A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications

Abstract

:1. Introduction

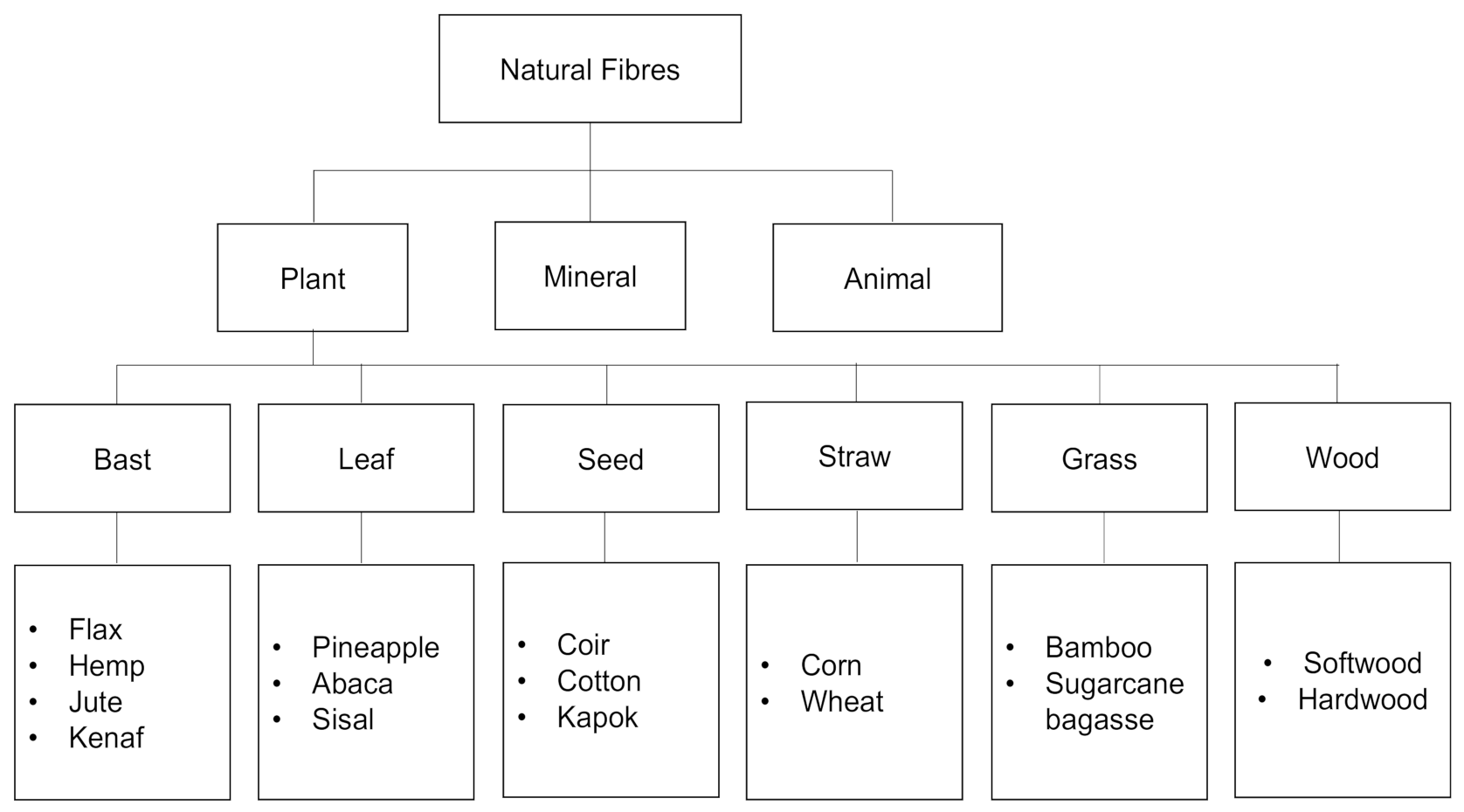

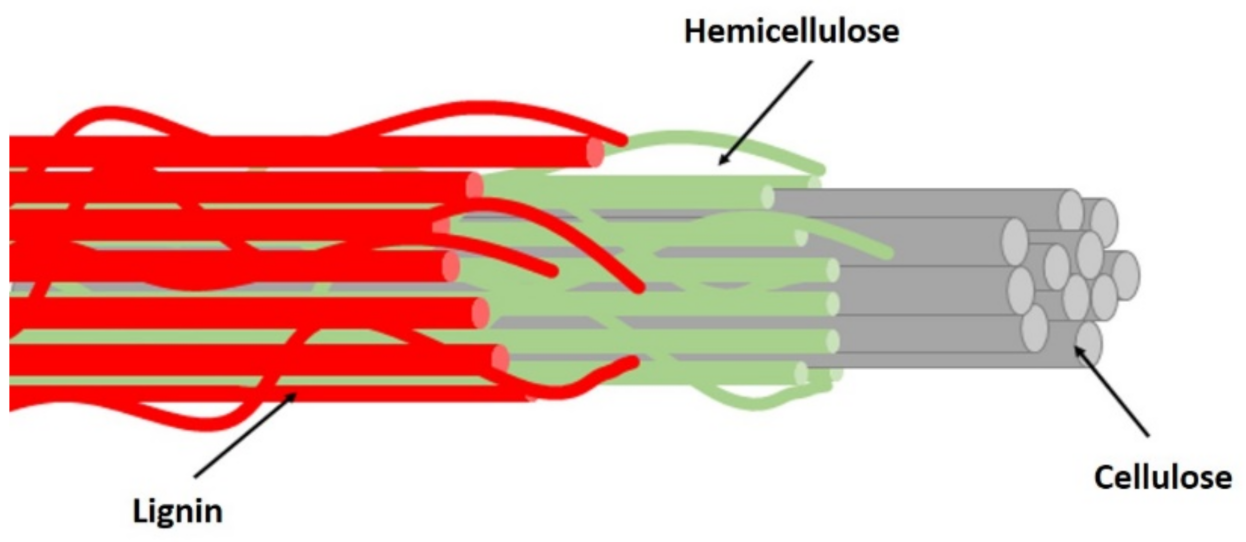

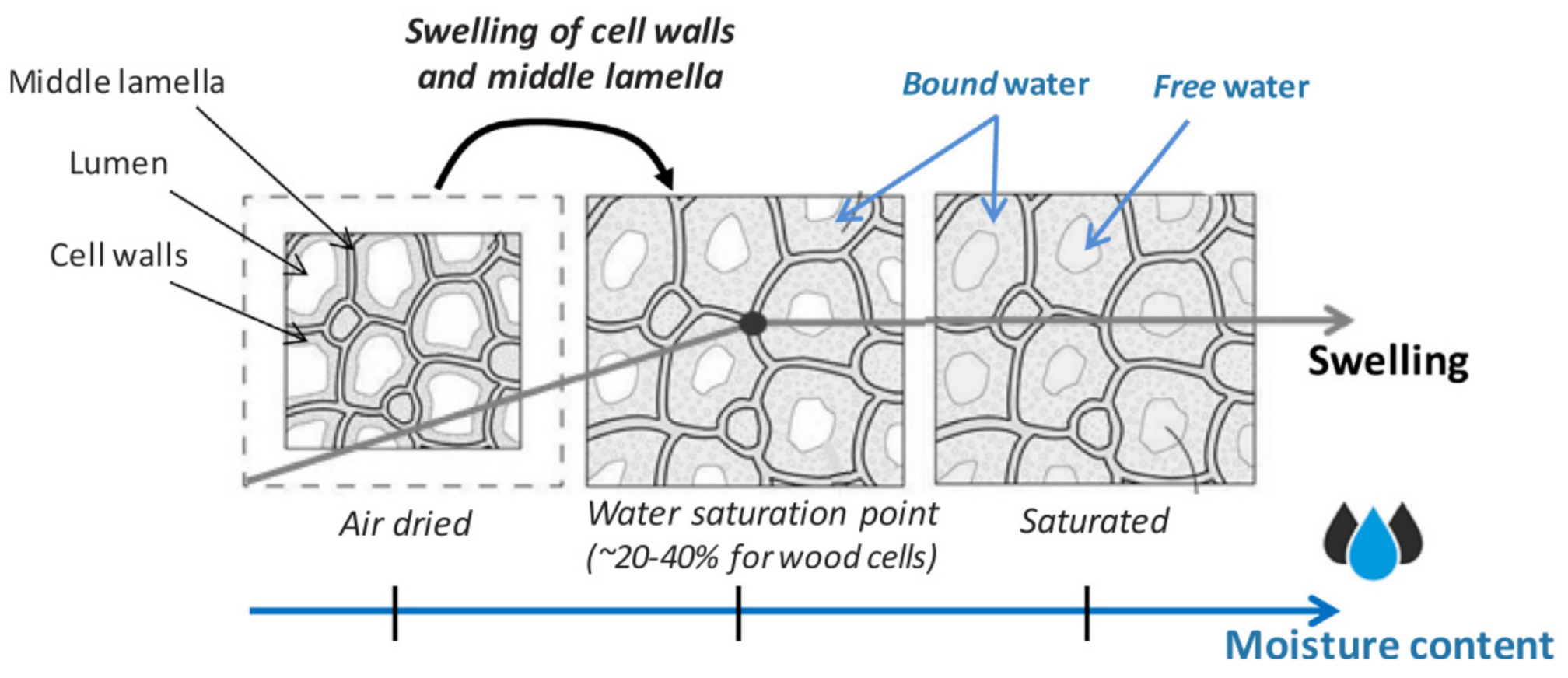

2. Natural Fiber

3. Static Mechanical Testing

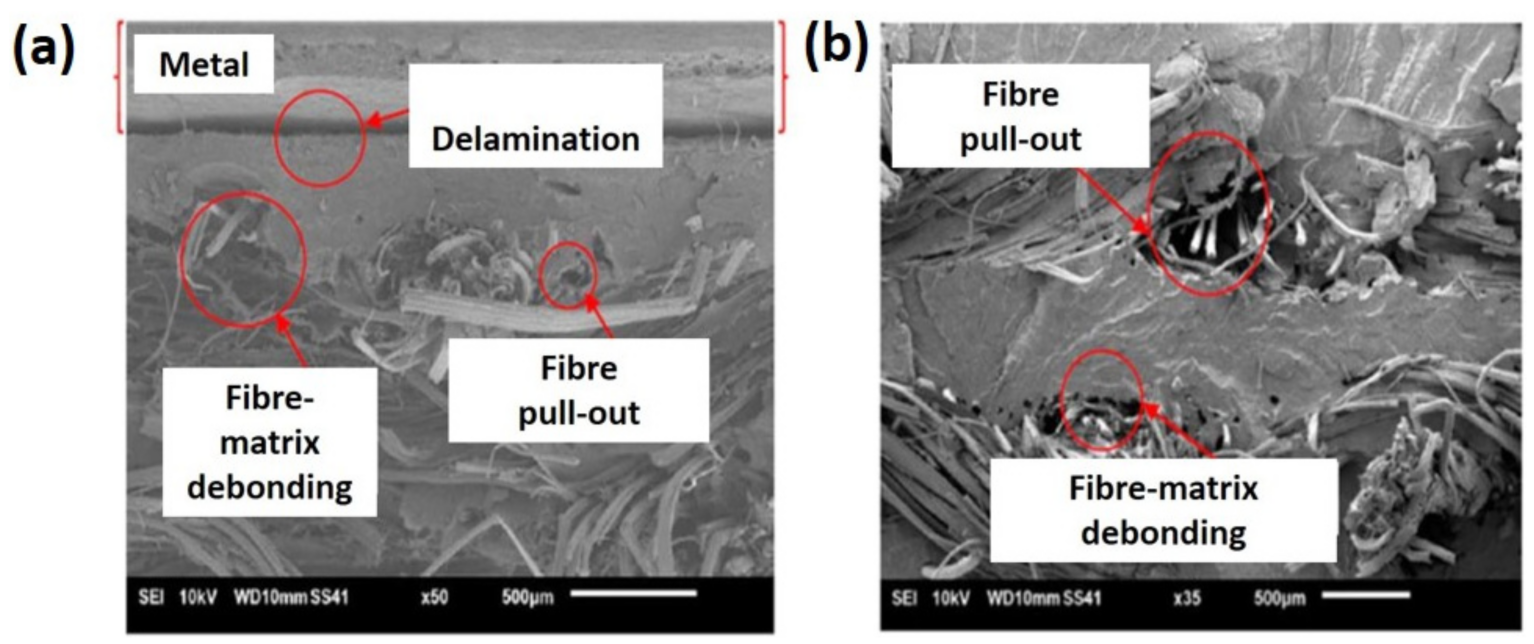

4. Factors Determine the Mechanical Failure

5. Failure Mechanism of Natural Fiber Hybrid Composites

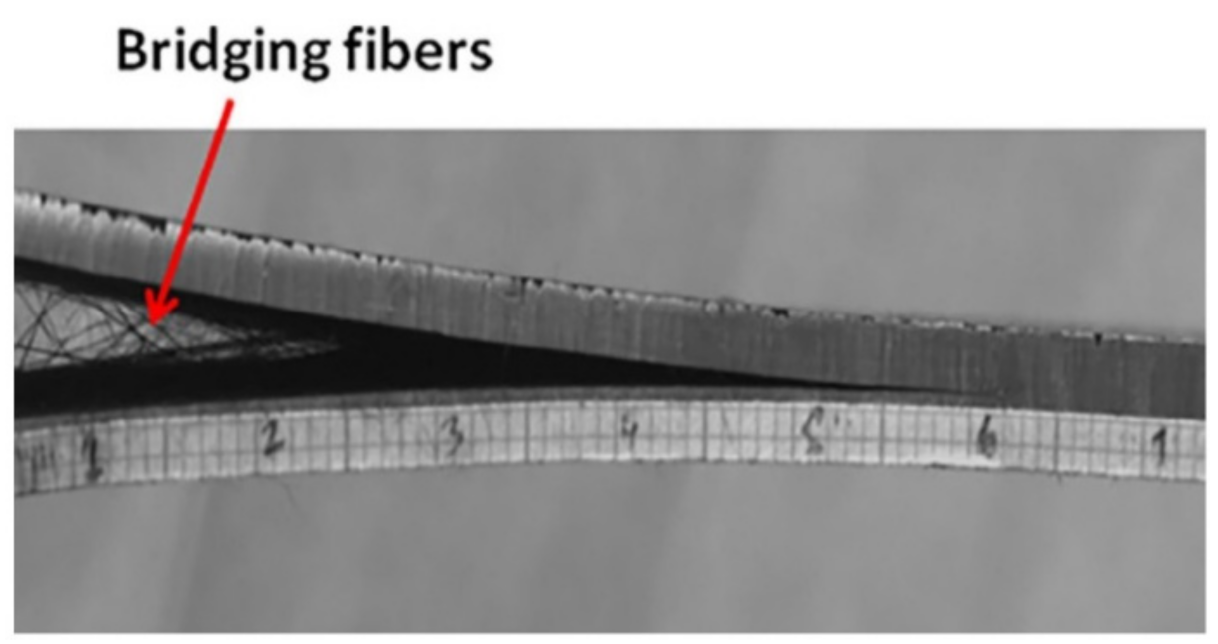

5.1. Crack Propagation and Delamination

5.2. Fatigue

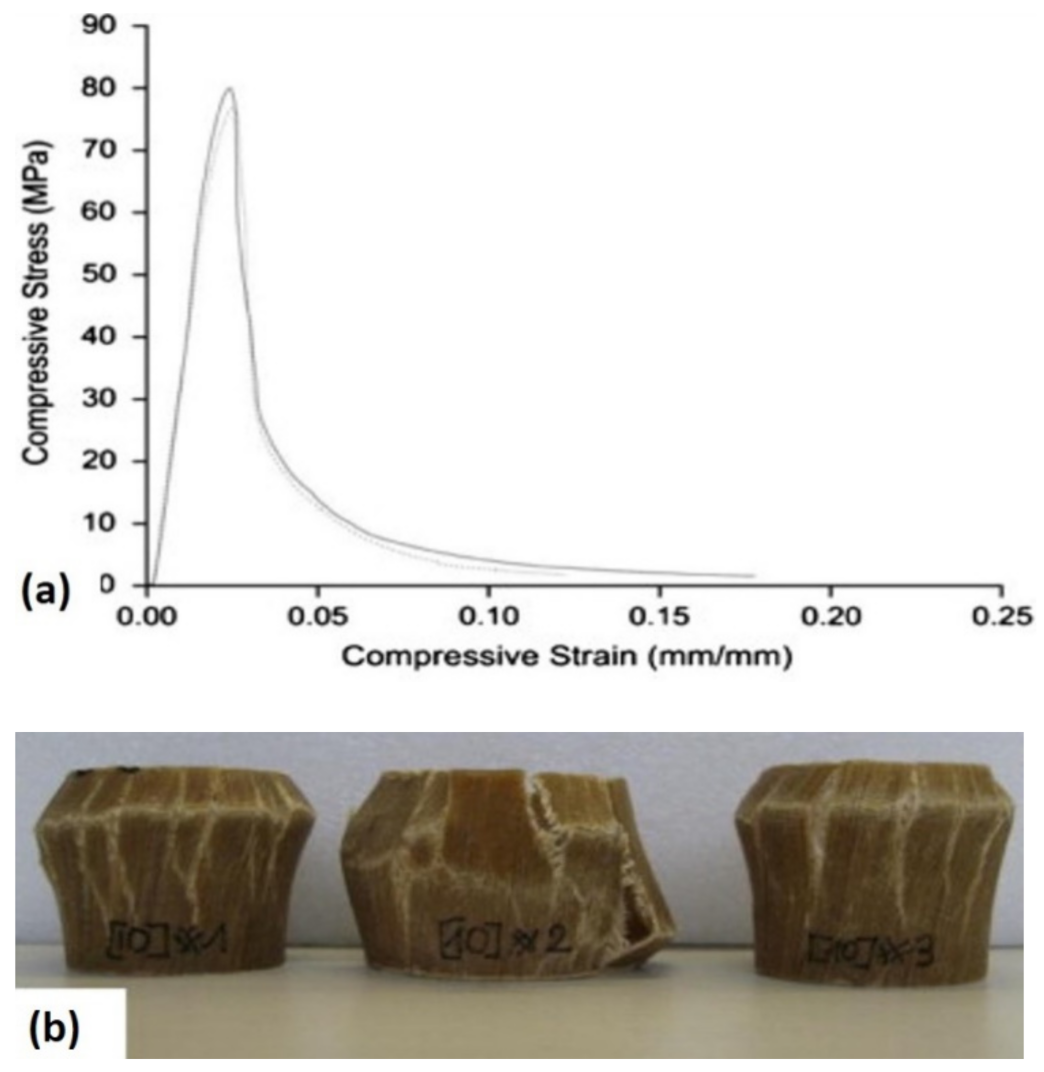

5.3. Microbuckling

6. Hybrid Natural Fiber Polymer Composites

6.1. Mechanical Performance of Hybrid Natural Fiber/Natural Fiber Polymer Composites

6.2. Mechanical Performance of Hybrid Natural Fiber/Synthetic Fiber-Reinforced Polymer Composites

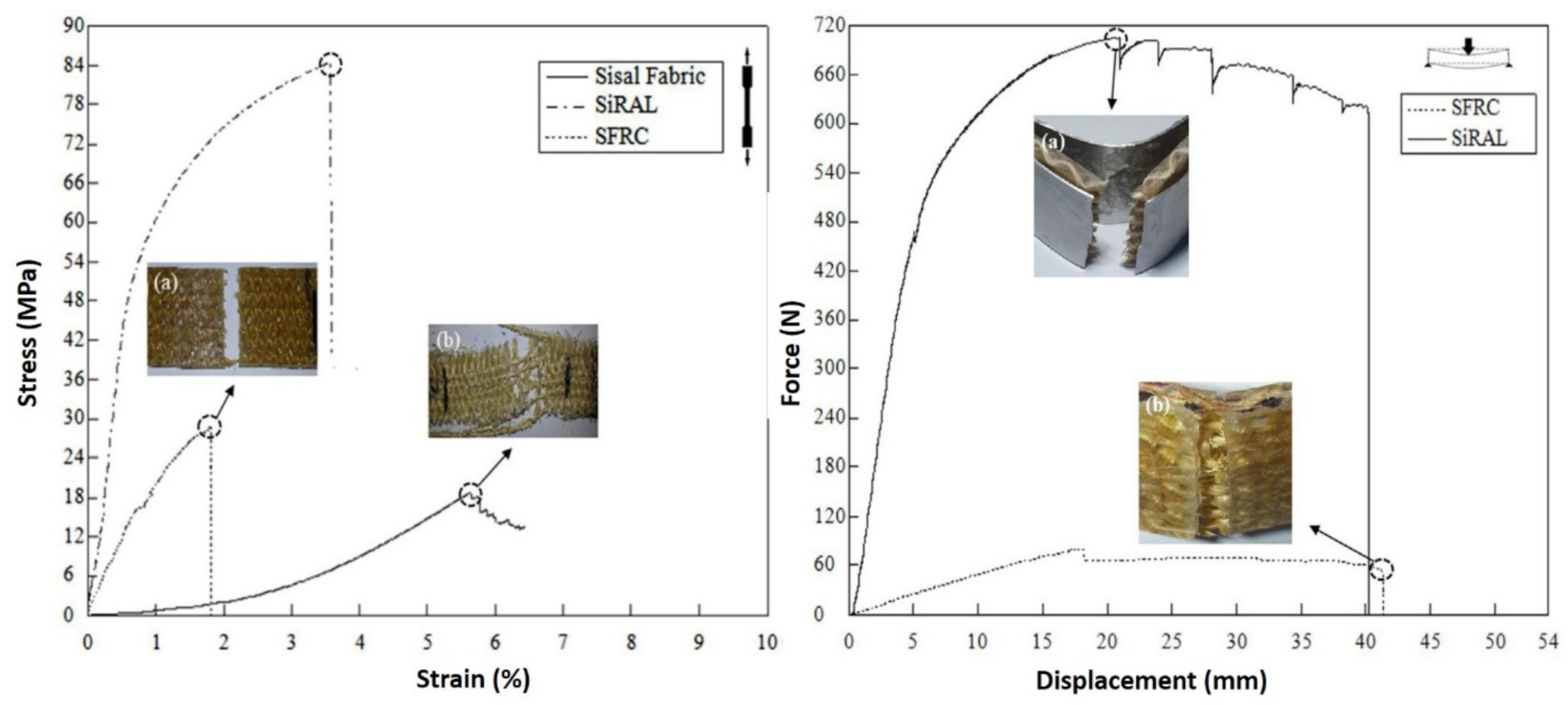

6.3. Mechanical Performance of Hybrid Natural Fiber/Metal-Reinforced Polymer Composites

6.4. Mechanical Performance of Hybrid Natural Fiber/Carbonaceous Material-Reinforced Polymer Composites

7. Applications of Hybrid Natural Fiber Polymer Composites

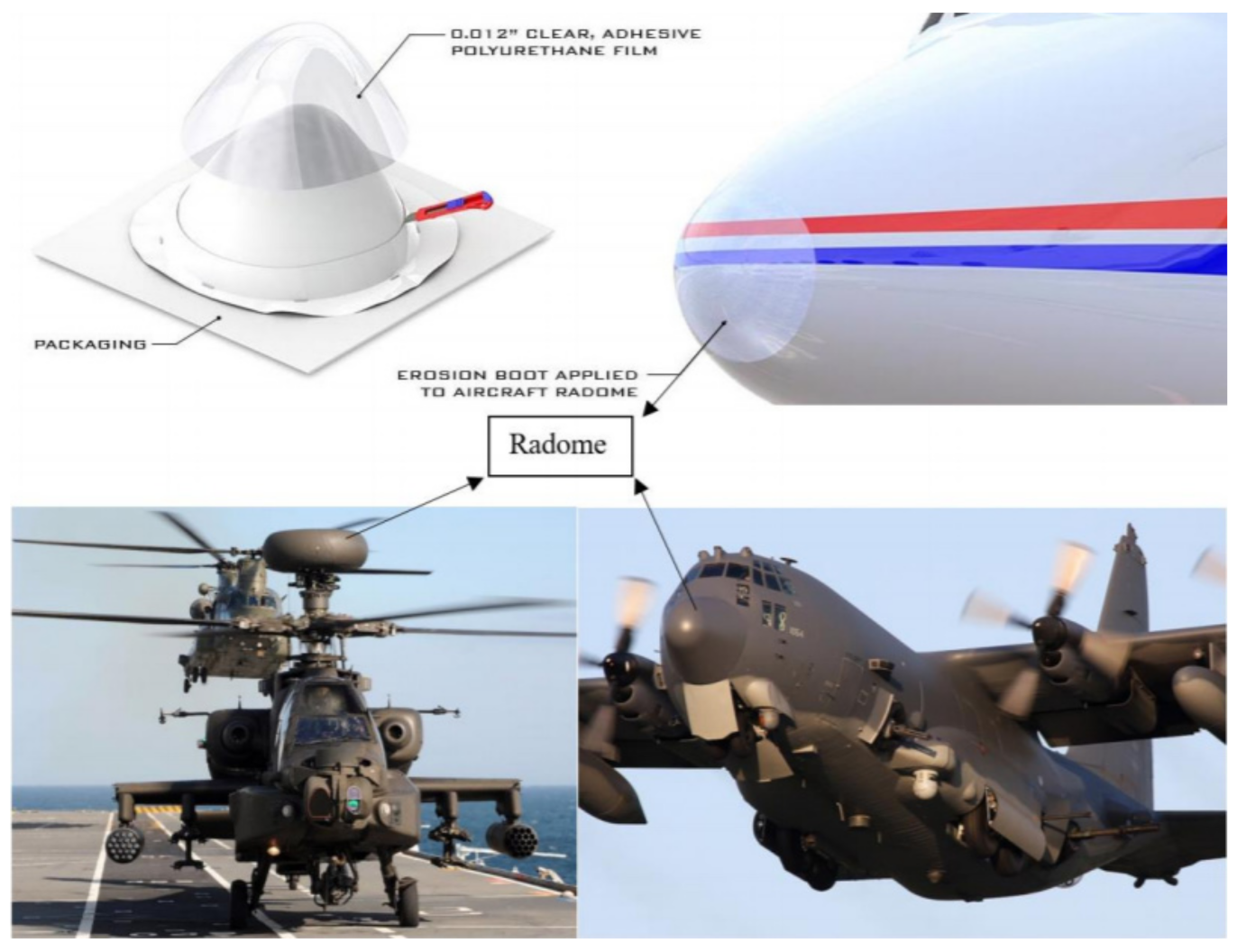

7.1. Aircraft Applications

7.2. Marine Applications

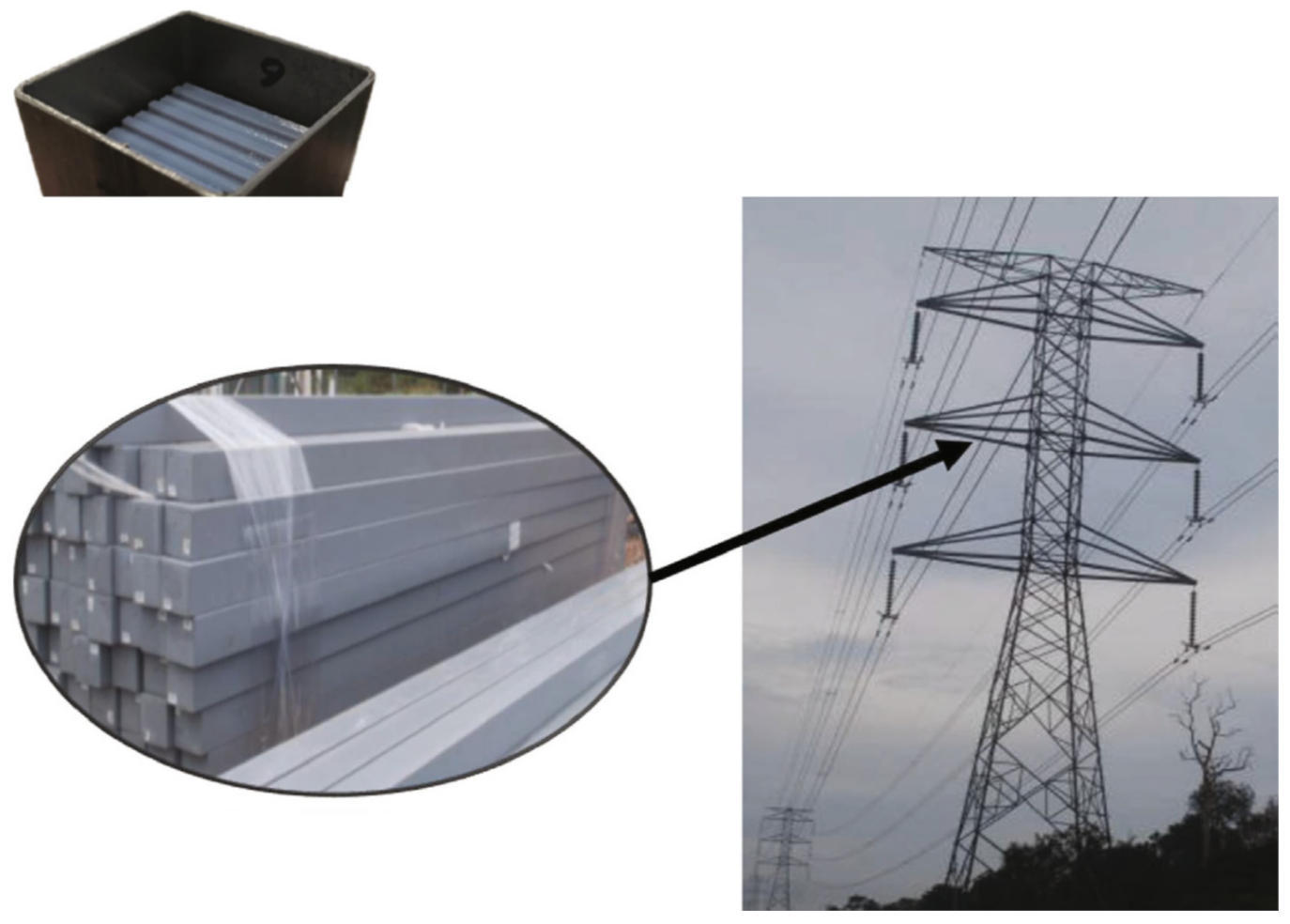

7.3. Civil Construction

7.4. Automotive

7.5. Sporting Goods

8. Conclusions and Future Outlooks

- (i)

- The most common source of crack propagation is composite cracking, which is caused by the formation of displacement discontinuity surfaces within the composites.

- (i)

- Fatigue failure may occur in a variety of structural components that are below the material’s ultimate tensile strength. Fatigue failure is thought to be responsible for half of all structural component failures.

- (ii)

- Microbuckling of fiber composite laminates begins at the open hole and spreads outward from the hole’s tip.

- (i)

- Improving moisture resistance and fire retardancy.

- (ii)

- Appropriate concept details can be created in order to popularize the use of these new materials. When hybridization is attempted, more research into the effects of natural fibers on aging is required.

- (iii)

- Since natural fiber-reinforced polymer composites do not provide the expected strength values based on the law of mixtures, comprehensive basic studies on factors related to strength, such as interface bonding and fracture mechanisms, will be conducted to aid the future production of these composites for appropriate applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bujjibabu, G.; Das, V.C.; Ramakrishna, M.; Nagarjuna, K. Mechanical and Water Absorption Behavior of Natural Fibers Reinforced Polypropylene Hybrid Composites. Mater. Today Proc. 2018, 5, 12249–12256. [Google Scholar] [CrossRef]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Shireesha, Y.; Nandipati, G.; Chandaka, K. Properties of hybrid composites and its applications: A brief review. Int. J. Sci. Technol. Res. 2019, 8, 335–341. [Google Scholar]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An overview: Natural fiber reinforced hybrid composites, chemical treatments and application areas. Mater. Today Proc. 2019, 27, 2828–2834. [Google Scholar] [CrossRef]

- Syduzzaman, M.; Al Faruque, M.A.; Bilisik, K.; Naebe, M. Plant-Based Natural Fibre Reinforced Composites: A Review on Fabrication, Properties and Applications. Coatings 2020, 10, 973. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A..; Drzal, L..; Misra, M.; Parija, S.; Nayak, S.; Tripathy, S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Reddy, G.V.; Naidu, S.V.; Rani, T.S. Impact properties of kapok based unsaturated polyester hybrid composites. J. Reinf. Plast. Compos. 2008, 27, 1789–1804. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Effects of environmental aging on the mechanical properties of bamboo–glass fiber reinforced polymer matrix hybrid composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 43–52. [Google Scholar] [CrossRef]

- Tsampas, S.A.; Greenhalgh, E.S.; Ankersen, J.; Curtis, P.T. Compressive failure of hybrid multidirectional fibre-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2015, 71, 40–58. [Google Scholar] [CrossRef] [Green Version]

- Nordin, H.; Täljsten, B. Testing of hybrid FRP composite beams in bending. Compos. Part B Eng. 2004, 35, 27–33. [Google Scholar] [CrossRef]

- Tran, L.Q.N.; Fuentes, C.; Verpoest, I.; Van Vuure, A.W. Tensile behavior of unidirectional bamboo/coir fiber hybrid composites. Fibers 2019, 7, 62. [Google Scholar] [CrossRef] [Green Version]

- Nurazzi, N.; Khalina, A.; Sapuan, S.; Laila, A.H.D.; Mohamed, R. Curing behaviour of unsaturated polyester resin and interfacial shear stress of sugar palm fibre. J. Mech. Eng. Sci. 2017, 11, 2650–2664. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Halim, N.A.; Shah, N.A.A.; Noor, S.A.M.; Jamal, S.H.; Ong, K.K.; Yunus, W.M.Z.W.; Farid, M.A.A.; et al. Performance evaluation of cellulose nanofiber reinforced polymer composites. Funct. Compos. Struct. 2021, 3, 024001. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Ariffin, H.; Yasim-Anuar, T.A.T.; Hassan, M.A.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Nishida, H. Performance Evaluation of Cellulose Nanofiber with Residual Hemicellulose as a Nanofiller in Polypropylene-Based Nanocomposite. Polymers 2021, 13, 1064. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, M.S.; Norizan, M.N.; Norrrahim, M.N.F.; Ibrahim, R.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; Izwan, S.; Azammi, A.M.N.; et al. Macro to nanoscale natural fiber composites for automotive components: Research, development, and application. In Biocomposite and Synthetic Composites for Automotive Applications; Sapuan, M.S., Ilyas, R.A., Eds.; Woodhead Publishing Series: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Kadier, A.; Kalil, M.S.; Atikah, M.S.N.; Ibrahim, R.; Asrofi, M.; Abral, H.; et al. Nanocellulose/Starch Biopolymer Nanocomposites: Processing, Manufacturing, and Applications. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Al-Oqla, F.M., Sapuan, S.M., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 65–88. [Google Scholar]

- Mtui, G.Y.S. Recent advances in pretreatment of lignocellulosic wastes and production of value added products. Afr. J. Biotechnol. 2009, 8, 1398–1415. [Google Scholar]

- Zakaria, M.R.; Fujimoto, S.; Hirata, S.; Hassan, M.A. Ball milling pretreatment of oil palm biomass for enhancing enzymatic hydrolysis. Appl. Biochem. Biotechnol. 2014, 173, 1778–1789. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef]

- Norizan, M.N.; Abdan, K.; Salit, M.S.; Mohamed, R. Physical, mechanical and thermal properties of sugar palm yarn fibre loading on reinforced unsaturated polyester composites. J. Phys. Sci. 2017, 28, 115–136. [Google Scholar] [CrossRef] [Green Version]

- Haghdan, S.; Renneckar, S.; Smith, G.D. Sources of Lignin. In Lignin in Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–11. ISBN 9780323355667. [Google Scholar]

- Azeez, M.A.; Orege, J.I. Bamboo, Its Chemical Modification and Products. In Bamboo—Current and Future Prospects; Abdul Khalil, H.P.S., Ed.; InTech: London, UK, 2018. [Google Scholar]

- Ansell, M.P.; Mwaikambo, L.Y. The structure of cotton and other plant fibres. In Handbook of Textile Fibre Structure; Elsevier: Amsterdam, The Netherlands, 2009; Volume 2, pp. 62–94. ISBN 9781845697310. [Google Scholar]

- Barreto, A.C.H.; Rosa, D.S.; Fechine, P.B.A.; Mazzetto, S.E. Properties of sisal fibers treated by alkali solution and their application into cardanol-based biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 492–500. [Google Scholar] [CrossRef]

- Daud, Z.; Mohd Hatta, M.Z.; Mohd Kassi, A.S.; Mohd Aripi, A. Analysis of the Chemical Compositions and Fiber Morphology of Pineapple (Ananas comosus) Leaves in Malaysia. J. Appl. Sci. 2014, 14, 1355–1358. [Google Scholar] [CrossRef]

- Zainudin, E.S.; Yan, L.H.; Haniffah, W.H.; Jawaid, M.; Alothman, O.Y. Effect of coir fiber loading on mechanical and morphological properties of oil palm fibers reinforced polypropylene composites. Polym. Compos. 2014, 35, 1418–1425. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Ariffin, H.; Norrrahim, M.N.F.; Hassan, M.A.; Andou, Y.; Tsukegi, T.; Nishida, H. Well-dispersed cellulose nanofiber in low density polyethylene nanocomposite by liquid-Assisted extrusion. Polymers 2020, 12, 927. [Google Scholar] [CrossRef] [Green Version]

- Yasim-anuar, T.A.T.; Ariffin, H.; Nor, M.; Norrrahim, F.; Hassan, M.A.; Tsukegi, T.; Nishida, H. Sustainable One-Pot Process for the Production of Cellulose Nanofiber and Polyethylene/Cellulose Nanofiber Composites. J. Clean. Prod. 2018, 207, 590–599. [Google Scholar] [CrossRef]

- Sharip, N.S.; Yasim-Anuar, T.A.T.; Norrrahim, M.N.F.; Shazleen, S.S.; Nurazzi, N.M.; Sapuan, S.M.; Ilyas, R.A. A Review on Nanocellulose Composites in Biomedical Application. In Composites in Biomedical Applications; Sapuan, S.M., Nukman, Y., Osman, N.A.A., Ilyas, R.A., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 161–190. [Google Scholar]

- Norrrahim, M.N.F.; Ariffin, H.; Yasim-Anuar, T.A.T.; Hassan, M.A.; Nishida, H.; Tsukegi, T. One-pot nanofibrillation of cellulose and nanocomposite production in a twin-screw extruder. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 1–9. [Google Scholar] [CrossRef]

- Fareez, I.M.; Jasni, A.H.; Norrrahim, M.N.F. Nanofibrillated Cellulose Based Bio-phenolic Composites. In Phenolic Polymers Based Composite Materials; Jawaid, M., Asim, M., Eds.; Springer: Singapore, 2020; pp. 139–151. [Google Scholar]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Misenan, M.S.M.; Janudin, N.; Shah, N.A.A.; Kasim, N.; Yusoff, W.Y.W.; Noor, S.A.M.; Jamal, S.H.; et al. Nanocellulose: A bioadsorbent for chemical contaminant remediation. RSC Adv. 2021, 11, 7347–7368. [Google Scholar] [CrossRef]

- Jones, D.; Ormondroyd, G.O.; Curling, S.F.; Popescu, C.-M. Chemical compositions of natural fibres. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 23–58. [Google Scholar]

- Smole, M.S.; Hribernik, S.; Kleinschek, K.S.; Kreže, T. Plant Fibres for Textile and Technical Applications. In Advances in Agrophysical Research; Grundas, S., Stepniewski, A., Eds.; IntechOpen: Rijeka, Croatia, 2013. [Google Scholar]

- Bouasker, M.; Belayachi, N.; Hoxha, D.; Al-Mukhtar, M. Physical Characterization of Natural Straw Fibers as Aggregates for Construction Materials Applications. Materials 2014, 7, 3034. [Google Scholar] [CrossRef] [Green Version]

- Smole, M.S.; Hribernik, S. Grass Fibers, Physical Properties. In Encyclopedia of Agrophysics; Encyclopedia of Earth Sciences Series; Gliński, J., Horabik, J., Lipiec, J., Eds.; Springer: Dordrecht, The Netherlands, 2011; pp. 333–334. [Google Scholar]

- González, O.M.; Velín, A.; García, A.; Arroyo, C.R.; Barrigas, H.L.; Vizuete, K.; Debut, A. Representative Hardwood and Softwood Green Tissue-Microstructure Transitions per Age group and their inherent relationships with physical-mechanical properties and potential applications. Forests 2020, 11, 569. [Google Scholar] [CrossRef]

- Allemang, R.; De Clerck, J.; Niezrecki, C.; Wicks, A. Preface. Conf. Proc. Soc. Exp. Mech. Ser. 2014, 45, 577–617. [Google Scholar]

- Srinivasa, C.V.; Bharath, K.N. Impact and Hardness Properties of Areca Fiber-Epoxy Reinforced Composites. J. Mater. Environ. Sci. 2011, 2, 351–356. [Google Scholar]

- Saba, N.; Jawaid, M.; Sultan, M.T.H. An overview of mechanical and physical testing of composite materials. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 1–12. [Google Scholar]

- Rahmat, M. Dynamic mechanical characterization of aluminum: Analysis of strain-rate-dependent behavior. Mech. Time Depend. Mater. 2019, 23, 385–405. [Google Scholar] [CrossRef]

- Food and Agriculture Organization (FAO) of the United Nations. Available online: http://www.fao.org/statistics/en/ (accessed on 20 June 2021).

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Thermoplastic polymers: Overview of several properties and their consequences in flax fibre reinforced composites. Polym. Test. 2001, 20, 885–893. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvalho, J.P.R.G.; Vieira, C.M.F.; Lopes, F.P.D.; Tonini Simonassi, N.; Da Luz, F.S.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2020, 9. [Google Scholar] [CrossRef]

- Ranalli, P.; Venturi, G. Hemp as a raw material for industrial applications. Euphytica 2004, 140, 1–6. [Google Scholar] [CrossRef]

- Pejic, B.; Kramar, A.; Obradović, B.M.; Kuraica, M.M. Effect of plasma treatment on chemical composition, structure and sorption properties of lignocellulosic hemp fibers (Cannabis sativa L.). Carbohydr. Polym. 2020. [Google Scholar] [CrossRef]

- Carus, M.; Sarmento, L. The European Hemp Industry: Cultivation, Processing and Applications for Fibres, Shivs, Seeds and Flowers; The European Industrial Hemp Association: Hürth, Germany, 2016; pp. 1–9. [Google Scholar]

- Gupta, M.K.; Srivastava, R.K.; Bisaria, H. Potential of Jute Fibre Reinforced Polymer Composites: A review. Int. J. Fiber Text. Res. 2015, 5, 30–38. [Google Scholar]

- Rohit, K.; Dixit, S. A Review—Future Aspect of Natural Fiber Reinforced Composite. Polym. Renew. Resour. 2016, 7, 43–59. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Thomas, J. Kenaf: Nature’s Little-Known Wonder—The Asean Post. Available online: https://theaseanpost.com/article/kenaf-natures-little-known-wonder (accessed on 10 June 2021).

- Leao, A.L.; Souza, S.F.; Cherian, B.M.; Frollini, E.; Thomas, S.; Pothan, L.A.; Kottaisamy, M. Agro-Based Biocomposites for Industrial Applications. Mol. Cryst. Liq. Cryst. 2010, 522, 318–327. [Google Scholar] [CrossRef]

- Odusote, J.K.; Kumar, V. Mechanical Properties of Pineapple Leaf Fibre Reinforced Polymer Composites for Application as Prosthetic Socket. J. Eng. Technol. 2016, 7, 125–139. [Google Scholar] [CrossRef] [Green Version]

- Todkar, S.S.; Patil, S.A. Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos. Part B Eng. 2019, 174, 106927. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Evaluation of Bending Strength of Abaca Reinforced Polymer Composites. Mater. Today Proc. 2018, 5, 7284–7288. [Google Scholar] [CrossRef]

- Abaca Natural Fiber. Available online: https://www.abc-oriental-rug.com/abaca-natural-fiber.html (accessed on 10 June 2021).

- Ranum, P.; Pablo, J.; Peña, R.; Garcia-Casal, M.N. Global maize production, utilization, and consumption. Ann. N. Y. Acad. Sci. 2014, 1312, 105–112. [Google Scholar] [CrossRef]

- Husseinsyah, S.; Mostapha, M.; Selvi, E. Bio composites From Polypropylene and Corn Cob: Effect Maleic Anhydride Polypropylene. Adv. Mater. Res. 2014, 3, 129–137. [Google Scholar] [CrossRef] [Green Version]

- Costa, L.A.D.S.; Assis, D.J.; Gomes, G.V.P.; Silva, J. Extraction and Characterization of Nanocellulose from Corn Stover. Mater. Today Proc. 2015, 2, 287–294. [Google Scholar] [CrossRef]

- Andrade, M.R.; Nery, T.B.R.; Santana, T.I.; Leal, I.L.; Rodrigues, L.A.P.; Reis, J.H.O.; Druzian, J.I.; Machado, B.A.S. Effect of Cellulose Nanocrystals from Different Lignocellulosic Residues to Chitosan/Glycerol Films. Polymers 2019, 11, 658. [Google Scholar] [CrossRef] [Green Version]

- Yu, M.; Huang, R.; He, C.; Wu, Q.; Zhao, X. Hybrid Composites from Wheat Straw, Inorganic Filler, and Recycled Polypropylene: Morphology and Mechanical and Thermal Expansion Performance. Int. J. Polym. Sci. 2016, 1–12. [Google Scholar] [CrossRef] [Green Version]

- USDA Cereal, Grasses, and Grains. Available online: https://www.fs.fed.us/wildflowers/ethnobotany/food/grains.shtml (accessed on 30 June 2021).

- Kapoor, M.; Panwar, D.; Kaira, G. Bioprocesses for Enzyme Production Using Agro-Industrial Wastes: Technical Challenges and Commercialization Potential. In Agro-Industrial Wastes as Feedstock for Enzyme Production; Dhillon, G.S., Kaur, S., Eds.; Academic Press: San Diego, CA, USA, 2016; pp. 61–93. [Google Scholar]

- Panthapulakkal, S.; Zereshkian, A.; Sain, M. Preparation and characterization of wheat straw fibers for reinforcing application in injection molded thermoplastic composites. Bioresour. Technol. 2016, 97, 265–272. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Biocomposites from wheat straw nanofibers: Morphology, thermal and mechanical properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- de Olveira, L.Á.; dos Santos, J.C.; Panzera, T.H.; Freire, R.T.S.; Vieira, L.M.G.; Rubio, J.C.C. Investigations on short coir fibre–reinforced composites via full factorial design. Polym. Polym. Compos. 2018, 26, 391–399. [Google Scholar] [CrossRef]

- Morais, J.P.S.; de Freitas Rosa, M.; de sá Filho, M.M.S.; Dias Nascimento, L.; Nascimento, D.M.; Cassales, A.R. Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr. Polym. 2013, 91, 229–235. [Google Scholar] [CrossRef] [Green Version]

- Perelshtein, I.; Applerot, N.P.; Wehrschuetz-Sigl, E.; Hasmann, A.; Guebitz, G.; Gedanken, A. CuO–cotton nanocomposite: Formation, morphology, and antibacterial activity. Surf. Coatings Technol. 2009, 201, 54–57. [Google Scholar] [CrossRef]

- Rana, M.; Hao, B.; Mu, L.; Chen, L.; Ma, P.-C. Development of multi-functional cotton fabrics with Ag/AgBr. Compos. Sci. Technol. 2016, 122, 104–112. [Google Scholar] [CrossRef]

- Chand, N.; Fahim, M. Cotton reinforced polymer composites. In Tribology of Natural Fiber Polymer Composites; Chand, N., Fahim, M., Eds.; Woodhead Publishing: Cambridge, UK, 2008; pp. 129–161. [Google Scholar]

- Jayaweera, C.D.; Karunaratne, D.W.T.S.; Bandara, S.T.S.; Walpalage, S. Investigation of the effectiveness of nanocellulose extracted from Sri Lankan Kapok, as a filler in Polypropylene polymer matrix. In Proceedings of the 2017 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 29–31 May 2017; pp. 1–6. [Google Scholar]

- Macedo, M.J.P.; Silva, G.S.; Feitor, M.C.; Costa, T.H.C. Composites from recycled polyethylene and plasma treated kapok fibers. Cellulose 2019, 27, 2115–2134. [Google Scholar] [CrossRef]

- Mani, G.K.; Rayappan, J.B.B.; Bisoyi, D.K. Synthesis and Characterization of Kapok Fibers and its Composites. J. Appl. Sci. 2012, 12, 1661–1665. [Google Scholar] [CrossRef] [Green Version]

- Chang, F.; Lee, S.-H.; Toba, K.; Nagatani, A.; Endo, T. Bamboo nanofiber preparation by HCW and grinding treatment and its application for nanocomposite. Wood Sci. Technol. 2012, 46, 393–403. [Google Scholar] [CrossRef]

- Han, S.; Yao, Q.; Jin, C.; Fan, B.; Zheng, H.; Sun, Q. Cellulose nanofibers from bamboo and their nanocomposites with polyvinyl alcohol: Preparation and characterization. Polym. Compos. 2016, 39, 1–9. [Google Scholar] [CrossRef]

- Md Shah, A.U.; Sultan, M.T.H.; Jawaid, M.; Cardona, F.; Abu Talib, A.R. A review on the tensile properties of bamboo fiber reinforced polymer composites. BioResources 2016, 11, 10654–10676. [Google Scholar] [CrossRef] [Green Version]

- Ghaderi, M.; Mousavi, M.; Yousefi, H.; Labbafi, M. All-cellulose nanocomposite film made from bagasse cellulose nanofibers for food packaging application. Carbohydr. Polym. 2014, 104, 59–65. [Google Scholar] [CrossRef]

- Verma, D. Bagasse fiber composites: A Review. J. Mater. Environ. Sci. 2012, 3, 1076–1092. [Google Scholar]

- Teboho, M.; Mochane, M.; Tshwafo, M.; Linganiso, L.Z. Sugarcane Bagasse and Cellulose Polymer Composites. In Sugarcane—Technology and Research; de Oliveira, A.B., Ed.; IntechOpen: London, UK, 2018; pp. 225–240. [Google Scholar]

- Panicker, A.M.; Rajesh, K.A.; Varghese, T.O. Mixed morphology nanocrystalline cellulose from sugarcane bagasse fibers/poly(lactic acid) nanocomposite films: Synthesis, fabrication and characterization. Iran. Polym. J. 2017, 26, 125–136. [Google Scholar] [CrossRef]

- Rowell, R.M. Natural fibres: Types and properties. In Properties and Performance of Natural-Fibre Composites; Pickering, K.L., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2008; pp. 3–66. ISBN 9781845692674. [Google Scholar]

- Asaee, Z.; Montesano, J.; Worswick, M. Assessing the failure mechanisms and mechanical performance of Co-moulded hybrid AA5182-O/GFRP hat-channel beams under quasi-static three-point bending. Compos. Struct. 2021, 256, 113007. [Google Scholar] [CrossRef]

- Türker, H.T. A modified beam theory for bending of eccentrically supported beams. Mech. Based Des. Struct. Mach. 2020. [Google Scholar] [CrossRef]

- Schmauder, S.; Chen, C.S.D.; Chawla, K.K.; Chawla, N.; Chen, W.; Kagawa, Y. Handbook of Mechanics of Materials; Springer: Singapore, 2019. [Google Scholar]

- Elishakoff, I. Who developed the so-called Timoshenko beam theory? Math. Mech. Solids 2020, 25. [Google Scholar] [CrossRef] [Green Version]

- Sayyad, A.S. Comparison of various refined beam theories for the bending and free vibration analysis of thick beams. Appl. Comput. Mech. 2011, 5, 217–230. [Google Scholar] [CrossRef]

- Zhu, X.; Xiong, C.; Yin, J.; Yin, D.; Deng, H. Bending experiment and mechanical properties analysis of composite sandwich laminated box beams. Materials 2019, 12, 2959. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Lauter, C.; Sanitther, B.; Camberg, A.; Troester, T. Manufacturing and investigation of steel-CFRP hybrid pillar structures for automotive applications by intrinsic resin transfer moulding technology. Int. J. Automot. Compos. 2016, 2. [Google Scholar] [CrossRef]

- Cerbu, C. Practical solution for improving the mechanical behaviour of the composite materials reinforced with flax woven fabric. Adv. Mech. Eng. 2015, 7, 1–11. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Licence, P.; Clifford, M.J. Determining the minimum, critical and maximum fibre content for twisted yarn reinforced plant fibre composites. Compos. Sci. Technol. 2012, 72. [Google Scholar] [CrossRef] [Green Version]

- Ghalia, M.A.; Abdelrasoul, A. Compressive and Fracture Toughness of Natural and Synthetic Fiber-Reinforced Polymer; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780081022924. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. Recent advances in fibre-hybrid composites: Materials selection, opportunities and applications. Int. Mater. Rev. 2019, 64, 181–215. [Google Scholar] [CrossRef]

- Schneider, K.; Lauke, B. Determination of compressive properties of fibre-reinforced polymers in the in-plane direction according to ISO 14126. Part 2: A critical investigation of failure behaviour. Appl. Compos. Mater. 2007, 14. [Google Scholar] [CrossRef]

- Garat, W.; Le Moigne, N.; Corn, S.; Beaugrand, J.; Bergeret, A. Swelling of natural fibre bundles under hygro- and hydrothermal conditions: Determination of hydric expansion coefficients by automated laser scanning. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105803. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; John, M.J. Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr. Polym. 2015, 131, 337–354. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.E. Interface Engineering of Natural Fibre Composites for Maximum Performance; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Engelund, E.T.; Thygesen, L.G.; Svensson, S.; Hill, C.A.S. A critical discussion of the physics of wood–water interactions. Wood Sci. Technol. 2013, 47, 141–161. [Google Scholar] [CrossRef] [Green Version]

- Fredriksson, M. On wood-water interactions in the over-hygroscopic moisture range-mechanisms, methods, and influence of wood modification. Forests 2019, 10, 779. [Google Scholar] [CrossRef] [Green Version]

- Placet, V.; Cisse, O.; Boubakar, M.L. Influence of environmental relative humidity on the tensile and rotational behaviour of hemp fibres. J. Mater. Sci. 2012, 47. [Google Scholar] [CrossRef]

- Zhang, D.; Milanovic, N.R.; Zhang, Y.; Su, F.; Miao, M. Effects of humidity conditions at fabrication on the interfacial shear strength of flax/unsaturated polyester composites. Compos. Part B Eng. 2014, 60. [Google Scholar] [CrossRef]

- Ashik, K.P.; Sharma, R.S.; Guptha, V.L.J. Investigation of moisture absorption and mechanical properties of natural/glass fiber reinforced polymer hybrid composites. Mater. Today Proc. 2018, 5, 3000–3007. [Google Scholar] [CrossRef]

- Jumahat, A.; Soutis, C.; Jones, F.R.; Hodzic, A. Fracture mechanisms and failure analysis of carbon fibre/toughened epoxy composites subjected to compressive loading. Compos. Struct. 2010, 92, 295–305. [Google Scholar] [CrossRef] [Green Version]

- Jegan, M.M.; Sathishkumar, T.P.; Anand, V.; Arun, G.R.; Logesh, R.C.; Mohanraj, K. Investigation of Fracture Behavior on Glass & Natural Fibre Reinforced Epoxy Composites. Int. J. Eng. Res. Technol. 2019, 7, 13–17. [Google Scholar]

- Bolf, D.; Zamarin, A.; Basan, R. Composite Material Damage Processes. J. Marit. Transp. Sci. 2020, 3, 307–323. [Google Scholar] [CrossRef]

- Greco, F.; Leonetti, L.; Lonetti, P.; Nevone Blasi, P. Crack propagation analysis in composite materials by using moving mesh and multiscale techniques. Comput. Struct. 2015, 153, 201–216. [Google Scholar] [CrossRef]

- Ma, Q.; Rejab, M.; Siregar, J.; Guan, Z. A review of the recent trends on core structures and impact response of sandwich panels. J. Compos. Mater. 2021. [Google Scholar] [CrossRef]

- Yao, L.; Cui, H.; Sun, Y.; Guo, L.; Chen, X.; Zhao, M.; Alderliesten, R.C. Fibre-bridged fatigue delamination in multidirectional composite laminates. Compos. Part A Appl. Sci. Manuf. 2018, 115, 175–186. [Google Scholar] [CrossRef] [Green Version]

- Khan, R. Fiber bridging in composite laminates: A literature review. Compos. Struct. 2019, 229, 111418. [Google Scholar] [CrossRef]

- Amiri, M.; Khonsari, M.M. Rapid determination of fatigue failure based on temperature evolution: Fully reversed bending load. Int. J. Fatigue 2010, 32. [Google Scholar] [CrossRef]

- Mejlej, V.G.; Osorio, D.; Vietor, T. An Improved Fatigue Failure Model for Multidirectional Fiber-reinforced Composite Laminates under any Stress Ratios of Cyclic Loading. Procedia CIRP 2017, 66, 27–32. [Google Scholar] [CrossRef]

- Barbero, E.J. Introduction to Composite Materials Design; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Talreja, R. Fatigue of Composite Materials. In Modern Trends in Composite Laminates Mechanics; Altenbach, H., Becker, W., Eds.; Springer: Vienna, Austria, 2003; pp. 281–294. [Google Scholar]

- Dong, H.; Li, Z.; Wang, J.; Karihaloo, B.L. A new fatigue failure theory for multidirectional fiber-reinforced composite laminates with arbitrary stacking sequence. Int. J. Fatigue 2016, 87, 294–300. [Google Scholar] [CrossRef]

- Barulich, N.D.; Godoy, L.A.; Barbero, E.J. On micro-buckling of unidirectional fiber-reinforced composites by means of computational micromechanics. Lat. Am. J. Solids Struct. 2016, 13. [Google Scholar] [CrossRef] [Green Version]

- Soutis, C. Compression Failure of Composite Laminates; Elsevier: Amsterdam, The Netherlands, 2016; Volume 1, ISBN 9781782422860. [Google Scholar]

- Soutis, C. Failure of Notched CFRP Laminates Due to Fibre Microbuckling: A Topical Review. J. Mech. Behav. Mater. 1996, 6, 309–330. [Google Scholar] [CrossRef]

- Chen, W.; Liu, Y.; Jiang, Z.; Tang, L.; Liu, Z.; Zhou, L. Modeling of compressive strength for unidirectional fiber reinforced composites with nanoparticle modified epoxy matrix. Materials 2019, 12, 3897. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, W.; Guan, Z.; Li, Z.; Zhang, M.; Huang, Y. Compressive failure analysis of unidirectional carbon/epoxy composite based on micro-mechanical models. Chin. J. Aeronaut. 2017, 30, 1907–1918. [Google Scholar] [CrossRef]

- Schultheisz, C.R.; Waas, A.M. Compressive failure of composites, Part I: Testing and micromechanical theories. Prog. Aerosp. Sci. 1996, 32, 1–42. [Google Scholar] [CrossRef]

- Wȩcławski, B.T.; Fan, M.; Hui, D. Compressive behaviour of natural fibre composite. Compos. Part B Eng. 2014, 67, 183–191. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Ilyas, R.A.; Nurazzi, N.M. A Review of Biocomposites in Biomedical Application. In Composites in Biomedical Applications; Sapuan, S.M., Nukman, Y., Osman, N.A.A., Ilyas, R.A., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 31–48. [Google Scholar]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, Morphological Chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 1–6. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F. Characteristics of kenaf fibre/epoxy composites subjected to thermal degradation. Polym. Degrad. Stab. 2013, 98, 2752–2759. [Google Scholar] [CrossRef]

- Kim, Y.K.; Chalivendra, V. Natural fibre composites (NFCs) for construction and automotive industries. In The Handbook of Natural Fibres: Volume Two, Processing and Applications; Kozłowski, R.M., Mackiewicz-Talarczyk, M., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; pp. 469–498. [Google Scholar]

- Mazani, N.; Sapuan, S.M.; Sanyang, M.L.; Atiqah, A.; Ilyas, R.A. Design and Fabrication of a Shoe Shelf from Kenaf Fiber Reinforced Unsaturated Polyester Composites. In Lignocellulose for Future Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 315–332. ISBN 9780128163542. [Google Scholar]

- Mohd Nurazzi, N.; Khalina, A.; Chandrasekar, M.; Aisyah, H.A.; Ayu Rafiqah, S.; Ilyas, R.A.; Hanafee, Z.M. Effect of fiber orientation and fiber loading on the mechanical and thermal properties of sugar palm yarn fiber reinforced unsaturated polyester resin composites. Polimery 2020, 65, 115–124. [Google Scholar] [CrossRef]

- Lu, H.; Liu, Y.; Gou, J.; Leng, J.; Du, S. Surface coating of multi-walled carbon nanotube nanopaper on shape-memory polymer for multifunctionalization. Compos. Sci. Technol. 2011, 71, 1427–1434. [Google Scholar] [CrossRef]

- Quanjin, M.; Sahat, I.M.; Rejab, M.R.M.; Hassan, S.A.; Zhang, B.; Merzuki, M.N. The energy-absorbing characteristics of filament wound hybrid carbon fiber-reinforced plastic/polylactic acid tubes with different infill pattern structures. J. Reinf. Plast. Compos. 2019, 38, 1067–1088. [Google Scholar] [CrossRef]

- Caseri, W.R. Nanocomposites of polymers and inorganic particles: Preparation, structure and properties. Mater. Sci. Technol. 2006, 22, 807–817. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and dynamic mechanical properties of bamboo/woven kenaf mat reinforced epoxy hybrid composites. Compos. Part B Eng. 2019, 163, 165–174. [Google Scholar] [CrossRef]

- Hamdan, M.H.M.; Siregar, J.P.; Thomas, S.; Jacob, M.J.; Jaafar, J.; Tezara, C. Mechanical performance of hybrid woven jute–roselle-reinforced polyester composites. Polym. Polym. Compos. 2019, 27, 407–418. [Google Scholar] [CrossRef]

- Maleque, M.; Belal, F.; Sapuan, S.M. Mechanical properties study of pseudo-stem banana fiber reinforced epoxy composite. Arab. J. Sci. Eng. 2007, 32, 359–364. [Google Scholar]

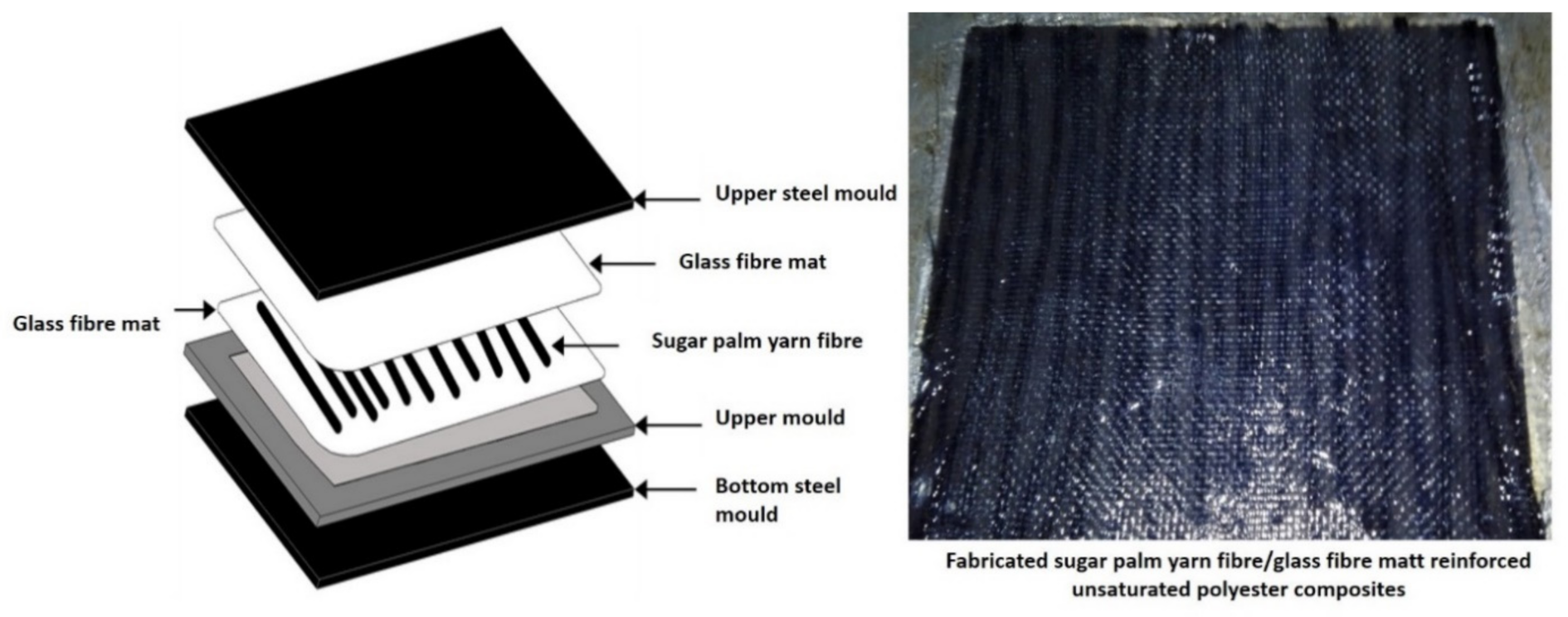

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Rahmah, M. Development of sugar palm yarn/glass fibre reinforced unsaturated polyester hybrid composites. Mater. Res. Express 2018, 5, 045308. [Google Scholar] [CrossRef]

- Khan, M.Z.R.; Srivastava, S.K.; Gupta, M. Tensile and flexural properties of natural fiber reinforced polymer composites: A review. J. Reinf. Plast. Compos. 2018, 37, 1435–1455. [Google Scholar] [CrossRef]

- Khan, T.; Sultan, M.T.H.; Shah, A.U.M.; Ariffin, A.H.; Jawaid, M. The Effects of Stacking Sequence on the Tensile and Flexural Properties of Kenaf/Jute Fibre Hybrid Composites. J. Nat. Fibers 2019, 18, 452–463. [Google Scholar] [CrossRef]

- Hanan, F.; Jawaid, M.; Md Tahir, P. Mechanical performance of oil palm/kenaf fiber-reinforced epoxy-based bilayer hybrid composites. J. Nat. Fibers 2020, 17, 155–167. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.R.; Alothman, O.Y. Effect of hybridization on the mechanical properties of pineapple leaf fiber/kenaf phenolic hybrid composites. J. Renew. Mater. 2018, 6, 38–46. [Google Scholar] [CrossRef]

- Dashtizadeh, Z.; Abdan, K.; Jawaid, M.; Khan, M.A.; Behmanesh, M.; Dashtizadeh, M.; Cardona, F.; Ishak, M. Mechanical and thermal properties of natural fibre based hybrid composites: A review. Pertanika J. Sci. Technol. 2017, 25, 1103–1122. [Google Scholar]

- Yorseng, K.; Rangappa, S.M.; Pulikkalparambil, H.; Siengchin, S.; Parameswaranpillai, J. Accelerated weathering studies of kenaf/sisal fiber fabric reinforced fully biobased hybrid bioepoxy composites for semi-structural applications: Morphology, thermo-mechanical, water absorption behavior and surface hydrophobicity. Constr. Build. Mater. 2020, 235, 117464. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Sultan, M.T.H.; Hassan, A. Physical and mechanical properties of woven Kenaf/Bamboo fiber mat reinforced epoxy hybrid composites. BioResources 2019, 14, 1390–1404. [Google Scholar] [CrossRef]

- Radzi, A.M.; Sapuan, S.M.; Jawaid, M.; Mansor, M.R. Mechanical performance of roselle/sugar palm fiber hybrid reinforced polyurethane composites. BioResources 2018, 13, 6238–6249. [Google Scholar] [CrossRef]

- Rahman, M.R.; Hamdan, S.; Elammaran Jayamani, A.K.; Bakri, M.K.; Yusof, F.A.B.M. Tert-butyl catechol/alkaline-treated kenaf/jute polyethylene hybrid composites: Impact on physico-mechanical, thermal and morphological properties. Polym. Bull. 2019, 76, 763–784. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crops Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A.; Bakar, A.A. Woven hybrid composites: Tensile and flexural properties of oil palm-woven jute fibres based epoxy composites. Mater. Sci. Eng. A 2011, 528, 5190–5195. [Google Scholar] [CrossRef]

- Kumar, K.S.; Siva, I.; Rajini, N.; Jappes, J.T.W.; Amico, S.C. Layering pattern effects on vibrational behavior of coconut sheath/banana fiber hybrid composites. Mater. Des. 2016, 90, 795–803. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Paridah, M.T.; Saba, N.; Nasir, M.; Shahroze, R.M. Dynamic and thermo-mechanical properties of hybridized kenaf/PALF reinforced phenolic composites. Polym. Compos. 2019, 40, 3814–3822. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Shahroze, R.M.; Ishak, M.R.; Saba, N.; Jawaid, M.; Senthilkumar, K.; Kumar, T.S.M.; Siengchin, S. Flax and sugar palm reinforced epoxy composites: Effect of hybridization on physical, mechanical, morphological and dynamic mechanical properties. Mater. Res. Express 2019, 6, 105331. [Google Scholar] [CrossRef]

- Cavalcanti, D.K.K.; Banea, M.D.; Neto, J.S.S.; Lima, R.A.A.; da Silva, L.F.M.; Carbas, R.J.C. Mechanical characterization of intralaminar natural fibre-reinforced hybrid composites. Compos. Part B Eng. 2019, 175, 107149. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Rajeswari, N.; Vishvak, R. Influence of sequential positioning of fibre mats in enhancing the properties of natural fibre mat hybrid composite. Mater. Today Proc. 2020, 28, 1144–1148. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M. Mechanical, dynamic, and thermomechanical properties of coir/pineapple leaf fiber reinforced polylactic acid hybrid biocomposites. Polym. Compos. 2018, 40, 2000–2011. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.P.; Kataria, R. Study on mechanical properties of fabricated hybrid natural fibre polymeric composites. Int. J. Mater. Prod. Technol. 2020, 60, 73–91. [Google Scholar] [CrossRef]

- Manral, A.; Ahmad, F.; Chaudhary, V. Static and dynamic mechanical properties of PLA bio-composite with hybrid reinforcement of flax and jute. Mater. Today Proc. 2020, 25, 577–580. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K.L. Effect of fiber hybridization and montmorillonite clay on properties of treated kenaf/aloe vera fiber reinforced PLA hybrid nanobiocomposite. Cellulose 2020, 27, 6977–6993. [Google Scholar] [CrossRef]

- Kanitkar, Y.M.; Kulkarni, A.P.; Wangikar, K.S. Characterization of glass hybrid composite: A review. Mater. Today Proc. 2017, 4, 9627–9630. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Yogesha, B. Study on mechanical properties of natural-glass fibre reinforced polymer hybrid composites: A review. Mater. Today Proc. 2015, 2, 2959–2967. [Google Scholar] [CrossRef]

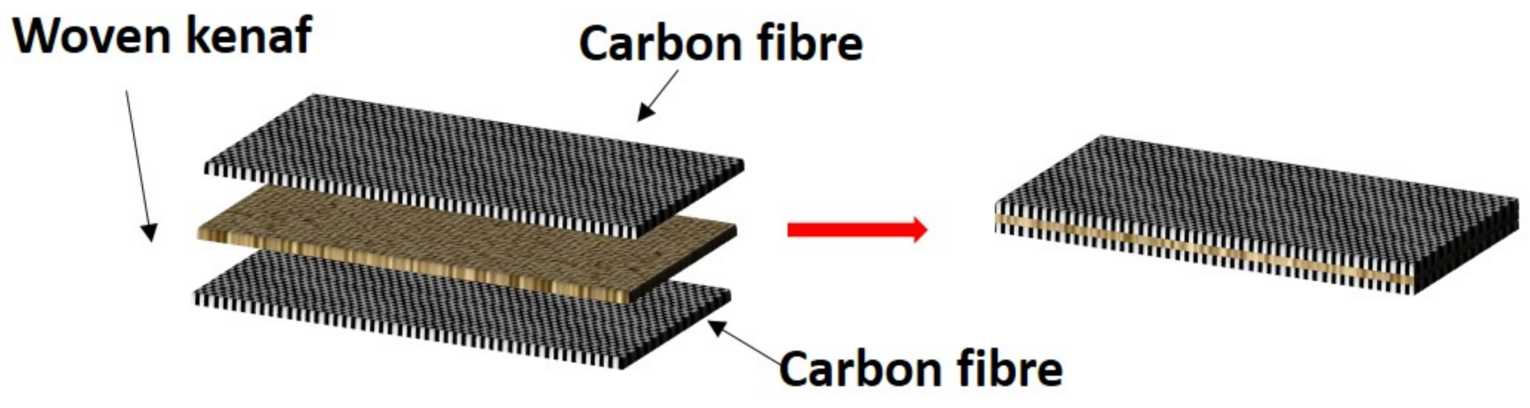

- Aisyah, H.A.; Paridah, M.T.; Khalina, A.; Sapuan, S.M.; Wahab, M.S.; Berkalp, O.B.; Lee, C.H.; Lee, S.H. Effects of fabric counts and weave designs on the properties of LaminatedWoven Kenaf/Carbon fibre reinforced epoxy hybrid composites. Polymers 2018, 10, 1320. [Google Scholar] [CrossRef] [Green Version]

- Khalil, H.A.; Hanida, S.; Kang, C.W.; Fuaad, N.N. Agro-hybrid composite: The effects on mechanical and physical properties of oil palm fiber (EFB)/glass hybrid reinforced polyester composites. J. Reinf. Plast. 2007, 26, 203–218. [Google Scholar] [CrossRef]

- Olorunnishola, A.A.G.; Adubi, E.G. A Comparative Analysis of a Blend of Natural Jute and Glass Fibers with Synthetic Glass FibersComposites as Car Bumper Materials. IOSR J. Mech. Civ. Eng. 2018, 15, 67–71. [Google Scholar]

- Petrucci, R.; Santulli, C.; Puglia, D.; Sarasini, F.; Torre, L.; Kenny, J.M. Mechanical characterisation of hybrid composite laminates based on basalt fibres in combination with flax, hemp and glass fibres manufactured by vacuum infusion. Mater. Des. 2013, 49. [Google Scholar] [CrossRef]

- Petrucci, R.; Santulli, C.; Puglia, D.; Nisini, E.; Sarasini, F.; Tirillò, J.; Torre, L.; Minak, G.; Kenny, J.M. Impact and post-impact damage characterisation of hybrid composite laminates based on basalt fibres in combination with flax, hemp and glass fibres manufactured by vacuum infusion. Compos. Part B Eng. 2015, 69. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Aslan, M.; Tufan, M.; Küçükömeroğlu, T. Tribological and mechanical performance of sisal-filled waste carbon and glass fibre hybrid composites. Compos. Part B Eng. 2018, 140, 241–249. [Google Scholar] [CrossRef]

- Sharba, M.J.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Hanim, M.A.A. Effects of Kenaf Fiber Orientation on Mechanical Properties and Fatigue Life of Glass/Kenaf Hybrid Composites. BioResources 2016, 11, 1448–1465. [Google Scholar] [CrossRef]

- Ferreira, B.T.; da Silva, L.J.; Panzera, T.H.; Santos, J.C.; Freire, R.T.S.; Scarpa, F. Sisal-glass hybrid composites reinforced with silica microparticles. Polym. Test. 2019, 74, 57–62. [Google Scholar] [CrossRef] [Green Version]

- Vinayagamoorthy, R.; Rajeswari, N. Mechanical performance studies on Vetiveria zizanioides/jute/glass fiber-reinforced hybrid polymeric composites. J. Reinf. Plast. Compos. 2014, 33, 81–92. [Google Scholar] [CrossRef]

- Zhang, Y.; Kou, K.; Zhang, S.; Ji, T. Improving thermal properties of ultrafine-glass-fiber reinforced PTFE hybrid composite via surface modification by (3-aminopropyl) triethoxysilane. J. Polym. Res. 2019, 26, 1–11. [Google Scholar] [CrossRef]

- Islam, M.; Gupta, A.; Rivai, M.; Beg, M. Characterization of microwave-treated oil palm empty fruit bunch/glass fibre/polypropylene composites. J. Thermoplast. Compos. Mater. 2015, 30, 986–1002. [Google Scholar] [CrossRef] [Green Version]

- Dong, C. Review of natural fibre-reinforced hybrid composites. J. Reinf. Plast. Compos. 2018, 37, 331–348. [Google Scholar] [CrossRef] [Green Version]

- Jothibasu, S.; Mohanamurugan, S.; Vijay, R.; Singaravelu, D.L.; Vinod, A.; Sanjay, M. Investigation on the mechanical behavior of areca sheath fibers/jute fibers/glass fabrics reinforced hybrid composite for light weight applications. J. Ind. Text. 2018, 49, 1036–1060. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical Properties of Longitudinal Basalt/Woven-Glass-Fiber-reinforced Unsaturated Polyester-Resin Hybrid Composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef]

- Patel, N.; Patel, K.; Gohil, P.; Chaudhry, V. Investigations on Mechanical Strength of Hybrid Basalt / Glass Polyester Composites. Int. J. Appl. Eng. Res. 2018, 13, 4083–4088. [Google Scholar]

- Rao, H.R.; Rajulu, A.V.; Reddy, G.R.; Reddy, K.H. Flexural and Compressive Properties of Bamboo and Glass Fiber-reinforced Epoxy Hybrid Composites. J. Reinf. Plast. Compos. 2009, 29, 1446–1450. [Google Scholar] [CrossRef]

- Retnam, B.S.J.; Sivapragash, M.; Pradeep, P. Effects of fibre orientation on mechanical properties of hybrid bamboo/glass fibre polymer composites. Bull. Mater. Sci. 2014, 37, 1059–1064. [Google Scholar] [CrossRef]

- Nisini, E.; Santulli, C.; Liverani, A. Mechanical and impact characterization of hybrid composite laminates with carbon, basalt and flax fibres. Compos. Part B Eng. 2017, 127. [Google Scholar] [CrossRef]

- Ralph, C.; Lemoine, P.; Archer, E.; McIlhagger, A. Mechanical properties of short basalt fibre reinforced polypropylene and the effect of fibre sizing on adhesion. Compos. Part B Eng. 2019, 176. [Google Scholar] [CrossRef]

- Arif, M.F.; Kumar, S.; Shah, T. Tunable morphology and its influence on electrical, thermal and mechanical properties of carbon nanostructure-buckypaper. Mater. Des. 2016, 101, 236–244. [Google Scholar] [CrossRef]

- Sivakumar, D.; Ng, L.F.; Selamat, M.Z. Investigation on fatigue life behaviour of sustainable bio-based fibre metal laminate. J. Mech. Eng. 2017, 1, 123–140. [Google Scholar]

- Vasumathi, M.; Murali, V. Effect of Alternate Metals for use in Natural Fibre Reinforced Fibre Metal Laminates under Bending, Impact and Axial Loadings. Procedia Eng. 2013, 64, 562–570. [Google Scholar] [CrossRef] [Green Version]

- Vieira, L.M.G.; dos Santos, J.C.; Panzera, T.H.; Rubio, J.C.C.; Scarpa, F. Novel fibre metal laminate sandwich composite structure with sisal woven core. Industrial Crops and Products. Ind. Crops Prod. 2017, 99, 189–195. [Google Scholar] [CrossRef] [Green Version]

- Chandrasekar, M.; Ishak, M.; Sapuan, S.M.; Leman, Z.; Jawaid, M.; Shahroze, R. Fabrication of Fibre Metal Laminate with Flax and Sugar Palm Fibre based Epoxy Composite and Evaluation of their Fatigue Properties. J. Polym. Mater. 2019, 35, 463–473. [Google Scholar] [CrossRef]

- Mohammed, I.; Talib, A.R.A.; Thariq, M.; Sultan, H.; Jawaid, M.; Ariffin, A.H.; Saadon, S. Mechanical Properties of Fibre-Metal Laminates Made of Natural/Synthetic Fibre Composites. BioResources 2018, 13, 2022–2034. [Google Scholar] [CrossRef]

- Krishnasamy, P.; Rajamurugan, G.; Thirumurugan, M. Performance of fiber metal laminate composites embedded with AL and CU wire mesh. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Ng, L.F.; Malingam, S.D.; Zakaria, K.; Bapokutty, O.; Subramonian, S. Influence of Kenaf Fibre Orientation Effect on the Mechanical Properties of Hybrid Structure of Fibre Metal Laminate. Pertanika J. Sci. Technol. 2017, 25, 1–8. [Google Scholar]

- Feng, N.L.; Malingam, S.D.; Ping, C.W. Mechanical characterisation of kenaf/PALF reinforced composite-metal laminates: Effects of hybridisation and weaving architectures. J. Reinf. Plast. Compos. 2021, 40, 193–205. [Google Scholar] [CrossRef]

- Chai, G.B.; Manikandan, P. Low velocity impact response of fibre-metal laminates–A review. Compos. Struct. 2014, 107, 363–381. [Google Scholar] [CrossRef]

- Carrillo, J.G.; Cantwell, W.J. Mechanical properties of a novel fiber-metal laminate based on a polypropylene composite. Mech. Mater. 2009, 41. [Google Scholar] [CrossRef]

- Cai, R.; Jin, T. The effect of microstructure of unidirectional fibre-reinforced composites on mechanical properties under transverse loading: A review. J. Reinf. Plast. Compos. 2018, 37, 1360–1377. [Google Scholar] [CrossRef]

- Ishak, N.M.; Malingam, S.D.; Mansor, M.R.; Razali, N.; Mustafa, Z.; Ghani, A.F.A. Investigation of natural fibre metal laminate as car front hood. Mater. Res. Express 2021, 8, 025303. [Google Scholar] [CrossRef]

- Sivakumar, D.; Ng, L.F.; Zalani, N.F.M.; Selamat, M.Z.; Ghani, A.F.A.; Fadzullah, S.H.S.M. Influence of kenaf fabric on the tensile performance of environmentally sustainable fibre metal laminates. Alexandria Eng. J. 2018, 57, 4003–4008. [Google Scholar] [CrossRef]

- Norizan, M.N.; Zulaikha, N.D.S.; Norhana, A.B.; Syakir, M.I.; Norli, A. Carbon nanotubes-based sensor for ammonia gas detection—An overview. Polimery 2021, 66, 175–186. [Google Scholar] [CrossRef]

- Norizan, M.N.; Moklis, M.H.; Ngah Demon, S.Z.; Halim, N.A.; Samsuri, A.; Mohamad, I.S.; Knight, V.F.; Abdullah, N. Carbon nanotubes: Functionalisation and their application in chemical sensors. RSC Adv. 2020, 10. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.H.; Ahmad, S.; Mahat, A.M.; Lee, C.L.; Aisyah, H.A.; et al. Fabrication, functionalization, and application of carbon nanotube-reinforced polymer composite: An overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef]

- Ahmadi, M.; Zabihi, O.; Masoomi, M.; Naebe, M. Synergistic effect of MWCNTs functionalization on interfacial and mechanical properties of multi-scale UHMWPE fibre reinforced epoxy composites. Compos. Sci. Technol. 2016, 134, 1–11. [Google Scholar] [CrossRef]

- Sarker, F.; Karim, N.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Potlur, P. High-Performance Graphene-Based Natural Fiber Composites. ACS Appl. Mater. Interfaces 2018, 10, 34502–34512. [Google Scholar] [CrossRef]

- Sarker, F.; Potluri, P.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Karim, N. Ultrahigh Performance of Nanoengineered Graphene-Based Natural Jute Fiber Composites. ACS Appl. Mater. Interfaces 2019, 11, 21166–21176. [Google Scholar] [CrossRef]

- de Lima, A.M.; del Pino, G.G.; Rivera, J.L.V.; Chong, K.B.; Bezazi, A.; Neto, J.C.; Valenzuela, M.; Dehaini, J.; Díaz, F.V. Characterization of Polyester Resin Nanocomposite with Curauá Fibers and Graphene Oxide. Rev. Ciencias Técnicas Agropecu. 2019, 28, 1–10. [Google Scholar]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; da Costa, G.F.F.; da Luz, F.S.; Pinheiro, W.A.; Monteiro, S.N. Mechanical properties of composites with graphene oxide functionalization of either epoxy matrix or curaua fiber reinforcement. J. Mater. Res. Technol. 2020, 9, 13390–13401. [Google Scholar] [CrossRef]

- Han, S.O.; Karevan, M.; Bhuiyan, M.A.; Park, J.H.; Kalaitzidou, K. Effect of exfoliated graphite nanoplatelets on the mechanical and viscoelastic properties of poly(lactic acid) biocomposites reinforced with kenaf fibers. J. Mater. Sci. 2012, 47, 3535–3543. [Google Scholar] [CrossRef]

- Chaharmahali, M.; Hamzeh, Y.; Ebrahimi, G.; Ashori, A.; Ghasemi, I. Effects of nano-graphene on the physico-mechanical properties of bagasse/polypropylene composites. Polym. Bull. 2014, 71, 337–349. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Z.; Lv, W.; Wang, C. Graphene oxide decorated sisal fiber/MAPP modified PP composites: Toward high-performance biocomposites. Polym. Compos. 2017, 39, E113–E121. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Pandey, C.N.; Kumar, R. Study on the effect of carbon nanotubes on plastic composite reinforced with natural fiber. J. Indian Acad. Wood Sci. 2014, 11, 82–86. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Mahmud, J. Mechanical properties of functionalised CNT filled kenaf reinforced epoxy composites. Mater. Res. Express 2018, 5, 045034. [Google Scholar] [CrossRef]

- Wu, G.; Gu, Y.; Hou, X.; Li, R.; Ke, H.; Xiao, X. Hybrid Nanocomposites of Cellulose/Carbon-Nanotubes/Polyurethane with Rapidly Water Sensitive Shape Memory Effect and Strain Sensing Performance. Polymers 2019, 11, 1586. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nabinejad, O.; Sujan, D.; Rahman, M.E.; Liew, W.Y.H.; Davies, I.J. Hybrid Composite Using Natural Filler and Multi-Walled Carbon Nanotubes (MWCNTs). Appl. Compos. Mater. 2018, 25, 1323–1337. [Google Scholar] [CrossRef]

- Prasob, P.A.; Sasikumar, M. Viscoelastic and mechanical behaviour of reduced graphene oxide and zirconium dioxide filled jute/epoxy composites at different temperature conditions. Mater. Today Commun. 2019, 19, 252–261. [Google Scholar] [CrossRef]

- Mohan, K.; Rajmohan, T. Fabrication and Characterization of MWCNT Filled Hybrid Natural Fiber Composites. J. Nat. Fibers 2017, 14, 864–874. [Google Scholar] [CrossRef]

- Thakur, A.; Purohit, R.; Rana, R.S.; Bandhu, D. Characterization and Evaluation of Mechanical Behavior of Epoxy-CNT-Bamboo Matrix Hybrid Composites. Mater. Today Proc. 2018, 5, 3971–3980. [Google Scholar] [CrossRef]

- Chen, P.-Y.; Lian, H.-Y.; Shih, Y.-F.; Chen-Wei, S.-M.; Jeng, R.-J. Preparation, characterization and crystallization kinetics of Kenaf fiber/multi-walled carbon nanotube/polylactic acid (PLA) green composites. Mater. Chem. Phys. 2017, 196, 249–255. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A.; Kargarfard, A. Evaluation of multiwalled carbon nanotubes as reinforcement for natural fiber-based composites. Polym. Compos. 2015, 37, 3269–3274. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Comparison of Static and Long-term Creep Behaviors between Balau Wood and Glass Fiber Reinforced Polymer Composite for Cross-arm Application. Fibers Polym. 2021, 22, 793–803. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 2061. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Nasir, M.; Saba, N. Effect of Fiber Loadings and Treatment on Dynamic Mechanical, Thermal and Flammability Properties of Pineapple Leaf Fiber and Kenaf Phenolic Composites. J. Renew. Mater. 2018, 6, 383–393. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atiqah, A.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Nurazzi, N.M.; Atikah, M.S.N.; Ansari, M.N.M.; et al. Sugar palm (Arenga pinnata [Wurmb.] Merr) starch films containing sugar palm nanofibrillated cellulose as reinforcement: Water barrier properties. Polym. Compos. 2020, 41. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 28, 2675–2695. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Rafidah, M.; Ilyas, R.A.; Razman, M.R. Potential application of green composites for cross arm component in transmission tower: A brief review. Int. J. Polym. Sci. 2020. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Atikah, M.; Asyraf, M.; Rafiqah, S.A.; Aisyah, H.; Nurazzi, N.M.; Norrrahim, M. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text. Res. J. 2020, 91, 152–167. [Google Scholar] [CrossRef]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Van Vuure, A.W.; Baets, J.; Wouters, K.; Hendrickx, K. Compressive properties of natural fibre composites. Mater. Lett. 2015, 149, 138–140. [Google Scholar] [CrossRef] [Green Version]

- Haris, M.Y.; Laila, D.; Zainudin, E.S.; Mustapha, F.; Zahari, R.; Halim, Z. Preliminary Review of Biocomposites Materials for Aircraft Radome Application. Key Eng. Mater. 2011, 471–472, 563–567. [Google Scholar] [CrossRef]

- Retegi, A.; Arbelaiz, A.; Alvarez, P.; Llano-Ponte, R.; Labidi, J.; Mondragon, I. Effects of hygrothermal ageing on mechanical properties of flax pulps and their polypropylene matrix composites. J. Appl. Polym. Sci. 2006, 102, 3438–3445. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Sarasini, F.; Tirilló, J.; Calabrese, L. Salt-fog spray aging of jute-basalt reinforced hybrid structures: Flexural and low velocity impact response. Compos. Part B Eng. 2017, 116, 99–112. [Google Scholar] [CrossRef]

- Bodur, M.S.; Englund, K.; Bakkal, M. Water absorption behavior and kinetics of glass fiber/waste cotton fabric hybrid composites. J. Appl. Polym. Sci. 2017, 134, 45506. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Scalici, T.; Valenza, A. Experimental assessment of the improved properties during aging of flax/glass hybrid composite laminates for marine applications. J. Appl. Polym. Sci. 2018, 136, 47203. [Google Scholar] [CrossRef]

- Misri, S.; Leman, Z.; Sapuan, S.M.; Ishak, M.R. Mechanical properties and fabrication of small boat using woven glass/sugar palm fibres reinforced unsaturated polyester hybrid composite. IOP Conf. Ser. Mater. Sci. Eng. 2010, 11, 012015. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef] [Green Version]

- Amir, N.; Abidin, K.A.Z.; Shiri, F.B.M. Effects of Fibre Configuration on Mechanical Properties of Banana Fibre/PP/MAPP Natural Fibre Reinforced Polymer Composite. Procedia Eng. 2017, 184, 573–580. [Google Scholar] [CrossRef]

- Yusof, N.S.B.; Sapuan, S.M.; Sultan, M.T.H.; Jawaid, M. Conceptual design of oil palm fibre reinforced polymer hybrid composite automotive crash box using integrated approach. J. Cent. South Univ. 2020, 27, 64–75. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. J. Mater. Res. Technol. 2020, 9, 2357–2368. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of creep testing rig for full-scale cross arm using TRIZ-Morphological chart-analytic network process technique. J. Mater. Res. Technol. 2019, 8, 5647–5658. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Evaluation of Design and Simulation of Creep Test Rig for Full-Scale Crossarm Structure. Adv. Civ. Eng. 2020, 2020, 6980918. [Google Scholar] [CrossRef]

- Mansor, M.R.; Sapuan, S.M.; Zainudin, E.S.; Nuraini, A.A.; Hambali, A. Hybrid natural and glass fibers reinforced polymer composites material selection using Analytical Hierarchy Process for automotive brake lever design. Mater. Des. 2013, 51, 484–492. [Google Scholar] [CrossRef]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of Natural Fiber Reinforced Polymer Composites in Sandwich Structures: A Review on Its Mechanical Properties. Polymers 2021, 13, 423. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef]

- Rashid, A.A.; Khalid, M.Y.; Imran, R.; Ali, U.; Koc, M. Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry. Materials 2020, 13, 3167. [Google Scholar] [CrossRef]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Creep behaviour monitoring of short-term duration for fiber-glass reinforced composite cross-arms with unsaturated polyester resin samples using conventional analysis. J. Mech. Eng. Sci. 2020, 14, 7361–7368. [Google Scholar] [CrossRef]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Influence of CaCO3 in pultruded glass fiber/unsaturated polyester resin composite on flexural creep behavior using conventional and time-temperature superposition principle methods. Polimery-Warsaw 2020, 65, 46–54. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Atikah, M.S.N.; Ibrahim, R.; Norrahim, M.N.F.; Yasim-Anuar, T.A.T.; Megashah, L.N. Mechanical and dynamic mechanical properties of macro-nanosized natural fibre reinforced polymer composite. In Mechanical and Dynamic Mechanical Analysis of Biocomposite; Kumar, S.M.K., Ed.; John Wiley & Sons, Inc.: London, UK, 2020. [Google Scholar]

- Sapuan, S.M.; Hemapriya, G.; Ilyas, R.A.; Atikah, M.S.N.; Asyraf, M.R.M.; Mansor, M.R. Implementation of design for sustainability in developing trophy plaque using green kenaf polymer composites. In Design for Sustainability: Green Materials and Processes; Sapuan, S.M., Mansor, M.R., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 85–103. [Google Scholar]

| Natural Fiber | Lignocellulosic Components (%) | Ref. | ||

|---|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | ||

| Sugar Palm | 43.88 | 7.24 | 33.24 | [21] |

| Bagasse | 32 to 34 | 19 to 24 | 25 to 32 | [22] |

| Bamboo | 73.83 | 12.49 | 10.15 | [23] |

| Flax | 60 to 81 | 14 to 20.6 | 2.2 to 5 | [24] |

| Hemp | 70 to 92 | 18 to 22 | 3 to 5 | |

| Jute | 51 to 84 | 12to 20 | 5 to 13 | |

| Kenaf | 44 to 87 | 22 | 15 to 19 | |

| Ramie | 68 to 76 | 13 to 15 | 0.6 to 1 | |

| Sisal | 65.8 | 12 | 9.9 | [25] |

| Pineapple | 66.2 | 19.5 | 4.2 | [26] |

| Coir | 32 to 43 | 0.15 to 0.25 | 40 to 45 | [27] |

| Fiber | Density (g/cm3) | Tensile Strength (MPa) | Elongation at Break (%) | Tensile Modulus (GPa) |

|---|---|---|---|---|

| Sugar Palm | 1.292 | 156.96 | 7.98 | 4.96 |

| Bagasse | 1.5 | 290 | - | 17 |

| Bamboo | 1.25 | 140 to 230 | - | 11 to 17 |

| Flax | 0.6 to 1.1 | 345 to 1035 | 2.7 to 3.2 | 27.6 |

| Hemp | 1.48 | 690 | 1.6 to 4 | 70 |

| Jute | 1.3 | 393 to 773 | 1.5 to 1.8 | 26.5 |

| Kenaf | 1.45 | 215.4 | 1.6 | 53 |

| Sisal | 1.5 | 511 to 535 | 2.0 to 2.5 | 9.4 to 22 |

| Ramie | 1.5 | 560 | 2.5 to 3.8 | 24.5 |

| Pineapple | 0.8 to 1.6 | 400 to 627 | 14.5 | 1.44 |

| Coir | 1.2 | 138.7 | 30 | 4 to 6 |

| E-Glass | 2.5 | 2000 to 3500 | 0.5 | 70 |

| S-Glass | 2.5 | 4570 | 2.8 | 86 |

| Aramid | 1.4 | 3000 to 3150 | 3.3 to 3.7 | 63.0 to 67.0 |

| Kevlar | 1.44 | 3000 | 2.5 to 3.7 | 60 |

| Natural Fiber | Description | Ref. |

|---|---|---|

| Bast fiber | ||

| Flax fiber |

| [43,44,45] |

| Hemp |

| [43,46,47,48,49] |

| Jute |

| [50,51] |

| Kenaf |

| [51,52,53] |

| Leaf fiber | ||

| Pineapple |

| [43,54,55,56] |

| Abaca |

| [43,57,58] |

| Sisal |

| [43,50,51] |

| Straw fiber | ||

| Corn |

| [59,60,61,62] |

| Wheat |

| [63,64,65,66,67] |

| Seed/fruit fiber | ||

| Coir |

| [43,52,68] |

| Cotton |

| [69,70,71,72] |

| Kapok |

| [73,74,75] |

| Grass/reed fiber | ||

| Bamboo |

| [76,77,78] |

| Sugarcane bagasse |

| [79,80,81,82] |

| f. Wood fiber | ||

| Softwood |

| [19,83] |

| Hardwood |

| [19,83] |

| Fiber 1 | Fiber 2 | Parameter | Matrix Type | Processing Technique | Mechanical Performance | Ref. |

|---|---|---|---|---|---|---|

| Oil palm empty fruit bunch (EFB) fiber mat | Woven jute (Jw) | Layering pattern of hybrid composite: EFB/Jw/EFB and Jw/EFB/Jw | Epoxy | Hand lay-up |

| [147] |

| Banana fibers (B) | Woven coconut sheath (C) | Random composite orientation: CBC, CCB, BCB, BBC, pure banana (BBB), and pure coconut sheath (CCC) | Unsaturated polyester | Compression molding |

| [148] |

| PALF | Kenaf fiber (KF) | Fiber loading: (PF:PALF:KF) 50:50:0, 50:35:15, 50:25:25, 50:15:35, 50:0:50 | Phenol formaldehyde | Hand lay-up |

| [140,149] |

| Unidirectional long flax fiber (F) | Woven sugar palm fiber (S) | Fiber stacking sequences: All F, All S, F/F/S/S/F/F and S/F/F/F/F/S | Epoxy | Hot press molding |

| [150] |

| Jute fiber (J) Sisal fiber (S) | Curaua fibers (C) | Fiber hybridization and treatment: Untreated J, treated J, mixed J Untreated J + C, Treated J + C, Mixed J + C Untreated S + C, Treated S+C, Mixed S + C | Epoxy | Hand lay-up |

| [151] |

| Aloe vera mat (AVM) and flax mat (FM) | Sisal fiber (SF) | Fiber arrangement: AVM-FM-SF-FM-AVM (S1) and FM-AVM-SF-AVM-FM (S2) | Epoxy | Hand lay-up |

| [152] |

| Roselle fiber (RF) | Sugar palm fibers (SPF) | Fiber ratios: 100RF, 70RF:30SPF, 50RF:50SPF, 30RF:70SPF and 100SPF. | PU | Melt mixing and hot compression |

| [144] |

| Coir fiber (CF) | PALF | Fiber loading of PLA:CF: PALF (wt %): 100:0:0, 70:30:0, 70:0:30, 70:15:15, 70:9:21, 70:21:9 | PLA | Melt mixing method |

| [153] |

| Sisal fiber | Hemp fiber | - | PLA | Melt processing and injection molding |

| [146] |

| Wood fiber | Rice husk | Wood content: 10%, 20%, and 30% Rice husk content: 10%, 20%, and 30% Hybrid content: 5%, 10%, and 15% | PP | Injection molding |

| [154] |

| Woven jute | Woven flax | Fiber ratio: Neat PLA, Jute/PLA, Flax/PLA, and Hybrid Jute Flax/PLA | PLA | Compression molding |

| [155] |

| Kenaf fiber (KF) | Aloe vera fiber (AF) | Composite compositions: PLA, PLA/treated KF, PLA/treated AF, PLA/treated KF/treated AF, PLA/treated KF/treated AF/1MMT and PLA/treated KF/treated AF/3MMT MMT = montmorillonite | PLA | Compression molding |

| [156] |

| Natural Fiber | Synthetic Fiber | Matrix Type | Processing Technique | Ref. |

|---|---|---|---|---|

| EFB | Glass | Unsaturated polyester | RTM | [160] |

| Basalt and flax | Carbon | Epoxy | Hand lay-up and vacuum bagging | [177] |

| Short basalt | Short fiber PP | Epoxy | Injection molding | [178] |

| Flax | Carbon | Epoxy | Vacuum-assisted resin transfer molding (VARTM) | [164] |

| Sisal | Glass | PP | Single extrusion machine and press consolidation | [165] |

| Vetiveria zizanioides/Jute | Glass | Vinyl ester | Hand lay-up | [168] |

| EFB | Glass | PP | Extrusion and injection molding | [170] |

| Areca sheath and jute | Woven-glass | Epoxy | Hand lay-up | [172] |

| Sugar palm yarn | Woven-glass | Unsaturated polyester | Hand lay-up | [136] |

| Longitudinal basalt | Woven-glass | Unsaturated polyester-resin | Hand lay-up | [173] |

| Bamboo powder | Glass | Epoxy | Hand lay-up | [179] |

| Bamboo | Glass | Epoxy | Curing | [175] |

| Bamboo | Glass | Unsaturated polyester | Hand lay-up | [176] |

| Natural Fiber | Metal Laminate Type | Matrix Type | Processing Technique | Ref. |

|---|---|---|---|---|

| Jute fiber | Aluminum and magnesium | Epoxy | Hand lay-up and compression molding | [181] |

| Plain sisal fabric | Aluminum | Epoxy | Cold pressing | [182] |

| Unidirectional tape flax fibers and sugar palm fibers | Aluminum alloy | Epoxy | Hand lay-up and hot press | [183] |

| Kenaf fiber, flax fiber, and carbon fiber | Aluminum alloy | Epoxy | Hand lay-up | [184] |

| Woven mat jute fiber | Aluminum and copper | Epoxy | Compression molding | [185] |

| Plain woven kenaf and woven E-glass | Annealed aluminum | PP | Hot pressing | [186] |

| Plain and twill woven kenaf and PALF | Aluminum | PP | Hot molding compression | [187] |

| Carbonaceous Material | Natural Fiber | Matrix Type | Key Findings | Ref. |

|---|---|---|---|---|

| GO and graphene flakes | Untreated jute fiber and alkaline-treated jute fiber | Epoxy | The Young’s modulus and tensile strength of graphene-based jute fiber composites jute−epoxy composites is increased by ≈324% and ≈110%, respectively, more than untreated jute fiber composites. | [198] |

| GO | Curaua fiber (CF) | Unsaturated polyester | The tensile and flexural strength of CF/GO-reinforced unsaturated polyester-based composites increased by 156% and 186%, respectively, in comparison to the neat unsaturated polyester. | [199] |

| GO | Curaua fiber (CF) | Epoxy | The CF/GO epoxy-based composites increased in yield strength by 64%, tensile strength by 40%, Young’s modulus by 60%, and toughness by 28% compared to the CF-reinforced epoxy composite. | [200] |

| Exfoliated graphite nanoplatelets | Kenaf fiber | PLA | The addition of 5 wt % xGnP increased the flexural modulus by 25 to 30% but did not increase the strength. The addition of xGnP to the heat distortion temperature had a beneficial impact but only at higher fiber loadings. | [201] |

| Graphene | Bagasse fiber (BS) | PP | Tensile, flexural, and notched impact strength values were greatest in composites containing 0.1 wt % graphene and 30 wt % BF. | [202] |

| GO | Sisal fiber (SF) | PP | The combined treatment of GO and maleic anhydride-grafted polypropylene (MAPP) improved the mechanical properties, melting temperature, and water resistance of the GO-SF/MAPP-PP composite significantly. | [203] |

| CNTs | Bamboo fiber | Epoxy | The composite’s mechanical (tensile, flexural, and impact) and water resistance properties increased after CNTs were added. There was a significant increase in impact strength by 84.5%. | [204] |

| CNTs, acid-treated (ACNT) and acid silane treated (SCNT) | Kenaf fiber | Epoxy | The tensile, flexural, and impact properties of the kenaf/epoxy composite were strengthened by 43.30%, 21.10%, and 130%, respectively, when 1 wt % acid-silane treated CNT was included. | [205] |

| MWCNTs) | Cotton cellulose nanofiber (CNF-C) | PU | The PU matrix completely cross-linked with CNF-C and CNTs demonstrated good mechanical properties and sensing efficiency. The hybrid composite can accurately sense massive strains more than 103 times, and water-induced form recovery can help to sustain sensing precision after material fatigue. | [206] |

| MWCNTs | Oil palm shell (OPS) | Unsaturated polyester | It was discovered that a small amount of pristine MWCNTs dispersed inside the natural filler unsaturated polyester composite may improve the mechanical properties of the hybrid composite. | [207] |

| Models | Brands | Components |

|---|---|---|

| C3 Picasso, C5 | Citroen | Boot linings, mud guards, interior door paneling, parcel shelves, and door panels |

| Passat Variant, Golf, A4, Bora | Volkswagen | Door panel, boot-liner, seat back, and boot-lid finish panel |

| Vectra, Astra, Zafira | Opel | Head-liner panel, pillar cover panel, door panels, and instrumental panel |

| 3, 5 and 7 series | BMW | Noise insulation panels, headliner panel, seat back, door panels, molded foot well linings, and boot-lining |

| Mondeo CD 162, Focus | Ford | Floor trays, door inserts, door panels, B-pillar, and boot-liner |

| C70, V70 | Volvo | Seat padding, natural foams, cargo floor tray, dash, boards and ceilings |

| Eco Elise | Lotus | Seats, interior carpets, body panels, and spoiler, |

| ES3 | Toyota | Pillar garnish and other interior parts |

| 2000 | Rover | Rear storage shelf/panel, and insulations |

| Fiat SpA | Mitsubishi | Indoor cladding, seat back, cargo area floor, door panels, lining, instrumental panel, floor mats, and floor panels |

| 406 | Peugeot | Seat backs, parcel shelf, front and rear door panels |

| A, C, E, and S class | Daimler Chrysler | Pillar cover panel, door panels, car windshield/car dashboard, and business table |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. https://doi.org/10.3390/polym13132170

Nurazzi NM, Asyraf MRM, Fatimah Athiyah S, Shazleen SS, Rafiqah SA, Harussani MM, Kamarudin SH, Razman MR, Rahmah M, Zainudin ES, et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers. 2021; 13(13):2170. https://doi.org/10.3390/polym13132170

Chicago/Turabian StyleNurazzi, N. M., M. R. M. Asyraf, S. Fatimah Athiyah, S. S. Shazleen, S. Ayu Rafiqah, M. M. Harussani, S. H. Kamarudin, M. R. Razman, M. Rahmah, E. S. Zainudin, and et al. 2021. "A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications" Polymers 13, no. 13: 2170. https://doi.org/10.3390/polym13132170

APA StyleNurazzi, N. M., Asyraf, M. R. M., Fatimah Athiyah, S., Shazleen, S. S., Rafiqah, S. A., Harussani, M. M., Kamarudin, S. H., Razman, M. R., Rahmah, M., Zainudin, E. S., Ilyas, R. A., Aisyah, H. A., Norrrahim, M. N. F., Abdullah, N., Sapuan, S. M., & Khalina, A. (2021). A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers, 13(13), 2170. https://doi.org/10.3390/polym13132170