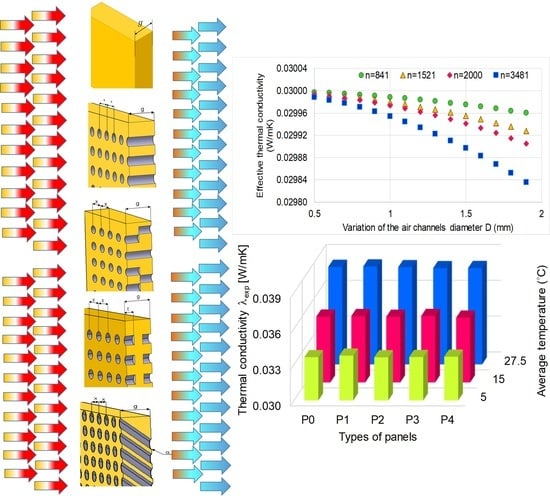

Design of Thermal Insulation Materials with Different Geometries of Channels

Abstract

:1. Introduction

- (a)

- fibrous insulations, which consist in fibers with small diameter and air within the interspaces. The fibers can be in parallel or perpendicular to the surface being insulated and can be either interconnected or loose. The fibers used are silica, glass, mineral wool, slag wool and alumina silica fibers. The most used insulations of this type are glass fibers and mineral wool [5,6,7].

- (b)

- (c)

- granular insulations, which are composed of small nodules that contain voids. They are not really cellular materials, since gases can be transferred between the individual spaces. This type of insulation can be produced as bulk material or in combination with a binder and fibers in order to obtain a rigid insulation. Some examples are calcium silicate, expanded vermiculite, perlite, cellulose, diatomaceous earth and expanded polystyrene [10,11,12].

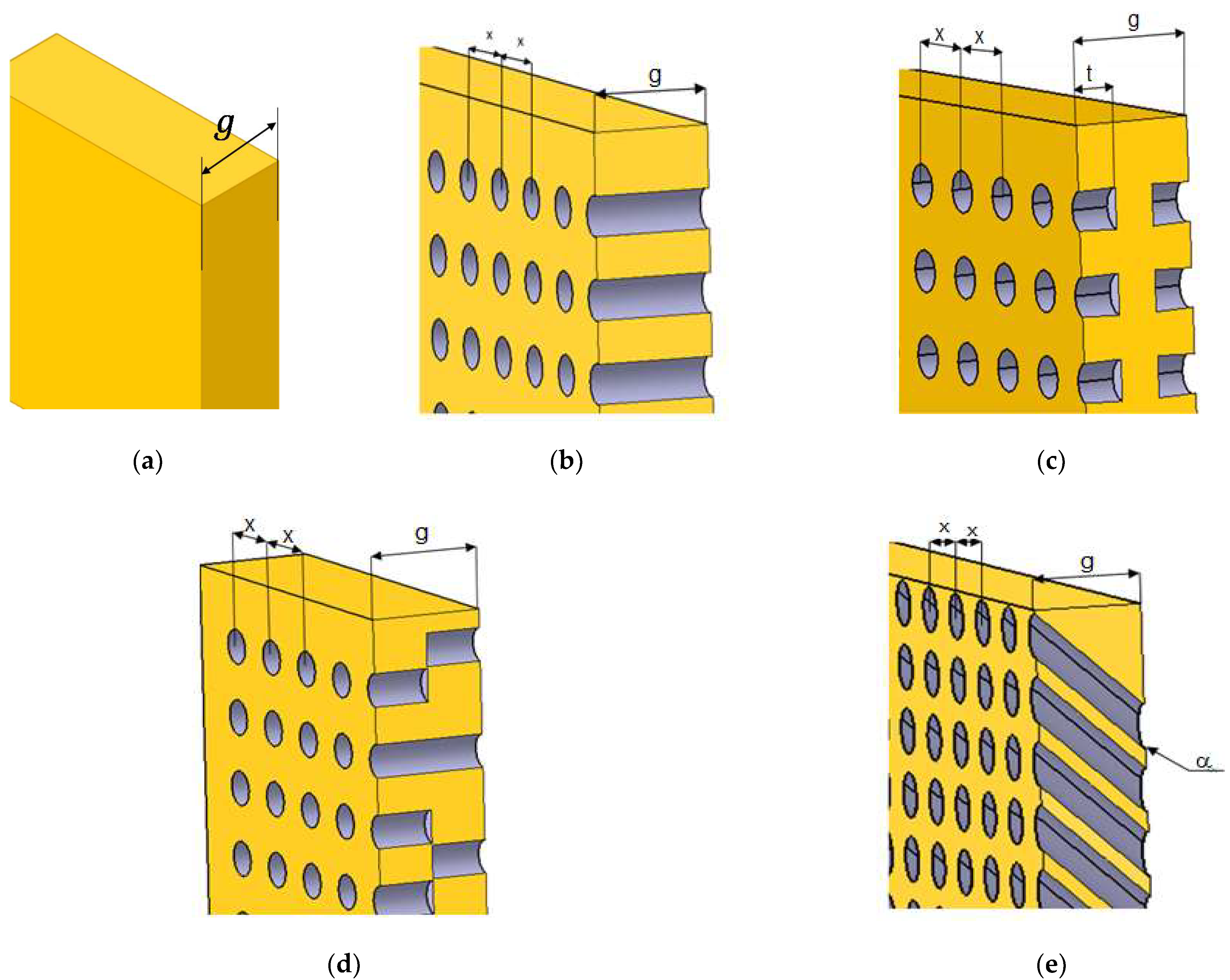

2. Materials, Methods and Equipment

2.1. Materials

2.2. Methods

2.2.1. The Analytical Description of the Thermal Conductivity

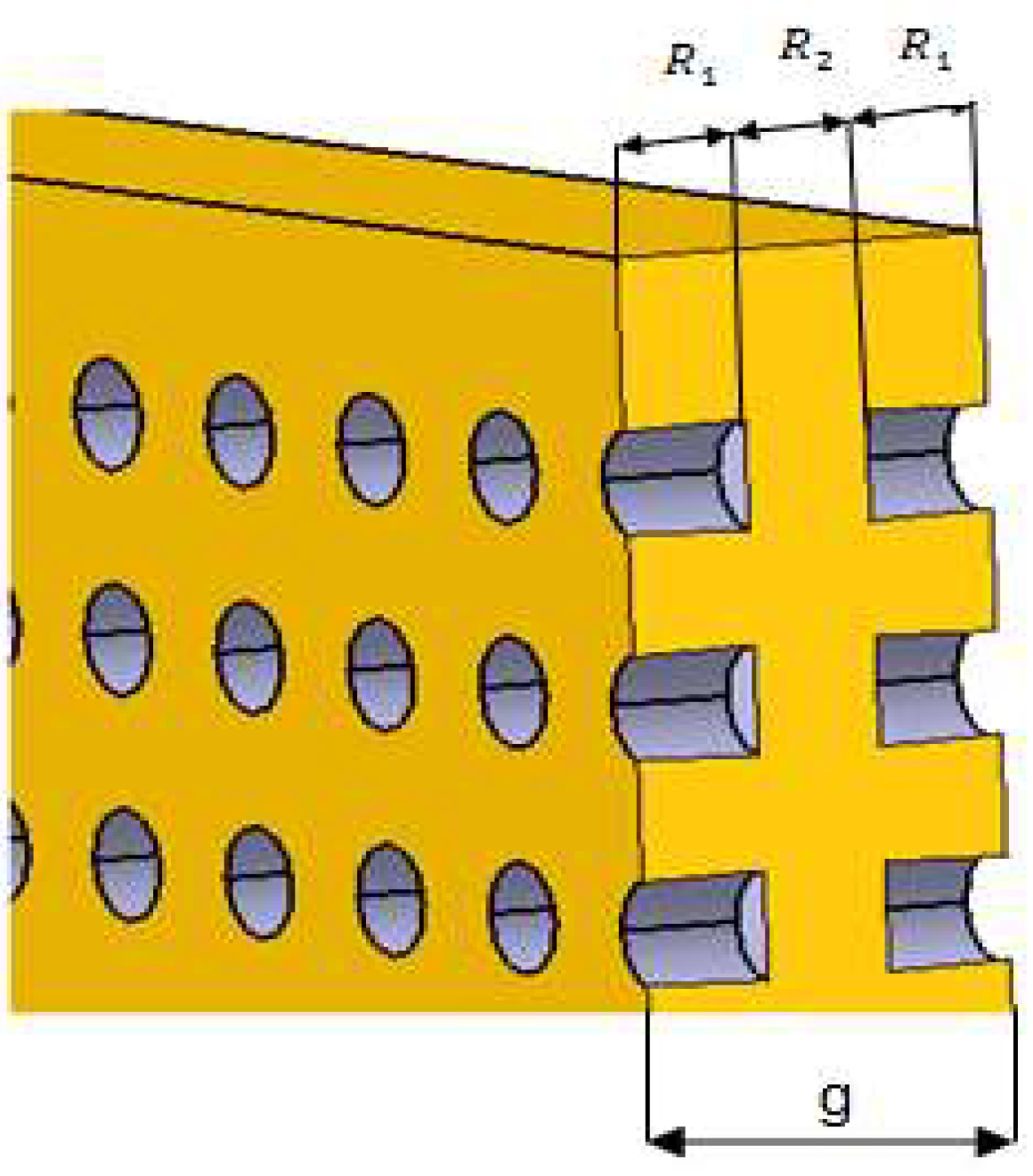

The Mathematical Model Applied to the Panels with Perforated Horizontal Channels

The Mathematical Model Applied to the Panels with Partly Perforated Channels

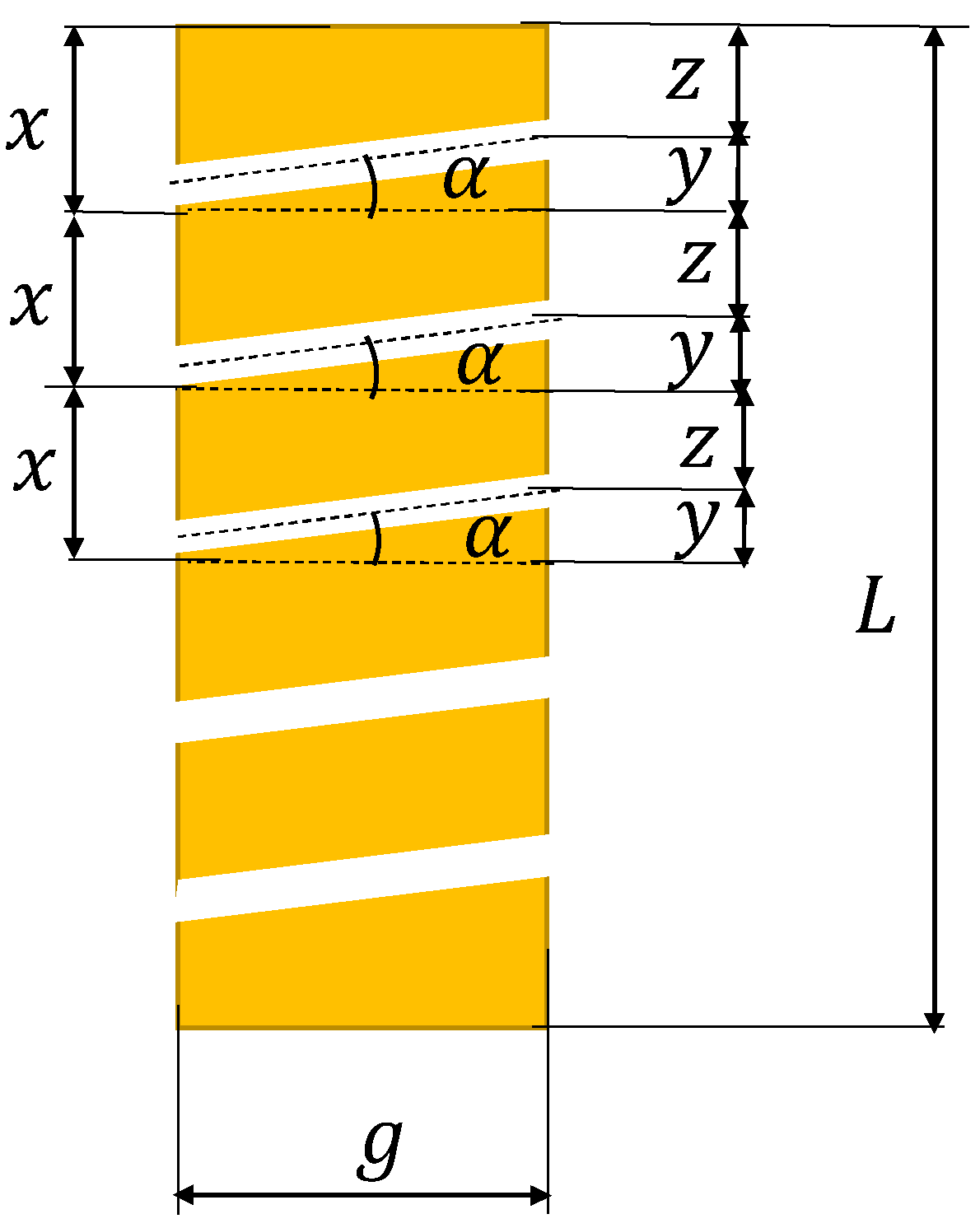

The Mathematical Model Applied to the Panels with Perforated Inclined Channels with an Angle α

2.2.2. Experimental Setup

3. Results and Discussion

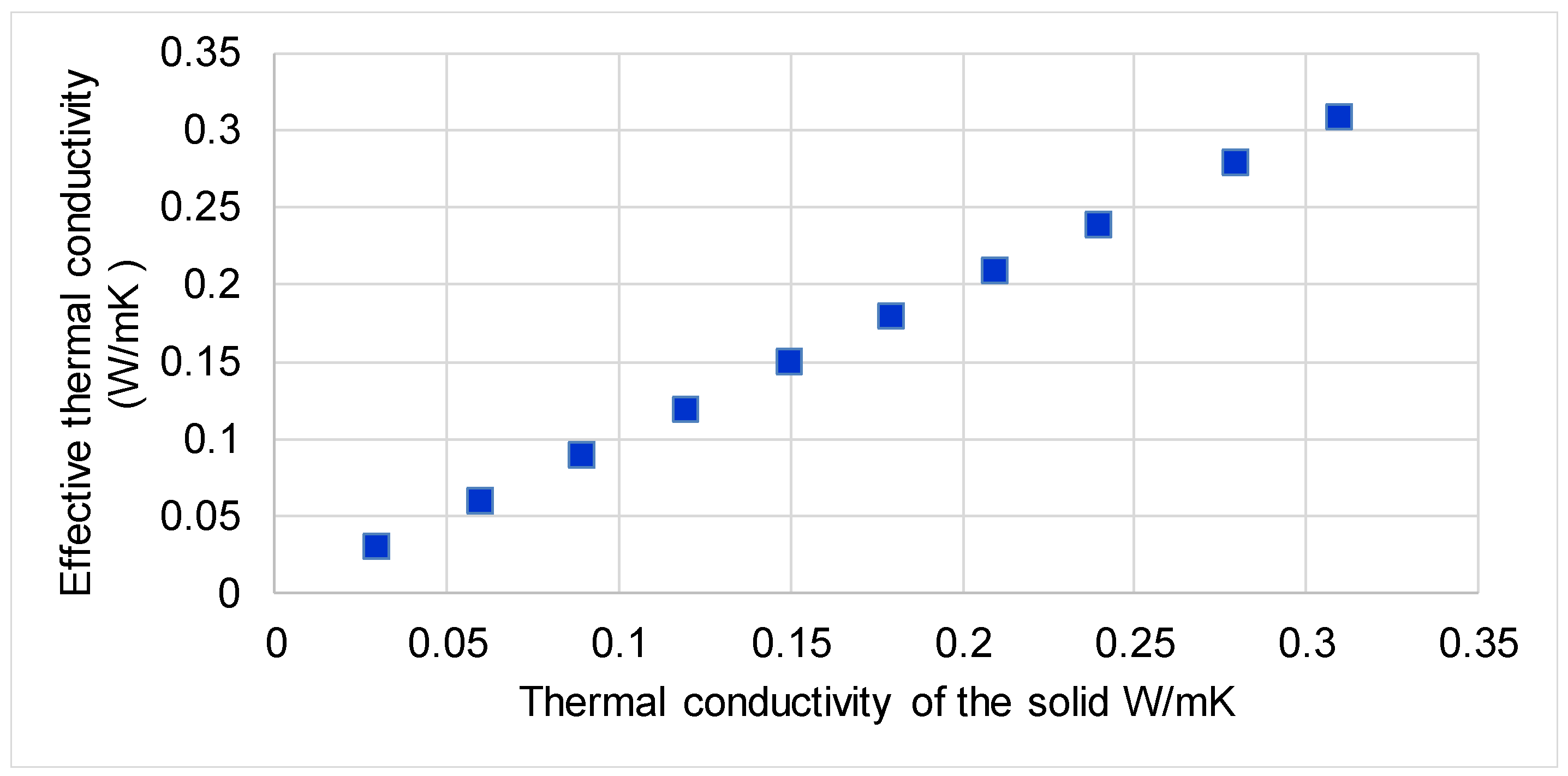

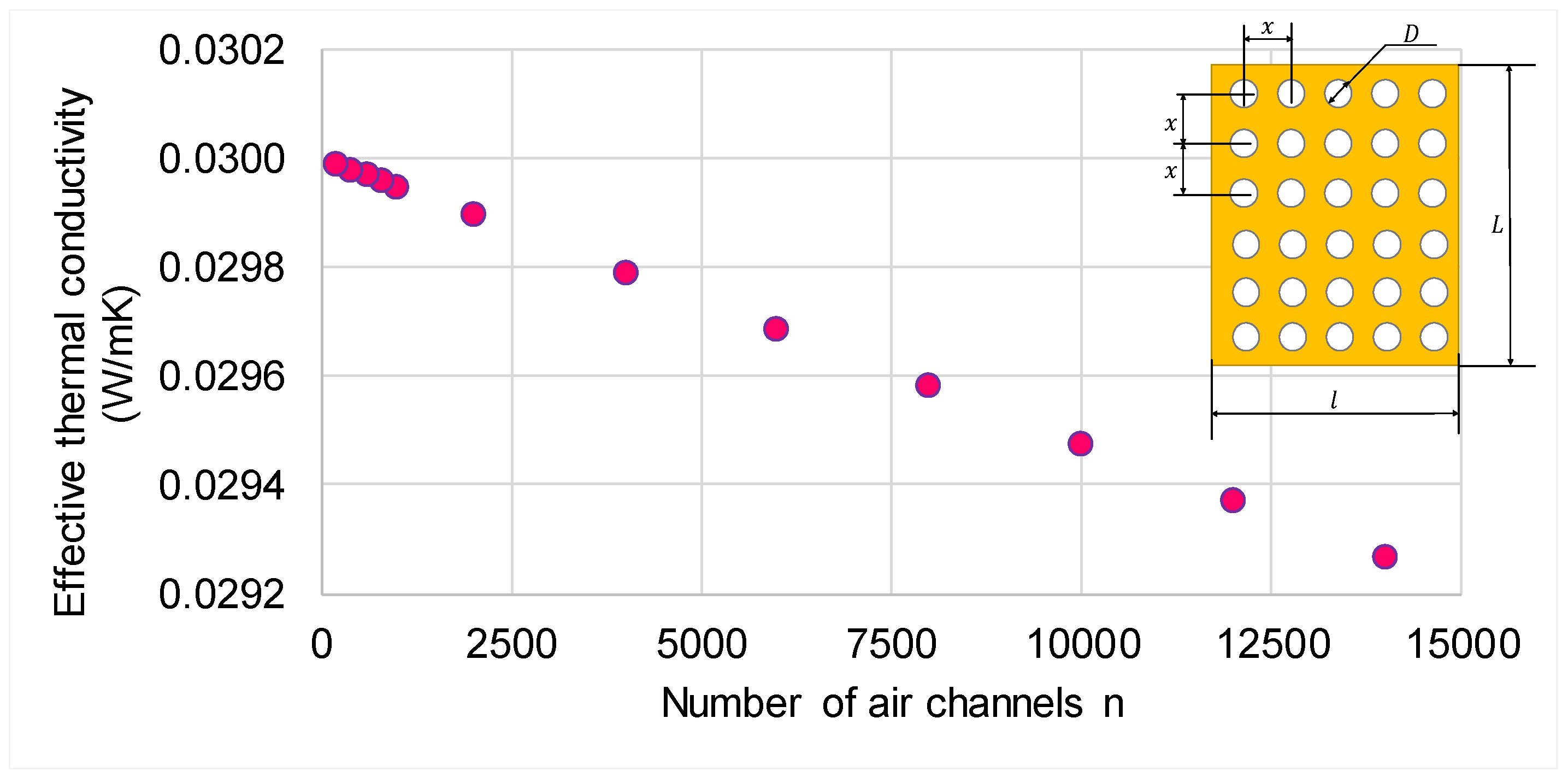

3.1. Analytical Models

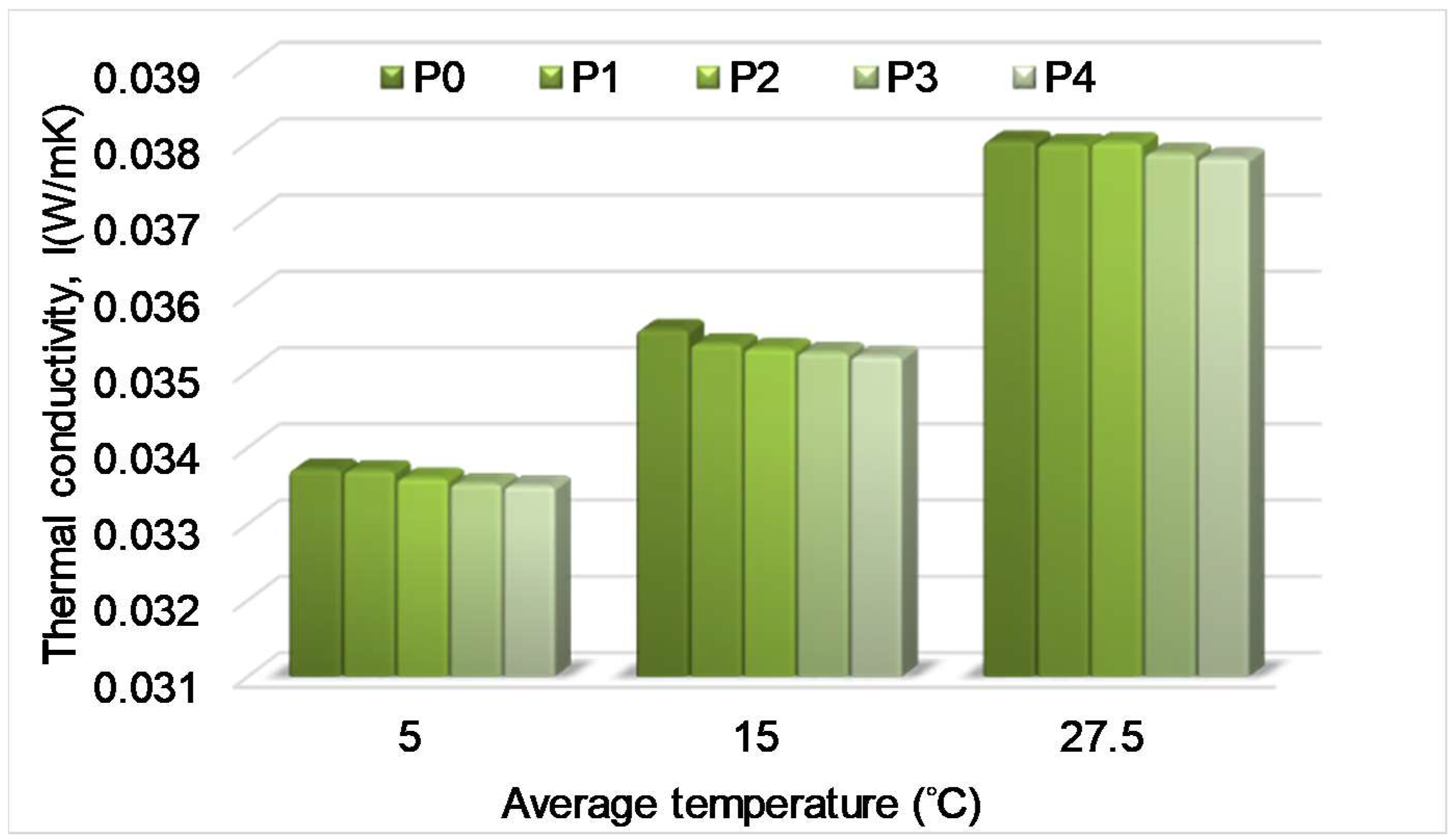

3.2. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dubois, S.; Lebeau, F. Design, construction and validation of a guarded hot plate apparatus for thermal conductivity measurement of high thickness crop-based specimens. Mater. Struct. 2013, 48, 407–421. [Google Scholar] [CrossRef]

- Shea, A.; Wall, K.; Walker, P. Evaluation of the thermal performance of an innovative prefabricated natural plant fibre building system. Build. Serv. Eng. Res. Technol. 2013, 34, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Incropera, F.P.; Dewit, D.P.; Bergman, T.; Lavine, A.S. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- Berge, A. Assessment of Novel Applications for Nano-Porous Thermal Insulation in District Heating Pipes and Building Walls. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 2016. Available online: https://core.ac.uk/download/pdf/70615476.pdf (accessed on 20 November 2020).

- Sharma, J.; Polizos, G. Hollow Silica Particles: Recent Progress and Future Perspectives. Nanomaterials 2020, 10, 1599. [Google Scholar] [CrossRef] [PubMed]

- Craig, S.; Grinham, J. Breathing walls: The design of porous materials for heat exchange and decentralized ventilation. Energy Build. 2017, 149, 246–259. [Google Scholar] [CrossRef]

- Meng, Q.; Xiang, S.; Zhang, K.; Wang, M.; Bu, X.; Xue, P.; Liu, L.; Sun, H.; Yang, B. A facile two-step etching method to fabricate porous hollow silica particles. J. Colloid Interface Sci. 2012, 384, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Raznjevic, K. Handbook of Thermodynamic Tables; Begell House: New York, NY, USA, 1995. [Google Scholar]

- Jelle, B.P.; Gustavsen, A.; Baetens, R. The path to the high performance thermal building insulation materials and solutions of tomorrow. J. Build. Phys. 2010, 34, 99–123. [Google Scholar] [CrossRef] [Green Version]

- Smith, D.S.; Alzina, A.; Bourret, J.; Nait-Ali, B.; Pennec, F.; Tessier-Doyen, N.; Otsu, K.; Matsubara, H.; Elser, P.; Gonzenbach, U.T. Thermal conductivity of porous materials. J. Mater. Res. 2013, 28, 2260–2272. [Google Scholar] [CrossRef] [Green Version]

- Alderman, R.J.; Yarbrough, D.W. Use of phase-change materials to enhance the thermal performance of building insulations. In Proceedings of the 29th International Thermal Conductivity Conference and the 17th International Thermal Expansion Symposium, ITCC 29 and ITES 17, Thermal Conductivity 29/Thermal Expansion 17, Birmingham, AL, USA, 24–27 June 2007; pp. 129–136. [Google Scholar]

- Araki, K.; Kamoto, D.; Matsuoka, S.-I. Optimization about multilayer laminated film and getter device materials of vacuum insulation panel for using at high temperature. J. Mater. Process. Technol. 2009, 209, 271–282. [Google Scholar] [CrossRef]

- Feinerman, D.; Lajos, R.; Sood, V.; Carlton, R.J. Vacuum insulation panels with supporting elements in tension. In Proceedings of the 29th International Thermal Conductivity Conference and the 17th International Thermal Expansion Symposium, ITCC 29 and ITES 17, Thermal Conductivity 29/Thermal Expansion 17, Birmingham, AL, USA, 24–27 June 2007; 2008; pp. 100–108. [Google Scholar]

- Alotaibi, S.S.; Riffat, S. Vacuum insulated panels for sustainable buildings: A review of research and applications. Int. J. Energy Res. 2013, 38, 1–19. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Thue, J.V.; Tenpierik, M.; Grynning, S.; Uvsløkk, S.; Gustavsen, A. Vacuum insulation panels for building applications: A review and beyond. Energy Build. 2010, 42, 147–172. [Google Scholar] [CrossRef] [Green Version]

- Kan, A.; Kang, L.; Wang, C.; Cao, D. A simple and effective model for prediction of effective thermal conductivity of vacuum insulation panels. Future Cities Environ. 2015, 1, 1–8. [Google Scholar] [CrossRef]

- Schwab, H.; Heinemann, U.; Beck, A.; Ebert, H.-P.; Fricke, J. Dependence of Thermal Conductivity on Water Content in Vacuum Insulation Panels with Fumed Silica Kernels. J. Therm. Envel. Build. Sci. 2005, 28, 319–326. [Google Scholar] [CrossRef]

- Imbabi, M.S.-E. A passive–active dynamic insulation system for all climates. Int. J. Sustain. Built Environ. 2012, 1, 247–258. [Google Scholar] [CrossRef] [Green Version]

- Şova, D.; Stanciu, M.D.; Belea, E.; Bidu, V.V. Innovative thermal insulation panels with air channels. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 444, p. 062005. [Google Scholar]

- Kosny, J.; Yarbrough, D.W.; Petrie, T.; Mohiuddin, S.A. Performance of thermal insulation containing microencapsulated phase change material. In Proceedings of the 29th International Thermal Conductivity Conference and the 17th International Thermal Expansion Symposium, ITCC 29 and ITES 17, Thermal Conductivity 29/Thermal Expansion 17, Birmingham, AL, USA, 24–27 June 2007; pp. 109–119. [Google Scholar]

- Kośny, J.; Miller, W.A.; Yarbrough, D.; Kossecka, E.; Biswas, K. Application of Phase Change Materials and Conventional Thermal Mass for Control of Roof-Generated Cooling Loads. Appl. Sci. 2020, 10, 6875. [Google Scholar] [CrossRef]

- Simmler, H.; Brunner, S. Vacuum insulation panels for building application–Basic properties, ageing mechanisms and service life. Energy Build. 2005, 37, 1122–1131. [Google Scholar] [CrossRef]

- EN 1266. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance; 2001. [Google Scholar]

- EN 12939. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Thick Products of High and Medium Thermal Resistance; 2000. [Google Scholar]

- Capozzoli, A.; Fantucci, S.; Favoino, F.; Perino, M. Vacuum Insulation Panels: Analysis of the Thermal Performance of Both Single Panel and Multilayer Boards. Energies 2015, 8, 2528–2547. [Google Scholar] [CrossRef] [Green Version]

| Code of Panel | Mass m (kg) | Density ρ (kg/m3) | Dimensions | ||

|---|---|---|---|---|---|

| Length (m) | Width (m) | Thickness (m) | |||

| P0 | 0.311 | 28.79 | 0.6 | 0.6 | 0.03 |

| P1 | 0.302 | 27.96 | 0.6 | 0.6 | 0.03 |

| P2 | 0.308 | 28.51 | 0.6 | 0.6 | 0.03 |

| P3 | 0.303 | 28.05 | 0.6 | 0.6 | 0.03 |

| P4 | 0.300 | 27.77 | 0.6 | 0.6 | 0.03 |

| Hot Plate Temperature (°C) | Cold Plate Temperature (°C) | Average Temperature (°C) | The Absolute Value of the Temperature Difference between the Two Control Thermocouples (°C) |

|---|---|---|---|

| −10 | 20 | 5 | 30 |

| 10 | 20 | 15 | 10 |

| 35 | 20 | 27.5 | 15 |

| Average Temperature (°C) | The Absolute Value of the Temperature Difference Δt (°C) | |||||

|---|---|---|---|---|---|---|

| P0 | P1 | P2 | P3 | P4 | ||

| 5 | 30 | 0.03363 | 0.03376 | 0.03362 | 0.03364 | 0.03367 |

| 15 | 10 | 0.03552 | 0.03556 | 0.03550 | 0.03557 | 0.03543 |

| 27.5 | 15 | 0.03818 | 0.03821 | 0.03815 | 0.03807 | 0.03808 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Șova, D.; Stanciu, M.D.; Georgescu, S.V. Design of Thermal Insulation Materials with Different Geometries of Channels. Polymers 2021, 13, 2217. https://doi.org/10.3390/polym13132217

Șova D, Stanciu MD, Georgescu SV. Design of Thermal Insulation Materials with Different Geometries of Channels. Polymers. 2021; 13(13):2217. https://doi.org/10.3390/polym13132217

Chicago/Turabian StyleȘova, Daniela, Mariana Domnica Stanciu, and Sergiu Valeriu Georgescu. 2021. "Design of Thermal Insulation Materials with Different Geometries of Channels" Polymers 13, no. 13: 2217. https://doi.org/10.3390/polym13132217

APA StyleȘova, D., Stanciu, M. D., & Georgescu, S. V. (2021). Design of Thermal Insulation Materials with Different Geometries of Channels. Polymers, 13(13), 2217. https://doi.org/10.3390/polym13132217