Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

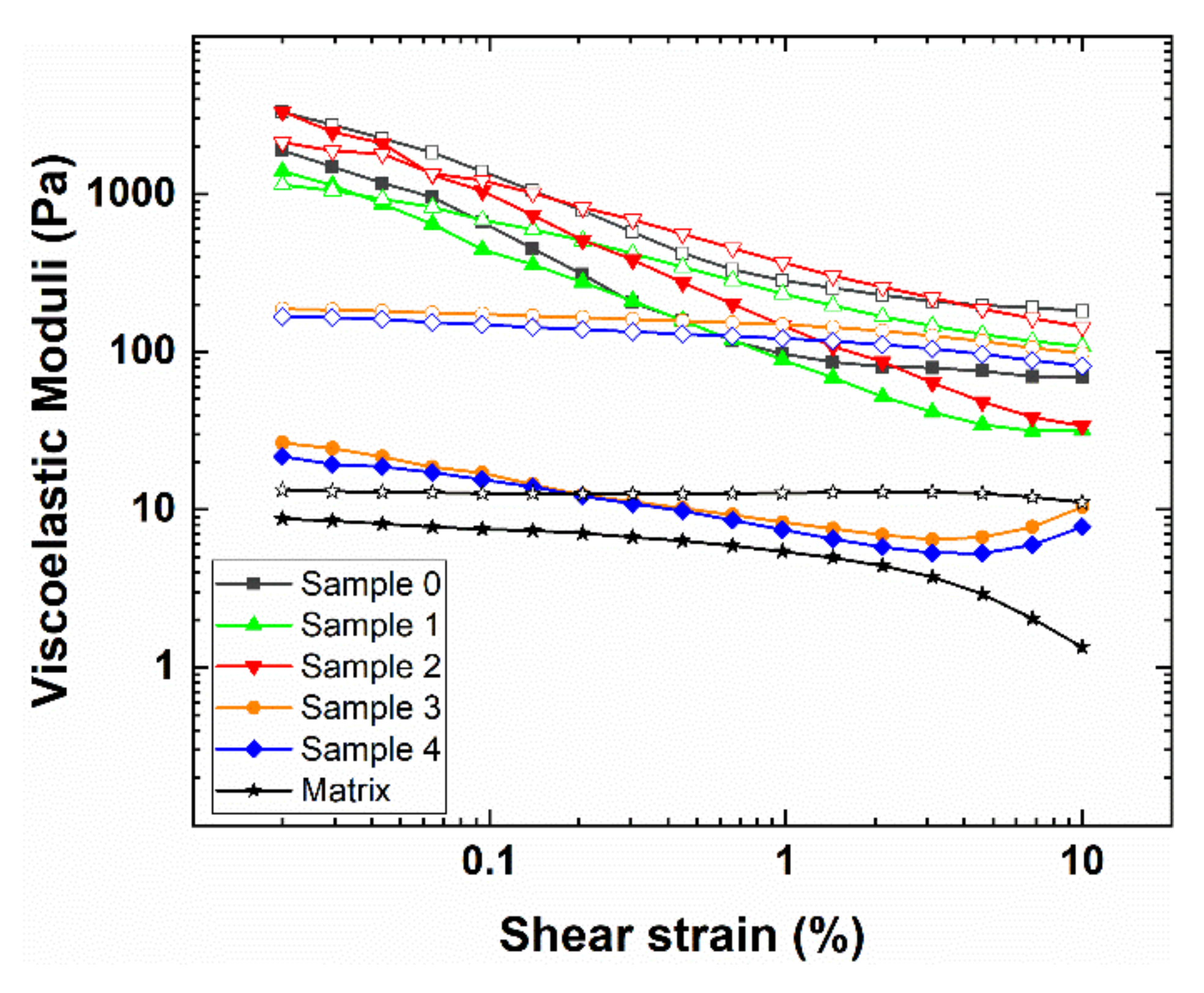

3.1. Rheological Measurements

3.2. Mechanical Tests

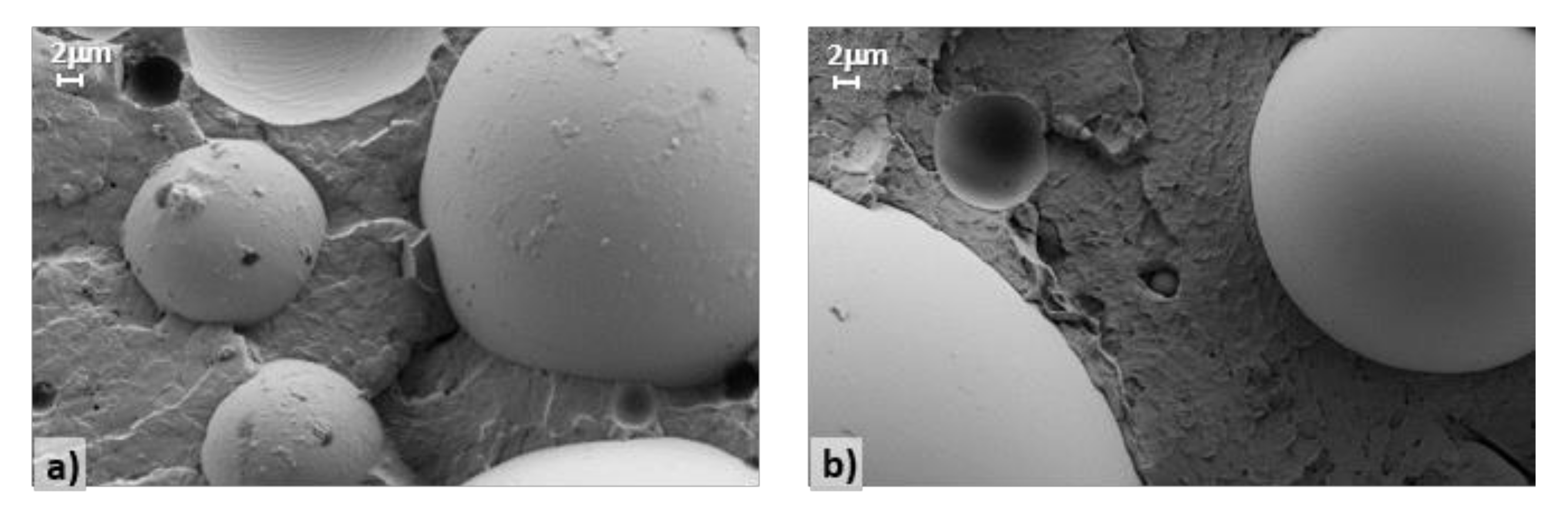

3.3. Morphological Characterization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wallström, E.; Jespersen, H.T.; Schaumburg, K. A new concept for anti-fouling paint for Yachts. In Proceedings of the Progress in Organic Coatings; Elsevier: Amsterdam, The Netherlands, 2011; Volume 72, pp. 109–114. [Google Scholar]

- Böß, V.; Denkena, B.; Dittrich, M.A.; Kenneweg, R. Mathematical description of aesthetic criteria for process planning and quality control of luxury yachts. In Proceedings of the Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 79, pp. 478–483. [Google Scholar]

- Armendáriz-Ontiveros, M.M.; Fimbres Weihs, G.A.; de los Santos Villalobos, S.; Salinas-Rodriguez, S.G. Biofouling of FeNP-Coated SWRO Membranes with Bacteria Isolated after Pre-Treatment in the Sea of Cortez. Coatings 2019, 9, 462. [Google Scholar] [CrossRef]

- Akuzov, D.; Franca, L.; Grunwald, I.; Vladkova, T. Sharply Reduced Biofilm Formation from Cobetia marina and in Black Sea Water on Modified Siloxane Coatings. Coatings 2018, 8, 136. [Google Scholar] [CrossRef]

- Delucchi, M.; Castellano, M.; Vicini, S.; Vita, S.; Finocchio, E.; Ricotti, R.; Cerisola, G. A methodological approach for monitoring the curing process of fairing compounds based on epoxy resins. Prog. Org. Coat. 2018, 123, 20–26. [Google Scholar] [CrossRef]

- Boote, D.; Vergassola, G.; Giannarelli, D.; Ricotti, R. Thermal load effects on side plates of superyachts. Mar. Struct. 2017, 56, 39–68. [Google Scholar] [CrossRef]

- Strong, A.B. Fundamentals of Composites Manufacturing: Materials, Methods and Applications; Society of Manufacturing Engineers: Dearborn, MI, USA, 2008; ISBN 9781613449677. [Google Scholar]

- Delucchi, M.; Finocchio, E.; Castellano, M.; Vicini, S.; Vita, S.; Cerisola, G.; Ricotti, R. Application of DSC and FTIR techniques for monitoring the curing process of epoxy fillers used for yacht application. Metall. Ital. 2017, 109, 107–110. [Google Scholar]

- Sharma, S.; Wetzel, K.K. Process Development Issues of Glass—Carbon Hybrid-reinforced Polymer Composite Wind Turbine Blades. J. Compos. Mater. 2010, 44, 437–456. [Google Scholar] [CrossRef]

- Delucchi, M.; Ricotti, R.; Cerisola, G. Influence of micro- and nano-fillers on chemico-physical properties of epoxy-based materials. In Proceedings of the Progress in Organic Coatings; Elsevier: Amsterdam, The Netherlands, 2011; Volume 72, pp. 58–64. [Google Scholar]

- Donnelly, B.; Bedwell, I.; Dimas, J.; Scardino, A.; Tang, Y.; Sammut, K. Effects of Various Antifouling Coatings and Fouling on Marine Sonar Performance. Polymers (Basel) 2019, 11, 663. [Google Scholar] [CrossRef]

- Santos, T.; Nunes, L.; Faria, P. Production of eco-efficient earth-based plasters: Influence of composition on physical performance and bio-susceptibility. J. Clean. Prod. 2017, 167, 55–67. [Google Scholar] [CrossRef]

- Bochen, J.; Labus, M. Study on physical and chemical properties of external lime-sand plasters of some historical buildings. Constr. Build. Mater. 2013, 45, 11–19. [Google Scholar] [CrossRef]

- Graham-Jones, J.; Summerscales, J. Marine Applications of Advanced Fibre-Reinforced Composites; Woodhead Publishing: Cambridge, UK, 2015; ISBN 9780081002001. [Google Scholar]

- Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Environmental impacts of natural and conventional building materials: A case study on earth plasters. J. Clean. Prod. 2014, 80, 179–186. [Google Scholar] [CrossRef]

- Micó-Vicent, B.; Jordán, J.; Perales, E.; Martínez-Verdú, F.M.; Cases, F. Finding the Additives Incorporation Moment in Hybrid Natural Pigments Synthesis to Improve Bioresin Properties. Coatings 2019, 9, 34. [Google Scholar] [CrossRef]

- Viesca, J.-L.; Anand, M.; Blanco, D.; Fernández-González, A.; García, A.; Hadfield, M. Tribological Behaviour of PVD Coatings Lubricated with a FAP− Anion-Based Ionic Liquid Used as an Additive. Lubricants 2016, 4, 8. [Google Scholar] [CrossRef]

- Gutiérrez-González, S.; Alonso, M.M.; Gadea, J.; Rodríguez, A.; Calderón, V. Rheological behaviour of gypsum plaster pastes with polyamide powder wastes. Constr. Build. Mater. 2013, 38, 407–412. [Google Scholar] [CrossRef]

- Patton, T.C. Paint Flow and Pigment Dispersion: A Rheological Approach to Coating and Ink; Wiley: Hoboken, NJ, USA, 1966; Volume 68, ISBN 978-0-471-03272-4. [Google Scholar]

- Tracton, A.A. Coatings Materials and Surface Coatings; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Shukla, S.; Seal, S. Thermodynamic tetragonal phase stability in sol-gel derived nanodomains of pure zirconia. J. Phys. Chem. B 2004, 108, 3395–3399. [Google Scholar] [CrossRef]

- Fujibayashi, T.; Okubo, M. Preparation and thermodynamic stability of micron-sized, monodisperse composite polymer particles of disc-like shapes by seeded dispersion polymerization. Langmuir 2007, 23, 7958–7962. [Google Scholar] [CrossRef]

- Jaglinski, T.; Kochmann, D.; Stone, D.; Lakes, R.S. Composite materials with viscoelastic stiffness greater than diamond. Science 2007, 315, 620–622. [Google Scholar] [CrossRef]

- Lova, P.; Giusto, P.; Di Stasio, F.; Manfredi, G.; Paternò, G.M.; Cortecchia, D.; Soci, C.; Comoretto, D. All-polymer methylammonium lead iodide perovskite microcavities. Nanoscale 2019, 11, 8978–8983. [Google Scholar] [CrossRef]

- Tsai, Y.T.; Chiou, J.Y.; Liao, C.Y.; Chen, P.Y.; Tung, S.H.; Lin, J.J. Organically modified clays as rheology modifiers and dispersing agents for epoxy packing of white LED. Compos. Sci. Technol. 2016, 132, 9–15. [Google Scholar] [CrossRef]

- Boccalero, G.; Jean-Mistral, C.; Castellano, M.; Boragno, C. Soft, hyper-elastic and highly-stable silicone-organo-clay dielectric elastomer for energy harvesting and actuation applications. Compos. Part B Eng. 2018, 146, 13–19. [Google Scholar] [CrossRef]

- Castellano, M.; Turturro, A.; Riani, P.; Montanari, T.; Finocchio, E.; Ramis, G.; Busca, G. Bulk and surface properties of commercial kaolins. Appl. Clay Sci. 2010, 48, 446–454. [Google Scholar] [CrossRef]

- Holmberg, K. Natural surfactants. Curr. Opin. Colloid Interface Sci. 2001, 6, 148–159. [Google Scholar] [CrossRef]

- Shinoda, W.; Devane, R.; Klein, M.L. Coarse-grained molecular modeling of non-ionic surfactant self-assembly. Soft Matter 2008, 4, 2454–2462. [Google Scholar] [CrossRef]

- Solè, I.; Maestro, A.; González, C.; Solans, C.; Gutiérrez, J.M. Optimization of nano-emulsion preparation by low-energy methods in an ionic surfactant system. Langmuir 2006, 22, 8326–8332. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Migas, D.B.; Panahandeh-Fard, M.; Chen, S.; Wang, Z.; Lova, P.; Soci, C. Charge redistribution at GaAs/P3HT heterointerfaces with different surface polarity. J. Phys. Chem. Lett. 2013, 4, 3303–3309. [Google Scholar] [CrossRef]

- Castellano, M.; Alloisio, M.; Darawish, R.; Dodero, A.; Vicini, S. Electrospun composite mats of alginate with embedded silver nanoparticles. J. Therm. Anal. Calorim. 2019, 137, 767–778. [Google Scholar] [CrossRef]

- Shamsuri, A.A.; Md. Jamil, S.N.A. Compatibilization Effect of Ionic Liquid-Based Surfactants on Physicochemical Properties of PBS/Rice Starch Blends: An Initial Study. Materials (Basel) 2020, 13, 1885. [Google Scholar] [CrossRef]

- Bertora, A.; Castellano, M.; Marsano, E.; Alessi, M.; Conzatti, L.; Stagnaro, P.; Colucci, G.; Priola, A.; Turturro, A. A new modifier for silica in reinforcing SBR elastomers for the tyre industry. Macromol. Mater. Eng. 2011, 296, 455–464. [Google Scholar] [CrossRef]

- Castellano, M.; Marsano, E.; Turturro, A.; Conzatti, L.; Busca, G. Dependence of surface properties of silylated silica on the length of silane arms. Adsorption 2012, 18, 307–320. [Google Scholar] [CrossRef]

- Tarsi, G.; Caputo, P.; Porto, M.; Sangiorgi, C. A Study of Rubber-REOB Extender to Produce Sustainable Modified Bitumens. Appl. Sci. 2020, 10, 1204. [Google Scholar] [CrossRef]

- Dörr, D.; Standau, T.; Murillo Castellón, S.; Bonten, C.; Altstädt, V. Rheology in the Presence of Carbon Dioxide (CO2) to Study the Melt Behavior of Chemically Modified Polylactide (PLA). Polymers (Basel) 2020, 12, 1108. [Google Scholar] [CrossRef]

- Shira, S.; Buller, C. Hollow Glass Microspheres for Plastics, Elastomers, and Adhesives Compounds; Elsevier: Amsterdam, The Netherlands, 2015; pp. 241–271. [Google Scholar] [CrossRef]

- ASTM D790 - 17 Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. Available online: https://www.astm.org/Standards/D790 (accessed on 8 June 2020).

- Glória, G.O.; Teles, M.C.A.; Neves, A.C.C.; Vieira, C.M.F.; Lopes, F.P.D.; de Gomes, M.A.; Margem, F.M.; Monteiro, S.N. Bending test in epoxy composites reinforced with continuous and aligned PALF fibers. J. Mater. Res. Technol. 2017, 6, 411–416. [Google Scholar] [CrossRef]

- Linhares, F.N.; Gabriel, C.F.S.; de Sousa, A.M.F.; Nunes, R.C.R. Mechanical and rheological properties of nitrile rubber/fluoromica composites. Appl. Clay Sci. 2018, 162, 165–174. [Google Scholar] [CrossRef]

- Senff, L.; Ascensão, G.; Ferreira, V.M.; Seabra, M.P.; Labrincha, J.A. Development of multifunctional plaster using nano-TiO2 and distinct particle size cellulose fibers. Energy Build. 2018, 158, 721–735. [Google Scholar] [CrossRef]

- Ochoa, R.E.; Gutiérrez, C.A.; López-Cuevas, J.; Rendón, J.; Rodríguez-Galicia, J.L.; Cruz-Álvarez, J. Effect of Water/Plaster Ratio on Preparing Molds for Slip Casting of Sanitaryware; Rheology of the Initial Plaster Slurry, Microstructure and Mold Properties. Trans. Indian Ceram. Soc. 2018, 77, 84–89. [Google Scholar] [CrossRef]

- Dodero, A.; Alloisio, M.; Vicini, S.; Castellano, M. Preparation of composite alginate-based electrospun membranes loaded with ZnO nanoparticles. Carbohydr. Polym. 2020, 227, 115371. [Google Scholar] [CrossRef]

- Chaudhary, A.K.; Jayaraman, K. Extrusion of linear polypropylene-clay nanocomposite foams. Polym. Eng. Sci. 2011, 51, 1749–1756. [Google Scholar] [CrossRef]

- Brunengo, E.; Castellano, M.; Conzatti, L.; Canu, G.; Buscaglia, V.; Stagnaro, P. PVDF-based composites containing PZT particles: How processing affects the final properties. J. Appl. Polym. Sci. 2020, 137, 48871. [Google Scholar] [CrossRef]

- Payne, A.R. The dynamic properties of carbon black loaded natural rubber vulcanizates. Part II. J. Appl. Polym. Sci. 1962, 6, 368–372. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Sensem, Z.; Surya, I.; Sahakaro, K.; Ismail, H. Synergistic Effect of Maleated Natural Rubber and Modified Palm Stearin as Dual Compatibilizers in Composites based on Natural Rubber and Halloysite Nanotubes. Polymers (Basel) 2020, 12, 766. [Google Scholar] [CrossRef]

- Srivastava, S.; Mishra, Y. Nanocarbon Reinforced Rubber Nanocomposites: Detailed Insights about Mechanical, Dynamical Mechanical Properties, Payne, and Mullin Effects. Nanomaterials 2018, 8, 945. [Google Scholar] [CrossRef] [PubMed]

- Ramier, J.; Gauthier, C.; Chazeau, L.; Stelandre, L.; Guy, L. Payne effect in silica-filled styrene–butadiene rubber: Influence of surface treatment. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 286–298. [Google Scholar] [CrossRef]

- Castellano, M.; Turturro, A.; Marsano, E.; Conzatti, L.; Vicini, S. Hydrophobation of silica surface by silylation with new organo-silanes bearing a polybutadiene oligomer tail. Polym. Compos. 2014, 35, 1603–1613. [Google Scholar] [CrossRef]

- Hentschke, R. The payne effect revisited. Express Polym. Lett. 2017, 11, 278–292. [Google Scholar] [CrossRef]

- Xu, H.; Fan, T.; Ye, N.; Wu, W.; Huang, D.; Wang, D.; Wang, Z.; Zhang, L. Plasticization Effect of Bio-Based Plasticizers from Soybean Oil for Tire Tread Rubber. Polymers (Basel) 2020, 12, 623. [Google Scholar] [CrossRef]

- Aranguren, M.I.; Mora, E.; DeGroot, J.V.; Macosko, C.W. Effect of reinforcing fillers on the rheology of polymer melts. J. Rheol. 1992, 36, 1165–1182. [Google Scholar] [CrossRef]

- Cassagnau, P. Melt rheology of organoclay and fumed silica nanocomposites. Polymer 2008, 49, 2183–2196. [Google Scholar] [CrossRef]

- Vallittu, P.K. High-aspect ratio fillers: Fiber-reinforced composites and their anisotropic properties. Dent. Mater. 2015, 31, 1–7. [Google Scholar] [CrossRef]

- Dybowska-Sarapuk, L.; Kielbasinski, K.; Arazna, A.; Futera, K.; Skalski, A.; Janczak, D.; Sloma, M.; Jakubowska, M. Efficient Inkjet Printing of Graphene-Based Elements: Influence of Dispersing Agent on Ink Viscosity. Nanomaterials 2018, 8, 602. [Google Scholar] [CrossRef]

- Ng, S.; Justnes, H. Influence of dispersing agents on the rheology and early heat of hydration of blended cements with high loading of calcined marl. Cem. Concr. Compos. 2015, 60, 123–134. [Google Scholar] [CrossRef]

- Zhan, Z.; He, H.; Zhu, Z.; Xue, B.; Wang, G.; Chen, M.; Xiong, C. Blends of rABS and SEBS: Influence of In-Situ Compatibilization on the Mechanical Properties. Materials (Basel) 2019, 12, 2352. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, Y.; Gu, C.; Liu, J.; Liu, Y.; Li, M.; Lu, Y. Enhancement of the Mechanical Properties of Basalt Fiber-Wood-Plastic Composites via Maleic Anhydride Grafted High-Density Polyethylene (MAPE) Addition. Materials (Basel) 2013, 6, 2483–2496. [Google Scholar] [CrossRef] [PubMed]

- Quitadamo, A.; Massardier, V.; Santulli, C.; Valente, M. Optimization of Thermoplastic Blend Matrix HDPE/PLA with Different Types and Levels of Coupling Agents. Materials (Basel) 2018, 11, 2527. [Google Scholar] [CrossRef] [PubMed]

| Label | Component A | Dispersing Agent | Microspheres | Anti-Foam Agent |

|---|---|---|---|---|

| Sample 0 (without dispersing agent) | 81.2 | 0.0 | 18.3 | 0.5 |

| Sample 1 (with additive 1) | 80.0 | 1.5 | 18.0 | 0.5 |

| Sample 2 (with additive 2) | 80.0 | 1.5 | 18.0 | 0.5 |

| Sample 3 (with additive 3) | 80.0 | 1.5 | 18.0 | 0.5 |

| Sample 4 (with additive 4) | 81.0 | 0.1 | 18.4 | 0.5 |

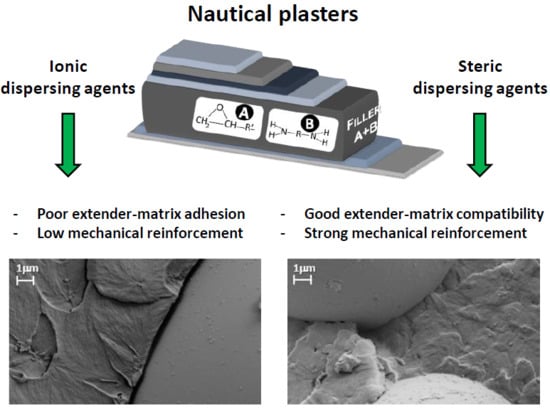

| Dispersing Agent | Nature | Label |

|---|---|---|

| Additive 1 | Ionic dispersants | Self-emulsifying soy lecithin |

| Additive 2 | N-tallow alkyl trimethylene diamine dioleate | |

| Additive 3 | Steric dispersants | Hyperbranched polyester |

| Additive 4 | Tetra(2,2-diallyloxymethylene-1-butyl)bis(ditridecyl phosphite) titanate |

| Sample. | G0* (Pa) | G∞* (Pa) | ΔG* (Pa) |

|---|---|---|---|

| Matrix | 15 ± 1 | 11 ± 0.5 | 4.8 ± 0.9 |

| Sample 0 | 3812 ± 11 | 119 ± 1 | 3693 ± 11 |

| Sample 1 | 1733 ± 70 | 104 ± 9 | 1629 ± 61 |

| Sample 2 | 3951 ± 4 | 148 ± 1 | 3803 ± 4 |

| Sample 3 | 193 ± 4 | 101 ± 3 | 91 ± 1 |

| Sample 4 | 169 ± 2 | 83 ± 4 | 87 ± 3 |

| Sample | Eb (MPa) | σb (MPa) | εb (%) | Extender–Matrix Distance (μm) |

|---|---|---|---|---|

| Sample 0 | 1454 ± 90 | 24.9 ± 1.8 | 1.80 ± 0.17 | 0.254 ± 0.047 |

| Sample 1 | 1444 ± 31 | 17.7 ± 0.9 | 1.34 ± 0.11 | 0.235 ± 0.023 |

| Sample 2 | 1490 ± 53 | 18.0 ± 0.7 | 1.26 ± 0.07 | 0.249 ± 0.051 |

| Sample 3 | 1866 ± 32 | 24.9 ± 1.3 | 1.38 ± 0.13 | - |

| Sample 4 | 1857 ± 59 | 24.4 ± 1.5 | 1.36 ± 0.14 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vita, S.; Ricotti, R.; Dodero, A.; Vicini, S.; Borchardt, P.; Pinori, E.; Castellano, M. Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials. Polymers 2020, 12, 1339. https://doi.org/10.3390/polym12061339

Vita S, Ricotti R, Dodero A, Vicini S, Borchardt P, Pinori E, Castellano M. Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials. Polymers. 2020; 12(6):1339. https://doi.org/10.3390/polym12061339

Chicago/Turabian StyleVita, Silvia, Rico Ricotti, Andrea Dodero, Silvia Vicini, Per Borchardt, Emiliano Pinori, and Maila Castellano. 2020. "Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials" Polymers 12, no. 6: 1339. https://doi.org/10.3390/polym12061339

APA StyleVita, S., Ricotti, R., Dodero, A., Vicini, S., Borchardt, P., Pinori, E., & Castellano, M. (2020). Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials. Polymers, 12(6), 1339. https://doi.org/10.3390/polym12061339