Mercerization Optimization of Bamboo (Bambusa vulgaris) Fiber-Reinforced Epoxy Composite Structures Using a Box–Behnken Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Design of the Experiment

2.2. Experimental Method

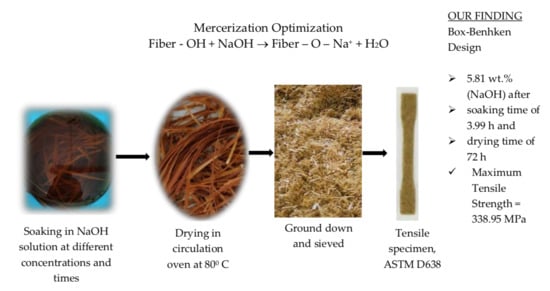

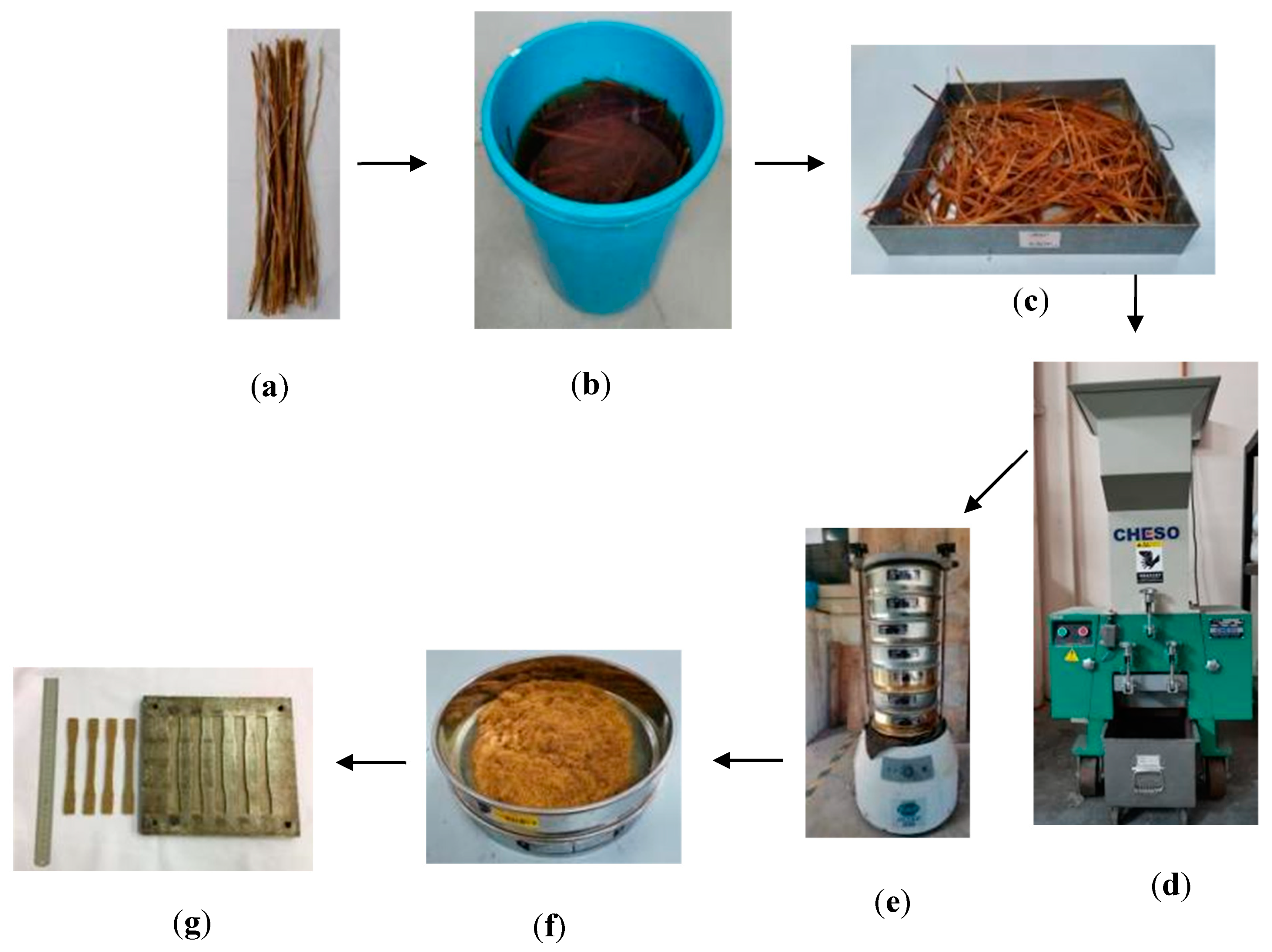

2.2.1. Alkaline Treatment and Bamboo Fiber-Reinforced Epoxy

2.2.2. Tensile Test of Bamboo Fiber-Reinforced Epoxy

2.2.3. Compression Test of Bamboo Fiber-Reinforced Epoxy Structure

3. Results and Discussion

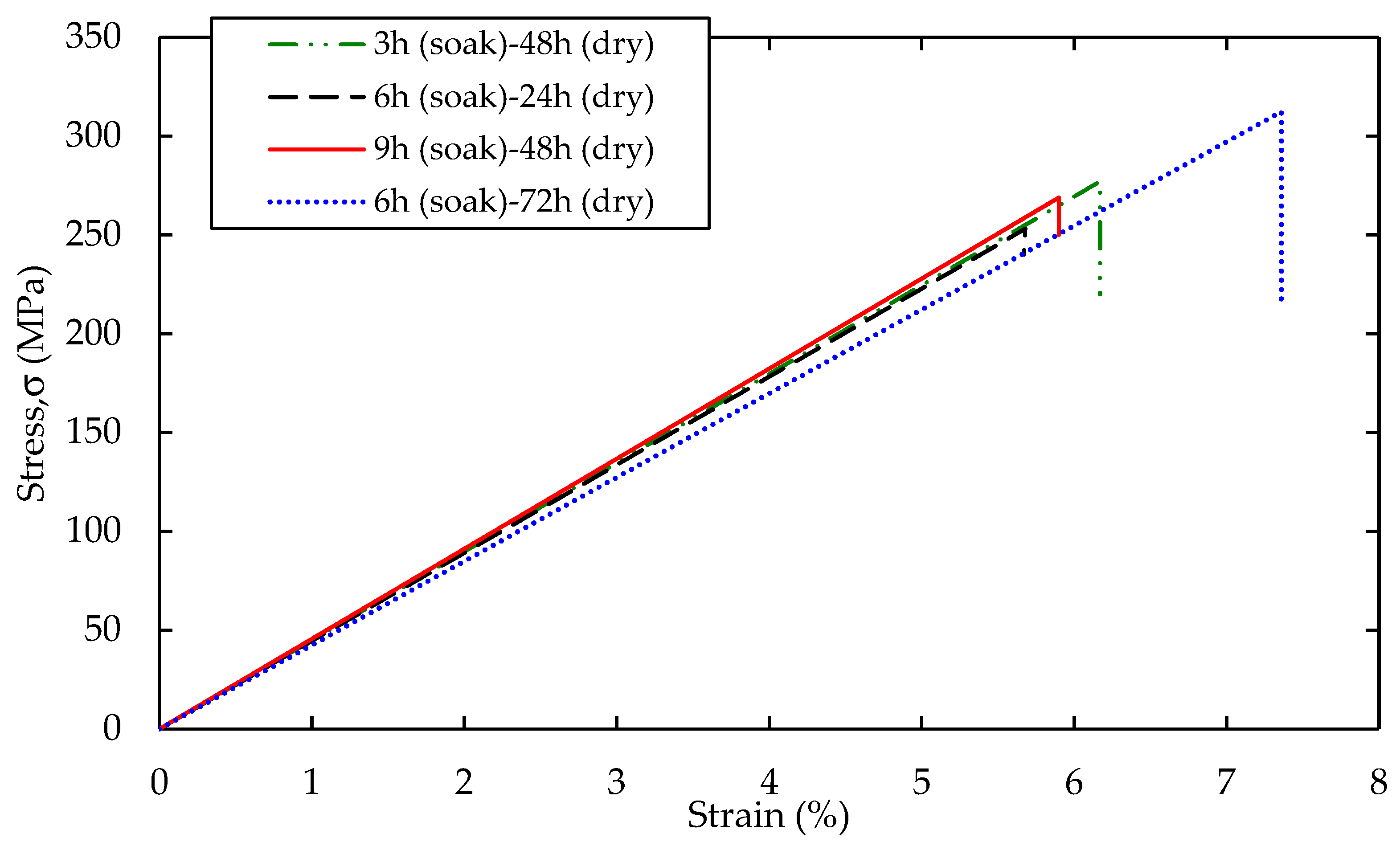

3.1. Tensile Properties of Bamboo Reinforced Epoxy Composites

3.2. Box Behnken Design (BBD) Analysis of Treated Bamboo Reinforced Epoxy Composites

− 0.27(X1 X2) + 0.066(X1 X3) − 0.073(X2 X3)

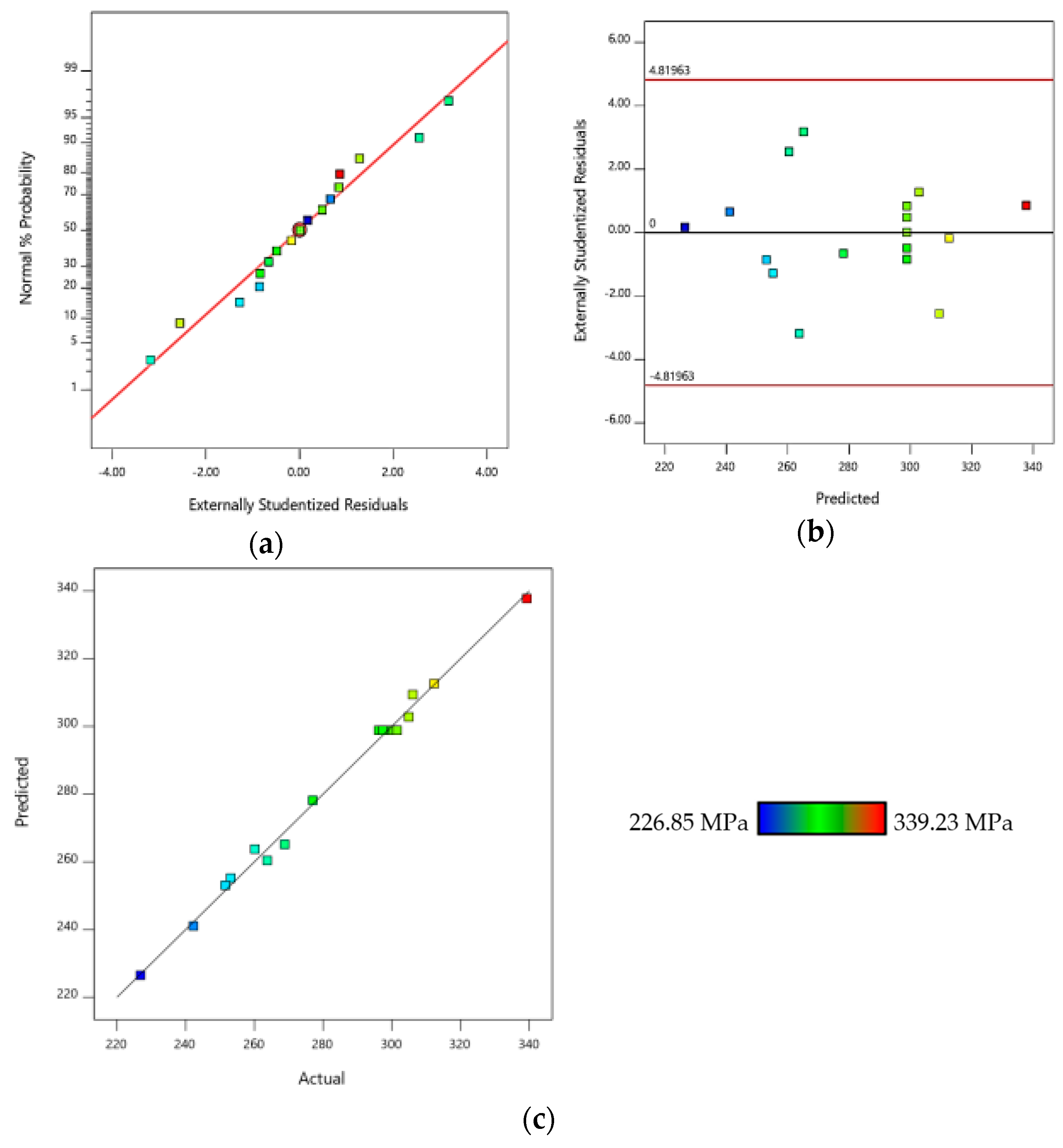

3.3. Diagnostic Plots of the Composites

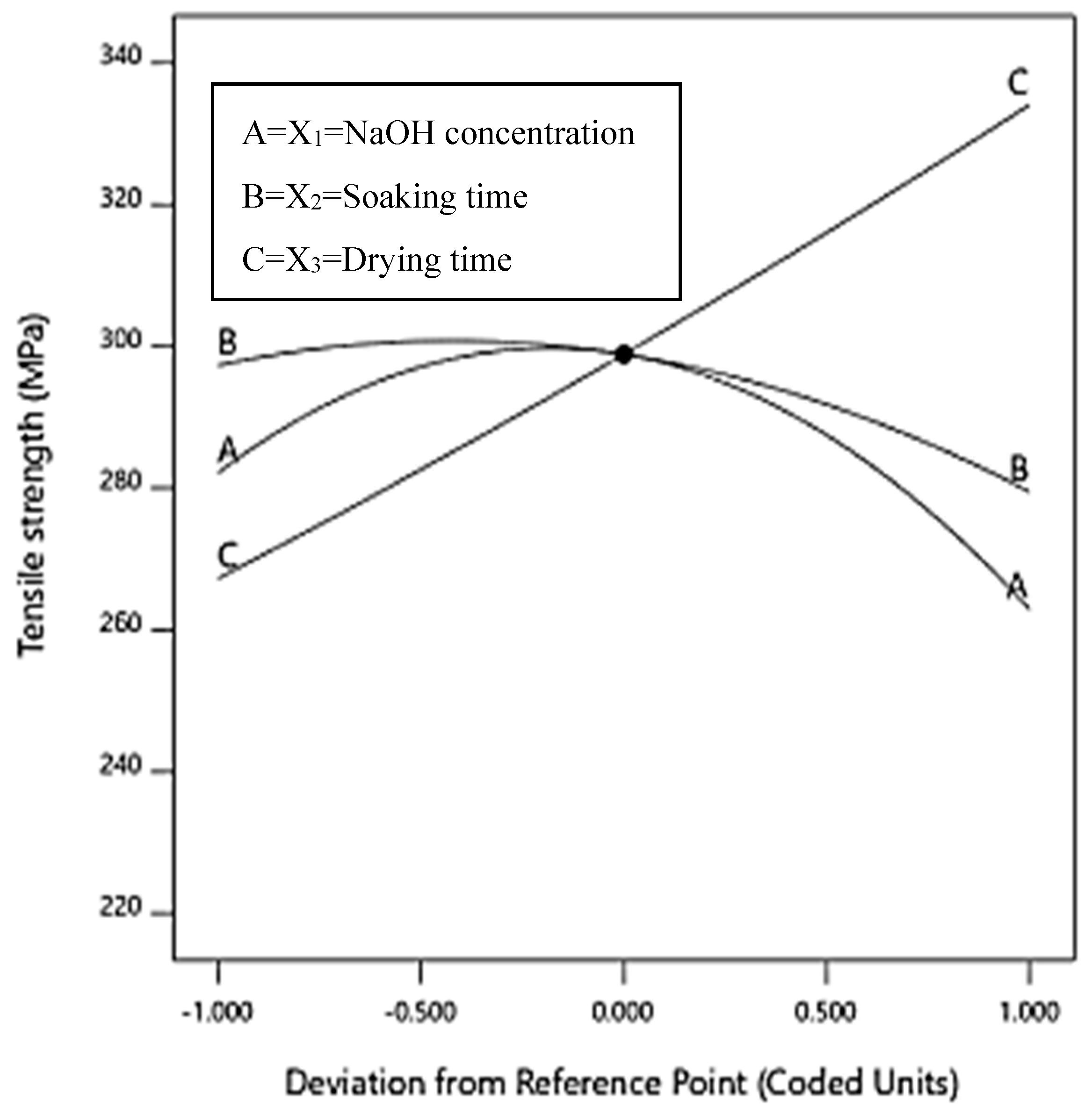

3.4. Response Surface Plots

3.5. Condition Optimization and Confirmation Tests

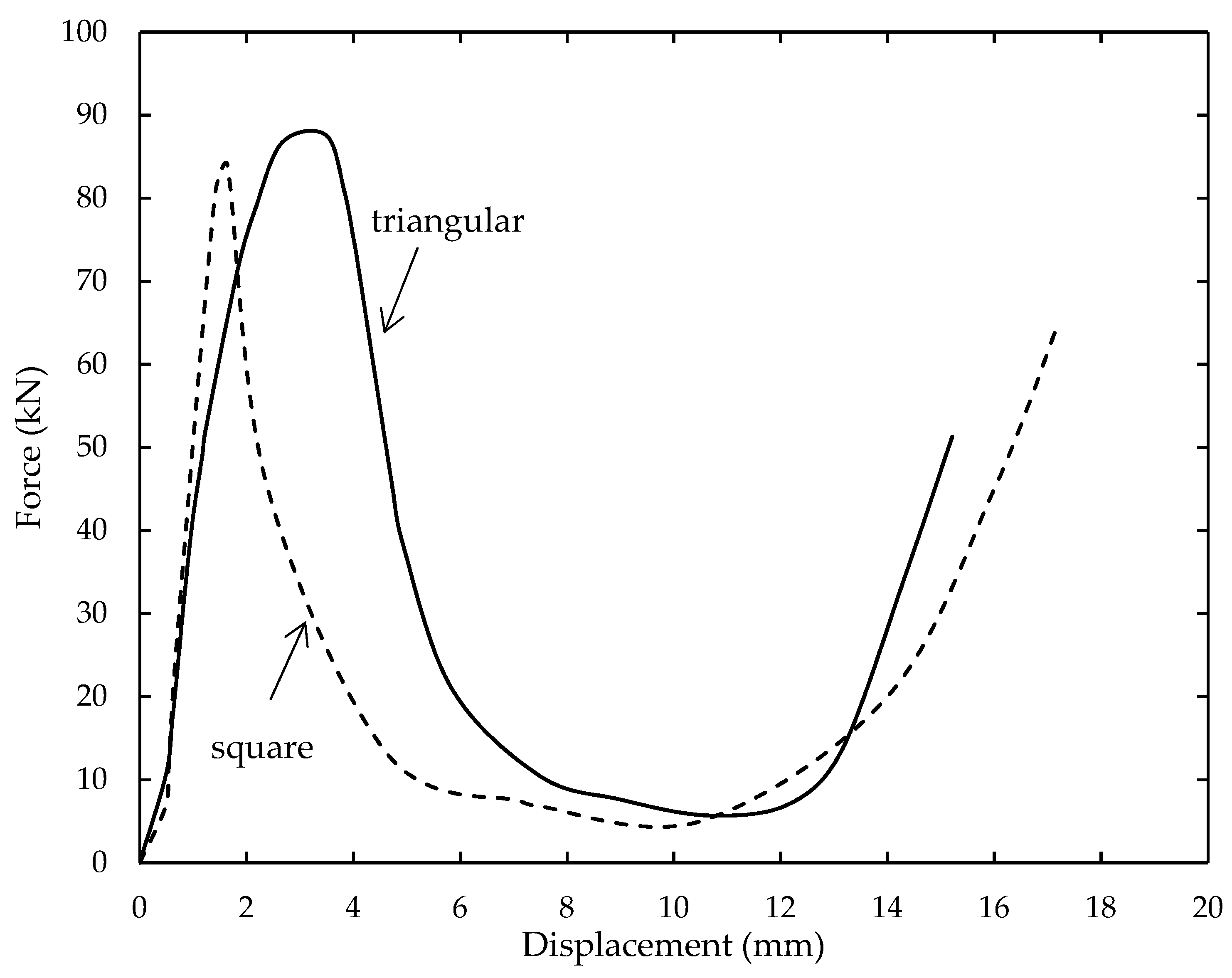

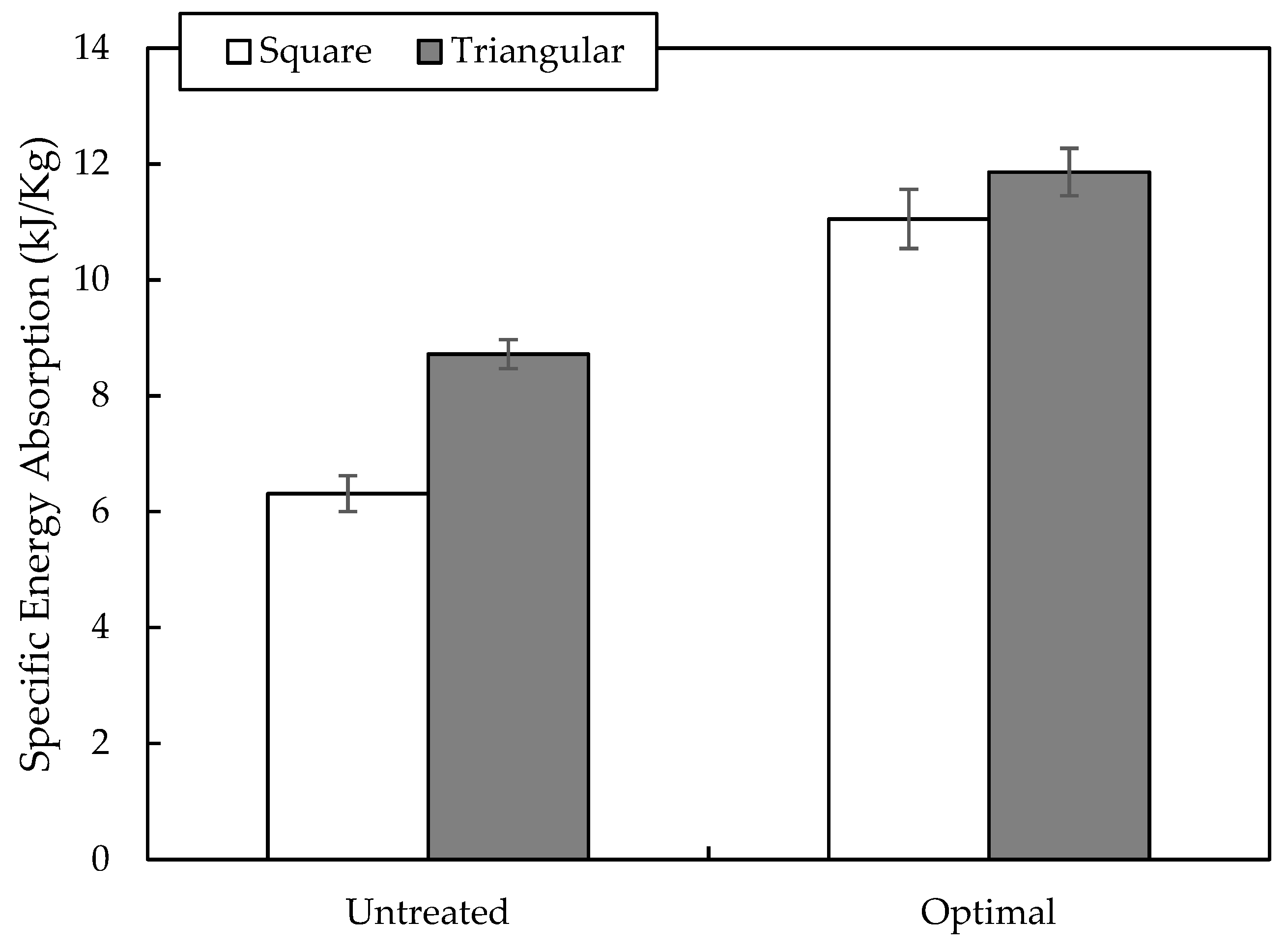

3.6. Compression Properties of Bamboo Reinforced Epoxy Structures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, J.; Hassan, M.Z.; Guan, Z.; Cantwell, W.J. The low velocity impact response of foam-based sandwich panels. Compos. Sci. Technol. 2012, 72, 1781–1790. [Google Scholar] [CrossRef]

- Hassan, M.; Guan, Z.; Cantwell, W.; Langdon, G.; Nurick, G. The influence of core density on the blast resistance of foam-based sandwich structures. Int. J. Impact. 2012, 50, 9–16. [Google Scholar] [CrossRef]

- Hassan, M.; Cantwell, W. The influence of core properties on the perforation resistance of sandwich structures–an experimental study. Compos. Part B Eng. 2012, 43, 3231–3238. [Google Scholar] [CrossRef]

- Enayati, M.S.; Behzad, T.; Sajkiewicz, P.; Bagheri, R.; Ghasemi-Mobarakeh, L.; Pierini, F. Theoretical and experimental study of the stiffness of electrospun composites of poly (vinyl alcohol), cellulose nanofibers, and nanohydroxy apatite. Cellulose 2018, 25, 65–75. [Google Scholar] [CrossRef]

- Enayati, M.S.; Neisiany, R.E.; Sajkiewicz, P.; Behzad, T.; Denis, P.; Pierini, F. Effect of nanofiller incorporation on thermomechanical and toughness of poly (vinyl alcohol)-based electrospun nanofibrous bionanocomposites. Theor. Appl. Fract. Mec. 2019, 99, 44–50. [Google Scholar] [CrossRef]

- Ibrahim, M.I.; Dolah, R.; Zuhri, M.; Sharif, S.; Hassan, M. Chemical treatment evaluation of tensile properties for single Kenaf fiber. J. Adv. Res. Appl. Mech. 2016, 32, 9–14. [Google Scholar]

- Hassan, M.Z.; Sapuan, S.; Roslan, S.A.; Sarip, S. Optimization of tensile behavior of banana pseudo-stem (Musa acuminate) fiber-reinforced epoxy composites using response surface methodology. J. Mater. Res. Technol. 2019, 8, 3517–3528. [Google Scholar] [CrossRef]

- Alaaeddin, M.; Sapuan, S.; Zuhri, M.; Zainudin, E.; AL-Oqla, F.M. Physical and Mechanical Properties of Polyvinylidene Fluoride-Short Sugar Palm Fiber Nanocomposites. J. Clean. Prod. 2019, 235, 473–482. [Google Scholar] [CrossRef]

- Khan, Z.; Yousif, B.; Islam, M. Fracture behaviour of bamboo fiber-reinforced epoxy composites. Compos. Part B Eng. 2017, 116, 186–199. [Google Scholar] [CrossRef]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Li, Y.; Waterhouse, G.I. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 589–597. [Google Scholar] [CrossRef]

- Manalo, A.C.; Wani, E.; Zukarnain, N.A.; Karunasena, W.; Lau, K.-t. Effects of alkali treatment and elevated temperature on the mechanical properties of bamboo fiber–polyester composites. Compos. Part B Eng. 2015, 80, 73–83. [Google Scholar] [CrossRef]

- Raghavendra Rao, H.; Varada Rajulu, A.; Ramachandra Reddy, G.; Hemachandra Reddy, K. Flexural and compressive properties of bamboo and glass fiber-reinforced epoxy hybrid composites. J. Reinf. Plast. Compos. 2010, 29, 1446–1450. [Google Scholar] [CrossRef]

- Nirmal, U.; Lau, S.T.; Hashim, J. Interfacial adhesion characteristics of kenaf fibers subjected to different polymer matrices and fiber treatments. J. Compos. 2014, 2014, 350737. [Google Scholar] [CrossRef]

- Vardhini, K.; Murugan, R.; Selvi, C.; Surjit, R. Optimization of alkali treatment of banana fibers on lignin removal. Indian J. Fibre Text. Res. 2016, 41, 156–160. [Google Scholar]

- Kim, I.; Han, J.-I. Optimization of alkaline pretreatment conditions for enhancing glucose yield of rice straw by response surface methodology. Biomass Bioenerg. 2012, 46, 210–217. [Google Scholar] [CrossRef]

- Singh, V.K.; Mukhopadhyay, S.; Das, D. Recipe optimization for sugarcane bagasse fiber-reinforced soy protein biocomposite. Indian J. Fibre Text. Res. 2017, 42, 132–137. [Google Scholar]

- Mishra, S.; Mohanty, A.; Drzal, L.; Misra, M.; Parija, S.; Nayak, S.; Tripathy, S. Studies on mechanical performance of biofiber/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Jayabal, S.; Sathiyamurthy, S.; Loganathan, K.; Kalyanasundaram, S. Effect of soaking time and concentration of NaOH solution on mechanical properties of coir–polyester composites. Bullet. Mater. Sci. 2012, 35, 567–574. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, L.; Xiong, C.; Peng, W. Effect of different surface treatment for bamboo fiber on the crystallization behavior and mechanical property of bamboo fiber/nanohydroxyapatite/poly (lactic-co-glycolic) composite. Ind. Eng. Chem. Res. 2015, 54, 12017–12024. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Sapuan, S.; Rasid, Z.A.; Nor, A.F.M.; Dolah, R.; Md Daud, M.Y. Impact damage resistance and post-impact tolerance of optimum banana-pseudo-stem-fiber-reinforced epoxy sandwich structures. Appl. Sci. 2020, 10, 684. [Google Scholar] [CrossRef]

- ASTM International. ASTM International. ASTM D638-14. In Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar] [CrossRef]

- Zuhri, M.; Guan, Z.; Cantwell, W. The mechanical properties of natural fiber based honeycomb core materials. Compos. Part B Eng. 2014, 58, 1–9. [Google Scholar] [CrossRef]

- ASTM International. ASTM International. ASTM C365/365M-16. In Standard Test Method for Flatwise Compressive Properties of Sandwich Cores; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Rout, J.; Misra, M.; Tripathy, S.; Nayak, S.; Mohanty, A. The influence of fiber treatment on the performance of coir-polyester composites. Compos. Sci. Technol. 2001, 61, 1303–1310. [Google Scholar] [CrossRef]

- El-Shekeil, Y.; Sapuan, S.; Khalina, A.; Zainudin, E.; Al-Shuja’a, O. Effect of alkali treatment on mechanical and thermal properties of Kenaf fiber-reinforced thermoplastic polyurethane composite. J. Therm. Anal. Calorim. 2012, 109, 1435–1443. [Google Scholar] [CrossRef]

- Zikri, M.; Ridzuan, M.; Majid, M.A.; Afendi, M.; Basaruddin, K. Effects of fiber loading and moisture absorption on the tensile properties of hybrid Napier/glass/epoxy composites. J. Phys. Conf. 2017, 1, 012014. [Google Scholar] [CrossRef]

- Girisha, C.; Sanjeevamurthy, G.; Srinivas, G. Sisal/coconut coir natural fibers-epoxy composites: Water absorption and mechanical properties. Int. J. Eng. Innov. Technol. 2012, 2, 166–170. [Google Scholar]

- Misra, S.; Misra, M.; Tripathy, S.; Nayak, S.; Mohanty, A. The influence of chemical surface modification on the performance of sisal-polyester biocomposites. Polym. Compos. 2002, 23, 164–170. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Hassani, F.O.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF–Polyurethane composite. S. Afr. J. Chem. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Joglekar, A.; May, A. Product excellence through design of experiments. Cereal Foods World 1987, 32, 857–868. [Google Scholar] [CrossRef]

- Manzato, L.; Takeno, M.L.; Pessoa-Junior, W.A.G.; Mariuba, L.A.M.; Simonsen, J. Optimization of cellulose extraction from jute fiber by Box–Behnken design. Fibers Polym. 2018, 19, 289–296. [Google Scholar] [CrossRef]

- Qiu, P.; Cui, M.; Kang, K.; Park, B.; Son, Y.; Khim, E.; Jang, M.; Khim, J. Application of Box–Behnken design with response surface methodology for modeling and optimizing ultrasonic oxidation of arsenite with H2O2. Open Chem. 2014, 12, 164–172. [Google Scholar] [CrossRef]

- Wu, L.; Yick, K.-L.; Ng, S.-P.; Yip, J. Application of the Box–Behnken design to the optimization of process parameters in foam cup molding. Expert Syst. Appl. 2012, 39, 8059–8065. [Google Scholar] [CrossRef]

- Sari, N.H.; Wardana, I.; Irawan, Y.S.; Siswanto, E. The effect of sodium hydroxide on chemical and mechanical properties of corn husk fiber. Orient. J. Chem. 2017, 33, 3037–3042. [Google Scholar] [CrossRef]

- Abu, M.L.; Nooh, H.M.; Oslan, S.N.; Salleh, A.B. Optimization of physical conditions for the production of thermostable T1 lipase in Pichia guilliermondii strain SO using response surface methodology. BMC Biotechnol. 2017, 17, 78. [Google Scholar] [CrossRef] [PubMed]

- Rauf, M.; Marzouki, N.; Körbahti, B.K. Photolytic decolorization of Rose Bengal by UV/H2O2 and data optimization using response surface method. J. Hazard. Mater. 2008, 159, 602–609. [Google Scholar] [CrossRef]

- Ammayappan, L.; Shakyawar, D.; Gupta, N. Optimization of dyeing condition for wool/cotton union fabric with direct dye using Box–Behnken design. Fibers Polym. 2011, 12, 957. [Google Scholar] [CrossRef]

- Karthikeyan, K.; Nanthakumar, K.; Shanthi, K.; Lakshmanaperumalsamy, P. Response surface methodology for optimization of culture conditions for dye decolorization by a fungus, Aspergillus niger HM11 isolated from dye affected soil. Iran J. Microbiol. 2010, 2, 213. [Google Scholar]

- Fu, J.; Zhao, Y.; Wu, Q. Optimising photoelectrocatalytic oxidation of fulvic acid using response surface methodology. J. Hazard. Mater. 2007, 144, 499–505. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, F.; Liang, W.; Wang, Z.; Duan, Z.; Yang, B. Thermal and mechanical properties of bamboo fiber-reinforced epoxy composites. Polymers 2018, 10, 608. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Nasir, M. Effect of alkali treatments on physical and mechanical strength of pineapple leaf fibers. IOP Conf. Ser. Mater. Sci. Eng. 2018, 290, 012030. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, S.; Yang, M.; Chen, Z.; Ran, S. Thermo-mechanical performance of polylactide composites reinforced with alkali-treated bamboo fibers. Polymers 2018, 10, 401. [Google Scholar] [CrossRef]

- Qian, S.; Mao, H.; Sheng, K.; Lu, J.; Luo, Y.; Hou, C. Effect of low-concentration alkali solution pretreatment on the properties of bamboo particles reinforced poly (lactic acid) composites. J. Appl. Polym. Sci. 2013, 130, 1667–1674. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Effect of silanes on mechanical properties of bamboo fiber-epoxy composites. J. Reinf. Plast. Compos. 2010, 29, 718–724. [Google Scholar] [CrossRef]

- Yamashita, M.; Gotoh, M. Impact behavior of honeycomb structures with various cell specifications—Numerical simulation and experiment. Int. J. Impact. 2005, 32, 618–630. [Google Scholar] [CrossRef]

- Hazizan, M.A.; Cantwell, W. The low velocity impact response of an aluminium honeycomb sandwich structure. Compos. Part B Eng. 2003, 34, 679–687. [Google Scholar] [CrossRef]

| Independent Variables | Symbols | Coded and Actual Levels | ||

|---|---|---|---|---|

| Low (−1) | Middle (0) | High (+1) | ||

| Concentration of NaOH (wt.%) | X1 | 3 | 6 | 9 |

| Soaking duration (hours) | X2 | 3 | 6 | 9 |

| Drying duration (hours) | X3 | 24 | 48 | 72 |

| RUN | Independent Variables | |||||

|---|---|---|---|---|---|---|

| Coded Values | Actual Values | |||||

| X1 | X2 | X3 | X1 | X2 | X3 | |

| 1 | 0 | +1 | −1 | 6 | 9 | 24 |

| 2 | 0 | 0 | 0 | 6 | 6 | 48 * |

| 3 | 0 | −1 | −1 | 6 | 3 | 24 |

| 4 | 0 | 0 | 0 | 6 | 6 | 48 * |

| 5 | 0 | +1 | +1 | 6 | 9 | 72 |

| 6 | +1 | −1 | 0 | 9 | 3 | 48 |

| 7 | 0 | 0 | 0 | 6 | 6 | 48 * |

| 8 | 0 | −1 | +1 | 6 | 3 | 72 |

| 9 | −1 | +1 | 0 | 3 | 9 | 48 |

| 10 | +1 | 0 | +1 | 9 | 6 | 72 |

| 11 | 0 | 0 | 0 | 6 | 6 | 48 * |

| 12 | −1 | −1 | 0 | 3 | 3 | 48 |

| 13 | −1 | 0 | +1 | 3 | 6 | 72 |

| 14 | −1 | 0 | −1 | 3 | 6 | 24 |

| 15 | 0 | 0 | 0 | 6 | 6 | 48 * |

| 16 | +1 | +1 | 0 | 9 | 9 | 48 |

| 17 | +1 | 0 | −1 | 9 | 6 | 24 |

| No. | Conditions | Tensile Strength, σ (MPa) | Strain at Break, ε (%) | Young’s Modulus E (GPa) |

|---|---|---|---|---|

| 0 | Untreated bamboo fiber | 138.88 ± 1.23 | 2.70 ± 0.45 | 4.96 ± 0.23 |

| 1 | 3 wt.% NaOH + 3 h soak + 48 h dry | 276.98 ± 1.45 | 7.68 ± 3.30 | 3.05 ± 0.84 |

| 2 | 3 wt.% NaOH + 6 h soak + 24 h dry | 253.09 ± 6.23 | 7.25 ± 1.33 | 3.66 ± 0.92 |

| 3 | 3 wt.% NaOH + 6 h soak + 72 h dry | 312.29 ± 2.45 | 8.49 ± 2.47 | 3.14 ± 0.62 |

| 4 | 3 wt.% NaOH + 9 h soak + 48 h dry | 268.82 ± 3.35 | 6.67 ± 1.78 | 3.74 ± 0.56 |

| 5 | 6 wt.% NaOH + 3 h soak + 24 h dry | 263.74 ± 2.25 | 5.90 ± 2.13 | 3.78 ± 0.72 |

| 6 | 6 wt.% NaOH + 3 h soak + 72 h dry | 339.27 ± 3.36 | 8.33 ± 2.73 | 3.70 ± 0.31 |

| 7 | 6 wt.% NaOH + 6 h soak + 48 h dry | 296.19 ± 4.26 | 7.59 ± 1.55 | 3.25 ± 0.69 |

| 8 | 6 wt.% NaOH + 9 h soak + 24 h dry | 301.52 ± 7.45 | 8.45 ± 3.34 | 3.00 ± 0.46 |

| 9 | 6 wt.% NaOH + 9 h soak + 72 h dry | 296.19 ± 4.26 | 7.59 ± 1.55 | 3.25 ± 0.69 |

| 10 | 9 wt.% NaOH + 3 h soak + 48 h dry | 260.13 ± 1.73 | 5.68 ± 2.05 | 4.50 ± 0.13 |

| 11 | 9 wt.% NaOH + 6 h soak + 24 h dry | 226.85 ± 0.83 | 7.36 ± 0.86 | 3.43 ± 0.55 |

| 12 | 9 wt.% NaOH + 6 h soak + 72 h dry | 304.92 ± 2.45 | 8.49 ± 2.47 | 3.14 ± 0.62 |

| 13 | 9 wt.% NaOH + 9 h soak + 48 h dry | 242.25 ± 2.24 | 6.17 ± 1.06 | 4.39 ± 0.37 |

| Run | Independent Variables | Tensile Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Coded Values | Actual Values | Experimental | Predicted | Residual | Error (%) | |||||

| X1 | X2 | X3 | X1 | X2 | X3 | |||||

| 1 | −1 | 0 | +1 | 3 | 6 | 72 | 312.29 | 312.61 | −0.325 | −0.102 |

| 2 | +1 | 0 | −1 | 9 | 6 | 24 | 226.85 | 226.53 | 0.325 | 0.141 |

| 3 | 0 | −1 | −1 | 6 | 3 | 24 | 263.74 | 260.42 | 3.32 | 1.259 |

| 4 | 0 | 0 | 0 | 6 | 6 | 48 | 298.89 | 298.86 | 0.03 | 0.010 |

| 5 | −1 | −1 | 0 | 3 | 3 | 48 | 276.98 | 278.17 | −1.19 | −0.430 |

| 6 | 0 | +1 | +1 | 6 | 9 | 72 | 306.08 | 309.40 | −3.32 | −1.085 |

| 7 | 0 | −1 | +1 | 6 | 3 | 72 | 339.27 | 337.75 | 1.52 | 0.448 |

| 8 | +1 | −1 | 0 | 9 | 3 | 48 | 260.13 | 263.77 | −3.64 | −1.399 |

| 9 | 0 | 0 | 0 | 6 | 6 | 48 | 301.52 | 298.86 | 2.66 | 0.882 |

| 10 | 0 | 0 | −1 | 6 | 9 | 24 | 251.55 | 253.07 | −1.52 | −0.604 |

| 11 | 0 | 0 | 0 | 6 | 6 | 48 | 297.25 | 298.86 | −1.61 | −0.542 |

| 12 | +1 | 0 | +1 | 9 | 6 | 72 | 304.92 | 302.79 | 2.13 | 0.699 |

| 13 | −1 | 0 | −1 | 3 | 6 | 24 | 253.09 | 255.22 | −2.13 | −0.842 |

| 14 | 0 | 0 | 0 | 6 | 6 | 48 | 300.45 | 298.86 | 1.59 | 0.529 |

| 15 | 0 | 0 | 0 | 6 | 6 | 48 | 296.19 | 298.86 | −2.67 | −0.901 |

| 16 | +1 | +1 | 0 | 9 | 9 | 48 | 242.25 | 241.06 | 1.19 | 0.491 |

| 17 | −1 | +1 | 0 | 3 | 9 | 48 | 268.82 | 265.18 | 3.64 | 1.354 |

| Source | Response Value |

|---|---|

| R-Squared (R2) | 0.994 |

| Adjusted R-Squared | 0.986 |

| Predicted R-Squared | 0.924 |

| Standard Deviation | 3.480 |

| C.V. % | 1.230 |

| Adequate Precision | 41.71 |

| Mean | 282.37 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value (Prob > F) |

|---|---|---|---|---|---|

| Model | 14051.43 | 9 | 1561.27 | 129.17 | <0.0001 * |

| X1- concentration | 741.7 | 1 | 741.7 | 61.36 | 0.0001 |

| X2- soaking | 637.6 | 1 | 637.6 | 52.75 | 0.0002 |

| X3- drying | 8933.17 | 1 | 8933.17 | 739.08 | <0.0001 |

| X12 | 23.62 | 1 | 23.62 | 1.95 | 0.2048 |

| X22 | 89.02 | 1 | 89.02 | 7.36 | 0.03 |

| X32 | 110.25 | 1 | 110.25 | 9.12 | 0.0194 |

| X1 X2 | 2922.08 | 1 | 2922.08 | 241.76 | <0.0001 |

| X1 X3 | 461.67 | 1 | 461.67 | 38.2 | 0.0005 |

| X2 X3 | 13.21 | 1 | 13.21 | 1.09 | 0.3306 |

| Residual | 84.61 | 7 | 12.09 | ||

| Lack of Fit | 65.28 | 3 | 21.76 | 4.5 | 0.09 ** |

| Pure Error | 19.33 | 4 | 4.83 | ||

| Cor total | 14136.03 | 16 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, M.Z.; Roslan, S.A.; Sapuan, S.M.; Rasid, Z.A.; Mohd Nor, A.F.; Md Daud, M.Y.; Dolah, R.; Mohamed Yusoff, M.Z. Mercerization Optimization of Bamboo (Bambusa vulgaris) Fiber-Reinforced Epoxy Composite Structures Using a Box–Behnken Design. Polymers 2020, 12, 1367. https://doi.org/10.3390/polym12061367

Hassan MZ, Roslan SA, Sapuan SM, Rasid ZA, Mohd Nor AF, Md Daud MY, Dolah R, Mohamed Yusoff MZ. Mercerization Optimization of Bamboo (Bambusa vulgaris) Fiber-Reinforced Epoxy Composite Structures Using a Box–Behnken Design. Polymers. 2020; 12(6):1367. https://doi.org/10.3390/polym12061367

Chicago/Turabian StyleHassan, Mohamad Zaki, Siti Amni Roslan, S. M. Sapuan, Zainudin A. Rasid, Ariff Farhan Mohd Nor, Mohd Yusof Md Daud, Rozzeta Dolah, and Mohd Zuhri Mohamed Yusoff. 2020. "Mercerization Optimization of Bamboo (Bambusa vulgaris) Fiber-Reinforced Epoxy Composite Structures Using a Box–Behnken Design" Polymers 12, no. 6: 1367. https://doi.org/10.3390/polym12061367

APA StyleHassan, M. Z., Roslan, S. A., Sapuan, S. M., Rasid, Z. A., Mohd Nor, A. F., Md Daud, M. Y., Dolah, R., & Mohamed Yusoff, M. Z. (2020). Mercerization Optimization of Bamboo (Bambusa vulgaris) Fiber-Reinforced Epoxy Composite Structures Using a Box–Behnken Design. Polymers, 12(6), 1367. https://doi.org/10.3390/polym12061367