Valorization of Invasive Plants from Macaronesia as Filler Materials in the Production of Natural Fiber Composites by Rotational Molding

Abstract

:1. Introduction

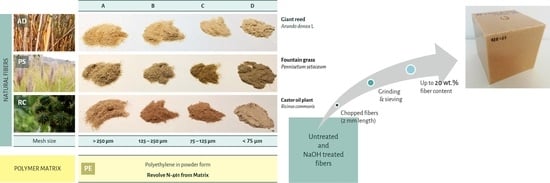

2. Materials and Methods

3. Results

3.1. Composites with Untreated Fibers

3.1.1. Composites Obtained with Arundo donax L.

3.1.2. Composites Obtained with Pennisetum Setaceum

3.1.3. Composites Obtained with Ricinus communis

3.2. Composites with Treated Fibers

3.2.1. Composites Obtained with Arundo donax L.

3.2.2. Composites Obtained with Pennisetum Setaceum

3.2.3. Composites Obtained with Ricinus Communis

3.3. Comparison of Vegetal Species

3.4. Morphology of Composites

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sundseth, K. Natura 2000 in the Macaronesian Region; Wegefelt, S., Ed.; Office for Official Publications of the European Communities: Luxemburg, 2009; ISBN 9789279117305. [Google Scholar]

- Ministerio Para la Transición Ecológica Catálogo Español de Especies Exóticas Invasoras. Available online: https://www.miteco.gob.es/es/biodiversidad/temas/conservacion-de-especies/especies-exoticas-invasoras/ce_eei_flora.aspx (accessed on 30 November 2018).

- Interreg Bionatura Agave Americana L. Pitera Común. Available online: www.interreg-bionatura.com/especies/pdf/Agaveamericana.pdf (accessed on 7 April 2021).

- Lowe, S.; Browne, M.; Boudjelas, S.; De Poorter, M. 100 de las Especies Exóticas Invasoras más Dañinas del Mundo; Grupo Especialista de Especies Invasoras (GEEI): Auckland, New Zealand, 2004. [Google Scholar]

- Ortega, Z.; Castellano, J.; Suárez, L.; Paz, R.; Díaz, N.; Benítez, A.N.; Marrero, M.D. Characterization of Agave americana L. plant as potential source of fibres for composites obtaining. SN Appl. Sci. 2019, 1, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Antonetti, C.; Bonari, E.; Licursi, D.; Di Nasso, N.N.; Galletti, A.M.R.; Cravotto, G.; Chemat, F. Hydrothermal conversion of giant reed to furfural and levulinic acid: Optimization of the process under microwave irradiation and investigation of distinctive agronomic parameters. Molecules 2015, 20, 21232–21353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mirza, N.; Mahmood, Q.; Pervez, A.; Ahmad, R.; Farooq, R.; Shah, M.M.; Azim, M.R. Phytoremediation potential of Arundo donax in arsenic-contaminated synthetic wastewater. Bioresour. Technol. 2010, 101, 5815–5819. [Google Scholar] [CrossRef]

- Martínez Gabarrón, A.; Flores Yepes, J.A.; Pastor Pérez, J.J.; Berná Serna, J.M.; Arnold, L.C.; Sánchez Medrano, F.J. Increase of the flexural strength of construction elements made with plaster (calcium sulfate dihydrate) and common reed (Arundo donax L.). Constr. Build. Mater. 2014, 66, 436–441. [Google Scholar] [CrossRef]

- Andreu-Rodriguez, J.; Medina, E.; Ferrandez-Garcia, M.T.; Ferrandez-Villena, M.; Ferrandez-Garcia, C.E.; Paredes, C.; Bustamante, M.A.; Moreno-Caselles, J. Agricultural and Industrial Valorization of Arundo donax L. Commun. Soil Sci. Plant Anal. 2013, 44, 598–609. [Google Scholar] [CrossRef]

- Fiore, V.; Botta, L.; Scaffaro, R.; Valenza, A.; Pirrotta, A. PLA based biocomposites reinforced with Arundo donax fillers. Compos. Sci. Technol. 2014, 105, 110–117. [Google Scholar] [CrossRef]

- Scalici, T.; Fiore, V.; Valenza, A. Effect of plasma treatment on the properties of Arundo Donax L. leaf fibres and its bio-based epoxy composites: A preliminary study. Compos. Part B Eng. 2016, 94, 167–175. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Proietti, S.; Moscatello, S.; Fagnano, M.; Fiorentino, N.; Impagliazzo, A.; Battistelli, A. Chemical composition and yield of rhizome biomass of Arundo donax L. grown for biorefinery in the Mediterranean environment. Biomass Bioenergy 2017, 107, 191–197. [Google Scholar] [CrossRef]

- García-Ortuño, T.; Andréu-Rodríguez, J.; Ferrández-García, M.T.; Ferrández-Villena, M.; Ferrández-García, C.E. Evaluation of the physical and mechanical properties of particleboard made from giant reed (Arundo donax L.). BioResources 2011, 6, 477–486. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Vitale, G.; Valenza, A. Static and dynamic mechanical properties of Arundo Donax fillers-epoxy composites. Mater. Des. 2014, 57, 456–464. [Google Scholar] [CrossRef]

- Stokes, T. Castor plant’s promising future. Trends Plant Sci. 2001, 6, 97. [Google Scholar] [CrossRef]

- Shen, X.; Chen, W.; Zheng, Y.; Lei, X.; Tang, M.; Wang, H.; Song, F. Chemical composition, antibacterial and antioxidant activities of hydrosols from different parts of Areca catechu L. and Cocos nucifera L. Ind. Crops Prod. 2017, 96, 110–119. [Google Scholar] [CrossRef]

- Grigoriou, A.H.; Ntalos, G.A. The potential use of Ricinus communis L. (Castor) stalks as a lignocellulosic resource for particleboards. Ind. Crops Prod. 2001, 13, 209–218. [Google Scholar] [CrossRef]

- Heitzmann, M.T.; Veidt, M.; Ng, C.T.; Lindenberger, B.; Hou, M.; Truss, R.; Liew, C.K. Single-Plant Biocomposite from Ricinus Communis: Preparation, Properties and Environmental Performance. J. Polym. Environ. 2013, 21, 366–374. [Google Scholar] [CrossRef]

- Vinayaka, D.L.; Vijaykumar, G.; Madhavi, D.; Arpitha, M.; Narendra, R. Ricinus communis plant residues as a source for natural cellulose fibers potentially exploitable in polymer composites. Ind. Crops Prod. 2017, 100, 126–131. [Google Scholar] [CrossRef]

- Ruiz Rallo, A. Programa Canario de Ecodiseño para el Desarrollo Local Sostenible. Available online: https://proceder.webs.ull.es/index.html (accessed on 7 April 2021).

- Hanana, F.E.; Rodrigue, D. Rotational molding of polymer composites reinforced with natural fibers. Plast. Eng. 2015, 71, 28–31. [Google Scholar] [CrossRef]

- Torres, F.G.; Aragon, C.L. Final product testing of rotational moulded natural fibre-reinforced polyethylene. Polym. Test. 2006, 25, 568–577. [Google Scholar] [CrossRef]

- Díaz, S.; Ortega, Z.; McCourt, M.; Kearns, M.P.; Benítez, A.N. Recycling of polymeric fraction of cable waste by rotational moulding. Waste Manag. 2018. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-treatment of Flax Fibers for use in Rotationally Molded Biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Monzón, M.D.; Ortega, Z.; Benítez, A.N.; Ortega, F.; Díaz, N.; Marrero, M.D. Developments towards a more sustainable rotational moulding process. In Proceedings of the ECCM 2012—Composites at Venice, Proceedings of the 15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012. [Google Scholar]

- López-Bañuelos, R.H.; Moscoso, F.J.; Ortega-Gudiño, P.; Mendizabal, E.; Rodrigue, D.; González-Núñez, R. Rotational molding of polyethylene composites based on agave fibers. Polym. Eng. Sci. 2012, 52, 2489–2497. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pérez-Fonseca, A.A.; González-García, Y.; Ramírez-Arreola, D.E.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Polylactic acid-agave fiber biocomposites produced by rotational molding: A comparative study with compression molding. Adv. Polym. Technol. 2018, 37, 2528–2540. [Google Scholar] [CrossRef]

- León, L.D.V.E.; Escocio, V.A.; Visconte, L.L.Y.; Junior, J.C.J.; Pacheco, E.B.A.V. Rotomolding and polyethylene composites with rotomolded lignocellulosic materials: A review. J. Reinf. Plast. Compos. 2020, 39, 459–472. [Google Scholar] [CrossRef]

- Höfler, G.; Jayaraman, K.; Lin, R. Rotational moulding and mechanical characterisation of micron-sized and nano-sized reinforced high density polyethylene. In Proceedings of the Key Engineering Materials; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2019; Volume 809, pp. 65–70. [Google Scholar]

- Cisneros-López, E.O.; González-López, M.E.; Pérez-Fonseca, A.A.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of fiber content and surface treatment on the mechanical properties of natural fiber composites produced by rotomolding. Compos. Interfaces 2017, 24, 35–53. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Effect of particle size, fiber content, and surface treatment on the mechanical properties of maple-reinforced LLDPE produced by rotational molding. Polym. Polym. Compos. 2021, 29, 343–353. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Andrzejewski, J.; Kosmela, P.; Piasecki, A.; Szostak, M.; Kuang, T. Rotational Molding of Linear Low-Density Polyethylene Composites Filled with Wheat Bran. Polymers 2020, 12, 1004. [Google Scholar] [CrossRef] [PubMed]

- Andrzejewski, J.; Krawczak, A.; Wesoły, K.; Szostak, M. Rotational molding of biocomposites with addition of buckwheat husk filler. Structure-property correlation assessment for materials based on polyethylene (PE) and poly(lactic acid) PLA. Compos. Part B Eng. 2020, 202, 108410. [Google Scholar] [CrossRef]

- Ortega, Z.; Monzón, M.D.; Benítez, A.N.; Kearns, M.; McCourt, M.; Hornsby, P.R. Banana and Abaca Fiber-Reinforced Plastic Composites Obtained by Rotational Molding Process. Mater. Manuf. Process. 2013, 28, 130614085148001. [Google Scholar] [CrossRef]

- Abhilash, S.S.; Singaravelu, D.L. Effect of Fiber Content on Mechanical and Morphological Properties of Bamboo Fiber-Reinforced Linear Low-Density Polyethylene Processed by Rotational Molding. Trans. Indian Inst. Met. 2020, 73, 1549–1554. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Rotational molding of self-hybrid composites based on linear low-density polyethylene and maple fibers. Polym. Compos. 2018, 39, 4094–4103. [Google Scholar] [CrossRef]

- Hanana, F.E.; Chimeni, D.Y.; Rodrigue, D. Morphology and Mechanical Properties of Maple Reinforced LLDPE Produced by Rotational Moulding: Effect of Fibre Content and Surface Treatment. Polym. Polym. Compos. 2018, 26, 299–308. [Google Scholar] [CrossRef]

- González-López, M.E.; Pérez-Fonseca, A.A.; Cisneros-López, E.O.; Manríquez-González, R.; ·Ramírez-Arreola, D.E.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of Maleated PLA on the Properties of Rotomolded PLA-Agave Fiber Biocomposites. J. Polym. Environ. 2019, 27, 61–73. [Google Scholar] [CrossRef]

- Sari, P.S.; Thomas, S.; Spatenka, P.; Ghanam, Z.; Jenikova, Z. Effect of plasma modification of polyethylene on natural fibre composites prepared via rotational moulding. Compos. Part B Eng. 2019, 177, 107344. [Google Scholar] [CrossRef]

- Oliveira, M.A.S.; Pickering, K.L.; Sunny, T.; Lin, R.J.T. Treatment of hemp fibres for use in rotational moulding. J. Polym. Res. 2021, 28, 3. [Google Scholar] [CrossRef]

| Code | Description |

|---|---|

| R.PE. | Rotomolded PE (neat PE) |

| R.PE.AD.20.A | Rotomolded PE with 20 wt% Arundo donax fiber (P.S. >250 μm) |

| R.PE.AD.20.B | Rotomolded PE with 20 wt% Arundo donax fiber (P.S. 125–250 μm) |

| R.PE.AD.20.C | Rotomolded PE with 20 wt% Arundo donax fiber (P.S. 75–125 μm) |

| R.PE.AD.20.D | Rotomolded PE with 20 wt% Arundo donax fiber (P.S. <75 μm) |

| R.PE.AD.5 | Rotomolded PE with 5 wt% Arundo donax fiber (non-sieved) |

| R.PE.AD.10 | Rotomolded PE with 10 wt% Arundo donax fiber (non-sieved) |

| R.PE.PS.20.A | Rotomolded PE with 20 wt% Pennisetum setaceum fiber (P.S. >250 μm) |

| R.PE.PS.20.B | Rotomolded PE with 20 wt% Pennisetum setaceum fiber (P.S. 125–250 μm) |

| R.PE.PS.20.C | Rotomolded PE with 20 wt% Pennisetum setaceum fiber (P.S. 75–125 μm) |

| R.PE.PS.20.D | Rotomolded PE with 20 wt% Pennisetum setaceum fiber (P.S. <75 μm) |

| R.PE.PS.5 | Rotomolded PE with 5 wt% Pennisetum setaceum fiber (non-sieved) |

| R.PE.PS.10 | Rotomolded PE with 10 wt% Pennisetum setaceum fiber (non-sieved) |

| R.PE.RC.20.A | Rotomolded PE with 20 wt% Ricinus communis fiber (P.S. >250 μm) |

| R.PE.RC.20.B | Rotomolded PE with 20 wt% Ricinus communis fiber (P.S. 125–250 μm) |

| R.PE.RC.20.C | Rotomolded PE with 20 wt% Ricinus communis fiber (P.S. 75–125 μm) |

| R.PE.RC.20.D | Rotomolded PE with 20 wt% Ricinus communis fiber (P.S. <75 μm) |

| R.PE.RC.5 | Rotomolded PE with 5 wt% Ricinus communis fiber (non-sieved) |

| R.PE.RC.10 | Rotomolded PE with 10 wt% Ricinus communis fiber (non-sieved) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega, Z.; Romero, F.; Paz, R.; Suárez, L.; Benítez, A.N.; Marrero, M.D. Valorization of Invasive Plants from Macaronesia as Filler Materials in the Production of Natural Fiber Composites by Rotational Molding. Polymers 2021, 13, 2220. https://doi.org/10.3390/polym13132220

Ortega Z, Romero F, Paz R, Suárez L, Benítez AN, Marrero MD. Valorization of Invasive Plants from Macaronesia as Filler Materials in the Production of Natural Fiber Composites by Rotational Molding. Polymers. 2021; 13(13):2220. https://doi.org/10.3390/polym13132220

Chicago/Turabian StyleOrtega, Zaida, Francisco Romero, Rubén Paz, Luis Suárez, Antonio Nizardo Benítez, and María Dolores Marrero. 2021. "Valorization of Invasive Plants from Macaronesia as Filler Materials in the Production of Natural Fiber Composites by Rotational Molding" Polymers 13, no. 13: 2220. https://doi.org/10.3390/polym13132220

APA StyleOrtega, Z., Romero, F., Paz, R., Suárez, L., Benítez, A. N., & Marrero, M. D. (2021). Valorization of Invasive Plants from Macaronesia as Filler Materials in the Production of Natural Fiber Composites by Rotational Molding. Polymers, 13(13), 2220. https://doi.org/10.3390/polym13132220