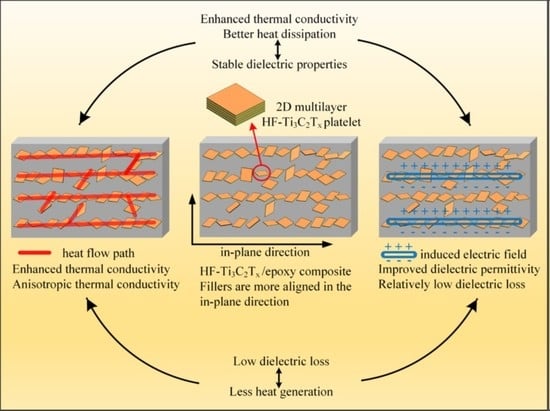

Simultaneously Improved Thermal and Dielectric Performance of Epoxy Composites Containing Ti3C2Tx Platelet Fillers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of HF-Ti3C2Tx and Epoxy Composites

2.3. Characterization and Measurements

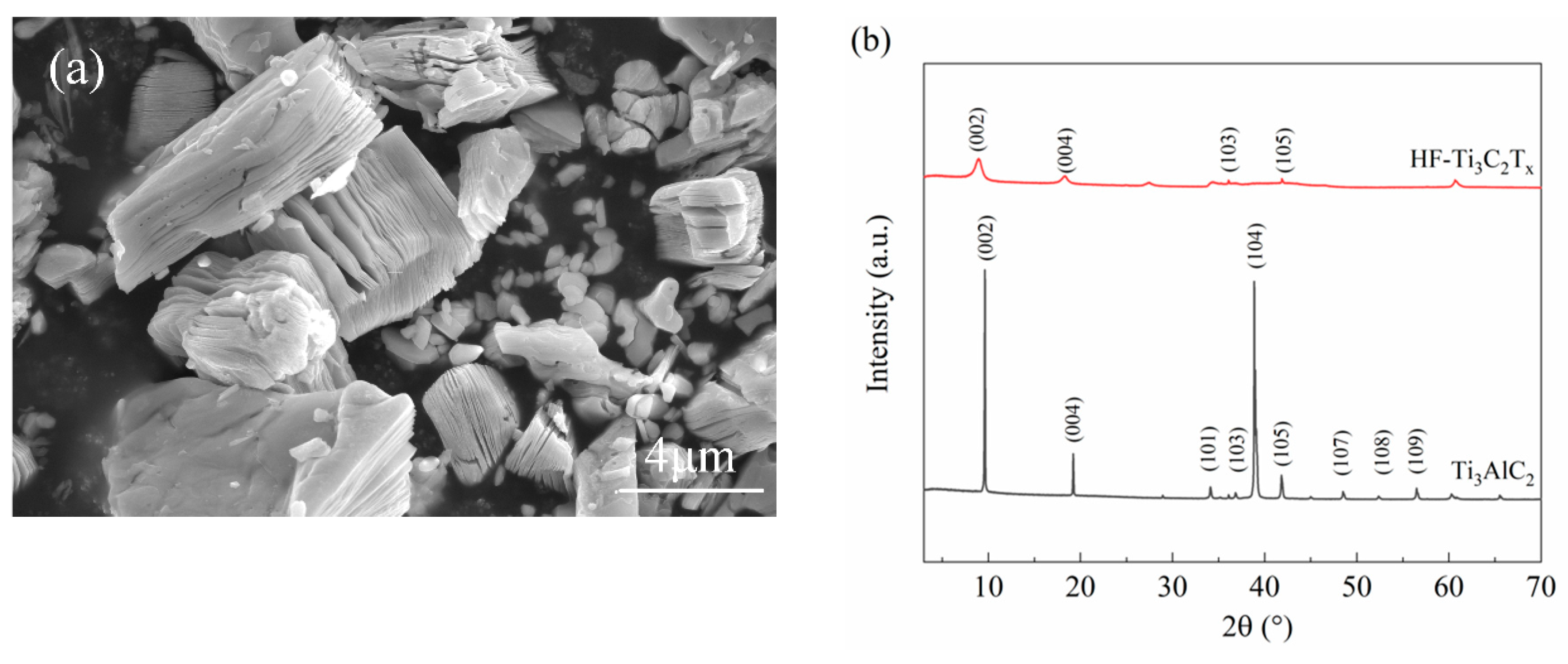

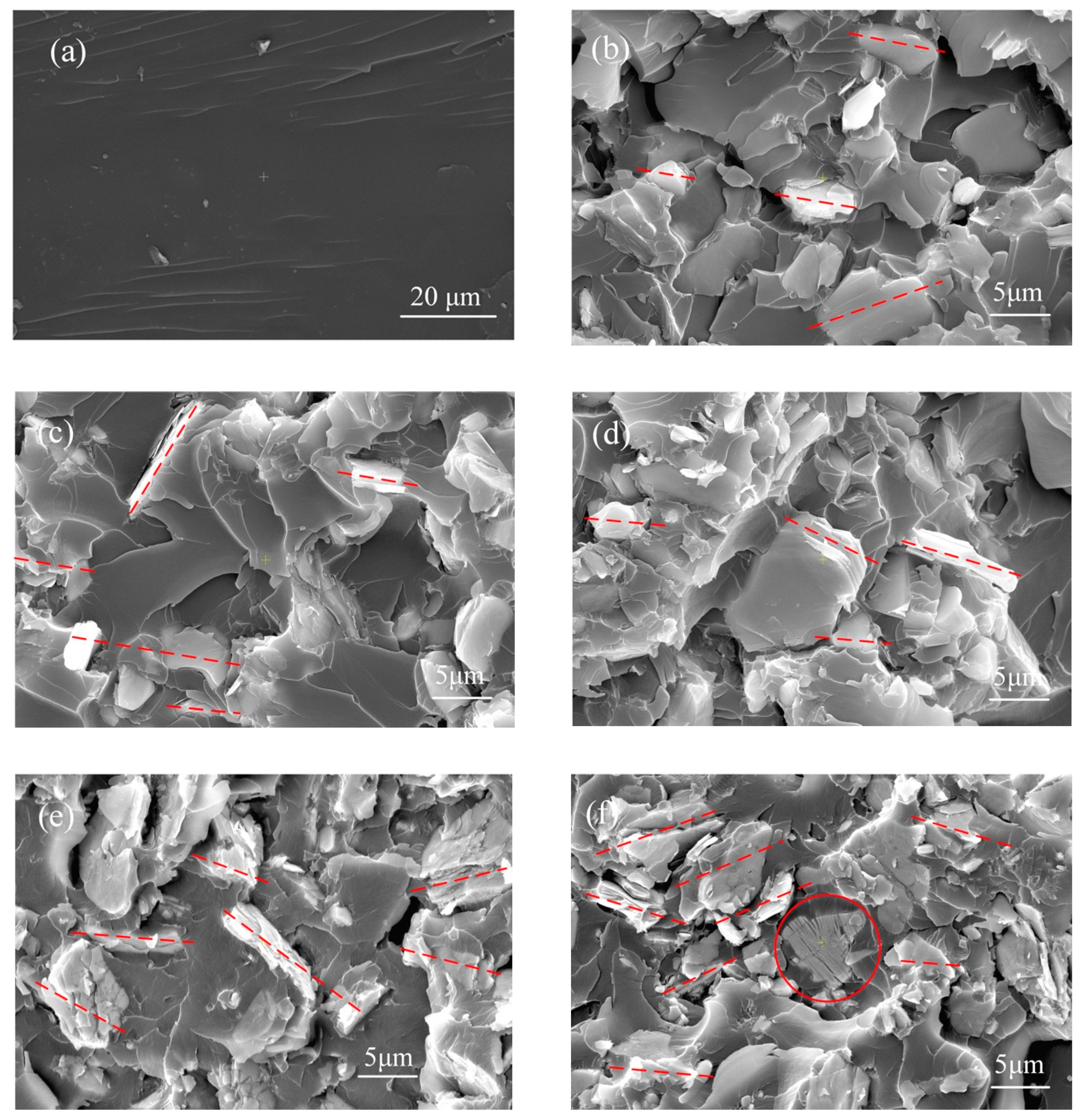

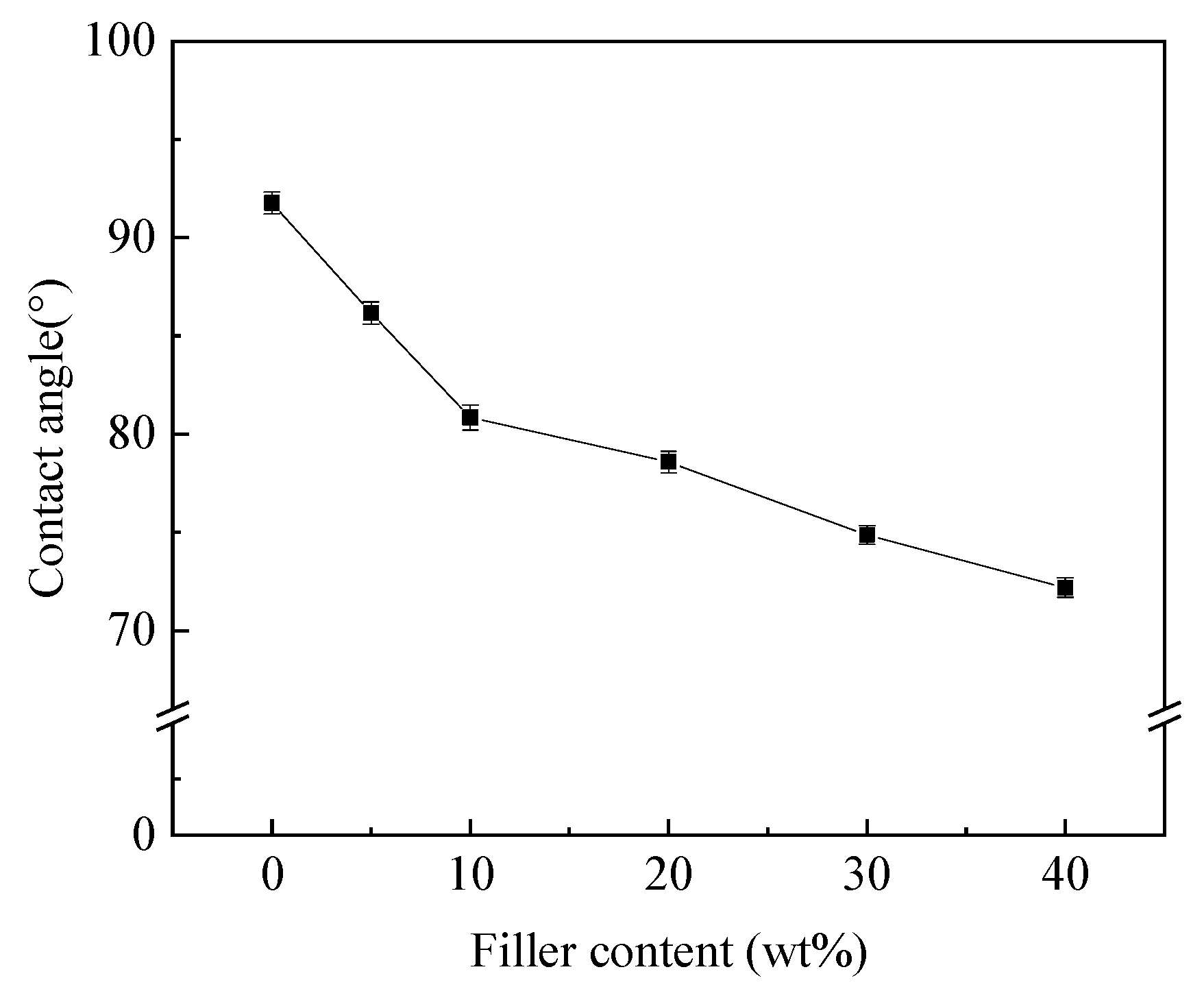

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Dang, Z.-M.; Yuan, J.-K.; Zha, J.-W.; Zhou, T.; Li, S.-T.; Hu, G.-H. Fundamentals, processes and applications of high-permittivity polymer–matrix composites. Prog. Mater. Sci. 2012, 57, 660–723. [Google Scholar] [CrossRef]

- Shahil, K.M.; Balandin, A.A. Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett. 2012, 12, 861–867. [Google Scholar] [CrossRef] [PubMed]

- Cao, B.-Y.; Kong, J.; Xu, Y.; Yung, K.-L.; Cai, A. Polymer Nanowire Arrays with High Thermal Conductivity and Superhydrophobicity Fabricated by a Nano-Molding Technique. Heat Transf. Eng. 2013, 34, 131–139. [Google Scholar] [CrossRef]

- Chen, K.; Chen, Y.; She, Y.; Song, M.; Wang, S.; Chen, L. Construction of effective symmetrical air-cooled system for battery thermal management. Appl. Therm. Eng. 2020, 166, 114679. [Google Scholar] [CrossRef]

- Chen, L.; Li, Z.; Guo, Z.-Y. Experimental investigation of plastic finned-tube heat exchangers, with emphasis on material thermal conductivity. Exp. Therm. Fluid Sci. 2009, 33, 922–928. [Google Scholar] [CrossRef]

- T’Joen, C.; Park, Y.; Wang, Q.; Sommers, A.; Han, X.; Jacobi, A. A review on polymer heat exchangers for HVAC&R applications. Int. J. Refrig. 2009, 32, 763–779. [Google Scholar]

- Arbatti, M.; Shan, X.; Cheng, Z.-Y. Ceramic-Polymer Composites with High Dielectric Constant. Adv. Mater. 2007, 19, 1369–1372. [Google Scholar] [CrossRef]

- Su, Y.; Ba, C.; Wang, F. Improved dielectric permittivity of NBCTO/epoxy composite films with low dielectric loss. SN Appl. Sci. 2019, 1, 1147. [Google Scholar] [CrossRef]

- Ran, F.; Xu, X.; Pan, D.; Liu, Y.; Bai, Y.; Shao, L. Ultrathin 2D Metal–Organic Framework Nanosheets In Situ Interpenetrated by Functional CNTs for Hybrid Energy Storage Device. Nano Micro Lett. 2020, 12, 46. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Naguib, M.; Mochalin, V.N.; Barsoum, M.W.; Gogotsi, Y. 25th anniversary article: MXenes: A new family of two-dimensional materials. Adv. Mater. 2014, 26, 992–1005. [Google Scholar] [CrossRef] [PubMed]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for Synthesis and Processing of Two-Dimensional Titanium Carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Miranda, A.; Halim, J.; Lorke, A.; Barsoum, M.W. Rendering Ti3C2Tx (MXene) monolayers visible. Mater. Res. Lett. 2017, 5, 322–328. [Google Scholar] [CrossRef]

- Lukatskaya, M.R.; Mashtalir, O.; Ren, C.E.; Dall’Agnese, Y.; Rozier, P.; Taberna, P.L.; Naguib, M.; Simon, P.; Barsoum, M.W.; Gogotsi, Y. Cation intercalation and high volumetric capacitance of two-dimensional titanium carbide. Science 2013, 341, 1502–1505. [Google Scholar] [CrossRef]

- Ghidiu, M.; Lukatskaya, M.R.; Zhao, M.Q.; Gogotsi, Y.; Barsoum, M.W. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 2014, 516, 78–81. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Man Hong, S.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef]

- Deng, B.; Xiang, Z.; Xiong, J.; Liu, Z.; Yu, L.; Lu, W. Sandwich-Like Fe&TiO2@C Nanocomposites Derived from MXene/Fe-MOFs Hybrids for Electromagnetic Absorption. Nano Micro Lett. 2020, 12, 55. [Google Scholar]

- Zhang, Q.; Teng, J.; Zou, G.; Peng, Q.; Du, Q.; Jiao, T.; Xiang, J. Efficient phosphate sequestration for water purification by unique sandwich-like MXene/magnetic iron oxide nanocomposites. Nanoscale 2016, 8, 7085–7093. [Google Scholar] [CrossRef] [PubMed]

- Rasool, K.; Helal, M.; Ali, A.; Ren, C.E.; Gogotsi, Y.; Mahmoud, K.A. Antibacterial Activity of Ti3C2Tx MXene. ACS Nano 2016, 10, 3674–3684. [Google Scholar] [CrossRef] [PubMed]

- Ling, Z.; Ren, C.E.; Zhao, M.Q.; Yang, J.; Giammarco, J.M.; Qiu, J.S.; Barsoum, M.W.; Gogotsi, Y. Flexible and conductive MXene films and nanocomposites with high capacitance. Proc. Natl. Acad. Sci. USA 2014, 111, 16676–16681. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Wang, Z.Y.; Wu, Y.; Liu, X.; He, Y.B.; Kim, J.K. Multilayer Graphene Enables Higher Efficiency in Improving Thermal Conductivities of Graphene/Epoxy Composites. Nano Lett. 2016, 16, 3585–3593. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, L.; Lin, J.; Cui, P.; Li, M.; Du, X. Thermal conductivity of epoxy composites filled by thermally reduced graphite oxide with different reduction degree. J. Compos. Mater. 2017, 51, 1743–1752. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, L.; Cui, L.; Zhang, Y.; Du, X. Molecular dynamics simulation of cross-linked epoxy resin and its interaction energy with graphene under two typical force fields. Comput. Mater. Sci. 2018, 143, 240–247. [Google Scholar] [CrossRef]

- Khan, M.; Khurram, A.A.; Li, T.H.; Zhao, T.K.; Subhani, T.; Gul, I.H.; Ali, Z.; Patel, V. Synergistic effect of organic and inorganic nano fillers on the dielectric and mechanical properties of epoxy composites. J. Mater. Sci. Technol. 2018, 34, 2424–2430. [Google Scholar] [CrossRef]

- Chen, L.; Shi, X.G.; Yu, N.J.; Zhang, X.; Du, X.Z.; Lin, J. Measurement and Analysis of Thermal Conductivity of Ti3C2Tx MXene Films. Materials 2018, 11, 1701. [Google Scholar] [CrossRef]

- Chang, F.; Li, C.; Yang, J.; Tang, H.; Xue, M. Synthesis of a new graphene-like transition metal carbide by de-intercalating Ti3AlC2. Mater. Lett. 2013, 109, 295–298. [Google Scholar] [CrossRef]

- Aakyiir, M.; Araby, S.; Michelmore, A.; Meng, Q.; Amer, Y.; Yao, Y.; Li, M.; Wu, X.; Zhang, L.; Ma, J. Elastomer nanocomposites containing MXene for mechanical robustness and electrical and thermal conductivity. Nanotechnology 2020, 31, 315715. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Zhou, A.; Shen, C.; Dai, Y.; Liu, F.; Chen, J.; Li, P.; Hu, Q. Effects of 2-D transition metal carbide Ti2CTx on properties of epoxy composites. RSC Adv. 2016, 6, 87341–87352. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H.; Chen, L.; Zhu, Z.; Zhao, J.; Zhang, Z. Graphene based silicone thermal greases. Phys. Lett. A 2014, 378, 207–211. [Google Scholar] [CrossRef]

- Tanimoto, M.; Yamagata, T.; Miyata, K.; Ando, S. Anisotropic thermal diffusivity of hexagonal boron nitride-filled polyimide films: Effects of filler particle size, aggregation, orientation, and polymer chain rigidity. ACS Appl. Mater. Interfaces 2013, 5, 4374–4382. [Google Scholar] [CrossRef] [PubMed]

- Xie, B.-H.; Huang, X.; Zhang, G.-J. High thermal conductive polyvinyl alcohol composites with hexagonal boron nitride microplatelets as fillers. Compos. Sci. Technol. 2013, 85, 98–103. [Google Scholar] [CrossRef]

- Su, Z.; Wang, H.; Tian, K.; Huang, W.; Guo, Y.; He, J.; Tian, X. Multifunctional anisotropic flexible cycloaliphatic epoxy resin nanocomposites reinforced by aligned graphite flake with non-covalent biomimetic functionalization. Compos. Part A Appl. Sci. Manuf. 2018, 109, 472–480. [Google Scholar] [CrossRef]

- Chen, L.; Sun, Y.-Y.; Xu, H.-F.; He, S.-J.; Wei, G.-S.; Du, X.-Z.; Lin, J. Analytic modeling for the anisotropic thermal conductivity of polymer composites containing aligned hexagonal boron nitride. Compos. Sci. Technol. 2016, 122, 42–49. [Google Scholar] [CrossRef]

- Chen, L.; Xu, H.F.; Sun, Y.Y.; Du, X.Z.; He, S.J.; Lin, J.; Nazarenko, S. Modeling of anisotropic thermal conductivity of polymer composites containing aligned boron nitride platelets: Effect of processing methods. Polym. Compos. 2017, 38, 2670–2678. [Google Scholar] [CrossRef]

- Ramajo, L.; Reboredo, M.M.; Castro, M.S. BaTiO3-Epoxy Composites for Electronic Applications. Int. J. Appl. Ceram. Technol. 2010, 7, 444–451. [Google Scholar]

- Tsangaris, G.M.; Psarras, G.C. The dielectric response of a polymeric three-component composite. J. Mater. Sci. 1999, 34, 2151–2157. [Google Scholar] [CrossRef]

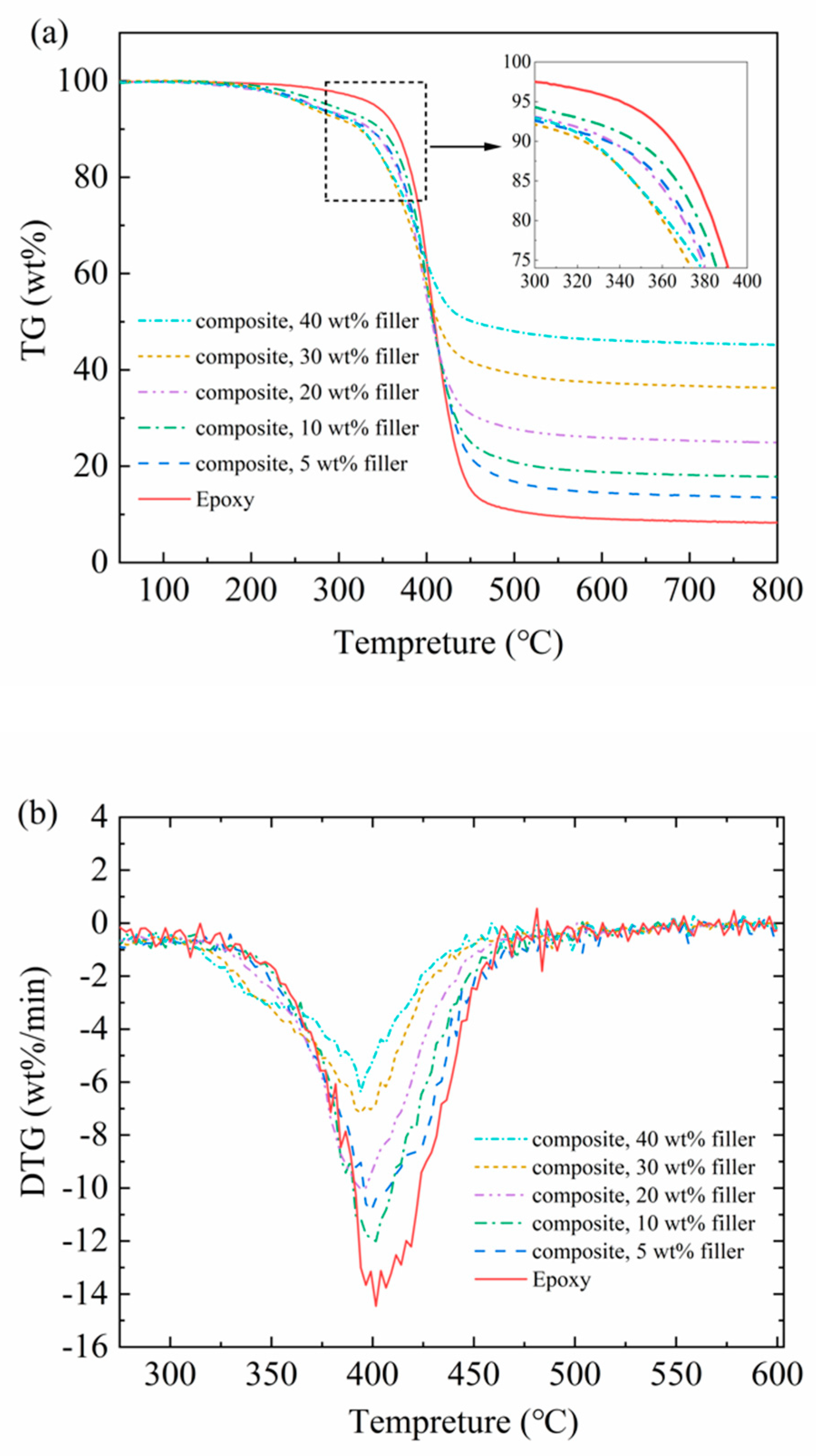

| Samples | Measured Residual Mass, (wt%) | Calculated Residual Mass (wt%) | Relative Deviation (%) | Temperature for 5 wt% of Material Degradation (°C) |

|---|---|---|---|---|

| HF-Ti3C2Tx | 92.3 | - | - | - |

| Epoxy | 8.3 | - | - | 364.3 |

| HF-Ti3C2Tx/epoxy composite, 5wt% | 13.5 | 12.5 | 8 | 333.6 |

| HF-Ti3C2Tx/epoxy composite, 10wt% | 17.8 | 16.7 | 7 | 347.5 |

| HF-Ti3C2Tx/epoxy composite, 20wt% | 24.9 | 25.1 | -1 | 335.5 |

| HF-Ti3C2Tx/epoxy composite, 30wt% | 36.3 | 33.5 | 8 | 322.7 |

| HF-Ti3C2Tx/epoxy composite, 40wt% | 45.2 | 41.9 | 8 | 326.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Cao, Y.; Guo, X.; Song, P.; Chen, K.; Li, D.; Lin, J. Simultaneously Improved Thermal and Dielectric Performance of Epoxy Composites Containing Ti3C2Tx Platelet Fillers. Polymers 2020, 12, 1608. https://doi.org/10.3390/polym12071608

Chen L, Cao Y, Guo X, Song P, Chen K, Li D, Lin J. Simultaneously Improved Thermal and Dielectric Performance of Epoxy Composites Containing Ti3C2Tx Platelet Fillers. Polymers. 2020; 12(7):1608. https://doi.org/10.3390/polym12071608

Chicago/Turabian StyleChen, Lin, Yu Cao, Xuebo Guo, Ping Song, Kai Chen, Diansen Li, and Jun Lin. 2020. "Simultaneously Improved Thermal and Dielectric Performance of Epoxy Composites Containing Ti3C2Tx Platelet Fillers" Polymers 12, no. 7: 1608. https://doi.org/10.3390/polym12071608

APA StyleChen, L., Cao, Y., Guo, X., Song, P., Chen, K., Li, D., & Lin, J. (2020). Simultaneously Improved Thermal and Dielectric Performance of Epoxy Composites Containing Ti3C2Tx Platelet Fillers. Polymers, 12(7), 1608. https://doi.org/10.3390/polym12071608