Development and Characterization of Electrospun Fiber-Based Poly(ethylene-co-vinyl Alcohol) Films of Application Interest as High-Gas-Barrier Interlayers in Food Packaging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Solutions

2.3. Characterization of the Solutions

2.4. Electrospinning Process

2.5. Film Preparation

2.6. Characterization of the Films

2.6.1. Electron Microscopy

2.6.2. Transparency

2.6.3. Color

2.6.4. Thermal Analysis

2.6.5. ATR-FTIR Spectroscopy

2.6.6. Mechanical Tests

2.6.7. Permeability Tests

2.7. Statistical Analysis

3. Results and Discussion

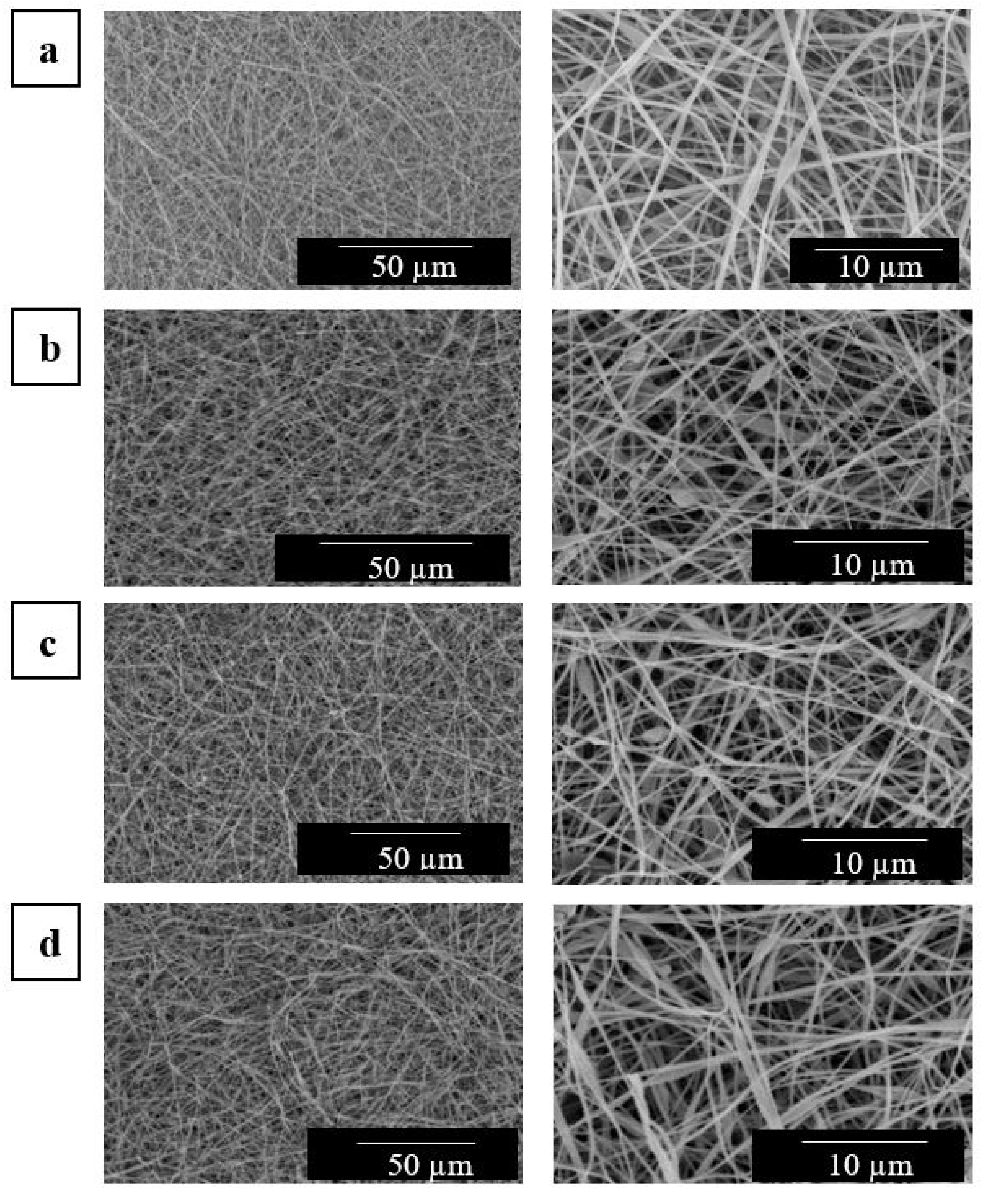

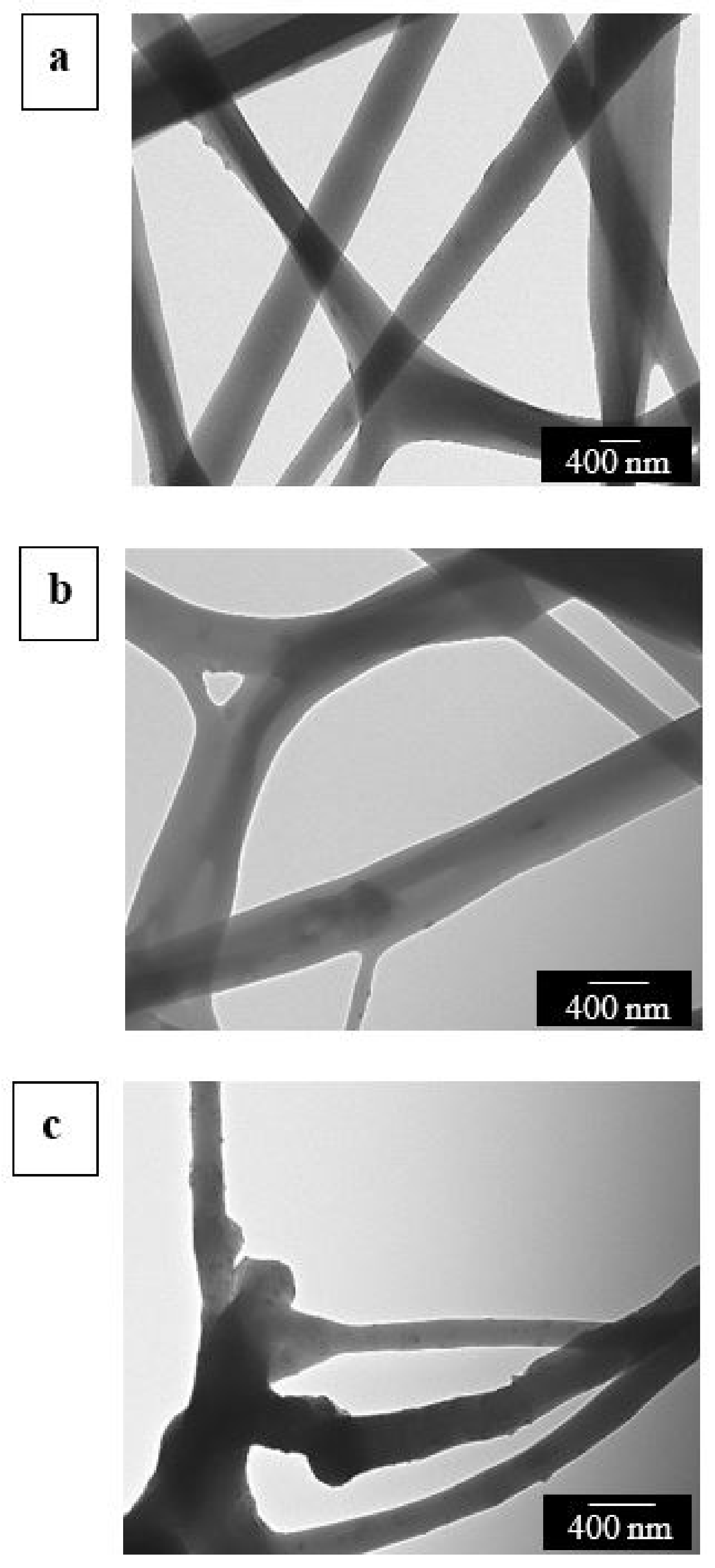

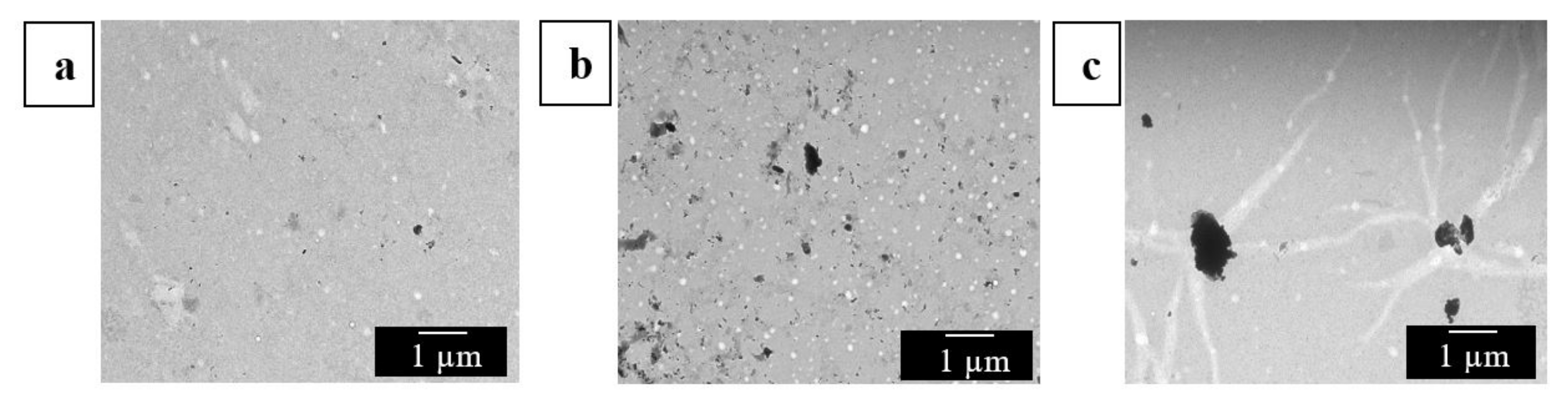

3.1. Solution Properties and Morphology

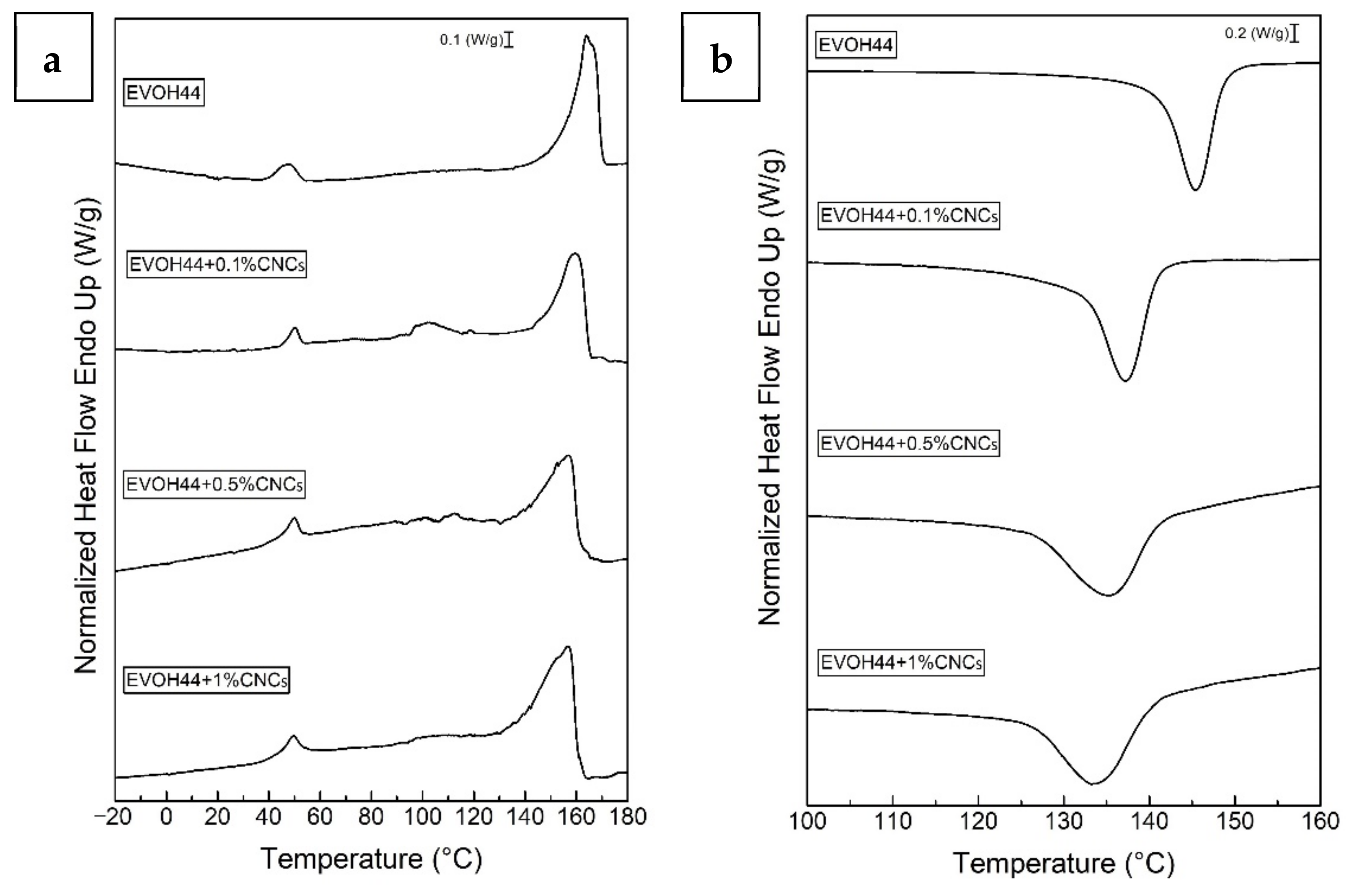

3.2. Thermal Properties of the Electrospun Fibers

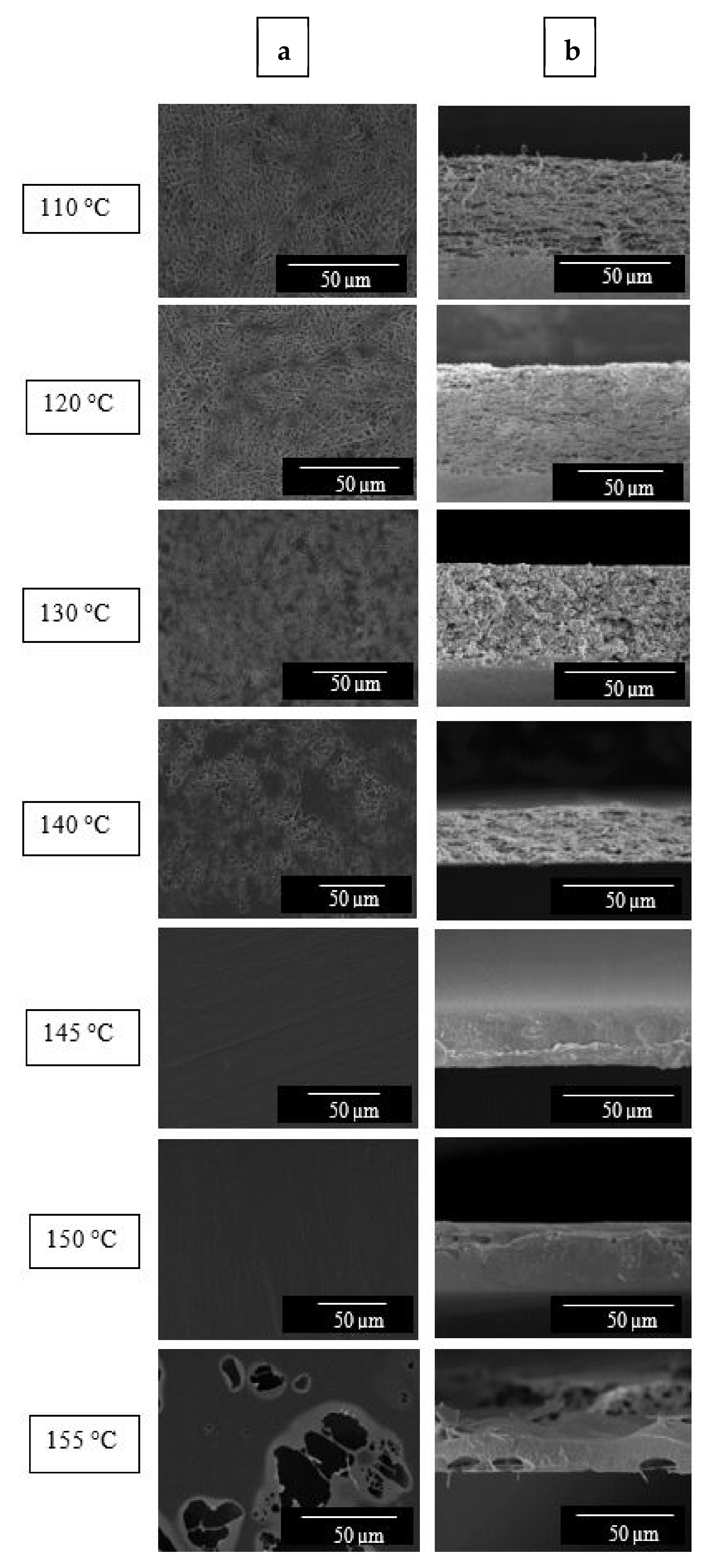

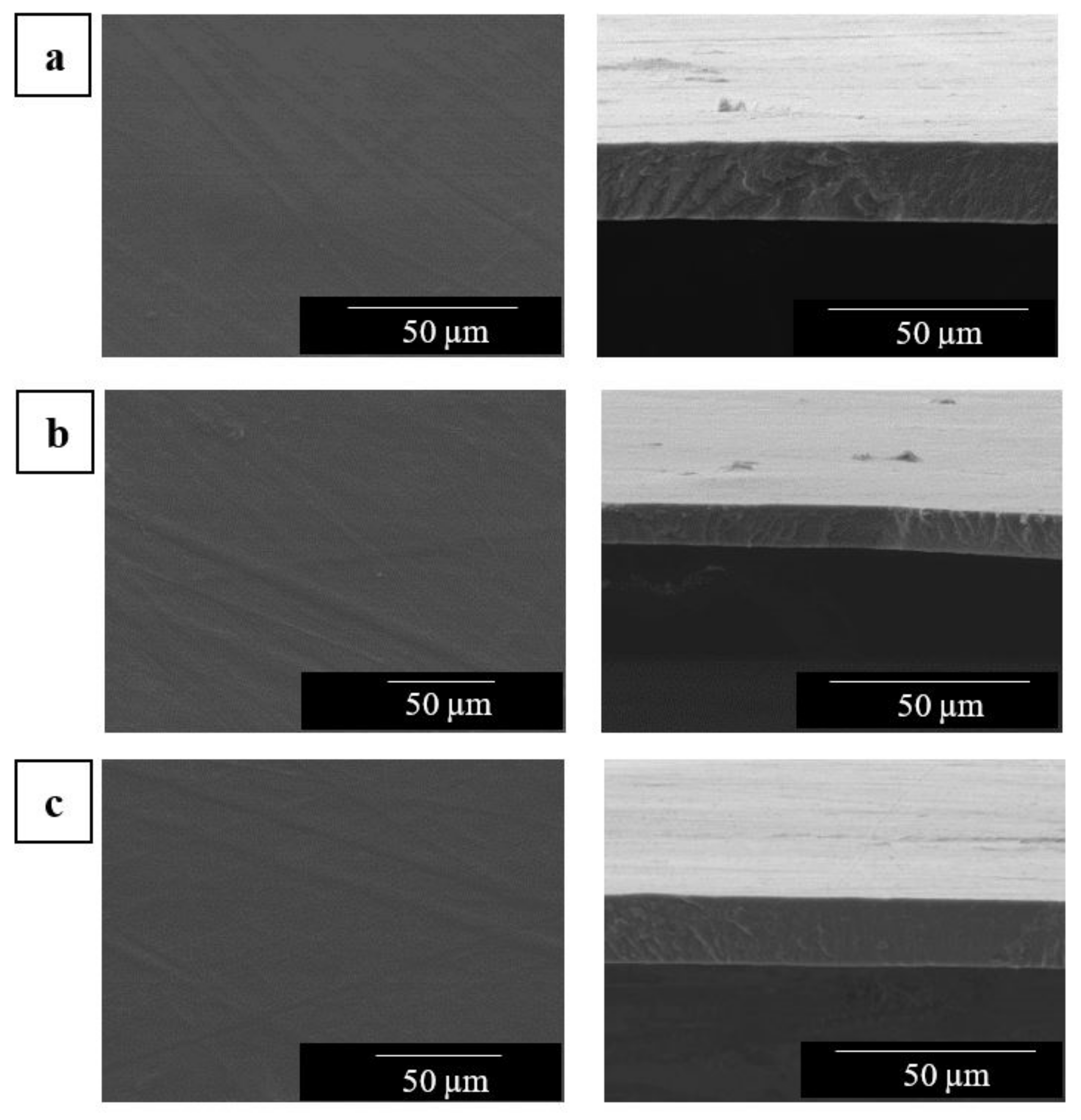

3.3. Film Forming by Interfiber Coalescence Induced by Annealing

3.4. Variable-Temperature FTIR Spectroscopy

3.5. Optical Properties of the Annealed Electrospun Films

3.6. Thermal Stability of the Annealed Electrospun Films

3.7. ATR-FTIR Spectroscopy of the Annealed Electrospun Films

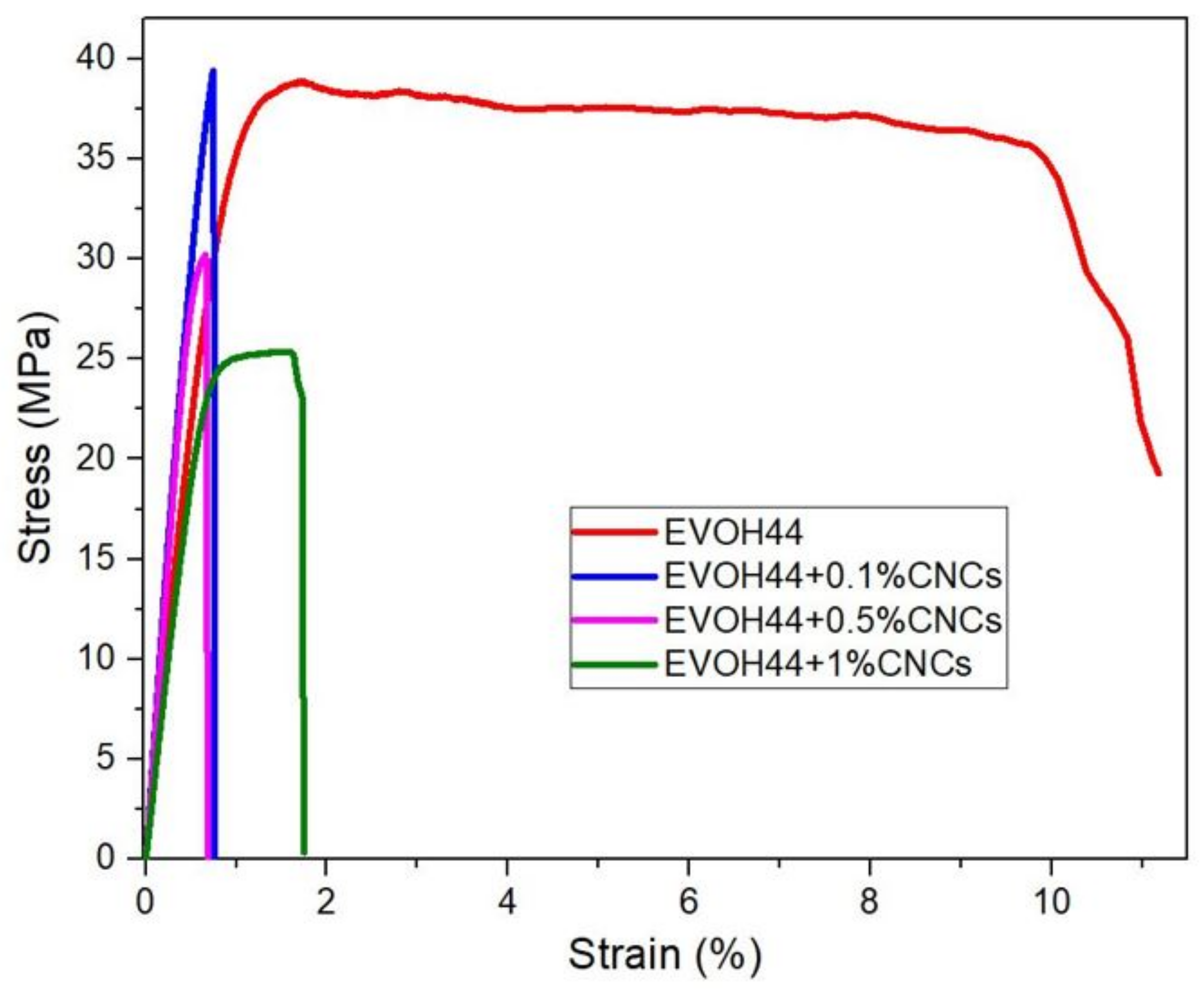

3.8. Mechanical Properties of the Annealed Electrospun Films

3.9. Barrier Properties of the Annealed Electrospun Films

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Torres-Giner, S.; Gil, L.; Pascual-Ramírez, L.; Garde-Belza, J.A. Packaging: Food Waste Reduction. In Encyclopedia of Polymer Applications; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Sidwell, J.A. Food Contact Polymeric Materials; Rapra Technology: Akron, OH, USA, 1992. [Google Scholar]

- Marie, E.; Chevalier, Y.; Issartel, N.; Eydoux, F.; Germanaud, L.; Flores, P. The Controlled Solvolysis of Ethylene−Vinyl Acetate Copolymers. Macromolecules 2001, 34, 5838–5847. [Google Scholar] [CrossRef]

- Mokwena, K.K.; Tang, J.; Dunne, C.P.; Yang, T.C.S.; Chow, E. Oxygen transmission of multilayer EVOH films after microwave sterilization. J. Food Eng. 2009, 92, 291–296. [Google Scholar] [CrossRef]

- Katayama, T. New development of ethylene-vinyl alcohol copolymer fiber. Kinoshi Kenkyu Kaishi Ann. High Perform. Pap. Soc. Jpn. 2005, 44, 43–48. [Google Scholar]

- Yokoyama, Y.; Kimata, H.; Mitarai, S.; Hirano, S.; Shirakawa, T. Ethylene vinyl alcohol (EVOH) fiber compared to cotton underwear in the treatment of childhood atopic dermatitis: A double-blind randomized study. Indian Pediatr. 2009, 46, 611–614. [Google Scholar]

- Luzi, F.; Torre, L.; Puglia, D. Antioxidant Packaging Films Based on Ethylene Vinyl Alcohol Copolymer (EVOH) and Caffeic Acid. Molecules 2020, 25, 3953. [Google Scholar] [CrossRef]

- Gavara, R.; Catalá, R.; López Carballo, G.; Cerisuelo, J.P.; Dominguez, I.; Muriel-Galet, V.; Hernandez-Muñoz, P. Use of EVOH for Food Packaging Applications. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Arboleda, C.E.; Mejía, A.I.G.; López, B.L.O. Poly (vinylalcohol-co-ethylene) biodegradation on semi solid fermentation by Phanerochaete chrysosporium. Acta Farm. Bonaer. 2004, 23, 123–128. [Google Scholar]

- Mejía, A.I.G.; López, B.L.O.; Sierra, L. Biodegradation of poly(vinylalcohol-co-ethylene) with the fungus phanerochaete chrysosporium. Mater. Res. Innov. 2001, 4, 148–154. [Google Scholar] [CrossRef]

- Erlandsson, B.; Karlsson, S.; Albertsson, A. Biodegradation of C-14 labeled poly (ethylene-co-vinyl alcohol). In Abstracts of Papers of the American Chemical Society; American Chemical Society: Washington, DC, USA, 1997. [Google Scholar]

- Tomita, K.; Kojoh, K.; Suzuki, A. Isolation of thermophiles assimilating poly(ethylene-co-vinyl alcohol). J. Ferment. Bioeng. 1997, 84, 400–402. [Google Scholar] [CrossRef]

- Cerrada, M.L.; Pérez, E.; Pereña, J.M.; Benavente, R. Wide-Angle X-ray Diffraction Study of the Phase Behavior of Vinyl Alcohol−Ethylene Copolymers. Macromolecules 1998, 31, 2559–2564. [Google Scholar] [CrossRef]

- Mokwena, K.K.; Tang, J. Ethylene Vinyl Alcohol: A Review of Barrier Properties for Packaging Shelf Stable Foods. Crit. Rev. Food Sci. Nutr. 2012, 52, 640–650. [Google Scholar] [CrossRef]

- Ito, K.; Saito, Y.; Yamamoto, T.; Ujihira, Y.; Nomura, K. Correlation Study between Oxygen Permeability and Free Volume of Ethylene−Vinyl Alcohol Copolymer through Positronium Lifetime Measurement. Macromolecules 2001, 34, 6153–6155. [Google Scholar] [CrossRef]

- Tajeddin, B. Cellulose-Based Polymers for Packaging Applications. In Lignocellulosic Polymer Composites; Scrivener Publishing LLC.: Beverly, MA, USA, 2014; pp. 477–498. [Google Scholar]

- De Souza Lima, M.M.; Borsali, R. Rodlike Cellulose Microcrystals: Structure, Properties, and Applications. Macromol. Rapid Commun. 2004, 25, 771–787. [Google Scholar] [CrossRef]

- García, A.; Gandini, A.; Labidi, J.; Belgacem, N.; Bras, J. Industrial and crop wastes: A new source for nanocellulose biorefinery. Ind. Crop. Prod. 2016, 93, 26–38. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Henriksson, M.; Henriksson, G.; Berglund, L.A.; Lindström, T. An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur. Polym. J. 2007, 43, 3434–3441. [Google Scholar] [CrossRef]

- Fortunati, E.; Armentano, I.; Zhou, Q.; Iannoni, A.; Saino, E.; Visai, L.; Berglund, L.A.; Kenny, J.M. Multifunctional bionanocomposite films of poly(lactic acid), cellulose nanocrystals and silver nanoparticles. Carbohydr. Polym. 2012, 87, 1596–1605. [Google Scholar] [CrossRef]

- Gatenholm, P.; Klemm, D. Bacterial nanocellulose as a renewable material for biomedical applications. MRS Bull. 2010, 35, 208–213. [Google Scholar] [CrossRef]

- Mariano, M.; El Kissi, N.; Dufresne, A. Cellulose nanocrystals and related nanocomposites: Review of some properties and challenges. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 791–806. [Google Scholar] [CrossRef]

- Ashori, A.; Jonoobi, M.; Ayrilmis, N.; Shahreki, A.; Fashapoyeh, M.A. Preparation and characterization of polyhydroxybutyrate-co-valerate (PHBV) as green composites using nano reinforcements. Int. J. Biol. Macromol. 2019, 136, 1119–1124. [Google Scholar] [CrossRef]

- Voronova, M.I.; Surov, O.V.; Guseinov, S.S.; Barannikov, V.P.; Zakharov, A.G. Thermal stability of polyvinyl alcohol/nanocrystalline cellulose composites. Carbohydr. Polym. 2015, 130, 440–447. [Google Scholar] [CrossRef]

- Perumal, A.B.; Sellamuthu, P.S.; Nambiar, R.B.; Sadiku, E.R. Development of polyvinyl alcohol/chitosan bio-nanocomposite films reinforced with cellulose nanocrystals isolated from rice straw. Appl. Surf. Sci. 2018, 449, 591–602. [Google Scholar] [CrossRef]

- Lei, W.; Fang, C.; Zhou, X.; Yin, Q.; Pan, S.; Yang, R.; Liu, D.; Ouyang, Y. Cellulose nanocrystals obtained from office waste paper and their potential application in PET packing materials. Carbohydr. Polym. 2018, 181, 376–385. [Google Scholar] [CrossRef] [PubMed]

- Pal, N.; Banerjee, S.; Roy, P.; Pal, K. Reduced graphene oxide and PEG-grafted TEMPO-oxidized cellulose nanocrystal reinforced poly-lactic acid nanocomposite film for biomedical application. Mater. Sci. Eng. C 2019, 104, 109956. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Li, H.; Fei, X.; Peng, L. Carboxymethyl cellulose/cellulose nanocrystals immobilized silver nanoparticles as an effective coating to improve barrier and antibacterial properties of paper for food packaging applications. Carbohydr. Polym. 2021, 252, 117156. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zhao, Y.; Mussana, H.; Tessema, M.; Liu, L. Characteristics of cotton fabric modified with chitosan (CS)/cellulose nanocrystal (CNC) nanocomposites. Mater. Lett. 2018, 211, 300–303. [Google Scholar] [CrossRef]

- Yu, X.; Tong, S.; Ge, M.; Wu, L.; Zuo, J.; Cao, C.; Song, W. Adsorption of heavy metal ions from aqueous solution by carboxylated cellulose nanocrystals. J. Environ. Sci. 2013, 25, 933–943. [Google Scholar] [CrossRef]

- Cherpinski, A.; Biswas, A.; Lagaron, J.M.; Dufresne, A.; Kim, S.; Buttrum, M.; Espinosa, E.; Cheng, H.N. Preparation and evaluation of oxygen scavenging nanocomposite films incorporating cellulose nanocrystals and Pd nanoparticles in poly(ethylene-co-vinyl alcohol). Cellulose 2019, 26, 7237–7251. [Google Scholar] [CrossRef]

- Yadav, M.; Liu, Y.-K.; Chiu, F.-C. Fabrication of Cellulose Nanocrystal/Silver/Alginate Bionanocomposite Films with Enhanced Mechanical and Barrier Properties for Food Packaging Application. Nanomaterials 2019, 9, 1523. [Google Scholar] [CrossRef] [Green Version]

- Miao, C.; Hamad, W.Y. Cellulose reinforced polymer composites and nanocomposites: A critical review. Cellulose 2013, 20, 2221–2262. [Google Scholar] [CrossRef]

- Venkatraman, P.; Gohn, A.M.; Rhoades, A.M.; Foster, E.J. Developing high performance PA 11/cellulose nanocomposites for industrial-scale melt processing. Compos. Part B Eng. 2019, 174, 106988. [Google Scholar] [CrossRef]

- Favier, V.; Canova, G.R.; Shrivastava, S.C.; Cavaillé, J.Y. Mechanical percolation in cellulose whisker nanocomposites. Polym. Eng. Sci. 1997, 37, 1732–1739. [Google Scholar] [CrossRef]

- Oksman, K.; Aitomäki, Y.; Mathew, A.P.; Siqueira, G.; Zhou, Q.; Butylina, S.; Tanpichai, S.; Zhou, X.; Hooshmand, S. Review of the recent developments in cellulose nanocomposite processing. Compos. Part A Appl. Sci. Manuf. 2016, 83, 2–18. [Google Scholar] [CrossRef] [Green Version]

- Khoshkava, V.; Kamal, M.R. Effect of Cellulose Nanocrystals (CNC) Particle Morphology on Dispersion and Rheological and Mechanical Properties of Polypropylene/CNC Nanocomposites. ACS Appl. Mater. Interfaces 2014, 6, 8146–8157. [Google Scholar] [CrossRef]

- Cao, Y.; Zavattieri, P.; Youngblood, J.; Moon, R.; Weiss, J. The relationship between cellulose nanocrystal dispersion and strength. Constr. Build. Mater. 2016, 119, 71–79. [Google Scholar] [CrossRef] [Green Version]

- Gupta, A.; Simmons, W.; Schueneman, G.T.; Hylton, D.; Mintz, E.A. Rheological and Thermo-Mechanical Properties of Poly(lactic acid)/Lignin-Coated Cellulose Nanocrystal Composites. ACS Sustain. Chem. Eng. 2017, 5, 1711–1720. [Google Scholar] [CrossRef]

- González, K.; Iturriaga, L.; González, A.; Eceiza, A.; Gabilondo, N. Improving mechanical and barrier properties of thermoplastic starch and polysaccharide nanocrystals nanocomposites. Eur. Polym. J. 2020, 123, 109415. [Google Scholar] [CrossRef]

- Arias, A.; Heuzey, M.-C.; Huneault, M.A.; Ausias, G.; Bendahou, A. Enhanced dispersion of cellulose nanocrystals in melt-processed polylactide-based nanocomposites. Cellulose 2015, 22, 483–498. [Google Scholar] [CrossRef]

- Zhang, W.; He, X.; Li, C.; Zhang, X.; Lu, C.; Zhang, X.; Deng, Y. High performance poly (vinyl alcohol)/cellulose nanocrystals nanocomposites manufactured by injection molding. Cellulose 2014, 21, 485–494. [Google Scholar] [CrossRef]

- Oksman, K.; Mathew, A.P.; Bondeson, D.; Kvien, I. Manufacturing process of cellulose whiskers/polylactic acid nanocomposites. Compos. Sci. Technol. 2006, 66, 2776–2784. [Google Scholar] [CrossRef]

- Sapkota, J.; Kumar, S.; Weder, C.; Foster, E.J. Influence of Processing Conditions on Properties of Poly (Vinyl acetate)/Cellulose Nanocrystal Nanocomposites. Macromol. Mater. Eng. 2015, 300, 562–571. [Google Scholar] [CrossRef]

- Roohani, M.; Habibi, Y.; Belgacem, N.M.; Ebrahim, G.; Karimi, A.N.; Dufresne, A. Cellulose whiskers reinforced polyvinyl alcohol copolymers nanocomposites. Eur. Polym. J. 2008, 44, 2489–2498. [Google Scholar] [CrossRef]

- Li, C.; Sun, C.; Wang, C.; Tan, H.; Xie, Y.; Zhang, Y. Cellulose nanocrystal reinforced poly(lactic acid) nanocomposites prepared by a solution precipitation approach. Cellulose 2020, 27, 7489–7502. [Google Scholar] [CrossRef]

- Sanders, J.E.; Han, Y.; Rushing, T.S.; Gardner, D.J. Electrospinning of Cellulose Nanocrystal-Filled Poly (Vinyl Alcohol) Solutions: Material Property Assessment. Nanomaterials 2019, 9, 805. [Google Scholar] [CrossRef] [Green Version]

- Fabra, M.J.; López-Rubio, A.; Ambrosio-Martín, J.; Lagaron, J.M. Improving the barrier properties of thermoplastic corn starch-based films containing bacterial cellulose nanowhiskers by means of PHA electrospun coatings of interest in food packaging. Food Hydrocoll. 2016, 61, 261–268. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Sanz, M.; Lopez-Rubio, A.; Villano, M.; Oliveira, C.S.S.; Majone, M.; Reis, M.; Lagarón, J.M. Production of bacterial nanobiocomposites of polyhydroxyalkanoates derived from waste and bacterial nanocellulose by the electrospinning enabling melt compounding method. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; Lopez-Rubio, A.; Lagaron, J.M. Dispersing Bacterial Cellulose Nanowhiskers in Polylactides via Electrohydrodynamic Processing. J. Polym. Environ. 2014, 22, 27–40. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; Olsson, R.T.; Lopez-Rubio, A.; Lagaron, J.M. Development of bacterial cellulose nanowhiskers reinforced EVOH composites by electrospinning. J. Appl. Polym. Sci. 2012, 124, 1398–1408. [Google Scholar] [CrossRef]

- Orr, M.P.; Shofner, M.L. Processing strategies for cellulose nanocrystal/polyethylene-co-vinyl alcohol composites. Polymer 2017, 126, 211–223. [Google Scholar] [CrossRef]

- Mehrasa, M.; Asadollahi, M.A.; Nasri-Nasrabadi, B.; Ghaedi, K.; Salehi, H.; Dolatshahi-Pirouz, A.; Arpanaei, A. Incorporation of mesoporous silica nanoparticles into random electrospun PLGA and PLGA/gelatin nanofibrous scaffolds enhances mechanical and cell proliferation properties. Mater. Sci. Eng. C 2016, 66, 25–32. [Google Scholar] [CrossRef]

- Zhang, D.; Karki, A.B.; Rutman, D.; Young, D.P.; Wang, A.; Cocke, D.; Ho, T.H.; Guo, Z. Electrospun polyacrylonitrile nanocomposite fibers reinforced with Fe3O4 nanoparticles: Fabrication and property analysis. Polymer 2009, 50, 4189–4198. [Google Scholar] [CrossRef]

- Melendez-Rodriguez, B.; Castro-Mayorga, J.L.; Reis, M.A.M.; Sammon, C.; Cabedo, L.; Torres-Giner, S.; Lagaron, J.M. Preparation and Characterization of Electrospun Food Biopackaging Films of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Derived From Fruit Pulp Biowaste. Front. Sustain. Food Syst. 2018, 2, 38. [Google Scholar] [CrossRef]

- Melendez-Rodriguez, B.; Torres-Giner, S.; Lorini, L.; Valentino, F.; Sammon, C.; Cabedo, L.; Lagaron, J.M. Valorization of Municipal Biowaste into Electrospun Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Biopapers for Food Packaging Applications. ACS Appl. Bio Mater. 2020, 3, 6110–6123. [Google Scholar] [CrossRef]

- Echegoyen, Y.; Fabra, M.J.; Castro-Mayorga, J.L.; Cherpinski, A.; Lagaron, J.M. High throughput electro-hydrodynamic processing in food encapsulation and food packaging applications: Viewpoint. Trends Food Sci. Technol. 2017, 60, 71–79. [Google Scholar] [CrossRef]

- Figueroa-Lopez, K.J.; Cabedo, L.; Lagaron, J.M.; Torres-Giner, S. Development of Electrospun Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Monolayers Containing Eugenol and Their Application in Multilayer Antimicrobial Food Packaging. Front. Nutr. 2020, 7, 140. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Pérez-Masiá, R.; Lagaron, J.M. A review on electrospun polymer nanostructures as advanced bioactive platforms. Polym. Eng. Sci. 2016, 56, 500–527. [Google Scholar] [CrossRef]

- Redondo, A.; Jang, D.; Korley, L.T.J.; Gunkel, I.; Steiner, U. Electrospinning of Cellulose Nanocrystal-Reinforced Polyurethane Fibrous Mats. Polymers 2020, 12, 1021. [Google Scholar] [CrossRef]

- Pirani, S.; Abushammala, H.M.N.; Hashaikeh, R. Preparation and characterization of electrospun PLA/nanocrystalline cellulose-based composites. J. Appl. Polym. Sci. 2013, 130, 3345–3354. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; Olsson, R.T.; Lopez-Rubio, A.; Lagaron, J.M. Development of electrospun EVOH fibres reinforced with bacterial cellulose nanowhiskers. Part I: Characterization and method optimization. Cellulose 2011, 18, 335–347. [Google Scholar] [CrossRef]

- Kenawy el, R.; Layman, J.M.; Watkins, J.R.; Bowlin, G.L.; Matthews, J.A.; Simpson, D.G.; Wnek, G.E. Electrospinning of poly(ethylene-co-vinyl alcohol) fibers. Biomaterials 2003, 24, 907–913. [Google Scholar] [CrossRef]

- Yu, D.-G.; Xu, Y.; Li, Z.; Du, L.-P.; Zhao, B.-G.; Wang, X. Coaxial Electrospinning with Mixed Solvents: From Flat to Round Eudragit L100 Nanofibers for Better Colon-Targeted Sustained Drug Release Profiles. J. Nanomater. 2014, 2014, 967295. [Google Scholar] [CrossRef]

- Shiku, Y.; Hamaguchi, P.Y.; Benjakul, S.; Visessanguan, W.; Tanaka, M. Effect of surimi quality on properties of edible films based on Alaska pollack. Food Chem. 2004, 86, 493–499. [Google Scholar] [CrossRef]

- Kanatt, S.R.; Rao, M.S.; Chawla, S.P.; Sharma, A. Active chitosan–polyvinyl alcohol films with natural extracts. Food Hydrocoll. 2012, 29, 290–297. [Google Scholar] [CrossRef]

- Arfat, Y.A.; Ahmed, J.; Hiremath, N.; Auras, R.; Joseph, A. Thermo-mechanical, rheological, structural and antimicrobial properties of bionanocomposite films based on fish skin gelatin and silver-copper nanoparticles. Food Hydrocoll. 2017, 62, 191–202. [Google Scholar] [CrossRef]

- Agüero, A.; Morcillo, M.d.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef] [Green Version]

- Faisant, J.B.; Aït-Kadi, A.; Bousmina, M.; Deschenes, L. Morphology, thermomechanical and barrier properties of polypropylene-ethylene vinyl alcohol blends. Polymer 1998, 39, 533–545. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Echegoyen, Y.; Teruel-Juanes, R.; Badia, J.D.; Ribes-Greus, A.; Lagaron, J.M. Electrospun Poly(ethylene-co-vinyl alcohol)/Graphene Nanoplatelets Composites of Interest in Intelligent Food Packaging Applications. Nanomaterials 2018, 8, 745. [Google Scholar] [CrossRef] [Green Version]

- Rojas-Lema, S.; Terol, J.; Fages, E.; Balart, R.; Quiles-Carrillo, L.; Prieto, C.; Torres-Giner, S. Microencapsulation of Copper(II) Sulfate in Ionically Cross-Linked Chitosan by Spray Drying for the Development of Irreversible Moisture Indicators in Paper Packaging. Polymers 2020, 12, 2039. [Google Scholar] [CrossRef]

- Beck, S.; Bouchard, J.; Berry, R. Dispersibility in Water of Dried Nanocrystalline Cellulose. Biomacromolecules 2012, 13, 1486–1494. [Google Scholar] [CrossRef]

- Di Giorgio, L.; Martín, L.; Salgado, P.R.; Mauri, A.N. Synthesis and conservation of cellulose nanocrystals. Carbohydr. Polym. 2020, 238, 116187. [Google Scholar] [CrossRef]

- Abdallah, W.; Kamal, M.R. Influence of process variables on physical characteristics of spray freeze dried cellulose nanocrystals. Cellulose 2018, 25, 5711–5730. [Google Scholar] [CrossRef]

- Khoshkava, V.; Kamal, M.R. Effect of drying conditions on cellulose nanocrystal (CNC) agglomerate porosity and dispersibility in polymer nanocomposites. Powder Technol. 2014, 261, 288–298. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; Lopez-Rubio, A.; Lagaron, J.M. Nanocomposites of ethylene vinyl alcohol copolymer with thermally resistant cellulose nanowhiskers by melt compounding (I): Morphology and thermal properties. J. Appl. Polym. Sci. 2013, 128, 2666–2678. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Gimenez, E.; Lagaron, J.M. Characterization of the morphology and thermal properties of Zein Prolamine nanostructures obtained by electrospinning. Food Hydrocoll. 2008, 22, 601–614. [Google Scholar] [CrossRef]

- Peresin, M.S.; Habibi, Y.; Zoppe, J.O.; Pawlak, J.J.; Rojas, O.J. Nanofiber Composites of Polyvinyl Alcohol and Cellulose Nanocrystals: Manufacture and Characterization. Biomacromolecules 2010, 11, 674–681. [Google Scholar] [CrossRef]

- Rojas, O.J.; Montero, G.A.; Habibi, Y. Electrospun nanocomposites from polystyrene loaded with cellulose nanowhiskers. J. Appl. Polym. Sci. 2009, 113, 927–935. [Google Scholar] [CrossRef]

- Park, W.-I.; Kang, M.; Kim, H.-S.; Jin, H.-J. Electrospinning of Poly(ethylene oxide) with Bacterial Cellulose Whiskers. Macromol. Symp. 2007, 249–250, 289–294. [Google Scholar] [CrossRef]

- Vannini, M.; Marchese, P.; Celli, A.; Lorenzetti, C. Strategy To Modify the Crystallization Behavior of EVOH32 through Interactions with Low-Molecular-Weight Molecules. Ind. Eng. Chem. Res. 2016, 55, 3517–3524. [Google Scholar] [CrossRef]

- López-de-Dicastillo, C.; Gallur, M.; Catalá, R.; Gavara, R.; Hernandez-Muñoz, P. Immobilization of β-cyclodextrin in ethylene-vinyl alcohol copolymer for active food packaging applications. J. Membr. Sci. 2010, 353, 184–191. [Google Scholar] [CrossRef] [Green Version]

- Fernández, A.; Sánchez, M.D.; Ankerfors, M.; Lagaron, J.M. Effects of ionizing radiation in ethylene-vinyl alcohol copolymers and in composites containing microfibrillated cellulose. J. Appl. Polym. Sci. 2008, 109, 126–134. [Google Scholar] [CrossRef]

- Lasagabaster, A.; Abad, M.J.; Barral, L.; Ares, A. FTIR study on the nature of water sorbed in polypropylene (PP)/ethylene alcohol vinyl (EVOH) films. Eur. Polym. J. 2006, 42, 3121–3132. [Google Scholar] [CrossRef]

- Coleman, M.M.; Yang, X.; Zhang, H.; Painter, P.C. Ethylene-co-vinyl alcohol blends. J. Macromol. Sci. Part B 1993, 32, 295–326. [Google Scholar] [CrossRef]

- Cava, D.; Sammon, C.; Lagaron, J.M. Water diffusion and sorption-induced swelling as a function of temperature and ethylene content in ethylene-vinyl alcohol copolymers as determined by attenuated total reflection fourier transform infrared spectroscopy. Appl. Spectrosc. 2006, 60, 1392–1398. [Google Scholar] [CrossRef] [PubMed]

- Nir, Y.; Narkis, M.; Siegmann, A. Morphology and infrared spectroscopy of strongly interacting polymer blends: EVOH/copolyamide-6/6.9. J. Macromol. Sci. Part B 1998, 37, 863–882. [Google Scholar] [CrossRef]

- Lagaron, J.M.; Gimenez, E.; Catala, R.; Gavara, R. Mechanisms of Moisture Sorption in Barrier Polymers Used in Food Packaging: Amorphous Polyamide vs. High-Barrier Ethylene-Vinyl Alcohol Copolymer Studied by Vibrational Spectroscopy. Macromol. Chem. Phys. 2003, 204, 704–713. [Google Scholar] [CrossRef]

- Mano, V.; Chimenti, S.; Ruggeri, G.; Pereira, F.V.; de Paula, E.L. P(CL-b-LLA) diblock copolymers grafting onto cellulosic nanocrystals. Polym. Bull. 2017, 74, 3673–3688. [Google Scholar] [CrossRef]

- Cheng, D.; Wen, Y.; Wang, L.; An, X.; Zhu, X.; Ni, Y. Adsorption of polyethylene glycol (PEG) onto cellulose nano-crystals to improve its dispersity. Carbohydr. Polym. 2015, 123, 157–163. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Kwon, H.; Seo, J. EVOH nanocomposite films with enhanced barrier properties under high humidity conditions. Polym. Compos. 2014, 35, 644–654. [Google Scholar] [CrossRef]

- Orr, M.P.; Sonekan, A.; Shofner, M.L. Effect of processing method on cellulose nanocrystal/polyethylene-co-vinyl alcohol composites. Polym. Eng. Sci. 2020, 60, 2979–2990. [Google Scholar] [CrossRef]

- Noorani, S.; Simonsen, J.; Atre, S. Nano-enabled microtechnology: Polysulfone nanocomposites incorporating cellulose nanocrystals. Cellulose 2007, 14, 577–584. [Google Scholar] [CrossRef]

- Singh, S.; Gaikwad, K.K.; Park, S.-I.; Lee, Y.S. Microwave-assisted step reduced extraction of seaweed (Gelidiella aceroso) cellulose nanocrystals. Int. J. Biol. Macromol. 2017, 99, 506–510. [Google Scholar] [CrossRef]

- Zaman, M.; Xiao, H.; Chibante, F.; Ni, Y. Synthesis and characterization of cationically modified nanocrystalline cellulose. Carbohydr. Polym. 2012, 89, 163–170. [Google Scholar] [CrossRef]

- Neto, W.P.F.; Silvério, H.A.; Dantas, N.O.; Pasquini, D. Extraction and characterization of cellulose nanocrystals from agro-industrial residue—Soy hulls. Ind. Crop. Prod. 2013, 42, 480–488. [Google Scholar] [CrossRef]

- Yan, H.; Chen, X.; Feng, M.; Shi, Z.; Zhang, W.; Wang, Y.; Ke, C.; Lin, Q. Entrapment of bacterial cellulose nanocrystals stabilized Pickering emulsions droplets in alginate beads for hydrophobic drug delivery. Colloids Surf. B Biointerfaces 2019, 177, 112–120. [Google Scholar] [CrossRef]

- Islam, M.S.; Karim, M.R. Fabrication and characterization of poly(vinyl alcohol)/alginate blend nanofibers by electrospinning method. Colloids Surf. A Physicochem. Eng. Asp. 2010, 366, 135–140. [Google Scholar] [CrossRef]

- Cha, R.; He, Z.; Ni, Y. Preparation and characterization of thermal/pH-sensitive hydrogel from carboxylated nanocrystalline cellulose. Carbohydr. Polym. 2012, 88, 713–718. [Google Scholar] [CrossRef]

- Sun, X.F.; Xu, F.; Sun, R.C.; Fowler, P.; Baird, M.S. Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr. Res. 2005, 340, 97–106. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; Lopez-Rubio, A.; Lagaron, J.M. Nanocomposites of ethylene vinyl alcohol copolymer with thermally resistant cellulose nanowhiskers by melt compounding (II): Water barrier and mechanical properties. J. Appl. Polym. Sci. 2013, 128, 2197–2207. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; Lopez-Rubio, A.; Lagaron, J.M. Optimization of the Dispersion of Unmodified Bacterial Cellulose Nanowhiskers into Polylactide via Melt Compounding to Significantly Enhance Barrier and Mechanical Properties. Biomacromolecules 2012, 13, 3887–3899. [Google Scholar] [CrossRef]

- Suryanegara, L.; Nakagaito, A.N.; Yano, H. The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA composites. Compos. Sci. Technol. 2009, 69, 1187–1192. [Google Scholar] [CrossRef]

- Yu, H.; Yan, C.; Yao, J. Fully biodegradable food packaging materials based on functionalized cellulose nanocrystals/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites. RSC Adv. 2014, 4, 59792–59802. [Google Scholar] [CrossRef]

- Yang, W.; Qi, G.; Kenny, J.M.; Puglia, D.; Ma, P. Effect of Cellulose Nanocrystals and Lignin Nanoparticles on Mechanical, Antioxidant and Water Vapour Barrier Properties of Glutaraldehyde Crosslinked PVA Films. Polymers 2020, 12, 1364. [Google Scholar] [CrossRef] [PubMed]

- Ogunsona, E.O.; Mekonnen, T.H. Multilayer assemblies of cellulose nanocrystal-polyvinyl alcohol films featuring excellent physical integrity and multi-functional properties. J. Colloid Interface Sci. 2020, 580, 56–67. [Google Scholar] [CrossRef] [PubMed]

- McCrum, N.G.; Buckley, C.P.; Bucknall, B. Principles of Polymer Engineering; Oxford University Press: Oxford, UK, 1988. [Google Scholar]

- Razi, P.S.; Portier, R.; Raman, A. Studies on Polymer-Wood Interface Bonding: Effect of Coupling Agents and Surface Modification. J. Compos. Mater. 1999, 33, 1064–1079. [Google Scholar] [CrossRef]

- Azizi Samir, M.A.S.; Alloin, F.; Dufresne, A. Review of Recent Research into Cellulosic Whiskers, Their Properties and Their Application in Nanocomposite Field. Biomacromolecules 2005, 6, 612–626. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Lim, L.-T.; Tung, M.A. Limonene transport and mechanical properties of EVOH and nylon 6,6 films as influenced by RH. J. Appl. Polym. Sci. 2001, 79, 1949–1957. [Google Scholar] [CrossRef]

- Lagaron, J.M.; Catalá, R.; Gavara, R. Structural characteristics defining high barrier properties in polymeric materials. Mater. Sci. Technol. 2004, 20, 1–7. [Google Scholar] [CrossRef]

- Maes, C.; Luyten, W.; Herremans, G.; Peeters, R.; Carleer, R.; Buntinx, M. Recent Updates on the Barrier Properties of Ethylene Vinyl Alcohol Copolymer (EVOH): A Review. Polym. Rev. 2018, 58, 209–246. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Shi, H.; He, Y.; Fei, X.; Peng, L. Preparation and characterization of carboxymethyl cellulose-based composite films reinforced by cellulose nanocrystals derived from pea hull waste for food packaging applications. Int. J. Biol. Macromol. 2020, 164, 4104–4112. [Google Scholar] [CrossRef] [PubMed]

- Karkhanis, S.S.; Stark, N.M.; Sabo, R.C.; Matuana, L.M. Water vapor and oxygen barrier properties of extrusion-blown poly(lactic acid)/cellulose nanocrystals nanocomposite films. Compos. Part A Appl. Sci. Manuf. 2018, 114, 204–211. [Google Scholar] [CrossRef]

- Chowdhury, R.A.; Nuruddin, M.; Clarkson, C.; Montes, F.; Howarter, J.; Youngblood, J.P. Cellulose Nanocrystal (CNC) Coatings with Controlled Anisotropy as High-Performance Gas Barrier Films. ACS Appl. Mater. Interfaces 2019, 11, 1376–1383. [Google Scholar] [CrossRef]

- Syverud, K.; Stenius, P. Strength and barrier properties of MFC films. Cellulose 2008, 16, 75. [Google Scholar] [CrossRef]

- Nair, S.S.; Zhu, J.Y.; Deng, Y.; Ragauskas, A.J. High performance green barriers based on nanocellulose. Sustain. Chem. Process. 2014, 2, 23. [Google Scholar] [CrossRef] [Green Version]

- Guinault, A.; Sollogoub, C.; Domenek, S.; Grandmontagne, A.; Ducruet, V. Influence of crystallinity on gas barrier and mechanical properties of pla food packaging films. Int. J. Mater. Form. 2010, 3, 603–606. [Google Scholar] [CrossRef]

- Belbekhouche, S.; Bras, J.; Siqueira, G.; Chappey, C.; Lebrun, L.; Khelifi, B.; Marais, S.; Dufresne, A. Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohydr. Polym. 2011, 83, 1740–1748. [Google Scholar] [CrossRef]

- Petersson, L.; Oksman, K. Biopolymer based nanocomposites: Comparing layered silicates and microcrystalline cellulose as nanoreinforcement. Compos. Sci. Technol. 2006, 66, 2187–2196. [Google Scholar] [CrossRef]

| Sample | Viscosity (cP) | Surface Tension (mN/m) | Conductivity (µS/cm) | Mean Fiber Diameter (nm) | Mean Diameter of Beaded Regions (µm) |

|---|---|---|---|---|---|

| EVOH44 | 71.9 ± 1.2 a | 23.8 ± 0.1 a | 11.63 ± 0.03 a | 410.0 ± 128.0 a | 1.1 ± 0.2 a |

| EVOH44 + 0.1 wt % CNCs | 74.3 ± 0.8 b | 24.1 ± 0.4 a,b | 11.80 ± 0.02 a,b | 410.4 ± 99.4 a | 1.3 ± 0.3 a,b |

| EVOH44 + 0.5 wt % CNCs | 77.4 ± 1.1 c | 24.3 ± 0.7 a,b | 12.00 ± 0.05 b,c | 501.7 ± 79.6 a | 1.5 ± 0.2 a,b |

| EVOH44 + 1 wt % CNCs | 80.1 ± 0.7 d | 24.9 ± 0.5 b | 12.10 ± 0.03 c | 592.4 ± 102.9 a | 1.8 ± 0.1 b |

| Sample | First Heating | Cooling | |||

|---|---|---|---|---|---|

| Tg (°C) | Tm (°C) | ΔHm (J/g) (%Xc) | Tc (°C) | ΔHc (J/g) | |

| EVOH44 | 40.6 ± 0.3 a | 163.9 ± 1.2 a | 60.1 ± 2.1 a(27.0) | 145.4 ± 0.8 a | 61.8 ± 2.1 a |

| EVOH44 + 0.1 wt % CNCs | 44.0 ± 0.5 b | 160.1 ± 2.2 b | 52.0 ± 1.0 b(23.4) | 137.2 ± 0.3 b | 50.1 ± 1.1 b |

| EVOH44 + 0.5 wt % CNCs | 42.5 ± 0.7 c | 157.2 ± 1.4 b | 53.4 ± 2.4 b(24.1) | 135.3 ± 1.0 c | 44.2 ± 1.5 c |

| EVOH44 + 1.0 wt % CNCs | 41.7 ± 0.2 c | 156.8 ± 1.6 b | 50.1 ± 1.1 b(22.8) | 133.2 ± 0.5 d | 38.5 ± 1.4 d |

| Film | a* | b* | L* | ΔE* | T | O |

|---|---|---|---|---|---|---|

| EVOH44 | 2.81 ± 0.02 a | −4.94 ± 0.04 a | 91.04 ± 0.05 a | - | 7.87 ± 0.04 a | 0.004 ± 0.001 a |

| EVOH44 + 0.1 wt % CNCs | 2.79 ± 0.03 a | −4.69 ± 0.03 b | 91.28 ± 0.03 b | 0.35 ± 0.03 a | 7.70 ± 0.03 a | 0.003 ± 0.002 a |

| EVOH44 + 0.5 wt % CNCs | 2.81 ± 0.01 a | −5.02 ± 0.05 a,c | 90.92 ± 0.04 a | 0.14 ± 0.04 b | 4.64 ± 0.02 b | 0.002 ± 0.001 a |

| EVOH44 + 1.0 wt % CNCs | 2.84 ± 0.02 a | −5.10 ± 0.04 c | 90.84 ± 0.04 a | 0.26 ± 0.03 a,b | 3.61 ± 0.03 c | 0.002 ± 0.001 a |

| Sample | T5% (°C) | Tdeg (°C) | Mass Loss at Tdeg (%) | Residual Mass (%) |

|---|---|---|---|---|

| CNCs | 215.6 ± 0.4 a | 288.9 ± 0.5 a | 41.3 ± 0.2 a | 5.8 ± 0.8 a |

| EVOH44 | 306.8 ± 0.9 b | 359.7 ± 0.7 b | 48.5 ± 0.3 b | 0.1 ± 0.1 b |

| EVOH44 + 0.1 wt % CNCs | 306.9 ± 0.7 b | 377.4 ± 1.4 c | 60.0 ± 0.5 c | 0.1 ± 0.1 b |

| EVOH44 + 0.5 wt % CNCs | 314.9 ± 1.5 c | 372.6 ± 1.1 d | 59.6 ± 0.8 c | 0.1 ± 0.1 b |

| EVOH44 + 1.0 wt % CNCs | 331.2 ± 0.3 d | 383.6 ± 1.4 e | 59.7 ± 0.4 c | 0.1 ± 0.1 b |

| Film | T (mJ/m3) | |||

|---|---|---|---|---|

| EVOH44 | 4699 ± 350 a | 38.7 ± 5.2 a | 10.4 ± 3.6 a | 3.2 ± 1.4 a |

| EVOH44 + 0.1 wt % CNCs | 6473 ± 257 b | 39.2± 8.6 a,b | 0.8 ± 0.5 b | 0.2 ± 0.1 b |

| EVOH44 + 0.5 wt % CNCs | 6022 ± 584 b | 30.2 ± 8.3 a,b | 0.7 ± 0.2 b | 0.2 ± 0.1 b |

| EVOH44 + 1.0 wt % CNCs | 4135 ± 399 a | 25.2 ± 7.7 b | 1.6 ± 0.7 b | 0.3 ± 0.1 b |

| Film | WVP × 1014 (kg·m·m−2·Pa−1·s−1) | OP × 1020 (m3·m·m−2·Pa−1·s−1) | ||

|---|---|---|---|---|

| 0% RH | 20% RH | 80% RH | ||

| EVOH44 | 1.6 ± 0.4 a | 1.1 ± 0.2 a | 0.10 ± 0.04 a | 4.7 ± 0.3 a |

| EVOH44 + 0.1 wt % CNCs | 3.7 ± 0.3 b | 1.4 ± 0.1 a | 0.38 ± 0.01 b | 8.3 ± 0.2 b |

| EVOH44 + 0.5 wt % CNCs | 4.1 ± 0.9 b,c | 2.7 ± 0.2 b | 0.53 ± 0.03 b,c | 8.8 ± 0.2 b |

| EVOH44 + 1.0 wt % CNCs | 4.5 ± 0.1 c | 2.3 ± 0.4 b | 0.61 ± 0.01 c | 8.7 ± 0.2 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melendez-Rodriguez, B.; Torres-Giner, S.; Zavagna, L.; Sammon, C.; Cabedo, L.; Prieto, C.; Lagaron, J.M. Development and Characterization of Electrospun Fiber-Based Poly(ethylene-co-vinyl Alcohol) Films of Application Interest as High-Gas-Barrier Interlayers in Food Packaging. Polymers 2021, 13, 2061. https://doi.org/10.3390/polym13132061

Melendez-Rodriguez B, Torres-Giner S, Zavagna L, Sammon C, Cabedo L, Prieto C, Lagaron JM. Development and Characterization of Electrospun Fiber-Based Poly(ethylene-co-vinyl Alcohol) Films of Application Interest as High-Gas-Barrier Interlayers in Food Packaging. Polymers. 2021; 13(13):2061. https://doi.org/10.3390/polym13132061

Chicago/Turabian StyleMelendez-Rodriguez, Beatriz, Sergio Torres-Giner, Lorenzo Zavagna, Chris Sammon, Luis Cabedo, Cristina Prieto, and Jose M. Lagaron. 2021. "Development and Characterization of Electrospun Fiber-Based Poly(ethylene-co-vinyl Alcohol) Films of Application Interest as High-Gas-Barrier Interlayers in Food Packaging" Polymers 13, no. 13: 2061. https://doi.org/10.3390/polym13132061

APA StyleMelendez-Rodriguez, B., Torres-Giner, S., Zavagna, L., Sammon, C., Cabedo, L., Prieto, C., & Lagaron, J. M. (2021). Development and Characterization of Electrospun Fiber-Based Poly(ethylene-co-vinyl Alcohol) Films of Application Interest as High-Gas-Barrier Interlayers in Food Packaging. Polymers, 13(13), 2061. https://doi.org/10.3390/polym13132061