Characterization of Two Cactus Formulation-Based Flocculants and Investigation on Their Flocculating Ability for Cationic and Anionic Dyes Removal

Abstract

1. Introduction

2. Materials and Methods

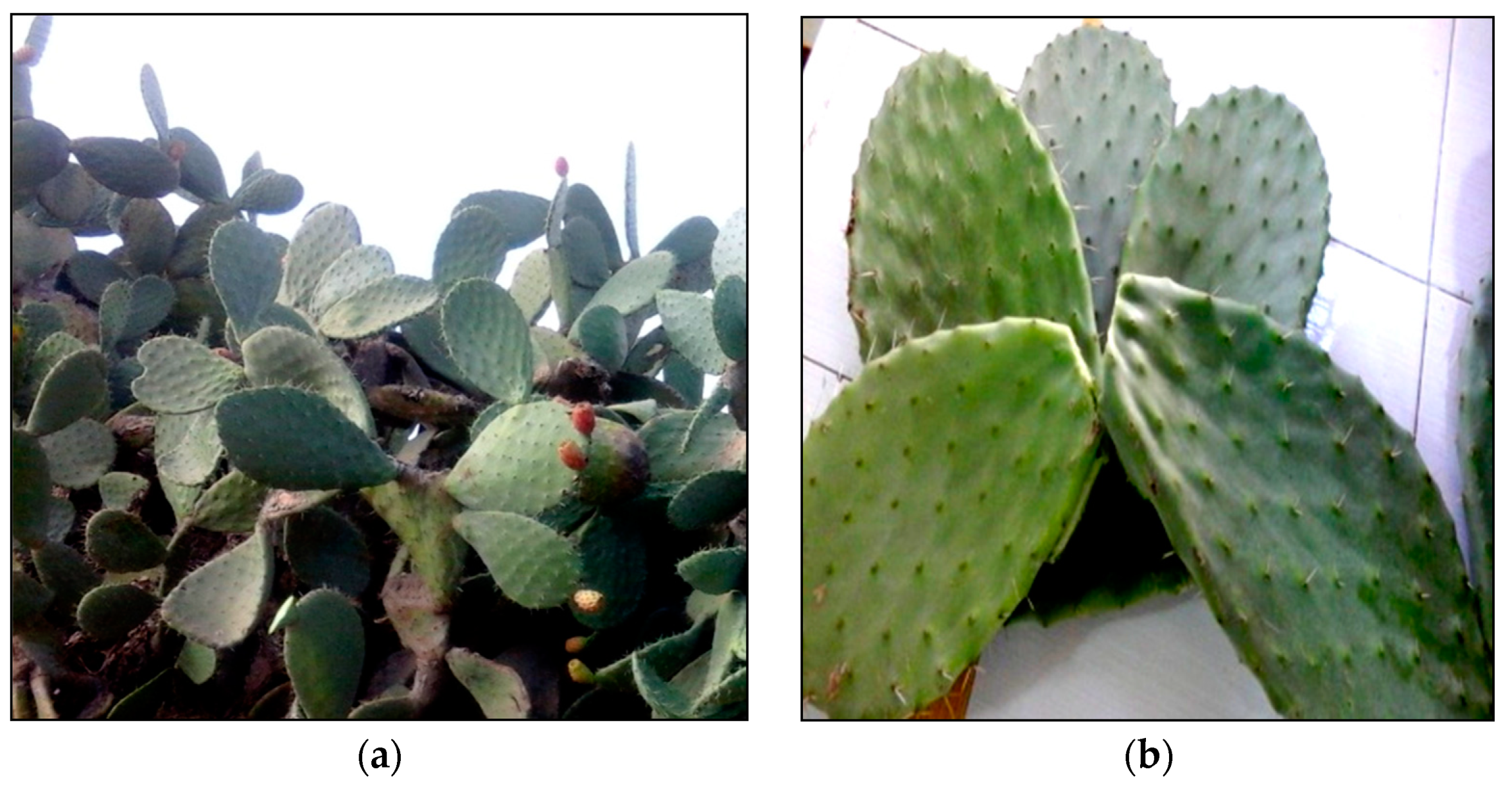

2.1. Materials

2.2. Preparation of Cactus Formulations

2.3. Physico-Chemical Characterization of Cactus Formulations

2.4. Preparation of Synthetic Dye Solutions

2.5. Coagulation-Flocculation Experiments

3. Results and Discussion

3.1. Bio-Flocculants Characterization

3.2. Methylene Blue (MB) and Methyl Orange (MO) Removal Using Cactus Formulations: Bio-Flocculants Optimal Dosage

3.3. Effect of Storage Period on the Flocculation Activity of LP

3.4. Plausible Mechanisms of Flocculation

3.5. Comparison of the Flocculating Ability of LP with the Well Known Chemical Flocculant (Polyacrylamide) and Some Other Bio-Based Flocculants

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Saxena, R.; Saxena, M.; Lochab, A. Recent Progress in Nanomaterials for Adsorptive Removal of Organic Contaminants from Wastewater. Chem. Sel. 2020, 5, 335–353. [Google Scholar] [CrossRef]

- Verma, A.K.; Dash, R.R.; Bhunia, P. A review on chemical coagulation/flocculation technologies for removal of colour from textile wastewaters. J. Environ. Manag. 2012, 93, 154–168. [Google Scholar] [CrossRef] [PubMed]

- Najafpoor, A.A.; Davoudi, M.; Rahmanpour Salmani, E. Decolorization of synthetic textile waste water using electrochemical cell divided by cellulosic separator. J. Environ. Health Sci. Eng. 2017, 15, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Franco, J.H.; Da Silva, B.F.; Dias, E.F.G.; De Castro, A.A.; Ramalho, T.C.; Zanoni, M.V.B. Influence of auxochrome group in disperse dyes bearing azo groups as chromophore center in the biotransformation and molecular docking prediction by reductase enzyme: Implications and assessment for environmental toxicity of xenobiotics. Ecotox. Environ. Saf. 2018, 160, 114–126. [Google Scholar] [CrossRef] [PubMed]

- Berradi, M.; Hsissou, R.; Khudhair, M.; Assouag, M.; Cherkaoui, O.; ElBachiri, A.; ElHarfi, A. Textile finishing dyes and their impact on aquatic environs. Heliyon 2019, 5, e02711. [Google Scholar] [CrossRef]

- Vikrant, K.; Giri, B.S.; Raza, N.; Roy, K.; Kim, K.-H.; Rai, B.N.; Singh, R.S. Recent advancements in bioremediation of dye: Current status and challenges. Bioresour. Technol. 2018, 253, 355–367. [Google Scholar] [CrossRef]

- Supelano, G.I.; GómezCuaspud, J.A.; Moreno-Aldana, L.C.; Ortiz, C.; Trujillo, C.A.; Palacio, C.A.; Parra Vargas, C.A.; Mejía Gómez, J.A. Synthesis of magnetic zeolites from recycled fly ash for adsorption of methylene blue. Fuel 2020, 263, 116800. [Google Scholar] [CrossRef]

- Rajasimman, M.; Babu, S.V.; Rajamohan, N. Biodegradation of textile dyeing industry wastewater using modified anaerobic sequential batch reactor—Start-up, parameter optimization and performance analysis. J. Taiwan Inst. Chem. Eng. 2017, 72, 171–181. [Google Scholar] [CrossRef]

- Zahrim, A.Y.; Hilal, N. Treatment of highly concentrated dye solution by coagulation/flocculation–sand filtration and nanofiltration. Water Resour. Ind. 2013, 3, 23–34. [Google Scholar] [CrossRef]

- Nguyen, C.H.; Tran, M.L.; Tran, T.T.V.; Juang, R.-S. Enhanced removal of various dyes from aqueous solutions by UV and simulated solar photocatalysis over TiO2/ZnO/rGO composites. Sep. Purif. Technol. 2020, 232, 115962. [Google Scholar] [CrossRef]

- Szygula, A.; Guibal, E.; Ruiz, M.; Sastre, A. The Removal of Sulphonated Azo Dyes by Coagulation with Chitosan. Colloids Surf. A Physicochem. Eng. Asp. 2008, 330, 219–226. [Google Scholar] [CrossRef]

- Ang, W.L.; Mohammad, A.W. State of the art and sustainability of natural coagulants in water and wastewater treatment. J. Clean. Prod. 2020, 262, 121267. [Google Scholar] [CrossRef]

- Mansour, H.; Boughzala, O.; Dridi, D.; Barillier, D.; Chekir-Ghedira, L.; Mosrati, R. Les colorants textiles sources de contamination de l’eau: CRIBLAGE de la toxicité et des méthodes de traitement. J. Water Sci. 2011, 24, 209–238. [Google Scholar] [CrossRef]

- Mallevialle, J.; Bruchet, A.; Fiessinger, F. How Safe Are Organic Polymers in Water Treatment? J. Am. Water Work. Assoc. 1984, 76, 87–93. [Google Scholar] [CrossRef]

- Martyn, C.N.; Osmond, C.; Edwardson, J.A.; Barker, D.J.P.; Harris, E.C.; Lacey, R.F. Geographical relation between Alzheimer’s disease and aluminiumin drinking water. Lancet 1989, 333, 61–62. [Google Scholar] [CrossRef]

- Zahrim, A.Y.; Dexter, Z.D.; Joseph, C.G.; Hilal, N. Effective coagulation-flocculation treatment of highly polluted palm oil mill biogas plant wastewater using dual coagulants: Decolourisation, kinetics and phytotoxicity studies. J. Water Process Eng. 2017, 16, 258–269. [Google Scholar] [CrossRef]

- Chethana, M.; Gayathri, S.L.; Vinay, B.M.; Vivek, R.V.; Raja, S. Application of biocoagulant Acanthocereus tetragonus (Triang lecactus) in dye waste water treatment. J. Environ. Res. Dev. 2015, 9, 813–821. [Google Scholar]

- Chen, F.; Liu, W.; Pan, Z.; Wang, Y.; Guo, X.; Sun, S.; Jia, R. Characteristics and mechanism of chitosan in flocculation for water coagulation in the Yellow River diversion reservoir. J. Water Process Eng. 2020, 34, 101191. [Google Scholar] [CrossRef]

- Grenda, K.; Arnold, J.; Gamelas, J.A.; Rasteiro, M.G. Environmentally friendly cellulose-based polyelectrolytes in wastewater treatment. Water Sci. Technol. 2017, 76, 1490–1499. [Google Scholar] [CrossRef]

- Pandey, N.; Gusain, R.; Suthar, S. Exploring the efficacy of powered guar gum (Cyamopsis tetragonolba) seeds, duckweed (Spirodela polyrhiza), and Indian plum (Ziziphus mauritiana) leaves in urban wastewater treatment. J. Clean. Prod. 2020, 121680. [Google Scholar] [CrossRef]

- Ben, R.F.; Siddeeg, S.M. Cactus an eco-friendly material for wastewater treatment: A review. JMES 2017, 8, 1770–1782. [Google Scholar]

- Al-Saati, N.H.A.; Hwaidi, E.H.; Jassam, S.H. Comparing cactus (Opuntia spp.) and alum as coagulants for water treatment at Al-Mashroo Canal: A case study. Int. J. Environ. Sci. Technol. 2016, 13, 2875–2882. [Google Scholar] [CrossRef]

- Shilpaa, B.; Akankshaa, K.; Girish, P. Evaluation of cactus and hyacinth be an peels as natural coagulants. Int. J. Chem. Environ. Eng. 2012, 3, 187–191. [Google Scholar]

- Bouatay, F.; Mhenni, F. Use of the cactus cladodes mucilage (Opuntia ficus-indica) as an eco-friendly focculants: Process development and optimization using statiscal analysis. Int. J. Environ. Res. 2014, 8, 1295–1308. [Google Scholar] [CrossRef]

- Othmani, B.; Rasteiro, M.G.; Khadhraoui, M. Toward green technology: A review on some efficient model plant-based coagulants/flocculants for fresh water and wastewater remediation. Clean Technol. Environ. Policy 2020, 22, 1025–1040. [Google Scholar] [CrossRef]

- Kazi, T.; Virupakshi, A. Treatment of tannery waste water using natural coagulants. Development 2013, 2, 4061–4068. [Google Scholar]

- Belbahloul, M.; Abdeljalil, Z.; Abdellah, A. Comparison of the Efficacy of Two Bioflocculants in Water Treatment. Int. J. Sci. Eng. Technol. 2014, 3, 734–737. [Google Scholar]

- Khadhraoui, M.; Sellami, M.; Zarai, Z.; Saleh, K.; Rebah, F.B.; Leduc, R. Cactus juice preparations as bioflocculant: Properties, characteristics and application. Environ. Eng. Manag. J. 2019, 18, 137–146. [Google Scholar]

- APHA Standard Methods for the Examination of Water and Wastewater; American Public Health Association (APHA), AWWA, WEF: Washington, DC, USA, 1999.

- Sellami, M.; Zarai, Z.; Khadhraoui, M.; Jdidi, N.; Leduc, R.; Ben Rebah, F. Cactus juice as bioflocculant in the coagulation–flocculation process for industrial wastewater treatment: A comparative study with polyacrylamide. Water Sci. Technol. 2014, 70, 1175–1181. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of Total Phenols and Other Oxidation Substrates & Antioxidants by Means of Folin-Ciocalteu Reagent. In Methods in Enzymology; Academic Press: Cambridge, MA, USA, 1999. [Google Scholar] [CrossRef]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R.J. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F.G. Colorimetric method for determination of sugars and related substances. Anal. Chem. 1956, 3, 350–356. [Google Scholar] [CrossRef]

- Blumenkrantz, N.; Asboe-Hansen, G. New method for quantitative determination of uronic acids. Anal. Biochem. 1973, 54, 484–489. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of structural carbohydrates and lignin in biomass. Lab. Anal. Proced. 2008, 1617, 1–16. [Google Scholar]

- AOAC Official Methods of Analysis; Association of Official Analytical Chemists: Washington, DC, USA, 1997.

- Patil, C.S.; Kadam, A.N.; Gunjal, D.B.; Naik, V.M.; Lee, S.-W.; Kolekar, G.B.; Gore, A.H. Sugarcane molasses derived carbon sheet@sea sand composite for direct removal of methylene blue from textile wastewater: Industrial wastewater remediation through sustainable, greener, and scalable methodology. Sep. Purif. Technol. 2020, 247, 116997. [Google Scholar] [CrossRef]

- Kaur, H.; Kamboj, V. Bioremediation of textile waste water by plant ash. Foods Raw Mater. 2019, 7, 240–246. [Google Scholar]

- Beyene, H.D.; Hailegebrial, T.D.; Dirersa, W.B. Investigation of coagulation activity of cactus powder in water treatment. J. Appl. Chem. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Aruwa, C.E.; Amoo, S.O.; Kudanga, T. Extractable and macromolecular antioxidants of Opuntia ficus-indica cladodes: Phytochemical profiling, antioxidant and anti bacterial activities. S. Afr. J. Bot. 2019, 125, 402–410. [Google Scholar] [CrossRef]

- Kharrassi, Y.E.; Mazri, M.A.; Mabrouk, A.; Nasser, B.; Mzouri, E.H.E. Flowering and fruiting phenology, and physico-chemical characteristicsof2-year-old plants of six species of Opuntia from eight regions of Morocco. J. Hortic. Sci. Biotechnol. 2015, 90, 682–688. [Google Scholar] [CrossRef]

- Hernández-Urbiola, M.I.; Pérez-Torrero, E.; Rodríguez-García, M.E. Chemical Analysis of Nutritional Content of Prickly Pads(Opuntiaficusindica) at Varied Ages in an Organic Harvest. Int. J. Environ. Res. Public Health 2011, 8, 1287–1295. [Google Scholar] [CrossRef]

- Cheikh Rouhou, M.; Abdelmoumen, S.; Thomas, S.; Attia, H.; Ghorbel, D. Use of green chemistry methods in the extraction of dietary fibers from cactus rackets (Opuntia ficus indica): Structural and microstructural studies. Int. J. Biol. Macromol. 2018, 116, 901–910. [Google Scholar] [CrossRef]

- El-Mostafa, K.; ElKharrassi, Y.; Badreddine, A.; Andreoletti, P.; Vamecq, J.; ElKebbaj, M.S.; Latruffe, N.; Lizard, G.; Nasser, B.; Cherkaoui-Malki, M. Nopal cactus (Opuntia ficus-indica) as a source of bioactive compounds for nutrition, health and disease. Molecules 2014, 19, 14879–14901. [Google Scholar] [CrossRef] [PubMed]

- Bicalho, U.O.; Penteado, M.D.V. Estudo do fruto e do articulo da opuntia ficus indica(L)Miler cultivation em valinhos SPI. characterisation bromatologicas. Rev. Farm. Bioquim. Univ. S. Paulo. 1981, 17, 93–101. [Google Scholar]

- Trachtenberg, S.; Mayer, A.M. Mucilagecells, calcium oxalate crystals and soluble calcium in Opuntia ficus-indica. Ann. Bot. 1982, 50, 549–557. [Google Scholar] [CrossRef]

- Choudhary, M.; Ray, M.B.; Neogi, S. Evaluation of the potential application of cactus (Opuntia ficus-indica) as a bio-coagulant for pre-treatment of oil sands process-affected water. Sep. Purif. Technol. 2019, 209, 714–724. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, L.; Zhuang, X.; Shi, J.; Wang, Y.; He, N.; Chang, Y.-I. Flocculation Characterization of a Bioflocculant from Bacillus licheniformis. Ind. Eng. Chem. Res. 2015, 54, 2894–2901. [Google Scholar] [CrossRef]

- Ventura-Aguilar, R.I.; Bosquez-Molina, E.; Bautista-Baños, S.; Rivera-Cabrera, F. Cactus stem (Opuntia ficus-indica Mill): Anatomy, physiology and chemical composition with emphasis on its biofunctional properties. J. Sci. Food Agric. 2017, 97, 5065–5073. [Google Scholar] [CrossRef]

- Bouaouine, O.; Bourven, I.; Khalil, F.; Bressollier, P.; Baudu, M. Identification and role of Opuntia ficus indica constituents in the flocculation mechanism of colloidal solutions. Sep. Purif. Technol. 2019, 209, 892–899. [Google Scholar] [CrossRef]

- Rodriguez-Felix, A.; Cantwell, M. Developmental changes in composition and quality of prickly pear cactus cladodes (napolitos). Plant Foods Hum. Nutr. 1988, 38, 83–93. [Google Scholar] [CrossRef]

- Lefèvre, K.U.; Tollens, B. Untersuchungen über die Glucuronsäure, ihre quantitative Bestimmung und ihre Farbenreaktionen. Ber. Der Dtsch. Ges. 1907, 40, 4513–4523. [Google Scholar] [CrossRef]

- Felkai-Haddache, L.; Remini, H.; Dulong, V.; Mamou-Belhabib, K.; Picton, L.; Madani, K.; Rihouey, C. Conventionaland Microwave-Assisted Extraction of Mucilage from Opuntia ficus-indica Cladodes: Physico-Chemical and Rheological Properties. Food Bioprocess Technol. 2016, 9, 481–492. [Google Scholar] [CrossRef]

- Miller, S.M.; Fugate, E.J.; Craver, V.O.; Smith, J.A.; Zimmerman, J.B. Toward understanding the efficacy and mechanism of Opuntia spp. as a natural coagulant for potential application in water treatment. Environ. Sci. Technol. 2008, 42, 4274–4279. [Google Scholar] [CrossRef] [PubMed]

- Amira, A.; Ali, A.; Omar, B. Synthesis and application of a new biomaterial based on Opuntia ficus indica(cactus)in water treatment. Alger. J. Eng. Res. AJER 2017, 2017, 11–17. [Google Scholar]

- De Souza, M.T.F.; De Almeida, C.A.; Ambrosio, E.; Santos, L.B.; De Freitas, T.K.F.S.; Manholer, D.D.; De Carvalho, G.M.; Garcia, J.C. Extraction and use of Cereus peruvianus cactus mucilage in the treatment of textile effluents. J. Taiwan Inst. Chem. Eng. 2016, 67, 174–183. [Google Scholar] [CrossRef]

- Vishali, S.; Karthikeyan, R. Cactus opuntia (ficus-indica): An eco-friendly alternative coagulant in the treatment of paint effluent. Desalin. Water Treat. 2015, 56, 1489–1497. [Google Scholar] [CrossRef]

- Noor, M.J.M.M.; Mohamed, E.H.; Mohammad, T.A.; Ghazali, A.H. Effectiveness of salt-extracted freeze-dried Moringa oleifera as a coagulant. Desalin. Water Treat. 2015, 55, 3621–3627. [Google Scholar] [CrossRef]

- Nireesha, R.G.; Divya, L.; Sowmya, C.; Venkateshan, N.; Niranjan Babu, M.; Lavakumar, V. Lyophilization/Freeze Drying—An Review. Int. J. Nov. Trends Pharm. Sci. 2013, 3, 87–98. [Google Scholar]

- DeSouza, M.T.F.; Ambrosio, E.; Almeida, C.A.; Freita, T.K.F.; Santos, L.B.; Almeida, V.C.; Garcia, J.C. The use of a natural coagulant (Opuntia ficus-indica) in the removal for organic materials of textile effluents. Environ. Monit. Assess. 2014, 186, 5261–5271. [Google Scholar] [CrossRef]

- Dalvand, A.; Gholibegloo, E.; Ganjali, M.R. Comparison of Moringa stenopetala seed extract as a clean coagulant with Alum and Moringa stenopetala-Alum hybrid coagulant to remove direct dye from Textile Wastewater. Environ. Sci. Pollut. Res. 2016, 23, 16396–16405. [Google Scholar] [CrossRef]

- Debora, J.; Theodoro, P.; Lenz, G.F.; Zara, R.F.; Bergamasco, R. Coagulants and natural polymers: Perspectives for the treatment of water. Plast. Polym. Technol. 2013, 2, 55–62. [Google Scholar]

- Bouaouine, O.; Bourven, I.; Khalil, F.; Baudu, M. Identification of functional groups of Opuntia ficus indica involved in coagulation process after its active extraction. Environ. Sci. Pollut. Res. 2018, 25, 11111–11119. [Google Scholar] [CrossRef]

- Azura, N.W.N.Z.; Fahmi, M.R.; Syakirah, A.M.; Lim, B.S. Study of Methylene Blue color removal effectiveness by Moringa Oleifera and Alum. In Proceedings of the 2nd International Malaysia-Ireland Joint Symposium on Engineering, Science and Business 2012 (IMiEJS2012), Kuala Lumpur, Malaysia, 18–20 June 2012; pp. 863–867. [Google Scholar]

- Zonoozi, M.H.; Alavi Moghaddam, M.R.; Arami, M. Study on the removal of acid dyes using chitosan as a natural coagulant/coagulant aid. Water Sci. Technol. 2011, 63, 403–409. [Google Scholar] [CrossRef] [PubMed]

- Lozano-Rivas, W.A.; Whiting, K.E.; Gómez-Lahoz, C.; Rodríguez-Maroto, J.M. Use of glycosides extracted from the fique (Furcraea sp.) in waste water treatment for textile industry. Int. J. Environ. Sci. Technol. 2016, 13, 1131–1136. [Google Scholar] [CrossRef][Green Version]

- Chethana, M.; Sorokhaibam, L.G.; Bhandari, V.M.; Raja, S.; Ranade, V.V. Green approach to dye wastewater treatment using biocoagulants. ACS Sustain. Chem. Eng. 2016, 4, 2495–2507. [Google Scholar] [CrossRef]

- Al-Gheethi, A.; Mohamed, R.; Wurochekke, A.; Nurulainee, N.; Mas Rahayu, J.; Amir Hashim, M. Efficiency of Moringa oleifera Seeds for Treatment of Laundry Wastewater. MATEC Web Conf. 2017, 103. [Google Scholar] [CrossRef]

- Kumar, V. Partial Replacement of Alum by Using Natural Coagulant Aid to Remove Turbidity from Institutional Wastewater. Int. J. Integr. Eng. 2020, 12, 241–251. [Google Scholar]

| Bio-Chemical Content | Protocol of Extraction | Reference |

|---|---|---|

| Total phenols | In a test tube, 5 mL of Folin-Ciocalteu reagent was mixed with 1 mL of cactus extract which was previously prepared by adding 2 g of powder to 20 mL of methanol. Thereafter, 4 mL of sodium carbonate solution (7.5%) was added to the mixture. The absorbance of the final solution was assessed at 760 nm using gallic acid as a standard reagent. | [31] |

| Proteins | 1 g of cactus powder was added to 20 mL of distilled water. 0.4 mL of this suspension was mixed with 4 mL of an analytical reagent previously prepared. Then, 0.4 mL of Folin-Ciocalteu reagent was added to the mixture. The analytical reagent was prepared by mixing 2 mL of solution 1, (CuSO4 (1.56 %, w/v) and sodium potassium tartrate (2.37 %, w/v) with 100 mL of solution 2 (Na2CO3 (2 %, w/v) and NaOH (0.4 % w/v). Proteins were determined by absorbance measurement at 660 nm using Bovine Serum Albumin as a standard solution. | [32] |

| Neutral Sugars | A cactus solution was prepared by mixing 0.5 g of cactus powder with 20 mL of concentrated sulfuric acid and adjusting with distilled water to 500 mL. From this solution, 2 mL was mixed with 1 mL of phenol (5%) followed by a supplement of 5 mL of sulfuric acid (96%). For neutral sugars estimation, glucose was used as standard solution and absorbance was measured at 490 nm. | [33] |

| Uronic Acids | To 1 mL of cactus sample prepared via an acidic hydrolysis of 50 mg of cactus powder, 6 mL of sulfuric acid solution containing 0.0125 M sodium tetraborate was added. Then, a supplement of 200 µL of m-hydroxybiphenyl was added to the mixture. Absorbance was registered at 520 nm and quantified based on galacturonic acid as a standard reagent. | [34] |

| Klason Lignin | 0.9 g of cactus powder was mixed with 9 mL of H2SO4 (72%). The mixture was placed into an autoclave at 121 °C for 1h. Thereafter, the suspension was filtered after settling overnight to acquire the klason lignin fraction which is the insoluble lignin obtained by oven-drying the filtration residue. The residue was then weighed using an accurate balance. | [35] |

| Dye | pH * | λ (nm) * | Turbidity (NTU) * | Structure |

|---|---|---|---|---|

| MB | 7.2 | 663 | 95.6 |  |

| MO | 6.2 | 464 | 80.2 |  |

| Composition (mg/g DW) | LP | DP |

|---|---|---|

| Total phenols | 2.3 | 2.0 |

| Proteins | 54 | 64 |

| Neutral sugars | 345 | 380 |

| Uronic acids | 682 | 546 |

| Klason lignin | 15.7 | 25.6 |

| Calcium (Ca) | 72.4 | 79.5 |

| Sodium (Na) | 1.5 | 2.3 |

| Magnesium (Mg) | 7.1 | 11.6 |

| Iron (Fe) | 0.035 | 0.075 |

| Wave Number (cm−1) | Functional Groups in Polysaccharides (Vibration Type) |

|---|---|

| 3355 | O–H (stretching) |

| 2931 | C–H (stretching) |

| ~1730 | Non-ionized COOH/substituent methyl ester (C=O stretching) |

| 1623 | Ionized COOH (COO− asymmetric stretching) |

| 1425 | Ionized COOH (COO− symmetric stretching) |

| 1046 | Alcohol/ether (C–O stretching) |

| Synthetic Dye Solution (0.10 g/L) | MB | MO | ||

|---|---|---|---|---|

| Cactus formulation | LP | DP | LP | DP |

| Optimum dose (g/L) | 0.37 | 1.46 | 0.37 | 1.10 |

| Color removal (%) | 83 ± 2.4 | 68 ± 2.0 | 63 ± 1.8 | 65 ± 2.0 |

| Turbidity removal (%) | 69 ± 2.0 | 70 ± 2.0 | 62 ± 1.8 | 37 ± 1.2 |

| Natural Coagulants/Flocculants | Treated Waters | Optimum Dose (g/L) | Color Removal (%) | Turbidity Removal (%) | References |

|---|---|---|---|---|---|

| Chitosan | Acid Blue 292 dye | 0.003 | 52 | n.d | [65] |

| Fique leaves | Textile industry | 0.01 | 89 | 93 | [66] |

| Cicer arietinum seeds | Congo red dye | 0.80 | 89 | n.d | [67] |

| Moringa seeds | Laundry wastewater | 0.12 | n.d | 83 | [68] |

| Cassava peels | Institutional wastewater | 0.40 | n.d | 81 | [69] |

| Moringa seeds | Methylene blue dye | 50 | 70 | n.d | [64] |

| Lyophilized cactus cladodes | Methylene blue dye | 0.37 | 83 | 69 | This study |

| Lyophilized cactus cladodes | Methyl Orange | 0.37 | 65 | 62 | This study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Othmani, B.; Gamelas, J.A.F.; Rasteiro, M.G.; Khadhraoui, M. Characterization of Two Cactus Formulation-Based Flocculants and Investigation on Their Flocculating Ability for Cationic and Anionic Dyes Removal. Polymers 2020, 12, 1964. https://doi.org/10.3390/polym12091964

Othmani B, Gamelas JAF, Rasteiro MG, Khadhraoui M. Characterization of Two Cactus Formulation-Based Flocculants and Investigation on Their Flocculating Ability for Cationic and Anionic Dyes Removal. Polymers. 2020; 12(9):1964. https://doi.org/10.3390/polym12091964

Chicago/Turabian StyleOthmani, Bouthaina, José A. F. Gamelas, Maria Graça Rasteiro, and Moncef Khadhraoui. 2020. "Characterization of Two Cactus Formulation-Based Flocculants and Investigation on Their Flocculating Ability for Cationic and Anionic Dyes Removal" Polymers 12, no. 9: 1964. https://doi.org/10.3390/polym12091964

APA StyleOthmani, B., Gamelas, J. A. F., Rasteiro, M. G., & Khadhraoui, M. (2020). Characterization of Two Cactus Formulation-Based Flocculants and Investigation on Their Flocculating Ability for Cationic and Anionic Dyes Removal. Polymers, 12(9), 1964. https://doi.org/10.3390/polym12091964