Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges

Abstract

:1. Introduction

2. Characteristics of WG in Concrete

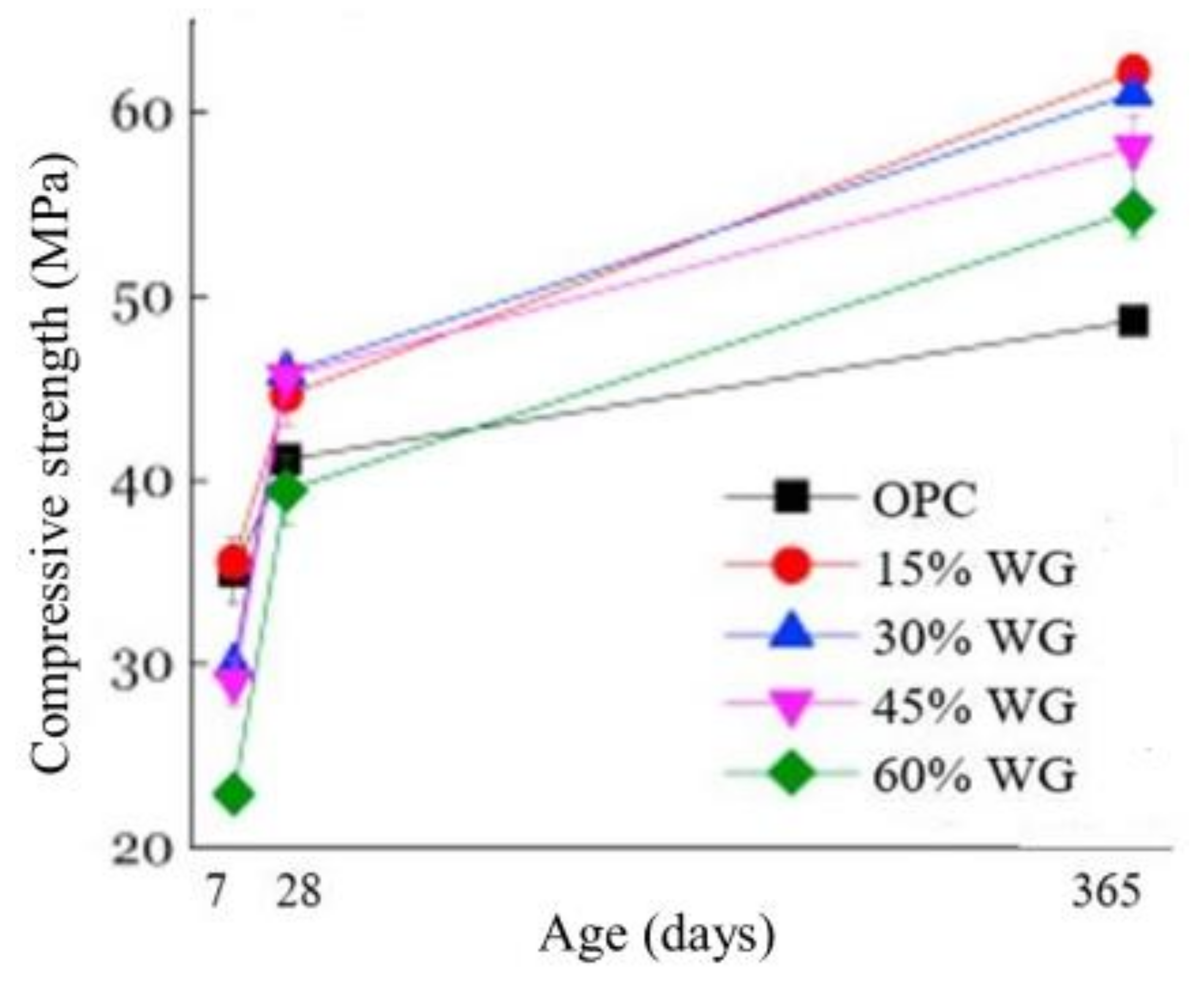

2.1. Role of WG in Cement Concrete

2.2. Role of WG in Geopolymer Concrete

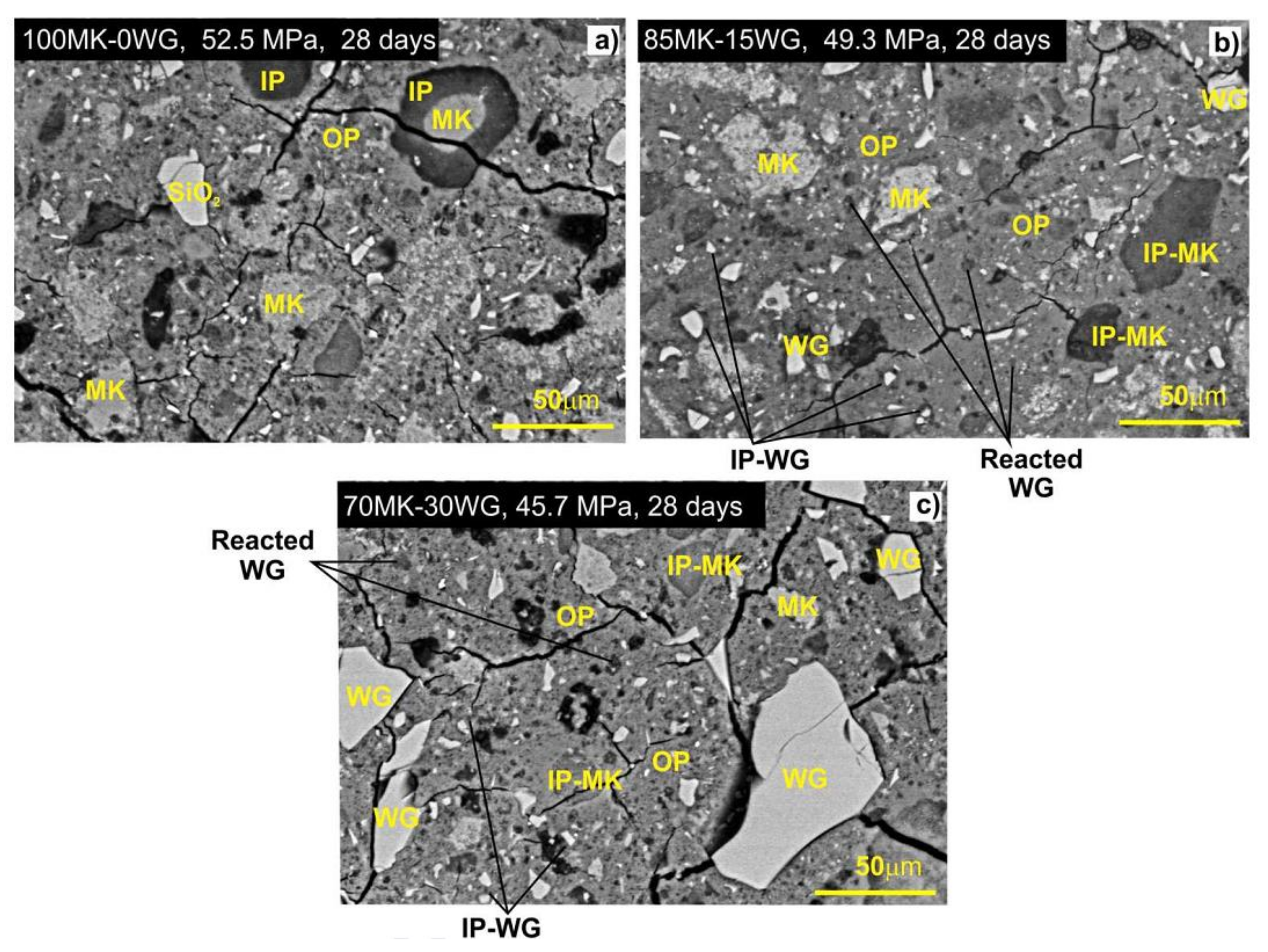

3. Microstructure of WG Concrete

4. The Durability of Concrete with WG

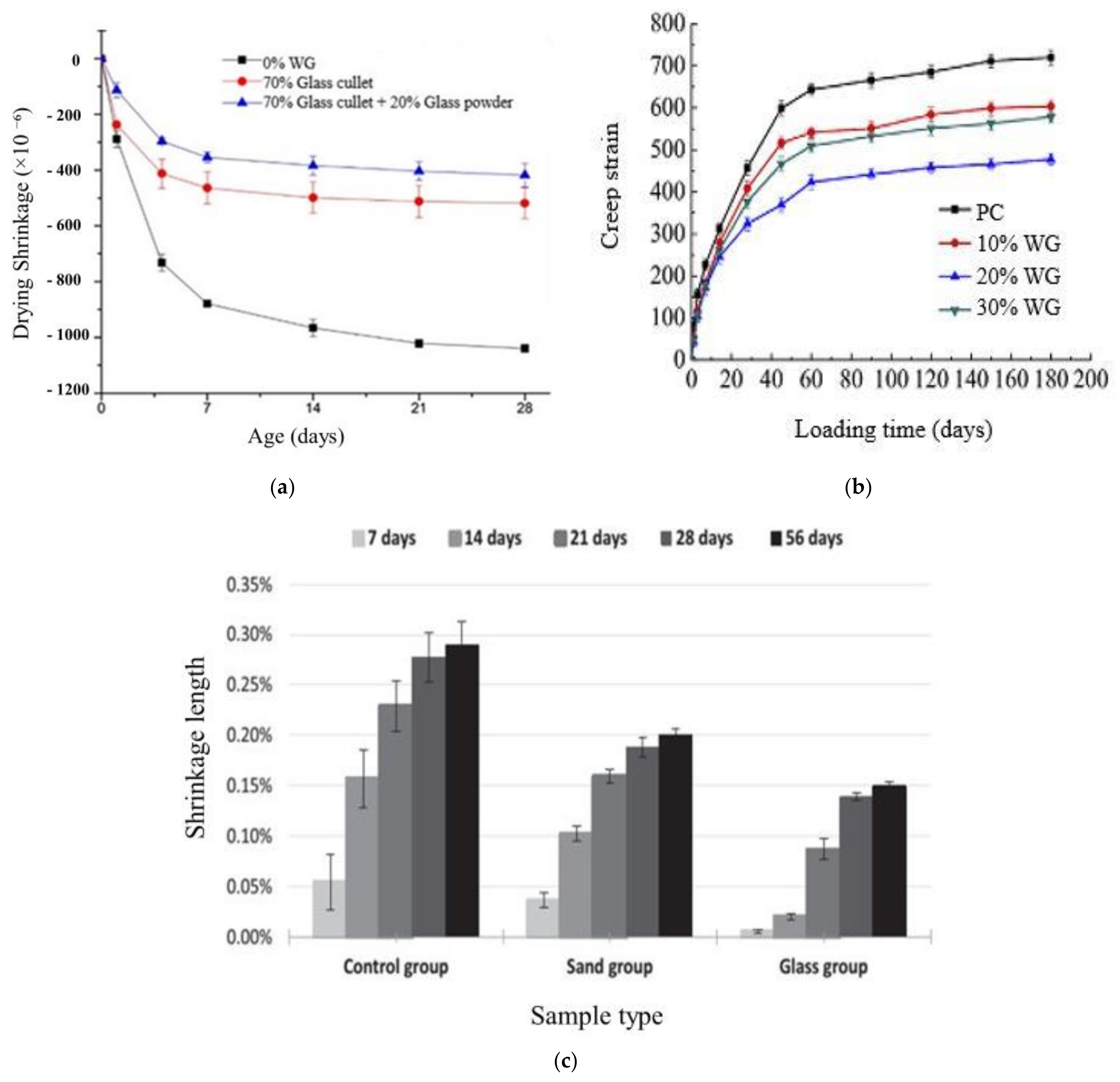

4.1. Drying Shrinkage

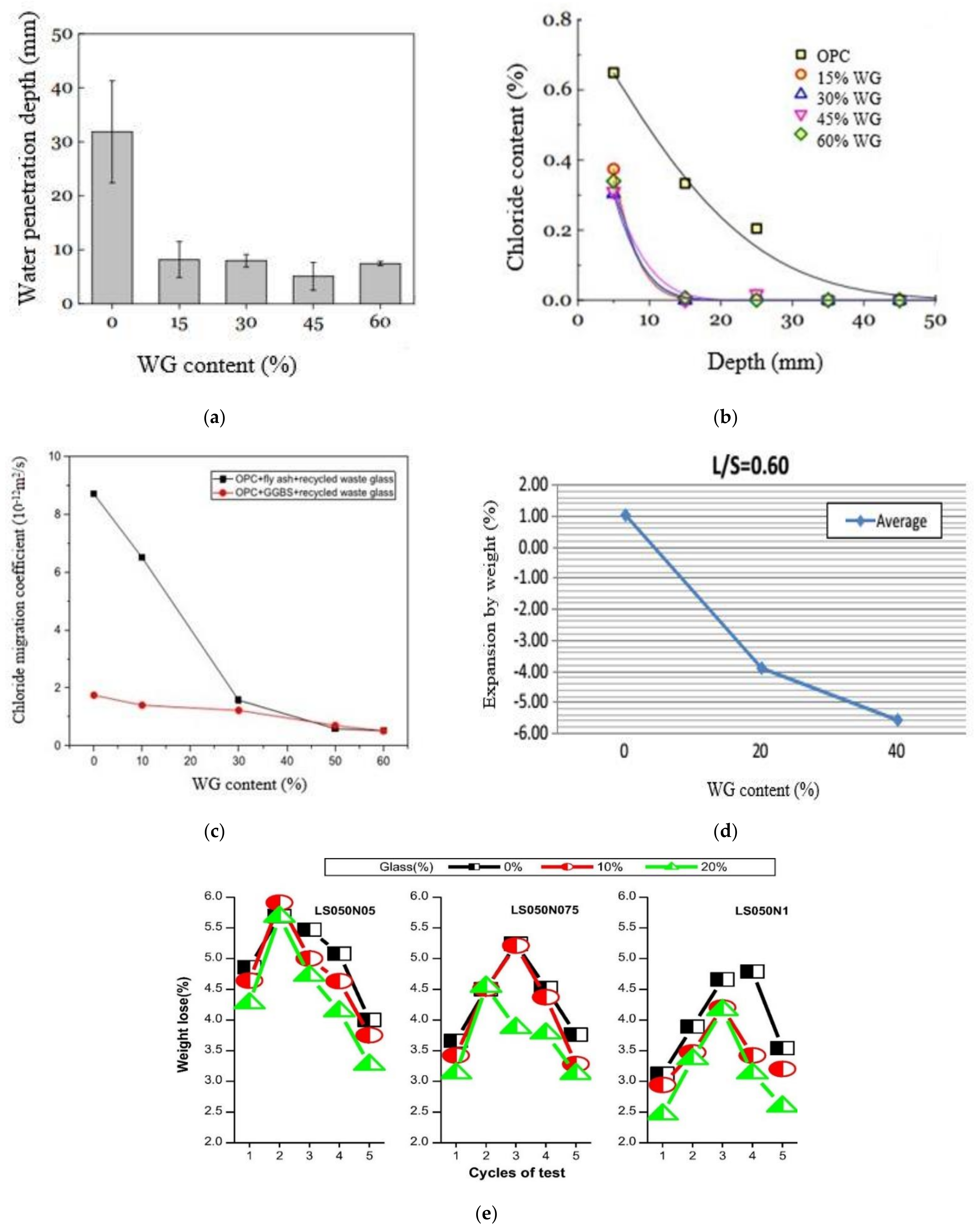

4.2. Performance in Chemical Exposure

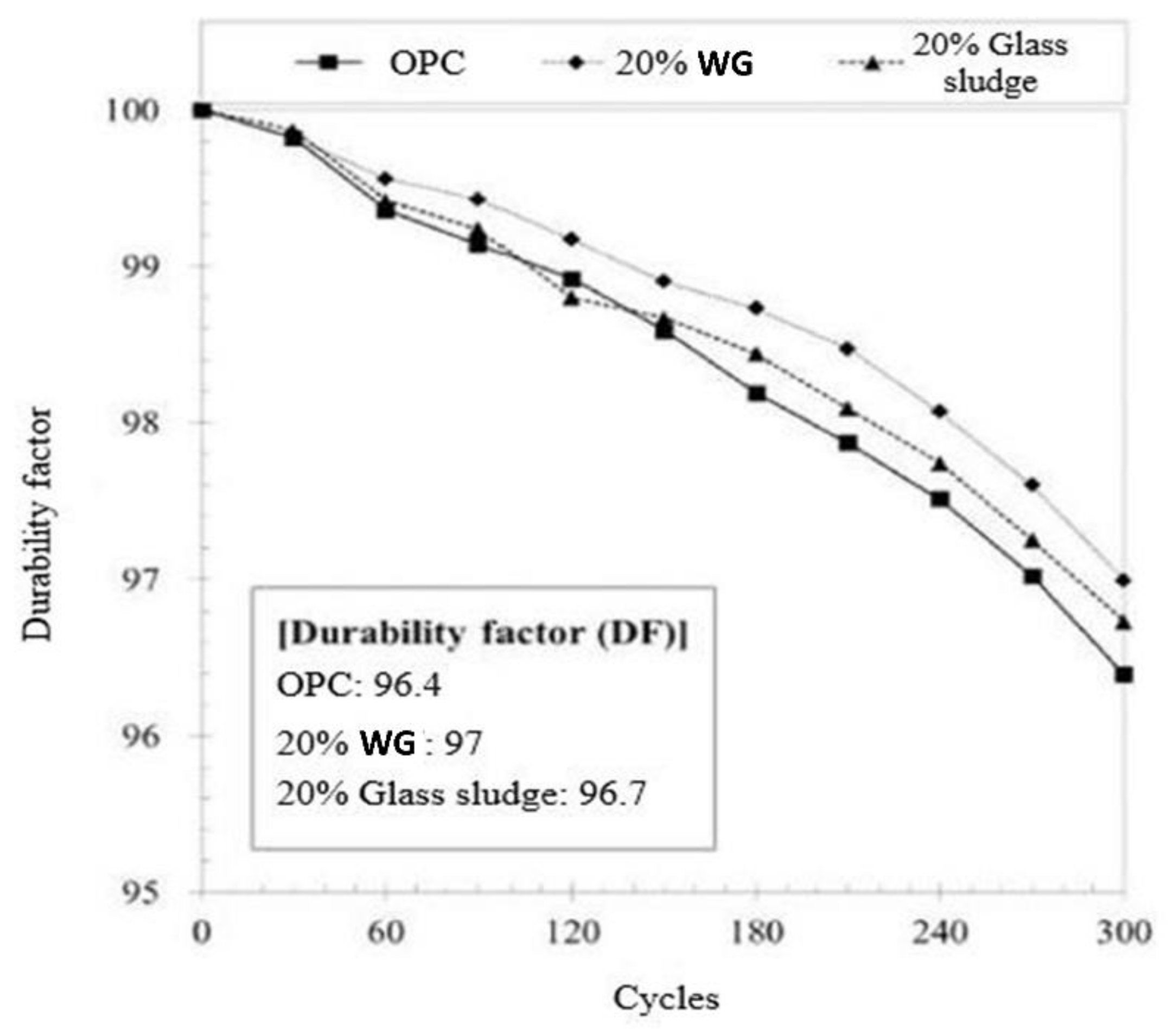

4.3. Freeze-Thaw Resistance

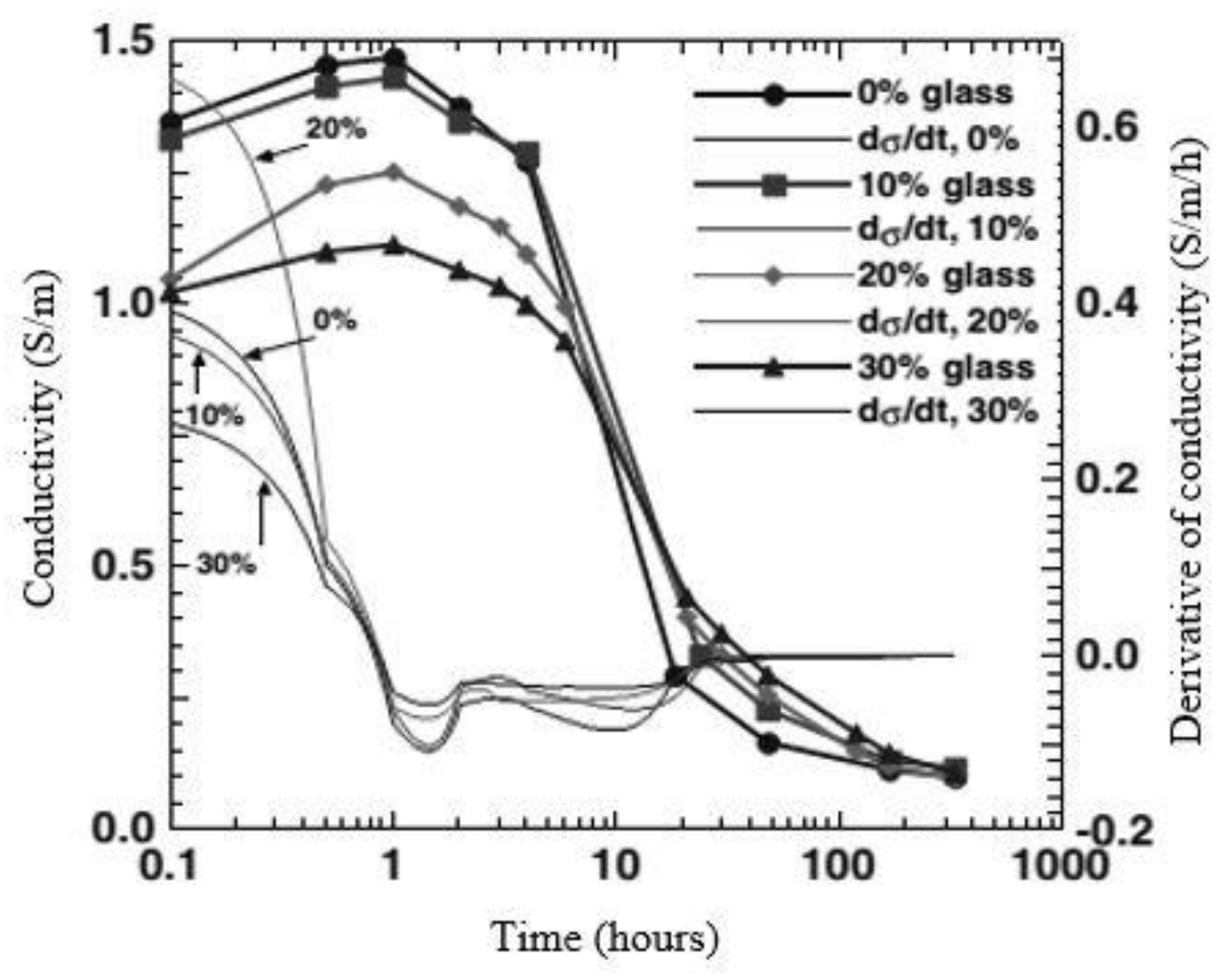

4.4. Electrical Resistivity

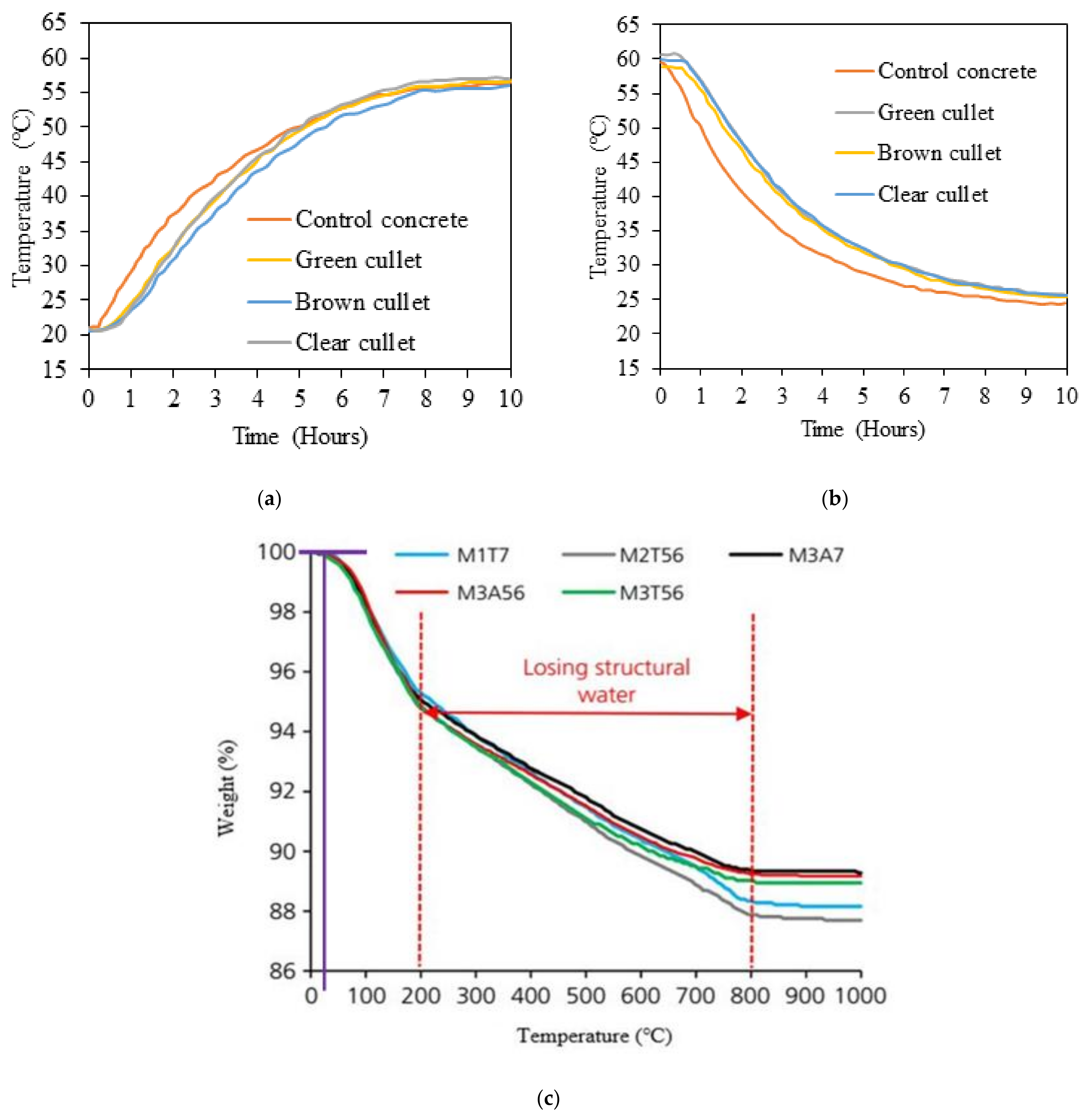

4.5. Thermal Properties

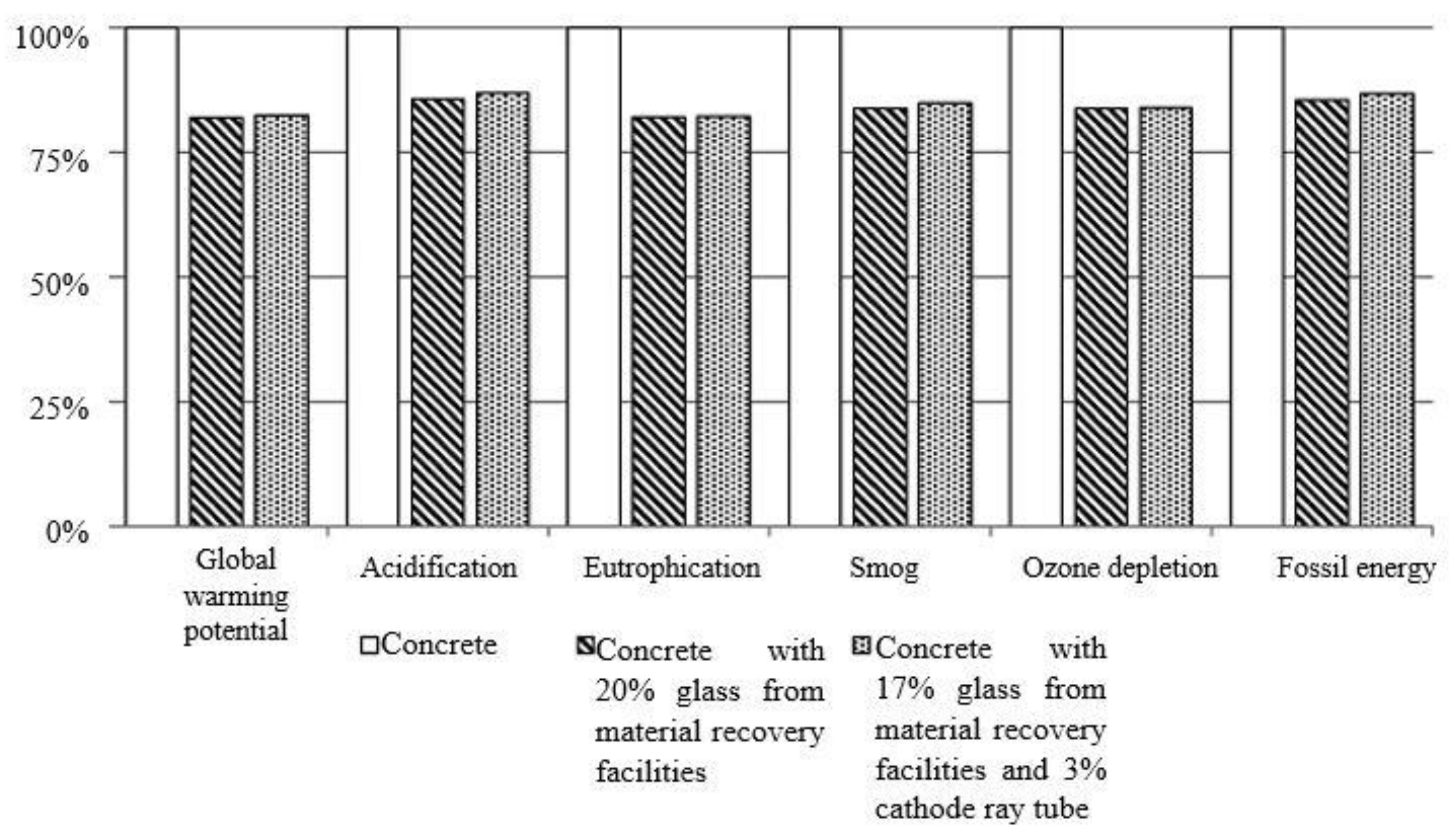

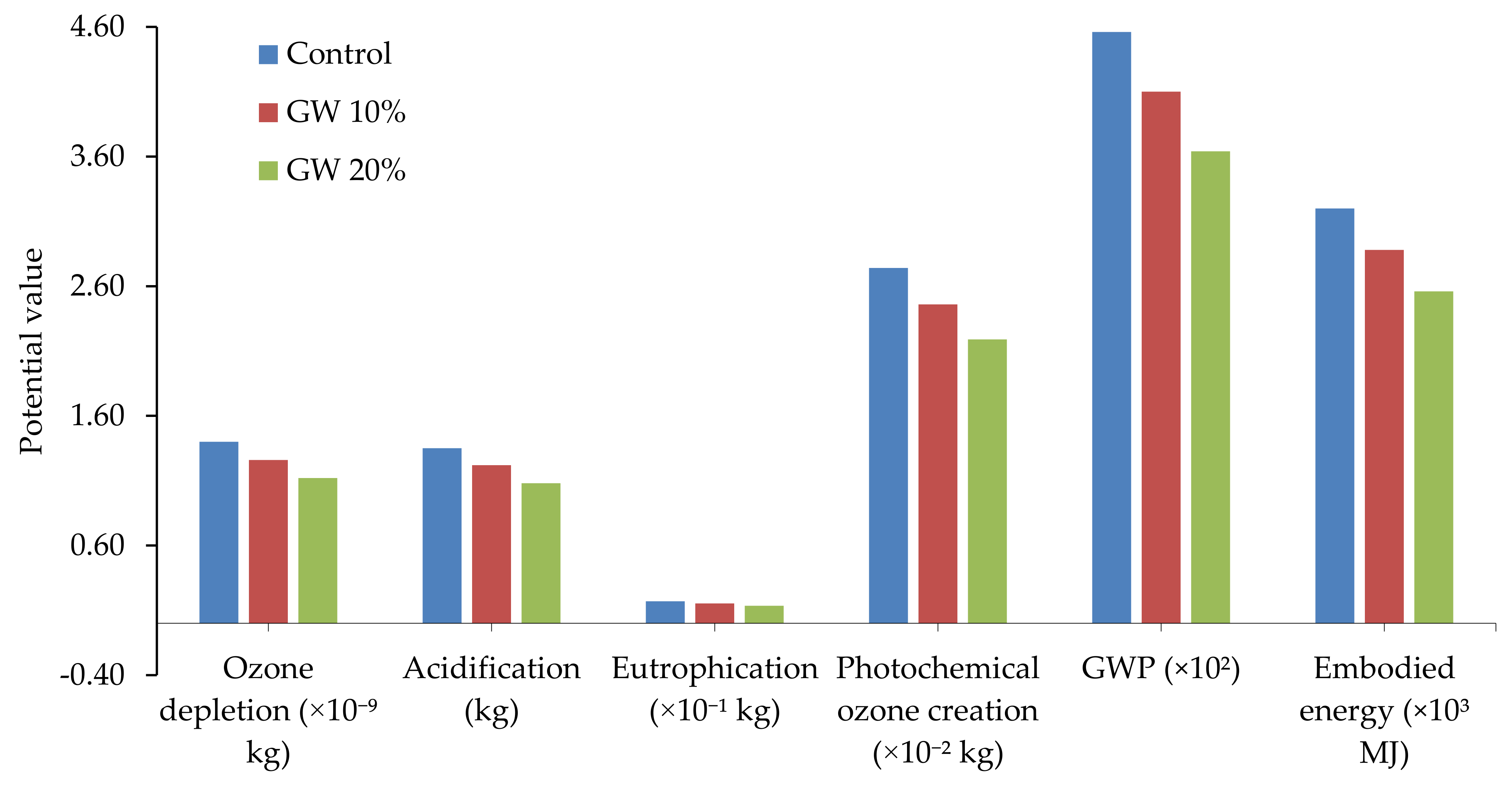

5. Environmental Benefit of WG Concrete

6. Challenges in WG Concrete and Remedies

6.1. ASR Expansion in WG-Based Concrete

6.2. Low Adhesion between WG and Cement-Paste

6.3. Other Challenges and Research Gaps

7. Conclusions

- The waste glass acts as a rich source of silica in concrete. Thus the pozzolanic activity increases, hydration product formation increases, and microstructures get improved after the addition of fine WG in concrete. Additionally, the silica dissolution in the geopolymer system also increases due to the presence of fine WG powder and consequently improved geopolymeric reaction. To optimize the silica dissolution and pozzolanicity, the optimum particle size of WG must be maintained as recommended around 38–75 µm.

- WG powder does not hold free water in the internal pores of the concrete and minimizes the pore connectivity. Thus a lower drying shrinkage occurred. Additionally, curing with raised temperature is effective to reduce the shrinkage and improve the micro-structure compactness.

- The high pozzolanic reactivity and filler effect of fine WG powder result in a high-performance composite with high durability against water, chloride, and sulphate penetration and adverse effect of any chemical attack. Concrete’s resistance to acid attack and carbonation is also improved. Besides, electrical charge flow, the thermal conductivity of glass-based concrete and geopolymers are reduced due to the addition of WG.

- Very limited research has been conducted on the durability of WG-based concrete; thus the recommendation for optimum level of WG inclusion replacing binders or aggregates in concrete remains an open research question. However, based on current knowledge, it is estimated that the optimum level of binder replacement could be around 20–30%, and this range is approximately 30–50% for fine aggregate. Beyond the optimum level of replacement, a porous concrete matrix will result in lower durability.

- The most critical issue of glass incorporation is the ASR and expansive gel formation within concrete. This issue is less critical for geopolymers compared with cement concrete. The ASR expansion can be minimized by using fine WG powder (<75 µm), replacing cement instead of aggregates, and adding recommended by-products, such as silica fume, fly ash, and slag optimum level of around 10–30%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bahoria, B.V.; Parbat, D.K.; Nagarnaik, P.B. XRD Analysis of Natural sand, Quarry dust, waste plastic (ldpe) to be used as a fine aggregate in concrete. In Materials Today: Proceedings; Elsevier: Amsterdam, The Netherlands, 2018; Volume 5, pp. 1432–1438. [Google Scholar]

- Islam, M.T.; Islam, M.; Siddika, A.; Mamun, M.A. Al Performance of rubberized concrete exposed to chloride solution and continuous wet–dry cycle. Innov. Infrastruct. Solut. 2021, 6, 67. [Google Scholar] [CrossRef]

- Siddika, A.; Amin, M.R.; Rayhan, M.A.; Islam, M.S.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.H.M. Performance of sustainable green concrete incorporated with fly ash rice husk ash and stone dust. Acta Polytech. 2021, 61, 279–291. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Siddika, A.; Shaikh, F.; Alamri, H.; Subaer, S.; Low, I.-M. Effect of Nanosilica on Mechanical Properties and Microstructure of PVA Fiber-Reinforced Geopolymer Composite (PVA-FRGC). Materials 2019, 12, 3624. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Mohammadhosseini, H. State-of-the-art-review on rice husk ash: A supplementary cementitious material in concrete. J. King Saud Univ. Eng. Sci. 2021, 33, 294–307. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.-W.; Nicolaides, D.; Luhar, I.; Panias, D.; Sakkas, K. Valorisation of glass wastes for the development of geopolymer composites—Durability, thermal and microstructural properties: A review. Constr. Build. Mater. 2019, 222, 673–687. [Google Scholar] [CrossRef]

- Burciaga-Díaz, O.; Durón-Sifuentes, M.; Díaz-Guillén, J.A.; Escalante-García, J.I. Effect of waste glass incorporation on the properties of geopolymers formulated with low purity metakaolin. Cem. Concr. Compos. 2020, 107, 103492. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Ali, M.H. Study on concrete with rice husk ash. Innov. Infrastruct. Solut. 2018, 3, 18. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Ferdous, W.; Saha, A.K.; Alyousef, R. 3D-printed concrete: Applications, performance, and challenges. J. Sustain. Cem. Mater. 2020, 9, 127–164. [Google Scholar] [CrossRef]

- Trends in Solid Waste Management. Available online: https://datatopics.worldbank.org/what-a-waste/trends_in_solid_waste_management.html (accessed on 14 May 2020).

- Harder, I.J. Glass Recycling—Current Market Trends—Recovery. Available online: https://www.recovery-worldwide.com/en/artikel/glass-recycling-current-market-trends_3248774.html (accessed on 5 April 2021).

- What a Waste: Australia Needs to Confront Recycling Crisis. Available online: https://www.news.com.au/technology/environment/australias-reliance-on-sending-waste-overseas-for-recycling-is-fuelling-a-crisis-in-the-industry/news-story/2921f34b88adcc7ad8925ca9430367ad (accessed on 18 March 2020).

- Hama, S.M.; Mahmoud, A.S.; Yassen, M.M. Flexural behavior of reinforced concrete beam incorporating waste glass powder. Structures 2019, 20, 510–518. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.-C.; Mo, K.H.; Shi, C. A critical review of waste glass powder—Multiple roles of utilization in cement-based materials and construction products. J. Environ. Manag. 2019, 242, 440–449. [Google Scholar] [CrossRef]

- Heriyanto, E.; Pahlevani, F.; Sahajwalla, V. From waste glass to building materials—An innovative sustainable solution for waste glass. J. Clean. Prod. 2018, 191, 192–206. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A. Durability of Geopolymer Mortar Based on Waste-Glass Powder and Calcium Aluminate Cement in Acid Solutions. J. Mater. Civ. Eng. 2017, 29, 04017196. [Google Scholar] [CrossRef]

- Al-Akhras, N.M. Performance of Glass Concrete Subjected to Freeze-Thaw Cycling. Open Constr. Build. Technol. J. 2012, 6, 392–397. [Google Scholar] [CrossRef] [Green Version]

- Hajimohammadi, A.; Ngo, T.; Vongsvivut, J. Interfacial chemistry of a fly ash geopolymer and aggregates. J. Clean. Prod. 2019, 231, 980–989. [Google Scholar] [CrossRef]

- Jubeh, A.I.; Al Saffar, D.M.; Tayeh, B.A. Effect of recycled glass powder on properties of cementitious materials contains styrene butadiene rubber. Arab. J. Geosci. 2019, 12, 39. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. Glass waste versus sand as aggregates: The characteristics of the evolving geopolymer binders. J. Clean. Prod. 2018, 193, 593–603. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Canbaz, M. Properties of concrete containing waste glass. Cem. Concr. Res. 2004, 34, 267–274. [Google Scholar] [CrossRef]

- Andiç-Çakır, Ö.; Üzüm, O.; Yüksel, C.; Sarikanat, M. Waste glass aggregate for cementitious and polymer concrete. Proc. Inst. Civ. Eng. Constr. Mater. 2016, 169, 106–116. [Google Scholar] [CrossRef]

- Williamson, T.; Juenger, M.C.G. The role of activating solution concentration on alkali–silica reaction in alkali-activated fly ash concrete. Cem. Concr. Res. 2016, 83, 124–130. [Google Scholar] [CrossRef] [Green Version]

- Hilton, B.; Bawden, K.; Winnebeck, K.; Chandrasiri, C.; Ariyachandra, E.; Peethamparan, S. The functional and environmental performance of mixed cathode ray tubes and recycled glass as partial replacement for cement in concrete. Resour. Conserv. Recycl. 2019, 151, 104451. [Google Scholar] [CrossRef]

- Si, R.; Dai, Q.; Guo, S.; Wang, J. Mechanical property, nanopore structure and drying shrinkage of metakaolin-based geopolymer with waste glass powder. J. Clean. Prod. 2020, 242, 118502. [Google Scholar] [CrossRef]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Paul, S.C.; Šavija, B.; Babafemi, A.J. A comprehensive review on mechanical and durability properties of cement-based materials containing waste recycled glass. J. Clean. Prod. 2018, 198, 891–906. [Google Scholar] [CrossRef]

- Federico, L.M.; Chidiac, S.E. Waste glass as a supplementary cementitious material in concrete—Critical review of treatment methods. Cem. Concr. Compos. 2009, 31, 606–610. [Google Scholar] [CrossRef]

- Kazmi, D.; Williams, D.J.; Serati, M. Waste glass in civil engineering applications—A review. Int. J. Appl. Ceram. Technol. 2020, 17, 529–554. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.-W.; Nicolaides, D.; Luhar, I.; Panias, D.; Sakkas, K. Valorisation of glass waste for development of Geopolymer composites—Mechanical properties and rheological characteristics: A review. Constr. Build. Mater. 2019, 220, 547–564. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Use of recycled CRT funnel glass as fine aggregate in dry-mixed concrete paving blocks. J. Clean. Prod. 2014, 68, 209–215. [Google Scholar] [CrossRef]

- Arabi, N.; Meftah, H.; Amara, H.; Kebaïli, O.; Berredjem, L. Valorization of recycled materials in development of self-compacting concrete: Mixing recycled concrete aggregates—Windshield waste glass aggregates. Constr. Build. Mater. 2019, 209, 364–376. [Google Scholar] [CrossRef]

- Liu, G.; Florea, M.V.A.; Brouwers, H.J.H. Characterization and performance of high volume recycled waste glass and ground granulated blast furnace slag or fly ash blended mortars. J. Clean. Prod. 2019, 235, 461–472. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and pozzolanic reactivity of glass powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- ASTM International. ACTM C 618-03 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2003; pp. 3–6. [Google Scholar]

- Ismail, Z.Z.; AL-Hashmi, E.A. Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef] [PubMed]

- Karamberi, A.; Moutsatsou, A. Participation of coloured glass cullet in cementitious materials. Cem. Concr. Compos. 2005, 27, 319–327. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of fine glass as ASR inhibitor in glass aggregate mortars. Constr. Build. Mater. 2010, 24, 1309–1312. [Google Scholar] [CrossRef]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Properties of high volume glass powder concrete. Cem. Concr. Compos. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- He, Z.; Zhan, P.; Du, S.; Liu, B.; Yuan, W. Creep behavior of concrete containing glass powder. Compos. Part B Eng. 2019, 166, 13–20. [Google Scholar] [CrossRef]

- Islam, G.M.S.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Mirzahosseini, M.; Riding, K.A. Effect of curing temperature and glass type on the pozzolanic reactivity of glass powder. Cem. Concr. Res. 2014, 58, 103–111. [Google Scholar] [CrossRef] [Green Version]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. Sustainable one-part geopolymer foams with glass fines versus sand as aggregates. Constr. Build. Mater. 2018, 171, 223–231. [Google Scholar] [CrossRef]

- Toniolo, N.; Taveri, G.; Hurle, K.; Roether, J.A.; Ercole, P.; Dlouhý, I.; Boccaccini, A.R. Fly-ash-based geopolymers: How the addition of recycled glass or red mud waste influences the structural and mechanical properties. J. Ceram. Sci. Technol. 2017, 8, 411–419. [Google Scholar]

- El-Naggar, M.R.; El-Dessouky, M.I. Re-use of waste glass in improving properties of metakaolin-based geopolymers: Mechanical and microstructure examinations. Constr. Build. Mater. 2017, 132, 543–555. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Seabra, M.P.; Labrincha, J.A. Waste glass from end-of-life fluorescent lamps as raw material in geopolymers. Waste Manag. 2016, 52, 245–255. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Menchaca-Ballinas, L.E.; Escalante-Garcia, J.I. Low CO2 emission cements of waste glass activated by CaO and NaOH. J. Clean. Prod. 2019, 239, 117992. [Google Scholar] [CrossRef]

- Cyr, M.; Idir, R.; Poinot, T. Properties of inorganic polymer (geopolymer) mortars made of glass cullet. J. Mater. Sci. 2012, 47, 2782–2797. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass as a precursor in alkaline activation: Chemical process and hydration products. Constr. Build. Mater. 2017, 139, 342–354. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N. An overview on the reuse of waste glasses in alkali-activated materials. Resour. Conserv. Recycl. 2019, 144, 297–309. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A. High strength geopolymer binder based on waste-glass powder. Adv. Powder Technol. 2017, 28, 215–222. [Google Scholar] [CrossRef]

- Zhang, S.; Keulen, A.; Arbi, K.; Ye, G. Waste glass as partial mineral precursor in alkali-activated slag/fly ash system. Cem. Concr. Res. 2017, 102, 29–40. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.Y.; Huang, W.L. A study on the properties of fresh self-consolidating glass concrete (SCGC). Constr. Build. Mater. 2010, 24, 619–624. [Google Scholar] [CrossRef]

- Lu, J.; Duan, Z.; Poon, C.S. Combined use of waste glass powder and cullet in architectural mortar. Cem. Concr. Compos. 2017, 82, 34–44. [Google Scholar] [CrossRef]

- Lu, J.-X.; Zheng, H.; Yang, S.; He, P.; Poon, C.S. Co-utilization of waste glass cullet and glass powder in precast concrete products. Constr. Build. Mater. 2019, 223, 210–220. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D.; Hajimohammadi, A. Effect of recycled glass fines on mechanical and durability properties of concrete foam in comparison with traditional cementitious fines. Cem. Concr. Compos. 2019, 99, 120–129. [Google Scholar] [CrossRef]

- Omran, A.; Tagnit-Hamou, A. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 2016, 109, 84–95. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, C.; Song, J. Effect of glass powder on chloride ion transport and alkali-aggregate reaction expansion of lightweight aggregate concrete. J. Wuhan Univ. Technol. Sci. Ed. 2009, 24, 312–317. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Hooton, R.D.; Scott, A.; Zibara, H. The effect of supplementary cementitious materials on chloride binding in hardened cement paste. Cem. Concr. Res. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Al Saffar, D.M.; Aadi, A.S.; Almeshal, I. Sulphate resistance of cement mortar contains glass powder. J. King Saud Univ. Eng. Sci. 2019, 32, 495–500. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Hosseini, S.M.; Nosouhian, F.; Ozbakkaloglu, T.; Tehrani, B.N. Durability of concrete containing recycled concrete coarse and fine aggregates and milled waste glass in magnesium sulfate environment. J. Build. Eng. 2020, 29, 101182. [Google Scholar] [CrossRef]

- Sales, R.B.C.; Sales, F.A.; Figueiredo, E.P.; dos Santos, W.J.; Mohallem, N.D.S.; Aguilar, M.T.P. Durability of Mortar Made with Fine Glass Powdered Particles. Adv. Mater. Sci. Eng. 2017, 2017, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Özkan, Ö.; Yüksel, İ. Studies on mortars containing waste bottle glass and industrial by-products. Constr. Build. Mater. 2008, 22, 1288–1298. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Tognonvi, M.T.; Tagnit-Hamou, A.; Puertas, F. Durability of Alkali-Activated Slag Concretes Prepared Using Waste Glass as Alternative Activator. ACI Mater. J. 2015, 112, 791–800. [Google Scholar] [CrossRef]

- Wang, C.-C.; Wang, H.-Y.; Chen, B.-T.; Peng, Y.-C. Study on the engineering properties and prediction models of an alkali-activated mortar material containing recycled waste glass. Constr. Build. Mater. 2017, 132, 130–141. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A.; Dong, P.; Bassim, N. Acid attack on geopolymer cement mortar based on waste-glass powder and calcium aluminate cement at mild concentration. Constr. Build. Mater. 2018, 193, 363–372. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Fly ash-based geopolymers: The relationship between composition, pore structure and efflorescence. Cem. Concr. Res. 2014, 64, 30–41. [Google Scholar] [CrossRef]

- Bobirică, C.; Shim, J.-H.; Park, J.-Y. Leaching behavior of fly ash-waste glass and fly ash-slag-waste glass-based geopolymers. Ceram. Int. 2018, 44, 5886–5893. [Google Scholar] [CrossRef]

- Wang, W.-C.; Chen, B.-T.; Wang, H.-Y.; Chou, H.-C. A study of the engineering properties of alkali-activated waste glass material (AAWGM). Constr. Build. Mater. 2016, 112, 962–969. [Google Scholar] [CrossRef]

- Abendeh, R.; Baker, M.B.; Salem, Z.A.; Ahmad, H. The Feasibility of Using Milled Glass Wastes in Concrete to Resist Freezing-Thawing Action. Int. J. Civ. Environ. Eng. 2015, 9, 1026–1029. [Google Scholar]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.H.M.; Aslani, F.; Alabduljabbar, H. Properties and utilizations of waste tire rubber in concrete: A review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Carsana, M.; Frassoni, M.; Bertolini, L. Comparison of ground waste glass with other supplementary cementitious materials. Cem. Concr. Compos. 2014, 45, 39–45. [Google Scholar] [CrossRef]

- Schwarz, N.; DuBois, M.; Neithalath, N. Electrical conductivity based characterization of plain and coarse glass powder modified cement pastes. Cem. Concr. Compos. 2007, 29, 656–666. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Li, X.; Tan, J.; Li, J. Electrical resistivity of fly ash and metakaolin based geopolymers. Constr. Build. Mater. 2020, 234, 117868. [Google Scholar] [CrossRef]

- Tan, K.H.; Du, H. Use of waste glass as sand in mortar: Part I—Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Cassar, J.; Camilleri, J. Utilisation of imploded glass in structural concrete. Constr. Build. Mater. 2012, 29, 299–307. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–113. [Google Scholar] [CrossRef]

- Kim, K.-H.; Jeon, S.-E.; Kim, J.-K.; Yang, S. An experimental study on thermal conductivity of concrete. Cem. Concr. Res. 2003, 33, 363–371. [Google Scholar] [CrossRef]

- Poutos, K.H.; Alani, A.M.; Walden, P.J.; Sangha, C.M. Relative temperature changes within concrete made with recycled glass aggregate. Constr. Build. Mater. 2008, 22, 557–565. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Dalvand, A.; Mastali, M.; Luukkonen, T.; Illikainen, M. Effects of waste ground glass and lime on the crystallinity and strength of geopolymers. Mag. Concr. Res. 2019, 71, 1218–1231. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Kamseu, E.; Leonelli, C. Thermal Behavior of Metakaolin-Based Geopolymer Cements Using Sodium Waterglass from Rice Husk Ash and Waste Glass as Alternative Activators. Waste Biomass Valoriz. 2017, 8, 573–584. [Google Scholar] [CrossRef]

- Temuujin, J.; Minjigmaa, A.; Rickard, W.; van Riessen, A. Thermal properties of spray-coated geopolymer-type compositions. J. Therm. Anal. Calorim. 2012, 107, 287–292. [Google Scholar] [CrossRef]

- Bai, C.; Li, H.; Bernardo, E.; Colombo, P. Waste-to-resource preparation of glass-containing foams from geopolymers. Ceram. Int. 2019, 45, 7196–7202. [Google Scholar] [CrossRef]

- Pan, Z.; Tao, Z.; Murphy, T.; Wuhrer, R. High temperature performance of mortars containing fine glass powders. J. Clean. Prod. 2017, 162, 16–26. [Google Scholar] [CrossRef]

- Fernandes, H.R.; Tulyaganov, D.U.; Ferreira, J.M.F. Preparation and characterization of foams from sheet glass and fly ash using carbonates as foaming agents. Ceram. Int. 2009, 35, 229–235. [Google Scholar] [CrossRef]

- Owoeye, S.S.; Matthew, G.O.; Ovienmhanda, F.O.; Tunmilayo, S.O. Preparation and characterization of foam glass from waste container glasses and water glass for application in thermal insulations. Ceram. Int. 2020, 46, 11770–11775. [Google Scholar] [CrossRef]

- Patel, D.; Shrivastava, R.; Tiwari, R.P.; Yadav, R.K. Properties of cement mortar in substitution with waste fine glass powder and environmental impact study. J. Build. Eng. 2020, 27, 100940. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass waste as supplementary cementing materials: The effects of glass chemical composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, W.; Zhou, W.; Byars, E.A. Expansion behaviour of glass aggregates in different testing for alkali-silica reactivity. Mater. Struct. 2009, 42, 485–494. [Google Scholar] [CrossRef]

- Lee, G.; Ling, T.C.; Wong, Y.L.; Poon, C.S. Effects of crushed glass cullet sizes, casting methods and pozzolanic materials on ASR of concrete blocks. Constr. Build. Mater. 2011, 25, 2611–2618. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Gnappi, G.; Moriconi, G.; Montenero, A. Reuse of ground waste glass as aggregate for mortars. Waste Manag. 2005, 25, 197–201. [Google Scholar] [CrossRef]

- Tamanna, N.; Tuladhar, R.; Sivakugan, N. Performance of recycled waste glass sand as partial replacement of sand in concrete. Constr. Build. Mater. 2020, 239, 117804. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Utilizing Waste Recycled Glass as Sand/Cement Replacement in Concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Kawamura, M.; Fuwa, H. Effects of lithium salts on ASR gel composition and expansion of mortars. Cem. Concr. Res. 2003, 33, 913–919. [Google Scholar] [CrossRef]

- Lee, J.-C.; Jang, B.-K.; Shon, C.-S.; Kim, J.-H.; Chung, C.-W. Potential use of borosilicate glass to make neutron shielding mortar: Enhancement of thermal neutron shielding and strength development and mitigation of alkali-silica reaction. J. Clean. Prod. 2019, 210, 638–645. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Effect of particle size on alkali–silica reaction in recycled glass mortars. Constr. Build. Mater. 2014, 66, 275–285. [Google Scholar] [CrossRef]

- Mehta, A.; Ashish, D.K. Silica fume and waste glass in cement concrete production: A review. J. Build. Eng. 2020, 29, 100888. [Google Scholar] [CrossRef]

- Olofinnade, O.M.; Ede, A.N.; Ndambuki, J.M.; Ngene, B.U.; Akinwumi, I.I.; Ofuyatan, O. Strength and microstructure of eco-concrete produced using waste glass as partial and complete replacement for sand. Cogent Eng. 2018, 5, 1483860. [Google Scholar] [CrossRef]

- Lu, J.-X.; Poon, C.S. Recycling of waste glass in construction materials. In New Trends in Eco-Efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 153–167. [Google Scholar]

| WG Type | Replacement Level | Durability Performance Compared with Control Specimen | Remarks | Ref. |

|---|---|---|---|---|

| Soda-lime glass bottles (<4.75 mm) | 0–100% fine aggregates |

| Micro-cracks in glass sand and weak bond with the cement paste resulted in low mechanical performance. | [79] |

| Mixed types (100–600 µm) | 0–50% cement |

| Fine WG powder reduced the ASR expansion risk and improved durability. | [80] |

| Soda-lime glass bottles | 0–60% cement |

| Dense interfacial transition zone (ITZ) formed due to fine WG powder | [41] |

| Glass bottle (fineness of 400 and 600 m2/kg) | 30% cement |

| Durability performance increases by increasing the fineness of WG powder. | [76] |

| WG (<14 mm for coarse aggregates and <4.75 mm for fine aggregates) | 10–30% fine aggregates and 5–15% 10 mm coarse aggregates |

| High content of WG aggregates may cause segregation in concrete. | [81] |

| Challenges | Techniques for Optimization | Ref. |

|---|---|---|

| ASR expansion in WG-based concrete |

| [23,29,40,60,99,100] |

| Author’s suggestion | |

| Low adhesion between WG and cement paste |

| Author’s suggestion |

| Suitable activator and compatible precursor for WG |

| [51,52,53,54,55] |

| Author’s suggestion |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddika, A.; Hajimohammadi, A.; Mamun, M.A.A.; Alyousef, R.; Ferdous, W. Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges. Polymers 2021, 13, 2071. https://doi.org/10.3390/polym13132071

Siddika A, Hajimohammadi A, Mamun MAA, Alyousef R, Ferdous W. Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges. Polymers. 2021; 13(13):2071. https://doi.org/10.3390/polym13132071

Chicago/Turabian StyleSiddika, Ayesha, Ailar Hajimohammadi, Md. Abdullah Al Mamun, Rayed Alyousef, and Wahid Ferdous. 2021. "Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges" Polymers 13, no. 13: 2071. https://doi.org/10.3390/polym13132071

APA StyleSiddika, A., Hajimohammadi, A., Mamun, M. A. A., Alyousef, R., & Ferdous, W. (2021). Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges. Polymers, 13(13), 2071. https://doi.org/10.3390/polym13132071