Surface Modification of Spruce and Fir Sawn-Timber by Charring in the Traditional Japanese Method—Yakisugi

Abstract

1. Introduction

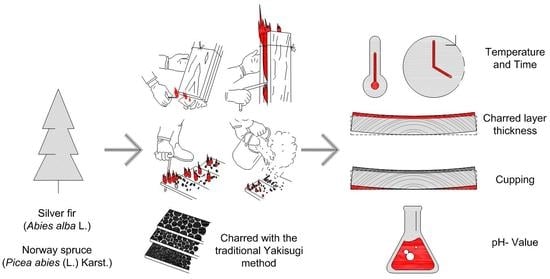

2. Materials and Methods

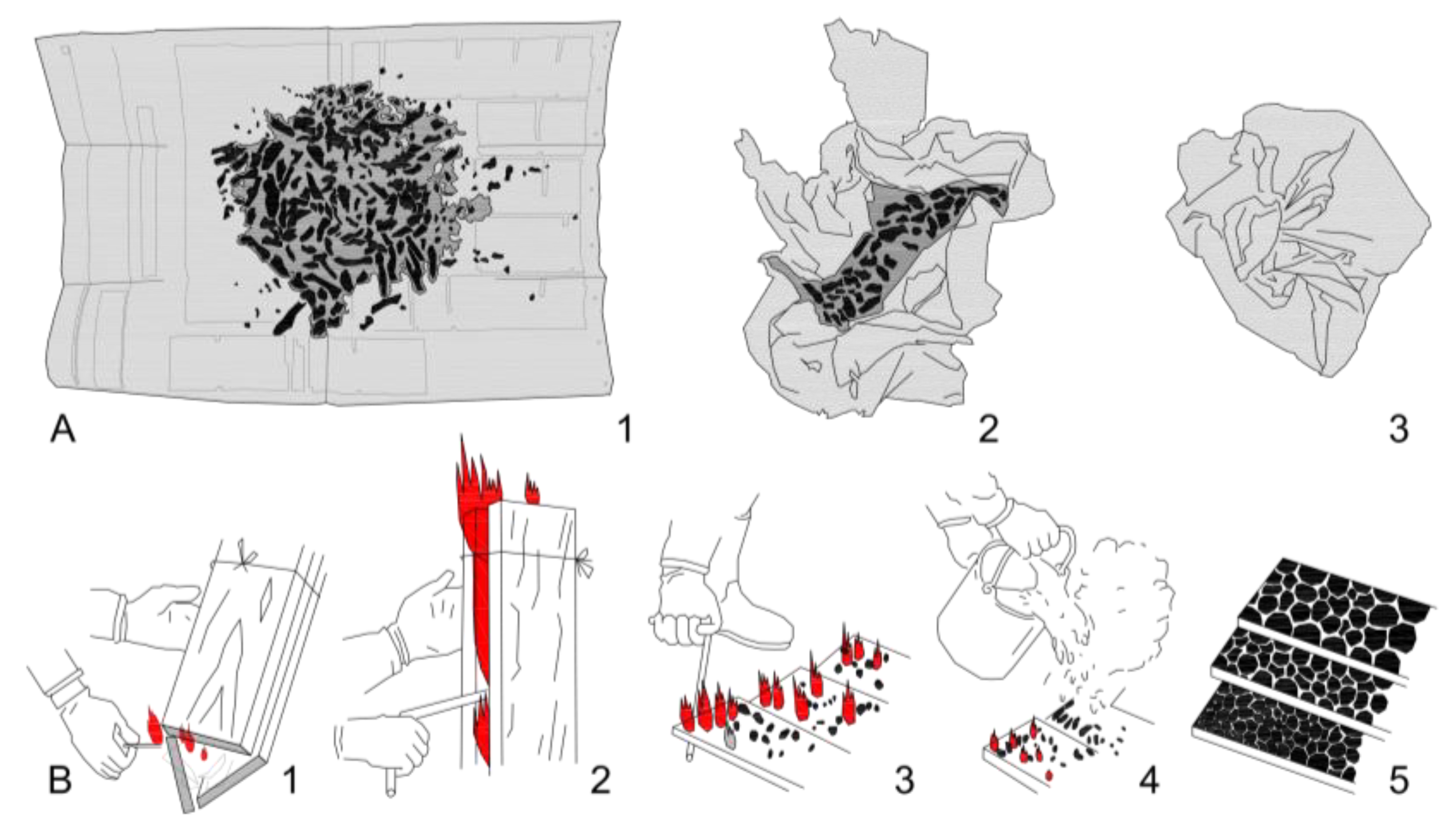

2.1. The Process of Timber Charring in the Traditional Japanese Method—Yakisugi

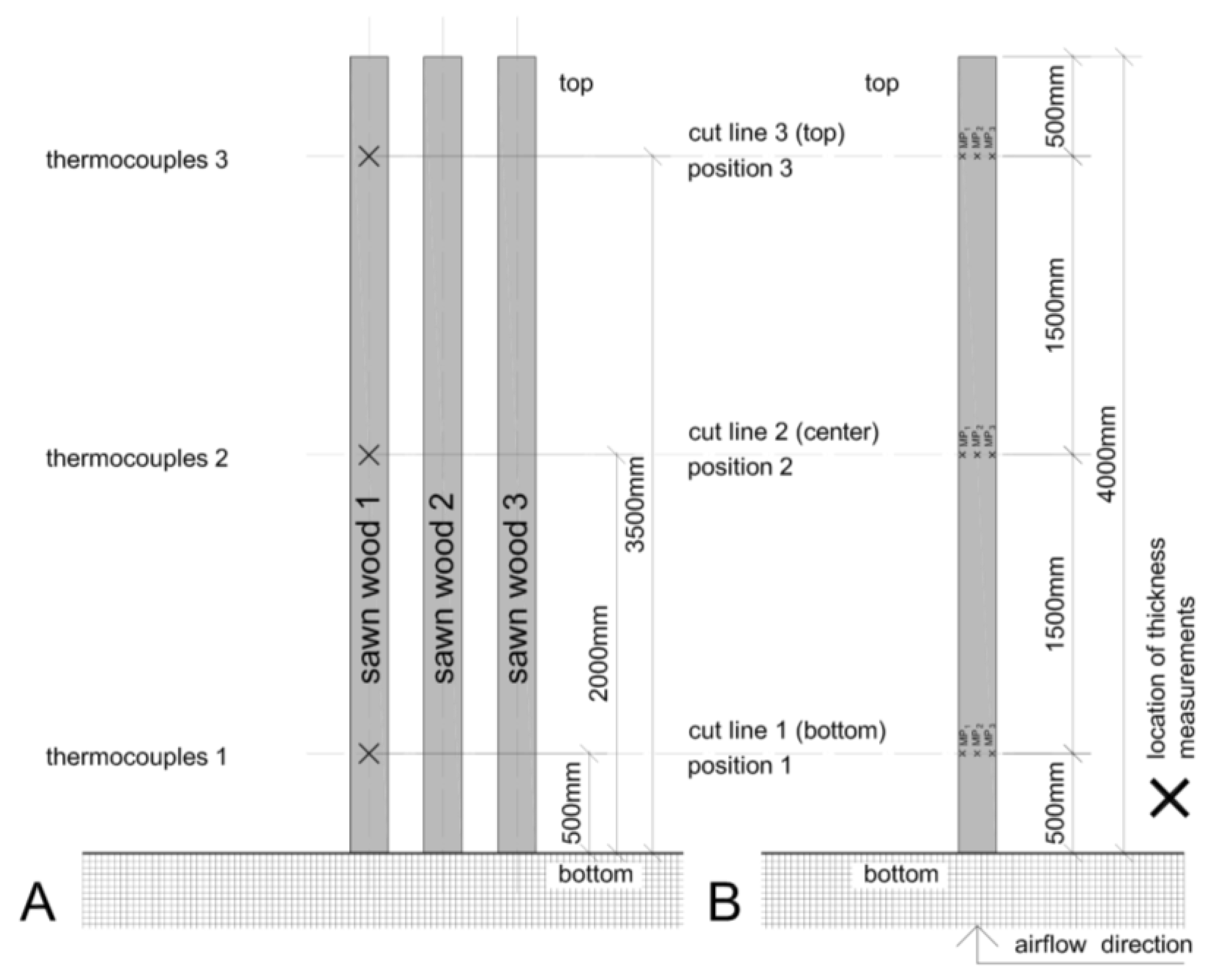

2.2. Surface Charring—Temperature and Time Measurements

2.3. Charred Layer Thickness Measurement

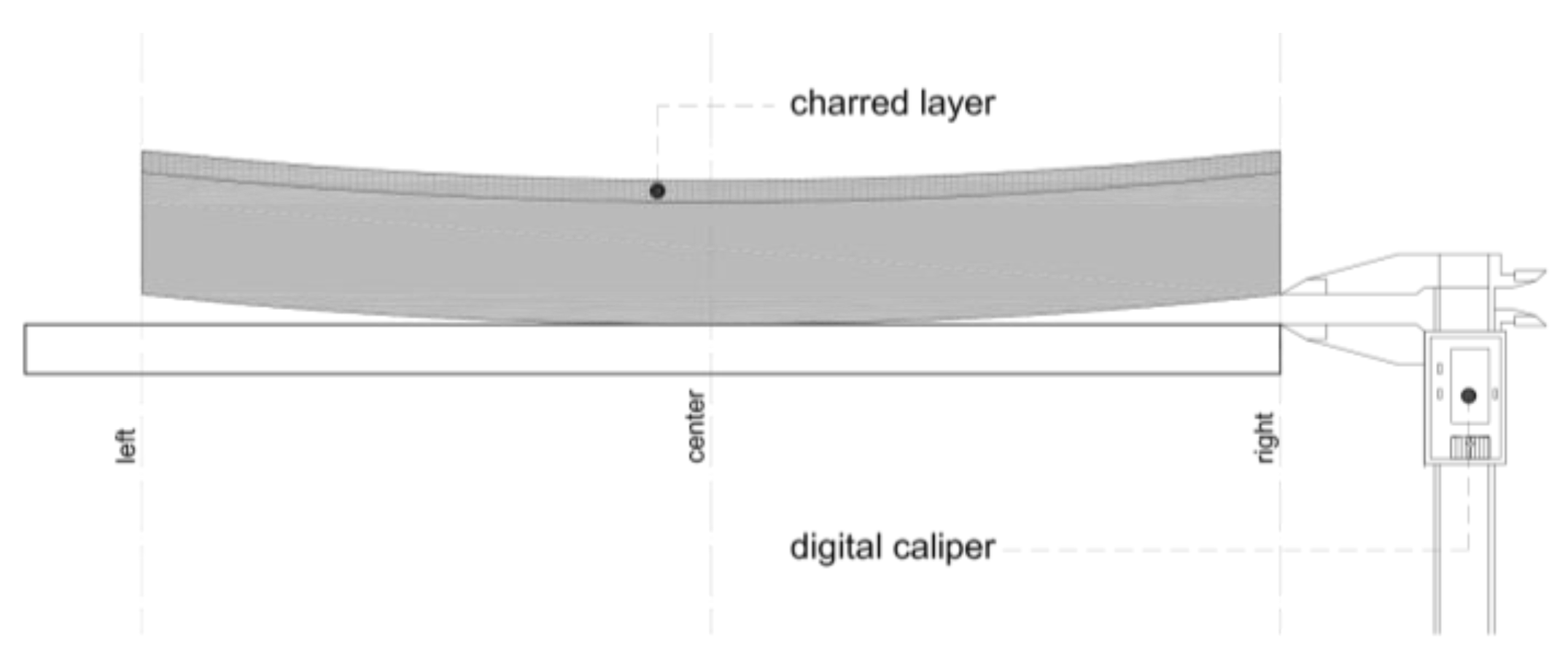

2.4. Measurement of Cupping Due to the Charring

2.5. pH Value Measurement

3. Results and Discussion

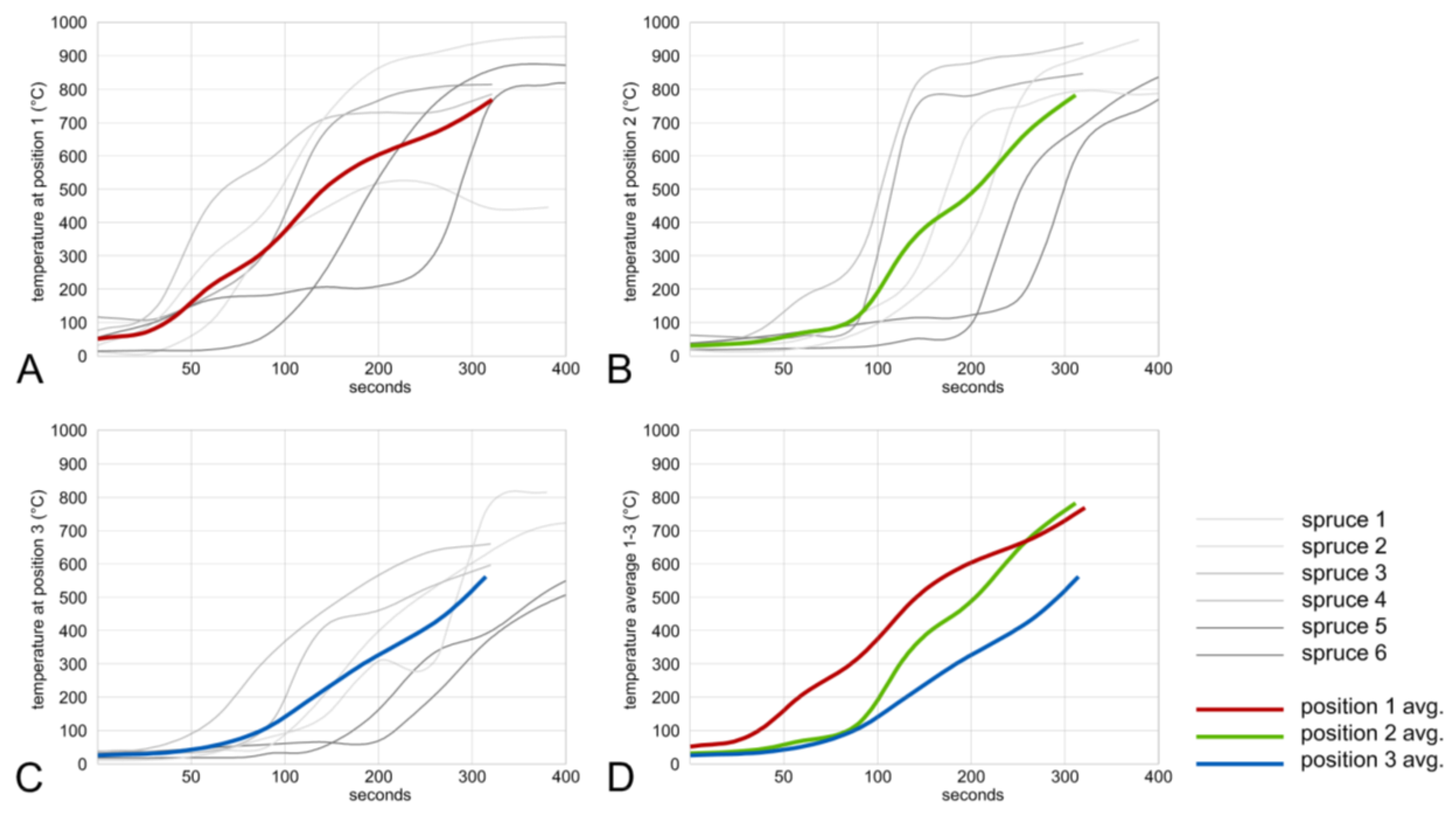

3.1. Charring—Temperature and Time

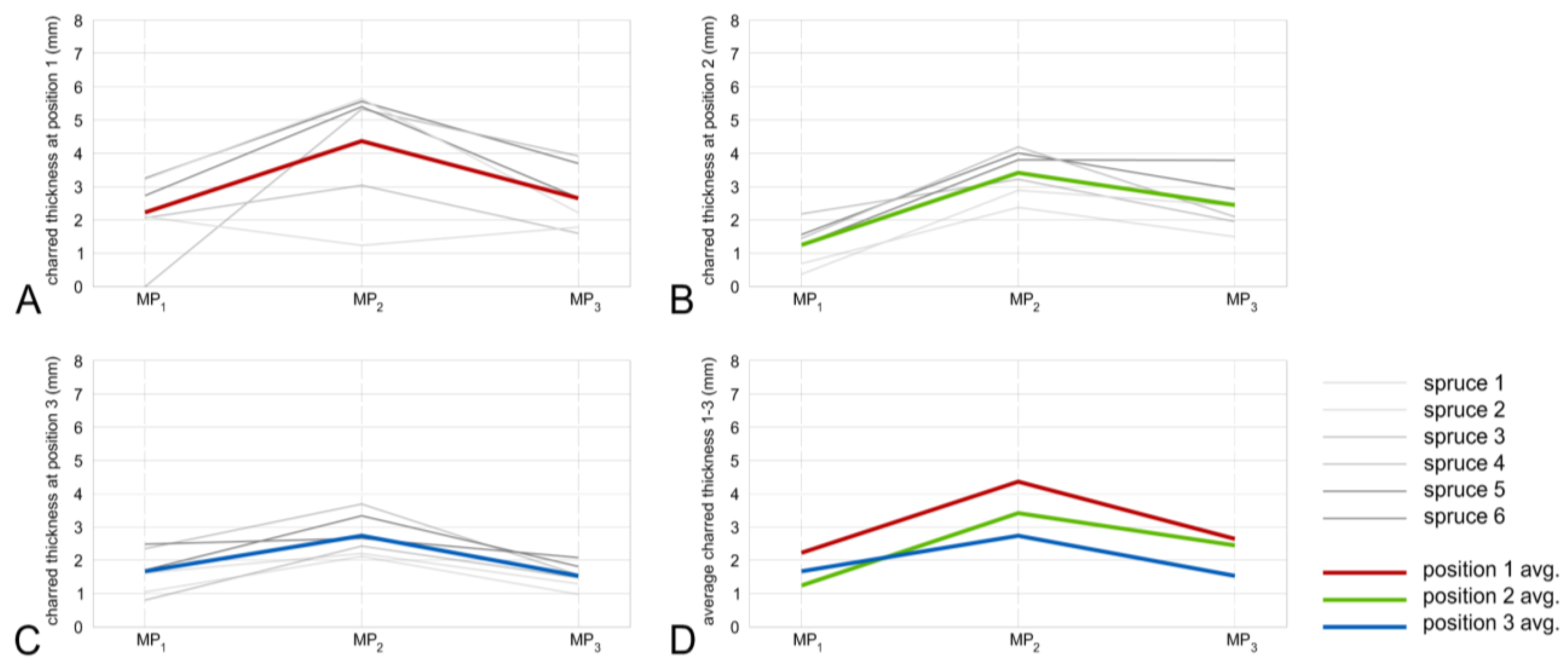

3.2. The Thickness of the Charred Layer

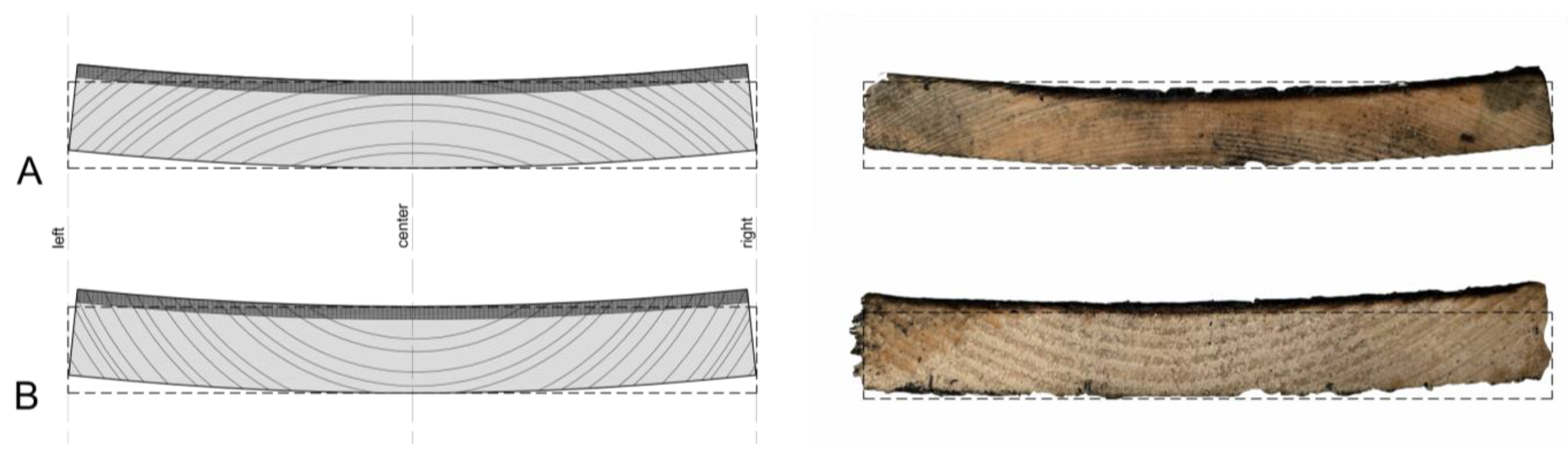

3.3. Cupping Caused by Surface Charring

3.4. pH Value

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Jones, D.; Brischke, C. Performance of Bio-Based Building Materials; Woodhead Publishing: Duxforf, UK, 2017. [Google Scholar]

- Hill, C. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons, Ltd.: West Sussex, UK, 2006. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest Biogeosci. For. 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Hautamäki, S.; Lillqvist, K.; Segerholm, K.; Rautkari, L. Surface modification of solid wood by charring. J. Mater. Sci. 2017, 52, 6111–6119. [Google Scholar] [CrossRef]

- Čermák, P.; Dejmal, A.; Paschova, Z.; Kymäläinen, M.; Dömény, J.; Brabec, M.; Hess, D.; Rautkari, L. One-sided surface charring of beech wood. J. Mater. Sci. 2019, 54, 9497–9506. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Turunen, H.; Rautkari, L. Effect of Weathering on Surface Functional Groups of Charred Norway Spruce Cladding Panels. Forests 2020, 11, 1373. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Turunen, H.; Čermák, P.; Hautamäki, S.; Rautkari, L. Sorption-Related Characteristics of Surface Charred Spruce Wood. Materials 2018, 11, 2083. [Google Scholar] [CrossRef] [PubMed]

- Gosselink, R.; Krosse, A.; van der Putten, J.; van der Kolk, J.; Klerk-Engels, B.; van Dam, J. Wood preservation by low-temperature carbonisation. Ind. Crop. Prod. 2004, 19, 3–12. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; Walter de Gruyter: New York, NY, USA, 1989. [Google Scholar]

- White, R.; Dietenberger, M. Wood products: Thermal degradation and fire. In Encyclopedia of Materials: Science and Technology; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2001; pp. 9712–9716. [Google Scholar]

- Shafizadeh, F. The chemistry of pyrolysis and combustion. In The Chemistry of Solid Wood; Rowell, R., Ed.; Advances in Chemistry Series 207; American Chemical Society: Washington, DC, USA, 1984; pp. 489–530. [Google Scholar]

- Beall, F.C.; Eickner, H.W. Thermal degradation of wood components: A review of the literature. In USDA Forest Service Research; Paper FPL130; University of Minnesota: Minneapolis, MN, USA, 1970. [Google Scholar]

- Stelzer, R. Oberflächliches Verkohlen von Schittholz für Einen Langanhaltenden Außen-und Inneneinsatz; Masterarbeit, Fachhochschule Salzburg: Salzburg, Kuchl, 2017. [Google Scholar]

- Suleiman, B.M.; Larfeldt, J.; Leckner, B.; Gustavsson, M. Thermal conductivity and diffusivity of wood. Wood Sci. Technol. 1999, 33, 465–473. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Rijsdijk, J.F.; Sander, C.; Kegel, E.; Tjeerdsma, B.; Militz, H.; Van Acker, J.; Stevens, M. Microstructural and physical aspects of heat-treated wood. Part 1. Softwoods. Maderas. Cienc. Y Tecnol. 2006, 8, 193–208. [Google Scholar]

- Virta, J. Wooden cladding boards in cyclic moisture conditions: Studies of cupping, moisture distribution and swelling stress. Build. Environ. 2005, 40, 1395–1399. [Google Scholar] [CrossRef]

- Niemz, P.; Sonderegger, W. Holzphysik: Physik des Holzes und der Holzwerkstoffe; Carl Hanser Verlag Gmbh & Co KG: Leipzig, Germany, 2017. [Google Scholar]

- Paulitsch, M.; Barbu, M. Holzwerkstoffe der Moderne; DRW-Verlag: Leinfelden-Echterdingen, Germany, 2015. [Google Scholar]

- Wagenführ, R. Holzatlas; Fachbuchverlag: Leipzig, Germany, 2007. [Google Scholar]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebner, D.H.; Barbu, M.-C.; Klaushofer, J.; Čermák, P. Surface Modification of Spruce and Fir Sawn-Timber by Charring in the Traditional Japanese Method—Yakisugi. Polymers 2021, 13, 1662. https://doi.org/10.3390/polym13101662

Ebner DH, Barbu M-C, Klaushofer J, Čermák P. Surface Modification of Spruce and Fir Sawn-Timber by Charring in the Traditional Japanese Method—Yakisugi. Polymers. 2021; 13(10):1662. https://doi.org/10.3390/polym13101662

Chicago/Turabian StyleEbner, David Hans, Marius-Catalin Barbu, Josef Klaushofer, and Petr Čermák. 2021. "Surface Modification of Spruce and Fir Sawn-Timber by Charring in the Traditional Japanese Method—Yakisugi" Polymers 13, no. 10: 1662. https://doi.org/10.3390/polym13101662

APA StyleEbner, D. H., Barbu, M.-C., Klaushofer, J., & Čermák, P. (2021). Surface Modification of Spruce and Fir Sawn-Timber by Charring in the Traditional Japanese Method—Yakisugi. Polymers, 13(10), 1662. https://doi.org/10.3390/polym13101662