Effect of Core Architecture on Charpy Impact and Compression Properties of Tufted Sandwich Structural Composites

Abstract

1. Introduction

2. Materials and Methods

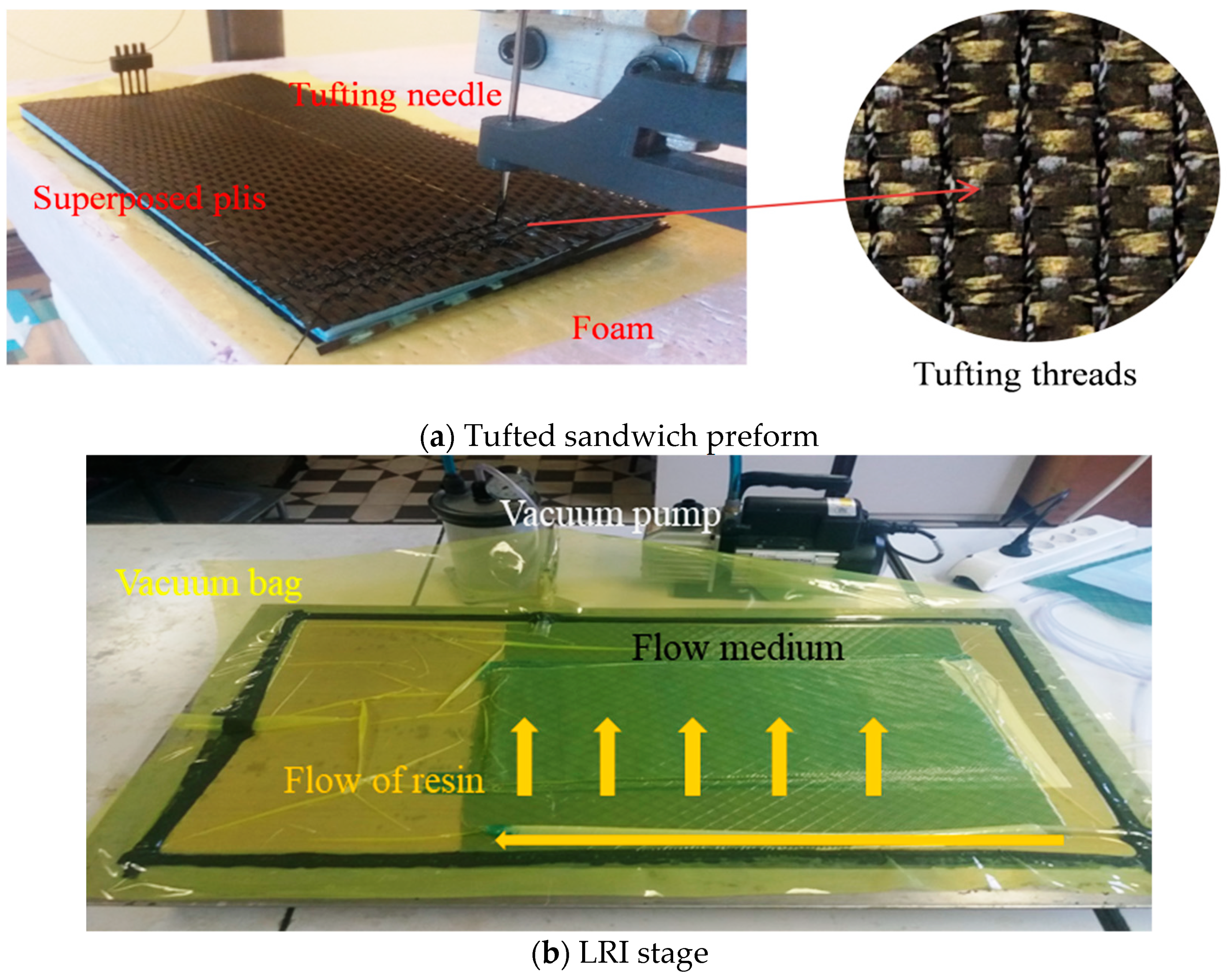

2.1. Process of Sandwich Composite Manufacturing

2.2. Experimental Methods

2.2.1. Flatwise CompressiveTtest

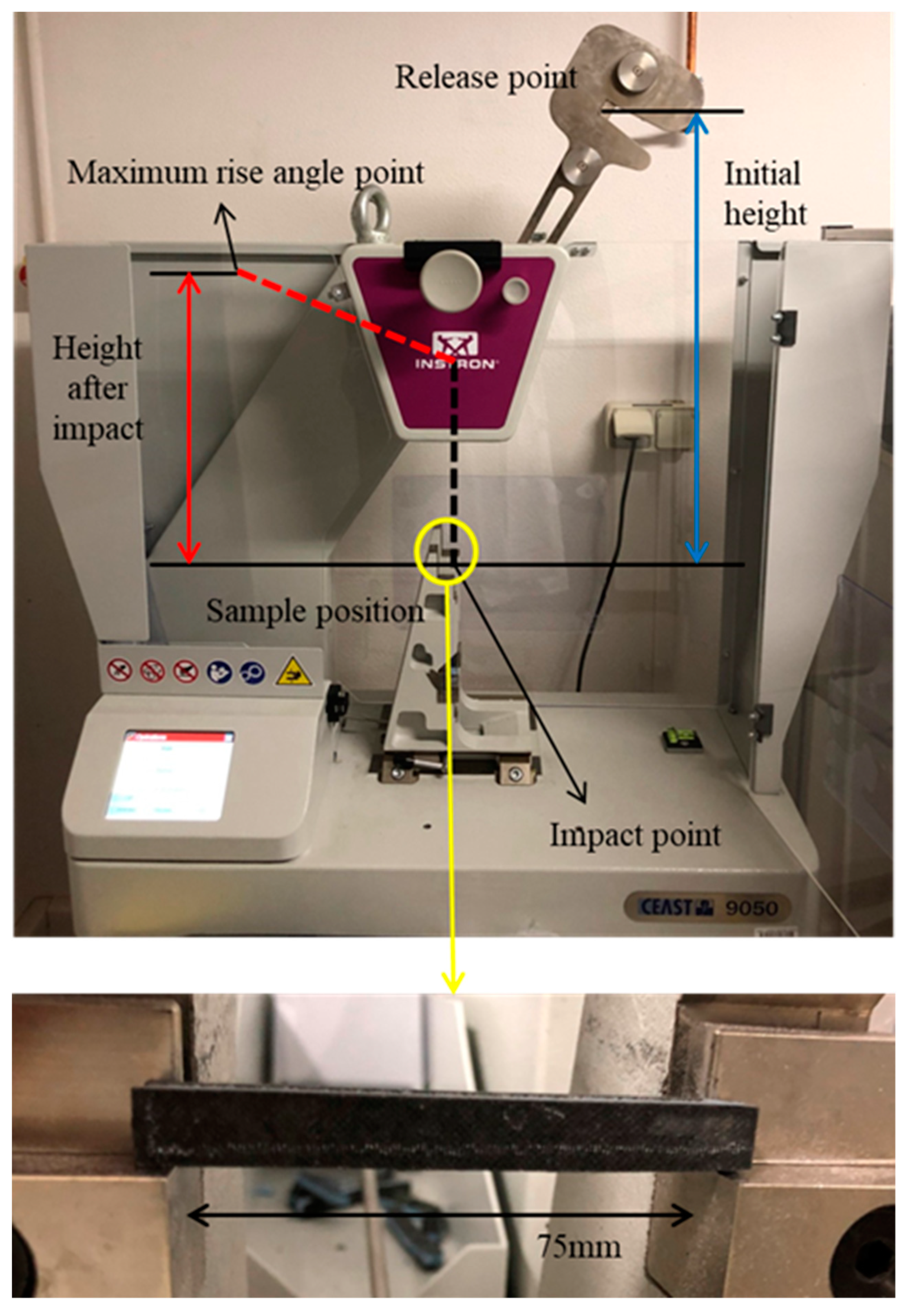

2.2.2. Charpy Impact Test

3. Results

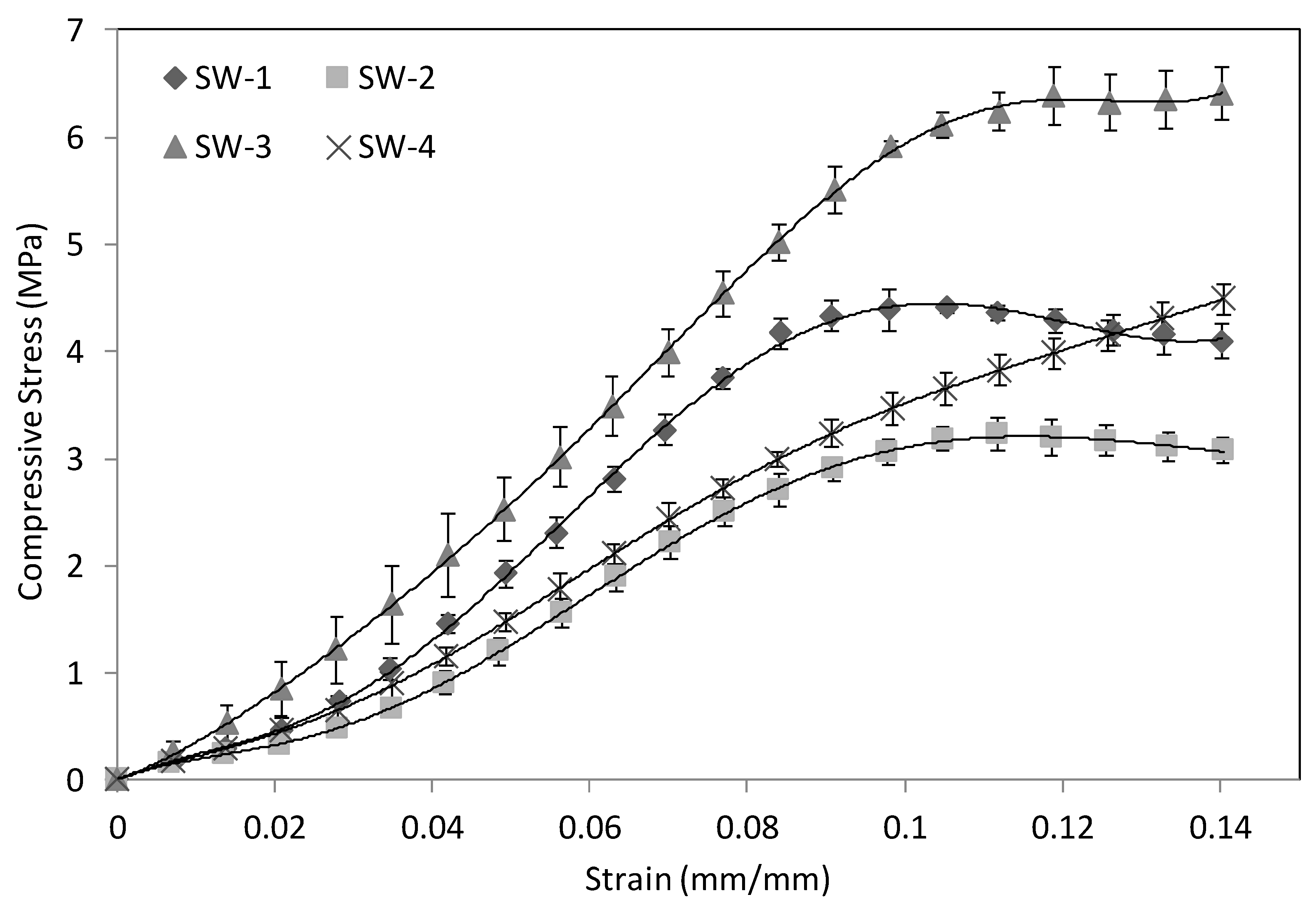

3.1. Compression

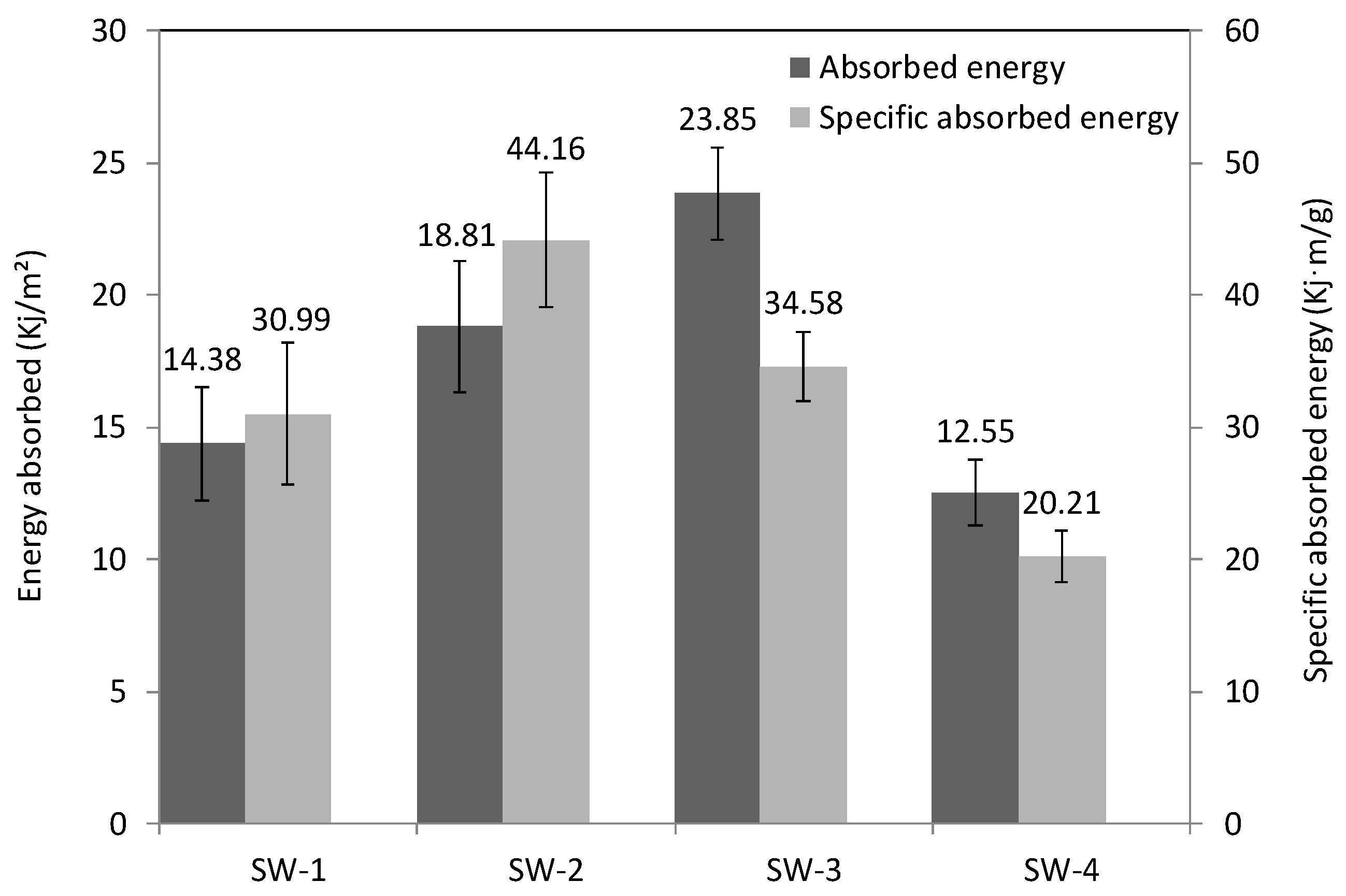

3.2. Charpy Impact

4. Conclusions

- Improvement of the manufacturing process to strictly control the resin content of the sample.

- A new observation method to determine the status of each reinforcement and the failure mode.

- Improvement of the calculation model to accurately determine the compressive strength and modulus.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-fatlawi, A.; Jármai, K.; Kovács, G. Optimal design of a fiber-reinforced plastic composite sandwich structure for the base plate of aircraft pallets in order to reduce weight. Polymers (Basel) 2021, 13, 834. [Google Scholar] [CrossRef]

- Mouritz, A.P. Compression properties of z-pinned sandwich composites. J. Mater. Sci. 2006, 41, 5771–5774. [Google Scholar] [CrossRef]

- Nanayakkara, A.; Feih, S.; Mouritz, A.P. Experimental analysis of the through-thickness compression properties of z-pinned sandwich composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1673–1680. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, J.; Wang, J.; Wu, Y. Interfacial Failure in Stitched Foam Sandwich Composites. Materials (Basel) 2021, 14, 2275. [Google Scholar] [CrossRef] [PubMed]

- Du, L.; Jiao, G. Indentation study of Z-pin reinforced polymer foam core sandwich structures. Compos. Part A Appl. Sci. Manuf. 2009, 40, 822–829. [Google Scholar] [CrossRef]

- Nanayakkara, A.; Feih, S.; Mouritz, A.P. Experimental impact damage study of a z-pinned foam core sandwich composite. J. Sandw. Struct. Mater. 2012, 14, 469–486. [Google Scholar] [CrossRef]

- Kaya, G.; Selver, E. Impact resistance of Z-pin-reinforced sandwich composites. J. Compos. Mater. 2019, 53, 3681–3699. [Google Scholar] [CrossRef]

- M’membe, B.; Gannon, S.; Yasaee, M.; Hallett, S.R.; Partridge, I.K. Mode II delamination resistance of composites reinforced with inclined Z-pins. Mater. Des. 2016, 94, 565–572. [Google Scholar] [CrossRef]

- Knopp, A.; Scharr, G. Tensile Properties of Z-Pin Reinforced Laminates with Circumferentially Notched Z-Pins. J. Compos. Sci. 2020, 4, 78. [Google Scholar] [CrossRef]

- Tekalur, S.A.; Bogdanovich, A.E.; Shukla, A. Shock loading response of sandwich panels with 3-D woven E-glass composite skins and stitched foam core. Compos. Sci. Technol. 2009, 69, 736–753. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Bannister, M.K.; Falzon, P.J.; Leong, K.H. Review of applications for advanced three-dimensional fibre textile composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1445–1461. [Google Scholar] [CrossRef]

- Gereke, T.; Cherif, C. A review of numerical models for 3D woven composite reinforcements. Compos. Struct. 2019, 209, 60–66. [Google Scholar] [CrossRef]

- Lascoup, B.; Aboura, Z.; Khellil, K.; Benzeggagh, M. Prediction of out-of-plane behavior of stitched sandwich structure. Compos. Part B Eng. 2012, 43, 2915–2920. [Google Scholar] [CrossRef]

- Lascoup, B.; Aboura, Z.; Khellil, K.; Benzeggagh, M. Homogenization of the core layer in stitched sandwich structures. Compos. Sci. Technol. 2010, 70, 350–355. [Google Scholar] [CrossRef]

- Zheng, X.T.; Zhang, J.F.; Yang, F.; Chai, Y.N.; Li, Y. Experimental and analytical study on the mechanical behavior of stitched sandwich composite panel with a foam core. Adv. Mater. Res. 2008, 33–37, 477–482. [Google Scholar] [CrossRef]

- Hao, S.; Wang, P.; Legrand, X.; Liu, L.; Soulat, D. Influence of the tufting pattern on the formability of tufted multi-layered preforms. Compos. Struct. 2019, 228, 111356. [Google Scholar]

- Liu, L.S.; Zhang, T.; Wang, P.; Legrand, X.; Soulat, D. Influence of the tufting yarns on formability of tufted 3-Dimensional composite reinforcement. Compos. Part A Appl. Sci. Manuf. 2015. [Google Scholar] [CrossRef]

- Dell’Anno, G.; Treiber, J.W.G.; Partridge, I.K. Manufacturing of composite parts reinforced through-thickness by tufting. Robot. Comput. Integr. Manuf. 2016, 37, 262–272. [Google Scholar] [CrossRef]

- Che, L.; Xu, G.D.; Zeng, T.; Cheng, S.; Zhou, X.W.; Yang, S.C. Compressive and shear characteristics of an octahedral stitched sandwich composite. Compos. Struct. 2014, 112, 179–187. [Google Scholar] [CrossRef]

- May-Pat, A.; Avilés, F.; Aguilar, J. Mechanical properties of sandwich panels with perforated foam cores. J. Sandw. Struct. Mater. 2011, 13, 427–444. [Google Scholar] [CrossRef]

- Jijun, H.; Zuoguang, Z.; Min, L.; Zhijie, S.; Yizuo, G. The influence of preparing method on novel x-truss/foam sandwich structure. J. Reinf. Plast. Compos. 2009, 28, 1553–1565. [Google Scholar] [CrossRef]

- Yalkin, H.E.; Icten, B.M.; Alpyildiz, T. Enhanced mechanical performance of foam core sandwich composites with through the thickness reinforced core. Compos. Part B Eng. 2015, 79, 383–391. [Google Scholar] [CrossRef]

- Zhou, D.; Stronge, W.J. Mechanical properties of fibrous core sandwich panels. Int. J. Mech. Sci. 2005, 47, 775–798. [Google Scholar] [CrossRef]

- Long, D.; Guiqiong, J.; Tao, H. Investigation of the effect of Z-pin reinforcement on the collapse of foam-cored sandwich panels. J. Reinf. Plast. Compos. 2008, 27, 1211–1224. [Google Scholar] [CrossRef]

- Cartié, D.D.; Fleck, N.A. The effect of pin reinforcement upon the through-thickness compressive strength of foam-cored sandwich panels. Compos. Sci. Technol. 2003, 63, 2401–2409. [Google Scholar] [CrossRef]

- Nishi, Y.; Tsuchikura, N.; Nanba, S.; Yamamoto, T.; Faudree, M.C. Charpy impact of sandwich structural composites (CFRP/PC/CFRP) of polycarbonate (PC) cores covered with carbon fiber cross textile reinforced epoxy polymer (CFRP) thin sheets as a function of temperature. Mater. Trans. 2012, 53, 1288–1294. [Google Scholar] [CrossRef]

- Srivastava, V.K. Impact Behaviour of Sandwich GFRP-Foam-GFRP Composites. Int. J. Compos. Mater. 2012, 2, 63–66. [Google Scholar] [CrossRef]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of natural fiber reinforced polymer composites in sandwich structures: A review on its mechanical properties. Polymers (Basel) 2021, 13, 423. [Google Scholar] [CrossRef]

- ASTM C365-16. Standard Test Method for Flatwise Compressive Properties of Sandwich Cores; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ISO 179-1: 2010. Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- Tita, V.; Caliri, M.F. Numerical simulation of anisotropic polymeric foams. Lat. Am. J. Solids Struct. 2012, 9, 259–279. [Google Scholar] [CrossRef]

- Mao, N.; Russell, S.J. Fibre to Fabric: Nonwoven Fabrics; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; ISBN 9780857095619. [Google Scholar]

- Albooyeh, A.; Eskandarzadeh, S.; Mousavi, A. Influence of different foaming conditions on the mechanical, physical, and structural properties of polypropylene foam. Mech. Adv. Compos. Struct. 2019, 6, 225–237. [Google Scholar] [CrossRef]

- Junaedi, H.; Albahkali, E.; Baig, M.; Dawood, A.; Almajid, A. Ductile to Brittle Transition of Short Carbon Fiber-Reinforced Polypropylene Composites. Adv. Polym. Technol. 2020, 2020, 1–10. [Google Scholar] [CrossRef]

| Sample ID | Core Material | TT Reinforcement | Thickness (mm) |

|---|---|---|---|

| SW-1 | 3 layers of foam | Yarn/resin cylinders | 7.27 ± 0.29 |

| SW-2 | Hollow | 6.75 ± 0.16 | |

| SW-3 | Foam/Non-woven | 6.58 ± 0.17 | |

| SW-4 | Pure resin cylinders | 6.46 ± 0.15 |

| Raw Materials | Weight Parameter | Young’s Modulus (GPa) | Elongation at Break |

|---|---|---|---|

| Skin fabric | 285 g/m2 | 24.4 | 3.5% |

| Non-woven | 210 g/m2 | 15.8 | - |

| Tufting yarn | Linear density: 2 × 67 Tex | 240.0 | 1.7% |

| Foam | Density: 0.01 g/cm3 | 1.6 × 10−2 | 6.7% |

| Epoxy resin | Density: 1.2 g/cm3 | 2.9 | 1.7% |

| Sample ID | Compressive Strength (MPa) | Specific Compressive Strength (kN·m/kg) | CV (Coefficient of Variation) | Compressive Modulus (MPa) | Specific Compressive Modulus (kN·m/kg) |

|---|---|---|---|---|---|

| SW-1 | 4.42 | 9.52 | 2.78% | 64.32 | 138.61 |

| SW-2 | 3.24 | 7.60 | 5.48% | 45.17 | 95.70 |

| SW-3 | 6.40 | 9.27 | 3.40% | 67.23 | 97.46 |

| SW-4 | 3.45 | 5.55 | 6.09% | 44.82 | 72.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Wang, P.; Legrand, X. Effect of Core Architecture on Charpy Impact and Compression Properties of Tufted Sandwich Structural Composites. Polymers 2021, 13, 1665. https://doi.org/10.3390/polym13101665

Chen C, Wang P, Legrand X. Effect of Core Architecture on Charpy Impact and Compression Properties of Tufted Sandwich Structural Composites. Polymers. 2021; 13(10):1665. https://doi.org/10.3390/polym13101665

Chicago/Turabian StyleChen, Chen, Peng Wang, and Xavier Legrand. 2021. "Effect of Core Architecture on Charpy Impact and Compression Properties of Tufted Sandwich Structural Composites" Polymers 13, no. 10: 1665. https://doi.org/10.3390/polym13101665

APA StyleChen, C., Wang, P., & Legrand, X. (2021). Effect of Core Architecture on Charpy Impact and Compression Properties of Tufted Sandwich Structural Composites. Polymers, 13(10), 1665. https://doi.org/10.3390/polym13101665