Correlation between Processing Parameters and Degradation of Different Polylactide Grades during Twin-Screw Extrusion

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Experimental Methods

3. Results

3.1. FT-IR Spectroscopic Analysis

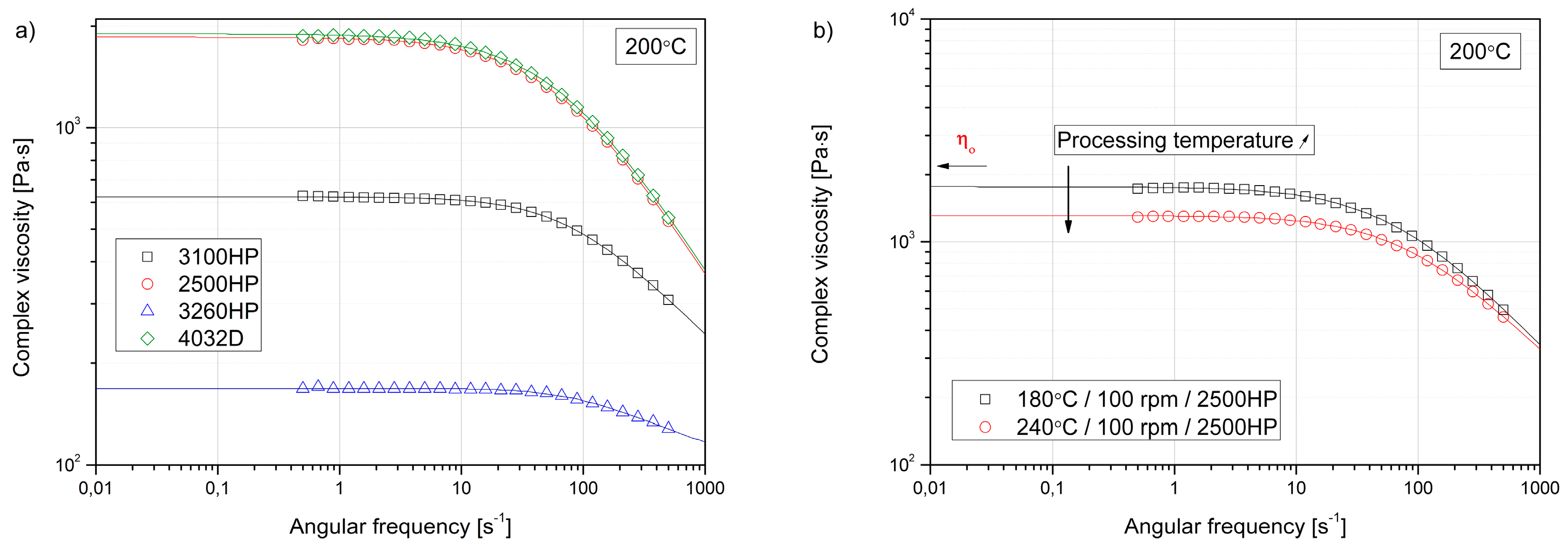

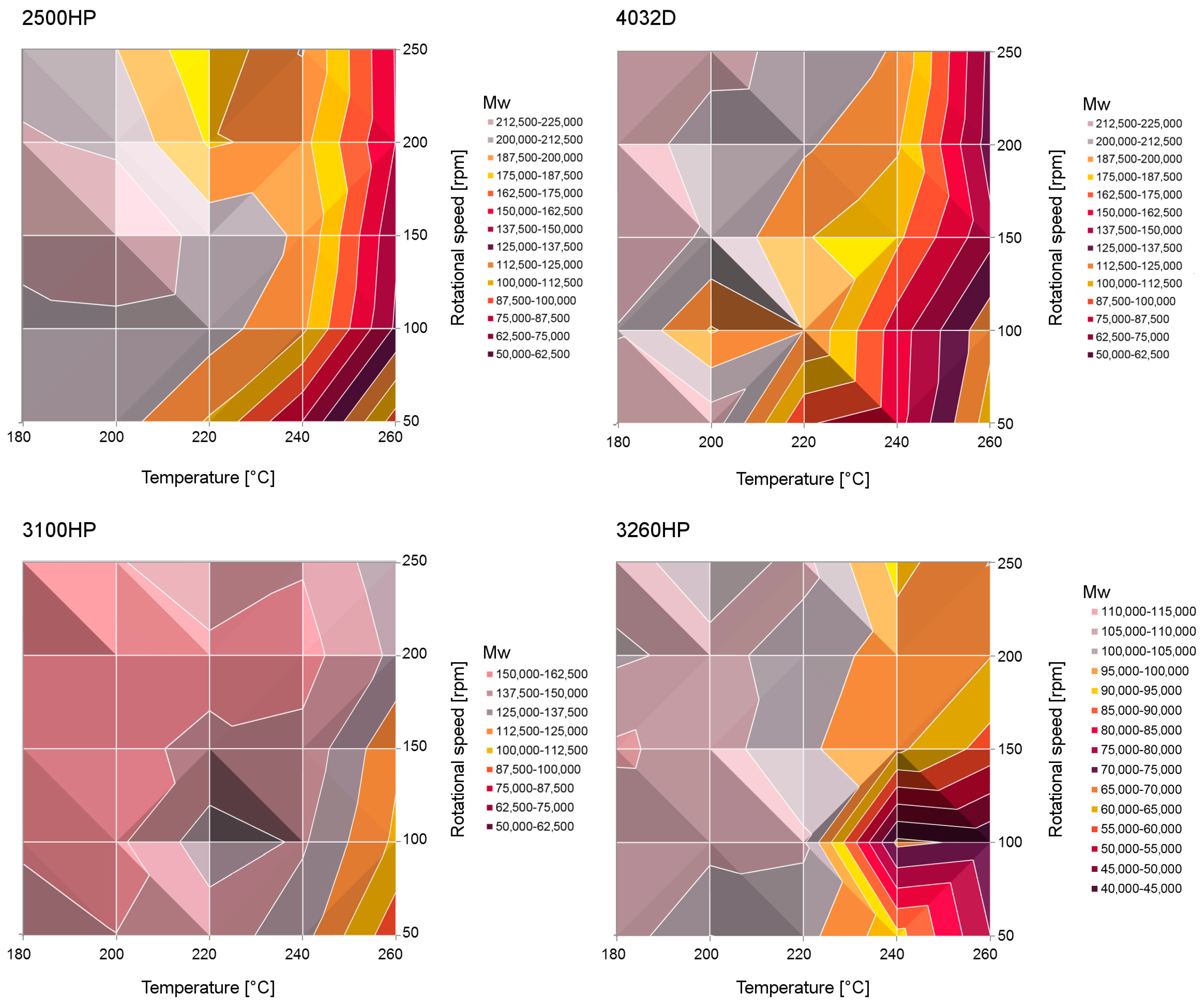

3.2. Rheological Evaluation of PLA Degradation

3.3. Calorimetric Investigation of PLA Morphology Change

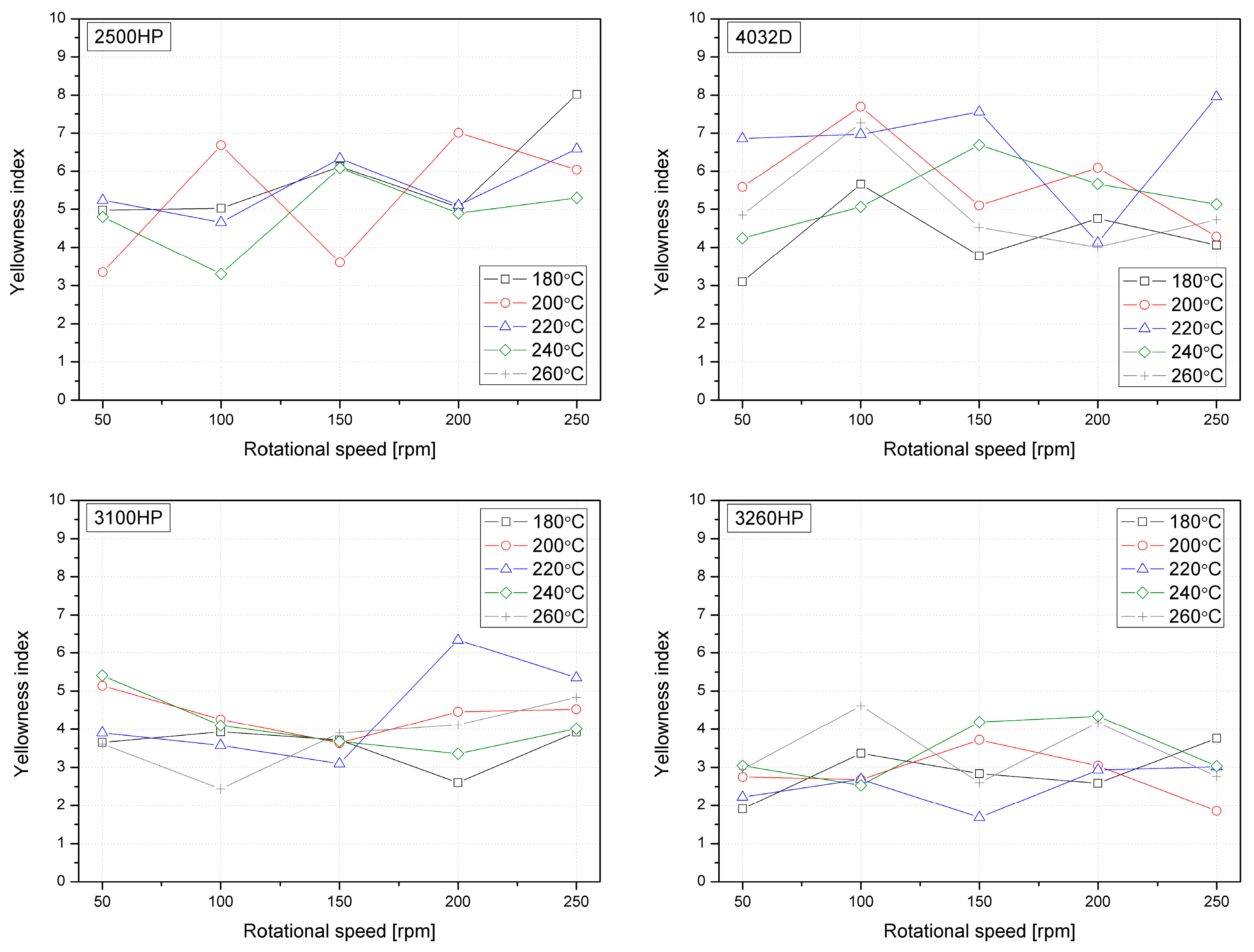

3.4. PLA Color Changes Induced by Thermomechanical Conditions of Twin-Screw Extrusion

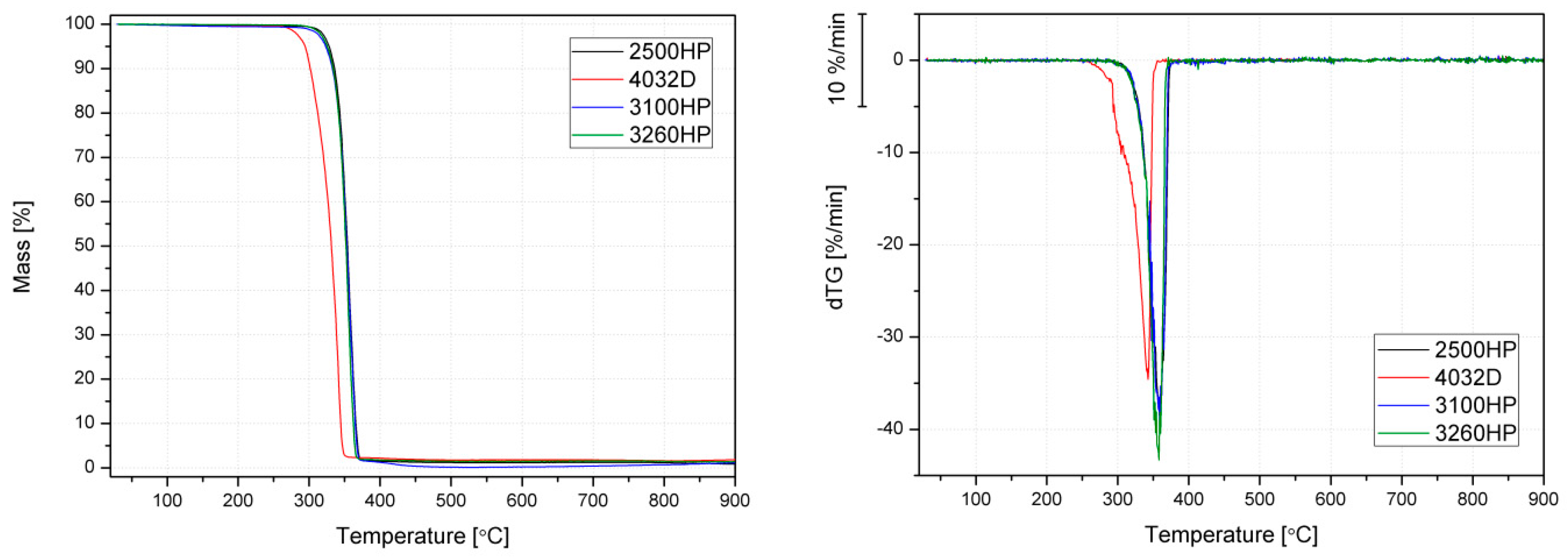

3.5. Thermal Stability of Extruded PLA Grades

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European-Bioplastics. Available online: https://www.european-bioplastics.org/ (accessed on 23 November 2018).

- Nafchi, A.M.; Moradpour, M.; Saeidi, M.; Alias, A.K. Thermoplastic starches: Properties, challenges, and prospects. Starch/Staerke 2013, 65, 61–72. [Google Scholar] [CrossRef]

- Chiarathanakrit, C.; Riyajan, S.A.; Kaewtatip, K. Transforming fish scale waste into an efficient filler for starch foam. Carbohydr. Polym. 2018, 188, 48–53. [Google Scholar] [CrossRef] [PubMed]

- Vytejčková, S.; Vápenka, L.; Hradecký, J.; Dobiáš, J.; Hajšlová, J.; Loriot, C.; Vannini, L.; Poustka, J. Testing of polybutylene succinate based films for poultry meat packaging. Polym. Test. 2017, 60, 357–364. [Google Scholar] [CrossRef]

- Chen, S.; Lin, S.; Hu, Y.; Ma, M.; Shi, Y.; Liu, J.; Zhu, F.; Wang, X. A lignin-based flame retardant for improving fire behavior and biodegradation performance of polybutylene succinate. Polym. Adv. Technol. 2018, 29, 3142–3150. [Google Scholar] [CrossRef]

- Stepczyńska, M.; Moraczewski, K.; Jagodziński, B.; Żenkiewicz, M. Durability studies of modifications effects of polyhydroxybutyrate surface layers. Polimery/Polymers 2018, 63, 275–282. [Google Scholar] [CrossRef]

- Przybysz, M.; Marć, M.; Klein, M.; Saeb, M.R.; Formela, K. Structural, mechanical and thermal behavior assessments of PCL/PHB blends reactively compatibilized with organic peroxides. Polym. Test. 2018, 67, 513–521. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Mittal, V.; Chaudhry, A.U.; Matsko, N.B. True biocomposites with biopolyesters and date seed powder: Mechanical, thermal, and degradation properties. J. Appl. Polym. Sci. 2014, 131, 1–15. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable biodegradable coffee grounds filler and its effect on the hydrophobicity, mechanical and thermal properties of biodegradable PBAT composites. J. Appl. Polym. Sci. 2017, 134, 1–11. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Moraczewski, K.; Stepczyńska, M.; Malinowski, R.; Budner, B.; Karasiewicz, T.; Jagodziński, B. Selected properties of polylactide containing natural antiaging compounds. Polym. Adv. Technol. 2018, 29, 2963–2971. [Google Scholar] [CrossRef]

- Sikorska, W.; Musioł, M.; Rydz, J.; Kowalczuk, M.; Adamus, G. Kompostowanie przemysłowe jako metoda zagospodarowania odpadów z materiałów poliestrowych otrzymywanych z surowców odnawialnych. Polimery 2019, 64, 818–827. [Google Scholar] [CrossRef]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef] [PubMed]

- Czarnecka-Komorowska, D.; Wiszumirska, K. Zrównoważone projektowanie opakowań z tworzyw sztucznych w gospodarce cyrkularnej. Polimery 2020, 65, 8–17. [Google Scholar] [CrossRef]

- Carrasco, F.; Pagès, P.; Gámez-Pérez, J.; Santana, O.O.; Maspoch, M.L. Processing of poly(lactic acid): Characterization of chemical structure, thermal stability and mechanical properties. Polym. Degrad. Stab. 2010, 95, 116–125. [Google Scholar] [CrossRef]

- Janorkar, A.V.; Metters, A.T.; Hirt, D.E. Modification of Poly(lactic acid) Films: Enhanced Wettability from Surface-Confined Photografting and Increased Degradation Rate Due to an Artifact of the Photografting Process. Macromolecules 2004, 37, 9151–9159. [Google Scholar] [CrossRef]

- Stepczyńska, M.; Rytlewski, P. Enzymatic degradation of flax-fibers reinforced polylactide. Int. Biodeterior. Biodegrad. 2018, 126, 160–166. [Google Scholar] [CrossRef]

- Olewnik-Kruszkowska, E.; Koter, I.; Skopińska-Wiśniewska, J.; Richert, J. Degradation of polylactide composites under UV irradiation at 254 nm. J. Photochem. Photobiol. A Chem. 2015, 311, 144–153. [Google Scholar] [CrossRef]

- Masek, A.; Latos-Brozio, M. The Effect of Substances of Plant Origin on the Thermal and Thermo-Oxidative Ageing of Aliphatic Polyesters (PLA, PHA). Polymers 2018, 10, 1252. [Google Scholar] [CrossRef] [PubMed]

- Cuadri, A.A.; Martín-Alfonso, J.E. Thermal, thermo-oxidative and thermomechanical degradation of PLA: A comparative study based on rheological, chemical and thermal properties. Polym. Degrad. Stab. 2018, 150, 37–45. [Google Scholar] [CrossRef]

- Kopinke, F.-D.; Remmler, M.; Mackenzie, K.; Möder, M.; Wachsen, O. Thermal decomposition of biodegradable polyesters—II. Poly(lactic acid). Polym. Degrad. Stab. 1996, 53, 329–342. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Richert, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M.; Karasiewicz, T. Characterisation of multi-extruded poly(lactic acid). Polym. Test. 2009, 28, 412–418. [Google Scholar] [CrossRef]

- Signori, F.; Coltelli, M.-B.; Bronco, S. Thermal degradation of poly(lactic acid) (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) and their blends upon melt processing. Polym. Degrad. Stab. 2009, 94, 74–82. [Google Scholar] [CrossRef]

- Taubner, V.; Shishoo, R. Influence of processing parameters on the degradation of poly(L-lactide) during extrusion. J. Appl. Polym. Sci. 2001, 79, 2128–2135. [Google Scholar] [CrossRef]

- Yahyaee, N.; Javadi, A.; Garmabi, H.; Khaki, A. Effect of Two-Step Chain Extension using Joncryl and PMDA on the Rheological Properties of Poly (lactic acid). Macromol. Mater. Eng. 2020, 305, 1900423. [Google Scholar] [CrossRef]

- Meng, Q.; Heuzey, M.-C.; Carreau, P.J. Control of thermal degradation of polylactide/clay nanocomposites during melt processing by chain extension reaction. Polym. Degrad. Stab. 2012, 97, 2010–2020. [Google Scholar] [CrossRef]

- Zhou, Q.; Xanthos, M. Nanoclay and crystallinity effects on the hydrolytic degradation of polylactides. Polym. Degrad. Stab. 2008, 93, 1450–1459. [Google Scholar] [CrossRef]

- Wan, L.; Zhang, Y. Jointly modified mechanical properties and accelerated hydrolytic degradation of PLA by interface reinforcement of PLA-WF. J. Mech. Behav. Biomed. Mater. 2018, 88, 223–230. [Google Scholar] [CrossRef]

- Shayan, M.; Azizi, H.; Ghasemi, I.; Karrabi, M. Effect of modified starch and nanoclay particles on biodegradability and mechanical properties of cross-linked poly lactic acid. Carbohydr. Polym. 2015, 124, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Palsikowski, P.A.; Kuchnier, C.N.; Pinheiro, I.F.; Morales, A.R. Biodegradation in Soil of PLA/PBAT Blends Compatibilized with Chain Extender. J. Polym. Environ. 2018, 26, 330–341. [Google Scholar] [CrossRef]

- Rytlewski, P.; Stepczynska, M.; Moraczewski, K.; Malinowski, R.; Jagodzinski, B.; Zenkiewicz, M. Mechanical properties and biodegradability of flax fiber-reinforced composite of polylactide and polycaprolactone. Polimery 2018, 63, 603–610. [Google Scholar] [CrossRef]

- Malinowski, R.; Krasowska, K.; Sikorska, W.; Moraczewski, K.; Kaczor, D.; Kosmalska, D.; Królikowski, B. Studies on Manufacturing, Mechanical Properties and Structure of Poly(butylene adipate-co-terephthalate)-based Green Composites Modified by Coconut Fibers. Int. J. Precis. Eng. Manuf. Technol. 2020. [Google Scholar] [CrossRef]

- Sałasinska, K.; Ryszkowska, J. Composites of polylactic acid reinforced with plant fillers obtained from farm and food industry. Przem. Chem. 2013, 92, 2027–2031. [Google Scholar]

- Kuciel, S.; Mazur, K.; Hebda, M. The Influence of Wood and Basalt Fibres on Mechanical, Thermal and Hydrothermal Properties of PLA Composites. J. Polym. Environ. 2020, 28, 1204–1215. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel biocomposites from biobased PC/PLA blend matrix system for durable applications. Compos. Part B Eng. 2017, 130, 158–166. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, L.; Liu, W.; Zeng, G.; Chen, Y. Preparation and Characteristic of PC/PLA/TPU Blends by Reactive Extrusion. Adv. Mater. Sci. Eng. 2015, 2015. [Google Scholar] [CrossRef]

- Hashima, K.; Nishitsuji, S.; Inoue, T. Structure-properties of super-tough PLA alloy with excellent heat resistance. Polymer 2010, 51, 3934–3939. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Skórczewska, K.; Kloziński, A. Improving the Toughness and Thermal Resistance of Polyoxymethylene/Poly(lactic acid) Blends: Evaluation of Structure–Properties Correlation for Reactive Processing. Polymers 2020, 12, 307. [Google Scholar] [CrossRef]

- Frone, A.N.; Batalu, D.; Chiulan, I.; Oprea, M.; Gabor, A.R.; Nicolae, C.-A.; Raditoiu, V.; Trusca, R.; Panaitescu, D.M. Morpho-Structural, Thermal and Mechanical Properties of PLA/PHB/Cellulose Biodegradable Nanocomposites Obtained by Compression Molding, Extrusion, and 3D Printing. Nanomaterials 2019, 10, 51. [Google Scholar] [CrossRef]

- Gamon, G.; Evon, P.; Rigal, L. Twin-screw extrusion impact on natural fibre morphology and material properties in poly(lactic acid) based biocomposites. Ind. Crops Prod. 2013, 46, 173–185. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Schmidt, B.; Spychaj, T. Starch graft copolymers as superabsorbents obtained via reactive extrusion processing. Pol. J. Chem. Technol. 2010, 12, 14–17. [Google Scholar] [CrossRef]

- Bula, K.; Klapiszewski, Ł.; Jesionowski, T. A novel functional silica/lignin hybrid material as a potential bio-based polypropylene filler. Polym. Compos. 2015, 36, 913–922. [Google Scholar] [CrossRef]

- Carreau, P.J. Rheology of Filled Polymeric Systems; Springer: Berlin, Germany, 1992. [Google Scholar]

- Han, C.D. Molecular Theories for the Viscoelasticity of Flexible Homogeneous Polymeric Liquids. In Rheology and Processing of Polymeric Materials: Volume 1: Polymer Rheology; Oxford University Press: Oxford, UK, 2007; pp. 91–151. ISBN 0195187822. [Google Scholar]

- Tung, L.H. Melt viscosity of polyethylene at zero shear. J. Polym. Sci. 1960, 46, 409–422. [Google Scholar] [CrossRef]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid Z. Z. Polym. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- International Commission on Illumination. Recommendations on uniform color spaces, color-difference equations, psychometric color terms. J. Opt. Soc. Am. 1978, 68, 1791. [Google Scholar]

- Bociaga, E.; Trzaskalska, M. Influence of polymer processing parameters and coloring agents on gloss and color of acrylonitrile-butadiene-styrene terpolymer moldings. Polimery 2016, 61, 544–550. [Google Scholar] [CrossRef]

- Amorin, N.S.Q.S.; Rosa, G.; Alves, J.F.; Gonçalves, S.P.C.; Franchetti, S.M.M.; Fechine, G.J.M. Study of thermodegradation and thermostabilization of poly(lactide acid) using subsequent extrusion cycles. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material valorisation of amorphous polylactide. Influence of thermo-mechanical degradation on the morphology, segmental dynamics, thermal and mechanical performance. Polym. Degrad. Stab. 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Le Marec, P.E.; Ferry, L.; Quantin, J.C.; Bénézet, J.C.; Bonfils, F.; Guilbert, S.; Bergeret, A. Influence of melt processing conditions on poly(lactic acid) degradation: Molar mass distribution and crystallization. Polym. Degrad. Stab. 2014, 110, 353–363. [Google Scholar] [CrossRef]

- Ekiert, M.; Mlyniec, A.; Uhl, T. The influence of degradation on the viscosity and molecular mass of poly(lactide acid) biopolymer. Diagnostyka 2015, 16, 63–70. [Google Scholar]

- Yu, T.; Wilkes, G.L. Influence of molecular weight distribution on the melt extrusion of high density polyethylene (HDPE): Effects of melt relaxation behavior on morphology and orientation in HDPE extruded tubular films. J. Rheol. 1996, 40, 1079–1093. [Google Scholar] [CrossRef]

- Rasselet, D.; Ruellan, A.; Guinault, A.; Miquelard-Garnier, G.; Sollogoub, C.; Fayolle, B. Oxidative degradation of polylactide (PLA) and its effects on physical and mechanical properties. Eur. Polym. J. 2014, 50, 109–116. [Google Scholar] [CrossRef]

- Magoń, A.; Pyda, M. Study of crystalline and amorphous phases of biodegradable poly(lactic acid) by advanced thermal analysis. Polymer 2009, 50, 3967–3973. [Google Scholar] [CrossRef]

- Wang, Y.; Mano, J.F. Influence of melting conditions on the thermal behaviour of poly(l-lactic acid). Eur. Polym. J. 2005, 41, 2335–2342. [Google Scholar] [CrossRef]

- Shieh, Y.-T.; Liu, G.-L. Temperature-modulated differential scanning calorimetry studies on the origin of double melting peaks in isothermally melt-crystallized poly(L-lactic acid). J. Polym. Sci. Part B Polym. Phys. 2007, 45, 466–474. [Google Scholar] [CrossRef]

- Pantani, R.; De Santis, F.; Sorrentino, A.; De Maio, F.; Titomanlio, G. Crystallization kinetics of virgin and processed poly(lactic acid). Polym. Degrad. Stab. 2010, 95, 1148–1159. [Google Scholar] [CrossRef]

- Cai, L.-H.; Qi, Z.-G.; Xu, J.; Guo, B.-H.; Huang, Z.-Y. Thermo-oxidative degradation of Nylon 1010 films: Colorimetric evaluation and its correlation with material properties. Chin. Chem. Lett. 2017, 28, 949–954. [Google Scholar] [CrossRef]

- Hopmann, C.; Schippers, S.; Höfs, C. Influence of recycling of poly(lactic acid) on packaging relevant properties. J. Appl. Polym. Sci. 2014. [Google Scholar] [CrossRef]

- Mamun, A.; Rahman, S.M.M.; Roland, S.; Mahmood, R. Impact of Molecular Weight on the Thermal Stability and the Miscibility of Poly(ε-caprolactone)/Polystyrene Binary Blends. J. Polym. Environ. 2018, 26, 3511–3519. [Google Scholar] [CrossRef]

| Property | 2500HP | 3100HP | 3260HP | 4032D |

|---|---|---|---|---|

| Mass average molar mass Mw (Da) | 193,250 | 148,250 | 107,500 | 202,000 |

| Polydispersity index (Mw/Mn) | 1.85 | 1.81 | 1.68 | 1.80 |

| Density (g/cm3) | 1.24 | 1.24 | 1.24 | 1.24 |

| Mass flow rate (g/10 min) | 8.0 | 24 | 65 | 7.0 |

| Yield strength (MPa) | 64 a/65.5 c | 65 a/64 c | 64 a | 60 a |

| Elongation at break (%) | 3.6 a/4.3 c | 3.4 a/2.2 c | 3.0 a/1.3 c | 6.0 a |

| Izod’s impact strength (J/m) | 18.7 a/40 c | 16.2 a/32 c | 16 a/16 c | 16.0 a |

| Heat deflection temperature (HDT) (°C) | 54 a/144 c | 54 a/149 c | 56 a/151 c | - |

| Melting temperature (°C) | 165–180 | 165–180 | 165–180 | 155–170 |

| Die Temperature (°C) | Screw Rotational Speed (rpm) | ||||

|---|---|---|---|---|---|

| 50 | 100 | 150 | 200 | 250 | |

| 180 | 180/50 | 180/100 | 180/150 | 180/200 | 180/250 |

| 200 | 200/50 | 200/100 | 200/150 | 200/200 | 200/250 |

| 220 | 220/50 | 220/100 | 220/150 | 220/200 | 220/250 |

| 240 | 240/50 | 240/100 | 240/150 | 240/200 | 240/250 |

| 260 | 260/50 | 260/100 | 260/150 | 260/200 | 260/250 |

| The Temperature of the Heating Zones (°C) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Die Temperature | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 180 | 180 | 175 | 175 | 170 | 165 | 155 | 150 | 135 |

| 200 | 195 | 185 | 175 | 170 | 165 | 155 | 150 | 135 |

| 220 | 215 | 205 | 195 | 195 | 170 | 160 | 150 | 135 |

| 240 | 230 | 220 | 210 | 195 | 180 | 170 | 150 | 135 |

| 260 | 250 | 240 | 230 | 210 | 190 | 170 | 160 | 135 |

| η0 (Pa·s)/λ (ms) | ||||||

|---|---|---|---|---|---|---|

| 2500HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 1844/14.5 | 1707/13.4 | 1223/9.8 | 580/37.4 | 119/18.9 | |

| 100 rpm | 1765/15.8 | 1806/13.7 | 1717/14.8 | 1312/12.0 | 414/11.4 | |

| 150 rpm | 2102/15.8 | 2305/13.3 | 1769/15.2 | 1521/13.0 | 458/17.7 | |

| 200 rpm | 1971/13.8 | 1836/14.8 | 1223/14.9 | 1340/11.0 | 582/18.0 | |

| 250 rpm | 1740/16.1 | 1570/13.5 | 1043/10.4 | 1582/12.6 | 573/7.5 | |

| 4032D | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 2088/14.5 | 2162/11.7 | 790/35.0 | 651/9.6 | 183/34.4 | |

| 100 rpm | 1902/13.9 | 1229/16.9 | 1552/16.6 | 673/36.2 | 244/41.7 | |

| 150 rpm | 2132/14.4 | 1872/14.0 | 1277/14.7 | 1040/8.9 | 478/30.0 | |

| 200 rpm | 2 295/16.4 | 1636/16.7 | 1224/14.5 | 1290/15.6 | 374/23.5 | |

| 250 rpm | 2 166/14.1 | 2149/13.7 | 1707/13.2 | 1542/15.5 | 397/15.3 | |

| 3100HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 546/14.6 | 586/7.7 | 526/5.2 | 354/11.5 | 108/15.3 | |

| 100 rpm | 621/8.6 | 622/16.2 | 364/11.6 | 455/12.6 | 204/22.4 | |

| 150 rpm | 642/8.1 | 610/8.2 | 567/25.0 | 540/11.2 | 237/66.1 | |

| 200 rpm | 618/19.0 | 651/16.3 | 617/8.7 | 634/1.9 | 406/13.7 | |

| 250 rpm | 723/9.3 | 598/22.2 | 509/8.2 | 572/7.0 | 354/54.5 | |

| 3260HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 191/24.8 | 147/9.8 | 156/10.5 | 111/10.7 | 56/25.8 | |

| 100 rpm | 182/4.2 | 184/7.1 | 180/28.7 | 141/20.5 | 47/54.5 | |

| 150 rpm | 210/4.7 | 189/12.4 | 152/2.2 | 129/60.3 | 95/57.2 | |

| 200 rpm | 169/13.6 | 184/5.0 | 162/8.2 | 137/14.5 | 125/3.7 | |

| 250 rpm | 187/17.2 | 158/17.0 | 183/24.2 | 117/10.2 | 149/3.5 | |

| Xc (%)/Tg (°C)/Tm (°C) | ||||||

|---|---|---|---|---|---|---|

| 2500HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 22.9/61.0/176.3 | 19.5/61.4/176.3 | 21.1/61.2/175.7 | 19.7/59.8/175.0 | 21.4/59.4/172.4 | |

| 100 rpm | 17.3/61.2/176.3 | 19.6/60.1/176.3 | 17.4/61.2/176.0 | 22.4/61.0/175.6 | 23.2/59.8/172.2 | |

| 150 rpm | 18.7/61.5/176.6 | 16.0/61.1/179.5 | 19.2/61.3/176.0 | 22.3/60.2/175.6 | 21.7/61.0/174.3 | |

| 200 rpm | 18.3/62.1/176.7 | 20.1/60.7/176.1 | 17.9/61.3/176.0 | 18.1/60.7/176.1 | 23.0/59.9/174.4 | |

| 250 rpm | 20.1/61.8/176.3 | 20.3/60.6/175.9 | 20.4/61.2/175.7 | 20.2/61.0/175.7 | 22.8/60.4/174.7 | |

| 4032D | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 9.9/60.4/169.9 | 10.9/61.3/170.2 | 9.6/60.8/ | 10.2/60.8/ | 11.7/59.8/168.2 | |

| 100 rpm | 11.1/60.6/170.0 | 13.8/59.8/ | 10.7/60.1/ | 12.7/60.6/ | 11.6/59.7/ | |

| 150 rpm | 13.6/61.3/ | 9.8/61.0/ | 12.2/60.6/ | 14.0/60.8/ | 9.8/60.1/ | |

| 200 rpm | 18.3/61.9/170.5 | 11.0/61.2/170.1 | 10.3/61.3/ | 13.7/60.7/ | 11.6/60.8/ | |

| 250 rpm | 12.0/60.0/ | 9.4/60.7/ | 10.4/60.8/ | 12.2/61.0/ | 9.9/60.5/ | |

| 3100HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 21.4/61.1/176.1 | 21.5/60.1/175.5 | 26.4/60.8/175.1 | 25.0/61.3/174.8 | 25.4/60.1/172.4 | |

| 100 rpm | 24.7/61.2/175.8 | 21.5/61.1/175.8 | 23.0/60.1/175.5 | 23.5/60.8/175.2 | 20.0/60.2/174.5 | |

| 150 rpm | 20.5/60.3/176.2 | 20.3/60.4/176.0 | 23.5/61.0/175.7 | 22.9/60.7/175.4 | 22.1/59.6/174.7 | |

| 200 rpm | 20.2/60.7/175.8 | 20.5/60.6/175.9 | 23.7/60.5/175.7 | 21.3/60.8/176.1 | 25.0/60.7/175.0 | |

| 250 rpm | 20.1/60.6/175.6 | 27.3/61.2/175.5 | 25.1/60.9/175.7 | 21.7/61.7/175.9 | 21.4/60.6/175.3 | |

| 3260HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 29.7/60.6/176.0 | 26.5/59.8/175.9 | 26.1/60.1/175.8 | 25.8/60.1/175.1 | 25.0/60.8/174.5 | |

| 100 rpm | 21.0/59.8/176.4 | 24.2/60.0/176.5 | 26.6/60.6/176.2 | 24.8/60.4/175.5 | 22.5/58.9/174.6 | |

| 150 rpm | 27.0/60.4/175.9 | 26.2/60.7/176.1 | 26.3/60.2/175.4 | 25.1/60.0/175.9 | 24.8/60.5/174.9 | |

| 200 rpm | 24.7/61.0/176.3 | 24.7/58.2/176.2 | 25.0/60.8/176.3 | 27.0/61.4/175.4 | 26.1/60.4/175.6 | |

| 250 rpm | 24.6/60.3/176.3 | 25.8/60.2/176.3 | 28.7/60.6/176.2 | 27.5/60.7/175.5 | 22.3/60.9/176.0 | |

| L*/a*/b*/ΔE | ||||||

|---|---|---|---|---|---|---|

| 2500HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 89.9/–0.6/2.7/1.4 | 89.7/–0.5/1.9/0.5 | 88.4/–0.5/2.8/1.8 | 89.0/–0.6/2.6/1.2 | 90.1/–0.3/1.5/0.6 | |

| 100 rpm | 88.6/–0.4/2.6/1.6 | 87.2/–0.53.5/3.2 | 88.3/–0.4/2.5/1.8 | 89.3/–0.3/1.7/0.8 | 89.3/–0.5/2.4/0.8 | |

| 150 rpm | 88.0/–0.5/3.2/2.3 | 89.3/–0.3/1.9/0.8 | 87.8/–0.6/3.4/2.7 | 88.2/–0.6/3.2/2.2 | 89.5/–0.5/2.1/0.6 | |

| 200 rpm | 88.4/–0.4/2.6/1.7 | 87.4/–0.6/3.7/3.1 | 88.5/–0.4/2.7/1.6 | 88.6/–0.3/2.5/1.5 | 88.8/–0.5/3.0/1.6 | |

| 250 rpm | 86.6/–0.6/4.2/4.1 | 87.3/–0.5/3.2/3.0 | 87.4/–0.3/3.4/3.0 | 88.0/–0.5/2.8/2.2 | 89.7/–0.2/–1.6/0.7 | |

| 4032D | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 89.5/–0.3/1.7/1.2 | 87.7/–0.4/2.9/2.5 | 87.5/–0.7/3.7/3.0 | 89.5/–0.5/2.3/0.8 | 88.7/–0.5/2.6/0.6 | |

| 100 rpm | 88.4/–0.6/3.0/1.9 | 86.5/–0.6/4.0/4.0 | 87.4/–0.6/1.7/3.0 | 88.6/–0.5/2.7/1.6 | 88.5/–0.8/3.9/2.3 | |

| 150 rpm | 89.0/–0.4/2.0/1.3 | 88.6/–0.5/2.7/1.6 | 87.6/–0.7/4.0/3.0 | 87.9/–0.7/3.6/2.5 | 89.4/–0.4/2.4/0.8 | |

| 200 rpm | 88.2/–0.5/2.5/2.0 | 87.4/–0.7/3.3/2.9 | 89.1/–0.3/2.2/1.2 | 88.5/–0.4/2.9/1.7 | 89.6/–0.4/2.1/0.7 | |

| 250 rpm | 89.0/–0.5/2.2/1.3 | 88.7/–0.4/2.3/1.6 | 87.2/0.6/4.2/3.4 | 88.3/–0.2/2.6/1.8 | 89.2/–0.6/2.6/1.0 | |

| 3100HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 89.3/–0.3/1.9/1.9 | 88.7/–0.3/2.7/2.8 | 89.4/–0.4/2.1/1.9 | 88.4/–0.3/2.8/3.1 | 90.1/–0.4/2.0/1.3 | |

| 100 rpm | 89.1/–0.4/2.1/2.1 | 89.2/–0.4/2.3/2.1 | 89.2/–0.3/1.9/2.0 | 88.8/–0.4/2.2/2.4 | 90.4/–0.2/1.3/0.6 | |

| 150 rpm | 88.7/–0.2/1.9/2.4 | 89.2/–0.3/1.9/2.0 | 89.3/–0.2/1.6/1.8 | 89.2/–0.2/1.9/1.9 | 89.4/–0.2/2.0/1.8 | |

| 200 rpm | 89.8/–0.3/1.4/1.2 | 88.4/–0.3/2.3/2.9 | 87.7/–0.5/3.3/4.0 | 89.3/–0.2/1.7/1.8 | 89.4/–0.3/2.2/1.9 | |

| 250 rpm | 89.3/–0.5/2.1/2.0 | 88.3/–0.3/2.3/3.0 | 88.5/–0.6/2.9/3.1 | 88.9/–0.2/2.9/2.3 | 89.3/–0.5/2.6/2.3 | |

| 3260HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 89.8/–0.2/1.0/1.7 | 89.7/–0.3/1.5/1.9 | 90.2/–0.3/1.2/1.3 | 90.0/–0.4/1.7/1.7 | 90.2/–0.3/1.6/1.4 | |

| 100 rpm | 89.4/–0.2/1.8/2.2 | 89.6/–0.3/1.4/2.0 | 89.6/–0.3/1.4/2.0 | 90.0/–0.3/1.4/1.6 | 89.2/–0.4/2.5/2.7 | |

| 150 rpm | 89.7/–0.3/1.5/1.9 | 89.1/–0.4/2.0/2.7 | 90.2/–0.2/0.9/1.3 | 89.0/–0.4/2.2/2.8 | 90.1/–0.3/1.4/1.5 | |

| 200 rpm | 89.6/–0.3/1.4/2.0 | 89.1/–0.3/1.6/2.5 | 89.4/–0.3/1.6/2.2 | 89.2/–0.4/2.3/2.7 | 89.5/–0.5/2.3/2.4 | |

| 250 rpm | 89.0/–0.3/2.0/2.7 | 89.2/–0.2/1.0/2.3 | 89.3/–0.2/1.6/2.3 | 89.9/–0.3/1.6/1.7 | 90.3/–0.3/1.5/1.3 | |

| T5% (°C)/T10% (°C) | ||||||

|---|---|---|---|---|---|---|

| 2500HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 328.0/335.6 | 304.2/314.5 | 324.9/333.9 | 326.6/334.9 | 323.3/332.8 | |

| 100 rpm | 329.2/337.0 | 329.5/337.3 | 329.2/336.9 | 328.5/336.5 | 327.9/336.8 | |

| 150 rpm | 328.1/335.5 | 326.9/334.5 | 328.8/336.2 | 329.7/337.6 | 328.6/337.0 | |

| 200 rpm | 328.4/335.8 | 329.3/337.5 | 326.5/333.5 | 327.8/335.8 | 326.6/335.3 | |

| 250 rpm | 330.0/337.8 | 329.1/336.7 | 325.8/333.0 | 328.1/336.5 | 328.0/335.5 | |

| 4032D | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 294.2/301.5 | 326.7/334.3 | 305.8/314.6 | 324.7/332.9 | 294.9/308.3 | |

| 100 rpm | 323.7/331.8 | 297.4/306.7 | 315.1/324.4 | 321.2/330.6 | 296.1/307.6 | |

| 150 rpm | 324.7/333.1 | 330.9/338.5 | 325.4/333.8 | 324.7/333.0 | 310.4/320.2 | |

| 200 rpm | 319.1/328.8 | 327.6/335.0 | 328.8/336.1 | 323.2/330.8 | 329.8/337.4 | |

| 250 rpm | 319.5/328.7 | 312.4/318.7 | 327.0/334.9 | 330.1/337.4 | 304.6/315.8 | |

| 3100HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 323.2/332.7 | 328.1/336.2 | 327.3/335.4 | 327.4/336.0 | 299.6/313.8 | |

| 100 rpm | 311.4/320.8 | 328.4/336.2 | 326.6/335.5 | 308.4/318.4 | 297.9/311.5 | |

| 150 rpm | 288.0/300.2 | 298.7/310.0 | 327.6/336.2 | 327.3/335.2 | 327.4/335.9 | |

| 200 rpm | 325.7/333.7 | 321.0/330.1 | 328.2/336.4 | 327.7/336.2 | 327.1/335.9 | |

| 250 rpm | 328.1/336.1 | 326.9/335.3 | 327.2/335.0 | 326.8/334.4 | 329.0/335.9 | |

| 3260HP | Screw Rotational Speed | Temperature | ||||

| 180 °C | 200 °C | 220 °C | 240 °C | 260 °C | ||

| 50 rpm | 325.4/333.7 | 325.3/334.4 | 317.5/328.5 | 328.1/336.2 | 297.1/312.4 | |

| 100 rpm | 326.8/335.0 | 326.6/335.1 | 326.8/335.7 | 326.2/334.9 | 324.0/333.1 | |

| 150 rpm | 325.8/334.5 | 327.8/336.3 | 325.9/334.6 | 325.6/335.0 | 320.7/330.6 | |

| 200 rpm | 323.5/331.6 | 327.8/336.6 | 325.1/334.1 | 325.3/334.4 | 278.2/289.8 | |

| 250 rpm | 327.4/336.1 | 319.5/329.7 | 327.3/335.7 | 325.6/333.0 | 326.9/335.4 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Matykiewicz, D. Correlation between Processing Parameters and Degradation of Different Polylactide Grades during Twin-Screw Extrusion. Polymers 2020, 12, 1333. https://doi.org/10.3390/polym12061333

Mysiukiewicz O, Barczewski M, Skórczewska K, Matykiewicz D. Correlation between Processing Parameters and Degradation of Different Polylactide Grades during Twin-Screw Extrusion. Polymers. 2020; 12(6):1333. https://doi.org/10.3390/polym12061333

Chicago/Turabian StyleMysiukiewicz, Olga, Mateusz Barczewski, Katarzyna Skórczewska, and Danuta Matykiewicz. 2020. "Correlation between Processing Parameters and Degradation of Different Polylactide Grades during Twin-Screw Extrusion" Polymers 12, no. 6: 1333. https://doi.org/10.3390/polym12061333

APA StyleMysiukiewicz, O., Barczewski, M., Skórczewska, K., & Matykiewicz, D. (2020). Correlation between Processing Parameters and Degradation of Different Polylactide Grades during Twin-Screw Extrusion. Polymers, 12(6), 1333. https://doi.org/10.3390/polym12061333