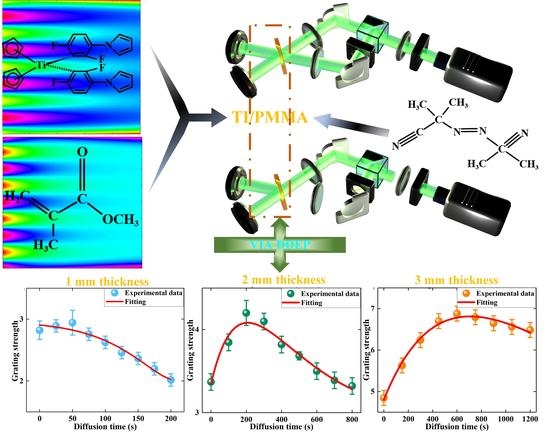

Holographic Grating Enhancement of TI/PMMA Polymers in the Dark Diffusion Process

Abstract

1. Introduction

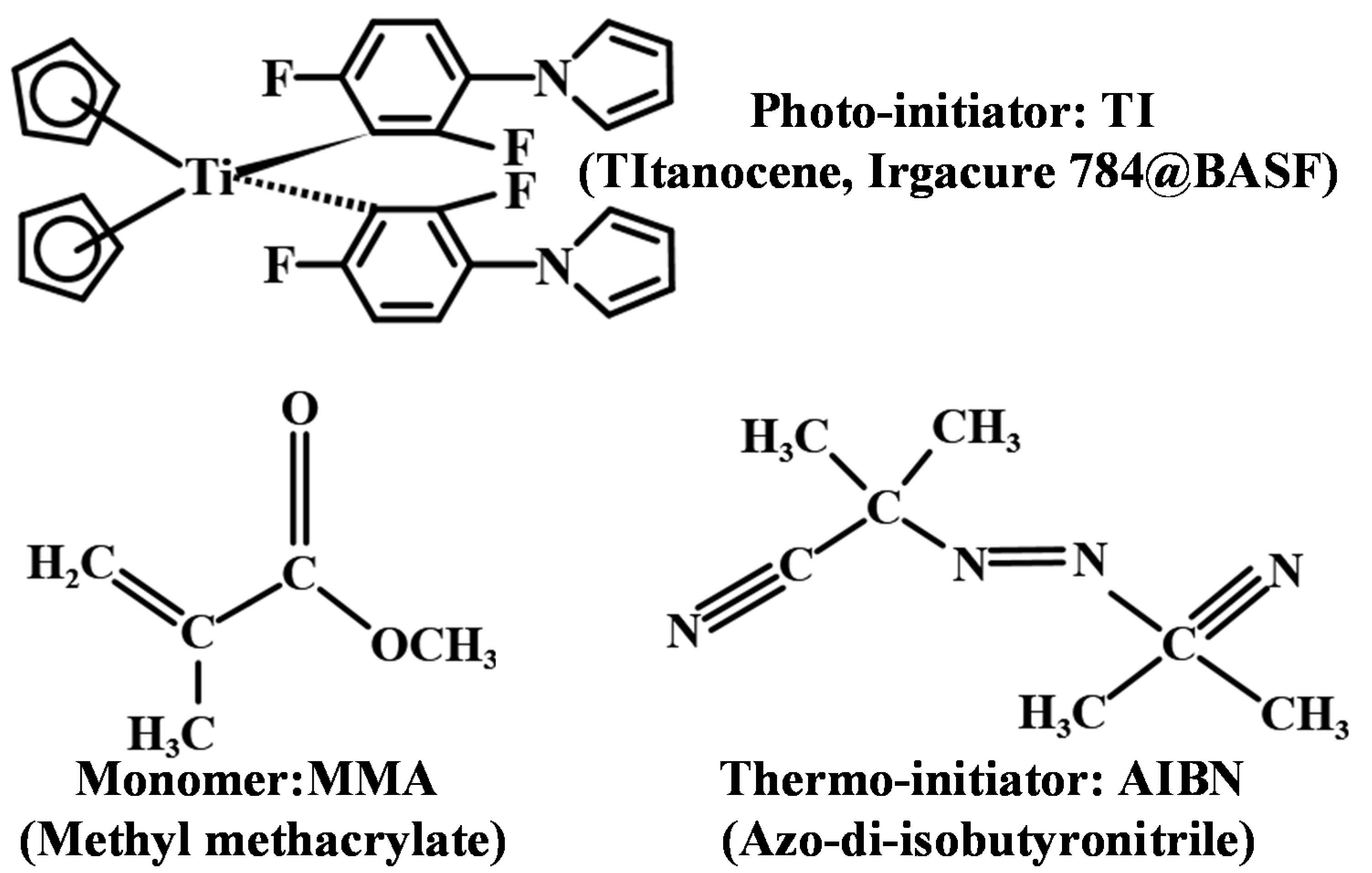

2. Materials and Methods

2.1. Materials and Preparations

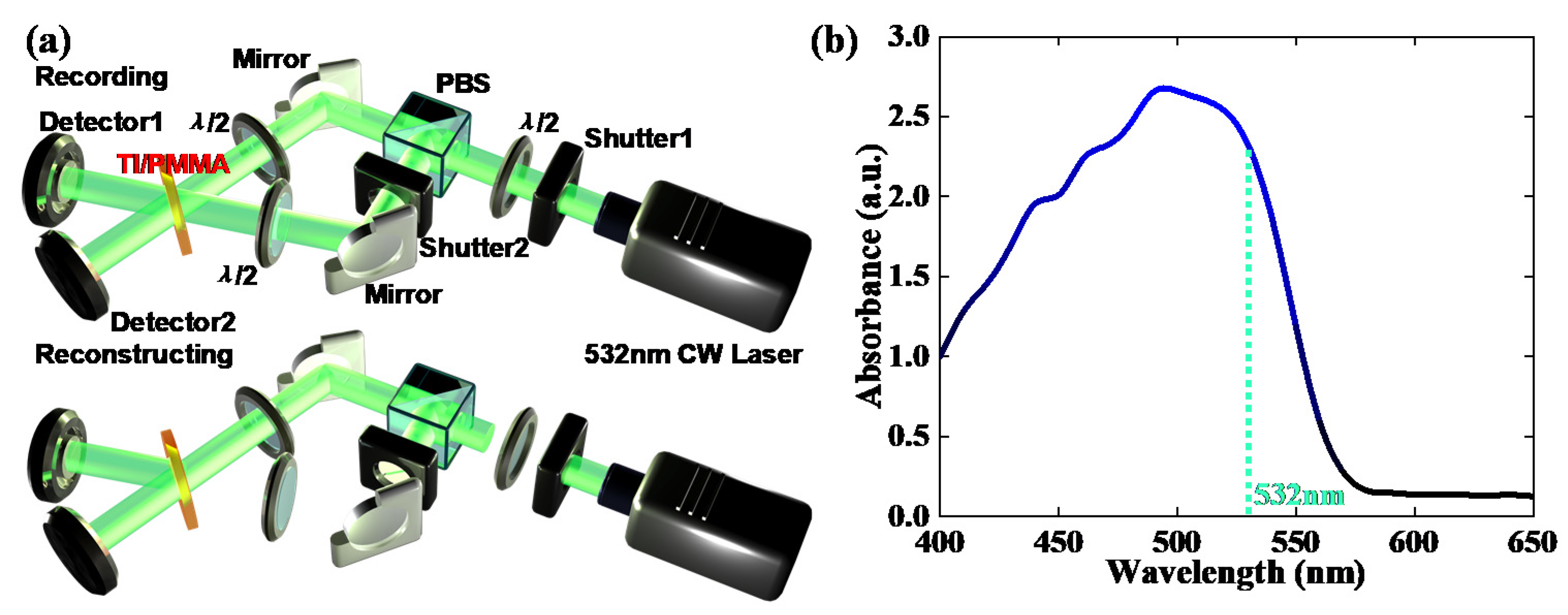

2.2. Holographic Setup

3. Results and Discussion

3.1. Theoretical Analysis on Dark Diffusion Enhancement Process (DDEP)

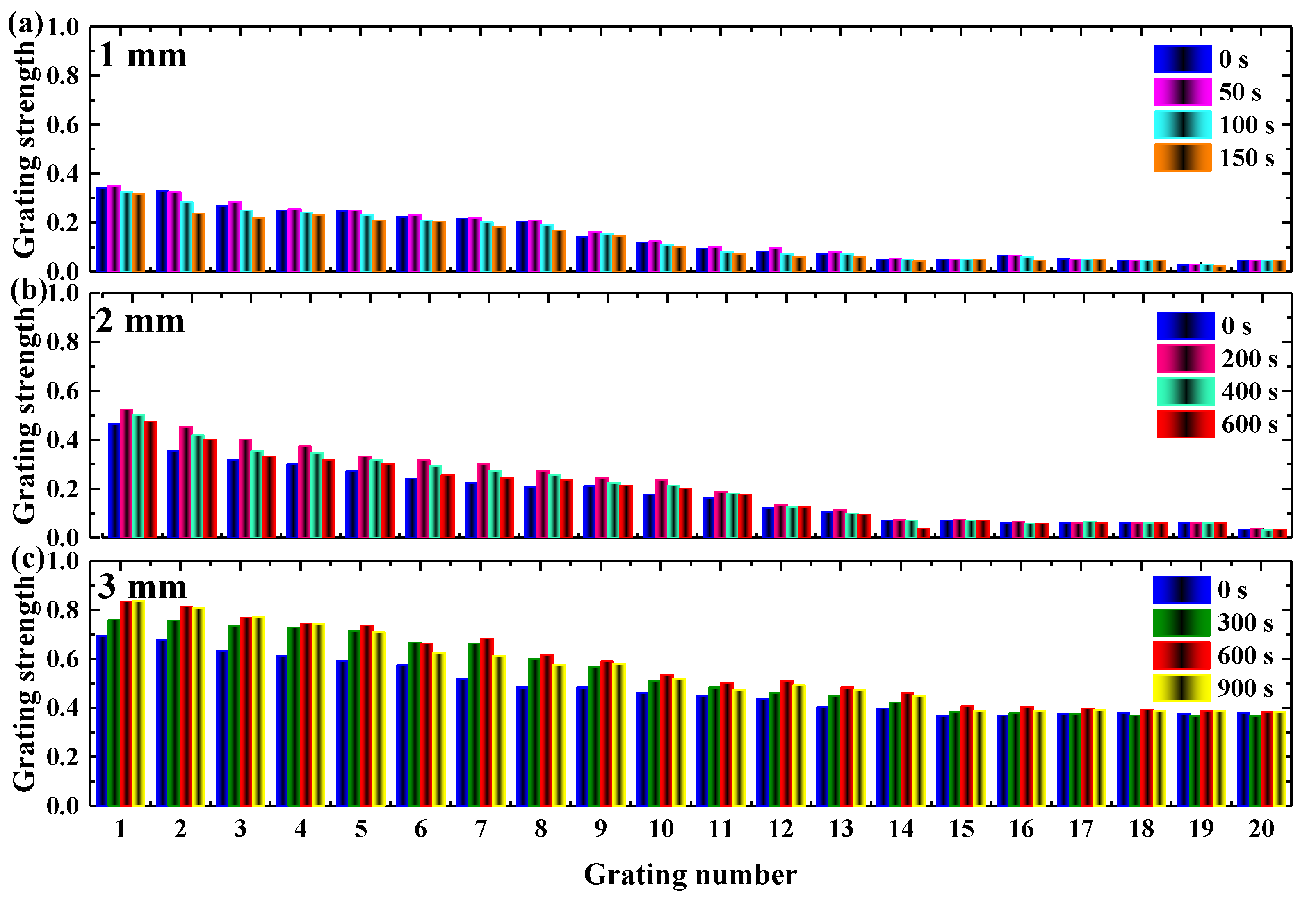

3.2. The Dark Diffusion Enhancement Process (DDEP) in TI/PMMA Polymers with Consecutive (Long-Time) Exposure

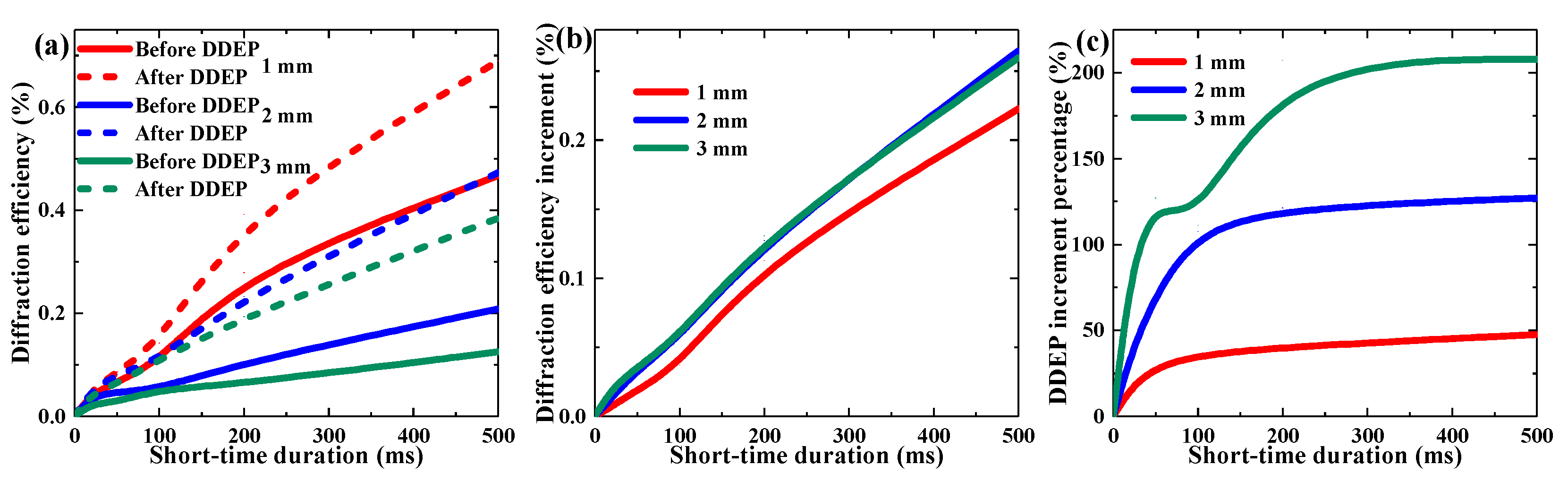

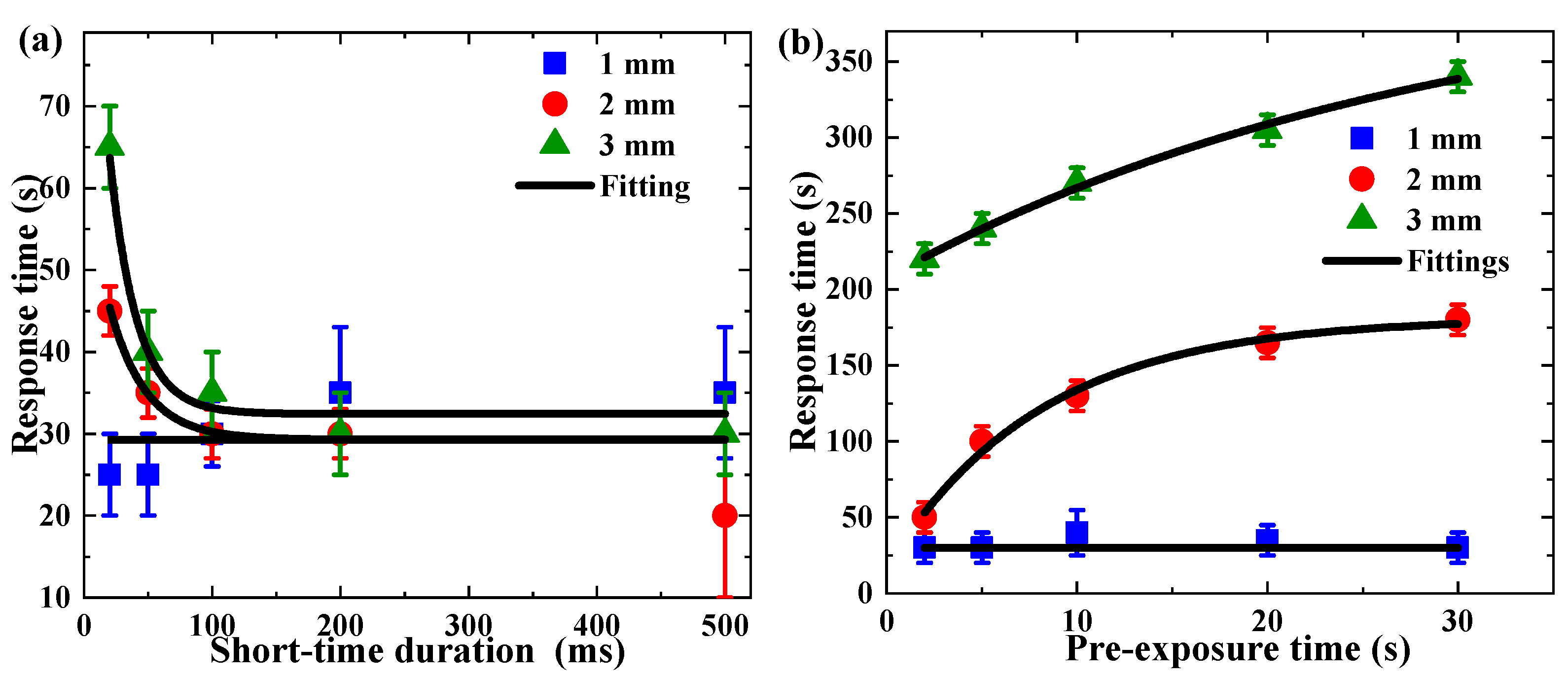

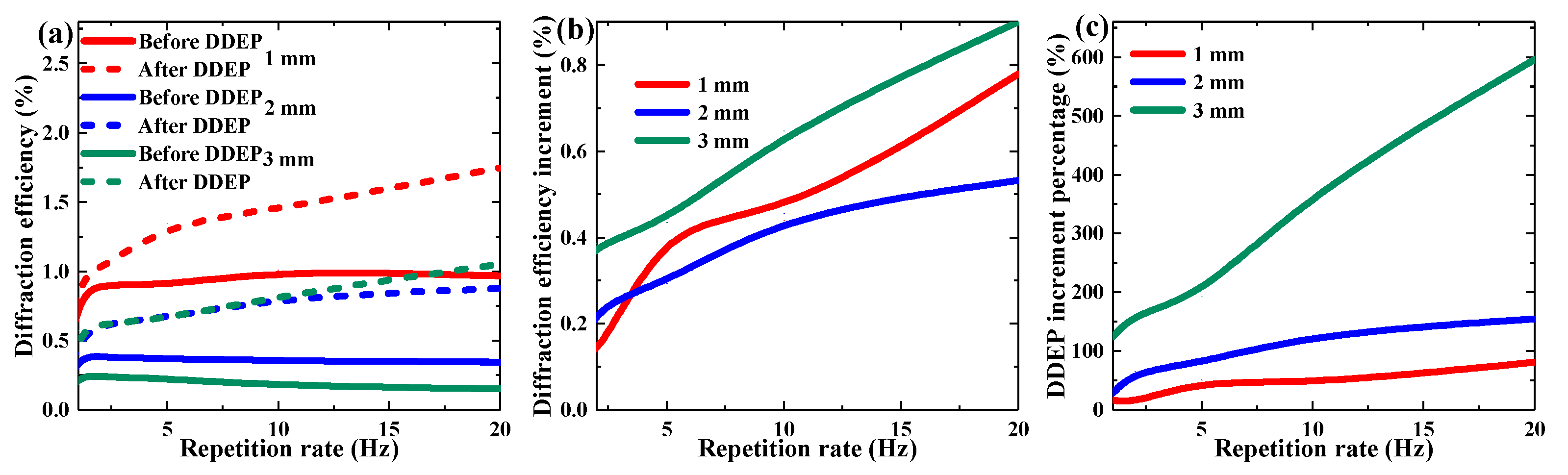

3.3. Dark Diffusion Enhancement Process (DDEP) in TI/PMMA Polymers with Short-Time Exposure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, L.; Wang, Z.; Zhang, H.; Jin, G.; Gu, C. Volume holographic printing using unconventional angular multiplexing for three-dimensional display. Appl. Phys. 2016, 55, 6046–6051. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.W.; Chen, Y.C.; Huang, K.H.; Cheng, C.Y. Reduction of phase error on phase-only volume-holographic disc rotation with pre-processing by phase integral. Opt. Express 2020, 28, 28573–28583. [Google Scholar] [CrossRef] [PubMed]

- Nobukawa, T.; Nomura, T. Multilevel recording of complex amplitude data pages in a holographic data storage system using digital holography. Opt. Express 2016, 24, 21001–21011. [Google Scholar] [CrossRef]

- Zhang, Y.; Andreas, A.P. Lubricant transfer model at the head-disk interface in magnetic storage considering lubricant–lubricant interaction. Tribol. Lett. 2016, 62, 38. [Google Scholar] [CrossRef]

- Sunil, B.N.; Srinatha, M.K.; Shanker, G.; Hegde, G.; Alaasar, M.; Tschierske, C. Effective tuning of optical storage devices using photosensitive bent-core liquid crystals. J. Mol. Liq. 2020, 304, 112719. [Google Scholar] [CrossRef]

- Nehra, M.; Dilbaghi, N.; Marrazza, G.; Kaushik, A.; Abolhassani, R.Y.; Mishra, K.; Kumar, S. 1D semiconductor nanowires for energy conversion, harvesting and storage applications. Nano Energy 2020, 76, 104991. [Google Scholar] [CrossRef]

- Burr, G.W.; Jefferson, C.M.; Coufal, H.; Jurich, M.; Hoffnagle, J.A.; Macfarlane, R.M.; Shelby, R.M. Volume holographic data storage at an areal density of 250 gigapixels/in2. Opt. Lett. 2001, 26, 444–446. [Google Scholar] [CrossRef] [PubMed]

- Orlov, S.S.; Phillips, W.; Bjornson, E.; Takashima, Y.; Sundaram, P.; Hesselink, L.; Snyder, R. High-transfer-rate high-capacity holographic disk data-storage system. Appl. Opt. 2004, 43, 4902–4914. [Google Scholar] [CrossRef] [PubMed]

- Malallah, R.E.; Li, H.; Kelly, D.P.; Healy, J.J.; Sheridan, J.T. A review of hologram storage and self-written waveguides formation in photopolymer media. Polymers 2017, 9, 337. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Zhao, Y.; Li, Z.; Sun, X. Improvement of ultrafast holographic performance in silver nanoprisms dispersed photopolymer. Opt. Express 2018, 26, 6993–7004. [Google Scholar] [CrossRef]

- Navarro-Fuster, V.; Ortuño, M.; Fernández, R.; Gallego, S.; Márquez, A.; Beléndez, A.; Pascual, I. Peristrophic multiplexed holograms recorded in a low toxicity photopolymer. Opt. Mater. Express 2017, 7, 133–147. [Google Scholar] [CrossRef]

- Lin, S.H.; Cho, S.L.; Lin, J.H.; Hsu, K.Y.; Chi, S. Influence of fabrication conditions on characteristics of phenanthrenequinone-doped poly (methyl methacrylate) photopolymer for holographic memory. Opt. Commun. 2014, 320, 145–150. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Geng, Y.; Wang, W.; Zhao, Y. Radical polymerization in holographic grating formation in PQ-PMMA photopolymer part I: Short exposure. Opt. Commun. 2014, 330, 191–198. [Google Scholar] [CrossRef]

- Liu, P.; Wang, L.; Zhao, Y.; Li, Z.; Sun, X. Holographic memory performances of titanocene dispersed poly (methyl methacrylate) photopolymer with different preparation conditions. Opt. Mater. Express 2018, 8, 1441–1453. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, F.; Hong, Y.; Zang, J.; Kang, G.; Tan, X. Volume holographic recording in Irgacure 784-doped PMMA photopolymer. Opt. Express 2017, 25, 20654–20662. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Wang, L.; Zhao, Y.; Li, Z.; Sun, X. Cationic photo-initiator titanocene dispersed PMMA photopolymers for holographic memories. OSA Continuum 2018, 1, 783–795. [Google Scholar] [CrossRef]

- Liu, P.; Sun, X.; Zhao, Y.; Li, Z. Ultrafast volume holographic recording with exposure reciprocity matching for TI/PMMAs application. Opt. Express 2019, 27, 19583–19595. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Sun, X.; Wang, L. Polarization holographic characteristics of TI/PMMA polymers by linearly polarized exposure. Opt. Mater. 2020, 107, 109992. [Google Scholar] [CrossRef]

- Liu, P.; Sun, X.; Wang, L. Holographic response characteristics influenced by an absorptive diffusion polymerization model in bulk TI/PMMAs. Appl. Opt. 2019, 58, 8622–8630. [Google Scholar] [CrossRef]

- Hsieh, M.L.; Chen, W.C.; Chen, H.Y.; Lin, S.Y. Optimization of light diffraction efficiency and its enhancement from a doped-PMMA volume holographic material. Opt. Commun. 2013, 308, 121–124. [Google Scholar] [CrossRef]

- Liu, H.; Yu, D.; Li, X.; Luo, S.; Jiang, Y.; Sun, X. Diffusional enhancement of volume gratings as an optimized strategy for holographic memory in PQ-PMMA photopolymer. Opt. Express 2010, 18, 6447–6454. [Google Scholar] [CrossRef]

- Gallego, S.; Márquez, A.; Marini, S.; Fernández, E.; Ortuño, M.; Pascual, I. In dark analysis of PVA/AA materials at very low spatial frequencies: Phase modulation evolution and diffusion estimation. Opt. Express 2009, 17, 18279–18291. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, F.; Tan, X. SiO2 NPs-PQ/PMMA Photopolymer material doped with a high-concentration photosensitizer for holographic storage. Polymers 2020, 12, 816. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, F.; Hong, Y.; Wu, A.; Zang, J.; Kang, G.; Tan, X.; Shimura, T. Volume holographic recording in Al nanoparticles dispersed phenanthrenequinone-doped poly (methyl methacrylate) photopolymer. Nanotechnology 2019, 30, 145202. [Google Scholar] [CrossRef]

- Lin, S.H.; Hsiao, Y.N.; Hsu, K.Y. Preparation and characterization of Irgacure 784 doped photopolymers for holographic data storage at 532 nm. J. Opt. A Pure Appl. Opt. 2009, 11, 024012. [Google Scholar] [CrossRef]

- Liu, P.; Chang, F.; Zhao, Y.; Li, Z.; Sun, X. Ultrafast volume holographic storage on PQ/PMMA photopolymers with nanosecond pulsed exposures. Opt. Express 2018, 26, 1072–1082. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Liu, H.; Geng, Y.; Wang, W.; Zhao, Y. Radical polymerization in holographic grating formation in PQ-PMMA photopolymer part II: Consecutive exposure and dark decay. Opt. Commun. 2014, 330, 199–207. [Google Scholar] [CrossRef]

- Veniaminov, A.V.; Bartsch, E. Diffusional enhancement of holograms: Phenanthrenequinone in polycarbonate. J. Opt. A Pure Appl. Opt. 2002, 4, 387–392. [Google Scholar] [CrossRef]

- Moreau, V.; Renotte, Y.; Lion, Y. Characterization of dupont photopolymer: Determination of kinetic parameters in a diffusion model. Appl. Opt. 2002, 41, 3427–3435. [Google Scholar] [CrossRef] [PubMed]

- Colvin, V.L.; Larson, R.G.; Harris, A.L.; Schilling, M.L. Quantitative model of volume hologram formation in photopolymers. J. Appl. Phys. 1997, 81, 5913–5923. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Jiang, Y.; Sun, X. Mutual diffusion dynamics with nonlocal response in SiO2 nanoparticles dispersed PQ-PMMA bulk photopolymer. Opt. Express 2011, 19, 13787–13792. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Wang, H.; Liu, H.; Wang, J.; Jiang, Y.Y.; Sun, X.D. Dark diffusional enhancement of holographic multiplexed gratings in phenanthrenequinone doped poly (methyl methacrylate) photopolymer. Chin. Phys. B 2011, 20, 114217. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Wang, J.; Jiang, Y.; Sun, X. Study on holographic characteristics in ZnMA doped PQ-PMMA photopolymer. Opt. Commun. 2011, 284, 2784–2788. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Sun, X. Holographic Grating Enhancement of TI/PMMA Polymers in the Dark Diffusion Process. Polymers 2021, 13, 1735. https://doi.org/10.3390/polym13111735

Liu P, Sun X. Holographic Grating Enhancement of TI/PMMA Polymers in the Dark Diffusion Process. Polymers. 2021; 13(11):1735. https://doi.org/10.3390/polym13111735

Chicago/Turabian StyleLiu, Peng, and Xiudong Sun. 2021. "Holographic Grating Enhancement of TI/PMMA Polymers in the Dark Diffusion Process" Polymers 13, no. 11: 1735. https://doi.org/10.3390/polym13111735

APA StyleLiu, P., & Sun, X. (2021). Holographic Grating Enhancement of TI/PMMA Polymers in the Dark Diffusion Process. Polymers, 13(11), 1735. https://doi.org/10.3390/polym13111735