The Use of Laminates of Commercially Available Fabrics for Anti-Stab Body-Armor

Abstract

1. Introduction

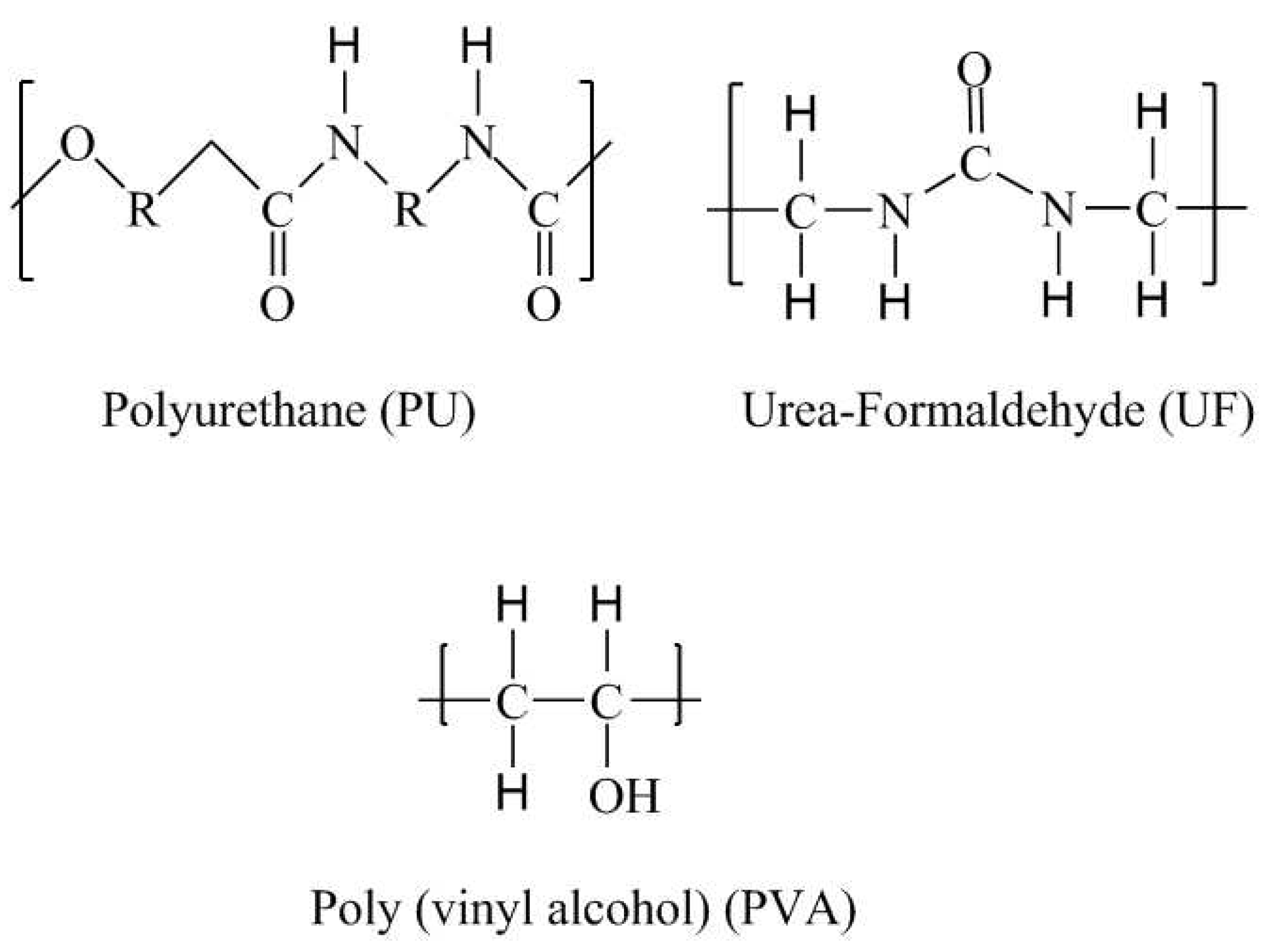

2. Material and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

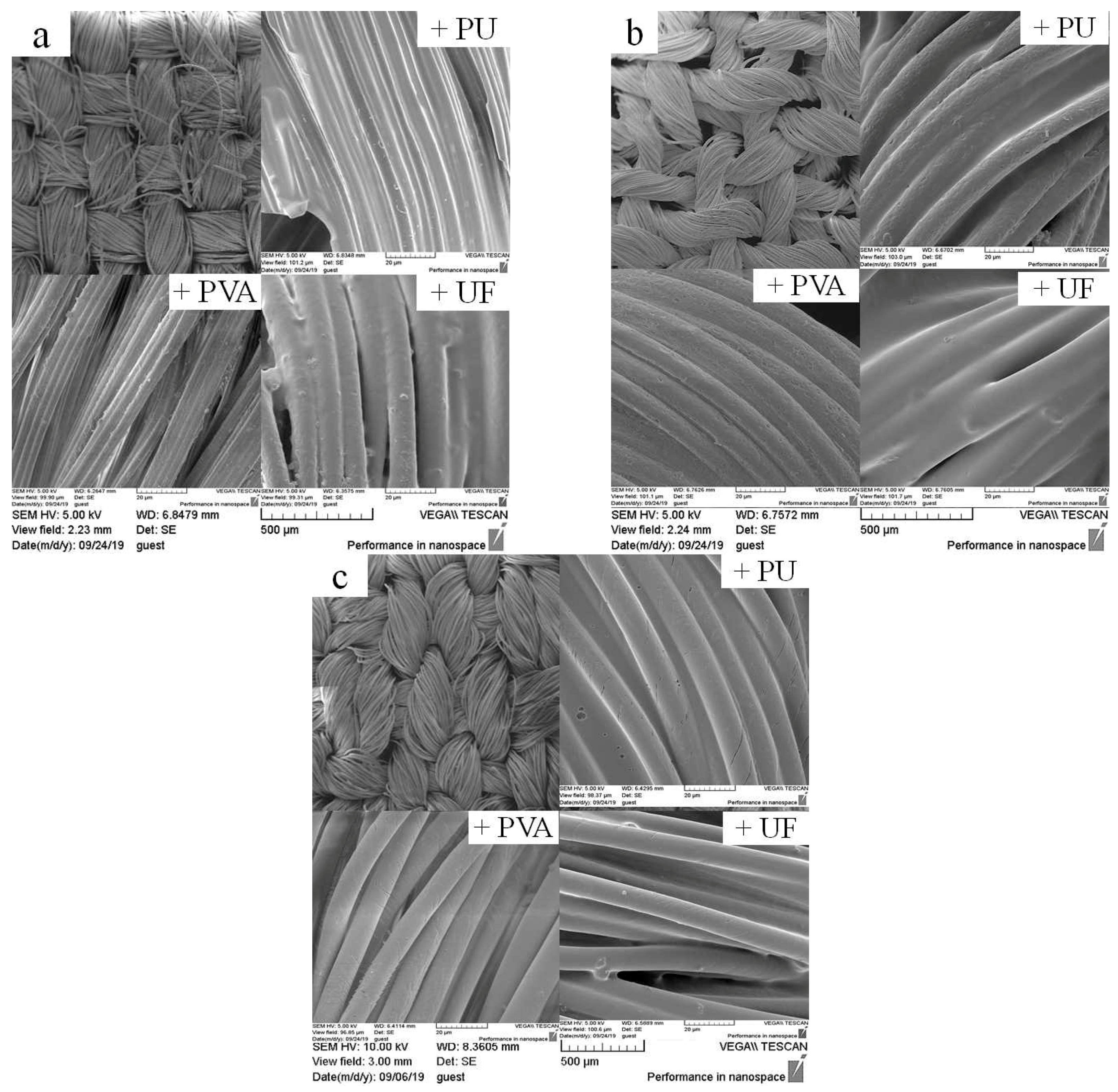

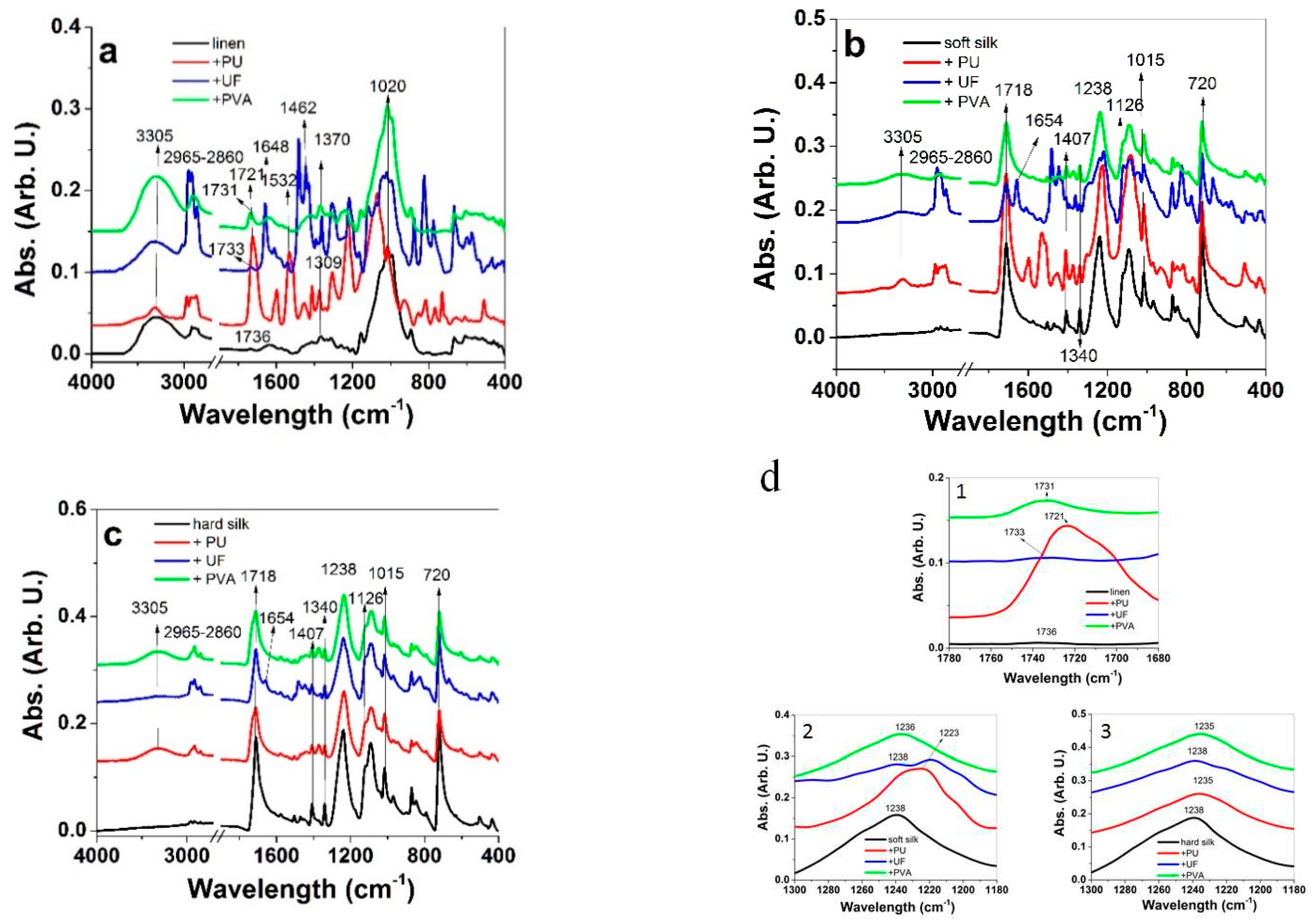

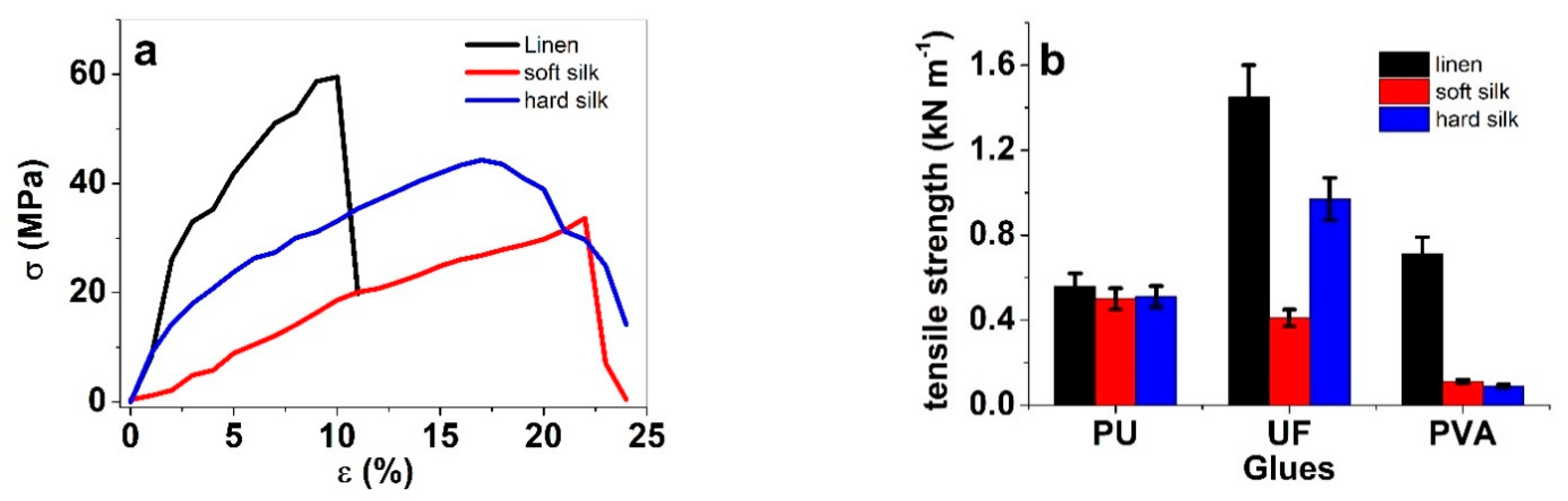

3.1. Influence of Adhesives on Fabrics

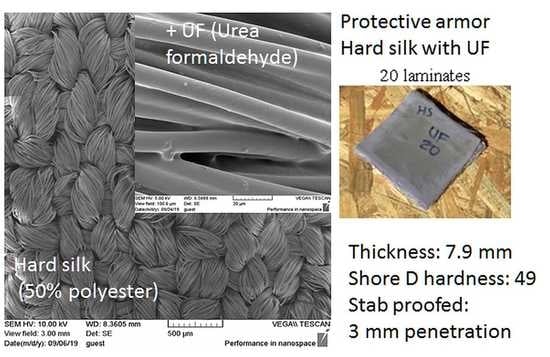

SEM Images

3.2. Material Properties

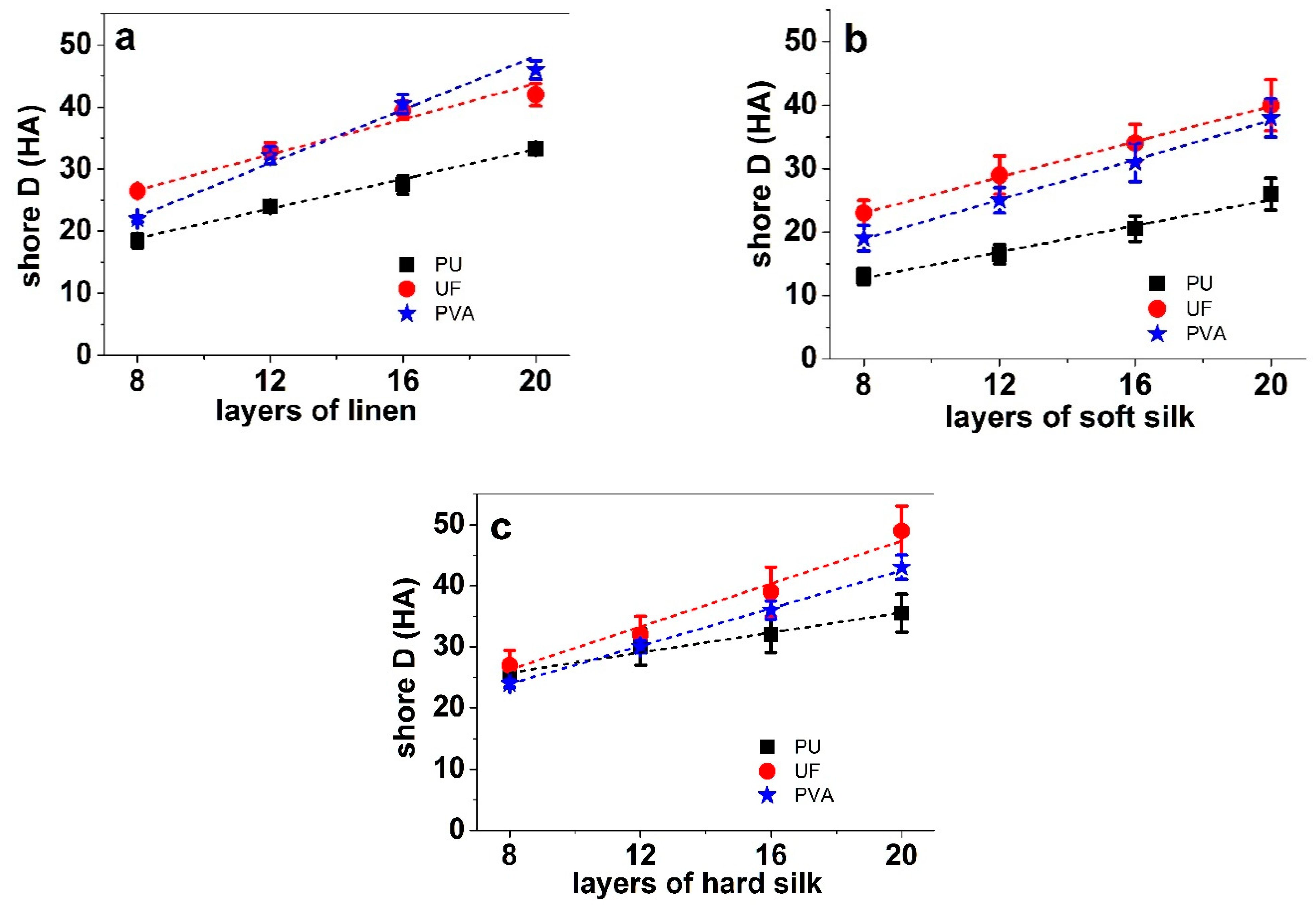

3.2.1. Shore Hardness of Laminates

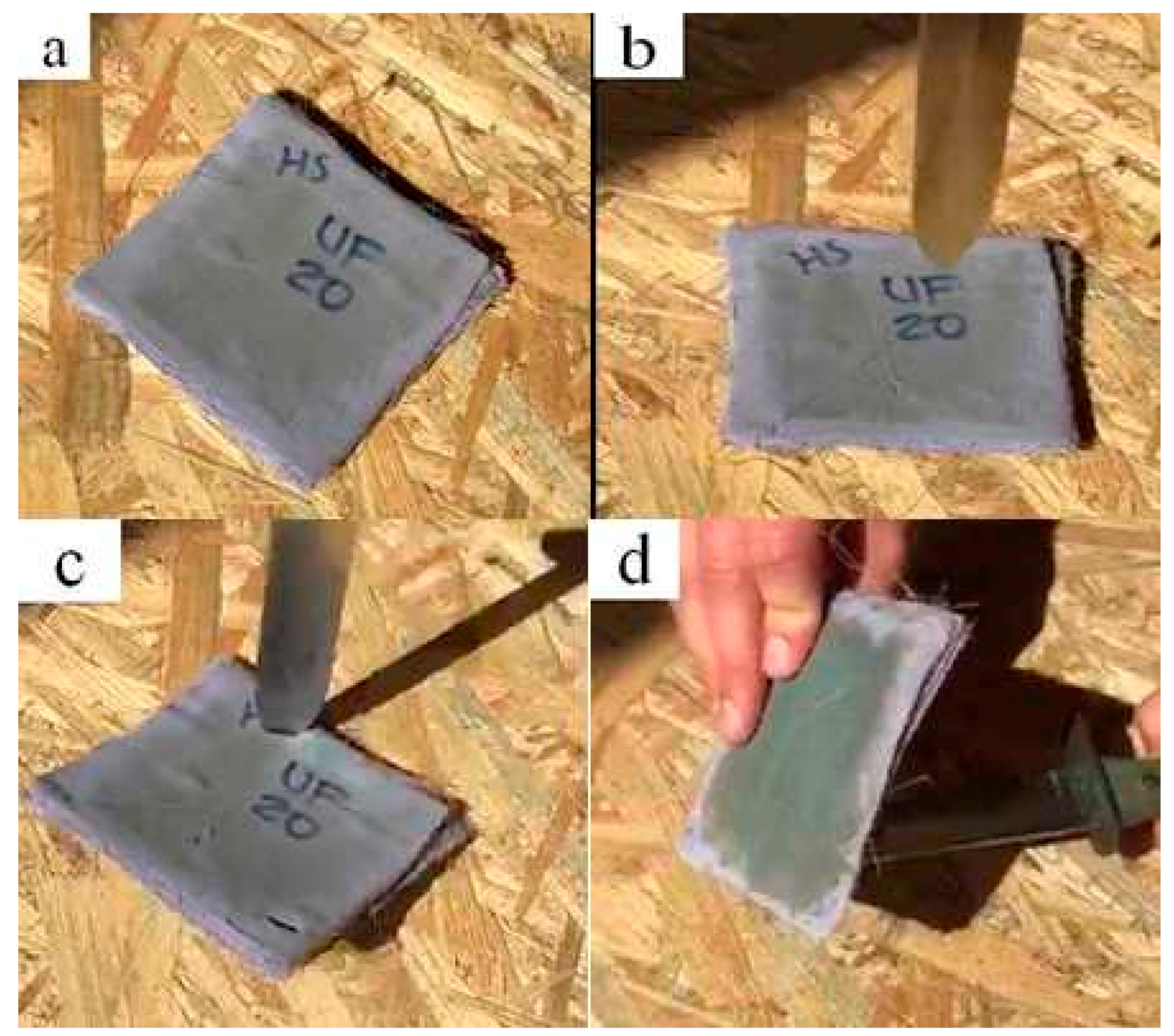

3.2.2. Stab-Proof and Bullet-Proof Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Laible, R.C.; Barron, E. History of Armor; Elsevier Scientific Publishing Company: Amsterdam, The Netherlands, 2012; Volume 5. [Google Scholar]

- Aldrete, G.S.; Bartell, S.; Aldrete, A. Reconstructing Ancient Linen Body Armor: Unraveling the Linothorax Mystery; The Johns Hopkins University Press: Baltimore, MD, USA, 2013; ISBN 978 1 421 408194. [Google Scholar]

- Hogg, P.J. Composites in armor. Science 2006, 314, 1100–1101. [Google Scholar] [CrossRef]

- Vishnu, G.; Chandrasenan, P.; Thankachan, A. Biomechanical Properties of Hybrid Kevlar/Linen/Epoxy Composite for Bone Plate Applications. Int. Res. J. Eng. Technol. 2018, 5, 4203–4208. [Google Scholar]

- Kanesalingam, S.; Nayak, R.; Wang, L.; Padhye, R.; Arnold, L. Stab and puncture resistance of silica-coated Kevlar–wool and Kevlar–wool–nylon fabrics in quasistatic conditions. Text. Res. J. 2019, 89, 2219–2235. [Google Scholar] [CrossRef]

- Annaidh, A.N.; Cassidy, M.; Curtis, M.; Destrade, M.; Gilchrist, M.D. Toward a predictive assessment of stab-penetration forces. Am. J. Forensic Med. Pathol. 2015, 36, 162–166. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.S.; Tan, V.B.C.; Shim, V.P.W. Modelling inter-yarn friction in woven fabric armour. Int. J. Numer. Methods Eng. 2006, 66, 1309–1330. [Google Scholar] [CrossRef]

- Majumdar, A.; Butola, B.S.; Srivastava, A. Optimal designing of soft body armour materials using shear thickening fluid. Mater. Des. 2013, 46, 191–198. [Google Scholar] [CrossRef]

- Crouch, I.G.; Arnold, L.; Pierlot, A.; Billon, H. Fibres, textiles and protective apparel. In The Science of Armour Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 269–330. ISBN 9780081007044. [Google Scholar]

- Nayak, R.; Crouch, I.; Kanesalingam, S.; Ding, J.; Tan, P.; Lee, B.; Miao, M.; Ganga, D.; Wang, L. Body armor for stab and spike protection, Part 1: Scientific literature review. Text. Res. J. 2018, 88, 812–832. [Google Scholar] [CrossRef]

- Hoang, L. Available online: https://tintucvietnam.vn/toi-pham-cuop-tai-san-tang-51-giet-nguoi-tang-39-d199466.html (accessed on 21 June 2019).

- Shaw, D. Ten Charts on the Rise of Knife Crime in England and Wales. Available online: https://www.bbc.com/news/uk-427490892019 (accessed on 23 February 2021).

- El Messiry, M.; Eltahan, E. Stab resistance of triaxial woven fabrics for soft body armor. J. Ind. Text. 2016, 45, 1062–1082. [Google Scholar] [CrossRef]

- Alevj, D. Available online: https://www.scribd.com/document/336241133/F904-16 (accessed on 18 June 2019).

- Mawkhlieng, U.; Majumdar, A. Soft body armour. Text. Prog. 2019, 51, 139–224. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications-a review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Zhu, Z.; Qian, K. Effects of the molecular structure of polyvinyl alcohol on the adhesion to fibre substrates. Fibres Text. East. Eur. 2007, 15, 82–85. [Google Scholar]

- DeMerlis, C.C.; Schoneker, D.R. Review of the oral toxicity of polyvinyl alcohol (PVA). Food Chem. Toxicol. 2003, 41, 319–326. [Google Scholar] [CrossRef]

- Kumar, B.; Hu, J. Woven fabric structures and properties. In Engineering of High-Performance Textiles; Woodhead Publishing: Cambridge, UK, 2018; pp. 133–151. ISBN 9780081012734. [Google Scholar]

- Zimniewska, M.; Rozańska, W.; Gryszczynska, A.; Romanowska, B.; Kicinska-Jakubowska, A. Antioxidant potential of hemp and flax fibers depending on their chemical composition. Molecules 2018, 23, 1993. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Tian, Y.; Zhao, G.Z.; Sun, Y.Y.; Zhu, F.T.; Cao, Y. Synthesis of urea-formaldehyde resin by melt condensation polymerization. J. Polym. Res. 2008, 15, 501–505. [Google Scholar] [CrossRef]

- Radice, S.; Turri, S.; Scicchitano, M. Fourier transform infrared studies on deblocking and crosslinking mechanisms of some fluorine containing monocomponent polyurethanes. Appl. Spectrosc. 2004, 58, 535–542. [Google Scholar] [CrossRef] [PubMed]

- Lima Da Silva, R.C.; Alves, C.; Nascimento, J.H.; Neves, J.R.O.; Teixeira, V. Surface modification of polyester fabric by non-thermal plasma treatment. J. Phys. Conf. Ser. 2012, 406, 012017. [Google Scholar] [CrossRef]

- Zięba-Palus, J. The usefulness of infrared spectroscopy in examinations of adhesive tapes for forensic purposes. Forensic Sci. Criminol. 2017, 2, 1–9. [Google Scholar] [CrossRef][Green Version]

- Boulet-Audet, M.; Vollrath, F.; Holland, C. Identification and classification of silks using infrared spectroscopy. J. Exp. Biol. 2015, 218, 3138–3149. [Google Scholar] [CrossRef] [PubMed]

- Pham, D.T.; Saelim, N.; Tiyaboonchai, W. Crosslinked fibroin nanoparticles using EDC or PEI for drug delivery: Physicochemical properties, crystallinity and structure. J. Mater. Sci. 2018, 53, 14087–14103. [Google Scholar] [CrossRef]

- Zorba, T.; Papadopoulou, E.; Hatjiissaak, A.; Paraskevopoulos, K.M.; Chrissafis, K. Urea-formaldehyde resins characterized by thermal analysis and FTIR method. J. Therm. Anal. Calorim. 2008, 92, 29–33. [Google Scholar] [CrossRef]

- Tetteh, G.; Khan, A.S.; Delaine-Smith, R.M.; Reilly, G.C.; Rehman, I.U. Electrospun polyurethane/hydroxyapatite bioactive Scaffolds for bone tissue engineering: The role of solvent and hydroxyapatite particles. J. Mech. Behav. Biomed. Mater. 2014, 39, 95–110. [Google Scholar] [CrossRef] [PubMed]

- Bexiga, N.M.; Bloise, A.C.; de Moraes, M.A.; Converti, A.; Beppu, M.M.; Polakiewicz, B. Production and characterization of fibroin hydrogel using waste silk fibers. Fibers Polym. 2017, 18, 57–63. [Google Scholar] [CrossRef]

- Cao, X.; Dong, H.; Li, C.M. New Nanocomposite Materials Reinforced with Flax Cellulose Nanocrystals in Waterborne Polyurethane. Biomacromolecules 2007, 8, 899–904. [Google Scholar] [CrossRef]

- Kim, U.J.; Park, J.; Li, C.; Jin, H.J.; Valluzzi, R.; Kaplan, D.L. Structure and properties of silk hydrogels. Biomacromolecules 2004, 5, 786–792. [Google Scholar] [CrossRef] [PubMed]

- Dillingham, R.G. Composite bond inspection. In Structural Integrity and Durability of Advanced Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 697–706. ISBN 9780081001387. [Google Scholar]

- Princi, E.; Vicini, S.; Pedemonte, E.; Arrighi, V.; McEwen, I.J. New polymeric materials for paper and textiles conservation. II. Grafting polymerization of ethyl acrylate/methyl methacrylate copolymers onto linen and cotton. J. Appl. Polym. Sci. 2007, 103, 90–99. [Google Scholar] [CrossRef]

- Shivaprakash, S.; Lamb, P.R.C.; Rahaman, S.A.; Somarajan, V.P.; Rasheed, A. Simulation and Hardness Test of Kevlar and Glass Fiber Composite for Bullet Proof and Stab Resistant Vest. Int. J. Res. Appl. Sci. Eng. Technol. 2019, 7, 3926–3934. [Google Scholar]

- Bleetman, A.; Watson, C.H.; Horsfall, I.; Champion, S.M. Wounding patterns and human performance in knife attacks: Optimising the protection provided by knife-resistant body armour. J. Clin. Forensic Med. 2003, 10, 243–248. [Google Scholar] [CrossRef]

| 20-Layer Laminates | Weight (g) | Weight Ratio (Fabric:Adhesive) |

|---|---|---|

| Linen | ||

| PVA | 209 ± 9 | 1:1 |

| UF | 187 ± 12 | 1.2:1 |

| PU | 160 ± 12 | 1.8:1 |

| Soft-silk | ||

| PVA | 174 ± 12 | 1:1 |

| UF | 179 ± 13 | 1:1.1 |

| PU | 153 ± 7 | 1.3:1 |

| Hard-silk | ||

| PVA | 164 ± 11 | 1.7:1 |

| UF | 237 ± 14 | 1:1.3 |

| PU | 230 ± 15 | 1:1.2 |

| 20 Layer Laminates | Thickness (mm) | Hardness Shore D (HA) |

|---|---|---|

| Linen | ||

| PVA | 5 ± 0.3 | 46 ± 2.5 |

| UF | 4.6 ± 0.2 | 42 ± 2.8 |

| PU | 4.2 ± 0.3 | 33 ± 2.0 |

| Soft silk | ||

| PVA | 5.9 ± 0.4 | 38 ± 2.8 |

| UF | 6 ± 0.4 | 40 ± 3.5 |

| PU | 5.6 ± 0.3 | 26 ± 1.5 |

| Hard silk | ||

| PVA | 6.4 ± 0.5 | 43 ± 3.9 |

| UF | 7.9 ± 0.5 | 49 ± 4.1 |

| PU | 7.7 ± 0.6 | 35 ± 3.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khuyen, N.Q.; Han, P.V.D.; Nguyen, N.T.; Le, Q.B.; Harjo, M.; Anbarjafari, G.; Kiefer, R.; Tamm, T. The Use of Laminates of Commercially Available Fabrics for Anti-Stab Body-Armor. Polymers 2021, 13, 1077. https://doi.org/10.3390/polym13071077

Khuyen NQ, Han PVD, Nguyen NT, Le QB, Harjo M, Anbarjafari G, Kiefer R, Tamm T. The Use of Laminates of Commercially Available Fabrics for Anti-Stab Body-Armor. Polymers. 2021; 13(7):1077. https://doi.org/10.3390/polym13071077

Chicago/Turabian StyleKhuyen, Nguyen Quang, Phan Vu Duc Han, Ngoc Tuan Nguyen, Quoc Bao Le, Madis Harjo, Gholamreza Anbarjafari, Rudolf Kiefer, and Tarmo Tamm. 2021. "The Use of Laminates of Commercially Available Fabrics for Anti-Stab Body-Armor" Polymers 13, no. 7: 1077. https://doi.org/10.3390/polym13071077

APA StyleKhuyen, N. Q., Han, P. V. D., Nguyen, N. T., Le, Q. B., Harjo, M., Anbarjafari, G., Kiefer, R., & Tamm, T. (2021). The Use of Laminates of Commercially Available Fabrics for Anti-Stab Body-Armor. Polymers, 13(7), 1077. https://doi.org/10.3390/polym13071077