Development and Characterization of Environmentally Friendly Wood Plastic Composites from Biobased Polyethylene and Short Natural Fibers Processed by Injection Moulding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Material Characterization

2.3.1. Mechanical Tests

2.3.2. Morphology

2.3.3. Thermal Analysis

2.3.4. Thermomechanical Characterization

2.3.5. Color Measurements

2.3.6. Water Uptake Characterization

2.3.7. Fire Behavior

3. Results

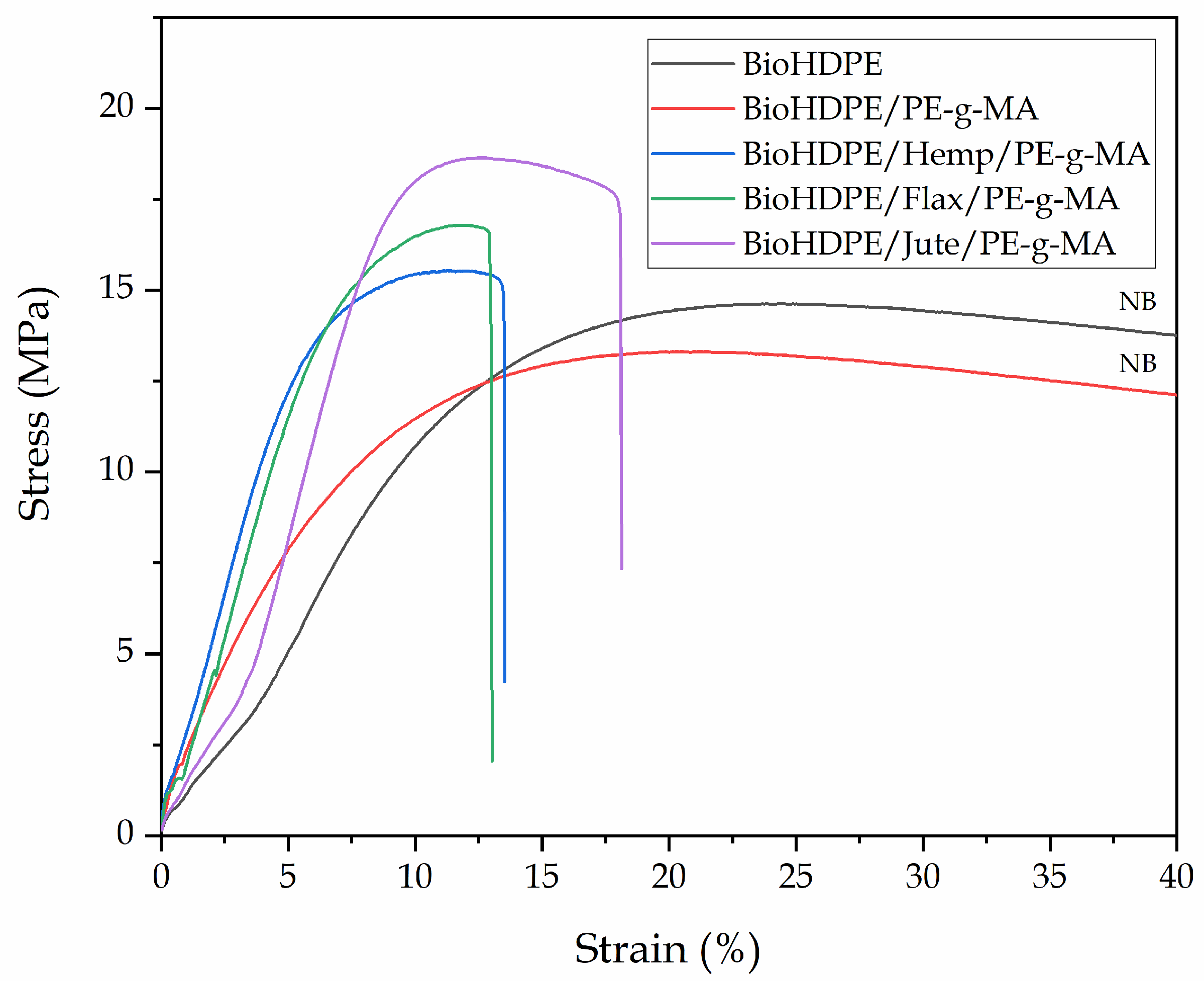

3.1. Mechanical Properties of BioHDPE-Natural Fiber Composites

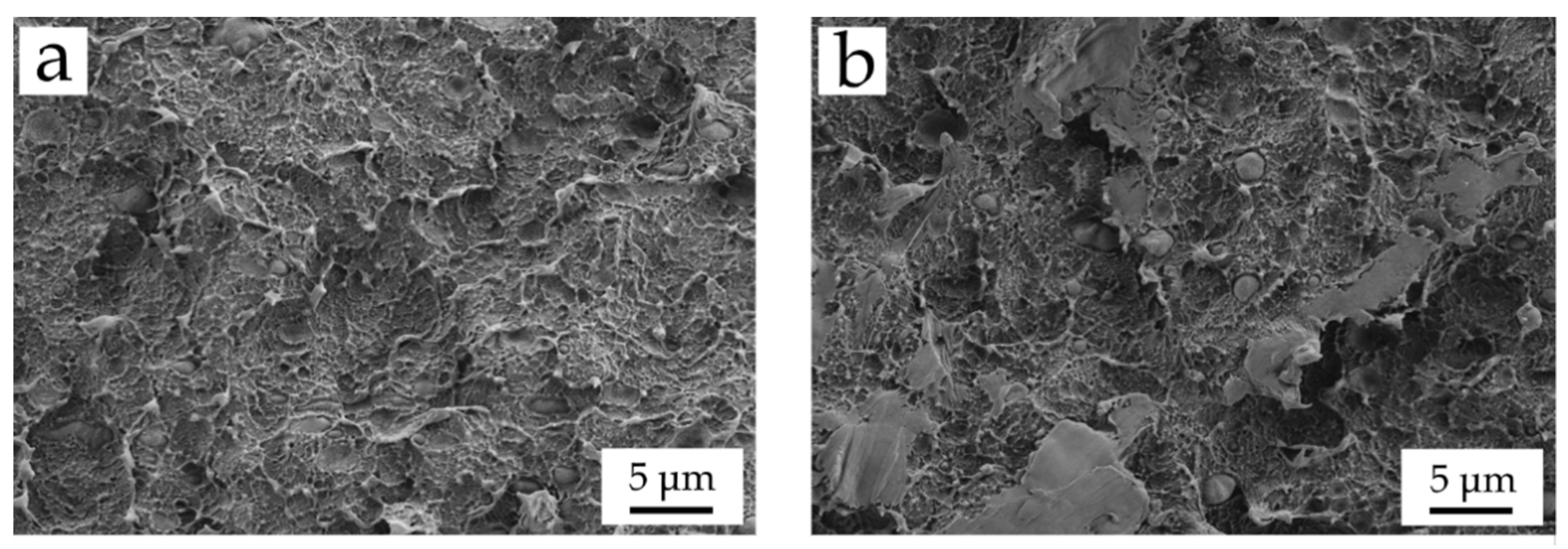

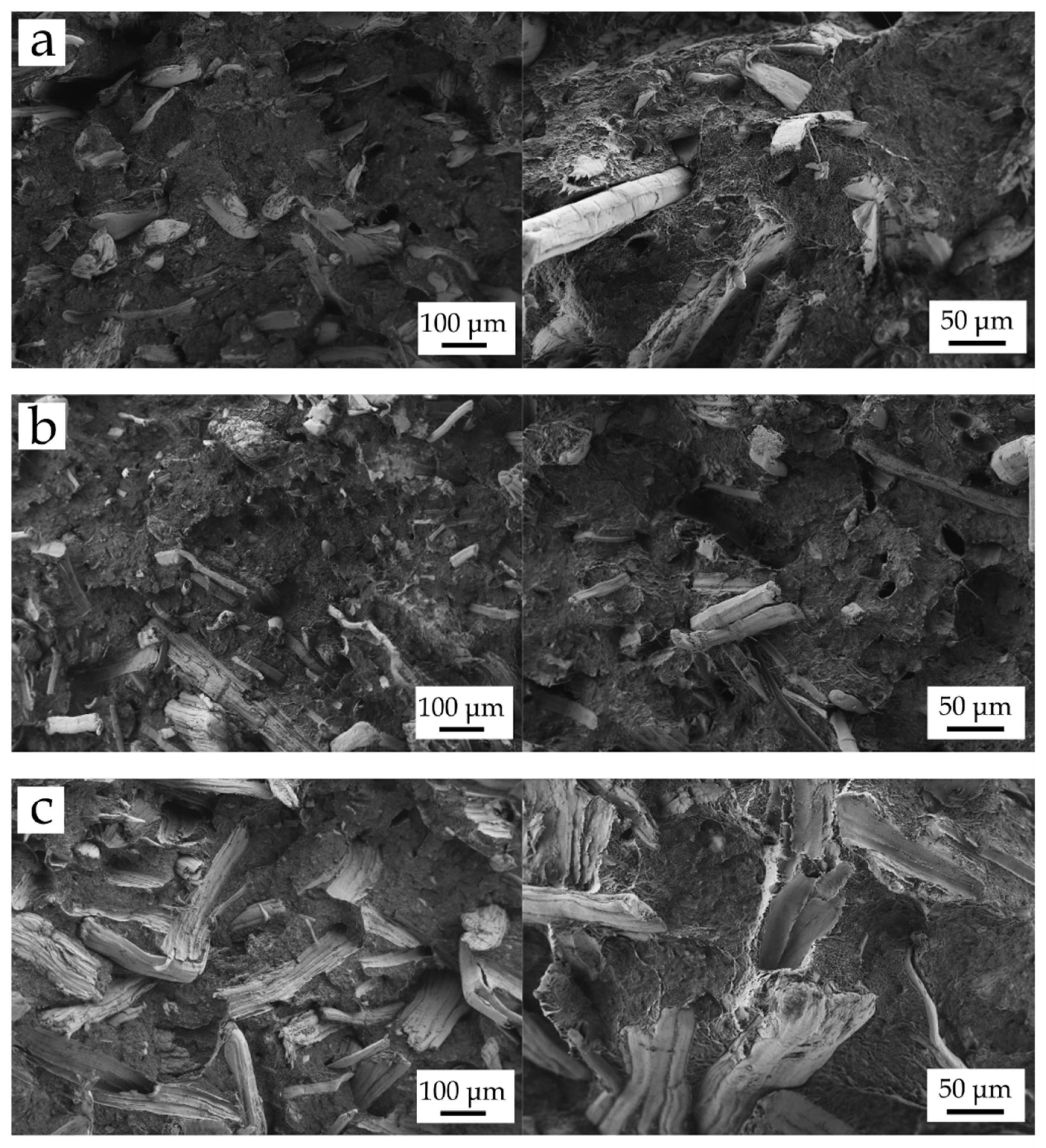

3.2. Morphology of BioHDPE-Natural Fiber Composites

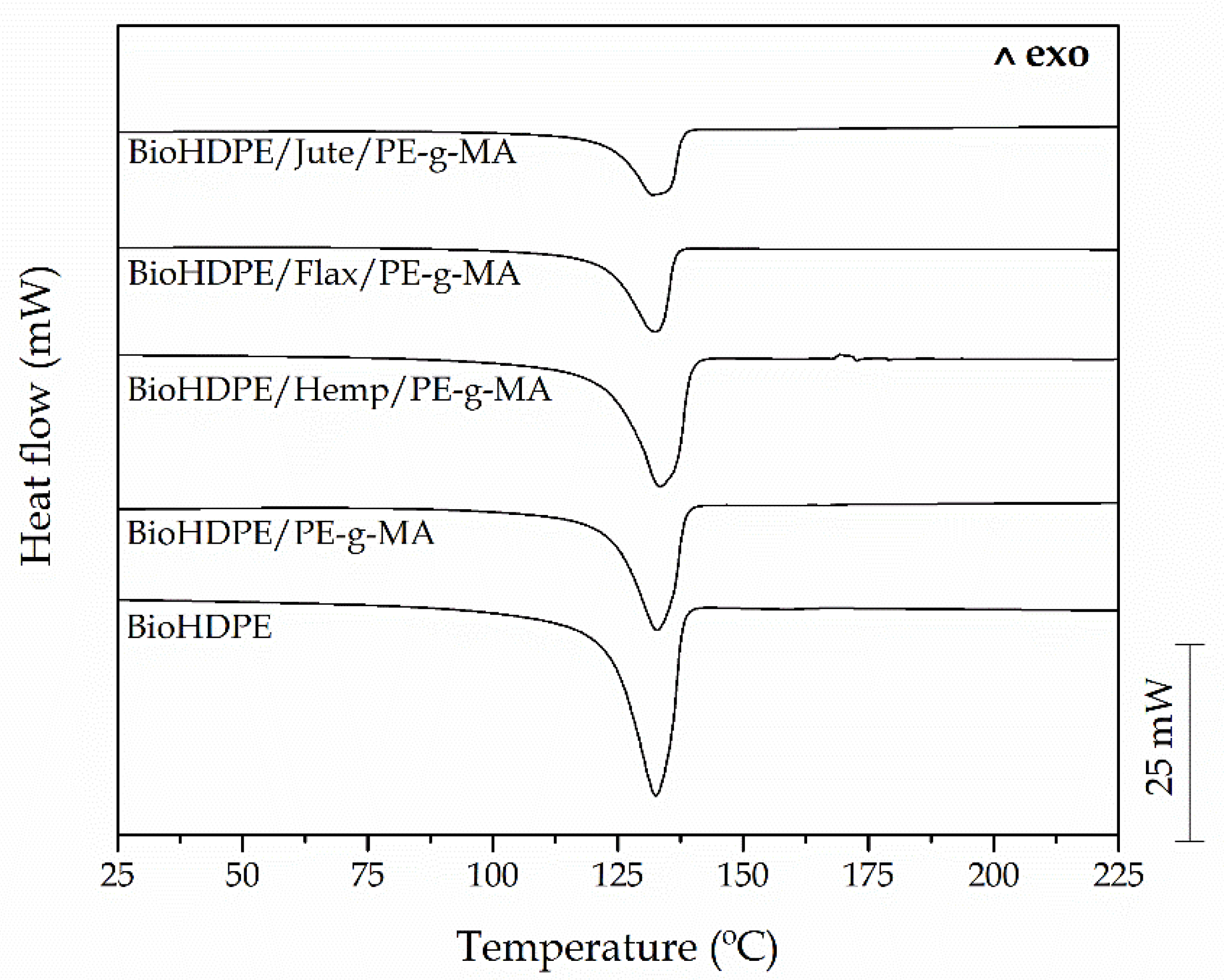

3.3. Thermal Properties of BioHDPE-Natural Fiber Composites

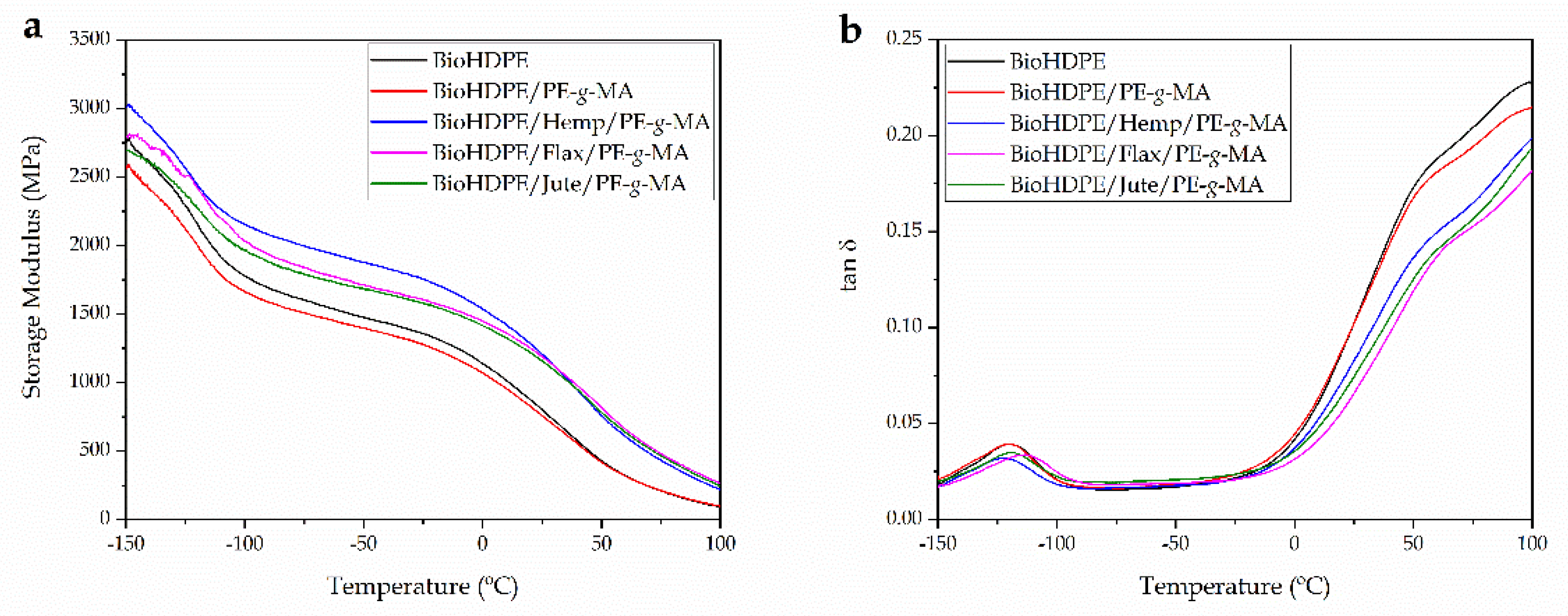

3.4. Thermomechanical Properties of PA1010/SFs Composites

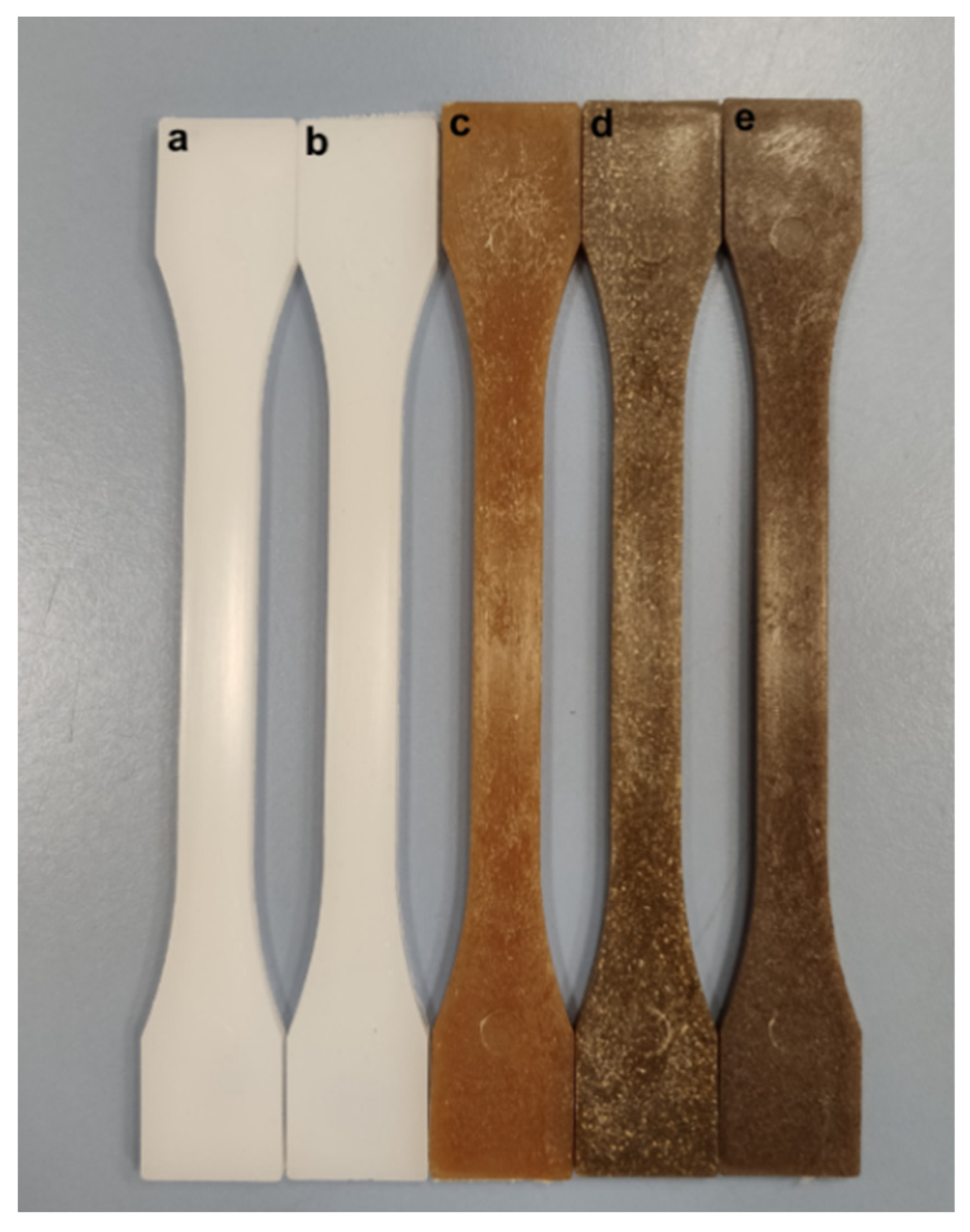

3.5. Color Measurement and Visual Appearance

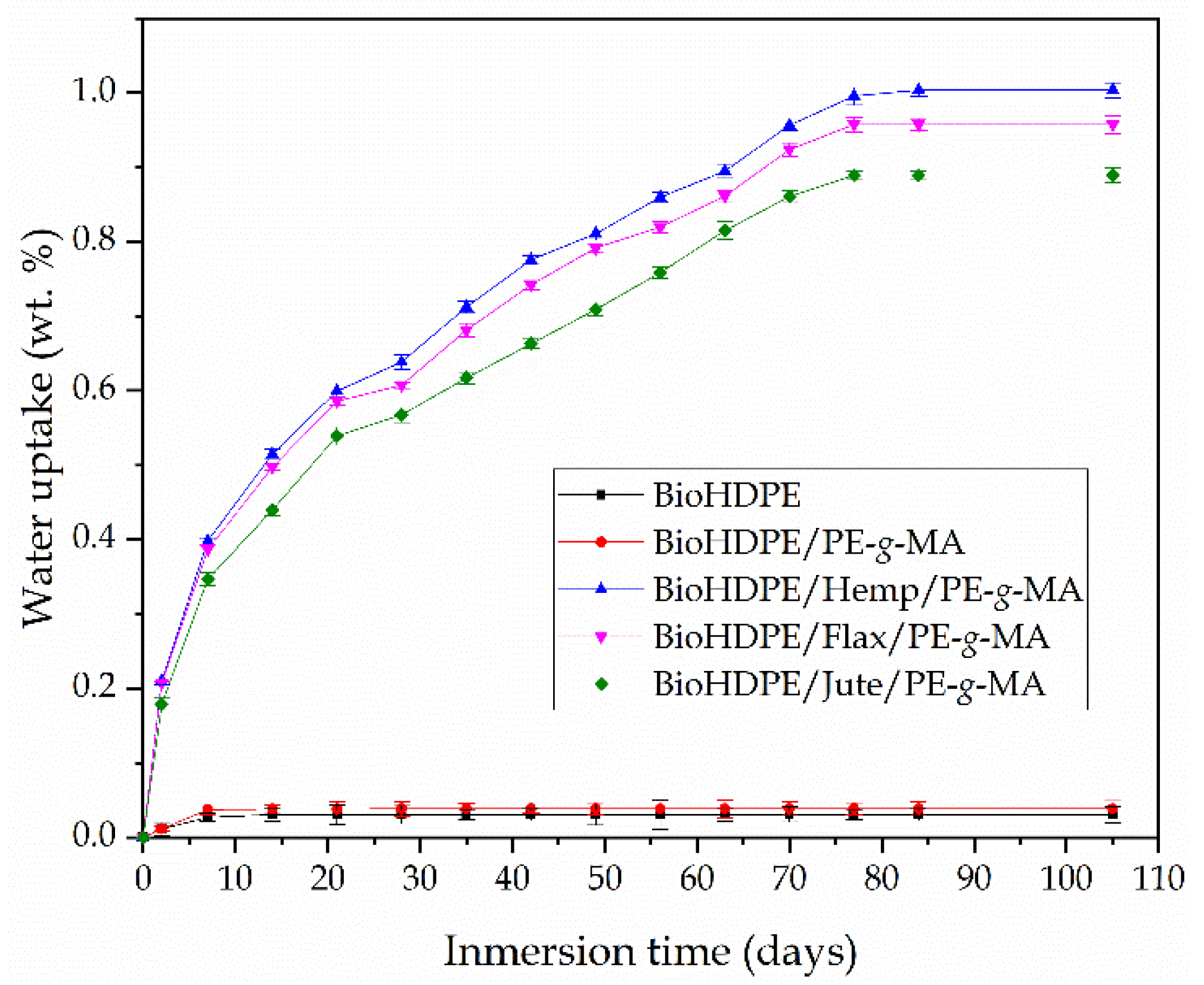

3.6. Water Uptake Characterization

3.7. Fire Behavior of BioHDPE-Natural Fiber Composites

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly (butylene succinate)(PBS) and almond shell flour with different compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Lascano, D.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Montanes, N. Toughened poly (lactic acid)—PLA formulations by binary blends with poly (butylene succinate-co-adipate)—PBSA and their shape memory behaviour. Materials 2019, 12, 622. [Google Scholar] [CrossRef] [PubMed]

- Tahir, N.; Bhatti, H.N.; Iqbal, M.; Noreen, S. Biopolymers composites with peanut hull waste biomass and application for Crystal Violet adsorption. Int. J. Biol. Macromol. 2017, 94, 210–220. [Google Scholar] [CrossRef] [PubMed]

- Quiles-Carrillo, L.; Montanes, N.; Jorda-Vilaplana, A.; Balart, R.; Torres-Giner, S. A comparative study on the effect of different reactive compatibilizers on injection-molded pieces of bio-based high-density polyethylene/polylactide blends. J. Appl. Polym. Sci. 2019, 136, 47396. [Google Scholar] [CrossRef]

- Aguero, A.; Quiles-Carrillo, L.; Jorda-Vilaplana, A.; Fenollar, O.; Montanes, N. Effect of different compatibilizers on environmentally friendly composites from poly (lactic acid) and diatomaceous earth. Polym. Int. 2019, 68, 893–903. [Google Scholar] [CrossRef]

- Andreeßen, C.; Steinbüchel, A. Recent developments in non-biodegradable biopolymers: Precursors, production processes, and future perspectives. Appl. Microbiol. Biotechnol. 2019, 103, 143–157. [Google Scholar] [CrossRef]

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef]

- García-Campo, M.J.; Boronat, T.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Manufacturing and characterization of toughened poly (lactic acid)(PLA) formulations by ternary blends with biopolyesters. Polymers 2018, 10, 3. [Google Scholar] [CrossRef]

- Önal, E.; Uzun, B.B.; Pütün, A.E. Bio-oil production via co-pyrolysis of almond shell as biomass and high density polyethylene. Energy Convers. Manag. 2014, 78, 704–710. [Google Scholar] [CrossRef]

- Chen, G.; Li, S.; Jiao, F.; Yuan, Q. Catalytic dehydration of bioethanol to ethylene over TiO2/γ-Al2O3 catalysts in microchannel reactors. Catal. Today 2007, 125, 111–119. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Torres, A.; Ferrándiz, M.; Fombuena, V.; Balart, R. Antimicrobial activity of metal cation-exchanged zeolites and their evaluation on injection-molded pieces of bio-based high-density polyethylene. J. Food Saf. 2017, 37, e12348. [Google Scholar] [CrossRef]

- Vasile, C.; Râpă, M.; Ştefan, M.; Stan, M.; Macavei, S.; Darie-Niţă, R.; Barbu-Tudoran, L.; Vodnar, D.; Popa, E.; Ştefan, R. New PLA/ZnO: Cu/Ag bionanocomposites for food packaging. Express Polym. Lett. 2017, 11, 531–544. [Google Scholar] [CrossRef]

- Dahy, H. Biocomposite materials based on annual natural fibres and biopolymers–Design, fabrication and customized applications in architecture. Constr. Build. Mater. 2017, 147, 212–220. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Mechanical properties of natural fibre polymer composites. J. Polym. Eng. 2017, 37, 879–895. [Google Scholar] [CrossRef]

- Agüero, Á.; Garcia-Sanoguera, D.; Lascano, D.; Rojas-Lema, S.; Ivorra-Martinez, J.; Fenollar, O.; Torres-Giner, S. Evaluation of different compatibilization strategies to improve the performance of injection-molded green composite pieces made of polylactide reinforced with short flaxseed fibers. Polymers 2020, 12, 821. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Julián, F.; Tarrés, Q.; Méndez, J.; Mutjé, P.; Espinach, F. Bio composite from bleached pine fibers reinforced polylactic acid as a replacement of glass fiber reinforced polypropylene, macro and micro-mechanics of the Young’s modulus. Compos. Part. B Eng. 2017, 125, 203–210. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Quiles-Carrillo, L.; Montanes, N.; Fombuena, V.; Balart, R. Manufacturing and Characterization of Composite Fibreboards with Posidonia oceanica Wastes with an Environmentally-Friendly Binder from Epoxy Resin. Materials 2018, 11, 35. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Boronat, T.; Quiles-Carrillo, L.; Fenollar, O.; Dominici, F.; Torre, L. Valorization of Cotton Industry Byproducts in Green Composites with Polylactide. J. Polym. Environ. 2020, 8, 2039–2053. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef]

- Kandemir, A.; Longana, M.L.; Panzera, T.H.; Del Pino, G.G.; Hamerton, I.; Eichhorn, S.J.J.M. Natural Fibres as a Sustainable Reinforcement Constituent in Aligned Discontinuous Polymer Composites Produced by the HiPerDiF Method. Materials 2021, 14, 1885. [Google Scholar] [CrossRef]

- Fitzgerald, A.; Proud, W.; Kandemir, A.; Murphy, R.J.; Jesson, D.A.; Trask, R.S.; Hamerton, I.; Longana, M.L.J.S. A life cycle engineering perspective on biocomposites as a solution for a sustainable recovery. Sustainability 2021, 13, 1160. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Bilitewski, B. The circular economy and its risks. Waste Manag. 2012, 1, 1–2. [Google Scholar] [CrossRef] [PubMed]

- Corrado, A.; Polini, W. Measurement of high flexibility components in composite material by touch probe and force sensing resistors. J. Manuf. Process. 2019, 45, 520–531. [Google Scholar] [CrossRef]

- Chen, J.; Gao, X. Directional dependence of electrical and thermal properties in graphene-nanoplatelet-based composite materials. Results Phys. 2019, 15, 102608. [Google Scholar] [CrossRef]

- Harada, J.; de Souza, A.G.; de Macedo, J.R.; Rosa, D.S. Soil culture: Influence of different natural fillers incorporated in biodegradable mulching film. J. Mol. Liq. 2019, 273, 33–36. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng. Sci. Technol. Int. J. 2016, 19, 717–736. [Google Scholar] [CrossRef]

- Assi, A.; Bilo, F.; Zanoletti, A.; Ducoli, S.; Ramorino, G.; Gobetti, A.; Zacco, A.; Federici, S.; Depero, L.E.; Bontempi, E. A Circular Economy Virtuous Example—Use of a Stabilized Waste Material Instead of Calcite to Produce Sustainable Composites. Appl. Sci. 2020, 10, 754. [Google Scholar] [CrossRef]

- Bledzki, A.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Lagaron, J.M.; Balart, R.; Torres-Giner, S. On the use of acrylated epoxidized soybean oil as a reactive compatibilizer in injection-molded compostable pieces consisting of polylactide filled with orange peel flour. Polym. Int. 2018, 67, 1341–1351. [Google Scholar] [CrossRef]

- Hoffmann, R.; Morais, D.; Braz, C.; Haag, K.; Wellen, R.; Canedo, E.; de Carvalho, L.; Koschek, K. Impact of the natural filler babassu on the processing and properties of PBAT/PHB films. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105472. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crop. Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Liu, W.; Misra, M.; Askeland, P.; Drzal, L.T.; Mohanty, A.K. ‘Green’composites from soy based plastic and pineapple leaf fiber: Fabrication and properties evaluation. Polymer 2005, 46, 2710–2721. [Google Scholar] [CrossRef]

- Kapatel, P.M. Investigation of green composite: Preparation and characterization of alkali-treated jute fabric-reinforced polymer matrix composites. J. Nat. Fibers 2021, 18, 510–519. [Google Scholar] [CrossRef]

- Srivastava, K.R.; Singh, M.K.; Mishra, P.K.; Srivastava, P. Pretreatment of banana pseudostem fibre for green composite packaging film preparation with polyvinyl alcohol. J. Polym. Res. 2019, 26, 95. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Hilliou, L.; Melendez-Rodriguez, B.; Figueroa-Lopez, K.J.; Madalena, D.; Cabedo, L.; Covas, J.; Vicente, A.A.; Lagaron, J. Melt processability, characterization, and antibacterial activity of compression-molded green composite sheets made of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) reinforced with coconut fibers impregnated with oregano essential oil. Food Packag. Shelf Life 2018, 17, 39–49. [Google Scholar] [CrossRef]

- Agüero, Á.; Lascano, D.; Garcia-Sanoguera, D.; Fenollar, O.; Torres-Giner, S. Valorization of linen processing by-products for the development of injection-molded green composite pieces of polylactide with improved performance. Sustainability 2020, 12, 652. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Ashori, A. Wood–plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef]

- Herrmann, A.; Nickel, J.; Riedel, U. Construction materials based upon biologically renewable resources—From components to finished parts. Polym. Degrad. Stab. 1998, 59, 251–261. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Alves, C.; Silva, A.; Reis, L.; Freitas, M.; Rodrigues, L.; Alves, D. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Jayaraman, K. Manufacturing sisal–polypropylene composites with minimum fibre degradation. Compos. Sci. Technol. 2003, 63, 367–374. [Google Scholar] [CrossRef]

- Wang, H.; Hassan, E.; Memon, H.; Elagib, T.; Abad AllaIdris, F.J.P. Characterization of natural composites fabricated from Abutilon-fiber-reinforced Poly (Lactic Acid). Processes 2019, 7, 583. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A.J.C.P. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.V.; Drzal, L.; Mohanty, A.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part. A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Lopresti, F. Physical properties of green composites based on poly-lactic acid or Mater-Bi® filled with Posidonia Oceanica leaves. Compos. Part A Appl. Sci. Manuf. 2018, 112, 315–327. [Google Scholar] [CrossRef]

- Hughes, M.; Carpenter, J.; Hill, C. Deformation and fracture behaviour of flax fibre reinforced thermosetting polymer matrix composites. J. Mater. Sci. 2007, 42, 2499–2511. [Google Scholar] [CrossRef]

- Garkhail, S.; Heijenrath, R.; Peijs, T. Mechanical properties of natural-fibre-mat-reinforced thermoplastics based on flax fibres and polypropylene. Appl. Compos. Mater. 2000, 7, 351–372. [Google Scholar] [CrossRef]

- Sharma, H.; Faughey, G.; Lyons, G. Comparison of physical, chemical, and thermal characteristics of water-, dew-, and enzyme-retted flax fibers. J. Appl. Polym. Sci. 1999, 74, 139–143. [Google Scholar] [CrossRef]

- Charlet, K.; Jernot, J.; Gomina, M.; Bréard, J.; Morvan, C.; Baley, C. Influence of an Agatha flax fibre location in a stem on its mechanical, chemical and morphological properties. Compos. Sci. Technol. 2009, 69, 1399–1403. [Google Scholar] [CrossRef]

- Correia, F.; Roy, D.; Goel, K. Chemistry and delignification kinetics of Canadian industrial hemp. J. Wood Chem. Technol. 2001, 21, 97–111. [Google Scholar] [CrossRef]

- Mohanty, A.; Tummala, P.; Liu, W.; Misra, M.; Mulukutla, P.; Drzal, L. Injection molded biocomposites from soy protein based bioplastic and short industrial hemp fiber. J. Polym. Environ. 2005, 13, 279–285. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Mortazavi, S.; Moghaddam, M.K. An analysis of structure and properties of a natural cellulosic fiber (Leafiran). Fibers Polym. 2010, 11, 877–882. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Elkhaoulani, A.; Arrakhiz, F.; Benmoussa, K.; Bouhfid, R.; Qaiss, A. Mechanical and thermal properties of polymer composite based on natural fibers: Moroccan hemp fibers/polypropylene. Mater. Des. 2013, 49, 203–208. [Google Scholar] [CrossRef]

- Islam, M.N.; Rahman, M.R.; Haque, M.M.; Huque, M.M. Physico-mechanical properties of chemically treated coir reinforced polypropylene composites. Compos. Part. A Appl. Sci. Manuf. 2010, 41, 192–198. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Preparation and properties of wood plastic composites made of recycled high-density polyethylene. J. Compos. Mater. 2009, 43, 877–883. [Google Scholar] [CrossRef]

- Arrakhiz, F.; El Achaby, M.; Malha, M.; Bensalah, M.; Fassi-Fehri, O.; Bouhfid, R.; Benmoussa, K.; Qaiss, A.J.M. Design. Mechanical and thermal properties of natural fibers reinforced polymer composites: Doum/low density polyethylene. Mater. Des. 2013, 43, 200–205. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Fombuena, V.; Balart, R.; Torres-Giner, S. Enhancement of the processing window and performance of polyamide 1010/bio-based high-density polyethylene blends by melt mixing with natural additives. Polym. Int. 2020, 69, 61–71. [Google Scholar] [CrossRef]

- Lima, P.S.; Trocolli, R.; Wellen, R.M.; Rojo, L.; Lopez-Manchado, M.A.; Fook, M.V.; Silva, S.M. HDPE/Chitosan Composites Modified with PE-g-MA. Thermal, Morphological and Antibacterial Analysis. Polymers 2019, 11, 1559. [Google Scholar] [CrossRef] [PubMed]

- Effah, B.; Van Reenen, A.; Meincken, M. Mechanical properties of wood-plastic composites made from various wood species with different compatibilisers. Eur. J. Wood Wood Prod. 2018, 76, 57–68. [Google Scholar] [CrossRef]

- Chimeni, D.Y.; Toupe, J.L.; Dubois, C.; Rodrigue, D. Effect of hemp surface modification on the morphological and tensile properties of linear medium density polyethylene (LMDPE) composites. Compos. Interfaces 2016, 23, 405–421. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; de Ballesteros, O.R.; Mollica, F.; Filippone, G. Reinforcing mechanisms of natural fibers in green composites: Role of fibers morphology in a PLA/hemp model system. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Ou, R.; Wang, Q. The properties of flax fiber reinforced wood flour/high density polyethylene composites. J. For. Res. 2018, 29, 533–540. [Google Scholar] [CrossRef]

- Jiang, H.; Kamdem, D.P. Development of poly (vinyl chloride)/wood composites. A literature review. J. Vinyl Addit. Technol. 2004, 10, 59–69. [Google Scholar] [CrossRef]

- Husseinsyah, S.; Amri, F.; Husin, K.; Ismail, H. Mechanical and thermal properties of chitosan-filled polypropylene composites: The effect of acrylic acid. J. Vinyl Addit. Technol. 2011, 17, 125–131. [Google Scholar] [CrossRef]

- Zhang, Q.; Khan, M.U.; Lin, X.; Cai, H.; Lei, H. Temperature varied biochar as a reinforcing filler for high-density polyethylene composites. Compos. Part B Eng. 2019, 175, 107151. [Google Scholar] [CrossRef]

- Abdul Wahab, M.K.; Ismail, H.; Othman, N. Compatibilization effects of PE-g-MA on mechanical, thermal and swelling properties of high density polyethylene/natural rubber/thermoplastic tapioca starch blends. Polym. Plast. Technol. Eng. 2012, 51, 298–303. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Boronat, T.; Montanes, N.; Balart, R.; Torres-Giner, S. Injection-molded parts of fully bio-based polyamide 1010 strengthened with waste derived slate fibers pretreated with glycidyl-and amino-silane coupling agents. Polym. Test. 2019, 77, 105875. [Google Scholar] [CrossRef]

- Pracella, M.; Chionna, D.; Anguillesi, I.; Kulinski, Z.; Piorkowska, E. Functionalization, compatibilization and properties of polypropylene composites with hemp fibres. Compos. Sci. Technol. 2006, 66, 2218–2230. [Google Scholar] [CrossRef]

- Piorkowska, E. Modeling of crystallization kinetics in fiber reinforced composites. Macromol. Symp. 2001, 169, 143–148. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. Thermal degradation of flax and jute fibers. J. Appl. Polym. Sci. 2001, 82, 1417–1422. [Google Scholar] [CrossRef]

- Chun, K.S.; Husseinsyah, S.; Osman, H. Mechanical and thermal properties of coconut shell powder filled polylactic acid biocomposites: Effects of the filler content and silane coupling agent. J. Polym. Res. 2012, 19, 1–8. [Google Scholar] [CrossRef]

- Rachini, A.; Le Troedec, M.; Peyratout, C.; Smith, A. Comparison of the thermal degradation of natural, alkali-treated and silane-treated hemp fibers under air and an inert atmosphere. J. Appl. Polym. Sci. 2009, 112, 226–234. [Google Scholar] [CrossRef]

- Kifani-Sahban, F.; Belkbir, L.; Zoulalian, A. Etude de la pyrolyse lente de l’Eucalyptus marocain par analyse thermique. Thermochim. Acta 1996, 284, 341–349. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Castro, D.; Ruvolo-Filho, A.; Frollini, E. Materials prepared from biopolyethylene and curaua fibers: Composites from biomass. Polym. Test. 2012, 31, 880–888. [Google Scholar] [CrossRef]

- Pegoretti, A.; Ashkar, M.; Migliaresi, C.; Marom, G. Relaxation processes in polyethylene fibre-reinforced polyethylene composites. Compos. Sci. Technol. 2000, 60, 1181–1189. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Torres-Giner, S.; Puglia, D.; Dominici, F.; Torre, L. Development of Compatibilized Polyamide 1010/Coconut Fibers Composites by Reactive Extrusion with Modified Linseed Oil and Multi-functional Petroleum Derived Compatibilizers. Fibers Polym. 2021, 1–17. [Google Scholar] [CrossRef]

- Gironès, J.; López, J.; Mutjé, P.; Carvalho, A.J.F.D.; Curvelo, A.A.D.S.; Vilaseca, F. Natural fiber-reinforced thermoplastic starch composites obtained by melt processing. Compos. Sci. Technol. 2012, 72, 858–863. [Google Scholar] [CrossRef]

- Liminana, P.; Quiles-Carrillo, L.; Boronat, T.; Balart, R.; Montanes, N. The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly (Butylene Succinate (PBS) Matrix Compatibilized with Maleinized Linseed Oil (MLO). Materials 2018, 11, 2179. [Google Scholar] [CrossRef] [PubMed]

- Barcík, Š.; Gašparík, M.; Razumov, E.Y. Effect of temperature on the color changes of wood during thermal modification. Cellul. Chem. Technol. 2015, 49, 789–798. [Google Scholar]

- Ostafi, M.-F.; Dinulică, F.; Nicolescu, V.-N. Physical properties and structural features of common walnut (Juglans regia L.) wood: A case-study/Physikalische Eigenschaften und strukturelle Charakteristika des Holzes der Walnuß (Juglans regia L.): Eine Fallstudie. Bodenkult. J. Land Manag. Food Environ. 2016, 67, 105–120. [Google Scholar] [CrossRef]

- Majid, R.A.; Ismail, H.; Taib, R.M. Effects of PE-g-MA on tensile properties, morphology and water absorption of LDPE/thermoplastic sago starch blends. Polym. Plast. Technol. Eng. 2009, 48, 919–924. [Google Scholar] [CrossRef]

- Najafi, S.K.; Tajvidi, M.; Chaharmahli, M.J.J.O.A.P.S. Long-term water uptake behavior of lignocellulosic-high density polyethylene composites. J. Appl. Polym. Sci. 2006, 102, 3907–3911. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Ni, A.; Chen, H.; Shen, P. Synthesis of a novel phosphorous-nitrogen based charring agent and its application in flame-retardant HDPE/IFR composites. Polymers 2019, 11, 1062. [Google Scholar] [CrossRef]

- Zhao, W.; Hu, Q.; Zhang, N.; Wei, Y.; Zhao, Q.; Zhang, Y.; Dong, J.; Sun, Z.; Liu, B.; Li, L. In situ inorganic flame retardant modified hemp and its polypropylene composites. RSC Adv. 2017, 7, 32236–32245. [Google Scholar] [CrossRef]

- Cheng, J.J.; Qu, W.J.; Sun, S.H. Effects of flame-retardant flax-fiber on enhancing performance of the rigid polyurethane foams. J. Appl. Polym. Sci. 2018, 135, 46436. [Google Scholar] [CrossRef]

- Wang, K.; Addiego, F.; Laachachi, A.; Kaouache, B.; Bahlouli, N.; Toniazzo, V.; Ruch, D. Dynamic behavior and flame retardancy of HDPE/hemp short fiber composites: Effect of coupling agent and fiber loading. Compos. Struct. 2014, 113, 74–82. [Google Scholar] [CrossRef]

- Dorez, G.; Taguet, A.; Ferry, L.; Lopez-Cuesta, J. Thermal and fire behavior of natural fibers/PBS biocomposites. Polym. Degrad. Stab. 2013, 98, 87–95. [Google Scholar] [CrossRef]

| Code | BioHDPE υBio-HDPE | Hemp υHemp | Flax υFlax | Jute υjute | PE-g-MA υPE-g-MA |

|---|---|---|---|---|---|

| BioHDPE | 1.000 | - | - | - | - |

| BioHDPE/PE-g-MA | 0.980 | - | - | - | 0.020 |

| BioHDPE/Hemp/PE-g-MA | 0.843 | 0.135 | - | - | 0.022 |

| BioHDPE/Flax/PE-g-MA | 0.840 | - | 0.138 | - | 0.022 |

| BioHDPE/Jute/PE-g-MA | 0.839 | - | - | 0.139 | 0.022 |

| Code | E (GPa) | σmax (MPa) | εb (%) | Shore D Hardness | Impact Strength (kJ/m2) |

|---|---|---|---|---|---|

| BioHDPE | 0.790 ± 0.008 | 14.5 ± 0.8 | NB | 56.0 ± 0.7 | 2.7 ± 0.2 |

| BioHDPE/PE-g-MA | 0.791 ± 0.014 | 13.3 ± 0.6 | NB | 55.8 ± 0.8 | 2.8 ± 0.3 |

| BioHDPE/Hemp/PE-g-MA | 1.730 ± 0.014 | 15.5 ± 1.4 | 3.4 ± 0.4 | 59.4 ± 1.1 | 3.9 ± 0.2 |

| BioHDPE/Flax/PE-g-MA | 1.630 ± 0.038 | 16.7 ± 1.1 | 2.8 ± 0.7 | 61.6 ± 0.5 | 3.0 ± 0.1 |

| BioHDPE/Jute/PE-g-MA | 1.675 ± 0.012 | 18.6 ± 0.3 | 4.4 ± 0.9 | 60.2 ± 1.2 | 3.7 ± 0.2 |

| Code | Tm (°C) | ∆Hm (J/g) | χc (%) |

|---|---|---|---|

| BioHDPE | 131.1 ± 1.5 | 202.9 ± 1.6 | 69.2 ± 1.5 |

| BioHDPE/PE-g-MA | 132.1 ± 1.1 | 161.8 ± 1.2 | 55.2 ± 0.9 |

| BioHDPE/Hemp/PE-g-MA | 132.4 ± 0.9 | 143.9 ± 1.1 | 61.4 ± 1.1 |

| BioHDPE/Flax/PE-g-MA | 131.9 ± 1.1 | 154.4 ± 1.3 | 65.9 ± 1.2 |

| BioHDPE/Jute/PE-g-MA | 131.6 ± 0.8 | 141.1 ± 0.9 | 60.2 ± 0.8 |

| Parts | T5% (°C) | Tdeg1 (°C) | Tdeg2 (°C) | Residual Weight (%) |

|---|---|---|---|---|

| BioHDPE | 341.6 ± 1.5 | - | 478.9 ± 2.6 | 0.4 ± 0.2 |

| BioHDPE/PE-g-MA | 331.3 ± 1.2 | - | 469.8 ± 1.7 | 0.1 ± 0.1 |

| BioHDPE/Hemp/PE-g-MA | 300.3 ± 1.1 | 352.8 ± 1.0 | 478.8 ± 1.5 | 1.6 ± 0.3 |

| BioHDPE/Flax/PE-g-MA | 305.2 ± 1.1 | 370.0 ± 1.4 | 482.9 ± 0.9 | 2.2 ± 0.4 |

| BioHDPE/Jute/PE-g-MA | 314.1 ± 0.9 | 369.9 ± 1.1 | 481.6 ± 1.2 | 1.5 ± 0.3 |

| Parts | E’ (MPa) at −145 °C | E’ (MPa) at 0 °C | E’ (MPa) at 75 °C | Tg (°C) |

|---|---|---|---|---|

| BioHDPE | 2664 ± 18 | 1151 ± 10 | 210 ± 5 | −120.1 ± 0.8 |

| BioHDPE/PE-g-MA | 2469 ± 19 | 1081 ± 9 | 210 ± 3 | −120.0 ± 0.9 |

| BioHDPE/Hemp/PE-g-MA | 2944 ± 29 | 1525 ± 14 | 430 ± 8 | −122.4 ± 0.9 |

| BioHDPE/Flax/PE-g-MA | 2781 ± 35 | 1429 ± 12 | 485 ± 9 | −113.3 ± 1.1 |

| BioHDPE/Jute/PE-g-MA | 2648 ± 28 | 1400 ± 14 | 460 ± 10 | −118.9 ± 1.0 |

| Code | L* | a* | b* |

|---|---|---|---|

| BioHDPE | 72.5 ± 0.5 | −2.1 ± 0.1 | −5.5 ± 0.1 |

| BioHDPE/PE-g-MA | 71.8 ± 0.7 | −2.3 ± 0.1 | −5.1 ± 0.1 |

| BioHDPE/Hemp/PE-g-MA | 44.9 ± 0.4 | 7.3 ± 0.1 | 17.0 ± 0.2 |

| BioHDPE/Flax/PE-g-MA | 40.7 ± 0.4 | 3.6 ± 0.1 | 10.4 ± 0.1 |

| BioHDPE/Jute/PE-g-MA | 38.7 ± 0.2 | 4.6 ± 0.1 | 8.1 ± 0.1 |

| Code | Heat Release (MJ/kg) | Dsmax | FST(s) | tinf (s) |

|---|---|---|---|---|

| BioHDPE | 46.5 ± 3.1 | 640.3 ± 5.9 | 159 ± 7 | >600 ± 12 |

| BioHDPE/PE-g-MA | 44.8 ± 2.5 | 580.9 ± 7.5 | 210 ± 9 | >600 ± 10 |

| BioHDPE/Hemp/PE-g-MA | 42.5 ± 1.9 | 864.8 ± 9.8 | 56 ± 3 | 303 ± 10 |

| BioHDPE/Flax/PE-g-MA | 40.6 ± 2.1 | 856.2 ± 14.9 | 53 ± 4 | 329 ± 12 |

| BioHDPE/Jute/PE-g-MA | 41.1 ± 2.3 | 792.8 ± 12.6 | 46 ± 3 | 294 ± 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolza, C.; Fages, E.; Gonga, E.; Gomez-Caturla, J.; Balart, R.; Quiles-Carrillo, L. Development and Characterization of Environmentally Friendly Wood Plastic Composites from Biobased Polyethylene and Short Natural Fibers Processed by Injection Moulding. Polymers 2021, 13, 1692. https://doi.org/10.3390/polym13111692

Dolza C, Fages E, Gonga E, Gomez-Caturla J, Balart R, Quiles-Carrillo L. Development and Characterization of Environmentally Friendly Wood Plastic Composites from Biobased Polyethylene and Short Natural Fibers Processed by Injection Moulding. Polymers. 2021; 13(11):1692. https://doi.org/10.3390/polym13111692

Chicago/Turabian StyleDolza, Celia, Eduardo Fages, Eloi Gonga, Jaume Gomez-Caturla, Rafael Balart, and Luis Quiles-Carrillo. 2021. "Development and Characterization of Environmentally Friendly Wood Plastic Composites from Biobased Polyethylene and Short Natural Fibers Processed by Injection Moulding" Polymers 13, no. 11: 1692. https://doi.org/10.3390/polym13111692

APA StyleDolza, C., Fages, E., Gonga, E., Gomez-Caturla, J., Balart, R., & Quiles-Carrillo, L. (2021). Development and Characterization of Environmentally Friendly Wood Plastic Composites from Biobased Polyethylene and Short Natural Fibers Processed by Injection Moulding. Polymers, 13(11), 1692. https://doi.org/10.3390/polym13111692