1. Introduction

Three-dimensional (3D) printing, also known as additive manufacturing (AM), is a rapid prototyping technology that was developed in the 1980s. This technology is based on the computer-aided design (CAD) model and helps to construct physical objects using powdered metal or plastic and other bondable materials [

1]. Fused deposition modelling (FDM), as an AM process, was initially developed in the early 1990s. It develops the components using layer by layer deposition with the thermoplastic material filaments extruded through a nozzle [

2]. Due to its safe, fast, and effective operation, freedom of customisation, and cost-effectiveness, FDM has become the most widely used AM process in customised and low-volume production industries [

3]. Apart from functional prototyping, FDM is also used in aerospace, automotive, medical and biomechanical sectors [

4,

5,

6,

7,

8].

Several different thermoplastic polymer materials are used in FDM. Acrylonitrile butadiene styrene (ABS) is the most commonly used plastic because of its low expense, high strength, and temperature resistance [

9]. Although the differences in the mechanical properties between FDM ABS and conventionally manufactured ABS have been discussed in the literature [

10,

11,

12,

13,

14,

15], the most common conclusion was that FDM ABS has 11% to 37% reduced modulus and 22% to 57% reduced strength [

16,

17]. Some studies evaluated the different printing parameter effects on FDM ABS mechanical properties (strength and modulus) [

18,

19,

20,

21,

22,

23]. Some studies attempted to improve the mechanical properties of FDM polymers by optimising the 3D printing parameters [

13,

24,

25,

26]. However, only a few studies focused on the fatigue behaviour of FDM ABS [

10,

27,

28,

29,

30,

31].

As a result of the propagation of cracks due to a repetitive or cyclic load, fatigue failure is normal in practical structures where the cyclic stresses are typically significantly less than yielding strength. Therefore, it is significant to evaluate the fatigue performance of the material. Safai et al. Shanmugam et al. and He et al. reviewed the fatigue behaviour of FDM polymeric materials [

8,

32,

33]. The results of their overview show that determining the best printing parameter combinations for fatigue strength is a challenge because of the synergism between variables and 3D printed material properties. The experimental studies are essential to understand how these parameters affect the fatigue behaviour. Therefore, some studies carried out the experimental works for different 3D printed polymers with variable parameters. Letcher and Waytashek and Afrose et al. all reported that 45

° building orientation generated the maximum fatigue strength for 3D printed polylactic acid (PLA) in tension fatigue tests [

34,

35,

36]. The results of a tension fatigue test for FDM ABS had the same conclusion [

10,

28,

29]. However, the 0°(X)/90°(Y) raster orientation had the best fatigue life in compact tension test for FDM PLA [

37]. X orientation provided the highest fatigue strength for FDM ABS in a tension fatigue test [

38]. For other printing parameters, some studies carried out the flexural fatigue tests for FDM PLA bar and the results showed that larger layer thickness and nozzle size both increased the fatigue life [

39,

40,

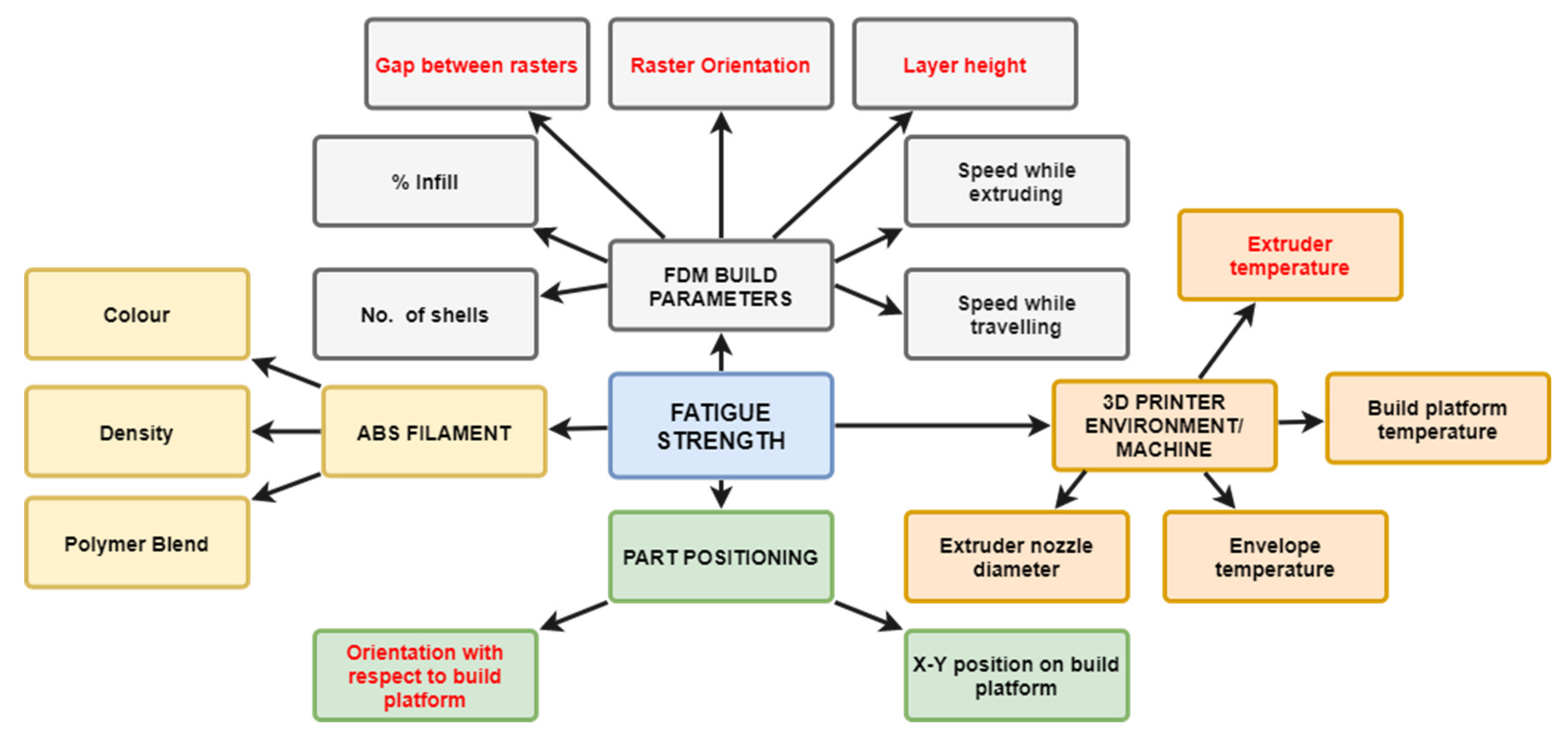

41]. However, similar research has not been carried out on FDM ABS. Jap et al. listed the potential printing parameters, depicted in

Figure 1 (dominant factors shown in red), which may affect the fatigue life of FDM ABS through many complex mechanisms and proposed that raster orientation is a critical parameter that is related to the tensile strength of FDM ABS [

27]. Sharma and Ziemian proposed that the 0° or +45°/−45° raster orientation achieved the most fatigue cycles to failure in a tension–tension fatigue test [

10,

28,

29]. By contrast, Hart and Wetzel confirmed that 90° laminae orientation had the highest fracture toughness [

30]. Padzi et al. carried out the fatigue test for ABS dog bone specimens and concluded that the 3D printed part had a lower fatigue life [

31].

After careful judgement, surprisingly, although there are several printing parameters that may affect the fatigue strength, only a few studies have tested the relationship between them and fatigue performance [

10,

27,

28,

29,

30,

31]; furthermore, these studies only investigated one or two specific parameters [

38]. Safai et al. and Shanmugam et al. presented an overview of the fatigue behavior of 3D printed polymers. However, previous studies only performed the tension–tension or rotating bending fatigue tests for FDM ABS [

32,

33], and as such, although Puigoriol-Forcada et al. investigated the flexural fatigue behaviors of FDM polycarbon (PC) and proposed that build orientation significantly affected the fatigue life due to the inner anisotropy [

42], there have been no studies on the bending/flexure fatigue test for FDM ABS. Additionally, no study has considered the thermo-mechanical loading conditions.

The coupled thermo-mechanical load is more common in an actual working environment, such as the 3D printed flex sensor and capacitive interface device working under temperature load [

43]. It even forms part of the development of the next-generation space exploration vehicle. NASA launched a FDM CubeSat Trailblazer in November 2013 to demonstrate the durability of 3D-printed devices with extreme thermal cycling [

44]. We evaluated the relationship between the several different critical printing parameters and the bending fatigue performance for the FDM ABS beam under different thermo-mechanical loading conditions. Compared with the prior research, the extra thermo loads and dynamic bending stress simulated the practical working conditions better. Building orientation, nozzle size and layer thickness were selected as the significant variables in the research, because the adjustment of these parameters can affect the printing quality, which related to the air-void defects in the specimen. In the study, the specimens with different printing parameters were tested under bending stress with the thermo loads. The fatigue life was measured to find the optimal printing parameter combination to guide the future FDM process and provide a better fatigue life for the FDM structure.

2. Methodology

2.1. Design of Experiment

The current study focused on three significant parameters (building orientation, nozzle size and layer thickness) and investigated their critical effects on the mechanical behaviour of 3D-printed ABS, as already mentioned in the introduction. These parameters also affect the other aspects of the FDM process, such as the manufacturing time and cost.

Building orientation: this can be defined as the path on which the nozzle moves on each layer of the FDM part. It can be set in the 3D printer’s software;

Nozzle size: this determines the diameter of the filament extruded from the printer’s nozzle. Different diameter nozzles can be replaced to print different specimens;

Layer thickness: this defines the height of each layer and the number of layers each part has. It can be set in the 3D printer’s software.

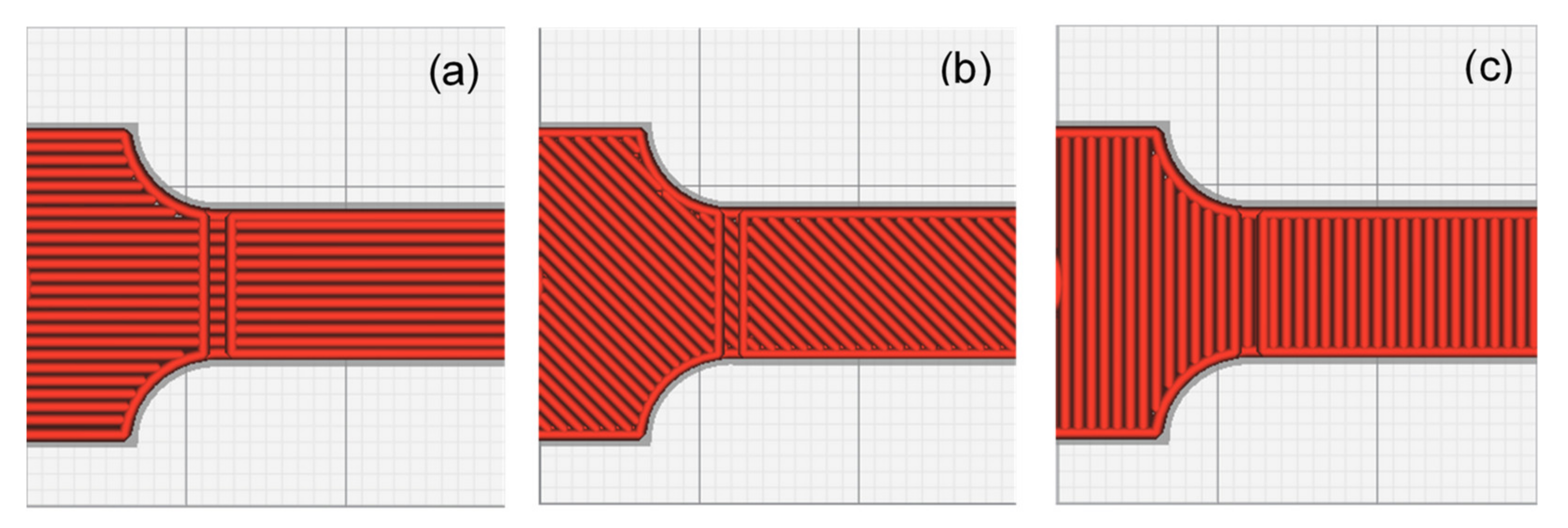

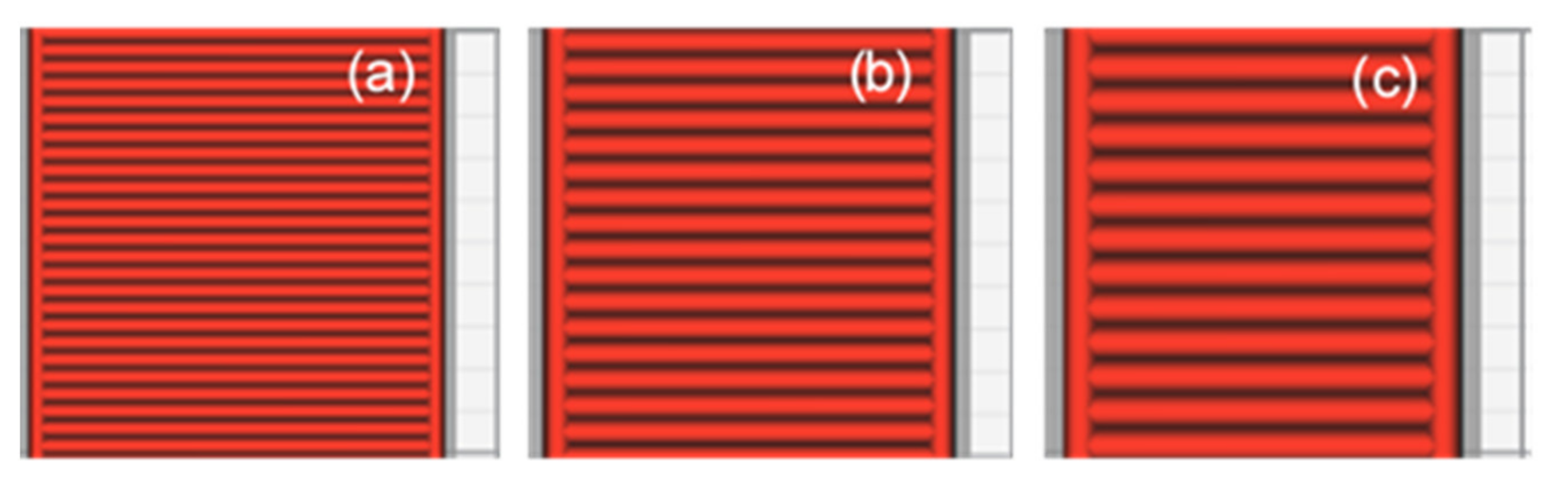

Three values, which are typically used as the default setting for 3D printing, were evaluated for each parameter to cover the typical range of printing parameters. This facilitated a comprehensive evaluation of the experimental results. In addition, the nozzle size and layer thickness were derived from the profile of the default 3D. These values not only provided excellent printing quality but also covered the typical setting range. The selected values for each parameter are listed in

Table 1 and depicted in

Figure 2,

Figure 3 and

Figure 4.

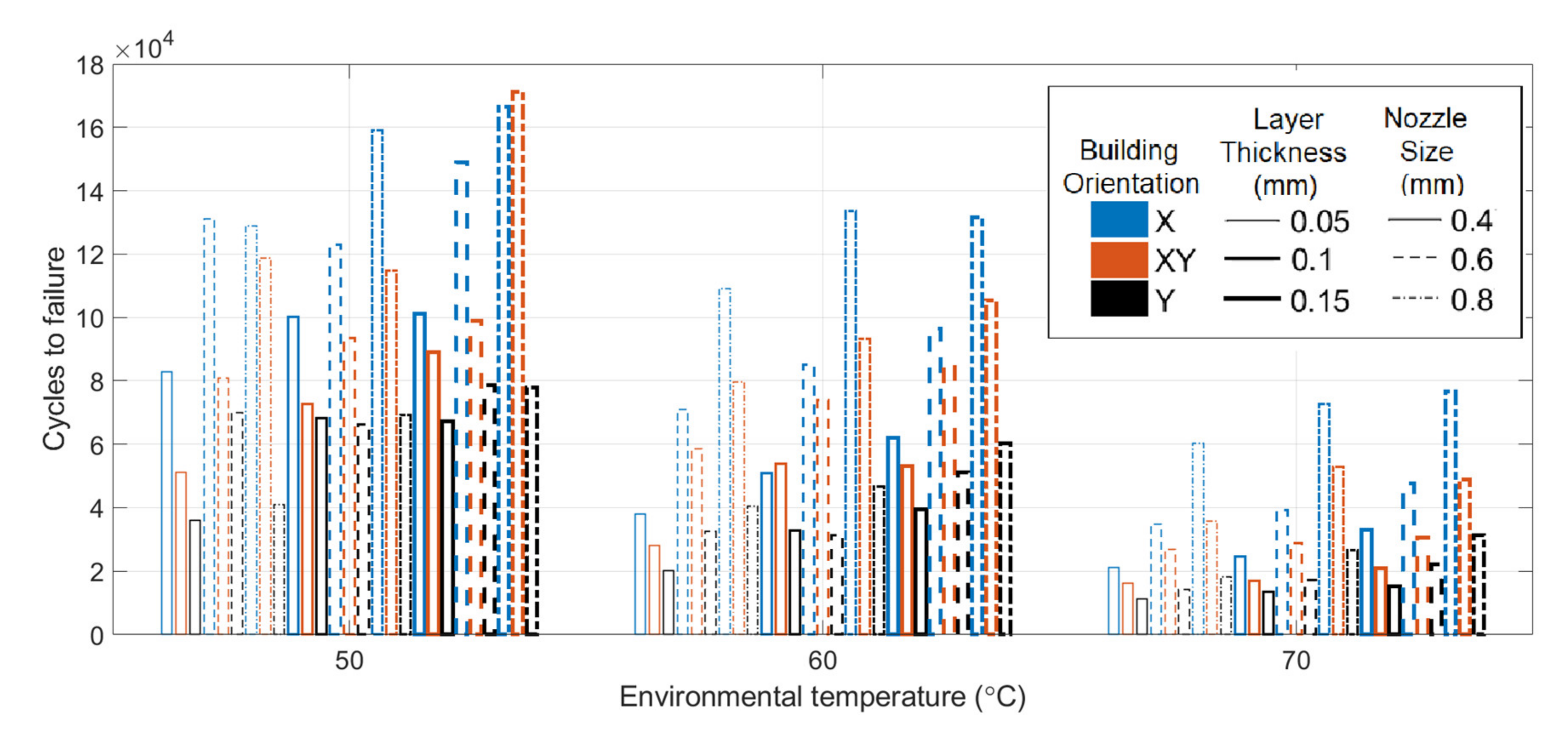

Because the mechanical properties of ABS change a lot when temperature changes, while the practical applications may work under different environmental temperature, a comparison of fatigue life under different temperature is significant in the research. Therefore, three different environmental temperatures, 40, 50 and 60 °C, were selected for this purpose. 60 °C was chosen as the upper limit of temperature because ABS is sensitive to the temperature. The mechanical strength decreases when increasing temperature. The structural strength is not strong enough to support the experiment when environmental temperature is over 60 °C due to softening.

Because each printing parameter had three options as shown in

Table 1, there were a total of 27 combinations of the printing parameters. Each combination was tested under three different temperatures, respectively. Consequently, 81 different types of specimen were printed for these parameters and the environmental temperature values. Three similar specimens were manufactured for each combination and tested under the same conditions for confirming the experimental repeatability of the results obtained.

2.2. Materials

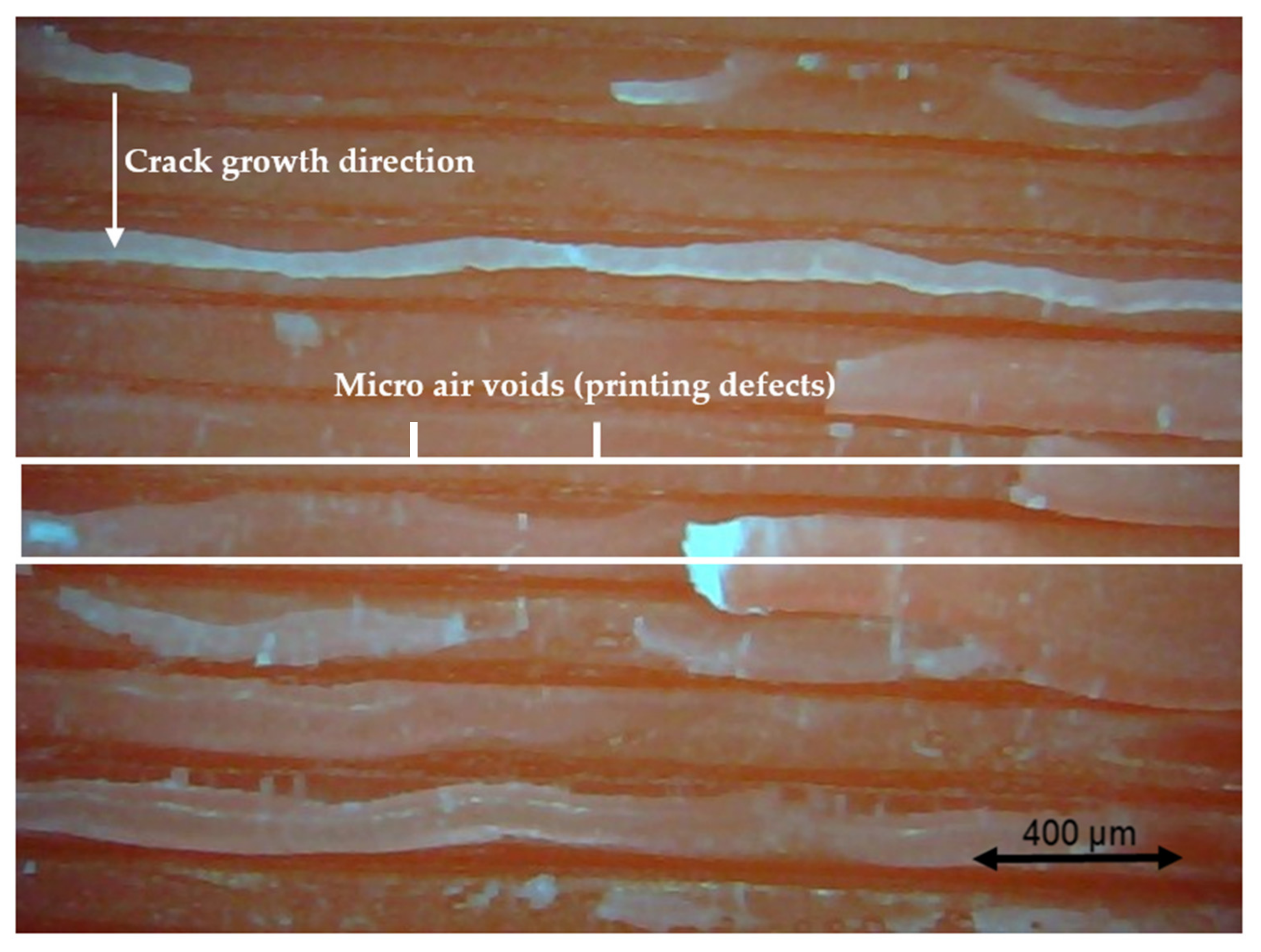

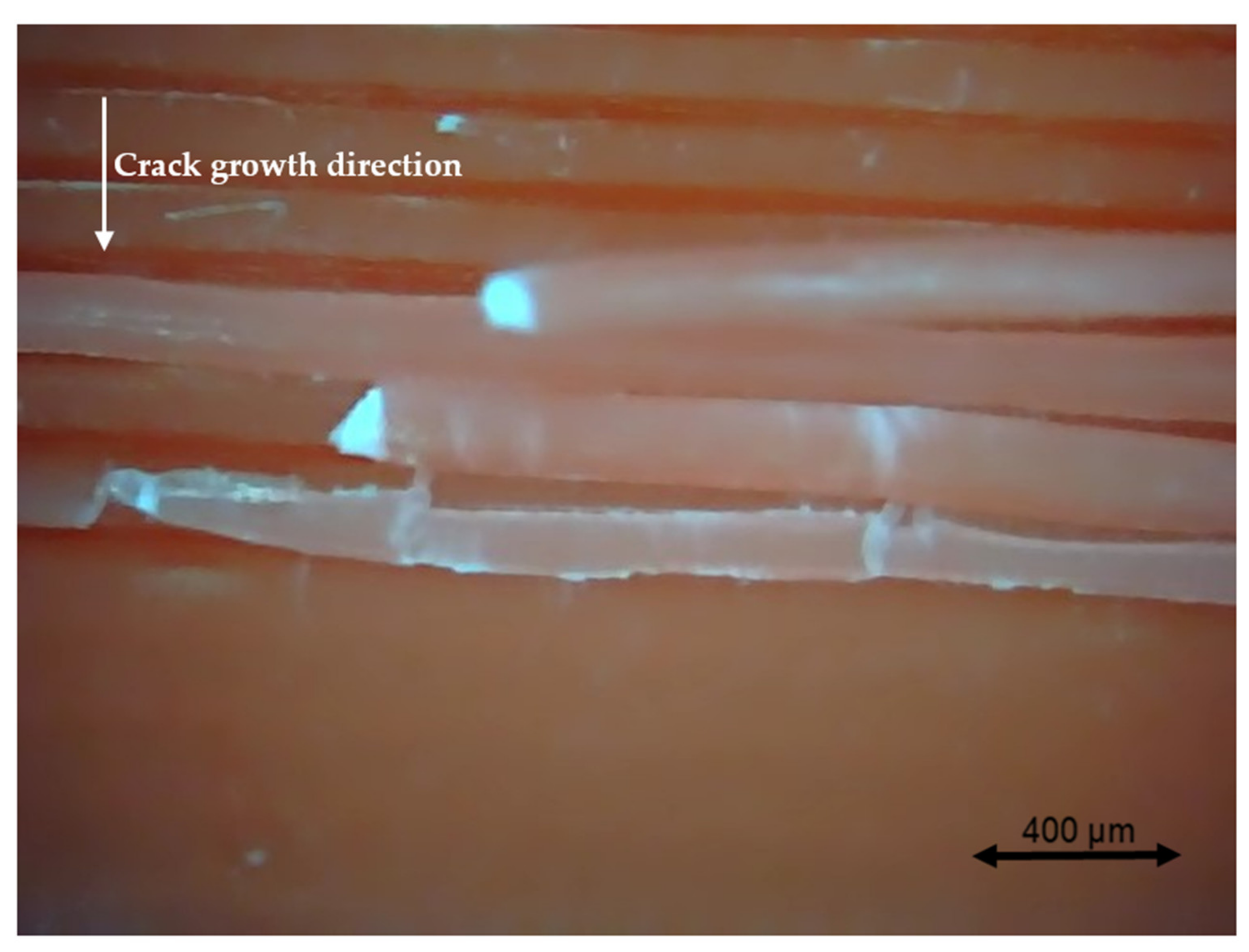

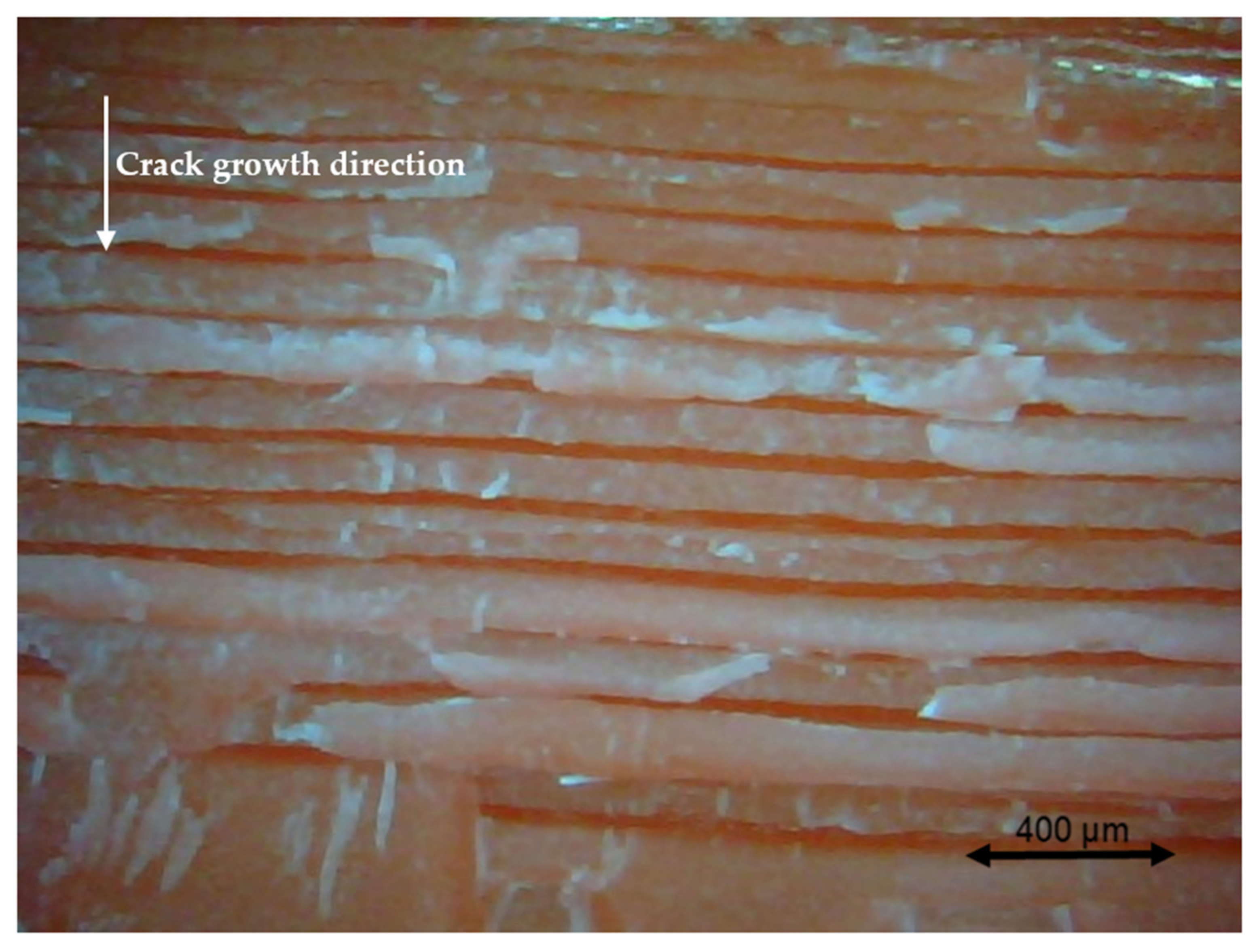

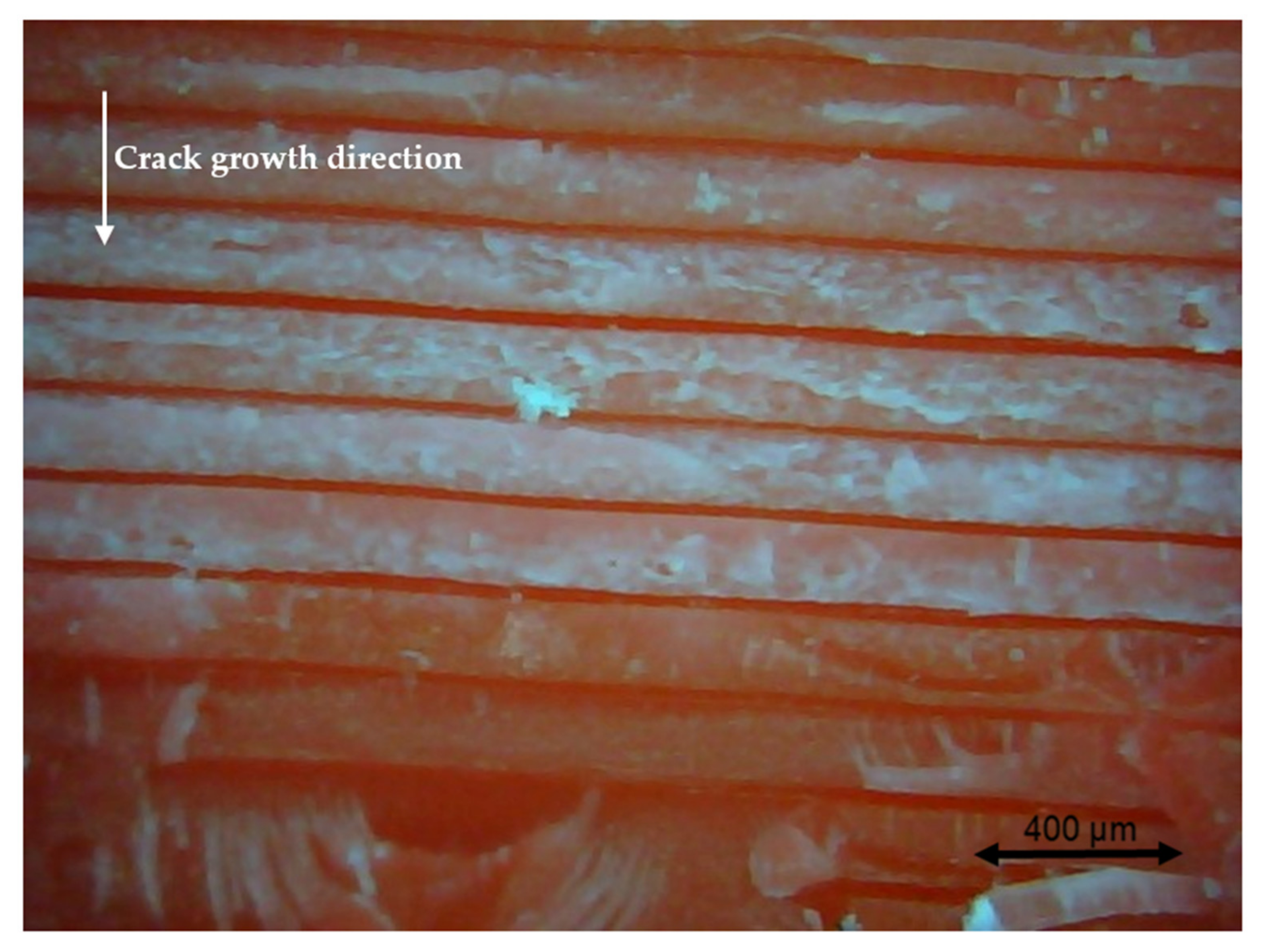

In this study, a red ABS filament fabricated by Ultimaker

® (Utrecht, Netherlands) was chosen as the raw material because the crack growth path and plastic zones can be clearly observed in this colour. More details of this material are presented in

Table 2.

2.3. Specimen Preparation

Currently, ASTM D7774 [

48] is the standard test method for flexural fatigue properties of plastics. Following the standard, the specimen is cyclically loaded equally in the positive and negative directions to a specific stress or strain level at a uniform frequency until the specimen ruptures or yields. This means the quasi-static loads are applied in the test.

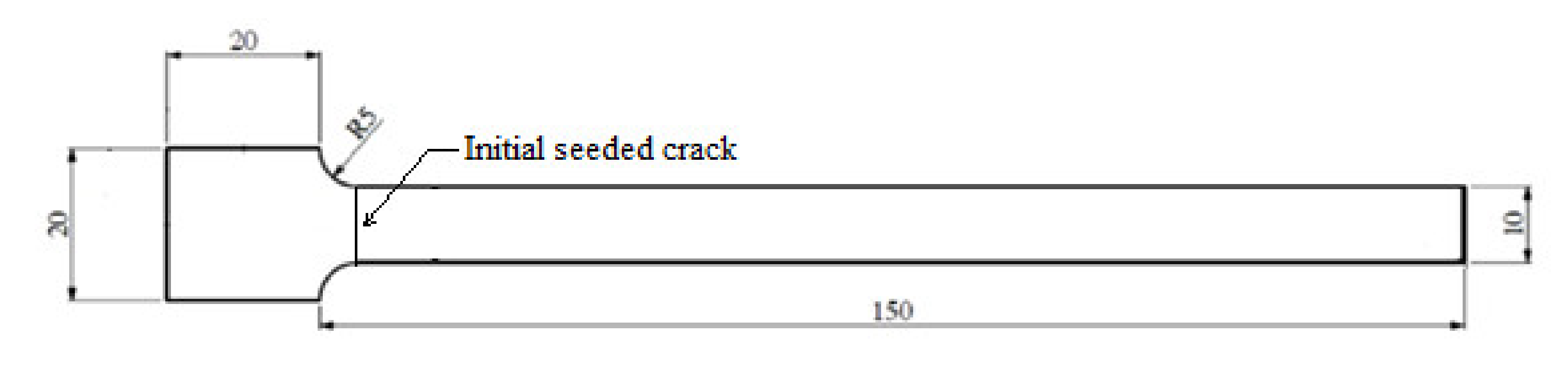

However, the 3D-printed polymers, rather than conventional manufactured polymers, were tested in this research. Extra thermo loads and dynamic mechanical loads were applied during the tests. This means the current standard that focuses on the bending fatigue test of polymers may be not suitable in this research. Therefore, a 3D printing ABS specimen was designed using the CATIA v5 CAD software. The geometry of the specimen is depicted in

Figure 5: 150 × 10 × 5 mm and was the same as that used in previous research [

49]; therefore, the experimental results of the current study and those of the previous study can be compared. An initial seeded crack with a depth of 0.5 mm was crafted close to the fixed end of the beam to ensure that the maximum stress concentration occurred at the same locations for all the specimens. Therefore, crack propagation in all the experiments was the same and closely resembled fatigue failures of an actual scenario. The test results thus obtained were then compared.

The specimen’s CAD model was converted to an STL file and imported to the Ultimaker CURA 4.6 software. Apart from the selected parameters presented in

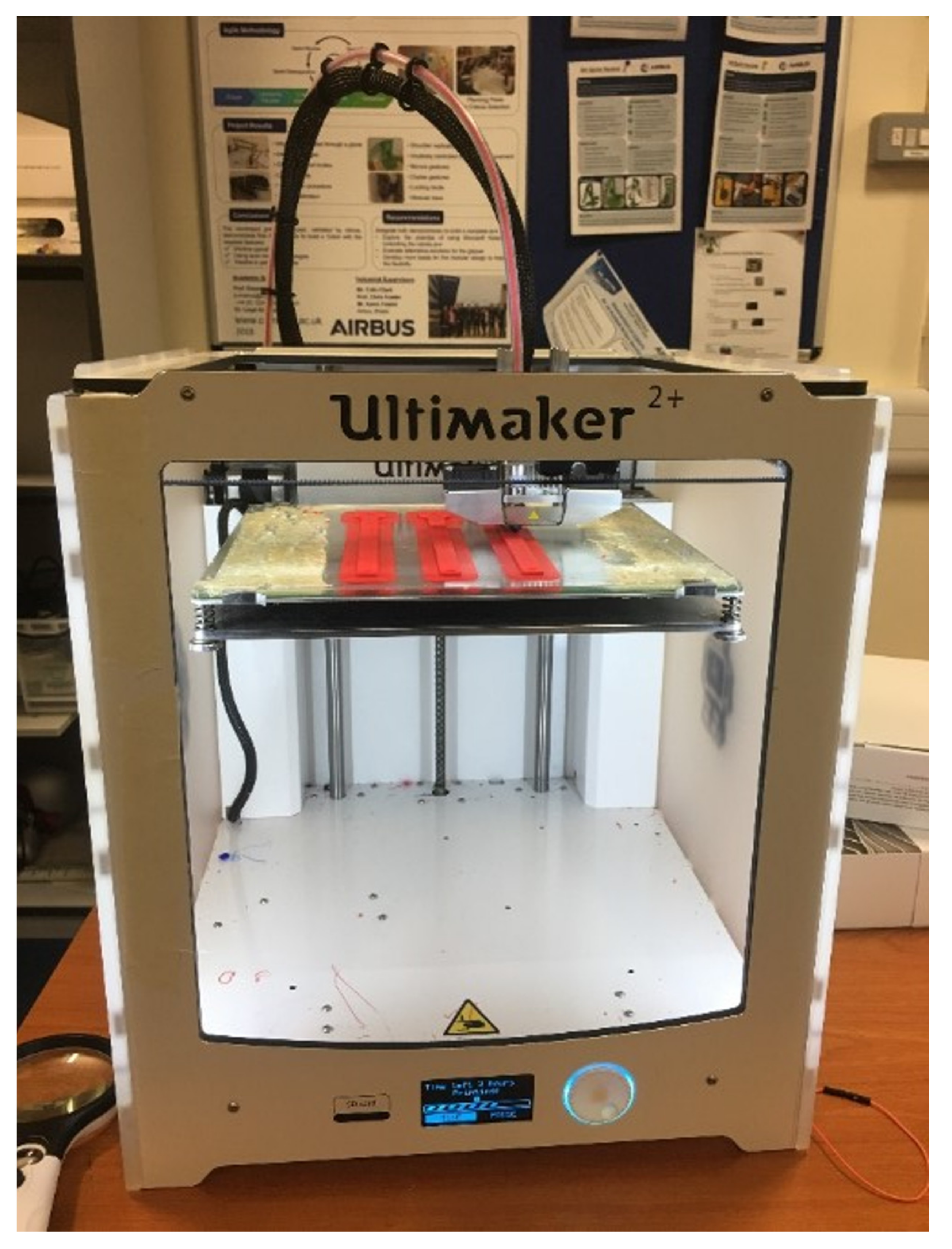

Table 2, there were a series of parameters in CURA. Because these parameters in CURA were not the focus of the current study, all these settings were held at recommended or default values during the printing process. Further, an infill density of 100% was selected. The appropriate set nozzle temperature was selected as 245 °C based on the recommendation of the printing setup. The bed temperature was set to 90 °C, which was the default value of the printer. Finally, the Ultimaker 2+ printer was used to print all the specimens, as shown in

Figure 6.

2.4. Experimental Scheme

The experiments were primarily divided into two parts. First, the number of cycles until the fracture of cantilever beams were evaluated using bending vibration tests. Then, dynamic mechanical analysis tests were performed for the specimens cut from the previous beams.

2.5. Experimental Setup and Procedure

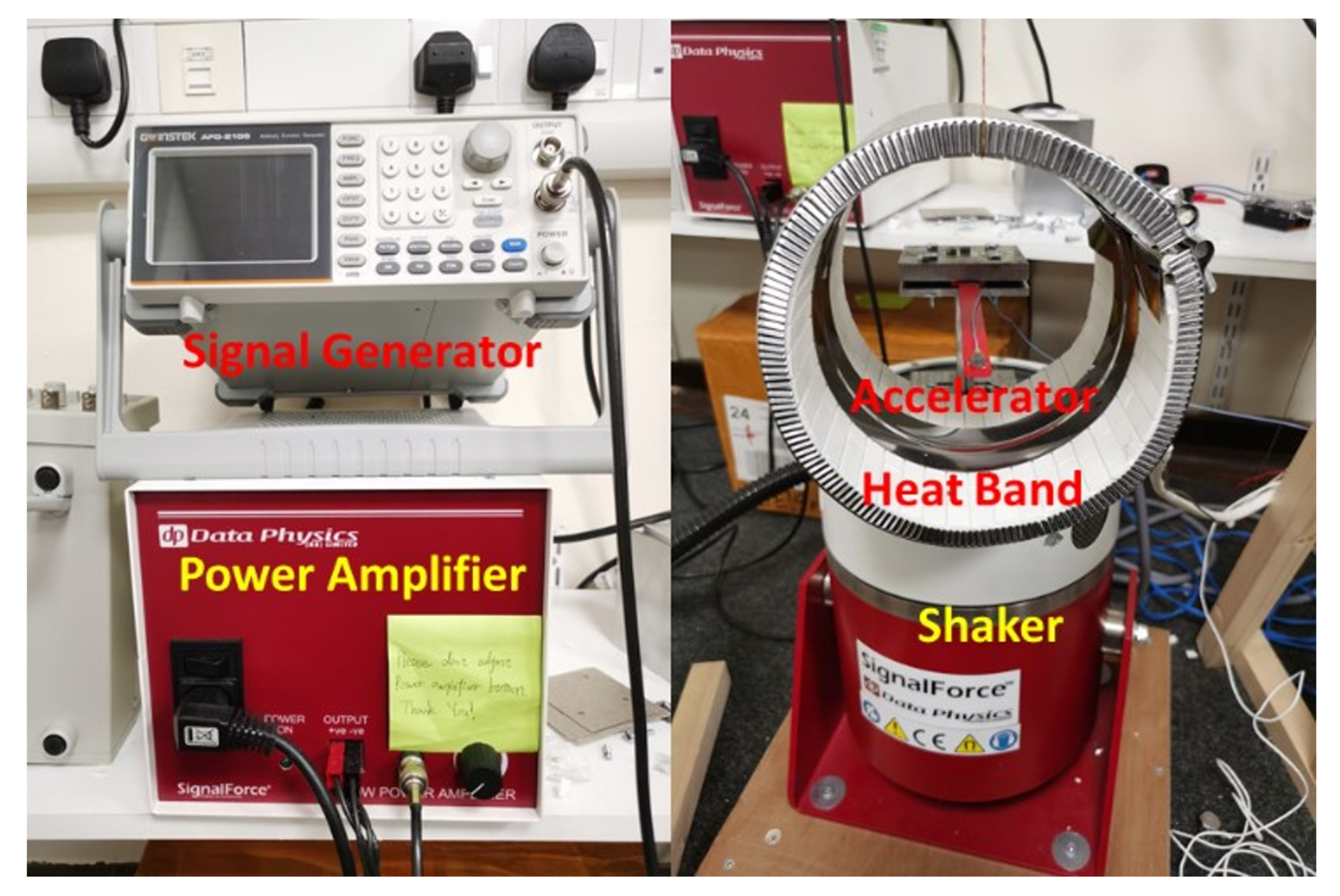

The experimental setup is illustrated in

Figure 7. The ABS specimen was fixed on the V55 shaker manufactured by Data Physics (Hailsham, UK). A mica band heater was used to provide the specimen’s constant thermal loads throughout the experiment. First, the specimen’s natural frequency was measured three times using an accelerometer in an impact test. The first-order natural frequency of the specimen can be calculated using Equation (1):

where

and

denote the time of the

th and

th peak amplitude, respectively. The vibration under natural frequency provided the initial maximum amplitude for the beam, and this significantly shortened the experiment time. The accelerometer recorded the acceleration and time data, imported them into Signal Express software via a DAQ card. The signal generator produced the sinusoidal output into the power amplifier. The power amplifier then transferred the signal into the shaker, following which the shaker vibrated with a 2 mm amplitude under the measured natural frequency of the beam. This implied that the beam was under resonation initially, following which the pre-seeded crack growth started. The shaker was running continuously until the beam’s final fracture occurred.

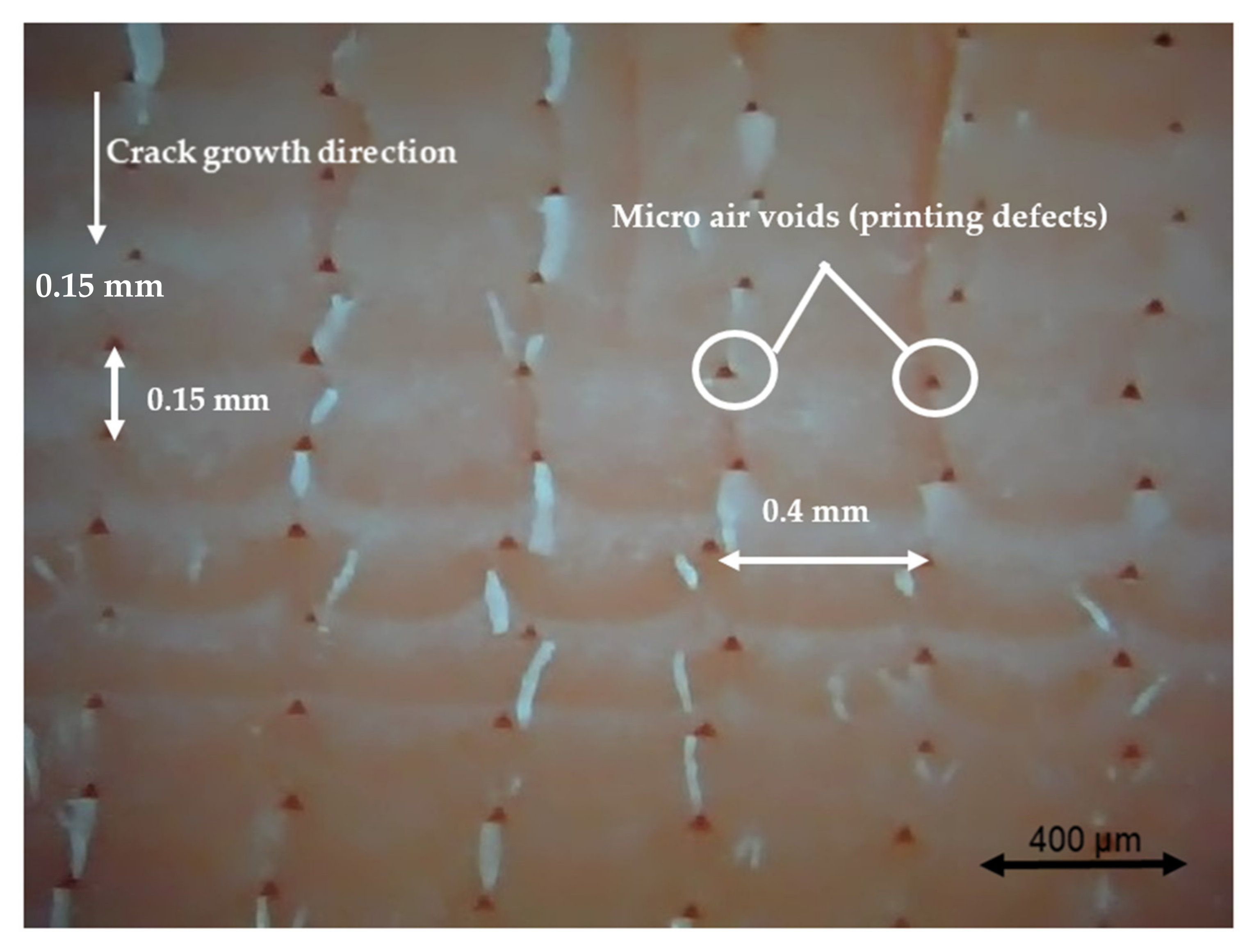

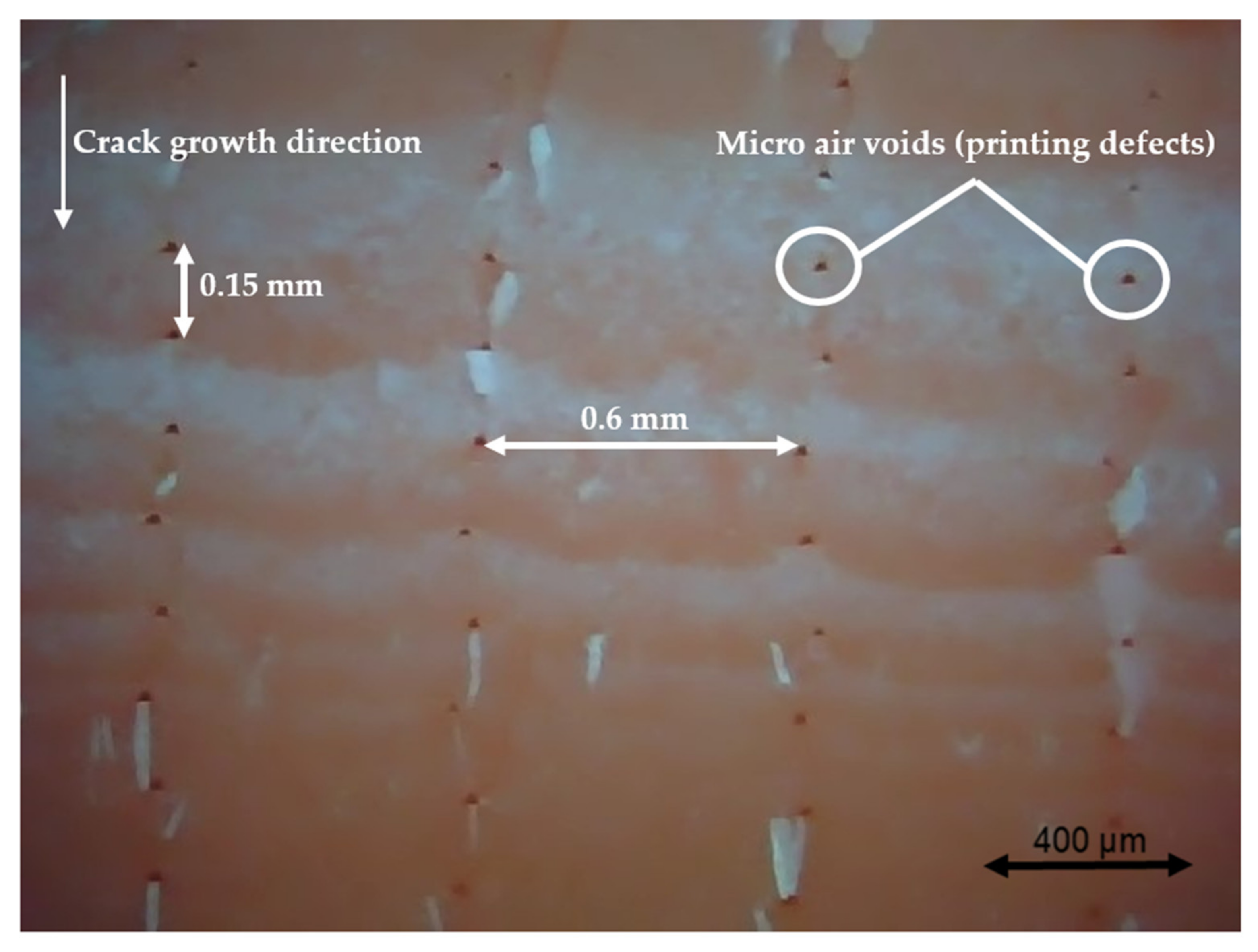

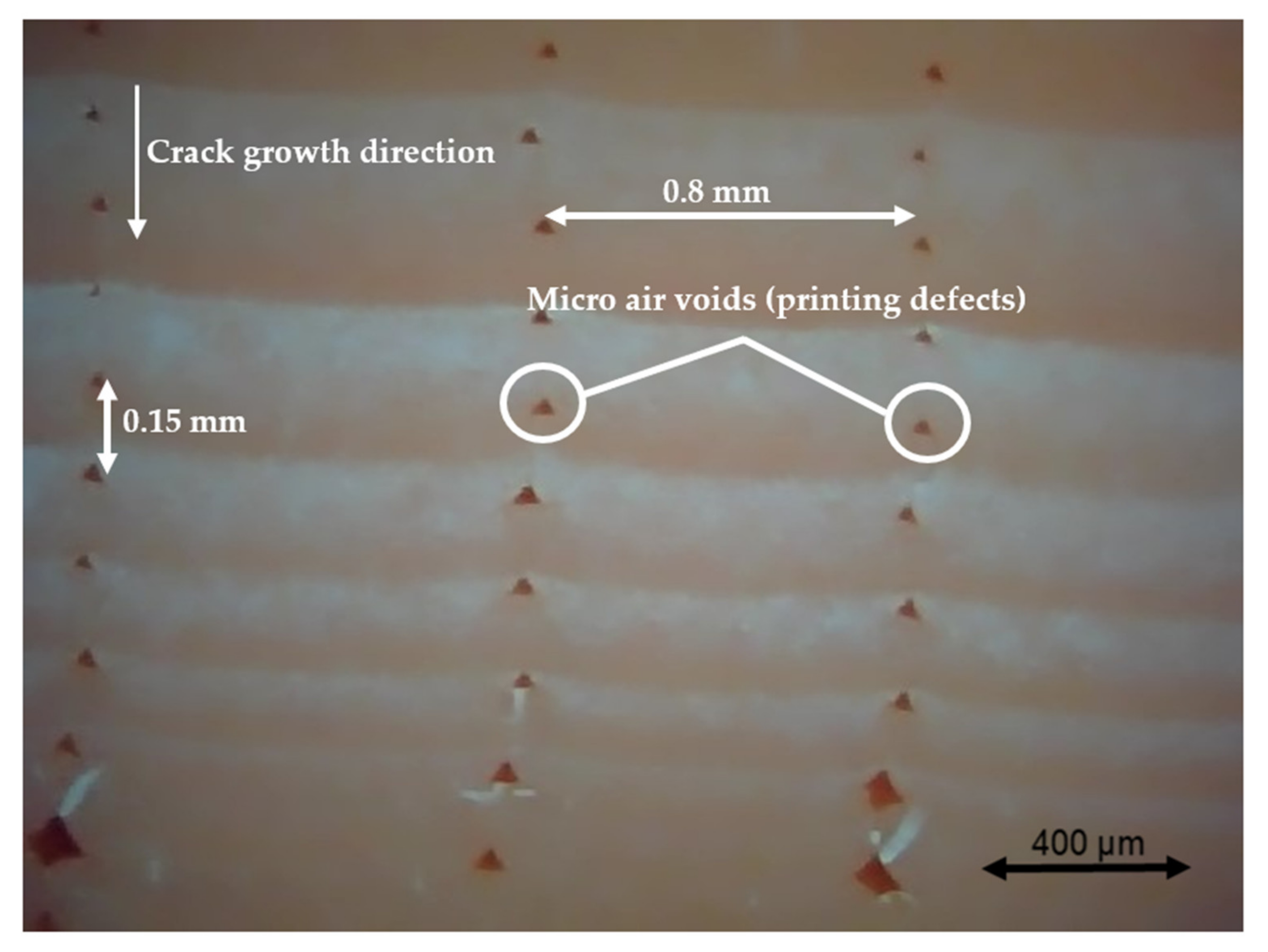

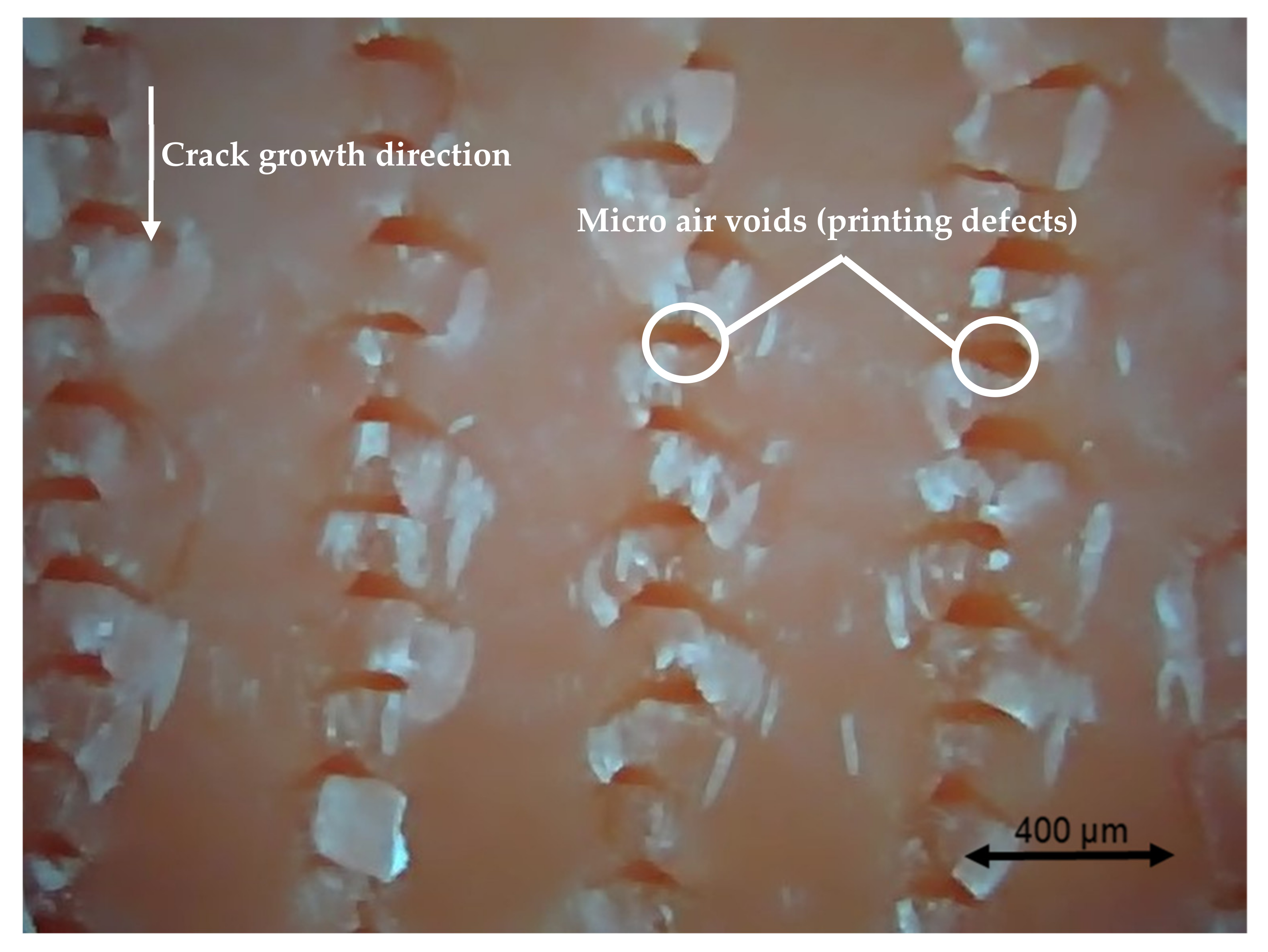

Compared with the traditional fatigue failure approach, which is defined as the number of cycles at which the stiffness of the material reduces by 50% (Nf50), the current study directly registered the number of cycles from the beginning of the run to the occurrence of fracture for the specimens because it was difficult to measure the stiffness for the cracked specimen. The results were recorded and then compared with each other. The 3D printing parameter combination corresponding to most cycles was determined as the optimal choice. The beam section after the fracture was captured using a 200× Dino-Lite microscope (AnMo Electronics Corporation, Hsinchu, China).

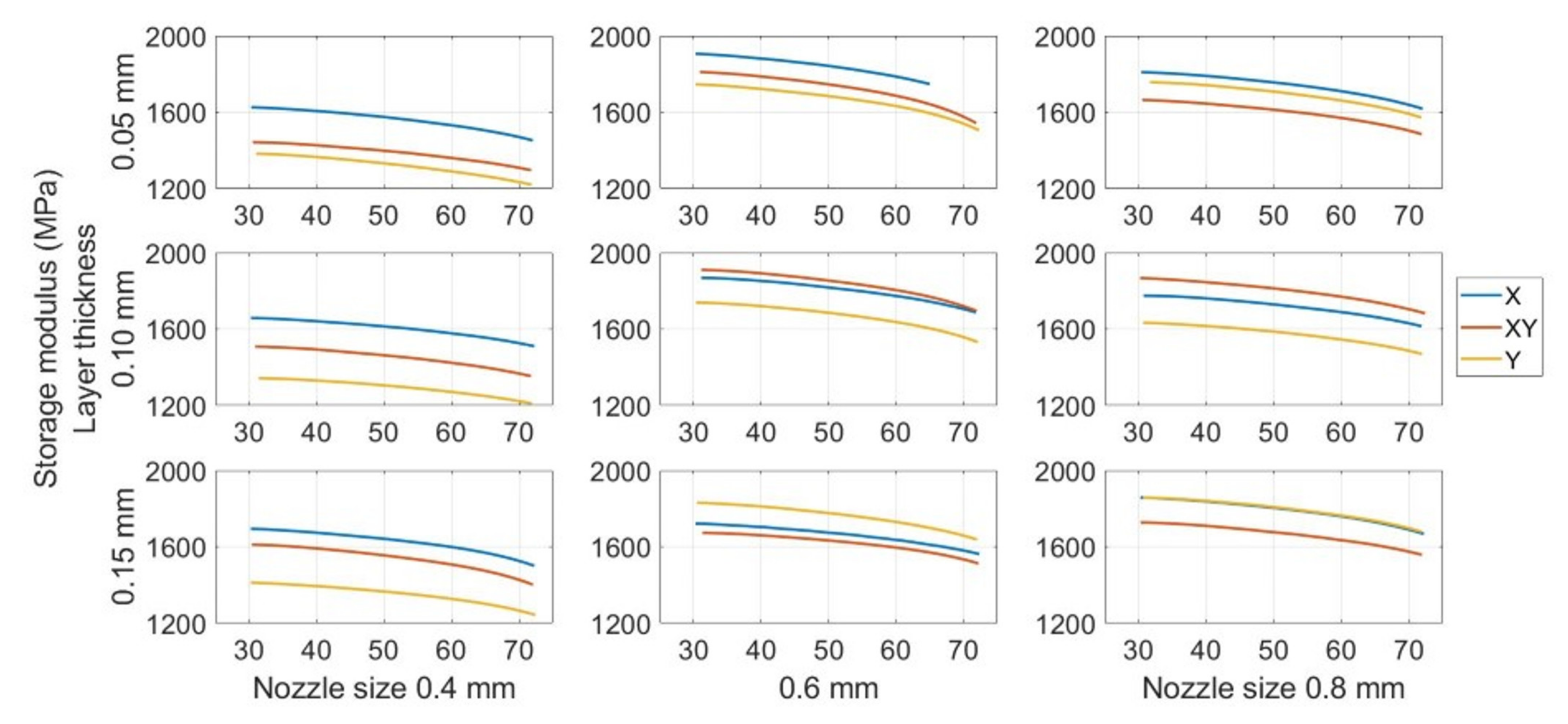

The DMA test was then performed using Q800 from TA Instruments (New Castle, TX, USA). The specimen was fixed in the chamber of Q800 by the dual cantilever clamp. The temperature ramp rate was 3.00 °C/min. The load oscillation frequency was 1 Hz. This measured the storage modulus of the parts cut from the previous bending fatigue specimens under the temperature range of 30 to 70 °C.