Significant Fatigue Life Enhancement in Multiscale Doubly-Modified Fiber/Epoxy Nanocomposites with Graphene Nanoplatelets and Reduced-Graphene Oxide

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Multi-Scale Nanocomposites

2.2.1. Two-Phase Graphene/Epoxy Composites

2.2.2. Three-Phase Laminated Composites

3. Characterization

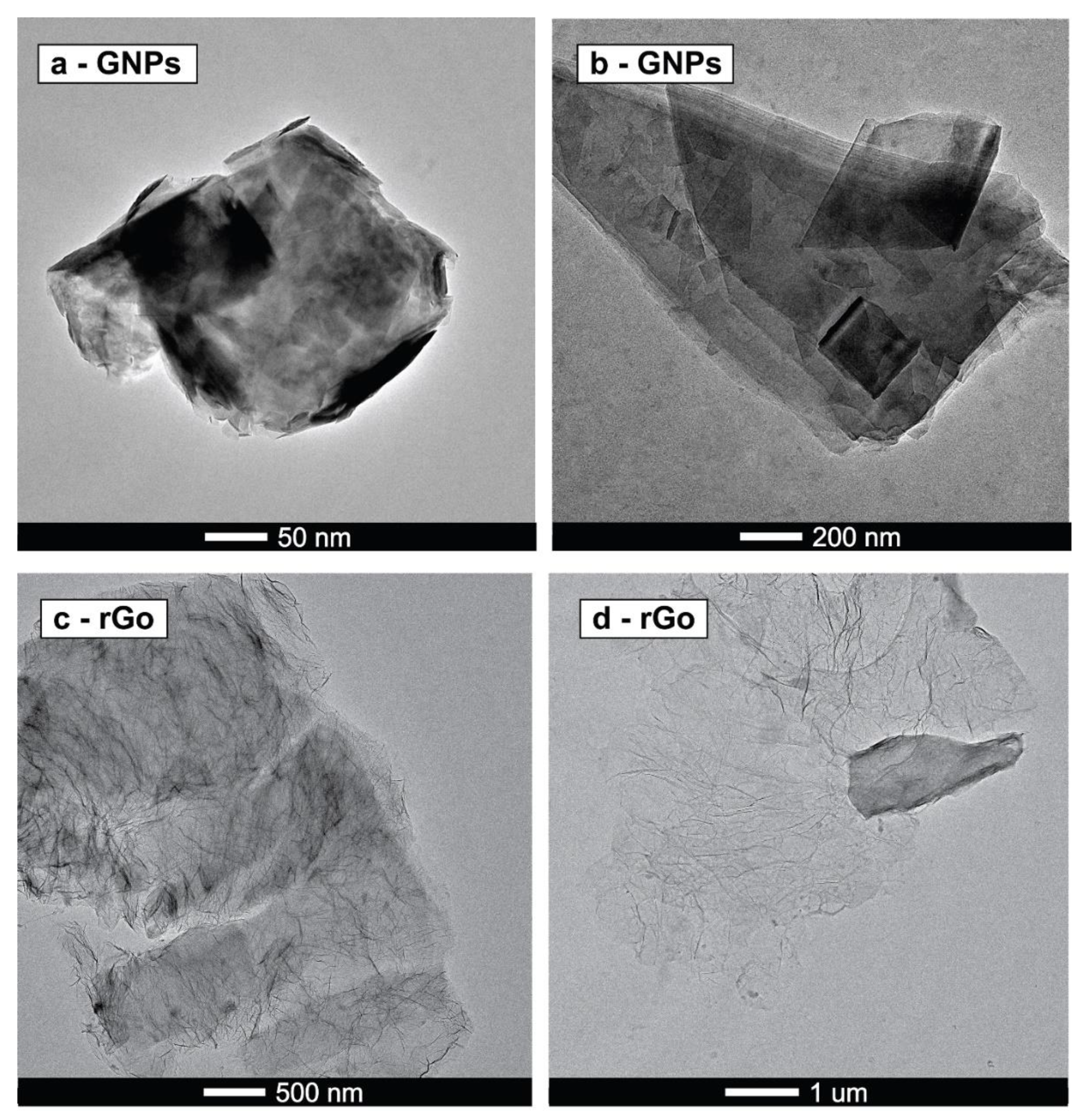

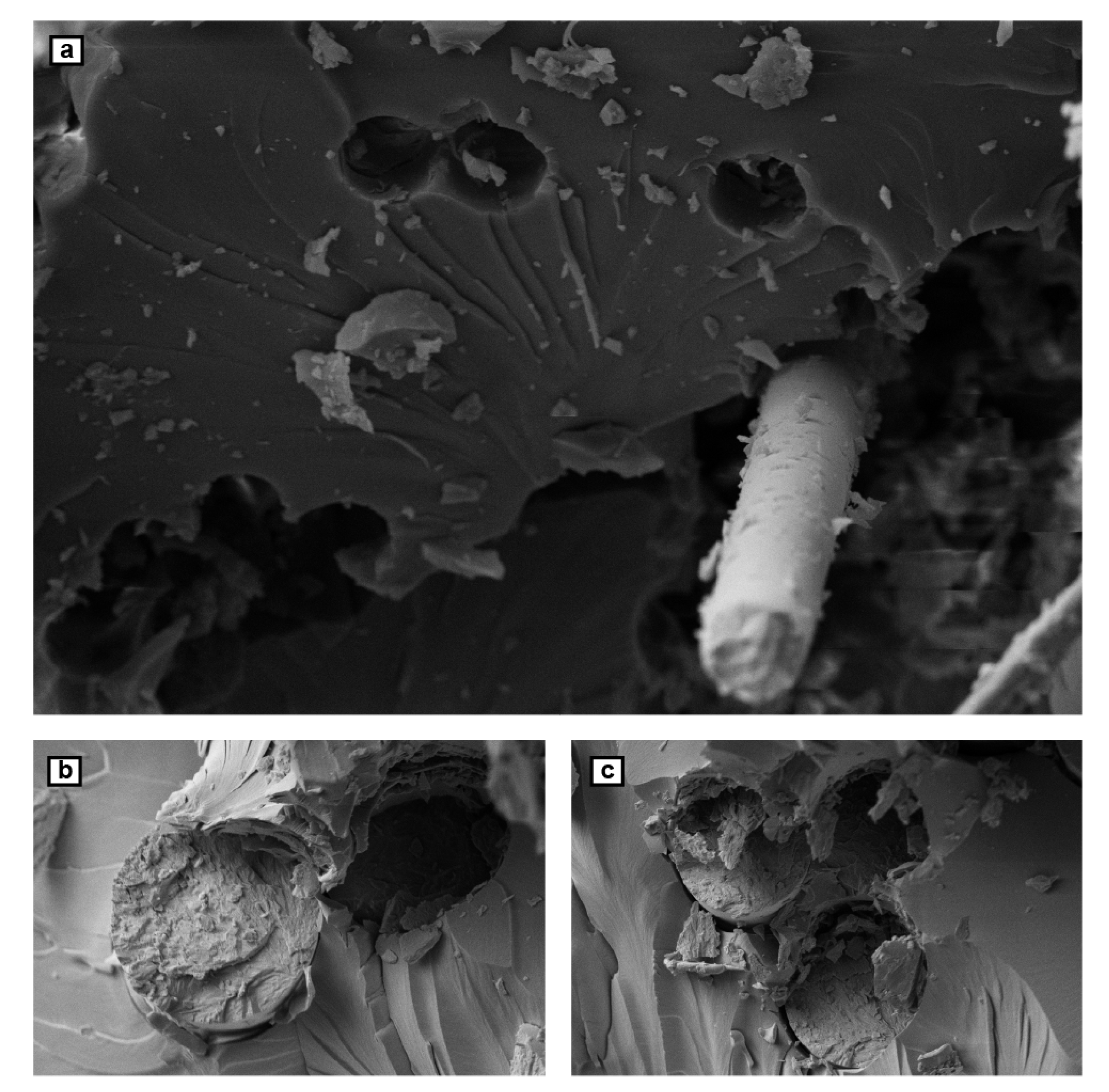

3.1. Morphological Study

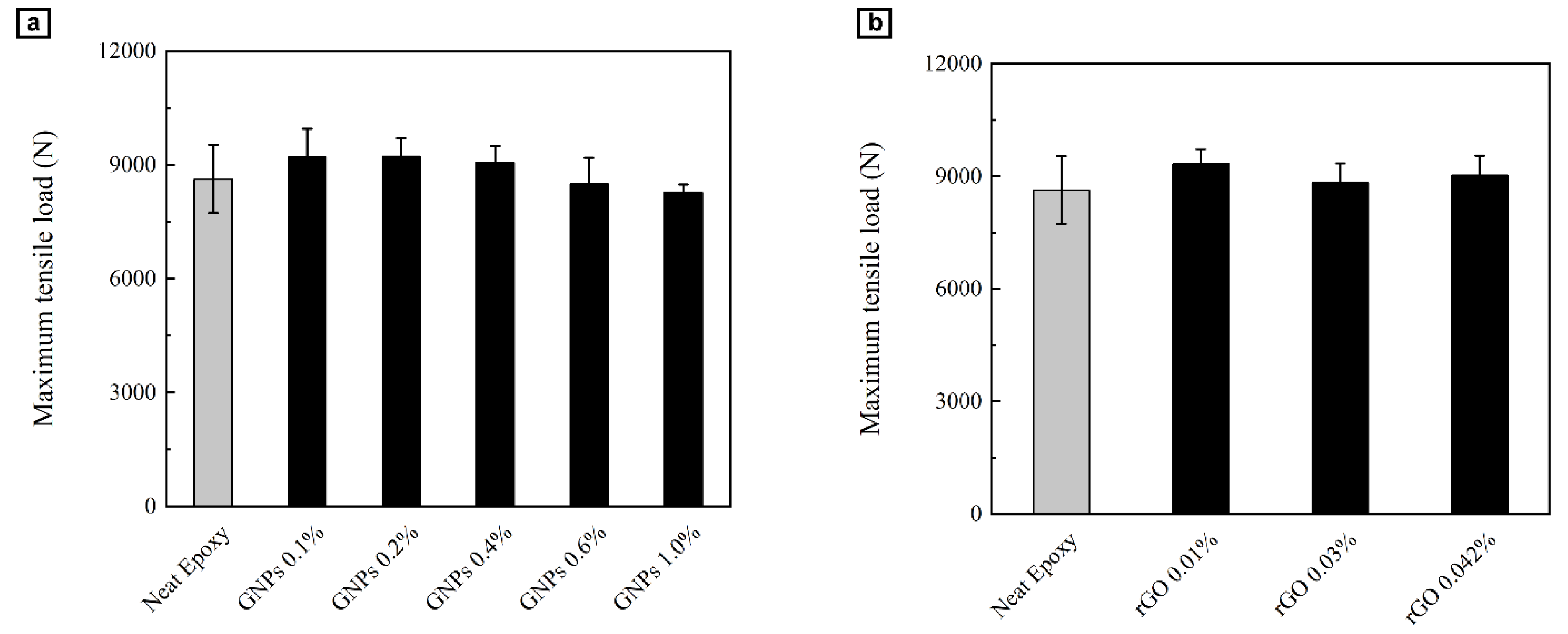

3.2. Tensile Properties

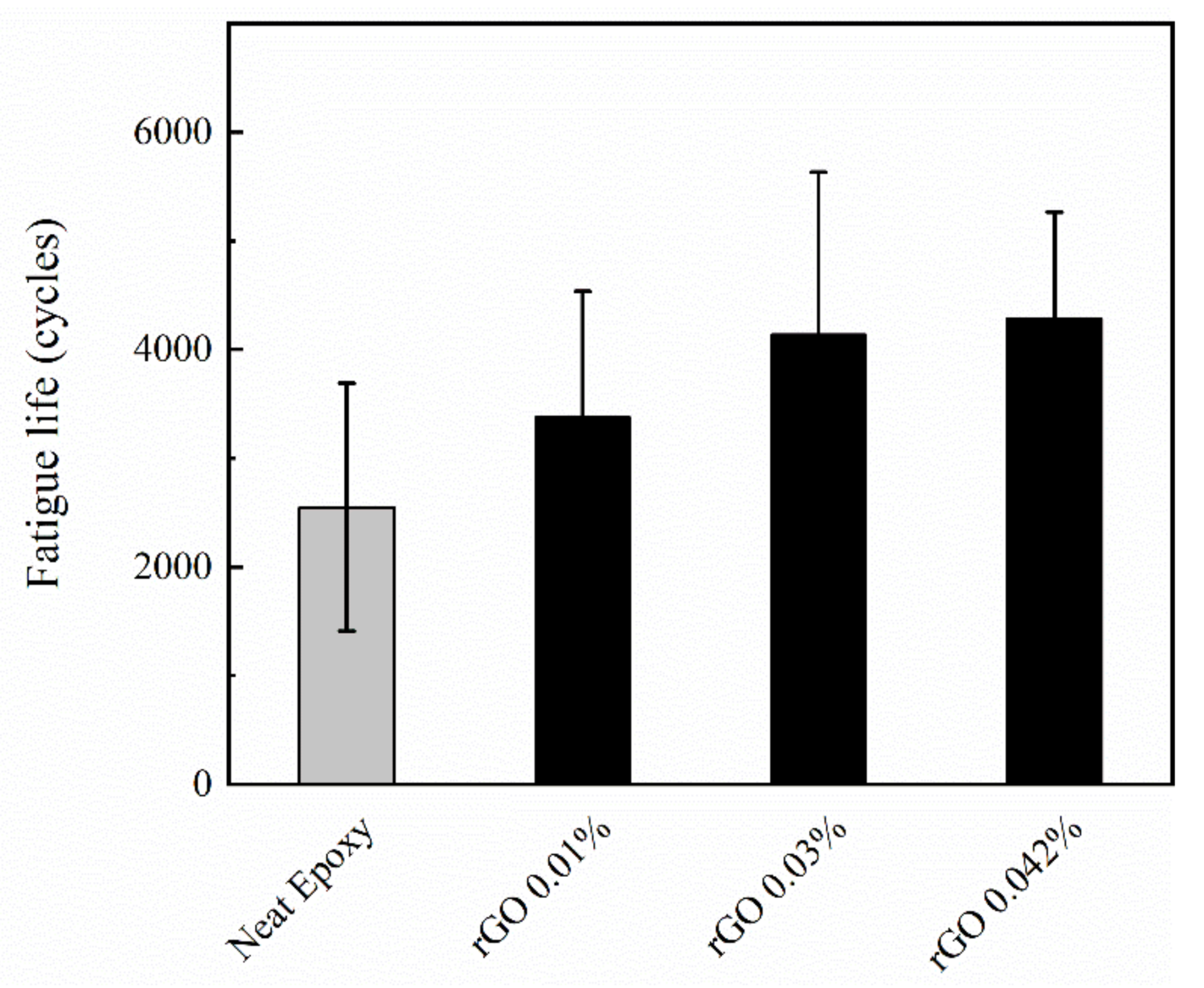

3.3. Fatigue

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rafiee, M.; Nitzsche, F.; Labrosse, M.R. Effect of functionalization of carbon nanotubes on vibration and damping characteristics of epoxy nanocomposites. Polym. Test. 2018, 69, 385–395. [Google Scholar] [CrossRef]

- Mutlay, I.; Tudoran, L.B. Percolation behavior of electrically conductive graphene nanoplatelets/polymer nanocomposites: Theory and experiment. Fuller. Nanotub. Carbon Nanostructur. 2014, 22, 413–433. [Google Scholar] [CrossRef]

- Rafiee, M.; Nitzsche, F.; Labrosse, M.R. Modeling and mechanical analysis of multiscale fiber-reinforced graphene composites: Nonlinear bending, thermal post-buckling and large amplitude vibration. Int. J. Non Linear Mech. 2018, 103, 104–111. [Google Scholar] [CrossRef]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Mechanical properties and thermal conductivity of graphene nanoplatelet/epoxy composites. J. Mater. Sci. 2015, 50, 1082–1093. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive manufacturing of PLA-based composites using fused filament fabrication: Effect of graphene nanoplatelet reinforcement on mechanical properties, dimensional accuracy and texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef]

- Vavouliotis, A.; Karapappas, P.; Loutas, T.; Voyatzi, T.; Paipetis, A.; Kostopoulos, V. Multistage fatigue life monitoring on carbon fibre reinforced polymers enhanced with multiwall carbon nanotubes. Plast. Rubber Compos. 2009, 38, 124–130. [Google Scholar] [CrossRef]

- Grimmer, C.S.; Dharan, C.K.H. High-cycle fatigue life extension of glass fiber/polymer composites with carbon nanotubes. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2009, 24, 167–173. [Google Scholar] [CrossRef]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Chou, T.W. Sensing of Damage Mechanisms in Fiber-Reinforced Composites under Cyclic Loading using Carbon Nanotubes. Adv. Funct. Mater. 2009, 19, 123–130. [Google Scholar] [CrossRef]

- Manjunatha, C.M.; Sprenger, S.; Taylor, A.C.; Kinloch, A.J. The Tensile Fatigue Behavior of a Glass-fiber Reinforced Plastic Composite Using a Hybrid-toughened Epoxy Matrix. J. Compos. Mater. 2010, 44, 2095–2109. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Taylor, A.C.; Kinloch, I.A. The effect of carbon nanotubes on the fracture toughness and fatigue performance of a thermosetting epoxy polym. J. Mater. Sci. 2011, 46, 7525–7535. [Google Scholar] [CrossRef]

- Leininger, W.; Wang, X.; Tangpong, X. Effects of MWCNT reinforcement on quasi-static and dynamic tensile properties of epoxy. J. Compos. Mater. 2013, 48, 2049–2057. [Google Scholar] [CrossRef]

- Jen, Y.-M.; Huang, C.-Y. Effect of temperature on fatigue strength of carbon nanotube/epoxy composites. J. Compos. Mater. 2014, 48, 3469–3483. [Google Scholar] [CrossRef]

- Moaseri, E.; Hasanabadi, S.; Maghrebi, M.; Baniadam, M. Improvements in fatigue life of amine-functionalized multi-walled carbon nanotube-reinforced epoxy composites: Effect of functionalization degree and microwave-assisted precuring. J. Compos. Mater. 2015, 49, 1961–1969. [Google Scholar] [CrossRef]

- Knoll, J.B.; Riecken, B.T.; Kosmann, N.; Chandrasekaran, S.; Schulte, K.; Fiedler, B. The effect of carbon nanoparticles on the fatigue performance of carbon fibre reinforced epoxy. Compos. Part A Appl. Sci. Manuf. 2014, 67, 233–240. [Google Scholar] [CrossRef]

- Takeda, T.; Shindo, Y.; Wei, Z.; Kuronuma, Y.; Narita, F. Fatigue failure and electrical resistance behaviors of carbon nanotube-based polymer composites under uniaxial tension-tension loading in a cryogenic environment. J. Compos. Mater. 2015, 49, 457–463. [Google Scholar] [CrossRef]

- Bortz, D.R.; Heras, E.G.; Martin-Gullon, I. Impressive fatigue life and fracture toughness improvements in graphene oxide/epoxy composites. Macromolecules 2012, 45, 238–245. [Google Scholar] [CrossRef]

- Yavari, F.; Rafiee, M.A.; Rafiee, J.; Yu, Z.Z.; Koratkar, N. Dramatic increase in fatigue life in hierarchical graphene composites. ACS Appl. Mater. Interfaces 2010, 2, 2738–2743. [Google Scholar] [CrossRef]

- Shen, M.Y.; Chang, T.Y.; Hsieh, T.H.; Li, Y.L.; Chiang, C.L.; Yang, H.; Yip, M.C. Mechanical Properties and Tensile Fatigue of Graphene Nanoplatelets Reinforced Polymer Nanocomposites. J. Nanomater. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Ghoreishi, S.M.; Esmkhani, M.; Zhao, Z. Effects of graphene nanoplatelets and graphene nanosheets on fracture toughness of epoxy nanocomposites. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1116–1123. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Esmkhani, M.; Taheri-Behrooz, F.; Haghighatkhah, A.R. Displacement-controlled flexural bending fatigue behavior of graphene/epoxy nanocomposites. J. Compos. Mater. 2014, 48, 2935–2944. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Esmkhani, M.; Haghighatkhah, A.R.; Zhao, Z. Flexural fatigue behavior of synthesized graphene/carbon-nanofiber/epoxy hybrid nanocomposites. Mater. Des. 2014, 62, 401–408. [Google Scholar] [CrossRef]

- Ladani, R.B.; Bhasin, M.; Wu, S.; Ravindran, A.R.; Ghorbani, K.; Zhang, J.; Kinloch, A.J.; Mouritz, A.P.; Wang, C.H. Fracture and fatigue behaviour of epoxy nanocomposites containing 1-D and 2-D nanoscale carbon fillers. Eng. Fract. Mech. 2018, 203, 102–114. [Google Scholar] [CrossRef]

- Bhasin, M.; Wu, S.; Ladani, R.B.; Kinloch, A.J.; Wang, C.H.; Mouritz, A.P. Increasing the fatigue resistance of epoxy nanocomposites by aligning graphene nanoplatelets. Int. J. Fatigue 2018, 113, 88–97. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Srivastava, I.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Fracture and fatigue in graphene nanocomposites. Small 2010, 6, 179–183. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, M.; Nitzsche, F.; Laliberte, J.; Hind, S.; Robitaille, F.; Labrosse, M.R. Thermal properties of doubly reinforced fiberglass/epoxy composites with graphene nanoplatelets, graphene oxide and reduced-graphene oxide. Compos. Part B Eng. 2019, 164, 1–9. [Google Scholar] [CrossRef]

- Lau, K.T.; Gu, C.; Hui, D. A critical review on nanotube and nanotube/nanoclay related polymer composite materials. Compos. Part B Eng. 2006, 37, 425–436. [Google Scholar] [CrossRef]

- Rafiee, M.; Nitzsche, F.; Laliberte, J.; Thibault, J.; Labrosse, M. Simultaneous reinforcement of matrix and fibers for enhancement of mechanical properties of graphene-modified laminated composites. Polym. Compos. 2019, 40, E1732–E1745. [Google Scholar] [CrossRef]

- Parente, J.M.; Santos, P.; Valvez, S.; Silva, M.P.; Reis, P.N.B. Fatigue behaviour of graphene composites: An overview. Procedia Struct. Integr. 2020, 25, 282–293. [Google Scholar] [CrossRef]

| Reinforcement | wt% of DGEBA | vol.% of DGEBA | wt% of Matrix (DGEBA+ DETDA) | vol.% of Matrix (DGEBA+ DETDA) | wt% of Total (DGEBA+ DETDA+ Fibers) | vol.% of Total (DGEBA+ DETDA+fibers) |

|---|---|---|---|---|---|---|

| GNP | 0.1 | 0.55 | 0.08 | 0.44 | 0.02 | 0.22 |

| 0.2 | 1.1 | 0.16 | 0.88 | 0.05 | 0.44 | |

| 0.4 | 2.2 | 0.33 | 1.76 | 0.1 | 0.88 | |

| 1 | 5.5 | 0.82 | 4.4 | 0.25 | 2.2 | |

| rGO | 0.01 | 1.1 | 0.008 | 0.88 | 0.002 | 0.44 |

| 0.03 | 3.3 | 0.025 | 2.64 | 0.007 | 1.32 | |

| 0.042 | 4.6 | 0.034 | 3.7 | 0.010 | 1.85 |

| Reinforcement | wt.% of DGEBA | vol.% of DGEBA | Sprayed Vol. % | Infusion Vol.% |

|---|---|---|---|---|

| GNP | 0.1 | 0.55 | 0.275 | 0.275 |

| 0.2 | 1.1 | 0.55 | 0.55 | |

| 0.4 | 2.2 | 1.1 | 1.1 | |

| 1 | 5.5 | 4.4 | 1.1 | |

| rGO | 0.01 | 1.1 | 0.55 | 0.55 |

| 0.03 | 3.3 | 2.2 | 1.1 | |

| 0.042 | 4.6 | 3.5 | 1.1 |

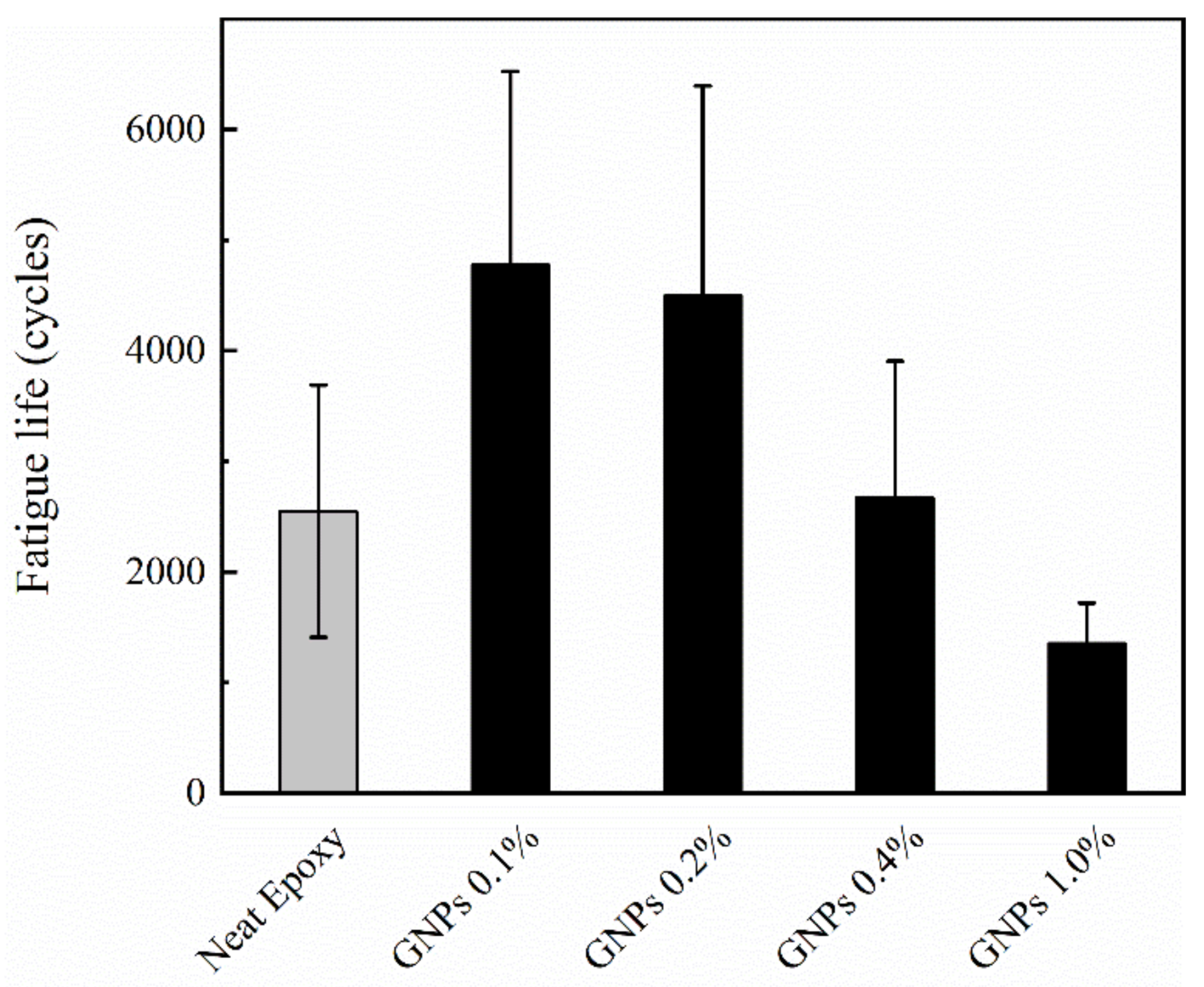

| Composition | Low Cycle Fatigue Life (Cycles) | % Relative Difference | p |

|---|---|---|---|

| Neat Epoxy | 2549 ± 1141 | ||

| GNPs 0.1% | 4779 ± 1750 | 2229 | 0.297 |

| GNPs 0.2% | 4496 ± 1899 | 1947 | 0.394 |

| GNPs 0.4% | 2413 ± 1275 | −136 | 1.000 |

| GNPs 1.0% | 1685 ± 940 | −865 | 0.942 |

| rGO 0.01% | 2706 ± 1376 | 156 | 0.999 |

| rGO 0.03% | 3740 ± 1654 | 1191 | 0.638 |

| rGO 0.042% | 4283 ± 981 | 1734 | 0.458 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rafiee, M.; Hosseini Rad, S.; Nitzsche, F.; Laliberte, J.; R. Labrosse, M. Significant Fatigue Life Enhancement in Multiscale Doubly-Modified Fiber/Epoxy Nanocomposites with Graphene Nanoplatelets and Reduced-Graphene Oxide. Polymers 2020, 12, 2135. https://doi.org/10.3390/polym12092135

Rafiee M, Hosseini Rad S, Nitzsche F, Laliberte J, R. Labrosse M. Significant Fatigue Life Enhancement in Multiscale Doubly-Modified Fiber/Epoxy Nanocomposites with Graphene Nanoplatelets and Reduced-Graphene Oxide. Polymers. 2020; 12(9):2135. https://doi.org/10.3390/polym12092135

Chicago/Turabian StyleRafiee, Mohammad, Somayeh Hosseini Rad, Fred Nitzsche, Jeremy Laliberte, and Michel R. Labrosse. 2020. "Significant Fatigue Life Enhancement in Multiscale Doubly-Modified Fiber/Epoxy Nanocomposites with Graphene Nanoplatelets and Reduced-Graphene Oxide" Polymers 12, no. 9: 2135. https://doi.org/10.3390/polym12092135

APA StyleRafiee, M., Hosseini Rad, S., Nitzsche, F., Laliberte, J., & R. Labrosse, M. (2020). Significant Fatigue Life Enhancement in Multiscale Doubly-Modified Fiber/Epoxy Nanocomposites with Graphene Nanoplatelets and Reduced-Graphene Oxide. Polymers, 12(9), 2135. https://doi.org/10.3390/polym12092135