Polymer Cold-Flow Improvers for Biodiesel

Abstract

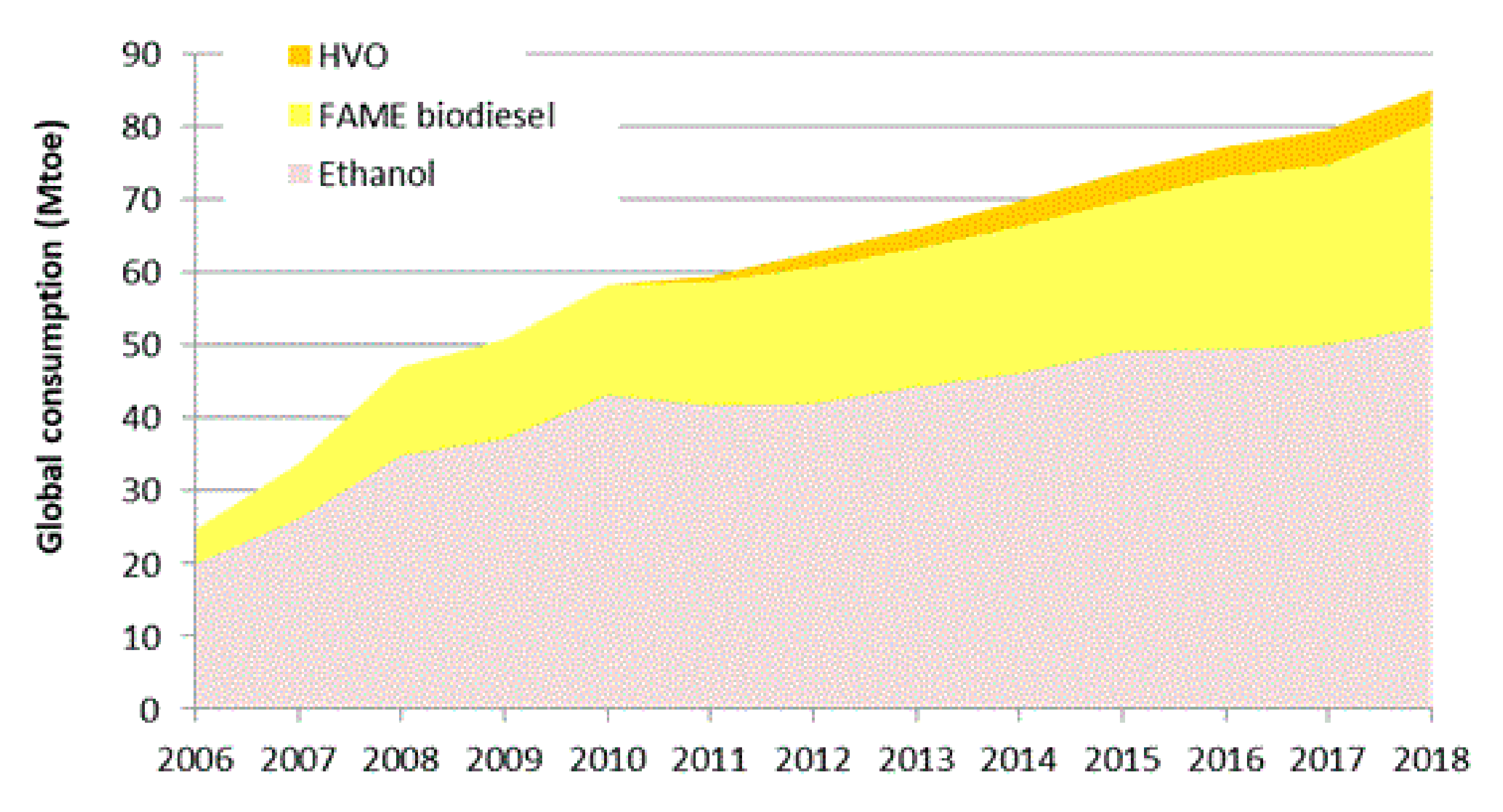

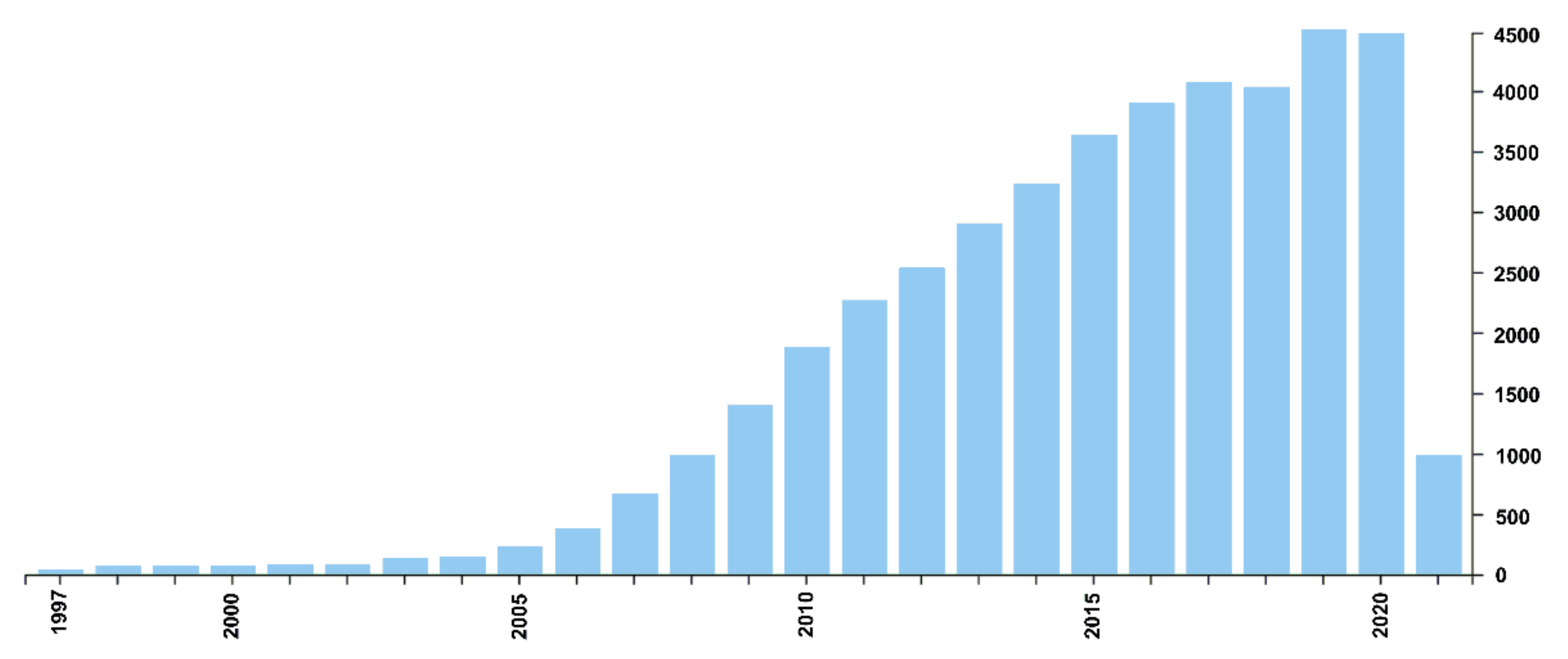

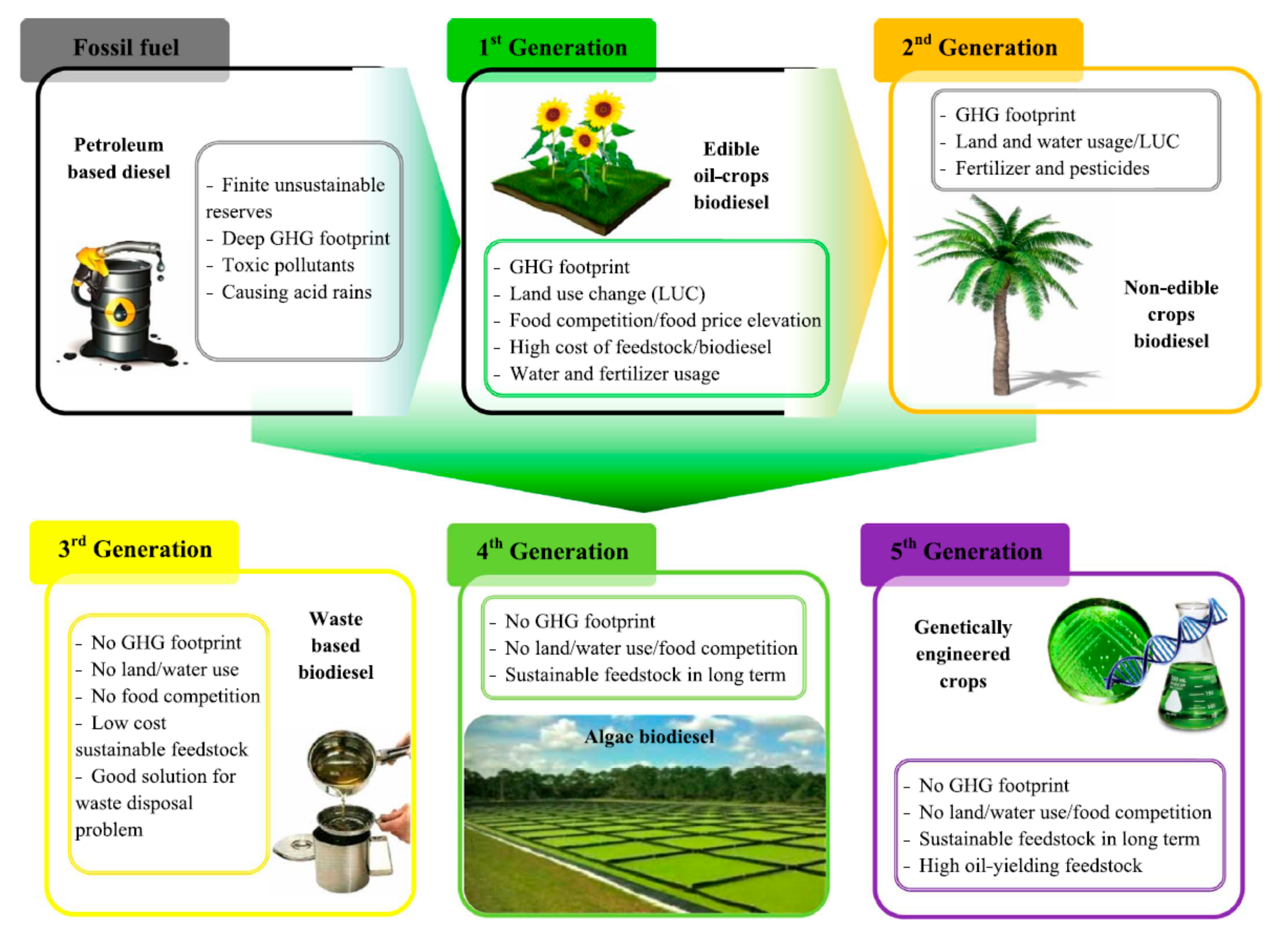

1. Introduction

2. Sources, Synthesis and Chemical Composition of BD

2.1. Oils, as Raw Material for the Production of BD

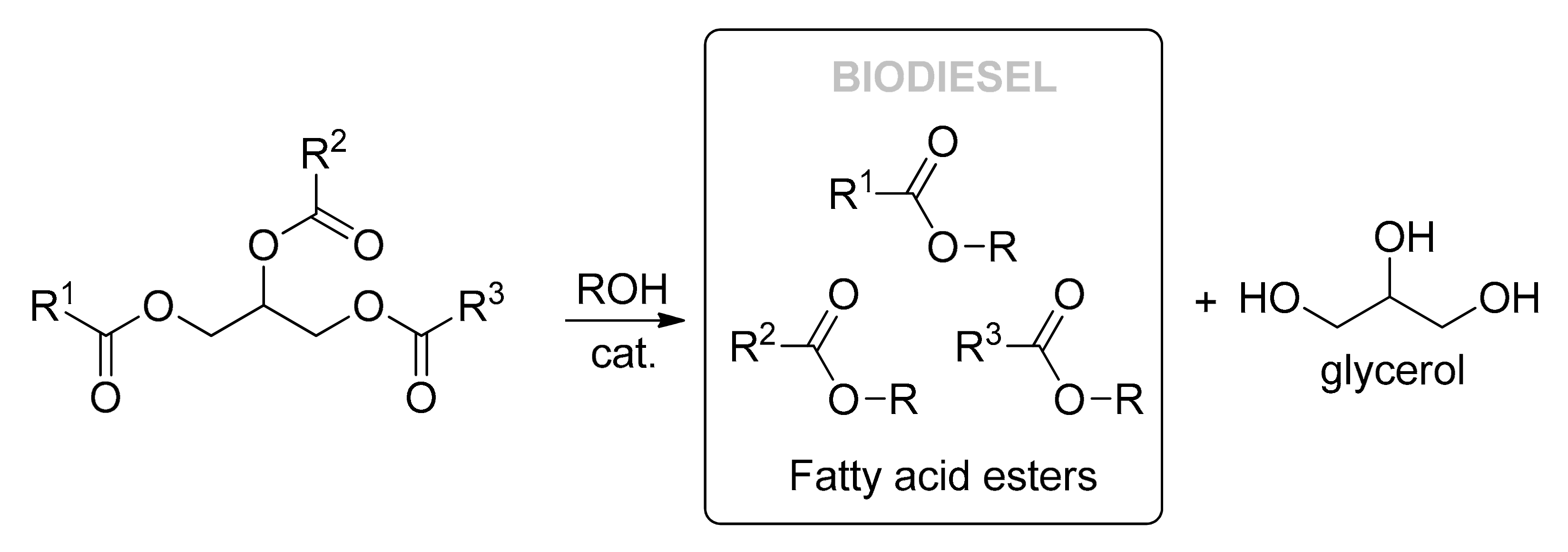

2.2. Synthesis of BD

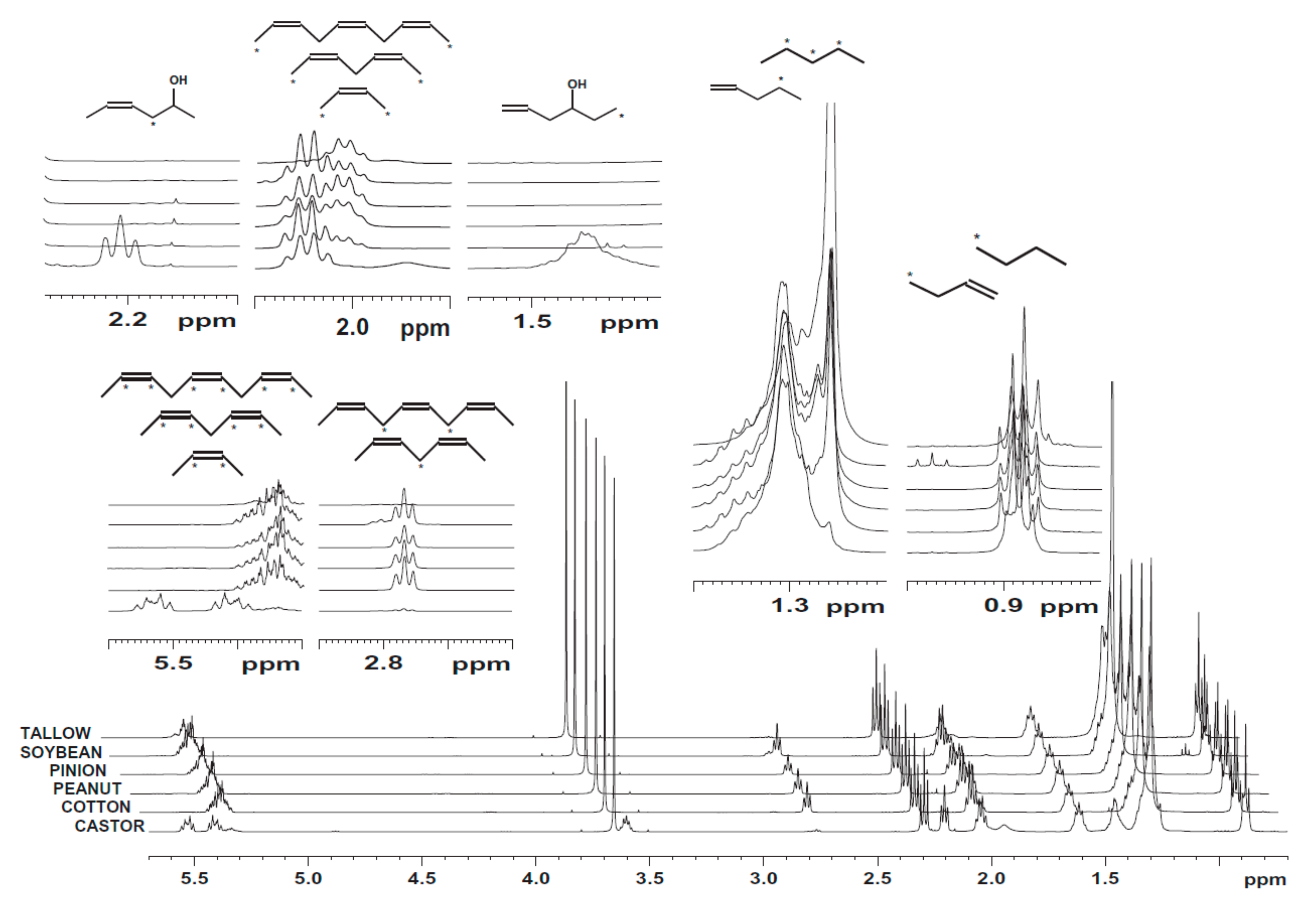

2.3. Chemical Composition of BD

3. Cold-Flow Properties of BD

3.1. Cold-Flow Properties: Standards and Analysis

3.2. Cold Flow Properties of BDs: FA Composition

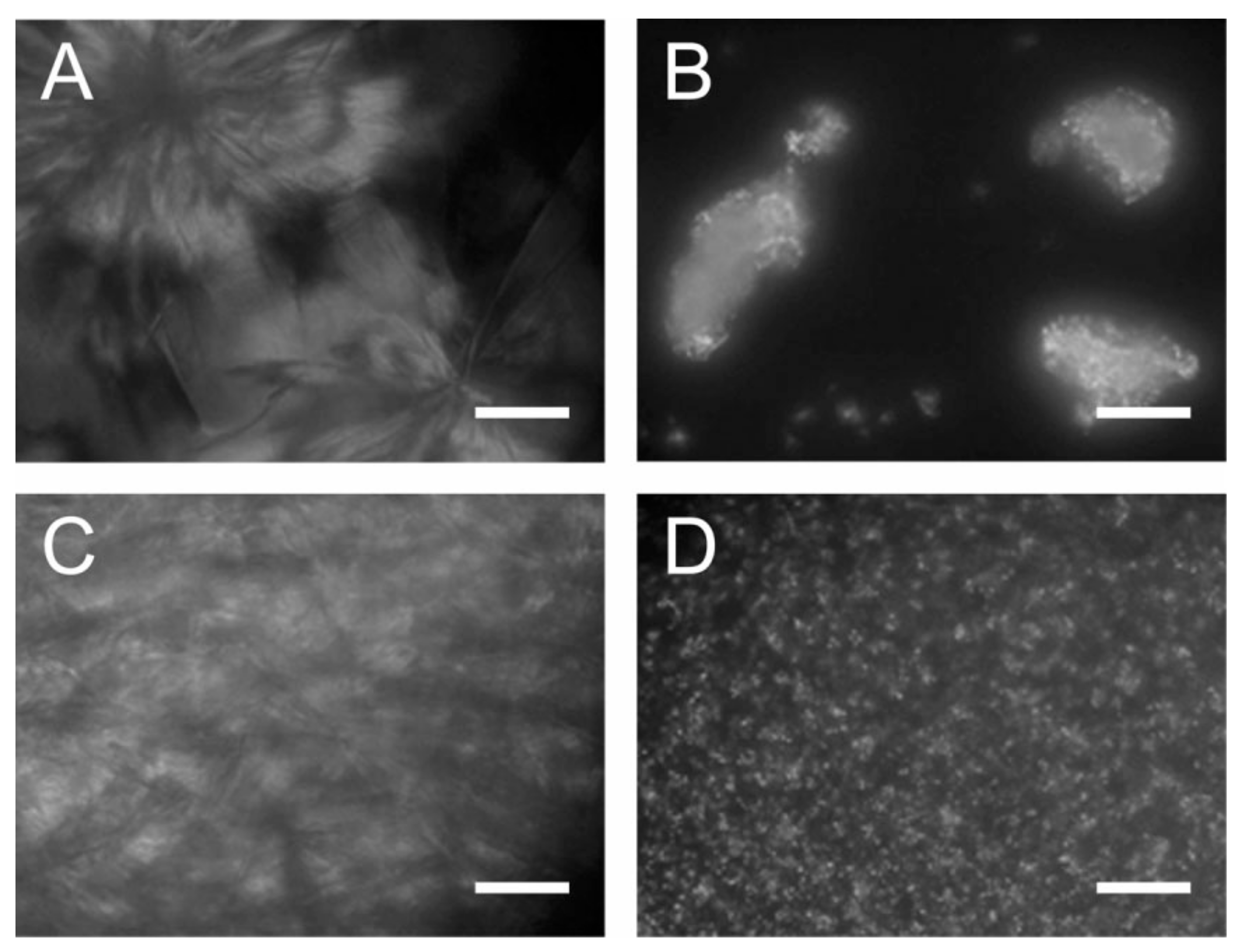

3.3. Microimpurities

4. Polymer Additives for BD

4.1. Polyolefins

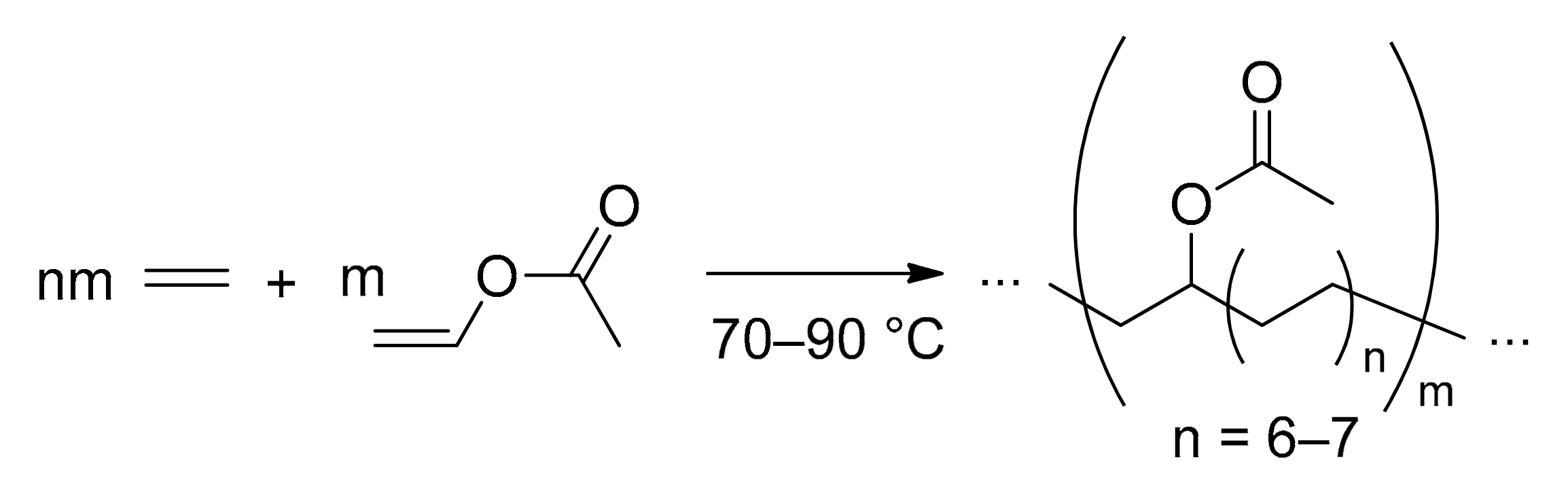

4.2. Ethylene/Vinyl Acetate Copolymers

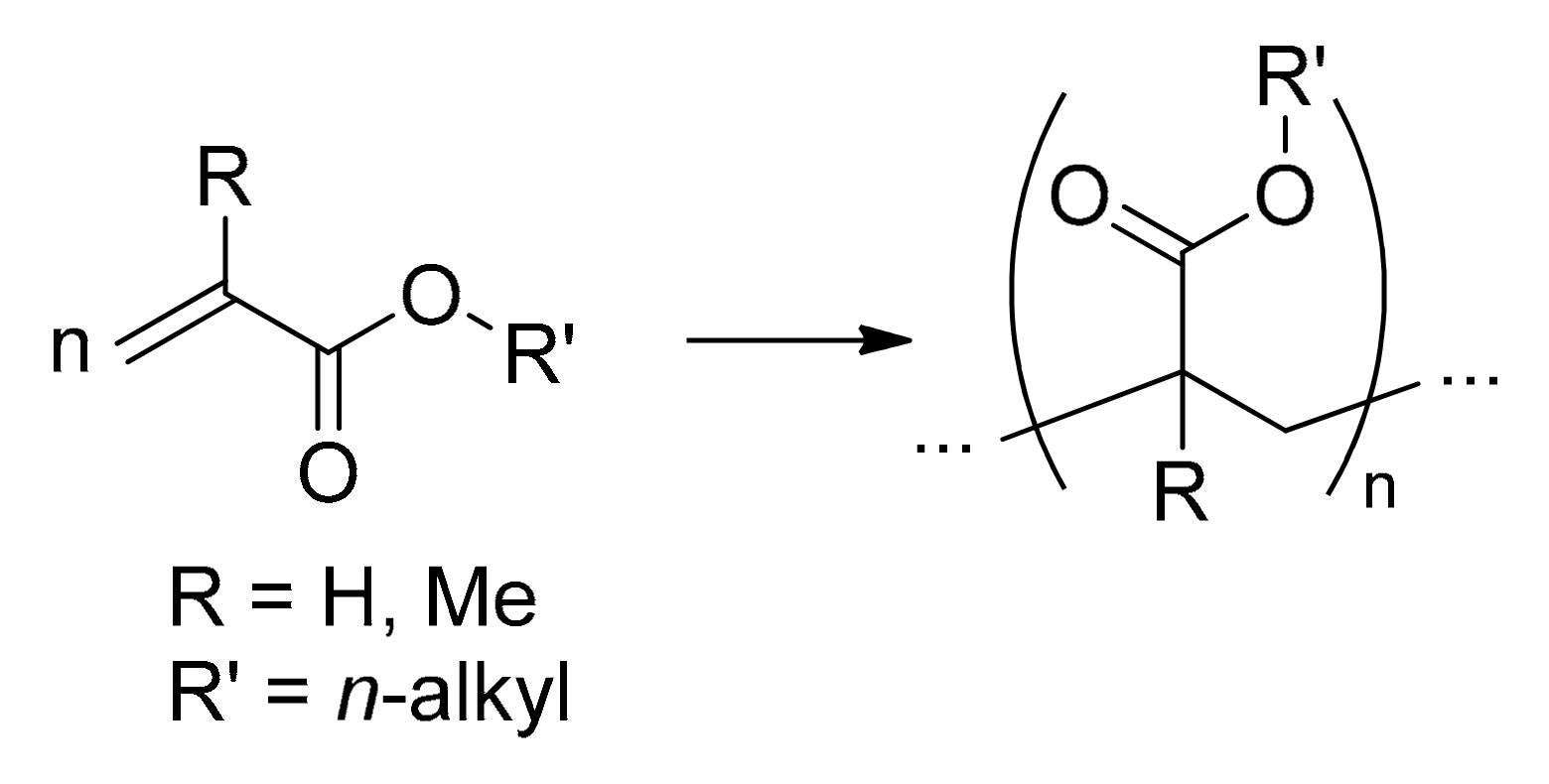

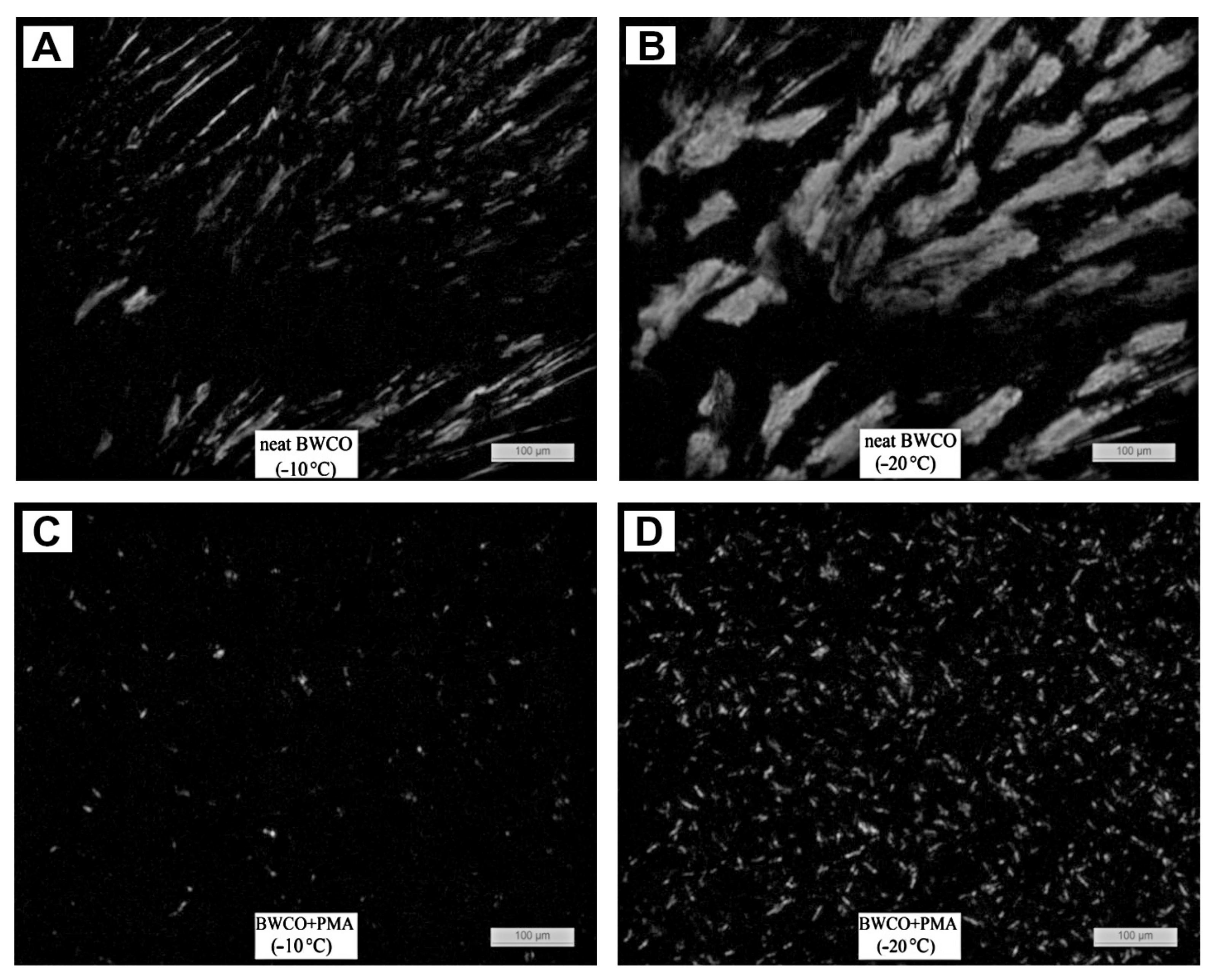

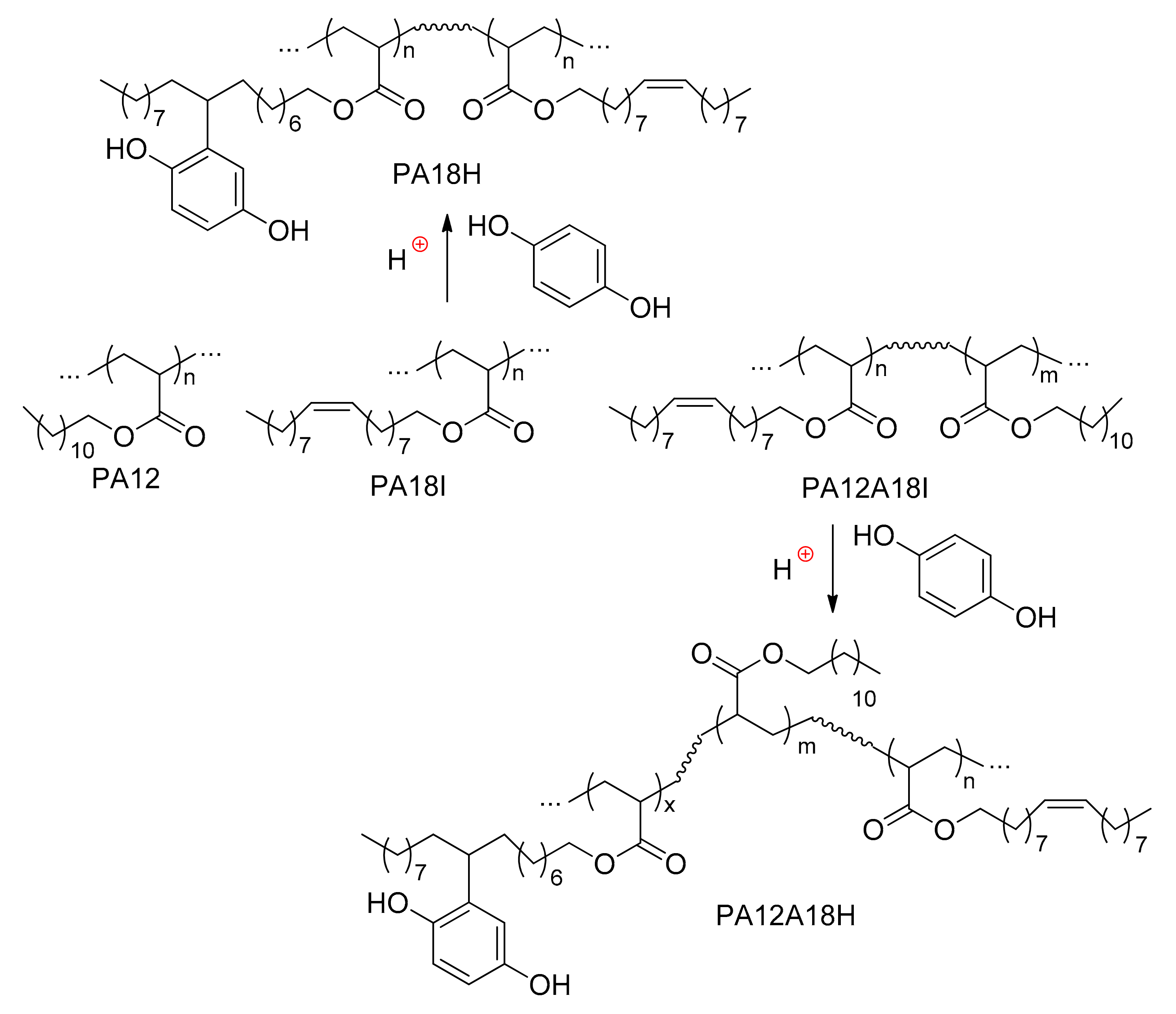

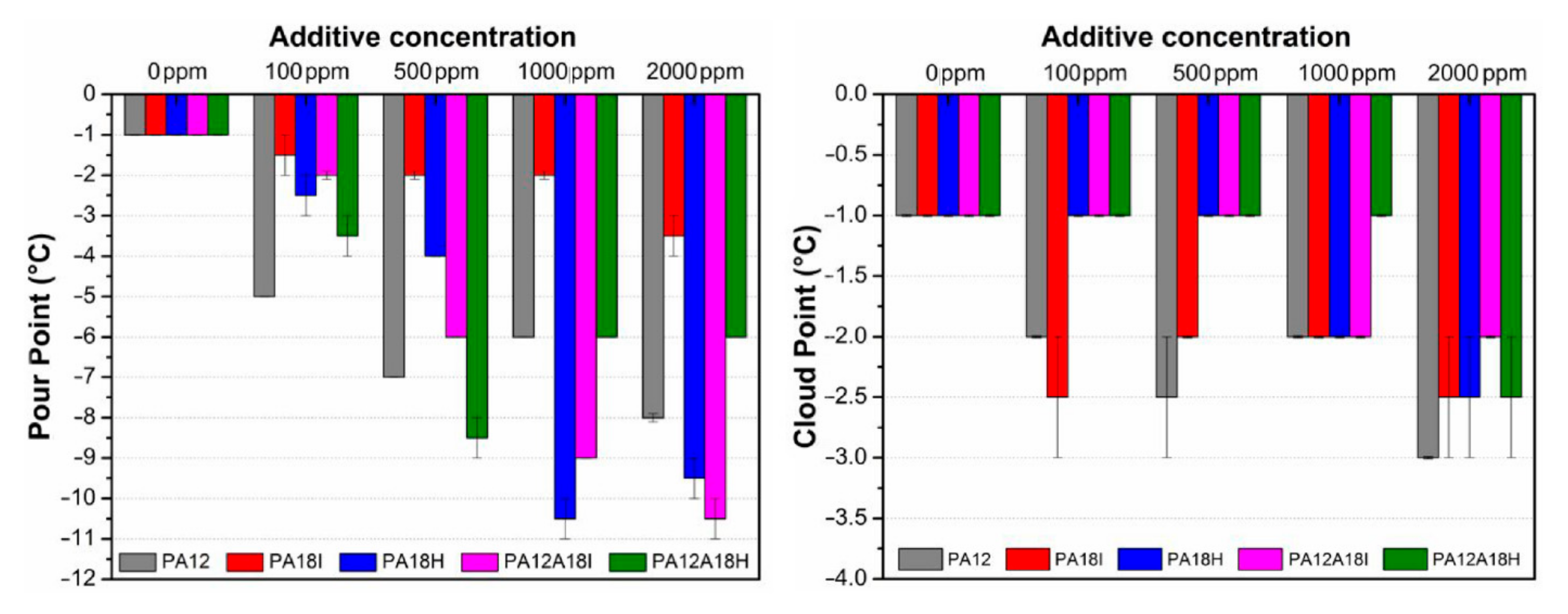

4.3. Polyacrylates and Related Copolymers

4.4. Maleic Anhydride Copolymers and Their Derivatives

4.5. Other Polymeric CFIs

5. Polymer Additives for BD/Petroleum Diesel Blends

6. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Huber, G.W.; Iborra, S.; Corma, A. Synthesis of transportation fuels from biomass: Chemistry, catalysts, and engineering. Chem. Rev. 2006, 106, 4044–4098. [Google Scholar] [CrossRef] [PubMed]

- Shylesh, S.; Gokhale, A.A.; Ho, C.R.; Bell, A.T. Novel strategies for the production of fuels, lubricants, and chemicals from biomass. Acc. Chem. Res. 2017, 50, 2589–2597. [Google Scholar] [CrossRef]

- Biofuels Dashboard 2020. Available online: https://www.ifpenergiesnouvelles.com/article/biofuels-dashboard-2020 (accessed on 15 April 2021).

- ExxonMobil. The Outlook for Energy: A View to 2040. Available online: https://corporate.exxonmobil.com/Energy-and-innovation/outlook-for-energy (accessed on 15 April 2021).

- Higher Blending Mandates in Key Markets Support Global Biodiesel and HVO Output in 2020. Available online: https://www.iea.org/reports/renewables-2020/transport-biofuels (accessed on 15 April 2021).

- Dwivedi, G.; Sharma, M.P. Impact of cold flow properties of biodiesel on engine performance. Renew. Sustain. Energy Rev. 2014, 31, 650–656. [Google Scholar] [CrossRef]

- Dwivedi, G.; Sharma, M.P. Cold flow behavior of biodiesel-A review. Int. J. Renew. Energy Resour. 2013, 3, 827–836. [Google Scholar]

- Demirbas, A. Biodiesel fuels from vegetable oils via catalytic and non-catalytic supercritical alcohol transesterifications and other methods: A survey. Energy Convers. Manag. 2003, 44, 2093–2109. [Google Scholar] [CrossRef]

- Gebremariam, S.N.; Marchetti, J.M. Economics of biodiesel production: Review. Energy Convers. Manag. 2018, 168, 74–84. [Google Scholar] [CrossRef]

- Basha, S.A.; Gopal, K.R. A review of the effects of catalyst and additive on biodiesel production, performance, combustion and emission characteristics. Renew. Sustain. Energy Rev. 2012, 16, 711–717. [Google Scholar] [CrossRef]

- Kannan, G.R.; Anand, R. Biodiesel as an alternative fuel for direct injection diesel engines: A review. J. Renew. Sustain. Energy 2012, 4, 012703. [Google Scholar] [CrossRef]

- Bateni, H.; Saraeian, A.; Able, C. A comprehensive review on biodiesel purification and upgrading. Biofuel Res. J. 2017, 4, 668–690. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, M.P. Selection of potential oils for biodiesel production. Renew. Sustain. Chem. Rev. 2016, 56, 1129–1138. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C.; Ceniceros, E.; Natarajan, M. Review of biodiesel composition, properties, and specifications. Renew. Sustain. Energy Rev. 2012, 16, 143–169. [Google Scholar] [CrossRef]

- Knothe, G.; Razon, L.F. Biodiesel fuels. Progr. Energy Combust. Sci. 2017, 58, 36–59. [Google Scholar] [CrossRef]

- Lanjekar, R.D.; Deshmukh, D. A review of the effect of the composition of biodiesel on NOx emission, oxidative stability and cold flow properties. Renew. Sustain. Energy Rev. 2016, 54, 1401–1411. [Google Scholar] [CrossRef]

- Joshi, G.; Pandey, J.K.; Rana, S.; Rawat, D.S. Challenges and opportunities for the application of biofuel. Renew. Sustain. Energy Rev. 2017, 79, 850–866. [Google Scholar] [CrossRef]

- Rodionova, M.V.; Poudyal, R.S.; Tiwari, I.; Voloshin, R.A.; Zharmukhamedov, S.K.; Nam, H.G.; Zayadan, B.K.; Bruce, B.D.; Hou, H.J.M.; Allakhverdiev, S.I. Biofuel production: Challenges and opportunities. Int. J. Hydrog. Energy 2017, 42, 8450–8461. [Google Scholar] [CrossRef]

- Azadi, P.; Malina, R.; Barrett, S.R.H.; Kraft, M. The evolution of the biofuel science. Renew. Sustain. Energy Rev. 2017, 76, 1479–1484. [Google Scholar] [CrossRef]

- Gaurav, N.; Sivasankari, S.; Kiran, G.S.; Ninawe, A.; Selvin, J. Utilization of bioresources for sustainable biofuels: A Review. Renew. Sustain. Energy Rev. 2017, 73, 205–214. [Google Scholar] [CrossRef]

- Acheampong, M.; Ertem, F.C.; Kappler, B.; Neubauer, P. In pursuit of Sustainable Development Goal (SDG) number 7: Will biofuels be reliable? Renew. Sustain. Energy Rev. 2017, 75, 927–937. [Google Scholar] [CrossRef]

- Mahmudul, H.M.; Hagos, F.Y.; Mamat, R.; Adam, A.A.; Ishak, W.F.W.; Alenezi, R. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines–A review. Renew. Sustain. Energy Rev. 2017, 72, 497–509. [Google Scholar] [CrossRef]

- Hajjari, M.; Tabatabaei, M.; Aghbashlo, M.; Ghanavati, H. A review on the prospects of sustainable biodiesel production: A global scenario with an emphasis on waste-oil biodiesel utilization. Renew. Sustain. Energy Rev. 2017, 72, 445–464. [Google Scholar] [CrossRef]

- Mardhiah, H.H.; Ong, H.C.; Masjuki, H.H.; Lim, S.; Lee, H.V. A review on latest developments and future prospects of heterogeneous catalyst in biodiesel production from non-edible oils. Renew. Sustain. Energy Rev. 2017, 67, 1225–1236. [Google Scholar] [CrossRef]

- Gopinath, A.; Sairam, K.; Velraj, R.; Kumaresan, G. Effects of the properties and the structural configurations of fatty acid methyl esters on the properties of biodiesel fuel: A review. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 229, 357–390. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, M.P. Assessment of potential of oils for biodiesel production. Renew. Sustain. Energy Rev. 2015, 44, 814–823. [Google Scholar] [CrossRef]

- Sorate, K.A.; Bhale, P.V. Biodiesel properties and automotive system compatibility issues. Renew. Sustain. Energy Rev. 2015, 41, 777–798. [Google Scholar] [CrossRef]

- Sakthivel, R.; Ramesh, K.; Purnachandran, R.; Shameer, P.M. A review on the properties, performance and emission aspects of the third generation biodiesels. Renew. Sustain. Energy Rev. 2018, 82, 2970–2992. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumari, D. Chemical compositions, properties, and standards for different generation biodiesels: A review. Fuel 2019, 253, 60–71. [Google Scholar] [CrossRef]

- Wu, G.; Ge, J.C.; Choi, N.J. A comprehensive review of the application characteristics of biodiesel blends in diesel engines. Appl. Sci. 2020, 10, 8015. [Google Scholar] [CrossRef]

- Ge, J.C.; Yoon, S.K.; Choi, N.J. Using canola oil biodiesel as an alternative fuel in diesel engines: A review. Appl. Sci. 2017, 7, 881. [Google Scholar] [CrossRef]

- Dunn, R.O.; Shockley, M.W.; Bagby, M.O. Improving the low-temperature properties of alternative diesel fuels: Vegetable oil-derived methyl esters. J. Am. Oil Chem. Soc. 1996, 73, 1719–1728. [Google Scholar] [CrossRef]

- Smith, P.C.; Ngothai, Y.; Nguyen, Q.D.; O’Neill, B.K. Improving the low-temperature properties of biodiesel: Methods and consequences. Renew. Energy 2010, 35, 1145–1151. [Google Scholar] [CrossRef]

- Dunn, R.O. Effects of minor constituents on cold flow properties and performance of biodiesel. Progr. Energy Combust. Sci. 2009, 35, 481–489. [Google Scholar] [CrossRef]

- Misra, R.D.; Murthy, M.S. Blending of additives with biodiesels to improve the cold flow properties, combustion and emission performance in a compression ignition engine–A review. Renew. Sustain. Energy Rev. 2011, 15, 2413–2422. [Google Scholar] [CrossRef]

- Ali, O.M.; Mamat, R.; Faizal, C.K.M. Review of the effects of additives on biodiesel properties, performance, and emission features. J. Renew. Sustain. Energy 2013, 5, 012701. [Google Scholar] [CrossRef]

- Monirul, I.M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Rashedul, H.K.; Rashed, M.M.; Imdadula, H.K.; Mosarof, M.H. A comprehensive review on biodiesel cold flow properties and oxidation stability along with their improvement processes. RSC Adv. 2015, 5, 86631–86655. [Google Scholar] [CrossRef]

- Liu, G. Development of low-temperature properties on biodiesel fuel: A review. Int. J. Energy Res. 2015, 39, 1295–1310. [Google Scholar] [CrossRef]

- Sierra-Cantora, J.F.; Guerrero-Fajardo, C.A. Methods for improving the cold flow properties of biodiesel with high saturated fatty acids content: A review. Renew. Sustain. Energy Rev. 2017, 72, 774–790. [Google Scholar] [CrossRef]

- Jing, G.; Yu, H.; Sun, Z.; Zhen, Z. Research progress on biodiesel pour point depressant: A mini-review. Pet. Chem. 2019, 59, 1023–1027. [Google Scholar] [CrossRef]

- Leng, L.; Li, W.; Li, H.; Jiang, S.; Zhou, W. Cold flow properties of biodiesel and the improvement methods: A review. Energy Fuels 2020, 34, 10364–10383. [Google Scholar] [CrossRef]

- Hazrat, M.A.; Rasul, M.G.; Mofijur, M.; Khan, M.M.K.; Djavanroodi, F.; Azad, A.K.; Bhuiya, M.M.K.; Silitonga, A.S. A mini review on the cold flow properties of biodiesel and its blends. Front. Energy Res. 2020, 8, 598651. [Google Scholar] [CrossRef]

- Sia, C.B.; Kansedo, J.; Tan, Y.H.; Lee, K.T. Evaluation on biodiesel cold flow properties, oxidative stability and enhancement strategies: A review. Biocatal. Agric. Biotechnol. 2020, 24, 101514. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P.; Dwivedi, G. Evaluation and enhancement of cold flow properties of palm oil and its biodiesel. Energy Rep. 2016, 2, 8–13. [Google Scholar] [CrossRef]

- Giraldo, S.Y.; Rios, L.A.; Suárez, N. Comparison of glycerol ketals, glycerol acetates and branched alcohol-derived fatty esters as cold-flow improvers for palm biodiesel. Fuel 2013, 108, 709–714. [Google Scholar] [CrossRef]

- Soriano, N.U., Jr.; Migo, V.P.; Matsumura, M. Ozonized vegetable oil as pour point depressant for neat biodiesel. Fuel 2006, 85, 25–31. [Google Scholar] [CrossRef]

- Elias, R.C.; Senra, M.; Soh, L. Cold flow properties of fatty acid methyl ester blends with and without triacetin. Energy Fuels 2016, 30, 7400–7409. [Google Scholar] [CrossRef]

- Leggieri, P.A.; Senra, M.; Soh, L. Cloud point and crystallization in fatty acid ethyl ester biodiesel mixtures with and without additives. Fuel 2018, 222, 243–249. [Google Scholar] [CrossRef]

- De Torres, M.; Jiménez-Osés, G.; Mayoral, J.A.; Pires, E. Fatty acid derivatives and their use as CFPP additives in biodiesel. Bioresour. Technol. 2011, 102, 2590–2594. [Google Scholar] [CrossRef]

- Dunn, R.O.; Wyatt, V.T.; Wagner, K.; Ngo, H.; Hums, M.E. The effect of branched-chain fatty acid alkyl esters on the cold-flow properties of biodiesel. J. Am. Oil Chem. Soc. 2019, 96, 805–823. [Google Scholar] [CrossRef]

- Sugami, Y.; Yoshidomi, S.; Minami, E.; Shisa, N.; Hayashi, H.; Saka, S. The effect of monoglyceride polymorphism on cold-flow properties of biodiesel model fuel. J. Am. Oil Chem. Soc. 2017, 94, 1095–1100. [Google Scholar] [CrossRef]

- Madihalli, C.; Sudhakar, H.; Doble, M. Mannosylerythritol lipid-a as a pour point depressant for enhancing the low-temperature fluidity of biodiesel and hydrocarbon fuels. Energy Fuels 2016, 30, 4118–4125. [Google Scholar] [CrossRef]

- Moser, B.R. Preparation and evaluation of multifunctional branched diesters as fuel property enhancers for biodiesel and petroleum diesel fuels. Energy Fuels 2014, 28, 3262–3270. [Google Scholar] [CrossRef]

- Mohanan, A.; Bouzidi, L.; Narine, S.S. Harnessing the synergies between lipid-based crystallization modifiers and a polymer pour point depressant to improve pour point of biodiesel. Energy 2017, 120, 895–906. [Google Scholar] [CrossRef]

- Bhale, P.V.; Deshpande, N.V.; Thombre, S.B. Improving the low temperature properties of biodiesel fuel. Renew. Energy 2009, 34, 794–800. [Google Scholar] [CrossRef]

- Abe, M.; Hirata, S.; Komatsu, H.; Yamagiwa, K.; Tajima, H. Thermodynamic selection of effective additives to improve the cloud point of biodiesel fuels. Fuel 2016, 171, 94–100. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, Y.; Sjoblom, J.; Li, C.; Paso, K.G. Polymeric wax inhibitors and pour point depressants for waxy crude oils: A critical review. J. Dispers. Sci. Technol. 2015, 36, 213–225. [Google Scholar] [CrossRef]

- Li, N.; Mao, G.-L.; Shi, X.-Z.; Tian, S.-W.; Liu, Y. Advances in the research of polymeric pour point depressant for waxy crude oil. J. Disp. Sci. Technol. 2017, 39, 1165–1171. [Google Scholar] [CrossRef]

- Ivchenko, P.V.; Nifant’ev, I.E. Polymer depressor additives: Synthesis, microstructure, efficiency. Polym. Sci. Ser. A 2018, 60, 577–593. [Google Scholar] [CrossRef]

- Knothe, G. A technical evaluation of biodiesel from vegetable oils vs. algae. Will algae-derived biodiesel perform? Green Chem. 2011, 13, 3048–3065. [Google Scholar] [CrossRef]

- Sims, R.E.H.; Mabee, W.; Saddler, J.N.; Taylor, M. An overview of second generation biofuel technologies. Bioresour. Technol. 2010, 101, 1570–1580. [Google Scholar] [CrossRef] [PubMed]

- Nautiyal, P.; Subramanian, K.A.; Dastidar, M.G. Production and characterization of biodiesel from algae. Fuel Proc. Technol. 2014, 120, 79–88. [Google Scholar] [CrossRef]

- Viêgas, C.V.; Hachemi, I.; Freitas, S.P.; Mäki-Arvela, P.; Aho, A.; Hemming, J.; Smeds, A.; Heinmaa, I.; Fontes, F.B.; da Silva Pereira, D.C.; et al. A route to produce renewable diesel from algae: Synthesis and characterization of biodiesel via in situ transesterification of Chlorella alga and its catalytic deoxygenation to renewable diesel. Fuel 2015, 155, 144–154. [Google Scholar] [CrossRef]

- Kligerman, D.C.; Bouwer, E.J. Prospects for biodiesel production from algae-based wastewater treatment in Brazil: A review. Renew. Sustain. Energy Rev. 2015, 52, 1834–1846. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. Composition, properties and challenges of algae biomass for biofuel application: An overview. Fuel 2016, 181, 1–33. [Google Scholar] [CrossRef]

- Piloto-Rodríguez, R.; Sánchez-Borroto, Y.; Melo-Espinosa, E.A.; Verhelst, S. Assessment of diesel engine performance when fueled with biodiesel from algae and microalgae: An overview. Renew. Sustain. Energy Rev. 2017, 69, 833–842. [Google Scholar] [CrossRef]

- Islam, M.A.; Heimann, K.; Brown, R.J. Microalgae biodiesel: Current status and future needs for engine performance and emissions. Renew. Sustain. Energy Rev. 2017, 79, 1160–1170. [Google Scholar] [CrossRef]

- Roveda, A.C.; Comin, M.; Caires, A.R.L.; Ferreira, V.S.; Trindade, M.A.G. Thermal stability enhancement of biodiesel induced by a synergistic effect between conventional antioxidants and an alternative additive. Energy 2016, 109, 260–265. [Google Scholar] [CrossRef]

- Sajjadi, B.; Raman, A.A.A.; Arandiyan, H. A comprehensive review on properties of edible and non-edible vegetable oil-based biodiesel: Composition, specifications and prediction models. Renew. Sustain. Energy Rev. 2016, 63, 62–92. [Google Scholar] [CrossRef]

- De Boer, K.; Bahri, P.A. Supercritical methanol for fatty acid methyl ester production: A review. Biomass Bioenergy 2011, 35, 983–991. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 276–297. [Google Scholar] [CrossRef]

- Saka, S.; Kusdiana, D. Biodiesel fuel from rapeseed oil as prepared in supercritical methanol. Fuel 2001, 80, 225–231. [Google Scholar] [CrossRef]

- Karki, S.; Sanjel, N.; Poudel, J.; Choi, J.H.; Oh, S.C. Supercritical transesterification of waste vegetable oil: Characteristic comparison of ethanol and methanol as solvents. Appl. Sci. 2017, 7, 632. [Google Scholar] [CrossRef]

- Lee, A.F.; Bennett, J.A.; Manayila, J.C.; Wilson, K. Heterogeneous catalysis for sustainable biodiesel production via esterification and transesterification. Chem. Soc. Rev. 2014, 43, 7887–7916. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.F.; Wilson, K. Recent developments in heterogeneous catalysis for the sustainable production of biodiesel. Catal. Today 2015, 242, 3–18. [Google Scholar] [CrossRef]

- Guldhe, A.; Singh, B.; Mutanda, T.; Permaul, K.; Bux, F. Advances in synthesis of biodiesel via enzyme catalysis: Novel and sustainable approaches. Renew. Sustain. Energy Rev. 2015, 41, 1447–1464. [Google Scholar] [CrossRef]

- Knothe, G. Analyzing biodiesel: Standards and other methods. J. Am. Oil. Chem. Soc. 2006, 83, 823–833. [Google Scholar] [CrossRef]

- Monteiro, M.R.; Ambrozin, A.R.P.; Lião, L.M.; Ferreira, A.G. Critical review on analytical methods for biodiesel characterization. Talanta 2008, 77, 593–605. [Google Scholar] [CrossRef]

- Nimal Ratnayake, W.M.; Hansen, S.L.; Kennedy, M.P. Evaluation of the CP-Sil 88 and SP-2560 GC columns used in the recently approved AOCS official method Ce 1h-05: Determination of cis-, trans-, saturated, monounsaturated, and polyunsaturated fatty acids in vegetable or non-ruminant animal oils and fats by capillary GLC method. J. Am. Oil Chem. Soc. 2006, 83, 475–488. [Google Scholar] [CrossRef]

- Pauls, R.E. A review of chromatographic characterization techniques for biodiesel and biodiesel blends. J. Chrom. Sci. 2011, 49, 384–396. [Google Scholar] [CrossRef] [PubMed]

- Tariq, M.; Ali, S.; Khali, N. Activity of homogeneous and heterogeneous catalysts, spectroscopic and chromatographic characterization of biodiesel: A review. Renew. Sustain. Energy Rev. 2012, 16, 6303–6316. [Google Scholar] [CrossRef]

- Flores, I.S.; Godinho, M.S.; de Oliveira, A.E.; Alcantara, G.B.; Monteiro, M.R.; Menezes, S.M.C.; Lião, L.M. Discrimination of biodiesel blends with 1H NMR spectroscopy and principal component analyses. Fuel 2012, 99, 40–44. [Google Scholar] [CrossRef]

- ASTM Updates Biodiesel Specifications for Measuring Cloud Point. Biodiesel Magasine. Available online: http://biodieselmagazine.com/articles/3420/astm-updates-biodiesel-specifications-for-measuring-cloud-point/ (accessed on 9 May 2021).

- Santos, N.A.; Rosenhaim, R.; Dantas, M.B.; Bicudo, T.C.; Cavalcanti, E.H.S.; Barro, A.K.; Santos, I.M.G.; Souza, A.G. Rheology and MT-DSC studies of the flow properties of ethyl and methyl babassu biodiesel and blends. J. Therm. Anal. Calorim. 2011, 106, 501–506. [Google Scholar] [CrossRef]

- Dunn, R.O. Cold flow properties of biodiesel: A guide to getting an accurate analysis. Biofuels 2015, 6, 115–128. [Google Scholar] [CrossRef]

- Chupka, G.M.; Fouts, L.; Lennon, J.A.; Alleman, T.L.; Daniels, D.A.; McCormick, R.L. Saturated monoglyceride effects on low-temperature performance of biodiesel blends. Fuel Proc. Technol. 2014, 118, 302–309. [Google Scholar] [CrossRef]

- Chen, W.; Chen, J. Crystallization behaviors of biodiesel in relation to its rheological properties. Fuel 2016, 171, 178–185. [Google Scholar] [CrossRef]

- Alicke, A.A.; Leopércio, B.C.; Marchesini, F.H.; de Souza Mendes, P.R. Guidelines for the rheological characterization of biodiesel. Fuel 2015, 140, 446–452. [Google Scholar] [CrossRef]

- Knothe, G.; Dunn, R.O. A comprehensive evaluation of the melting points of fatty acids and esters determined by differential scanning calorimetry. J. Am. Oil Chem. Soc. 2009, 86, 843–856. [Google Scholar] [CrossRef]

- Kerschbaum, S.; Rinke, G.; Schubert, K. Winterization of biodiesel by micro process engineering. Fuel 2008, 87, 2590–2597. [Google Scholar] [CrossRef]

- Yuan, M.-H.; Chen, Y.-H.; Chen, J.-H.; Luo, Y.-M. Dependence of cold filter plugging point on saturated fatty acid profile of biodiesel blends derived from different feedstocks. Fuel 2017, 195, 59–68. [Google Scholar] [CrossRef]

- Liu, X.; Gibbs, A.S.; Nichol, G.S.; Tang, C.C.; Knight, K.S.; Dowding, P.J.; Mored, I.; Pulham, C.R. Temperature-induced polymorphism in methyl stearate. CrystEngComm 2018, 20, 6885–6893. [Google Scholar] [CrossRef]

- Liu, X.; Bull, C.L.; Kleppe, A.K.; Dowding, P.J.; Lewtas, K.; Pulham, C.R. High-pressure crystallisation studies of biodiesel and methyl stearate. CrystEngComm 2019, 21, 4427–4436. [Google Scholar] [CrossRef]

- Prathapa, S.J.; Slabbert, C.; Fernandes, M.A.; Lemmerer, A. Structure determination of fatty acid ester biofuels via in situ cryocrystallisation and single crystal X-ray diffraction. CrystEngComm 2018, 21, 41–52. [Google Scholar] [CrossRef]

- Lacoste, F.; Dejean, F.; Griffon, H.; Rouquette, C. Quantification of free and esterified steryl glucosides in vegetable oils and biodiesel. Eur. J. Lipid Sci. Technol. 2009, 111, 822–828. [Google Scholar] [CrossRef]

- Chupka, G.M.; Yanowitz, J.; Chiu, G.; Alleman, T.L.; McCormick, R.L. Effect of Saturated Monoglyceride Polymorphism on Low-Temperature Performance of Biodiesel. Energy Fuels 2011, 25, 398–405. [Google Scholar] [CrossRef]

- Chiu, C.-W.; Schumacher, L.G.; Suppes, G.J. Impact of cold flow improvers on soybean biodiesel blend. Biomass Bioenergy 2004, 27, 485–491. [Google Scholar] [CrossRef]

- Wang, J.; Cao, L.; Han, S. Effect of polymeric cold flow improvers on flow properties of biodiesel from waste cooking oil. Fuel 2014, 117, 876–881. [Google Scholar] [CrossRef]

- Echim, C.; Maes, J.; De Greyt, W. Improvement of cold filter plugging point of biodiesel from alternative feedstocks. Fuel 2012, 93, 642–648. [Google Scholar] [CrossRef]

- Chastek, T.Q. Improving cold flow properties of canola-based biodiesel. Biomass Bioenergy 2011, 35, 600–607. [Google Scholar] [CrossRef]

- Chen, W.; Zhao, Z.; Yin, C. The interaction of waxes with pour point depressants. Fuel 2010, 89, 1127–1132. [Google Scholar] [CrossRef]

- Xue, Y.; Zhao, Z.; Xu, G.; Lian, X.; Yang, C.; Zhao, W.; Ma, P.; Lin, H.; Han, S. Effect of poly-alpha-olefin pour point depressant on cold flow properties of waste cooking oil biodiesel blends. Fuel 2016, 184, 110–117. [Google Scholar] [CrossRef]

- Cao, L.; Wang, J.; Liu, C.; Chen, Y.; Liu, K.; Han, S. Ethylene vinyl acetate copolymer: A bio-based cold flow improver for waste cooking oil derived biodiesel blends. Appl. Energy 2014, 132, 163–167. [Google Scholar] [CrossRef]

- Zhou, M.; He, Y.; Lin, H.; Han, S. Effect of MC–MA polymer pour point depressants on the flow properties of biodiesel. Energy Sources Part A Rec. Util. Environ. Eff. 2016, 38, 1962–1968. [Google Scholar] [CrossRef]

- Sern, C.H.; May, C.Y.; Zakaria, Z.; Daik, R.; Foon, C.S. The effect of polymers and surfactants on the pour point of palm oil methyl esters. Eur. J. Lipid Sci. Technol. 2007, 109, 440–444. [Google Scholar] [CrossRef]

- Boshui, C.; Yuqiu, S.; Jianhua, F.; Jiu, W.; Jiang, W. Effect of cold flow improvers on flow properties of soybean biodiesel. Biomass Bioenergy 2010, 34, 1309–1313. [Google Scholar] [CrossRef]

- Muniz, A.S.; Vlnieska, V.; Ferraz, F.A.; dos Santos Oliveira, A.R.; Ramos, L.P.; César-Oliveira, M.A.F. Polymer Additives as Cold Flow Improvers for Palm Oil Methyl Esters. Macromol. Symp. 2019, 383, 1800026. [Google Scholar] [CrossRef]

- Nie, S.; Cao, L. Effect of mixed commercial cold flow improvers on flow properties of biodiesel from waste cooking oil. Processes 2020, 8, 1094. [Google Scholar] [CrossRef]

- Xue, Y.; Yin, S.; Jin, D.; Zhu, X.; Yang, T.; Yuan, M.; Li, X.; Lin, H.; Han, S. Nitrogen-Containing Ternary Polymer Biodiesel Pour Point Depressant, Preparation Method and Application Thereof. Patent CN111826222, 27 October 2020. [Google Scholar]

- Jawak, D.A.; Mitra, P.; Kariparambil, S.K. A Pour Point Depressant Polymer Composition. Patent Application WO2009/047786, 16 April 2009. [Google Scholar]

- Lin, H.; Yuan, M.; Yin, S.; Li, X.; Su, B.; Yang, T.; Wu, J.; Xue, Y.; Han, S. Biodiesel Pour Point Depressant Composition as Well as Preparation and Application Thereof. Patent CN111676072, 19 September 2020. [Google Scholar]

- Yadav, K.; Kumar, N.; Chaudhary, R. A review on cold flow properties of biodiesel and their improvement. IOP Conf. Ser. Mater. Sci. Eng. 2020, 804, 012027. [Google Scholar] [CrossRef]

- Leube, W.; Monkenbusch, M.; Schneiders, D.; Richter, D.; Adamson, D.; Fetters, L.; Dounis, P.; Lovegrove, R. Wax-crystal modification for fuel oils by self-aggregating partially crystallizable hydrocarbon block copolymers. Energy Fuels 2000, 14, 419–430. [Google Scholar] [CrossRef]

- Monkenbusch, M.; Schneiders, D.; Richter, D.; Willner, L.; Leube, W.; Fetters, L.J.; Huang, J.S.; Lin, M. Aggregation behaviour of PE-PEP copolymers and the winterization of diesel fuel. Phys. B Condens. Matter 2000, 276–278, 941–943. [Google Scholar] [CrossRef]

- Ashbaugh, H.S.; Fetters, L.J.; Adamson, D.H.; Prud’homme, R.K. Flow improvement of waxy oils mediated by self-aggregating partially crystallizable diblock copolymers. J. Rheol. 2002, 46, 763–776. [Google Scholar] [CrossRef]

- Schwahn, D.; Richter, D.; Wright, P.J.; Symon, C.; Fetters, L.J.; Lin, M. Self-assembling behavior in decane solution of potential wax crystal nucleators based on poly(co-olefins). Macromolecules 2002, 35, 861–870. [Google Scholar] [CrossRef]

- Schwahn, D.; Richter, D.; Lin, M.; Fetters, L.J. Cocrystallization of a poly(ethylene-butene) random copolymer with C24 in n-decane. Macromolecules 2002, 35, 3762–3768. [Google Scholar] [CrossRef]

- Guo, X.; Pethica, B.A.; Huang, J.S.; Prud’homme, R.K.; Adamson, D.H.; Fetters, L.J. Crystallization of mixed paraffin from model waxy oils and the influence of micro-crystalline poly(ethylene-butene) random copolymers. Energy Fuels 2004, 18, 930–937. [Google Scholar] [CrossRef]

- Guo, X.; Pethica, B.A.; Huang, J.S.; Adamson, D.H.; Prud’homme, R.K. Effect of cooling rate on crystallization of model waxy oils with microcrystalline poly(ethylene butene). Energy Fuels 2006, 20, 250–256. [Google Scholar] [CrossRef]

- Tinsley, J.F.; Prud’homme, R.K.; Guo, X.; Adamson, D.H.; Callahan, S.; Amin, D.; Shao, S.; Kriegel, R.M.; Saini, R. Novel laboratory cell for fundamental studies of the effect of polymer additives on wax deposition from model crude oils. Energy Fuels 2007, 21, 1301–1308. [Google Scholar] [CrossRef]

- Ilnycky, S.J.; Rupar, C.B. Ethylene-Vinyl Ester Pour Depressant for Middle Distillates. U.S. Patent 3048479, 7 August 1962. [Google Scholar]

- Chen, J.C. Cold Flow Improver. U.S. Patent 4512775, 23 April 1985. [Google Scholar]

- Botros, M.G. Ethylene Vinyl Acetate and Isobutylene Terpolymer as a Cold Flow Improver for Distillate Fuel Compositions. U.S. Patent 5681359, 28 October 1997. [Google Scholar]

- Machado, A.L.C.; Lucas, E.F.; Gonzalez, G. Poly(ethylene-co-vinyl acetate) (EVA) as wax inhibitor of a Brazilian crude oil: Oil viscosity, pour point and phase behavior of organic solutions. J. Petrol. Sci. Eng. 2001, 32, 159–165. [Google Scholar] [CrossRef]

- Jafari Ansaroudi, H.R.; Vafaie-Sefti, M.; Masoudi, S.; Jafari Behbahani, T.; Jafari, H. Study of the morphology of wax crystals in the presence of ethylene-co-vinyl acetate copolymer. Pet. Sci. Technol. 2013, 31, 643–651. [Google Scholar] [CrossRef]

- Mähling, F.-O.; Sondjaja, R.; Hess, B.; Couet, J.; Thong, D. Cold Flow Improver with Broad Applicability in Mineral Diesel, Biodiesel and Blends. U.S. Patent Application 2015344801, 3 December 2015. [Google Scholar]

- Hamada, H.; Kato, H.; Ito, N.; Takase, Y.; Nanbu, H.; Mishima, S.; Sakaki, H.; Sato, K. Effects of polyglycerol esters of fatty acids and ethylene-vinyl acetate co-polymer on crystallization behavior of biodiesel. Eur. J. Lipid Sci. Technol. 2010, 112, 1323–1330. [Google Scholar] [CrossRef]

- Bartl, H.; Hardt, D. Graft Polymerization of Vinyl Compounds on Ethylene-Vinyl Acetate Copolymers. In Advances in Chemistry; Platzer, N., Ed.; American Chemical Society: Washington, DC, USA, 1969; Volume 91, pp. 477–488. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Su, B.-Y. Substantial modifications of ethylene/vinyl acetate copolymers: Saponification and graft copolymerization. Angew. Makromol. Chem. 1993, 212, 77–91. [Google Scholar] [CrossRef]

- Ren, Y.; Fang, L.; Chen, Z.; Du, H.; Zhang, X. Synthesis and evaluation of grafted EVAL as pour point depressant for waxy crude oil. Ind. Eng. Chem. Res. 2018, 57, 8612–8619. [Google Scholar] [CrossRef]

- Sweeney, W.M. Polyacrylates and Waxy Residual Fuel Compositions Thereof. U.S. Patent US3904385, 9 September 1975. [Google Scholar]

- Soldi, R.A.; Oliveira, A.R.S.; Barbosa, R.V.; Cesar-Oliveira, M.A.F. Polymethacrylates: Pour point depressants in diesel oil. Eur. Polym. J. 2007, 43, 3671–3678. [Google Scholar] [CrossRef]

- Ma, P.; Xue, Y.; Zhao, W.; Lan, G.; Hang, Z.; Liu, F.; Han, S. Study on the performance mechanism of methacrylate pour point depressant in soybean biodiesel blends. RSC Adv. 2015, 5, 90144–90149. [Google Scholar] [CrossRef]

- Xue, Y.; Yang, C.; Xu, G.; Zhao, Z.; Lian, X.; Sheng, H. The influence of polymethyl acrylate as a pour point depressant for biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 17–22. [Google Scholar] [CrossRef]

- Roy, M.M.; Calder, J.; Wang, W.; Mangad, A.; Diniz, F.C.M. Emission analysis of a modern Tier 4 DI diesel engine fueled by biodiesel-diesel blends with a cold flow improver (Wintron Synergy) at multiple idling conditions. Appl. Energy 2016, 179, 45–54. [Google Scholar] [CrossRef]

- Martyak, N.M.; Masy, N.E.; Gernon, M.D.; Schmidt, S.C.; Dowling, C.M. Acrylic Polymer Low Temperature Flow Modifiers in Bio-Derived Fuels. U.S. Patent US8236069, 7 August 2012. [Google Scholar]

- Muniz, A.S.; Inoue, M.H.; Oliveira, D.C.; Oliveira, A.R.S.; Ramos, L.P.; Mittelbach, M.; César-Oliveira, M.A.F. Bifunctional additives to improve the cold flow properties and oxidation stability of soybean oil biodiesel. Energy Fuels 2020, 34, 5907–5916. [Google Scholar] [CrossRef]

- Lutz, J.-F. Sequence-controlled polymerizations: The next Holy Grail in polymer science? Polym. Chem. 2010, 1, 55–62. [Google Scholar] [CrossRef]

- Lappalainen, E.; Koskimies, S. Preparation of alternating olefine maleic anhydride copolymers from C4-C6 hydrocarbon mixtures formed in petrochemical cracking units. J. Polym. Sci. Part C Polym. Lett. 1986, 24, 17–23. [Google Scholar] [CrossRef]

- Davis, F.; Hodge, P.; Towns, C.R.; Ali-Adib, Z. Langmuir and Langmuir-Blodgett films of derivatives of alternating copolymers of straight-chain α-olefins and maleic anhydride. Macromolecules 1991, 24, 5695–5703. [Google Scholar] [CrossRef]

- Martínez, F.; Uribe, E.; Olea, A.F. Copolymerization of maleic anhydride with styrene and α-olefins. Molecular and thermal characterization. J. Macromol. Sci. Part A Pure Appl. Chem. 2005, 42, 1063–1072. [Google Scholar] [CrossRef]

- Davies, M.C.; Dawkins, J.V.; Hourston, D.J.; Meehan, E. Molar mass determination of poly(octadecene-alt-maleic anhydride) copolymers by size exclusion chromatography and dilute solution viscometry. Polymer 2002, 43, 4311–4314. [Google Scholar] [CrossRef]

- Li, L.; Xu, J.; Tinsley, J.; Adamson, D.H.; Pethica, B.A.; Huang, J.S.; Prud’homme, R.K.; Guo, X. Improvement of oil flowability by assembly of comb-type copolymers with paraffin and asphaltene. AIChE J. 2012, 58, 2254–2261. [Google Scholar] [CrossRef]

- Mazi, H.; Kibarer, G.; Emregul, E.; Rzaev, Z.M.O. Bioengineering Functional Copolymers. IX. Poly[(maleic anhydride-co-hexene-1)-g-poly(ethylene oxide)]. Macromol. Biosci. 2006, 6, 311–321. [Google Scholar] [CrossRef] [PubMed]

- Nifant’ev, I.; Vinogradov, A.; Vinogradov, A.; Ivchenko, P. DFT modeling of the alternating radical copolymerization and alder-ene reaction between maleic anhydride and olefins. Polymers 2020, 12, 744. [Google Scholar] [CrossRef]

- Soni, H.P.; Kiranbala, A.K.S.; Nagar, A.; Bharambe, D.P. Designing maleic anhydride-a-olifin copolymeric combs as wax crystal growth nucleators. Fuel Proc. Technol. 2010, 91, 997–1004. [Google Scholar] [CrossRef]

- Ke-Jian, L.; Yuchin, Z. A study of three kinds of alkohols esterified copolymer of maleic anhydride and olefins as pour-point depressant for diesels. Pet. Sci. Technol. 1998, 16, 971–977. [Google Scholar] [CrossRef]

- Nifant’ev, I.E.; Vinogradov, A.A.; Bondarenko, G.N.; Korchagina, S.A.; Shlyakhtin, A.V.; Roznyatovsky, V.A.; Ivchenko, P.V. Copolymers of maleic anhydride and methylene alkanes: Synthesis, modification, and pour point depressant properties. Polym. Sci. Ser. B 2018, 60, 469–480. [Google Scholar] [CrossRef]

- Usta, N.; Aydoğan, B.; Çon, A.H.; Uğuzdoğan, E.; Özkal, S.G. Properties and quality verification of biodiesel produced from tobacco seed oil. Energy Convers. Manag. 2011, 52, 2031–2039. [Google Scholar] [CrossRef]

- Li, X.H.; Soriano, N.U.; Bode, H. Cold Flow Additive for Middle Distillate Fuels. Patent Application WO2020014189, 16 January 2020. [Google Scholar]

- Tasić, I.; Tomić, M.D.; Aleksić, A.L.J.; Đurišić-Mladenović, N.; Martinović, F.L.; Mićić, R.D. Improvement of low-temperature characteristics of biodiesel by additivation. Hemijska Ind. 2019, 73, 103–114. [Google Scholar] [CrossRef]

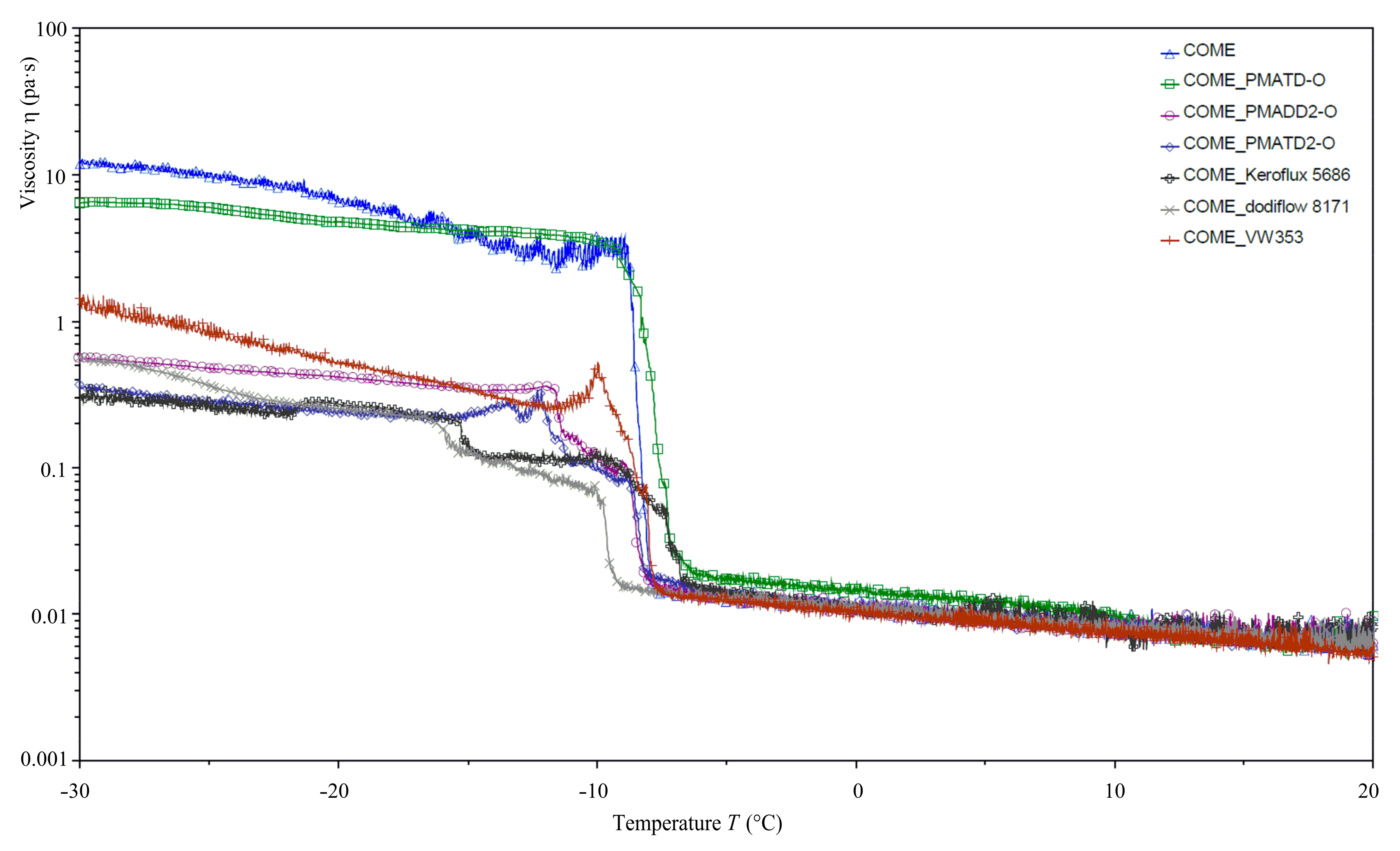

- Vinogradov, A.A.; Nifant’ev, I.E.; Vinogradov, A.A.; Borisov, R.S.; Ivchenko, P.V. Precision rheological study of the effectiveness of polymer cold flow improvers for corn oil based biodiesel. Mendeleev Commun. accepted.

- Tesfaye, M.; Katiyar, V. Microwave assisted synthesis of biodiesel from soybean oil: Effect of poly (lactic acid)-oligomer on cold flow properties, IC engine performance and emission characteristics. Fuel 2016, 170, 107–114. [Google Scholar] [CrossRef]

- Abe, M.; Komatsu, H.; Yamagiwa, K.; Tajima, H. Evaluation of the separation of saturated fatty acid methyl esters obtained from additive winterization using a nonionic surfactant. Fuel 2018, 214, 607–613. [Google Scholar] [CrossRef]

- Davies, B.W.; Lewtas, K.; Lombardi, A. Oil Additives and Compositions. U.S. Patent US5743923, 28 April 1998. [Google Scholar]

- Monirul, I.M.; Kalam, M.A.; Masjuki, H.H.; Zulkifli, N.W.M.; Shahir, S.A.; Mosarof, M.H.; Ruhul, A.M. Influence of poly(methyl acrylate) additive on cold flow properties of coconut biodiesel blends and exhaust gas emissions. Renew. Energy 2017, 101, 702–712. [Google Scholar] [CrossRef]

- Monirul, I.M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Shancita, I. Influence of polymethyl acrylate additive on the formation of particulate matter and NOX emission of a biodiesel–diesel-fueled engine. Environ. Sci. Pollut. Res. 2017, 24, 18479–18493. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.M.; Hassan, M.H.; Kalam, M.A.; binti Mohd Zulkifli, N.W.; Habibullah, M.; Hossain, M.M. Improvement of cold flow properties of Cocos nucifera and Calophyllum inophyllum biodiesel blends using polymethyl acrylate additive. J. Clean. Product. 2016, 137, 322–329. [Google Scholar] [CrossRef]

- Stohr, T.; Schnabel, J.; Janssen, D.; Muller, M. Motor Fuel Composition Comprising Renewable Raw Materials. U.S. Patent Application US2009064568, 12 March 2009. [Google Scholar]

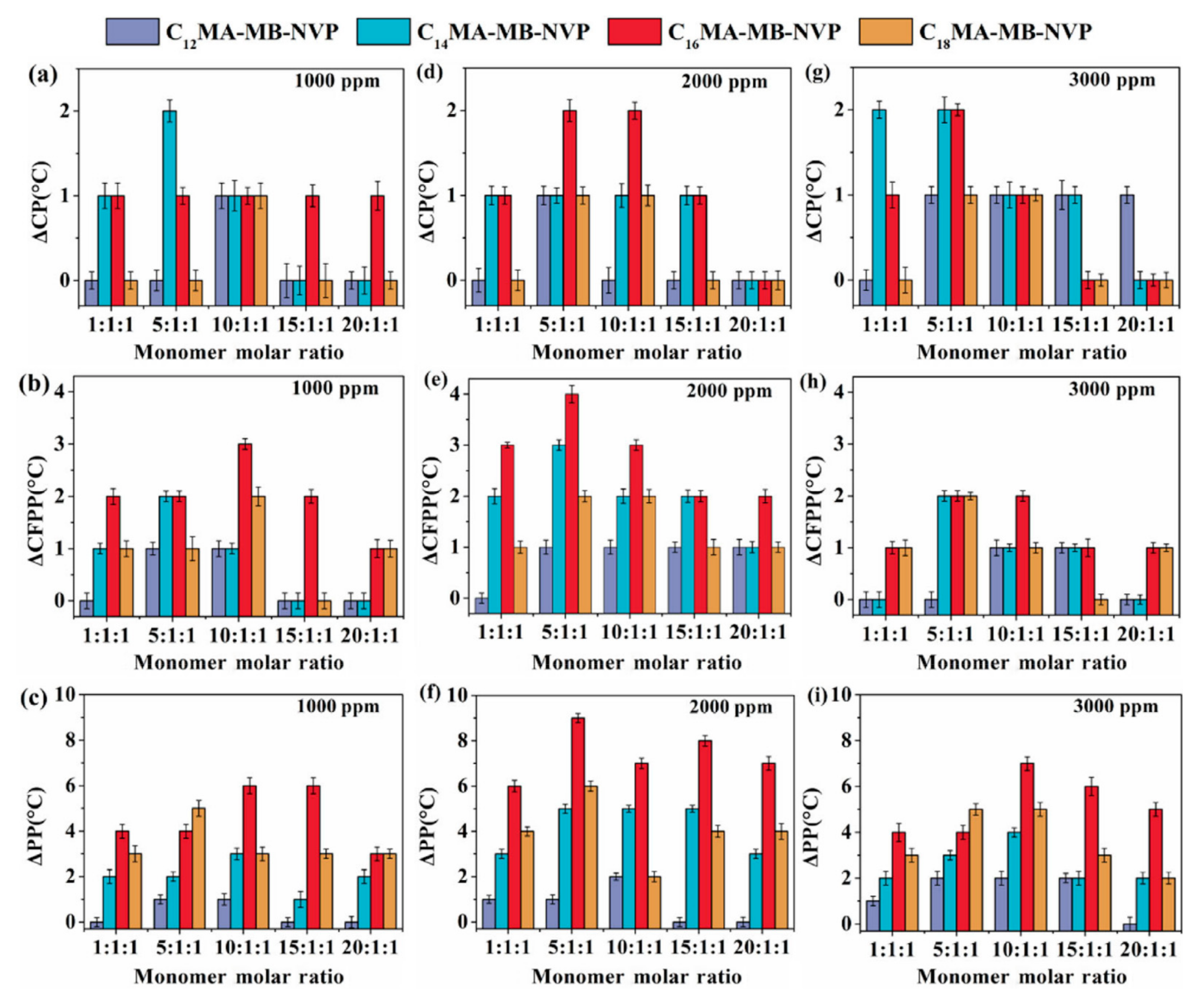

- Lin, H.; Xie, M.; Yin, S.; Yang, T.; Su, B.; Chen, F.; Han, S.; Xue, Y. Influence of methacrylate-benzyl methacrylate-N-vinyl-2-pyrrolidone as pour point depression on cold flow properties of diesel fuel. Energy Fuels 2020, 34, 1514–1523. [Google Scholar] [CrossRef]

- Su, B.; Wang, L.; Xue, Y.; Yan, J.; Dong, Z.; Lin, H.; Han, S. Effect of pour point depressants combined with dispersants on the cold flow properties of biodiesel-diesel blends. J. Am. Oil Chem. Soc. 2021, 98, 163–172. [Google Scholar] [CrossRef]

- Lai, Y.; Chen, X.; Yuan, Y. Improving the cold flow properties of biodiesel derived from palm. Adv. Mater. Res. 2011, 236-238, 164–168. [Google Scholar] [CrossRef]

- Lv, P.; Cheng, Y.; Yang, L.; Yuan, Z.; Li, H.; Luo, W. Improving the low temperature flow properties of palm oil biodiesel: Addition of cold flow improver. Fuel Proc. Technol. 2013, 110, 61–64. [Google Scholar] [CrossRef]

- Shrestha, D.S.; Van Gerpen, J.; Thompson, J. Effectiveness of cold flow additives on various biodiesels, diesel, and their blends. Trans. ASABE 2008, 51, 1365–1370. [Google Scholar] [CrossRef]

| Acid Name | Percent Composition in Oil 1 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Common | Lipid | RS | CA | CR | SU | SB | P | PK | OL | PN | CO | SA | TL | AlC 2 |

| Caproic | 6:0 | – | – | – | – | – | – | tr–1.5 | – | – | 0–0.8 | – | – | – |

| Caprylic | 8:0 | – | – | – | – | – | tr | 3–5 | – | – | 5–9 | – | – | – |

| Capric | 10:0 | – | – | – | – | tr | tr | 3–7 | – | – | 6–10 | – | – | – |

| Lauric | 12:0 | – | – | – | – | tr | tr | 40–52 | – | – | 44–52 | – | tr–0.2 | – |

| Myristic | 14:0 | – | – | tr–1.7 | – | tr | 0.5–6 | 14–18 | 0.1–1.2 | tr–1 | 13–19 | tr | 2–8 | 2.0 |

| Palmitic | 16:0 | 1–3 | 4 | 8–12 | 3–6 | 7–11 | 32–45 | 7–9 | 7–16 | 6–9 | 8–11 | 3–6 | 24–37 | 19.6 |

| Stearic | 18:0 | 0.4–3.5 | 2 | 2–5 | 1–3 | 2–6 | 2–7 | 1–3 | 1–3 | 3–6 | 1–3 | 1–4 | 14–29 | 3.3 |

| Arachidic | 20:0 | 0.5–2.4 | – | tr | 0.6–4 | 0.3–3 | tr | tr–1 | 0.1–0.3 | 2–4 | 0–0.4 | tr–0.2 | tr–1.2 | – |

| Behenic | 22:0 | 0.6–2.1 | – | tr | tr–0.8 | tr | – | – | – | 1–3 | – | – | – | – |

| Palmitoleic | 16:1 | 0.2–3 | – | 0.2–1.6 | tr | tr | 0.8–1.8 | tr–1 | tr | tr–1.7 | 0–1 | – | 1.9–2.7 | 0.8 |

| Oleic | 18:1 | 12–24 | 61 | 19–49 | 14–43 | 15–33 | 38–52 | 11–19 | 65–85 | 53–71 | 5–8 | 13–21 | 40–50 | 5.7 |

| Gadoleic | 20:1 | 4–12 | – | – | – | – | – | – | – | – | – | – | – | 0.1 |

| Erucic | 22:1 | 40–55 | tr | – | – | – | – | – | – | – | – | – | – | – |

| Linoleic | 18:2 | 12–16 | 21 | 34–62 | 44–75 | 43–56 | 5–11 | 0.5–2 | 4–15 | 13–27 | tr–2.5 | 73–79 | 1–5 | 11.8 |

| Linolenic | 18:3 | 7–10 | 9–12 | tr | tr | 5–11 | tr | – | tr–1 | tr | – | tr | – | 22.3 |

| Timnodonic | 20:5 | – | – | – | – | – | – | – | – | – | – | – | – | 1.3 |

| M. P. (°C) | M. P. (°C) | ||||

|---|---|---|---|---|---|

| Saturated Esters | Me | Et | Unsaturated Esters | Me | Et |

| 8:0 | −37.4 | –44.7 | 16:1 Δ9c | −34.1 | –36.7 |

| 10:0 | −13.5 | –20.4 | 18:1 Δ6c | −1.0 | –7.7 |

| 12:0 | 4.3 | –1.8 | 18:1 Δ9c | –20.2 | –20.3 |

| 14:0 | 18.1 | 12.5 | 18:1 Δ9t | 9.9 | 4.2 |

| 16:0 | 28.5 | 23.2 | 18:1 Δ11c | −24.3 | –36.5 |

| 18:0 | 37.7 | 32.9 | 18:2 Δ9c, Δ12c | −43.1 | –56.7 |

| 20:0 | 46.4 | 41.3 | 18:3 Δ9c, Δ12c, Δ15c | –52 | –61.7 |

| 22:0 | 53.2 | 48.6 | 20:1 Δ11c | −7.8 | –8.8 |

| 24:0 | 58.6 | 55.9 | 22:1 Δ13c | −3.1 | –10.5 |

| Biodiesel | Polymer CFIs Added | ΔCP, °C | ΔPP, °C | ΔCFPP, °C | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Name | Saturated FAMEs wt% | Type | Composition/ MW/ÐM | Concentration, wt% | No. | Rating 1 | |||

| Canola | 6.2 | EVA | – 2/–/– | 1 | 0 | 11 | – | 100 | Q1 |

| Canola | 6.2 | poly(acrylate) | +/+/+ | 0.5–1 | – | 30 | – | 100 | Q1 |

| Canola | – | poly(acrylate) | –/–/– | 2 | 5 | – | – | 135 | Q1 |

| Canola | – | MA/C18OCH=CH2 | +/+/– | 1 | – | 3 | – | 100 | Q1 |

| Rapeseed | – | MA/olefin/acrylate | –/–/– | 0.5 | – | 2 | 4 | 151 | Q3 |

| Rapeseed | ~10 | poly(acrylate) | +/+/+ | 0.3–0.5 | – | 9 | 6 | 126 | P |

| Rapeseed/soybean | 10.0 | EVA-g-acrylate | +/+/+ | 0.5 | – | 15 | 5 | 126 | P |

| Rapeseed/soybean | 10.0 | EVA-acrylate | +/+/+ | 0.3 | 2 | – | 9 | 126 | P |

| Soybean | 14.3 | EVA | –/–/– | 0.01 | – | 2 | 1 | 106 | Q1 |

| Soybean | 17.4 | poly(acrylate) | –/–/– | 0–1 | – | – | 0 | 133 | Q1 |

| Soybean | – | poly(acrylate) | –/–/– | 0.5–1 | – | 12 | – | 110 | P |

| Soybean | – | poly(acrylate) | +/+/+ | 0.1 | – | 5 | – | 136 | P |

| Soybean | – | poly(acrylate) | +/+/+ | 0.2 | 3 | 9 | – | 137 | Q1 |

| Soybean | 14.5 | poly(acrylate) | –/–/– | 0.5 | – | 30 | – | 24 | Q1 |

| Palm | 43.6 | polyolefin | 1-decene/–/– | 0–2 | 0 | 0 | 0 | 105 | Q1 |

| Palm | 46 | EVA | –/–/– | 1 | – | 6 | 127 | Q1 | |

| Palm | – | poly(acrylate) | +/+/+ | 0.01–0.1 | – | 0 | – | 107 | Q3 |

| Palm | – | poly(acrylate) | –/–/– | 0.5–1 | – | 9 | – | 110 | P |

| Palm | 36.9 | poly(acrylate) | +/–/– | 0–2 | 0 | 0 | 0 | 105 | Q1 |

| Palm | 36.9 | MA/C18 | +/–/– | 2 | – | 6 | – | 105 | Q1 |

| Tobacco seed | 12 | MA/C18 | +/–/– | 1 | – | – | 7 | 149 | Q1 |

| Waste cooking | – | polyolefin | –/–/– | 0.1 | – | 2–3 | 2–3 | 108 | Q2 |

| Waste cooking | – | polyolefin | –/–/– | 0.02–0.08 | 1 | 1 | 3 | 98 | Q1 |

| Waste cooking | – | EVA | –/–/– | 0.02–0.08 | 2 | 6 | 2 | 98 | Q1 |

| Waste cooking | 43.5 | EVA | –/–/– | 0.02–0.08 | 0 | 3 | 1 | 103 | Q1 |

| Waste cooking | – | poly(acrylate) | –/–/– | 0.02–0.08 | 0 | 8 | 6 | 98 | Q1 |

| Waste cooking | 32 | poly(acrylate) | –/–/– | 0.5 | – | – | 7 | 134 | Q3 |

| Waste cooking | – | MA/acrylate/C14N | +/–/– | 0.05 | – | 13 | – | 104 | Q3 |

| – | – | MA/C18/ON 3 | +/+/+ | 0.01 | 5 | – | – | 150 | P |

| – | – | acrylate/acrylamide | –/–/– | 0.5 | – | <5 | <5 | 109 | P |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nifant’ev, I.; Ivchenko, P. Polymer Cold-Flow Improvers for Biodiesel. Polymers 2021, 13, 1580. https://doi.org/10.3390/polym13101580

Nifant’ev I, Ivchenko P. Polymer Cold-Flow Improvers for Biodiesel. Polymers. 2021; 13(10):1580. https://doi.org/10.3390/polym13101580

Chicago/Turabian StyleNifant’ev, Ilya, and Pavel Ivchenko. 2021. "Polymer Cold-Flow Improvers for Biodiesel" Polymers 13, no. 10: 1580. https://doi.org/10.3390/polym13101580

APA StyleNifant’ev, I., & Ivchenko, P. (2021). Polymer Cold-Flow Improvers for Biodiesel. Polymers, 13(10), 1580. https://doi.org/10.3390/polym13101580