignin | PBS70/L30 | 70 | 30 | 3 | 0 |

| PBS/Modified Lignin | PBS70/ML30 | 70 | 30 | 3 | 0 |

| PBS/Lignin/KCF | PBS60/L30/KCF10 | 60 | 30 | 3 | 10 |

| PBS/Modified Lignin/KCF | PBS60/ML30/KCF10 | 60 | 30 | 3 | 10 |

| PBS/Lignin/KCF | PBS50/L30/KCF20 | 50 | 30 | 3 | 20 |

| PBS/Modified Lignin/KCF | PBS50/ML30/KCF20 | 50 | 30 | 3 | 20 |

| Composites | Density (g/cm3) |

|---|---|

| PBS100 | 1.26 ± 0.26 |

| PBS70/L30 | 1.43 ± 0.21 |

| PBS70/ML30 | 1.41 ± 0.08 |

| PBS60/L30/KCF10 | 1.37 ± 0.46 |

| PBS60/ML30/KCF10 | 1.39 ± 0.78 |

| PBS50/L30/KCF20 | 1.34 ± 0.72 |

| PBS50/ML30/KCF20 | 1.38 ± 0.68 |

| Composites | Thermal Conductivity (W/mk) |

|---|---|

| PBS100 | 0.0903 ± 0.0005 |

| PBS70/L30 | 0.0942 ± 0.0009 |

| PBS70/ML30 | 0.0970 ± 0.0013 |

| PBS60/L30/KCF10 | 0.0918 ± 0.0009 |

| PBS60/ML30/KCF10 | 0.0983 ± 0.0005 |

| PBS50/L30/KCF20 | 0.0965 ± 0.0007 |

| PBS50/ML30/KCF20 | 0.0983 ± 0.0005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saffian, H.A.; Yamaguchi, M.; Ariffin, H.; Abdan, K.; Kassim, N.K.; Lee, S.H.; Lee, C.H.; Shafi, A.R.; Humairah Alias, A. Thermal, Physical and Mechanical Properties of Poly(Butylene Succinate)/Kenaf Core Fibers Composites Reinforced with Esterified Lignin. Polymers 2021, 13, 2359. https://doi.org/10.3390/polym13142359

Saffian HA, Yamaguchi M, Ariffin H, Abdan K, Kassim NK, Lee SH, Lee CH, Shafi AR, Humairah Alias A. Thermal, Physical and Mechanical Properties of Poly(Butylene Succinate)/Kenaf Core Fibers Composites Reinforced with Esterified Lignin. Polymers. 2021; 13(14):2359. https://doi.org/10.3390/polym13142359

Chicago/Turabian StyleSaffian, Harmaen Ahmad, Masayuki Yamaguchi, Hidayah Ariffin, Khalina Abdan, Nur Kartinee Kassim, Seng Hua Lee, Ching Hao Lee, Ayu Rafiqah Shafi, and Aisyah Humairah Alias. 2021. "Thermal, Physical and Mechanical Properties of Poly(Butylene Succinate)/Kenaf Core Fibers Composites Reinforced with Esterified Lignin" Polymers 13, no. 14: 2359. https://doi.org/10.3390/polym13142359

APA StyleSaffian, H. A., Yamaguchi, M., Ariffin, H., Abdan, K., Kassim, N. K., Lee, S. H., Lee, C. H., Shafi, A. R., & Humairah Alias, A. (2021). Thermal, Physical and Mechanical Properties of Poly(Butylene Succinate)/Kenaf Core Fibers Composites Reinforced with Esterified Lignin. Polymers, 13(14), 2359. https://doi.org/10.3390/polym13142359