Morphological Analysis of Several Bamboo Species with Potential Structural Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

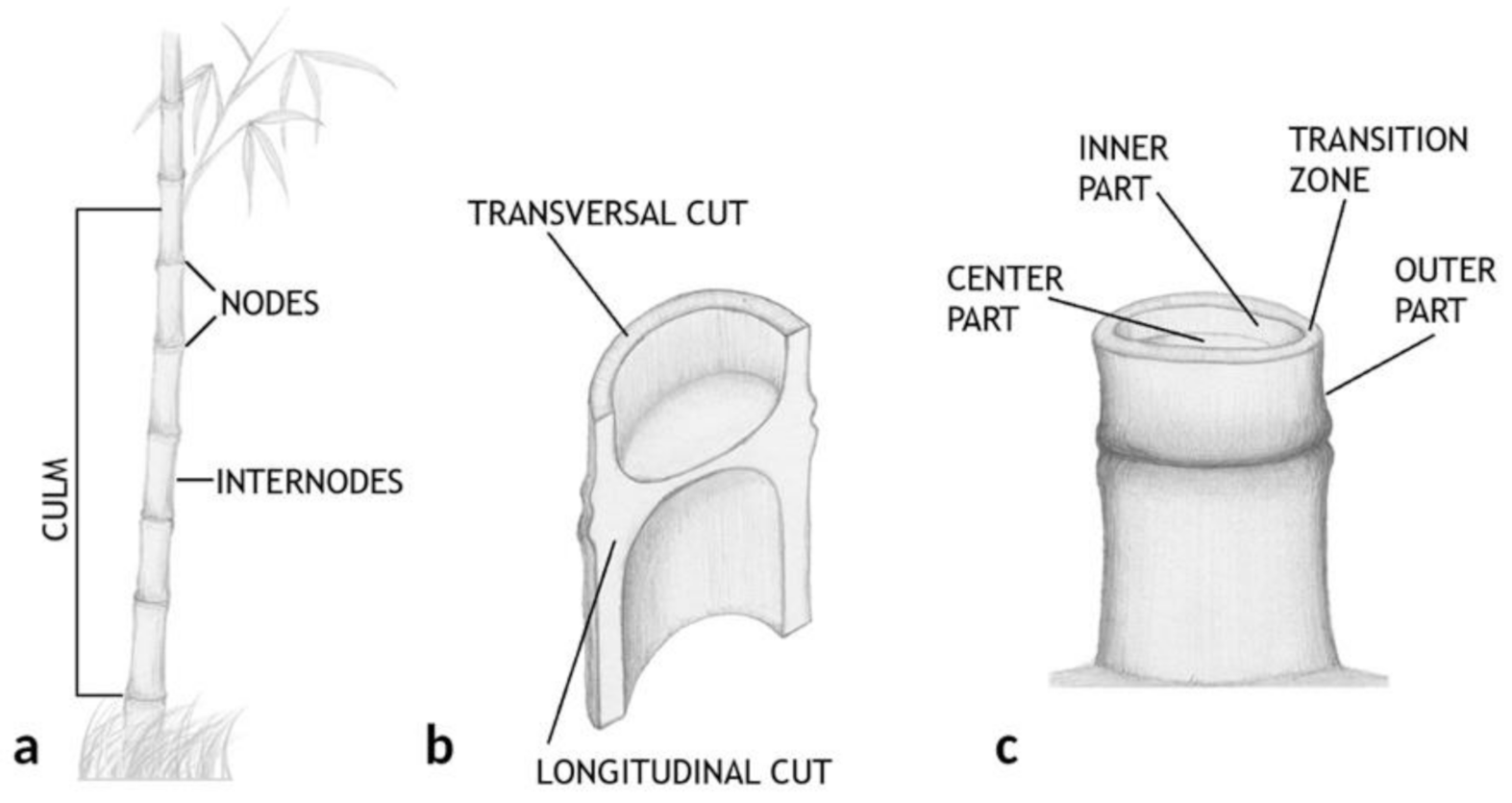

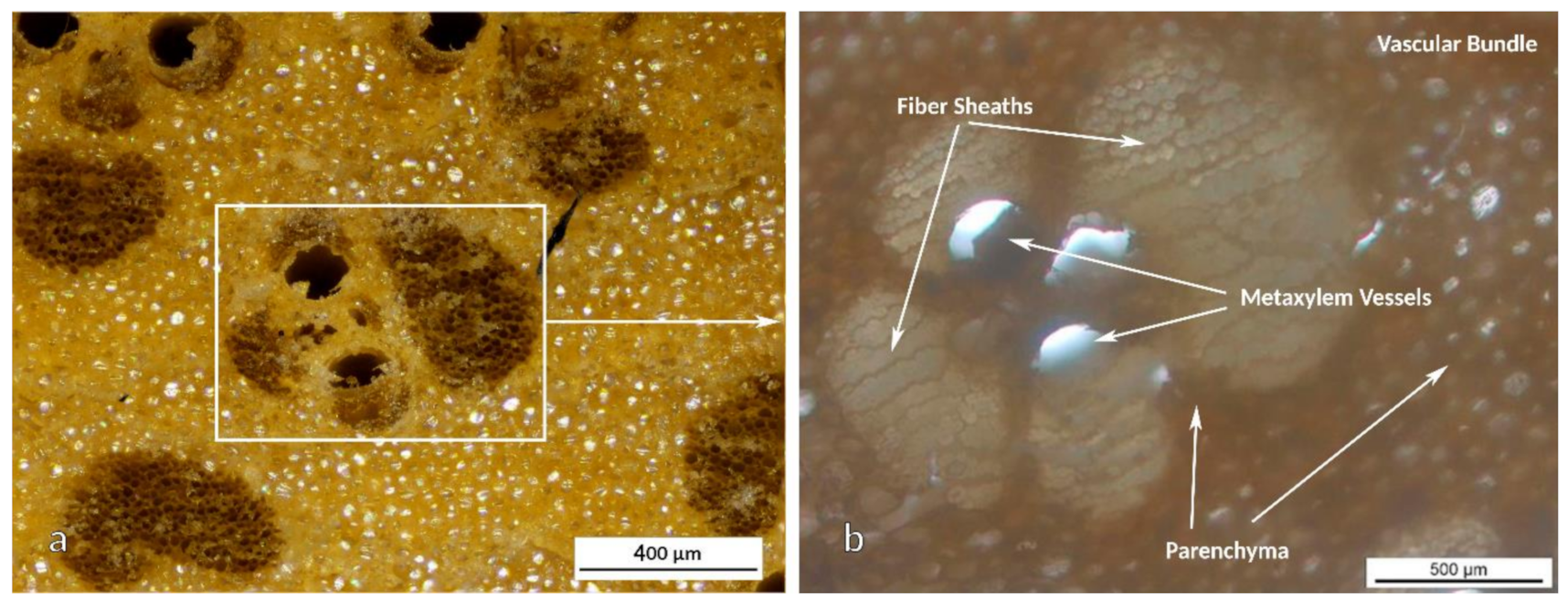

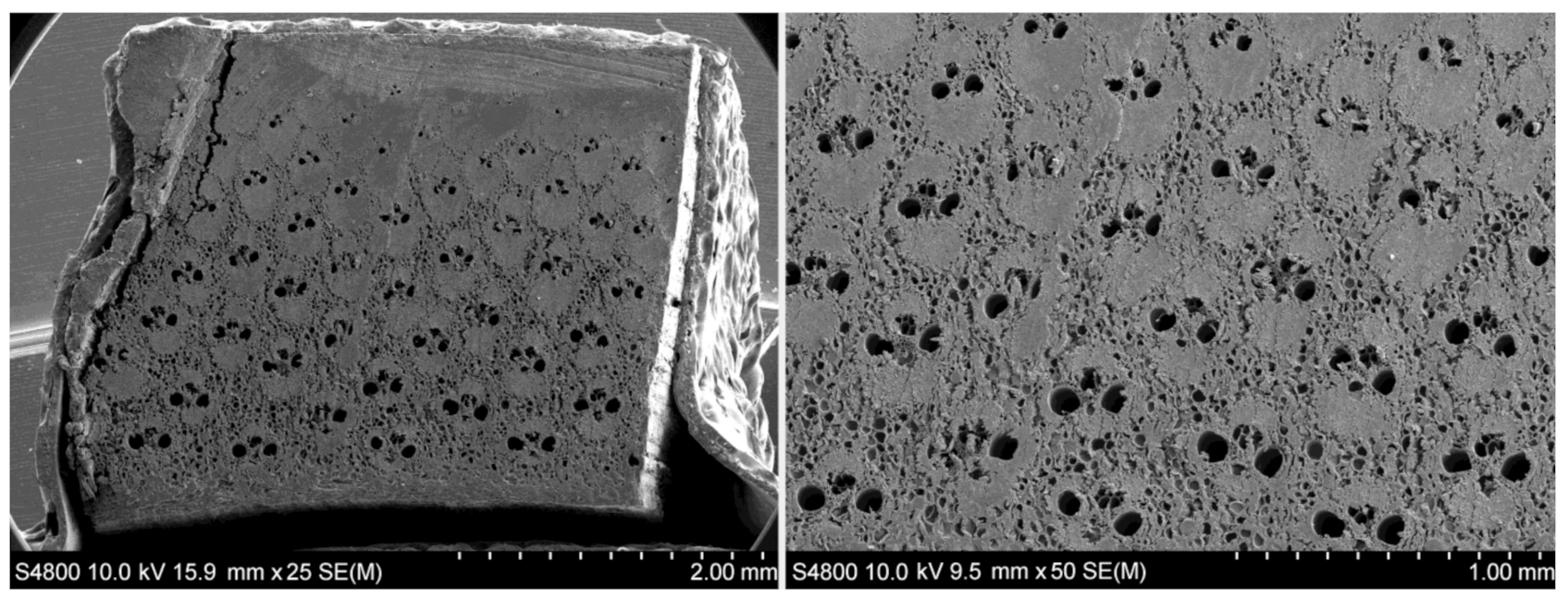

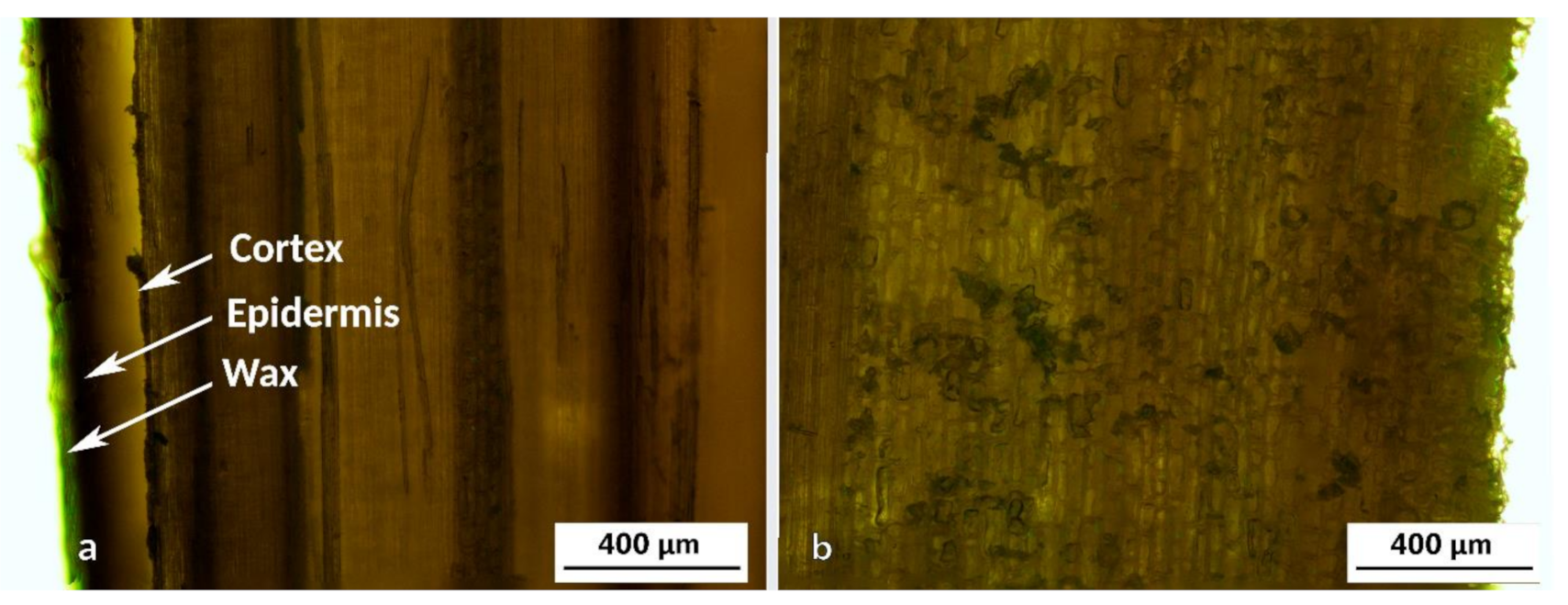

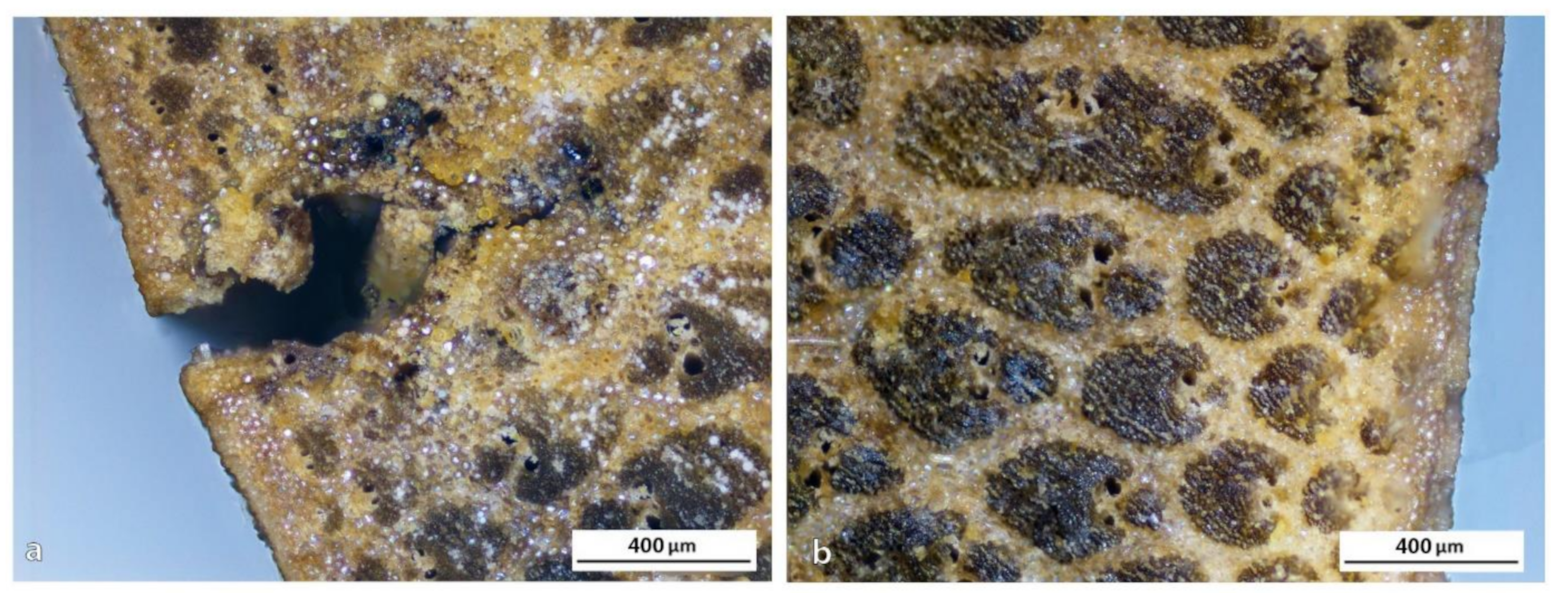

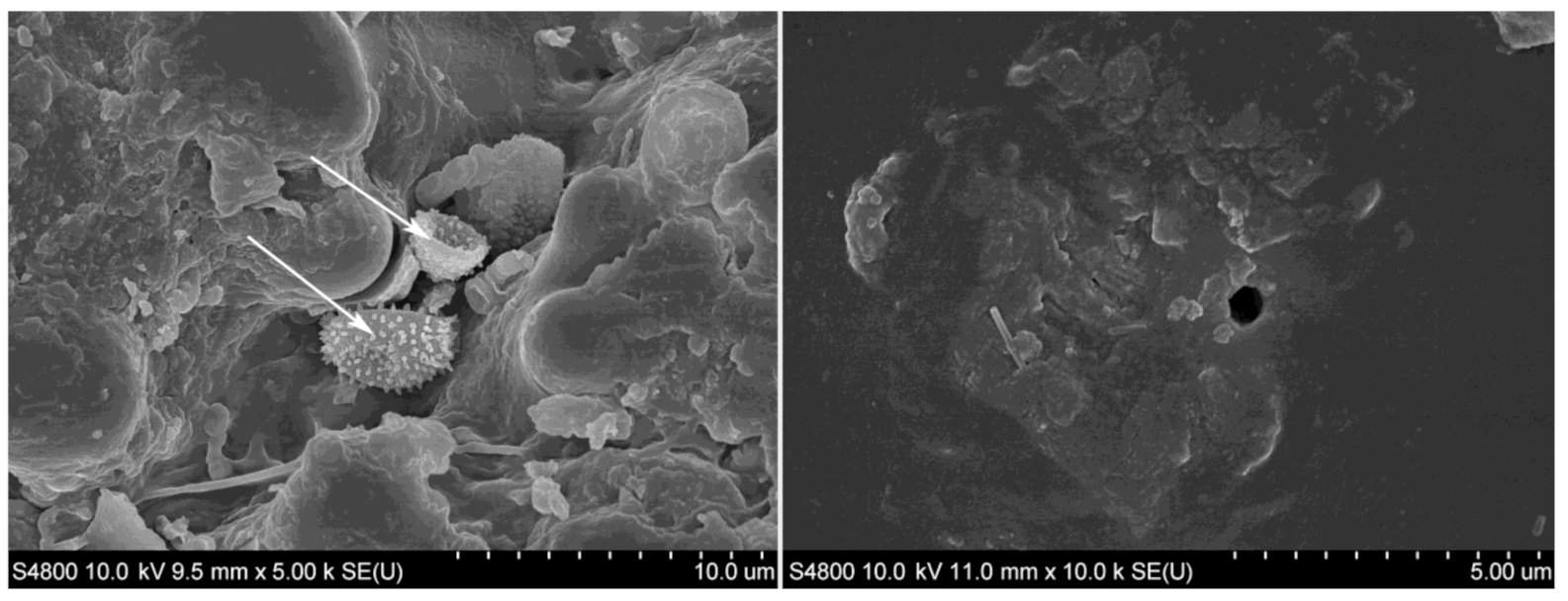

3.1. General Morphology of Bamboo

3.2. Morphological Comparison of Different Species

3.3. Morphology, Impregnation and Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zou, L.; Jin, H.; Lu, W.-Y.; Li, X. Nanoscale structural and mechanical characterization of the cell wall of bamboo fibres. Mater. Sci. Eng. C 2009, 29, 1375–1379. [Google Scholar] [CrossRef]

- Li, Y.; Yin, L.; Huang, C.; Meng, Y.; Fu, F.; Wang, S.; Wu, Q. Quasi-static and dynamic nanoindentation to determine the influence of thermal treatment on the mechanical properties of bamboo cell walls. Holzforschung 2015, 69, 909–914. [Google Scholar] [CrossRef]

- Jiao, Y.; Wan, C.; Li, J. Synthesis of carbon fibre aerogel from natural bamboo fibre and its application as a green high-efficiency and recyclable adsorbent. Mater. Des. 2016, 107, 26–32. [Google Scholar] [CrossRef]

- Lakkad, S.; Patel, J. Mechanical properties of bamboo, a natural composite. Fibre. Sci. Technol. 1980, 14, 319–322. [Google Scholar] [CrossRef]

- Amada, S.; Ichikawa, Y.; Munekata, T.; Nagase, Y.; Shimizu, H. Fibre texture and mechanical graded structure of bamboo. Compos. Part B 1997, 28, 13–20. [Google Scholar] [CrossRef]

- Chun, Q.; Van Balen, K.; Pan, J. Experimental study on flexural performance of small fir and pine timber beams strengthened with near-surface mounted carbon-fibre-reinforced polymer plates and rods. Int. J. Archit. Herit. 2014, 10, 106–117. [Google Scholar] [CrossRef]

- Glišović, I.; Stevanovic, B.; Petrovic, M. Bending behaviour of glulam beams reinforced with carbon FRP plates. J. Civ. Eng. Manag. 2015, 21, 923–932. [Google Scholar] [CrossRef]

- Sutharsan, R.; Ramprasanna, S.R.; Gnanappa, S.B.; Ganesh, A.C. Experimental study on bamboo as a reinforcing material in concrete. AIP Conf. Proc. 2020, 2204, 020024. [Google Scholar]

- Nayak, A.; Bajaj, A.S.; Jain, A.; Khandelwal, A.; Tiwari, H. Replacement of steel by bamboo reinforcement. IOSR J. Mech. Civ. Eng. 2013, 8, 50–61. [Google Scholar] [CrossRef]

- Sofiana, Y.; Wahidiyat, M.; Caroline, O.; Caroline, O.S. Bamboo as sustainable material for furniture design in disaster and remote areas in Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2018, 128, 012150. [Google Scholar] [CrossRef]

- Kaur, P.J. Bamboo availability and utilization potential as a building material. Forest Res. Eng. Int. J. 2018, 2, 240–242. [Google Scholar] [CrossRef][Green Version]

- Beraldo, A.; Pereira, M.A. Bambu de Corpo e Alma; Canal 6 Editora: Bauru, Brazil, November 2016. (In Portuguese) [Google Scholar]

- Yadav, M.; Mathur, A. Bamboo as a sustainable material in the construction industry: An overview. Mater. Today Proc. 2021, 43, 2872–2876. [Google Scholar] [CrossRef]

- Jit Kaura, P.; Pantb, K.K.; Satyaa, S.; Naika, S.N. Bamboo: The material of future. J. Interdiscip. Multidiscip. Res. 2016, 2, 17. [Google Scholar] [CrossRef]

- Terra, G. Aspectos da História de Vida de Guadua Tagoara (Nees) Kunth (Poaceae: Bambuseae) na Serra dos Órgãos, Post graduated Dissertation (Mestrado em Ecologia)—Programa de Pós Graduação em Ecologia e Recursos Naturais. Universidade Federal de São Carlos, São Carlos, Brazil, 2007. (In Portuguese). [Google Scholar]

- Thomas, W.; Judziewicz, E.J.; Clark, L.G.; Londono, X.; Stern, M.J. The American Bamboos; Smithsonian Institution Press: Washington, DC, USA, 1999. [Google Scholar] [CrossRef]

- Correal, J.F. Bamboo Design and Construction, Nonconventional and Vernacular Construction Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2020. [Google Scholar] [CrossRef]

- Hsiung, W. Prospects for bamboo development in the world. J. Am. Bamboo Soc. 1988, 8, 168. [Google Scholar]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Ramage, M.H. Ramage. Effect of processing methods on the mechanical properties of engineered bamboo. Constr. Build. Mater. 2015, 83, 95–101. [Google Scholar] [CrossRef]

- Albermani, F.; Goh, G.; Chan, S.L. Lightweight bamboo double layer grid system. Eng. Struct. 2007, 29, 1499–1506. [Google Scholar] [CrossRef]

- Nogata, F.; Takahashi, H. Intelligent functionally graded material: Bamboo. Compos. Eng. 1995, 5, 743–751. [Google Scholar] [CrossRef]

- Wang, X.; Ren, H.; Zhang, B.; Fei, B.; Burgert, I. Cell wall structure and formation of maturing fibres of P.a. bamboo (Phyllostachys pubescens) increase buckling resistance. J. R. Soc. Interface 2012, 9, 988–996. [Google Scholar] [CrossRef]

- Okubo, K.; Fujii, T.; Yamamoto, Y. Development of bamboo-based polymer composites and their mechanical properties. Compos. Part A Appl. Sci. 2004, 35, 377–383. [Google Scholar] [CrossRef]

- Nugroho, N.; Ando, N. Development of structural composite products made from bamboo: Fundamental properties of bamboo zephyr board. J. Wood Sci. 2000, 46, 68–74. [Google Scholar] [CrossRef]

- Nugroho, N.; Ando, N. Development of structural composite products made from bamboo: Fundamental properties of laminated bamboo lumber. J. Wood Sci. 2001, 47, 237–242. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fibre reinforced composite via mechanical treatments. Compos. Part B Eng. 2014, 56, 48–53. [Google Scholar] [CrossRef]

- Shangguan, W.; Gong, Y.; Zhao, R.; Ren, H. Effects of heat treatment on the properties of bamboo scrimber. J. Wood Sci. 2016, 62, 383–391. [Google Scholar] [CrossRef]

- Wei, Y.; Ji, X.; Duan, M.; Li, G. Flexural performance of bamboo scrimber beams strengthened with fibre-reinforced polymer. Constr. Build. Mater. 2017, 142, 66–82. [Google Scholar] [CrossRef]

- Zhong, Y.; Wu, G.; Ren, H.; Jiang, Z. Bending properties evaluation of newly designed reinforced bamboo scrimber composite beams. Constr. Build. Mater. 2017, 143, 61–70. [Google Scholar] [CrossRef]

- Correal, J.F.; Echeverry, J.S.; Ramírez, F.; Yamin, L. Experimental evaluation of physical and mechanical properties of Glued Laminated Guadua angustifolia Kunth. Constr. Build. Mater. 2014, 73, 105–112. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, R.; Shan, B. Production, environmental impact and mechanical properties of glubam. Constr. Build. Mater. 2013, 44, 765–773. [Google Scholar] [CrossRef]

- Liese, W. Bamboos—Biology, silvics, properties, utilization. Dtsch. Ges. Tech. Zs. 1985, 180, 63. [Google Scholar]

- Liese, W. The anatomy of bamboo culms. In Technical Report No. 18 International Network for Bamboo and Rattan; INBAR: Beijing, China, 1998. [Google Scholar]

- Chaurasia, S.K.; Singh, S.P.; Naithani, S.; Srivastava, P. A comprehensive study on proximate chemical composition of melocanna baccifera (Muli Bamboo) and its suitability for pulp and paper production. For. Res. Open Access 2016, 5, 1–4. [Google Scholar] [CrossRef]

- Li, X.; Sun, C.; Zhou, B.; He, Y. Determination of hemicellulose, cellulose and lignin in Moso Bamboo by near infrared spectroscopy. Sci. Rep. 2015, 5, 17210. [Google Scholar] [CrossRef]

- Brahma, S.; Brahma, B. Understanding of Bamboo as timber substitute: Chemical and anatomical properties of bambusa pallida Munro of Kokrajhar district, Assam, India. Int. J. Innov. Res. Sci. Eng. Tech. 2017, 6, 14462–14467. [Google Scholar] [CrossRef]

- Gnanaharan, R.; Janssen, J.J.A. Bending strength of Guadua bamboo, comparison of different testing procedures. INBAR Working Paper No. 3. 1994. [Google Scholar]

- Xing, D.; Chen, W.; Xing, D.; Yang, T. Lightweight Design for thin-walled cylindrical shell based on action mechanism of bamboo node. J. Mech. Des. 2013, 135. [Google Scholar] [CrossRef]

- Wang, F.; Shao, Z.; Wu, Y.; Wu, D. The toughness contribution of bamboo node to the mode I interlaminar fracture toughness of bamboo. Wood Sci. Technol. 2013, 48, 1257–1268. [Google Scholar] [CrossRef]

- Taylor, D.; Kinane, B.; Sweeney, C.; Sweetnam, D.; O’Reilly, P.; Duan, K. The biomechanics of bamboo: Investigating the role of the nodes. Wood Sci. Technol. 2014, 49, 345–357. [Google Scholar] [CrossRef]

- Chen, Q.; Dai, C.; Fang, C.-H.; Chen, M.; Zhang, S.; Liu, R.; Liu, X.; Fei, B. Mode I interlaminar fracture toughness behavior and mechanisms of bamboo. Mater. Des. 2019, 183, 108132. [Google Scholar] [CrossRef]

- Jiang, Z. Bamboo and Rattan in the World; China Forestry Publishing House: Beijing, China, 2007. [Google Scholar]

- Peng, G.; Jiang, Z.; Xe Liu, B.; Fei, S.; Yang, D.; Qin, H.; Yu Ren, Y.; Xie, H. Detection of complex vascular system in bamboo node by X-ray μCT imaging technique. Holzforschung 2014, 68, 223–227. [Google Scholar] [CrossRef]

- Chen, G.; Luo, H. Effects of node with discontinuous hierarchical fibers on the tensile fracture behaviors of natural bamboo. Sustain. Mater. Technol. 2020, 26, e00228. [Google Scholar] [CrossRef]

- Dabo, S.M.; Taliaferro, C.M.; Coleman, S.W. Anatomical and histological factors affecting the ruminal degradation of stem tissues in Bothriochloa species. Anim. Feed Sci. Technol. 1997, 67, 299–309. [Google Scholar] [CrossRef]

- Perik, R.R.; Razé, D.; Harkema, H.; Zhong, Y.; van Doorn, W.G. Bending in cut Gerbera jamesonii flowers relates to adverse water relations and lack of stem sclerenchyma development, not to expansion of the stem central cavity or stem elongation. Postharvest Biol. Technol. 2012, 74, 11–18. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elejoste, A.; Arevalillo, A.; Gabilondo, N.; Butron, A.; Peña-Rodriguez, C. Morphological Analysis of Several Bamboo Species with Potential Structural Applications. Polymers 2021, 13, 2126. https://doi.org/10.3390/polym13132126

Elejoste A, Arevalillo A, Gabilondo N, Butron A, Peña-Rodriguez C. Morphological Analysis of Several Bamboo Species with Potential Structural Applications. Polymers. 2021; 13(13):2126. https://doi.org/10.3390/polym13132126

Chicago/Turabian StyleElejoste, Asier, Alfonso Arevalillo, Nagore Gabilondo, Amaia Butron, and Cristina Peña-Rodriguez. 2021. "Morphological Analysis of Several Bamboo Species with Potential Structural Applications" Polymers 13, no. 13: 2126. https://doi.org/10.3390/polym13132126

APA StyleElejoste, A., Arevalillo, A., Gabilondo, N., Butron, A., & Peña-Rodriguez, C. (2021). Morphological Analysis of Several Bamboo Species with Potential Structural Applications. Polymers, 13(13), 2126. https://doi.org/10.3390/polym13132126