Effect of Fique Fibers in the Behavior of a New Biobased Composite from Renewable Mopa-Mopa Resin

Abstract

1. Introduction

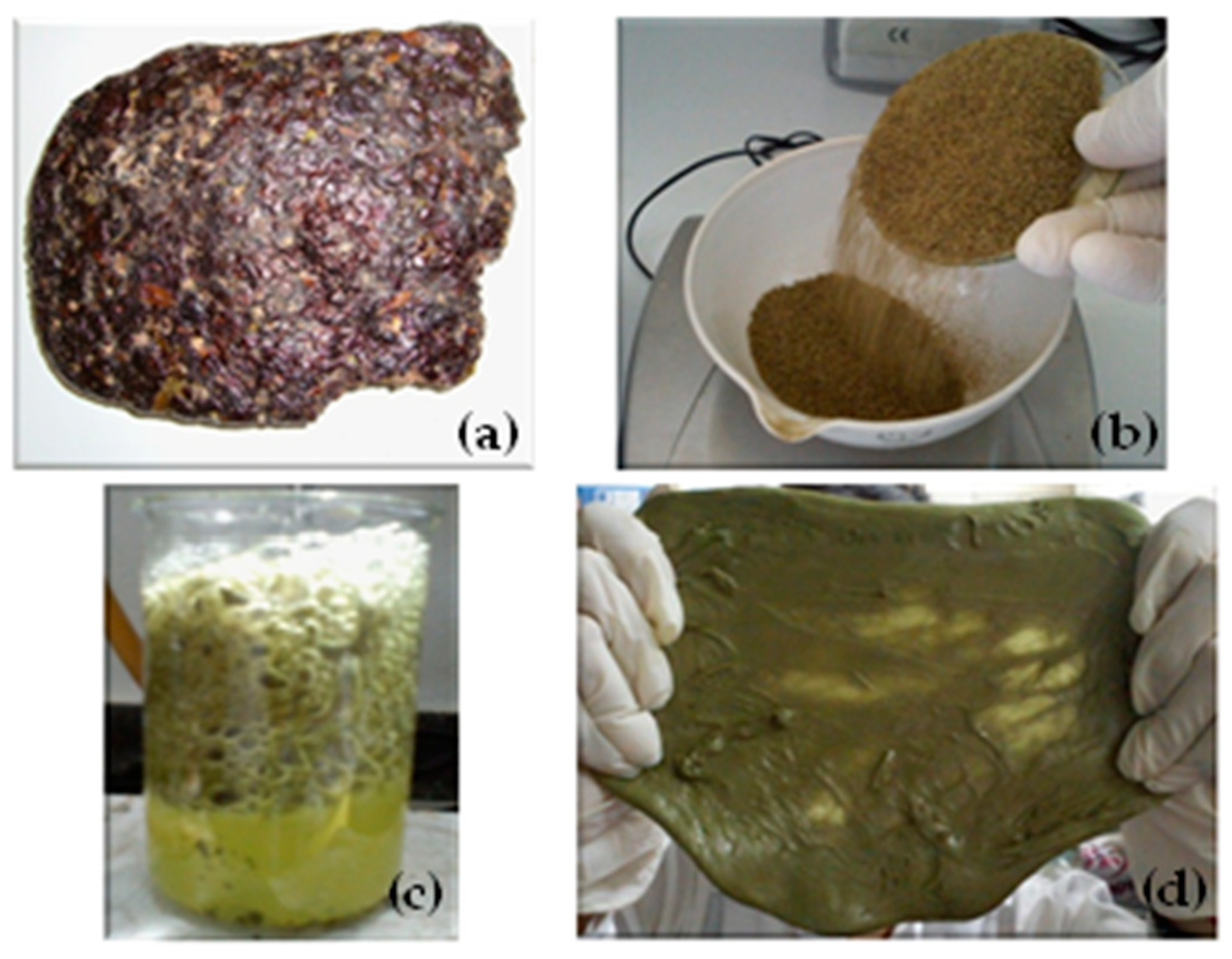

2. Materials

3. Experimental Procedure

3.1. Obtaining the Mopa-Mopa Resin

3.2. Surface Modification by Alkalization of Fique Fibers

3.3. Preparation of the Biobased Composite

3.4. Fourier Transform Infrared Spectroscopy (FTIR)

3.5. Moisture Adsorption

3.6. Density Determination

3.7. Tension Test

3.8. Scanning Electron Microscopy (SEM)

4. Results and Discussion

4.1. Fourier Transform Infrared Spectroscopy (FTIR)

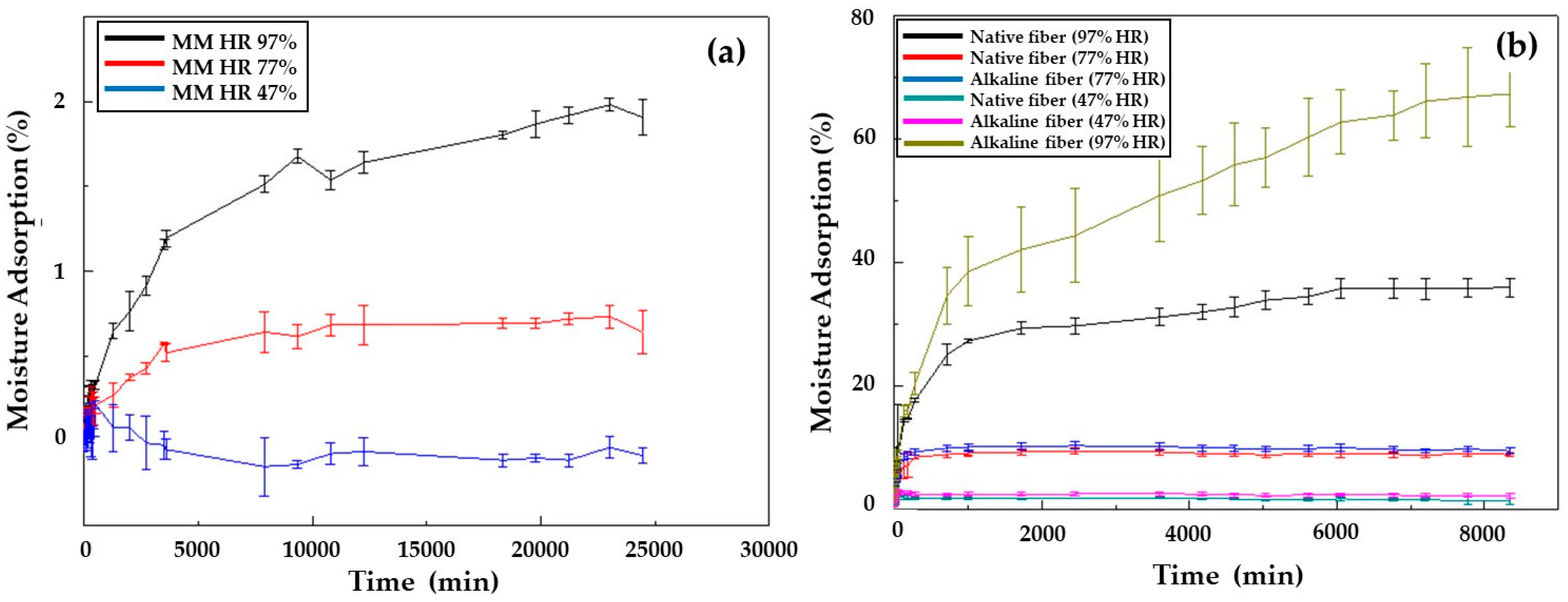

4.2. Moisture Adsorption

4.3. Density Estimation

4.4. Tensile Strength

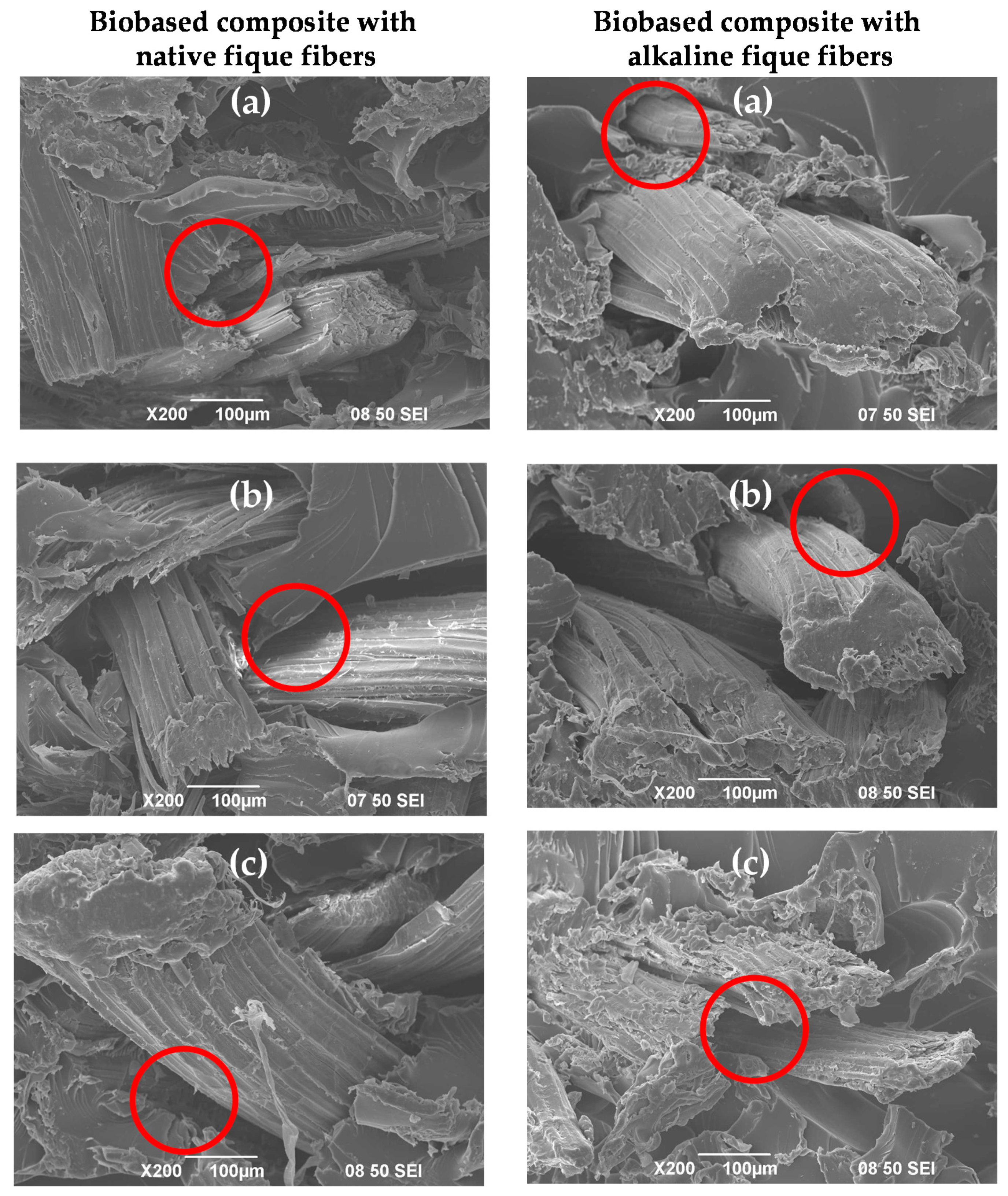

4.5. Scanning Electron Microscopy (SEM)

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing Biobased Recyclable Polymers for Plastics. Trends Biotechnol. 2019, 38, 50–67. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bio-nano composites. Carbohydr. Polym. 2018, 200, 186–202. [Google Scholar] [CrossRef] [PubMed]

- Yatigala, N.S.; Bajwa, D.S.; Bajwa, S.G. Compatibilization improves physico-mechanical properties of biodegradable biobased polymer composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 315–325. [Google Scholar] [CrossRef]

- Maqsood, M.; Seide, G. Development of biobased socks from sustainable polymer and statistical modeling of their thermo-physiological properties. J. Clean. Prod. 2018, 197, 170–177. [Google Scholar] [CrossRef]

- Huang, M.; Yu, J.; Ma, X. Ethanolamine as a novel plasticizer for thermoplastic starch. Polym. Degrad. Stab. 2005, 90, 501–507. [Google Scholar] [CrossRef]

- Guan, J.; Eskridge, K.M.; Hanna, M. Acetylated starch-polylactic acid loose-fill packaging materials. Ind. Crops Prod. 2005, 22, 109–123. [Google Scholar] [CrossRef]

- Lai, S.M.; Don, T.M.; Huang, Y.C. Preparation and properties of biodegradable thermoplastic starch/poly(hydroxybutyrate) blends. J. Appl. Polym. Sci. 2006, 100, 2371–2379. [Google Scholar] [CrossRef]

- Kong, X.; Omonov, T.S.; Curtis, J.M. The development of canola oil based bio-resins. Lipid Technol. 2012, 24, 7–10. [Google Scholar] [CrossRef]

- Lagel, M.; Hai, L.; Pizzi, A.; Basso, M.; Delmotte, L.; Abdalla, S.; Zahed, A.; Al-Marzouki, F. Automotive brake pads made with a bioresin matrix. Ind. Crops Prod. 2016, 85, 372–381. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Bucinell, R.; Li, B. Bioresin infused then cured mycelium-based sandwich-structure biocomposites: Resin transfer molding (RTM) process, flexural properties, and simulation. J. Clean. Prod. 2019, 207, 123–135. [Google Scholar] [CrossRef]

- Rad, E.R.; Vahabi, H.; De Anda, A.R.; Saeb, M.R.; Thomas, S. Bio-epoxy resins with inherent flame retardancy. Prog. Org. Coat. 2019, 135, 608–612. [Google Scholar] [CrossRef]

- A Baroncini, E.; Yadav, S.K.; Palmese, G.R.; Stanzione, I.J.F. Recent advances in bio-based epoxy resins and bio-based epoxy curing agents. J. Appl. Polym. Sci. 2016, 133, 44103. [Google Scholar] [CrossRef]

- Ávila, M.P.; Ochoa, I.C.; Rodríguez, C.E. Memoria de oficio: Mopa Mopa Pasto; Atesanías de Colombia: Bogotá, Colombia, 2016. [Google Scholar]

- Cortés, C. La lógica de la representación en lo artesanal; un asunto de identidad. Revista Estudios Latinoamericanos. 2000, 1, 42–62. [Google Scholar]

- Newman, R.; Kaplan, E.; Derrick, M. Mopa mopa: Scientific analysis and history of an unusual South American resin used by the inka and Artisans in pasto, Colombia. J. Am. Inst. Conserv. 2015, 54, 123–148. [Google Scholar] [CrossRef]

- Insuasty, B.; Argoti, J.; Altarejos, J.; Cuenca, G.; Chamorro, E. Caracterización Fisicoquímica preliminar de la resina del Mopa-Mopa (Elaeagia pastoensis Mora), Barniz de Pasto. Scientia et Technica 2007, 1, 365–368. [Google Scholar]

- Mina, J.; Anderson, S.; Bolaños, C.; Toro, E. Preparación y caracterización físico-química y térmica de mezclas binarias de resina Mopa-Mopa (elaegia pastoensis Mora) y policaprolactona (PCL). Revista Latinoamericana de Metalurgía y Materiales 2012, 32, 176–184. [Google Scholar]

- Toro, E.; Mina, J.; Bolaños, C. Estudio físico-mecánico y térmico de una resina natural Mopa-Mopa acondicionada a diferentes humedades relativas. Biotecnología en el Sector Agropecuario y Agroindustrial 2013, 11, 30–36. [Google Scholar]

- Gañán, P.F.; Mondragon, I. Surface modification of fique fibers. Effect on their physico-mechanical properties. Polym. Compos. 2002, 23, 383–394. [Google Scholar] [CrossRef]

- Mina, J.; Valadez, A.; Muñoz, M. Micro- and Macro mechanical Properties of a Composite with a Ternary PLA–PCL–TPS Matrix Reinforced with Short Fique Fibers. Polymers 2020, 12, 58. [Google Scholar] [CrossRef]

- Hoyos, C.G.; Vazquez, A. Flexural properties loss of unidirectional epoxy/fique composites immersed in water and alkaline medium for construction application. Compos. Part B Eng. 2012, 43, 3120–3130. [Google Scholar] [CrossRef]

- Pereira, A.C.; De Assis, F.S.; Filho, F.D.C.G.; Oliveira, M.S.; Demosthenes, L.C.D.C.; Lopera, H.A.C.; Monteiro, S.N. Ballistic performance of multilayered armor with intermediate polyester composite reinforced with fique natural fabric and fibers. J. Mater. Res. Technol. 2019, 8, 4221–4226. [Google Scholar] [CrossRef]

- Salazar, M.A.H.; Correa, J.P.; Hidalgo-Salazar, A.M.; Juan, P. Mechanical and thermal properties of biocomposites from nonwoven industrial Fique fiber mats with Epoxy Resin and Linear Low Density Polyethylene. Results Phys. 2018, 8, 461–467. [Google Scholar] [CrossRef]

- Botina, R.; Mejía, M. Contribución al Conocimiento del Barniz o "Mopa-Mopa”, Elaeagia pastoensis Mora. Acta Agron. 1987, 37, 56–65. [Google Scholar]

- ASTM D638-14. Standard Test Method for Tensile Properties of Plastics; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.; Olayo, R.; Franco, P.J.H. Chemical modification of henequén fibers with an organosilane coupling agent. Compos. Part B Eng. 1999, 30, 321–331. [Google Scholar] [CrossRef]

- ASTM E104-02. Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D792-13. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM D3822-07. Standard Test Method for Tensile Properties of Single Textile Fibers; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Mina, J.H.; Valadez, A.; Franco, P.J.H.; Toledano, T. Influencia del tiempo de almacenamiento en las propiedades estructurales de un almidón termoplástico de yuca (TPS). Ingeniería y competitividad 2011, 11, 53–61. [Google Scholar] [CrossRef]

- Mina, J. Preparación y caracterización fisicoquímica y mecánica de materiales compuestos de PLA/PCL/TPS reforzados con fibras de fique. Ph.D. Thesis, Universidad del Valle, Cali, Colombia, 2010. [Google Scholar]

- Muñoz, M. Desarrollo y caracterización fisicoquímica y mecánica de un material compuesto de matriz PEBD/Al reforzado con fibras cortas de fique. Master’s Thesis, Universidad del Valle, Cali, Colombia, 2012. [Google Scholar]

- Muñoz-Vélez, M.F.; Salazar, M.A.H.; Hernandez, J.H.M. Effect of Content and Surface Modification of Fique Fibers on the Properties of a Low-Density Polyethylene (LDPE)-Al/Fique Composite. Polymers 2018, 10, 1050. [Google Scholar] [CrossRef]

- Dikobe, D.; Luyt, A. Thermal and mechanical properties of PP/HDPE/wood powder and MAPP/HDPE/wood powder polymer blend composites. Thermochim. Acta 2017, 654, 40–50. [Google Scholar] [CrossRef]

- Dehghani, S.; Peighambardoust, S.H.; Hosseini, S.V.; Regenstein, J.M. Improved mechanical and antibacterial properties of active LDPE films prepared with combination of Ag, ZnO and CuO nanoparticles. Food Packag. Shelf Life 2019, 22, 1–8. [Google Scholar] [CrossRef]

- Shogren, R. Effect of moisture content on the melting and subsequent physical aging of cornstarch. Carbohydr. Polym. 1992, 19, 83–90. [Google Scholar] [CrossRef]

- Delgado, A.; Aperador, W.; Gómez, W. Mejoramiento de las Propiedades de Tensión en WPC de LDPE: HIPS/Fibra Natural Mediante Entrecruzamiento con DCP. Polímeros Ciência e Tecnología. 2014, 24, 291–299. [Google Scholar]

- Lima, L.D.P.F.C.D.; Santana, R.M.C.; Chamorro, C.D. Influence of Coupling Agent in Mechanical, Physical and Thermal Properties of Polypropylene/Bamboo Fiber Composites: Under Natural Outdoor Aging. Polymers 2020, 12, 929. [Google Scholar] [CrossRef] [PubMed]

| Description | |

|---|---|

| Division | Trachelophyta |

| Subdivision | Angiospermae |

| Class | Dicotyledonae |

| Order | Rubiales |

| Family | Rubiaceae |

| Genus | Elaeagia |

| Species | Elaeagia pastoensis Mora |

| Shapes | Elaeagia pastoensis Mora fma pastoensis |

| Elaeagia pastoensis Mora fina acuminata Mora | |

| Synonym | Elaeagia pastoganomophora |

| Wavenumber (cm−1) | Type of Link | |||

|---|---|---|---|---|

| Dry Sample | HR 47% | HR 77% | HR 97% | |

| 2979.59 | 2976.70 | 2985.38 | 2977.66 | Tension C-H |

| 2951.04 | 2951.07 | 2952.45 | 2974.32 | Tension C-H |

| 1751.01 | 1751.00 | 1750.81 | 1751.11 | Tension C=O |

| 1656.55 | 1658.62 | 1656.55 | 1654.62 | Tension C=C |

| 1474.86 | 1473.96 | 1474.21 | 1475.38 | Tension C=C |

| 1394.64 | 1394.69 | 1394.80 | 1394.27 | C-O; C-H |

| 1293.28 | 1293.85 | 1294.20 | 1292.83 | C-O; C-H |

| 1203.09 | 1201.79 | 1203.06 | 1200.74 | C-O; C-H |

| 1123.33 | 1123.15 | 1123.70 | 1123.29 | C-O; C-H |

| 1055.42 | 1056.63 | 1054.87 | 1055.59 | C-O; C-H |

| Time 1 (Before Conditioning) | Time 2 (3 Days of Conditioning) | Time 3 (15 Days of Conditioning) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | Strain (mm/mm) | Young’s Modulus (MPa) | Tensile Strength (MPa) | Strain (mm/mm) | Young’s Modulus (MPa) | Tensile Strength (MPa) | Strain (mm/mm) | Young’s Modulus (MPa) | |

| MM HR 97% | 10.42 ± 1.83 | 1.44 ± 0.63 | 35.78 ± 5.22 | 3.15 ± 0.65 | 1.36 ± 0.35 | 3.27 | 2.36 ± 0.82 | 0.89 ± 0.30 | 3.18 |

| MM HR 77% | 5.51 ± 1.00 | 1.37 ± 0.37 | 11.44 | 3.9 ± 1.43 | 1.11 ± 0.36 | 7.10 | |||

| MM HR 47% | 7.21 ± 1.59 | 1.43 ± 0.39 | 23.03 | 11.6 ± 2.53 | 0.89 ± 0.34 | 20.09 | |||

| MM/FN 10 (HR 97%) | 11.34 ± 4.44 | 0.09 ± 0.02 | 739.8 | 7.21 ± 2.15 | 0.06 ± 0.03 | 627.21 | 6.36 ± 1.47 | 0.09 ± 0.03 | 267.04 |

| MM/FN 10 (HR 77%) | 10.51 ± 1.92 | 0.13 ± 0.03 | 512.84 | 8.53 ± 1.34 | 0.14 ± 0.03 | 325.83 | |||

| MM/FN 10 (HR 47%) | 15.13 ± 1.77 | 0.07 ± 0.02 | 920.29 | 12.16 ± 1.08 | 0.19 ± 0.04 | 857.65 | |||

| MM/FA 10 (HR 97%) | 15.07 ± 2.68 | 0.01 ± 0.02 | 1321.98 | 6.73 ± 1.04 | 0.13 ± 0.04 | 545.12 | 4.25 ± 0.68 | 0.17 ± 0.04 | 143.37 |

| MM/FA 10 (HR 77%) | 11.7 ± 1.34 | 0.10 ± 0.03 | 790.57 | 8.05 ± 0.87 | 0.14 ± 0.06 | 325.14 | |||

| MM/FA 10 (HR 47%) | 19.57 ± 2.25 | 0.1 ± 0.04 | 817.75 | 10.2 ± 1.24 | 0.14 ± 0.03 | 590.32 | |||

| MM/FN 20 (HR 97%) | 20.02 ± 7.99 | 0.05 ± 0.01 | 1135.86 | 7.52 ± 1.55 | 0.11 ± 0.03 | 288.54 | 6.09 ± 0.94 | 0.25 ± 0.06 | 201.62 |

| MM/FN 20 (HR 77%) | 10.96 ± 2.25 | 0.09 ± 0.02 | 688.83 | 10.87 ± 2.56 | 0.04 ± 0.02 | 621.69 | |||

| MM/FN 20 (HR 47%) | 16.17 ± 4.55 | 0.04 ± 0.01 | 1022.74 | 15.22 ± 2.54 | 0.02 ± 0.01 | 872.45 | |||

| MM/FA 20 (HR 97%) | 32.73 ± 10.13 | 0.02 ± 0.01 | 2128.36 | 12.85 ± 2.48 | 0.08 ± 0.03 | 483.14 | 5.98 ± 0.74 | 0.12 ± 0.04 | 388.62 |

| MM/FA 20 (HR 77 %) | 16.65 ± 4.14 | 0.06 ± 0.02 | 1667.61 | 7.43 ± 2.76 | 0.09 ± 0.02 | 400.55 | |||

| MM/FA 20 (HR 47 %) | 28.85 ± 6.63 | 0.05 ± 0.01 | 1667.61 | 18.49 ± 4.23 | 0.03 ± 0.01 | 1417.07 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mina Hernandez, J.H.; Toro Perea, E.F.; Caicedo Mejía, K.; Meneses Jacobo, C.A. Effect of Fique Fibers in the Behavior of a New Biobased Composite from Renewable Mopa-Mopa Resin. Polymers 2020, 12, 1573. https://doi.org/10.3390/polym12071573

Mina Hernandez JH, Toro Perea EF, Caicedo Mejía K, Meneses Jacobo CA. Effect of Fique Fibers in the Behavior of a New Biobased Composite from Renewable Mopa-Mopa Resin. Polymers. 2020; 12(7):1573. https://doi.org/10.3390/polym12071573

Chicago/Turabian StyleMina Hernandez, José Herminsul, Edward Fernando Toro Perea, Katherine Caicedo Mejía, and Claudia Alejandra Meneses Jacobo. 2020. "Effect of Fique Fibers in the Behavior of a New Biobased Composite from Renewable Mopa-Mopa Resin" Polymers 12, no. 7: 1573. https://doi.org/10.3390/polym12071573

APA StyleMina Hernandez, J. H., Toro Perea, E. F., Caicedo Mejía, K., & Meneses Jacobo, C. A. (2020). Effect of Fique Fibers in the Behavior of a New Biobased Composite from Renewable Mopa-Mopa Resin. Polymers, 12(7), 1573. https://doi.org/10.3390/polym12071573