Figure 1.

Gradation of the crumb rubber modifier (CRM) used.

Figure 1.

Gradation of the crumb rubber modifier (CRM) used.

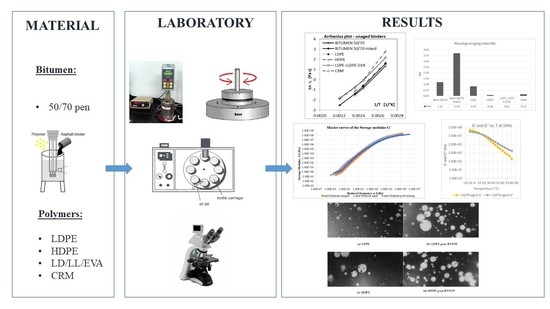

Figure 2.

Logarithm of dynamic viscosity against the reciprocal of absolute temperature (Arrhenius plot) for the binder studied: (a) before aging; (b) after aging at the RTFOT.

Figure 2.

Logarithm of dynamic viscosity against the reciprocal of absolute temperature (Arrhenius plot) for the binder studied: (a) before aging; (b) after aging at the RTFOT.

Figure 3.

Effect of polymer introduction on the activation energy, pre and post aging.

Figure 3.

Effect of polymer introduction on the activation energy, pre and post aging.

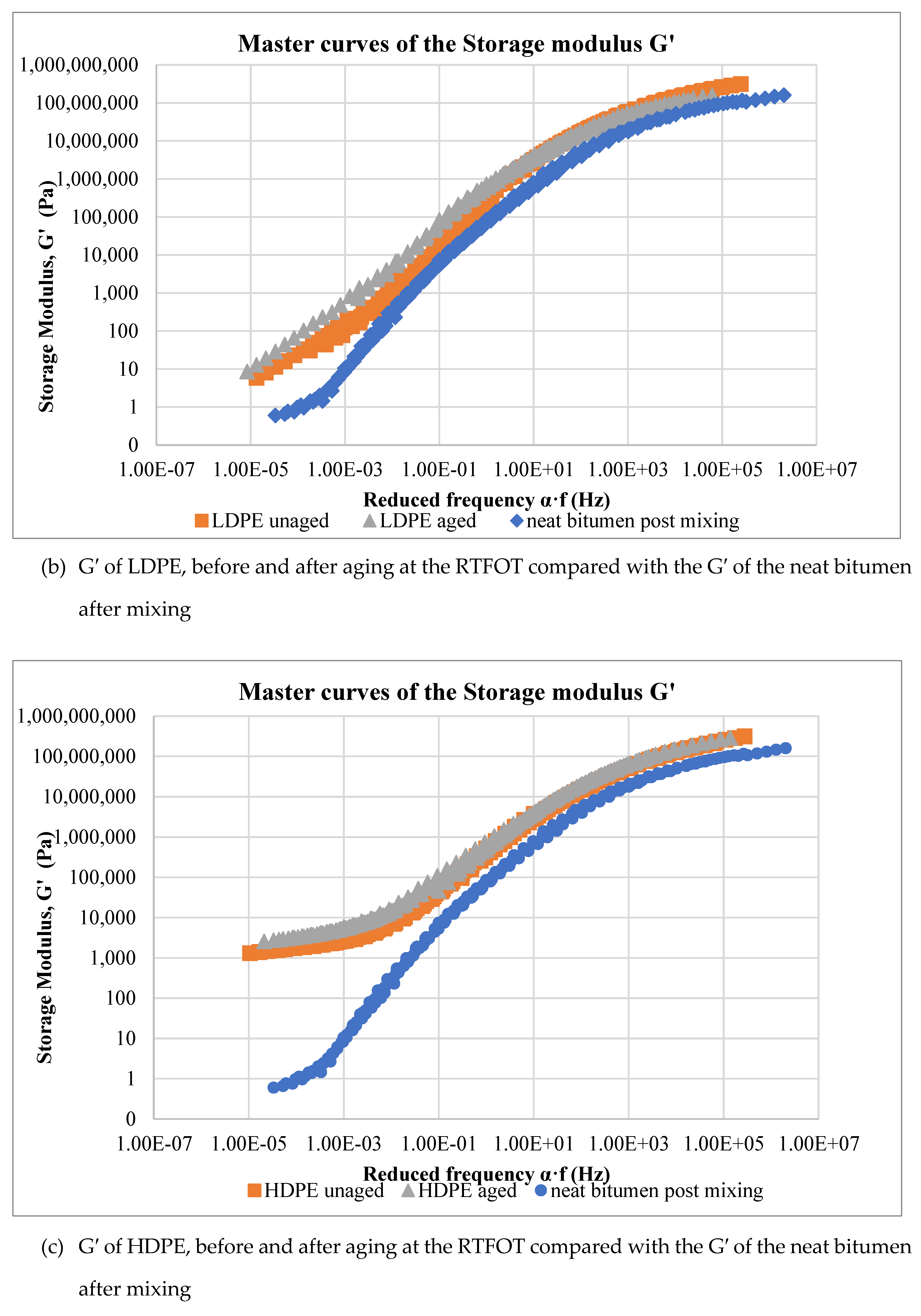

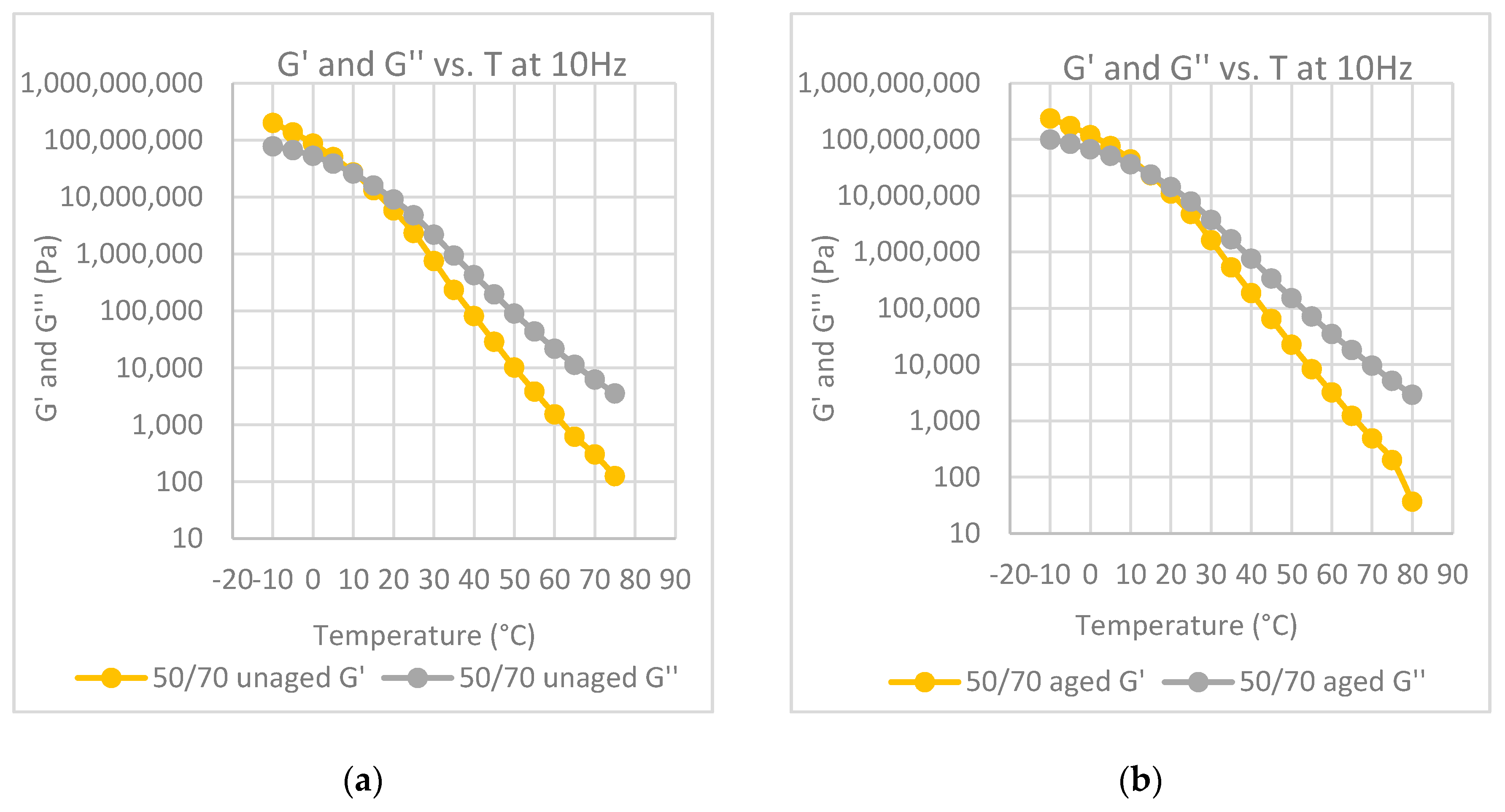

Figure 4.

Master curves of G′ at 30°C for each polymer-modified bitumen (PMB) at aged and unaged conditions.

Figure 4.

Master curves of G′ at 30°C for each polymer-modified bitumen (PMB) at aged and unaged conditions.

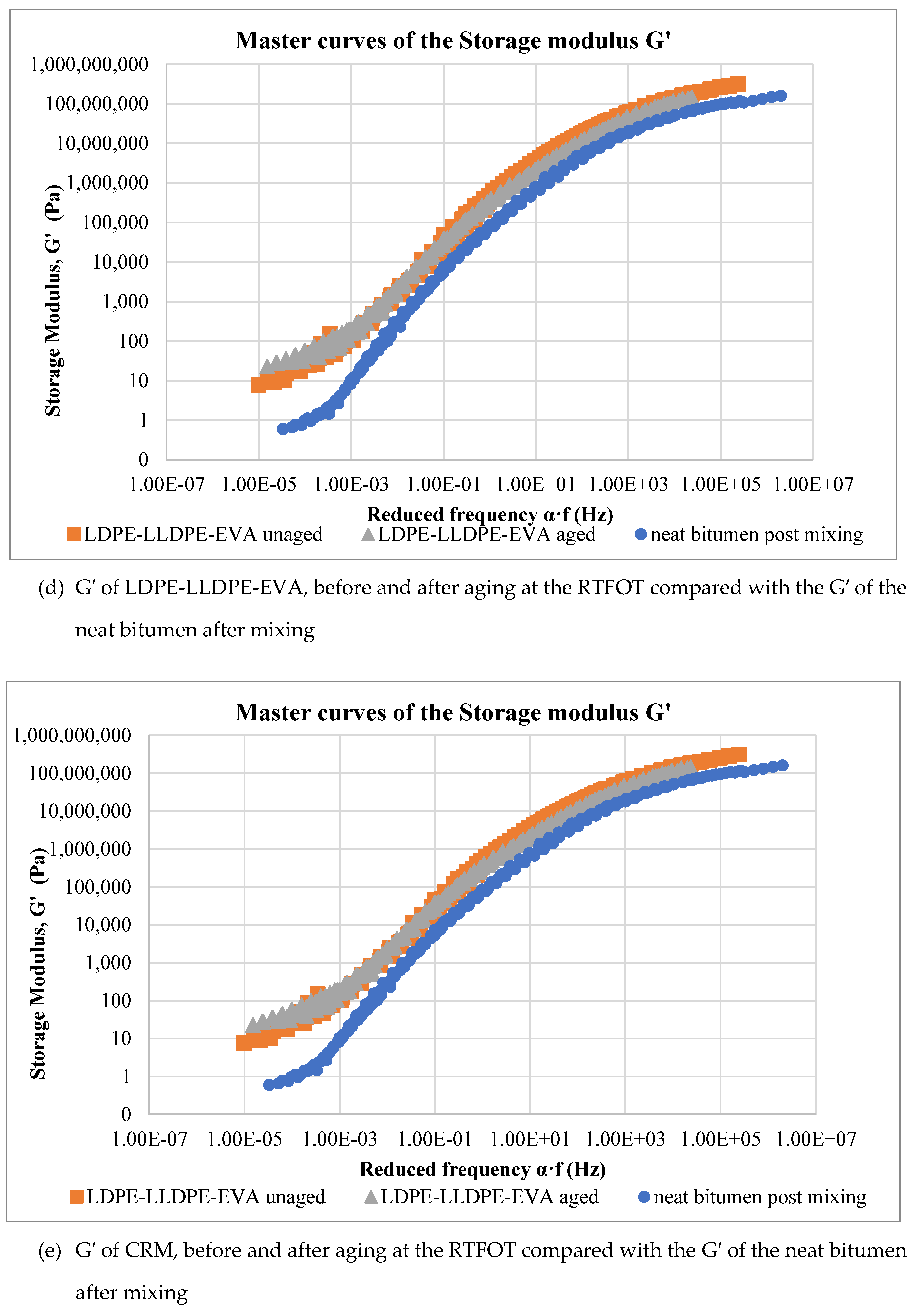

Figure 5.

Rheological Aging Index, RAI, for the different binders studied.

Figure 5.

Rheological Aging Index, RAI, for the different binders studied.

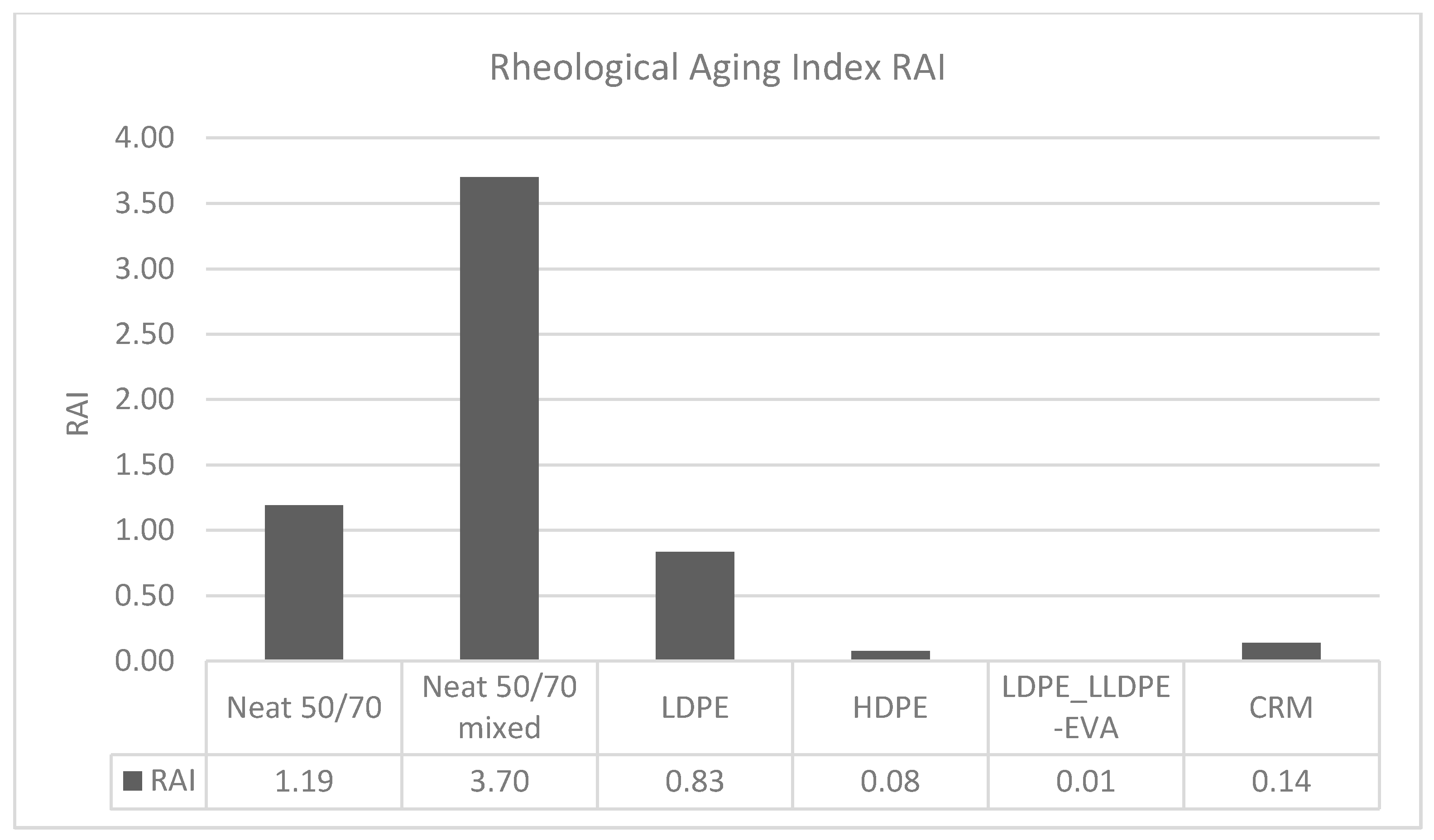

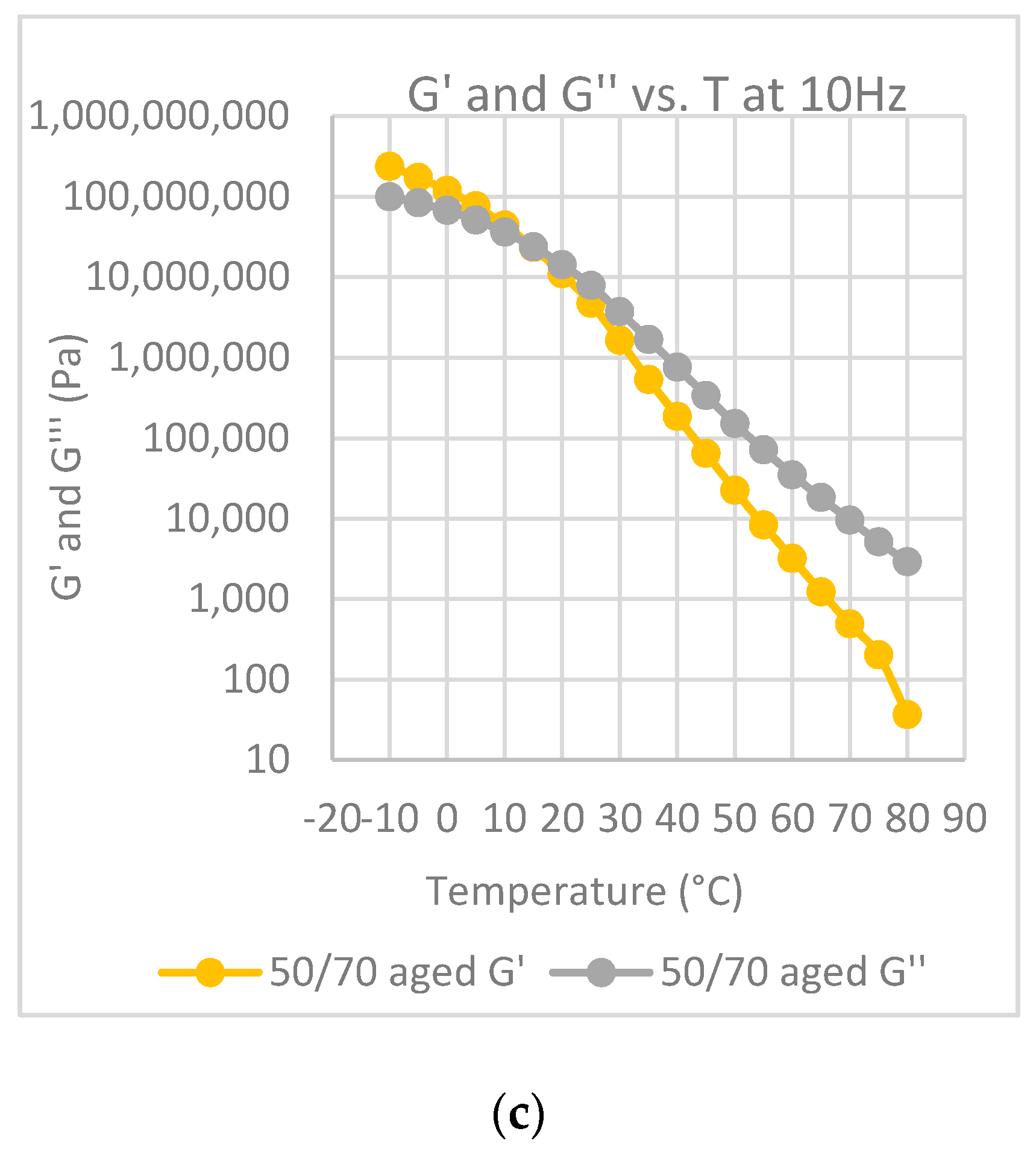

Figure 6.

Elastic modulus, G′ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) neat bitumen before aging; (b) neat bitumen after aging at the RTFOT; (c) neat bitumen after mixing protocol at high temperature.

Figure 6.

Elastic modulus, G′ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) neat bitumen before aging; (b) neat bitumen after aging at the RTFOT; (c) neat bitumen after mixing protocol at high temperature.

Figure 7.

Elastic modulus, G′ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) binder modified with LDPE before aging; (b) binder modified with LDPE after aging at the RTFOT.

Figure 7.

Elastic modulus, G′ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) binder modified with LDPE before aging; (b) binder modified with LDPE after aging at the RTFOT.

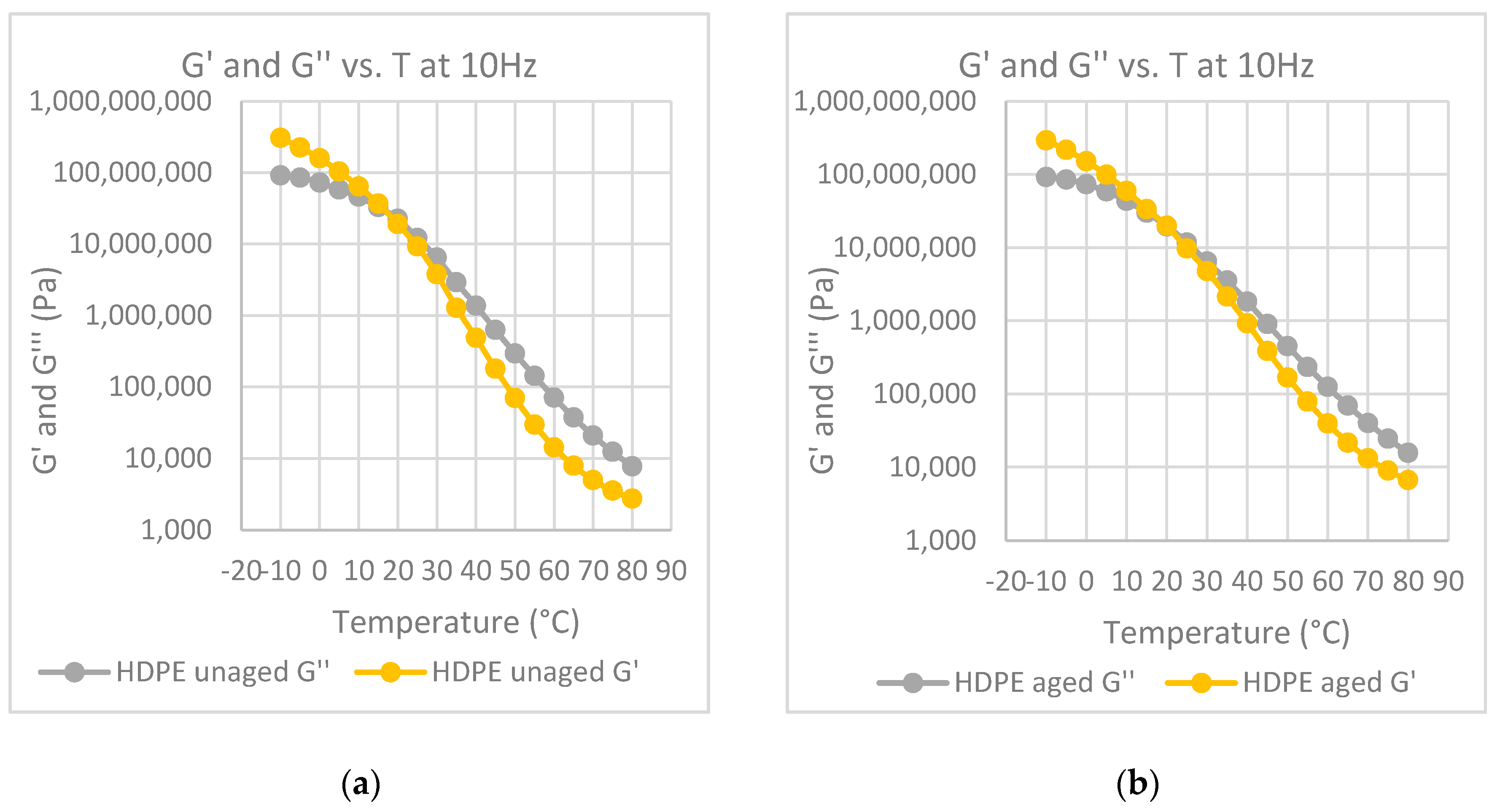

Figure 8.

Elastic modulus, G,’ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) binder modified with HDPE before aging; (b) binder modified with HDPE after aging at the RTFOT.

Figure 8.

Elastic modulus, G,’ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) binder modified with HDPE before aging; (b) binder modified with HDPE after aging at the RTFOT.

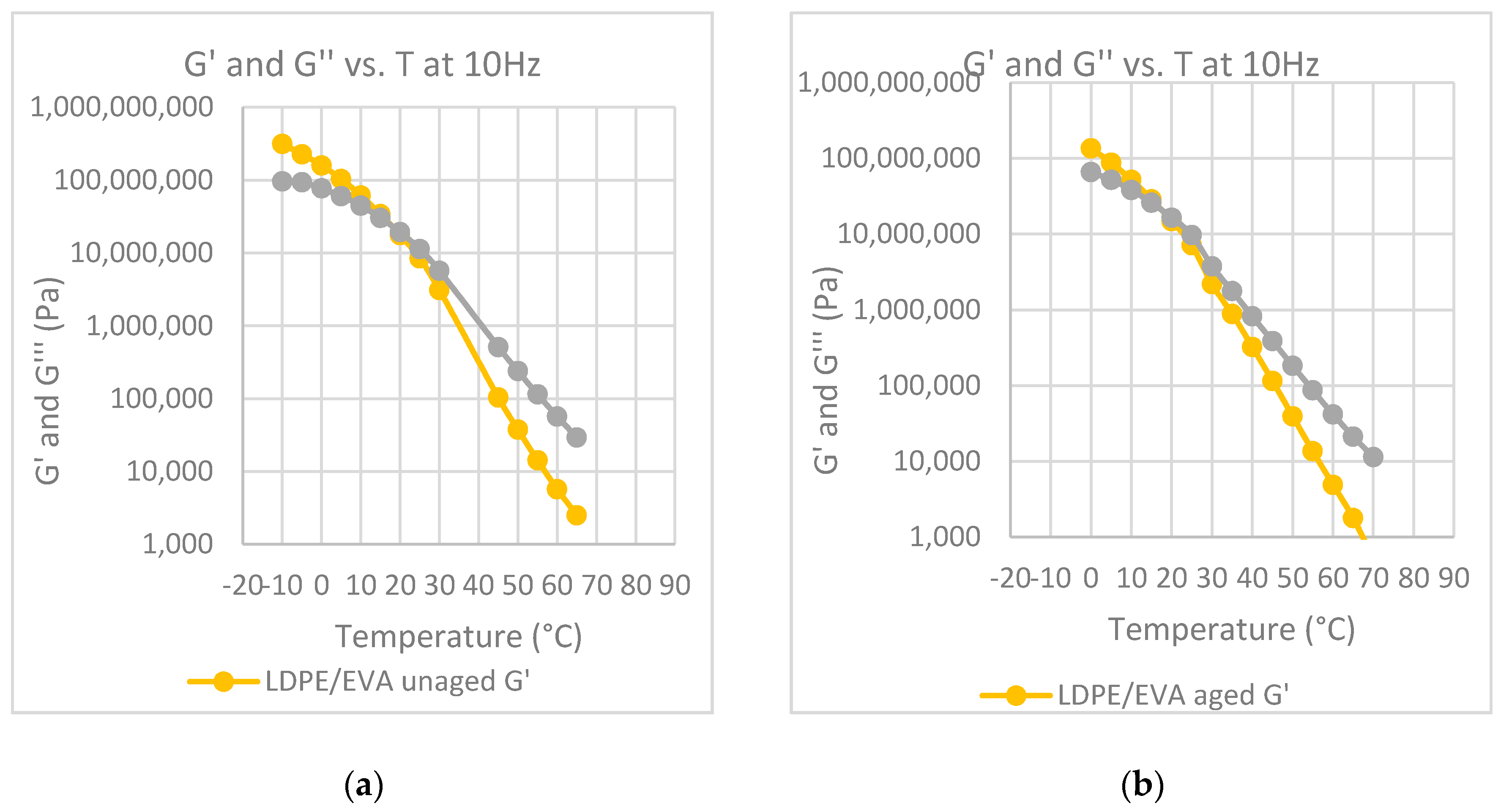

Figure 9.

Elastic modulus, G′ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) binder modified with LDPE-LLDPE-EVA before aging; (b) binder modified LDPE-LLDPE-EVA after aging at the RTFOT.

Figure 9.

Elastic modulus, G′ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) binder modified with LDPE-LLDPE-EVA before aging; (b) binder modified LDPE-LLDPE-EVA after aging at the RTFOT.

Figure 10.

Elastic modulus, G′ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) binder modified with CRM before aging; (b) binder modified CRM after aging at the RTFOT.

Figure 10.

Elastic modulus, G′ and loss modulus, G″, at 10 Hz, as a function of temperature: (a) binder modified with CRM before aging; (b) binder modified CRM after aging at the RTFOT.

Figure 11.

Crossover temperature, Tc, at 10 Hz, for all the binders studied.

Figure 11.

Crossover temperature, Tc, at 10 Hz, for all the binders studied.

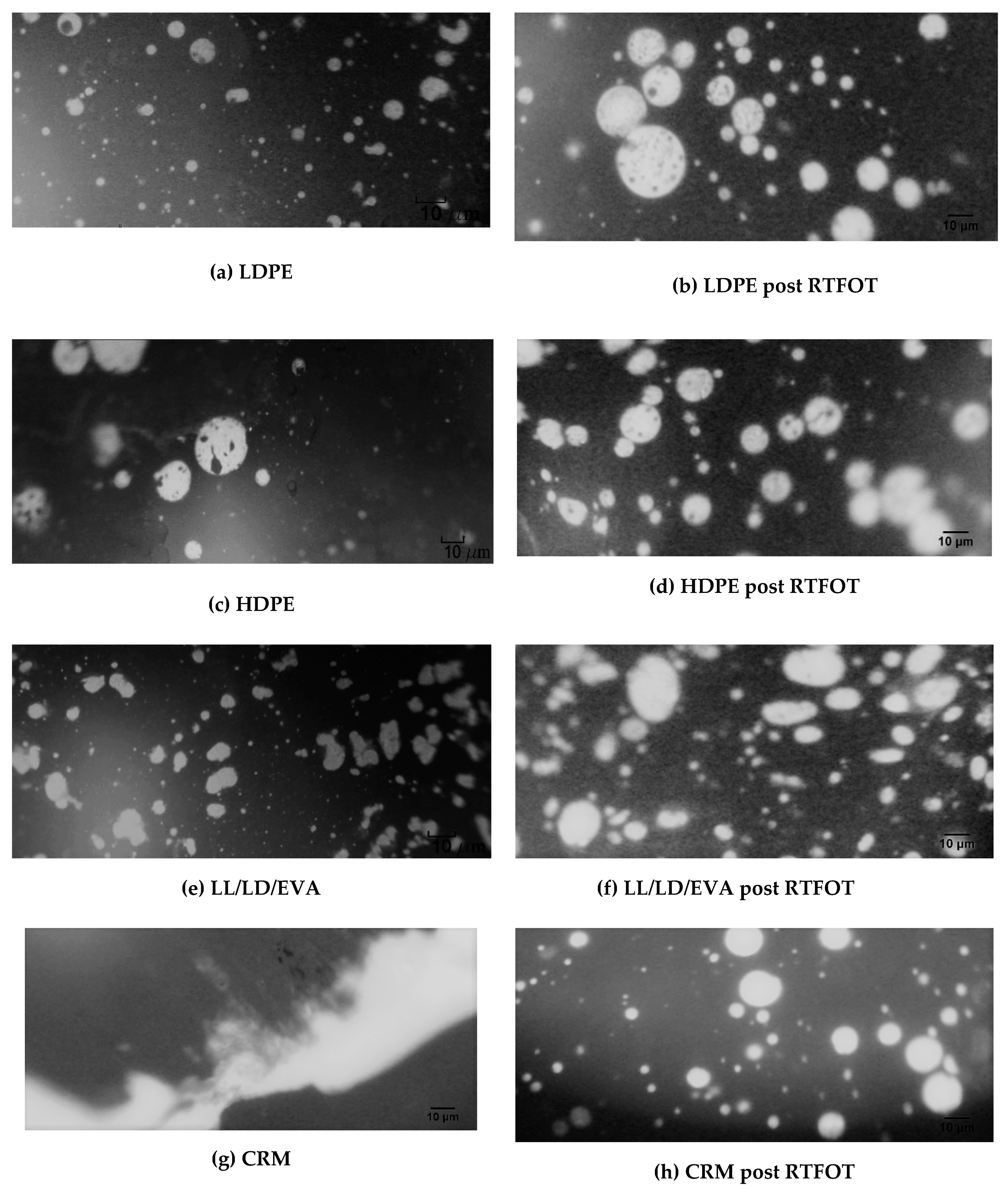

Figure 12.

Micrographs of the PMBs produced, before and after short-term aging: (a) binder modified with LDPE before aging; (b) binder modified with LDPE after aging at the RTFOT; (c) binder modified with HDPE before aging; (d) binder modified with HDPE after aging at the RTFOT; (e) binder modified with LDPE-LLDPE-EVA before aging; (f) binder modified with LD/LL/EVA after aging at the RTFOT; (g) binder modified with CRM before aging; (h) binder modified with CRM after aging at the RTFOT.

Figure 12.

Micrographs of the PMBs produced, before and after short-term aging: (a) binder modified with LDPE before aging; (b) binder modified with LDPE after aging at the RTFOT; (c) binder modified with HDPE before aging; (d) binder modified with HDPE after aging at the RTFOT; (e) binder modified with LDPE-LLDPE-EVA before aging; (f) binder modified with LD/LL/EVA after aging at the RTFOT; (g) binder modified with CRM before aging; (h) binder modified with CRM after aging at the RTFOT.

Table 1.

Conventional properties of the neat bitumen.

Table 1.

Conventional properties of the neat bitumen.

| Physical Properties | Specific Gravity @25 °C | Penetration | Softening Point | Fraass Breaking Point | Ductility |

|---|

| Units | g/cm3 | 0.1 mm | (°C) | (°C) | (mm) |

| Specification | EN-ISO-3838 | EN 1426 | EN 1427 | EN 12593 | EN 13398 |

| Test results | 1.051 | 68 | 50.5 | −12 | over 100 |

| Requirements | - | 50–70 | 46–54 | ≤−8 | ≥100 |

Table 2.

SARA fraction characteristics of the neat bitumen.

Table 2.

SARA fraction characteristics of the neat bitumen.

| Fraction | Polarity | Percentage (%) | Characteristics | Color |

|---|

| Saturates | Non-polar | 2.4 | Viscous oil | White |

| Aromatics | Non-polar | 55.6 | Viscous liquid | Dark brown |

| Resins | Highly polar | 25.4 | Solid to semi-solid | Dark brown |

| Asphaltenes | Highly polar | 16.6 | Solid | Brown to black |

Table 3.

Polymers used in this work.

Table 3.

Polymers used in this work.

| Polymer | Sample Code | MFI,

g/10 min | Density (g/cm3) | Melting Point (°C) | Degree of Crystallinity (%) |

|---|

| LDPE, | Riblene FC39 | 0.25 | 0.924 | 114 | 32 |

| HDPE, | Eraclene MP 90 | 7 | >0.96 | 137 | 67 |

| LLDPE | Clearflex FG106 | 1 | 0.918 | 125 | - |

| EVA 1 | Greenflex ML 60 | 2.5 | - | 74 | 7 |

Table 4.

Crumb rubber characteristics.

Table 4.

Crumb rubber characteristics.

| Characteristic | Description |

|---|

| Type | Powder and fine granulate |

| Specific gravity [g/cm3] | 1.10–1.20 |

| Color | Black |

| Grinding method | mechanical |

| source | Rubber granulate from waste tires |

| Average diameter [mm] | <0.4 |

Table 5.

Letter coding description according to EN13632:2005.

Table 5.

Letter coding description according to EN13632:2005.

| Phase continuity | P: continuous polymer phase |

| | B: Continuous bitumen phase |

| | X: Continuity of both (crosslinking) |

| Phase description | H: Homogeneous |

| | I: Heterogeneous |

| Size description | S: Small (<10 μm) |

| | M: Medium (from 10 μm to 100 μm) |

| | L: Large (>100 μm) |

| Shape description | r: Round, cylindrical |

| | s: Elongated |

| | o: Other |

Table 6.

Conventional tests of polymer-modified binders post rolling thin film oven test (RTFOT).

Table 6.

Conventional tests of polymer-modified binders post rolling thin film oven test (RTFOT).

| Requirement | Pen @ 25 °C | TR&B | Penetration Index PI | Pen @ 25 °C | TR&B | Penetration Index PI | ∆TR&B | Change in mass |

|---|

| Characteristics | Pre-RTFO | Post-RTFOT | | M |

| Standard | EN 1426 | EN 1427 | EN 12591 | EN 1426 | EN 1427 | EN 12591 | EN 12607-1 |

| Unit | dmm | °C | | dmm | °C | | °C | % |

| BITUMEN 50/70 | 68 | 50 | −0.46 | 44 | 54 | −0.55 | 4 | −0.19 |

| LDPE | 35.7 | 56 | −0.57 | 23 | 62.25 | −0.23 | 6.25 | −0.82 |

| HDPE | 25.7 | 58 | −0.81 | 18.4 | 64.25 | −0.29 | 6.25 | −0.87 |

| LD/LL/EVA | 35 | 61 | 0.39 | 20 | 63 | −0.72 | 2 | −0.47 |

| CRM | 45 | 58 | 0.36 | 28 | 63 | 0.29 | 5 | |

Table 7.

Storage stability and elastic recovery.

Table 7.

Storage stability and elastic recovery.

| Requirements | Storage Stability | Elastic Recovery |

|---|

| Characteristics | ∆TR&B | Average |

| Standard | EN 13399 | EN 13398 |

| Unit | °C | % |

| LDPE FC39 | 28 | 9.25 |

| HDPE MP90 | 20 | 9.5 |

| LD/LL/EVA | 5 | 15 |

| CRM | 14 | 60 |

Table 8.

Dynamic viscosity for the binder studied, before and after aging.

Table 8.

Dynamic viscosity for the binder studied, before and after aging.

| Test | Dynamic Viscosity

Pre-RTFO | Dynamic Viscosity

Post-RTFOT |

|---|

| Temperature (°C) | 180 | 150 | 135 | 100 | 180 | 150 | 135 | 100 |

| Standard | EN 13702 |

| unit | Pa∙s |

| Bitumen 50/70 | - | 0.22 | 0.44 | 3.92 | 0.05 | 0.23 | 0.47 | 4.50 |

| Bitumen 50/70 mixed | 0.08 | 0.25 | 0.52 | 4.91 | 0.10 | 0.32 | 0.67 | 7.13 |

| LDPE FC39 | 0.15 | 0.46 | 0.92 | 8.78 | 0.18 | 0.58 | 1.23 | 13.30 |

| HDPE MP90 | 0.15 | 0.46 | 0.98 | 16.30 | 0.21 | 0.67 | 1.43 | 28.20 |

| LD/LL/EVA | 0.17 | 0.50 | 1.00 | 8.28 | 0.20 | 0.64 | 1.34 | 12.70 |

| CRM | - | 0.32 | 0.59 | 5.47 | 0.23 | 0.70 | 1.46 | 15.30 |

Table 9.

Parameters of the Arrhenius equation for the binders studied before and after aging.

Table 9.

Parameters of the Arrhenius equation for the binders studied before and after aging.

| Stage | Unaged | After Short-Term Aging |

|---|

| Binder | A | Ea (kJ/mol) | R² | A | Ea (kJ/mol) | R² |

|---|

| Bitumen 50/70 | 8 × 10−11 | 72.46 | 0.9921 | 5 × 10−10 | 77.79 | 0.9993 |

| Bitumen 50/70 mixed | 3 × 10−10 | 72.88 | 0.9941 | 1 × 10−10 | 76.41 | 0.9939 |

| LDPE | 7 × 10−10 | 71.67 | 0.9921 | 3 × 10−10 | 76.05 | 0.9924 |

| HDPE | 3 × 10−11 | 82.98 | 0.9795 | 2 × 10−10 | 86.76 | 0.9769 |

| LD/LL/EVA | 2 × 10−9 | 69.97 | 0.9911 | 6 × 10−10 | 73.82 | 0.9934 |

| CRM | 1 × 10−10 | 75.51 | 0.9961 | 5 × 10−10 | 74.76 | 0.9918 |

Table 10.

Aging indices for rotational viscosity, penetration, and ring and ball temperature.

Table 10.

Aging indices for rotational viscosity, penetration, and ring and ball temperature.

| Polymer | AIRV | AITR&B | AIPEN (%) |

|---|

| T (°C) | 180 | 150 | 135 | 100 | | |

|---|

| Bitumen 50/70 | - | 1.02 | 1.08 | 1.15 | 1.08 | 64.71 |

| Bitumen 50/70 mixed | 1.19 | 1.26 | 1.29 | 1.45 | - | - |

| LDPE | 1.19 | 1.25 | 1.34 | 1.51 | 1.11 | 64.43 |

| HDPE | 1.40 | 1.45 | 1.46 | 1.73 | 1.10 | 71.6 |

| LD/LL/EVA | 1.19 | 1.30 | 1.37 | 1.48 | 1.03 | 71.43 |

| CRM | - | 2.17 | 2.46 | 2.80 | 1.09 | 62.22 |

Table 11.

Morphological characterization of the PMBs studied.

Table 11.

Morphological characterization of the PMBs studied.

| STAGE | Unaged | After Short-Term Aging |

|---|

| PMB | Phase continuity | Phase description | Size description | Shape description | Phase continuity | Phase description | Size description | Shape description |

| LDPE | B | I | S | r/o | B | I | M | r |

| HDPE | B | I | M | r/o | B | I | M | r/o |

| LD/LL/EVA | B | H | S | s/r | B | I | M | s/r |

| CRM | X | I/H | S | r/o | B | I | M | r |