1. Introduction

The point of reference used in the uncertainty assessment of life cycle assessment (LCA) results is the environmental evaluation of a life cycle, treated as a certain measurement technique based on a given methodology [

1]. Its application leads to the “measurement” of two basic elements: environmental aspects that occur in the life cycles of products and subsequent environmental impacts [

1,

2,

3,

4].

Never can a single value without an uncertainty range represent the true value of an environmental impact because each measurement has uncertainty [

5,

6]. The process of producing bottles made of polylactide adopted in this paper focuses on the assessment of six technological operations, and concerns primarily the consumption of electricity, water and CO

2 emissions. The implementation of biodegradable polymers into the production process is the result of increasing amounts of residual polymer waste. For years, plastics were produced to obtain durable, environmentally sensitive products. A change in strategy seeking alternative sources of materials has resulted in the development of biodegradable plastics. Therefore, research based on the LCA technique, presenting the potential size of environmental impacts, should also include the impact of uncertainty and the variability of results [

7]. This approach is proposed by Lloyd and Riesa [

8] at the stage of modeling the uncertainty of characterization test results.

Parameter uncertainty refers to the value of a parameter such as energy or raw material found in processes or products. In contrast, the uncertainty of the model refers to the specific model used, such as the model developed by ReCiPe for life cycle impact assessment (LCIA) by converting emissions and the extraction of resources into a limited number of environmental impact assessments using so-called characterizing factors [

9].

The uncertainty analysis of life cycle inventory (LCI) data sets can be divided into quantitative and semi-quantitative analysis. The first is based on statistical methods for the quantitative uncertainty assessment of the LCI database [

10,

11,

12,

13], and the second on the data quality indicator (DQI) method [

9,

14,

15,

16,

17].

Among the methods of semi-quantitative uncertainty analysis, it is worth considering the DQI semi-quantitative approach based on a qualitative assessment of data quality due to its widespread use in the field of LCA. The DQI approach can be divided into qualitative and semi-quantitative approaches. A qualitative approach evaluates data quality in terms of qualitative descriptors, such as good, fair and poor data quality, which depends on a rather subjective assessment. Usually, the method is subject to a qualitative approach [

18,

19]. The semi-quantitative approach adopts a numerical rating system, and the assigned quality rating is processed to obtain a single data quality score based on a probability distribution [

20,

21].

Sonnemann et al. [

22] conducted a quantitative analysis of data uncertainty based on the Monte Carlo simulation, indicating its positive cognitive features. Maurice et al. [

12] pointed out that quantitative uncertainty analysis is too time consuming. Lloyd and Ries, however, concluded that current quantitative uncertainty analysis does not address significant factors contributing to the uncertainty of LCA results due to the complexity of LCA models [

8]. In their research, they also highlighted the problem associated with the long-term and time-consuming process of collecting input data from outside the data library, for example, Ecoinvent available in specific software, e.g., SimaPro or Gabi, which contributes to frequent references to literature. This is one of the reasons why semi-quantitative uncertainty analysis has been used in many studies [

9,

14,

17].

The term uncertainty has a number of interpretations, including those that exclude related terms such as variability and sensitivity [

23]. According to the international dictionary of metrological terms, uncertainty is a parameter associated with a measurement result characterizing the scatter of values which can reasonably be attributed to the measured quantity [

24,

25]. Uncertainty is characterized by a scatter of values (interval size), within which it is possible to place the measured value with a satisfying probability [

26,

27]. In the case of LCA, uncertainty is contained in the results of “measurement” obtained at different research levels, that is, after the analysis of a set of entries and exits related to environmental aspects (LCI results) and after the environmental impact life cycle assessment (LCIA results) [

28].

Considering the complexity of calculations, it is very difficult to present the uncertainty of LCA results in the form of a single equation describing the probability distribution of the values obtained. Therefore, in order to estimate these uncertainties, numeric simulations are conducted. B. Steen [

29] indicates that sensitivity analysis enables one to express uncertainty in the form of probability, hence the need to estimate the degree of uncertainty and the distribution of probability. When analysing the LCA method, Kowalski and Kulczycka [

30] recommend thorough sensitivity analysis or, if possible, partial uncertainty analysis of selected results and parameters whose uncertainty ranges are known, e.g., by means of the Monte Carlo (MC) simulation. He also indicates that some studies involving the use of LCA are subject to uncertainty, which can result in doubts regarding the value of final indicators, eco-indicators that determine the potential environmental impact of a product or process. The uncertainty of model correctness results from the fact that analysed models are never real. Every LCA is subject to uncertainty which is due to subjective choices made in order to design the model [

31].

The existing literature on the theoretical foundations of the mathematical computational structure for performing uncertainty analysis in LCA is still hardly practiced [

32]. However, there are various techniques for uncertainty analysis, such as: the theory of possibilities, e.g., [

33], fuzzy theory, e.g., [

34,

35], data quality indicators, e.g., [

9,

14,

15,

16,

17] and expert opinions, e.g., [

36,

37] or a combination of two or more techniques, e.g., [

20,

30,

31,

38]. Despite the wide range of approaches available, the analysis of uncertainty in LCA in the scientific and business process of bottle production remains largely unexplored.

Stochastic modeling, mainly in the form of MC simulations, is the most commonly used approach to analyzing uncertainty among various processes, research areas and industry sectors [

39,

40,

41,

42]. The usefulness of MC simulation becomes apparent when enough tests have been performed to make a claim regarding data distribution and uncertainty [

30]. However, the combination of two elements of stochastic modeling and uncertainty analysis can be problematic. It most often lists three main reasons: (1) there is a need for a larger amount of data to be available than is available [

43,

44,

45]; (2) there are no clearly described guidelines as to the size of the data set, and this extends the duration of the analysis and the complexity of calculations considerably [

46]; (3) the choice of combined research methods seems to be too complex [

47]. The most common in the literature are works carried out omitting accuracy analysis [

48], or those using error propagation methods, including sampling techniques [

49]; much less research is carried out using MC simulation.

The uncertainty of data can be expressed by means of the probability distribution thereof, e.g., the standard deviation or variance. This enables one to specify the range of values they can take. According to R. Heijugns [

50], using the MC simulation in iterative LCA is time-consuming, but this disadvantage can be dealt with by calculating the propagation of uncertainty within the LCA methodology. H. Imbeault-Tétrault [

51], when comparing the uncertainty propagation calculations with the MC simulation for uncertainty analyses within the LCA methodology, confirmed that the calculation of uncertainty propagation requires less computation time than the MC simulation and suggested that the analytical approach should be used instead. Heijugns and Lenzen [

49] describe in detail where uncertainty can be encountered in LCA. MC is time- and cost-efficient, enabling one to determine the confidence level [

52].

Uncertainty in studies involving the use of LCA can result in doubts regarding the value of final indicators (eco-indicators) that determine the potential environmental impact of a product or process. There are three types of uncertainty: uncertainty of data, uncertainty related to the correctness (representativeness) of the model applied and uncertainty caused by incompleteness of the model.

In the analysis of data uncertainty conducted by Lewandowska and Fołtynowicz [

31], the basic assumption is that the quality of input data should increase with its importance. The authors propose analyzing data quality after having evaluated their environmental impact. As impact assessment is performed for the whole system within precisely specified boundaries, the final result pertains not only to the main data input, but also to the data of all the processes it represents.

Using statistical terms, LCA is used to study and compare systems of products in terms of the same feature, that is, environmental impact [

53]. Uncertainty analysis, however, is reduced to determining the feature diversification level for each of the systems. The more diversified the feature is (scatter) the higher the uncertainty it represents [

26,

52,

54].

This article aims to supplement the issues and knowledge about the environmental impact of the bottle shaping process presented in [

55] by addressing the quality issues of the required data and the complexity of stochastic modeling for uncertainty and sensitivity analysis, thereby offering a new life cycle assessment model not yet practiced by food sector companies in Poland. The purpose of this paper, therefore, is to propose an evaluation method based on the use of the DQI semi-quantitative approach, stochastic modeling and sensitivity analysis to (1) analyze the uncertainty of beverage bottle production parameters, (2) analyze the uncertainty and accuracy of LCA results for the bottle shaping process and (3) recognize the effects of input parameters on the final results obtained.

4. Discussion

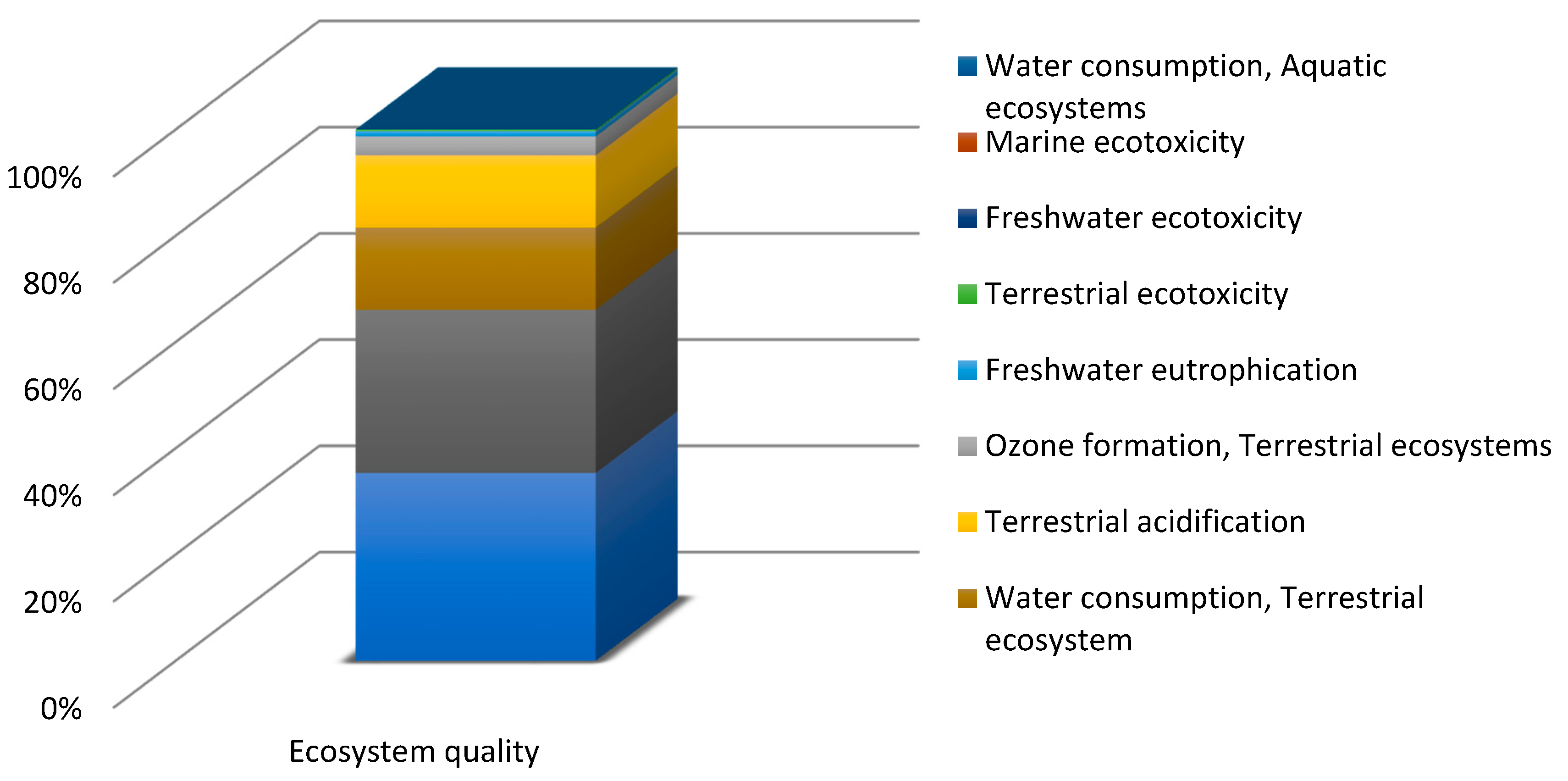

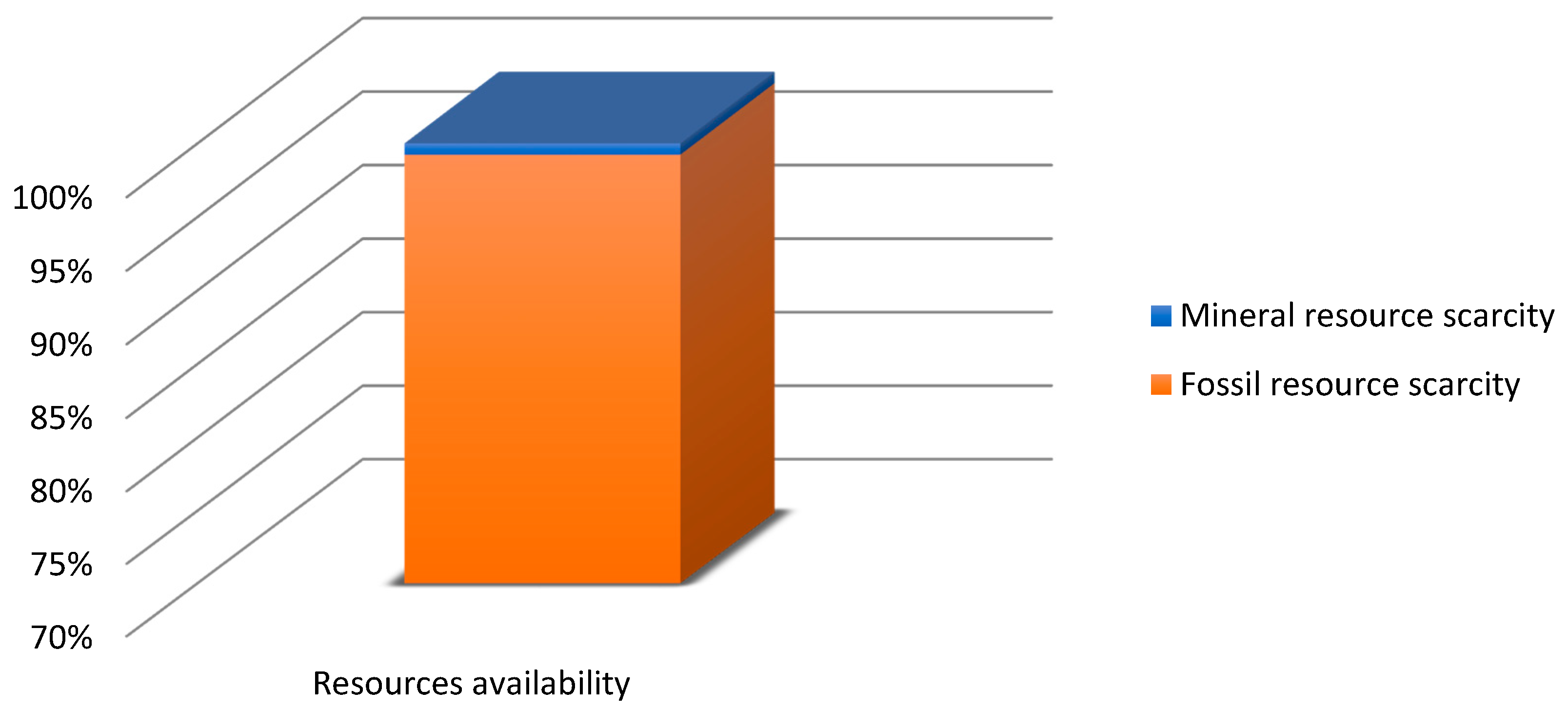

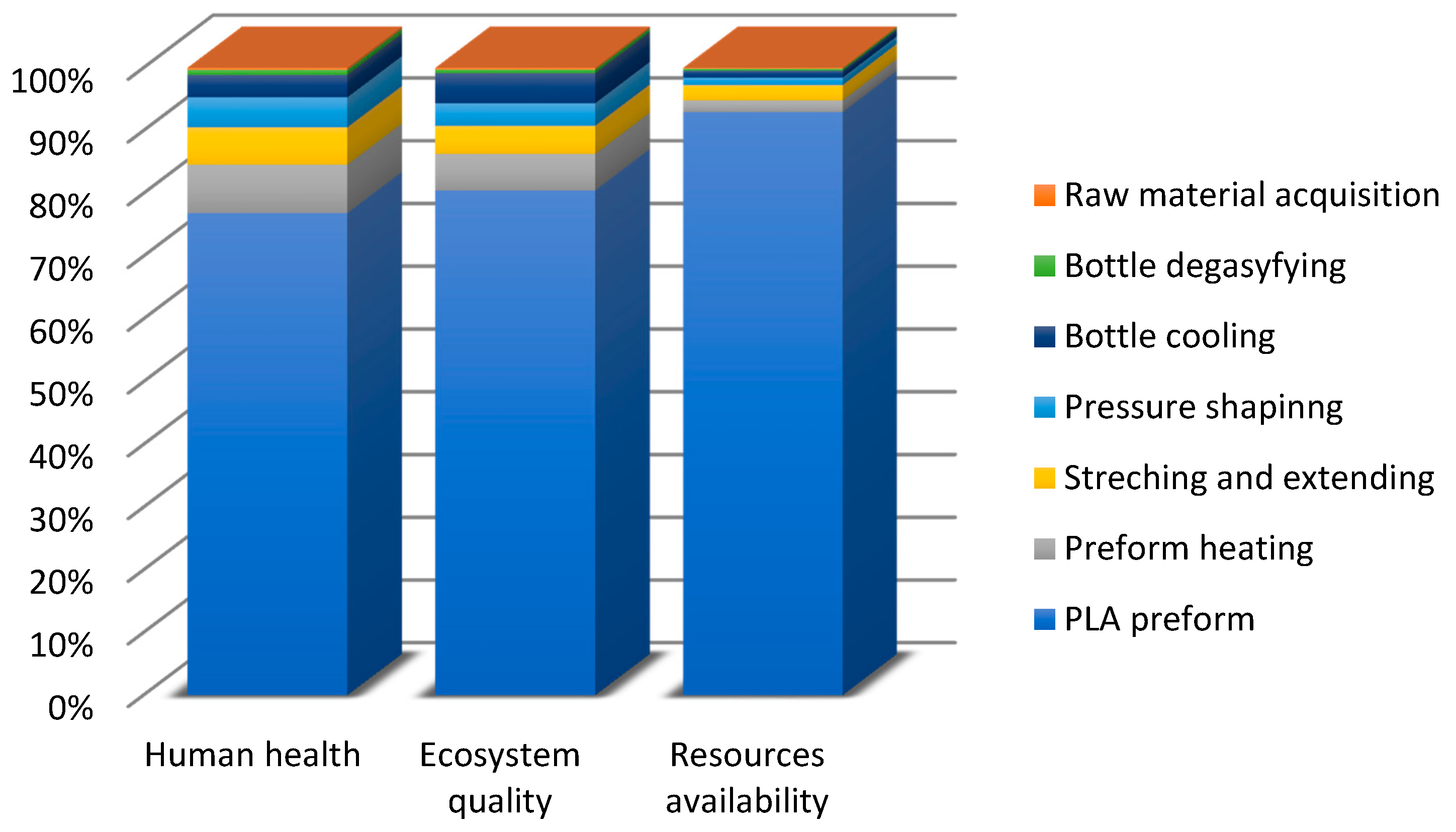

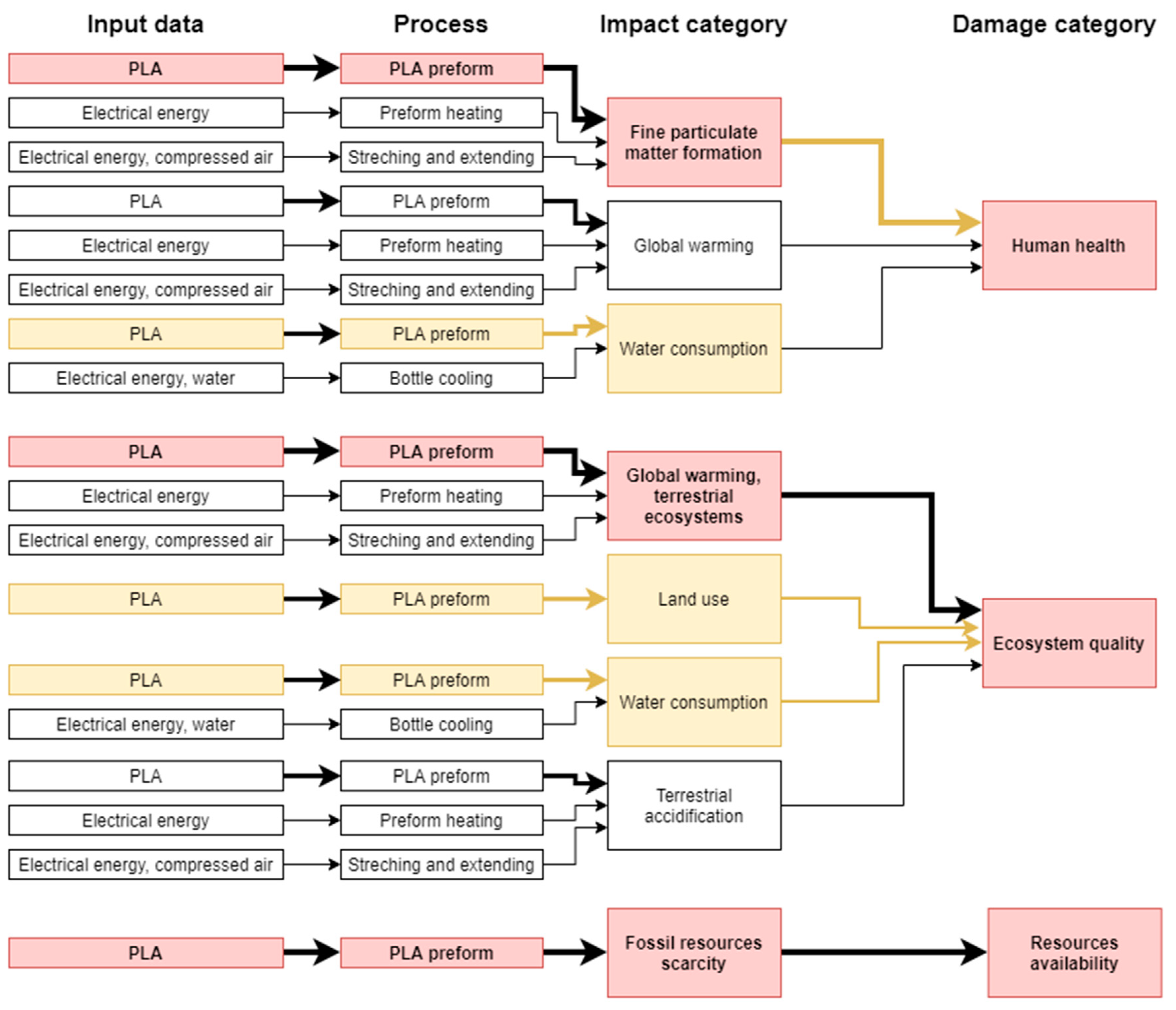

The focus of this paper is on the evaluation and analysis of LCA results for the bottle moulding process. The results of contribution analysis presented in

Section 3.1 show impact categories and stages of the bottle moulding process with the greatest effect on and share in damage categories for LCA results (

Figure 4,

Figure 5,

Figure 6 and

Figure 7). When analysing shares of the process stages in midpoint impact categories, as well as in total impacts in damage areas, one has to conclude that pre-forms made of PLA take the first place and are followed by bottle degasifying and pressure shaping as far as negative environmental impacts are concerned (

Figure 4,

Figure 5,

Figure 6 and

Figure 7). Stages of the bottle moulding process are closely related to input (inventory) data (

Table 4), hence any solutions designed to improve the environmental impact of the bottle shaping process should be directed mainly towards reducing the PLA usage in the production of bottles and reducing the electric energy consumption in the pre-form heating processes (e.g., by means of replacing infrared lamps by less energy-intensive ones), pre-form stretching or cooling. The contribution analysis performed as the first step of the procedure enabled us to determine relevant impact categories to be subjected to the uncertainty and sensitivity analysis.

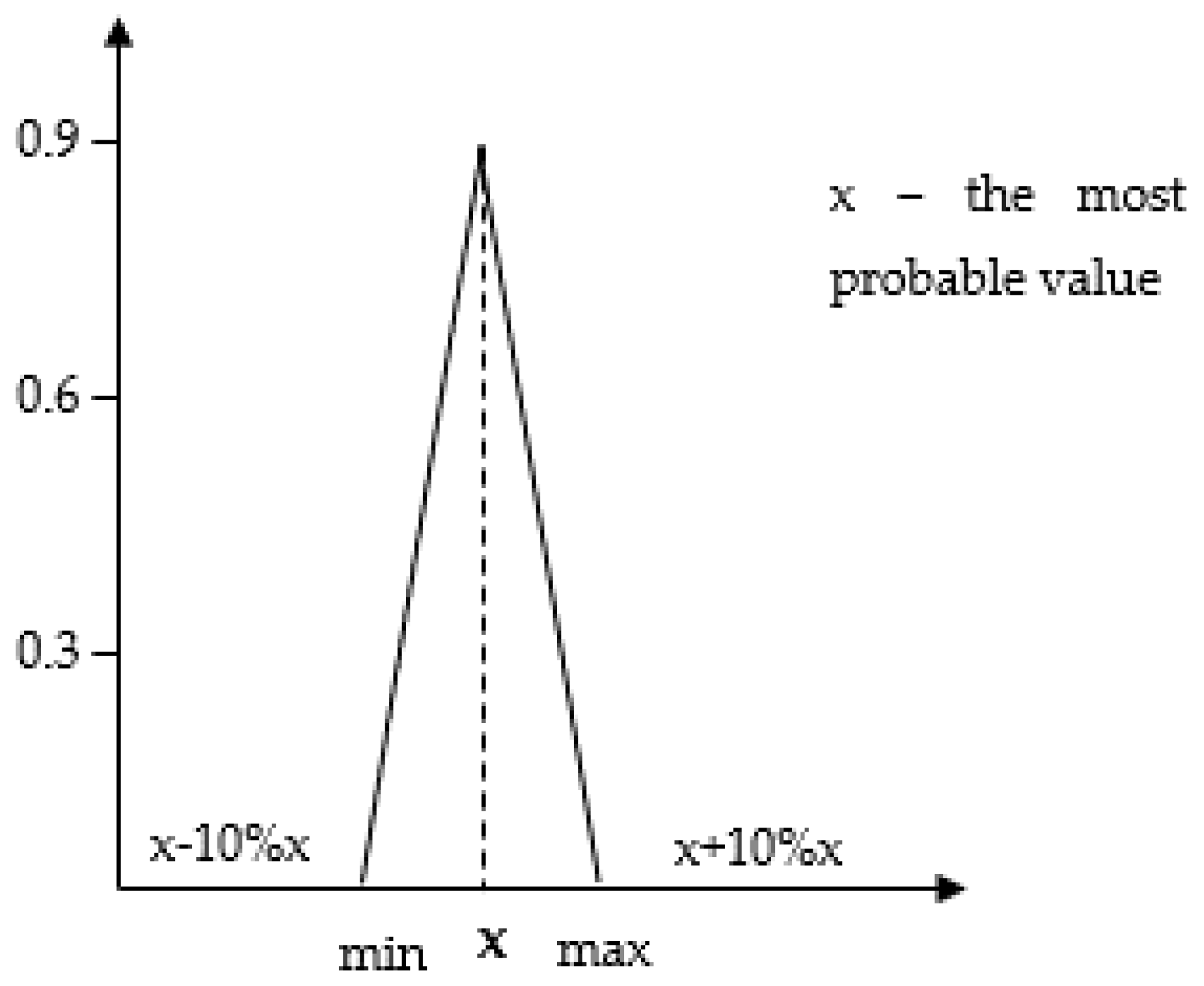

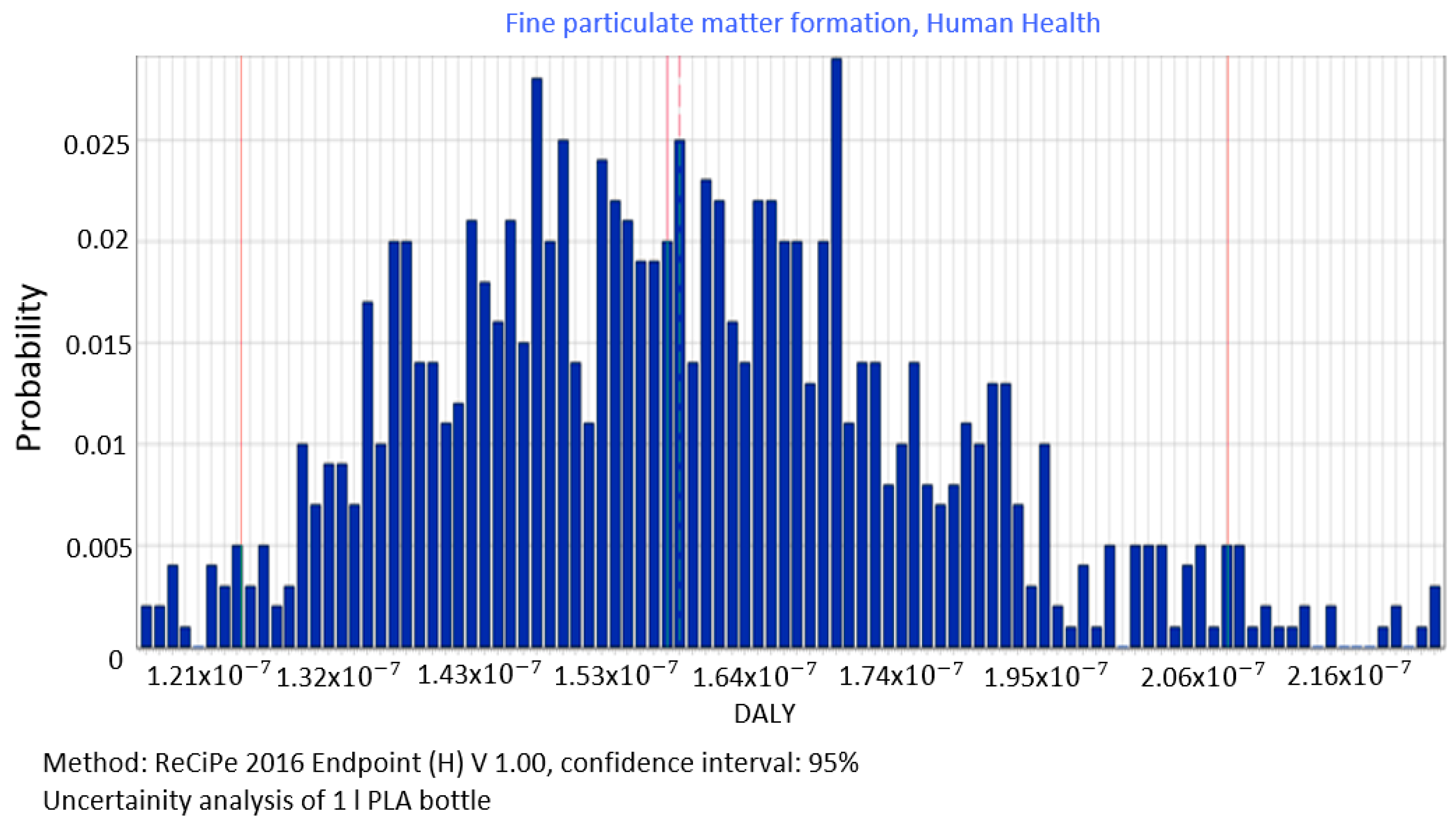

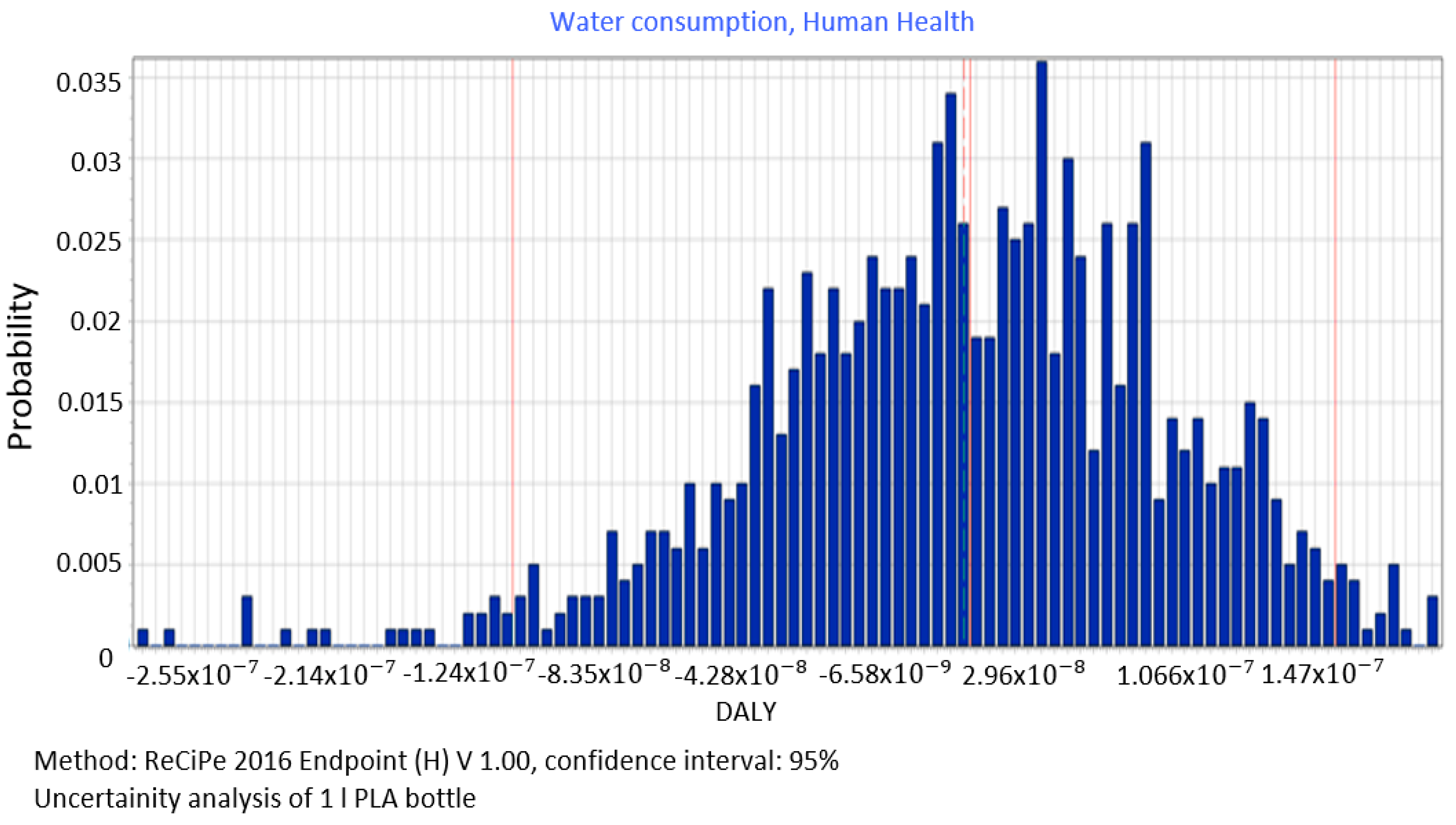

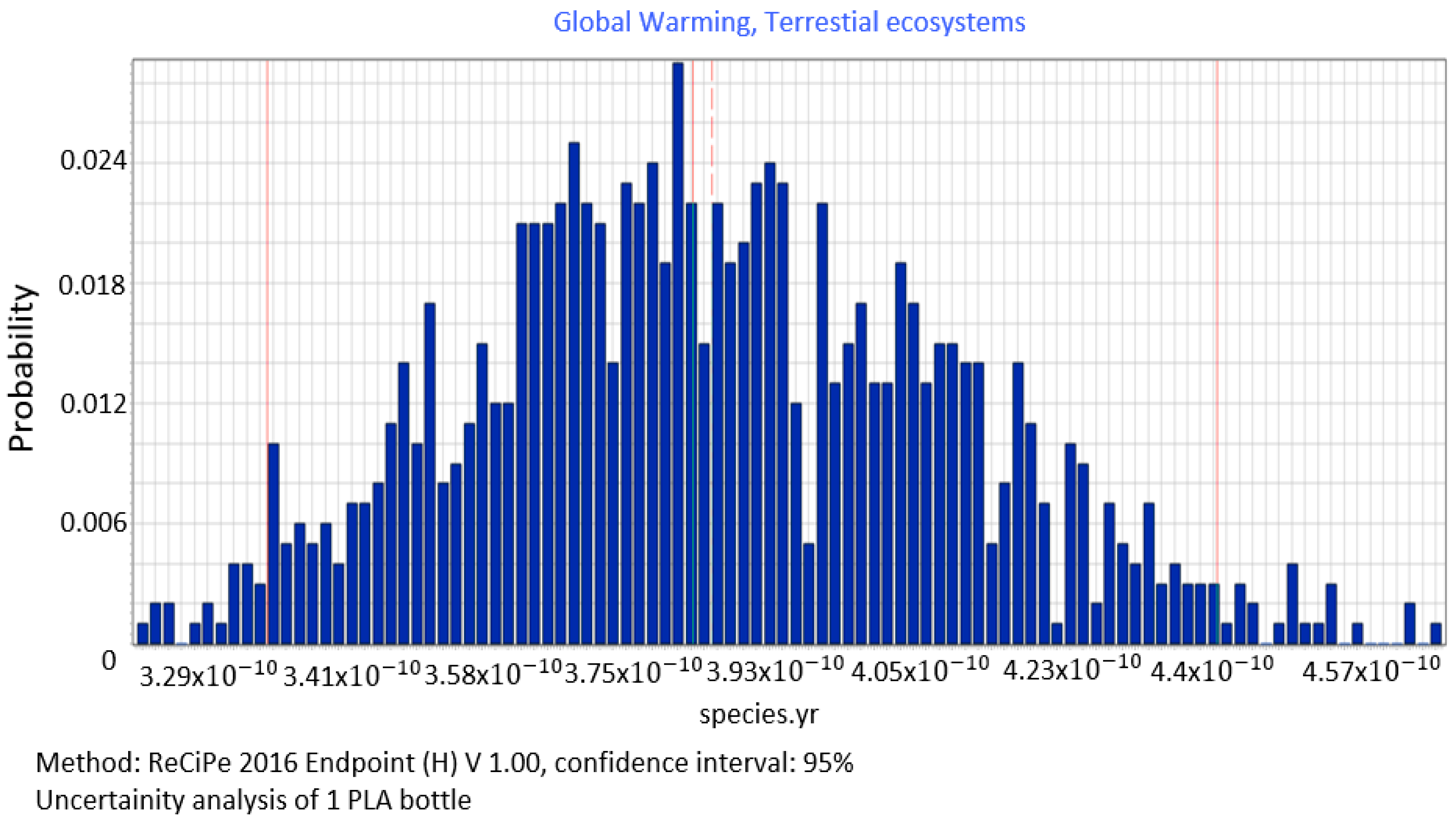

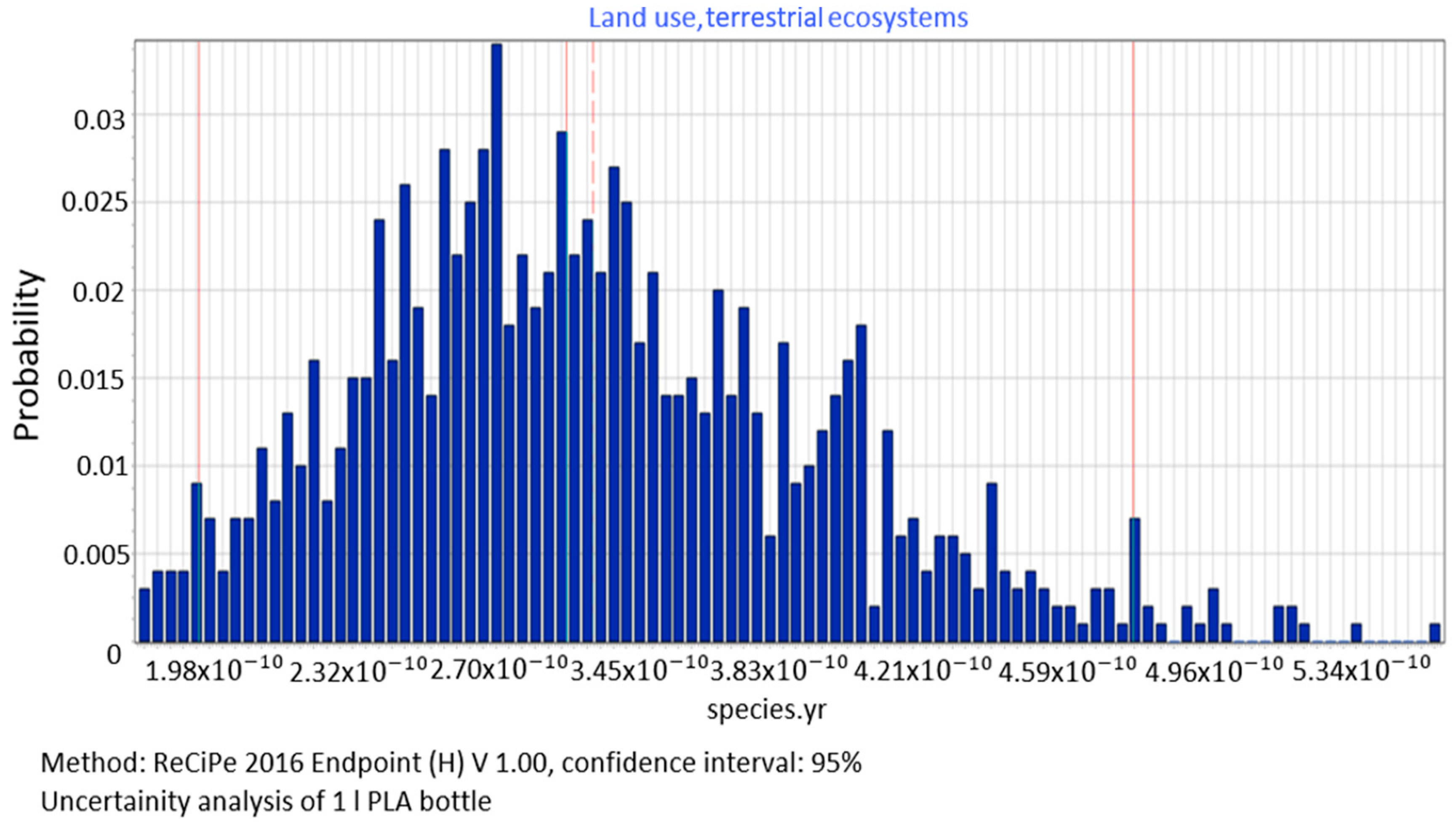

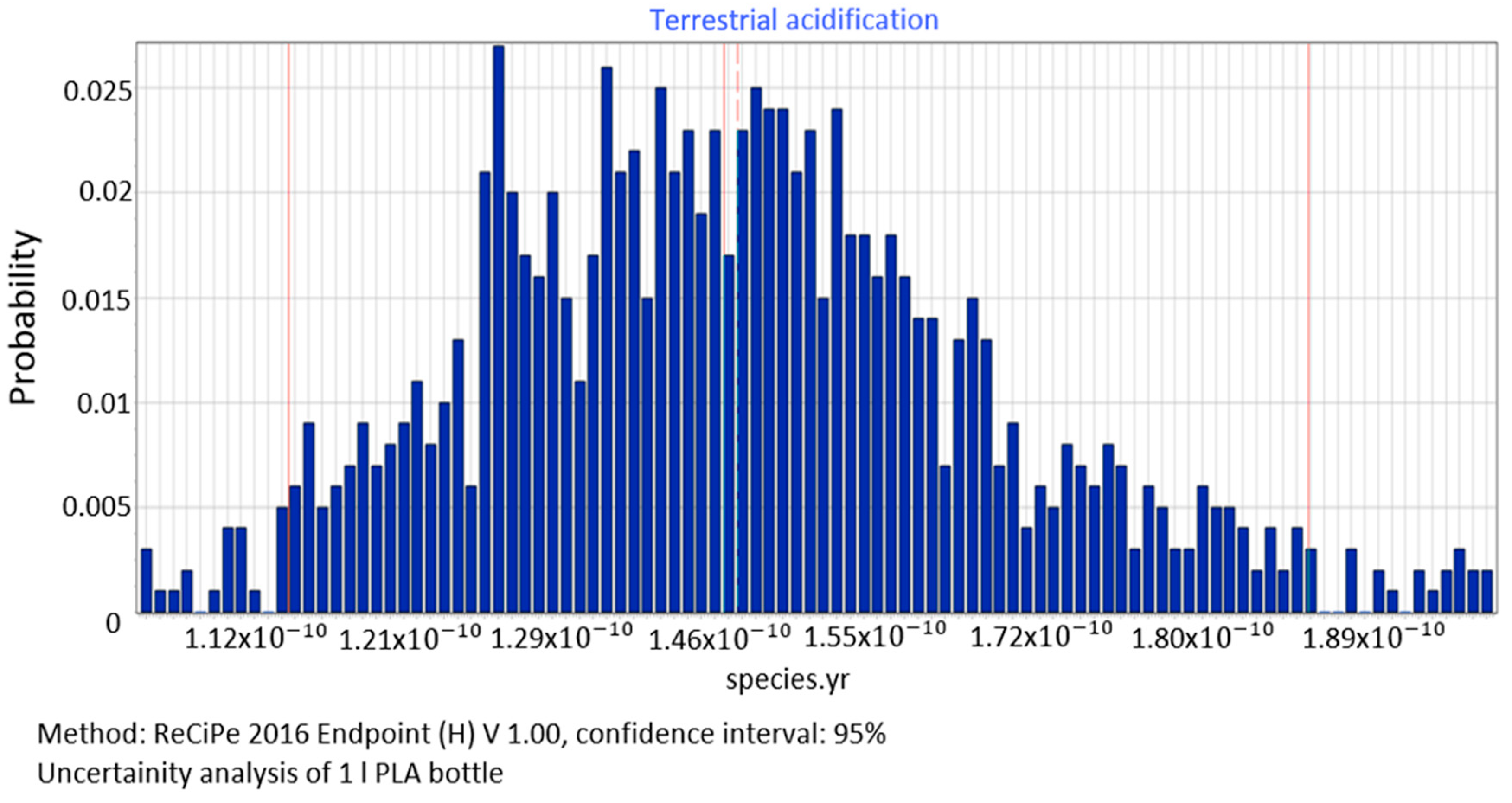

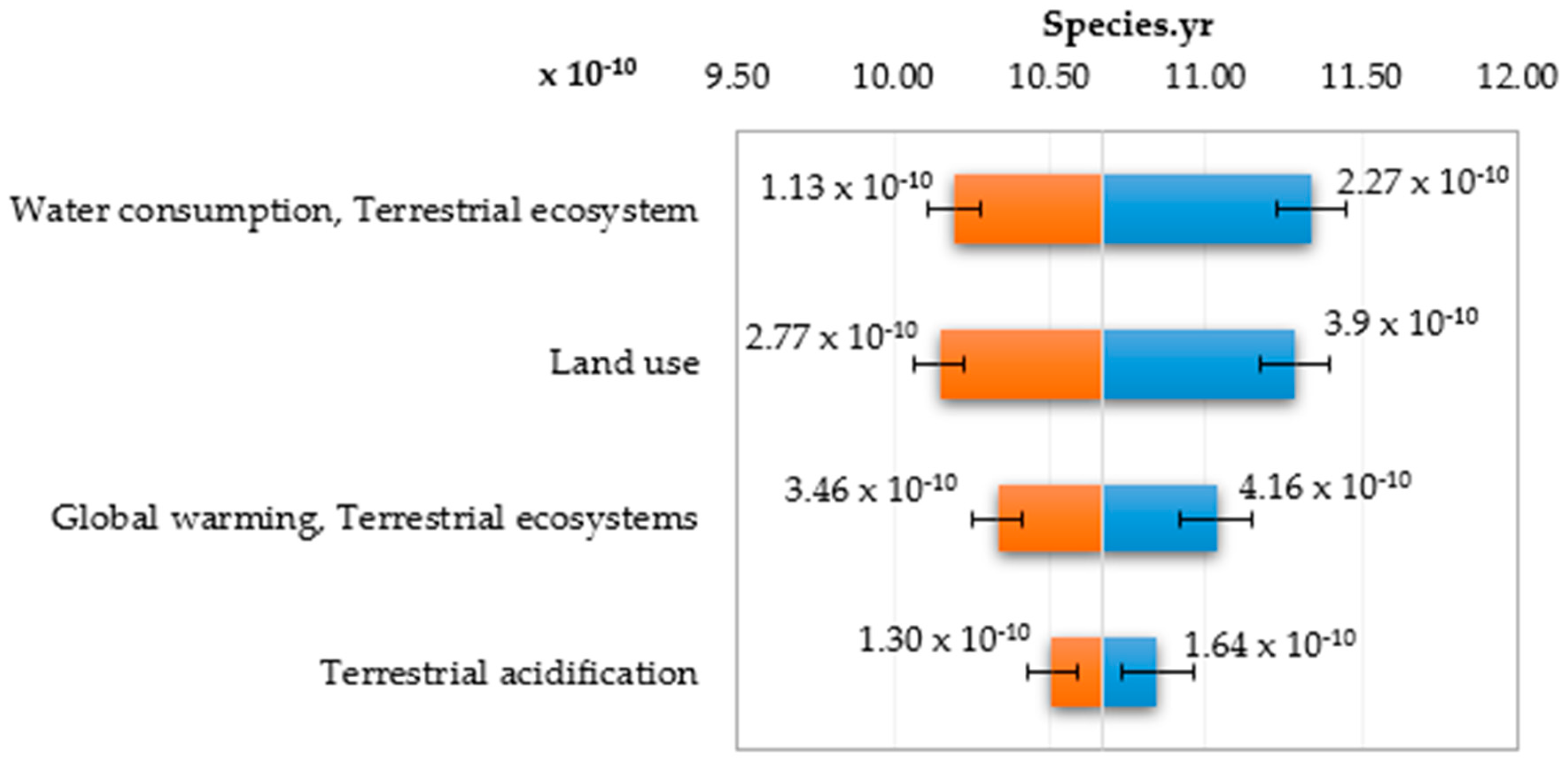

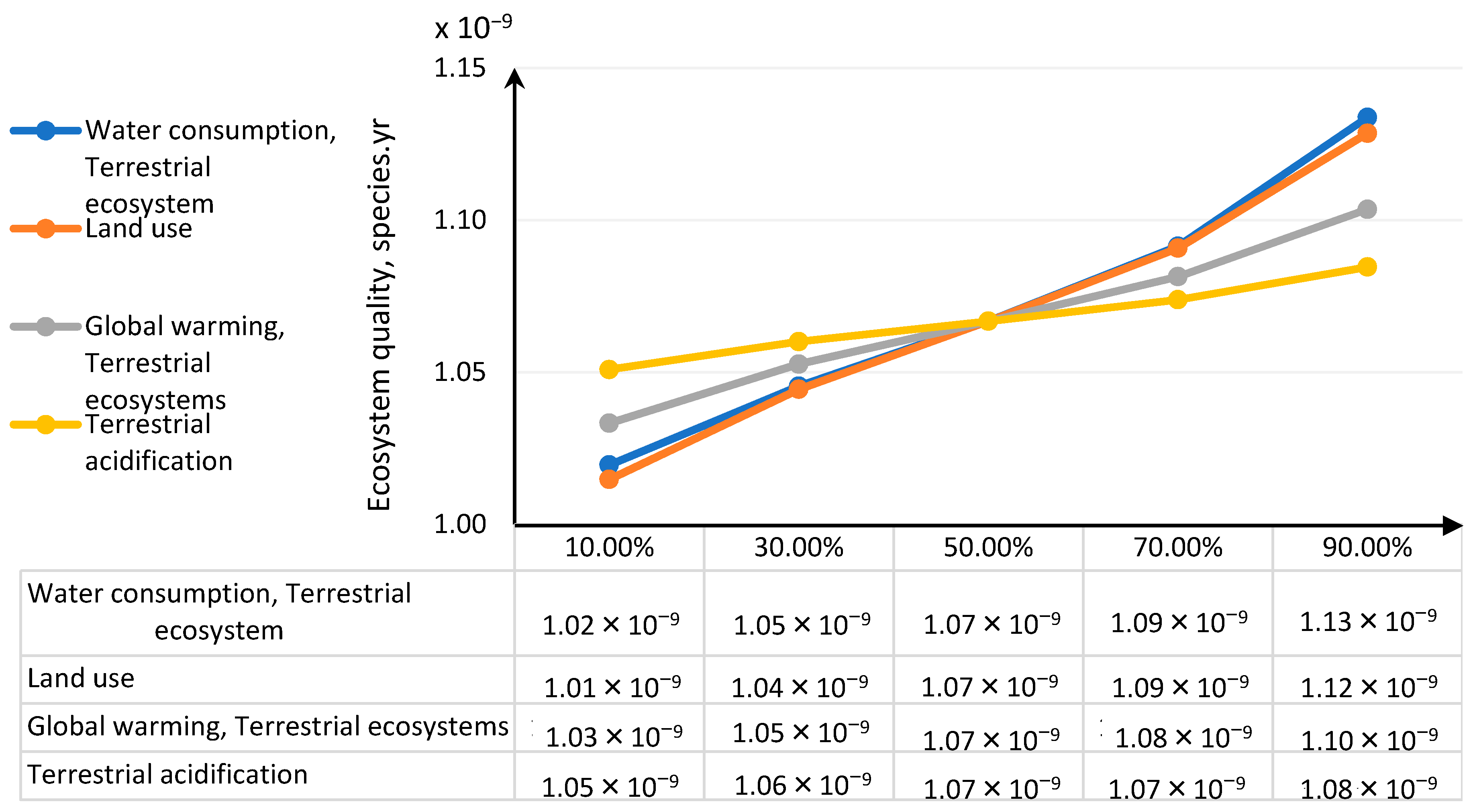

The procedure proposed in this study required us to perform data quality analysis in order to determine parameters of input data distribution for an uncertainty analysis to be conducted using the MC simulation. In this way, the process of stochastic search for the input parameters distribution was simplified by proposing a triangular distribution as PDF, with deviations from 10% to 50%, depending on the ADUI result. Determining the level of deviations is one of the elements of this search and affects the simulated values of expected results. The input data collected by us were characterised by high quality (ADQI = 5) and precision, as they were obtained directly form a manufacturing company. In the uncertainty analysis, a deviation of ±10% was used, according to the triangular distribution. The analysis of the diagrams presented in

Figure 8,

Figure 9 and

Figure 10 shows that the category associated with the use of water resources (

Figure 10) has the largest variability range (deviation 26.8%), thus being the most critical input variable affecting human health throughout the life cycle of the product considered. Yet in the category of harmful impact on the ecosystem, the widest variability interval was found for the category of land use (deviation 25.1%,

Figure 12) and water consumption connected, terrestrial ecosystems (deviation 25.1%,

Figure 13). In the resource availability damage category, the variability of the prevailing impact category of fossil resources scarcity was 10.8% (

Figure 15). The pre-form material was a key determinant of this category value. Input data deviations for the above-listed categories in the range of 10% translated into a significant variability of results, therefore the precision and accuracy of the input data will be of key importance to the values of these categories. With imprecise, low quality data, the result is least certain in these categories. As far as the final result is concerned, it is most important to measure the mass of the pre-form to be used in the blowing process and the consumption of water at the bottle cooling stage with greatest precision.

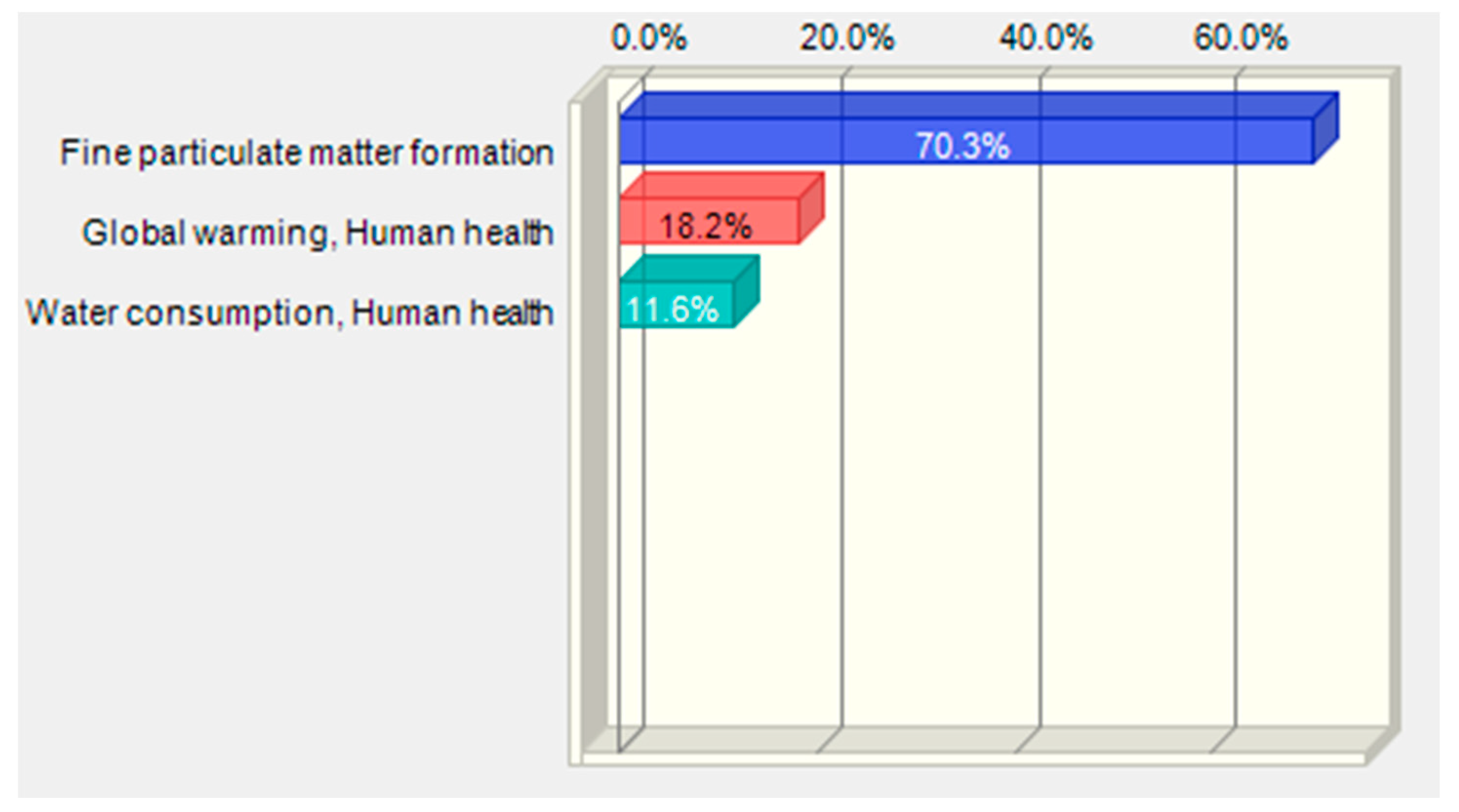

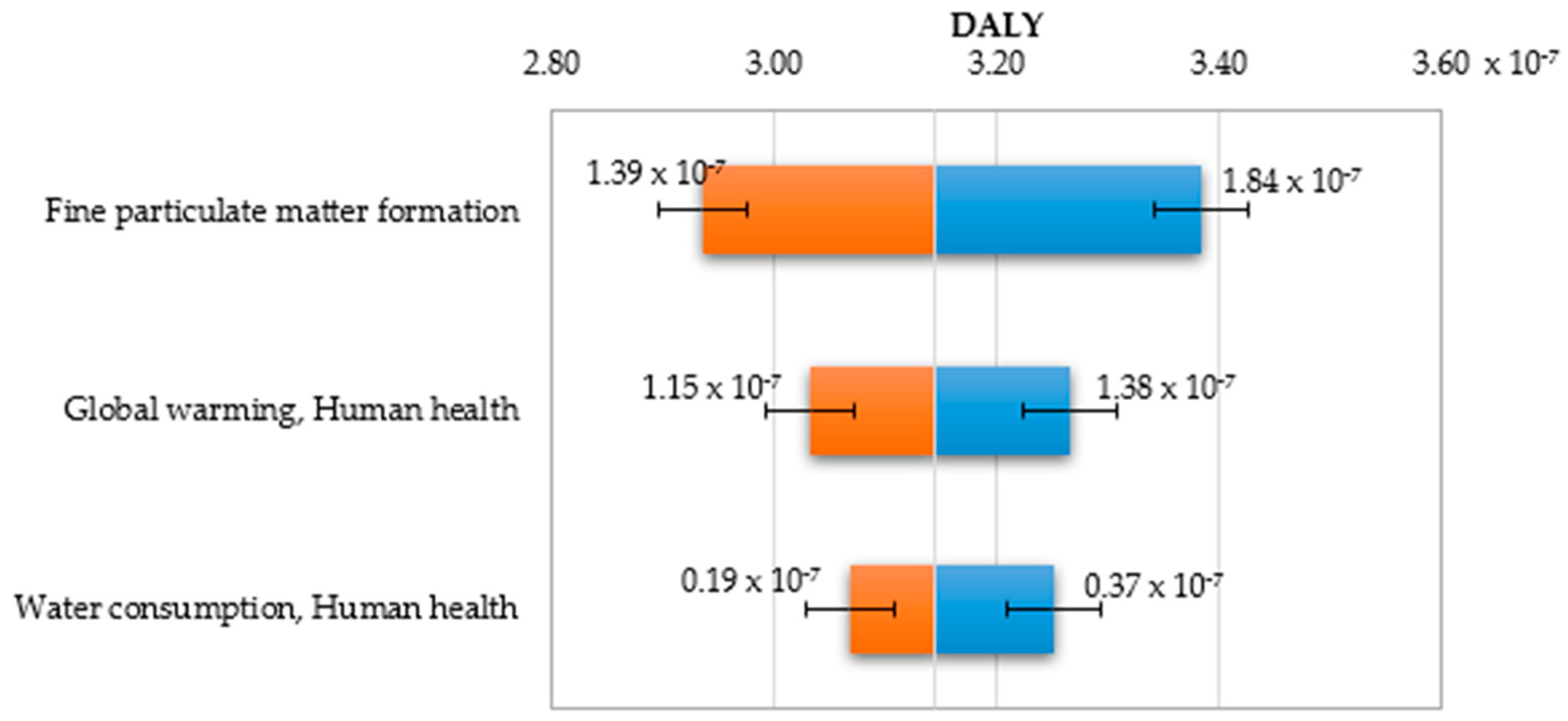

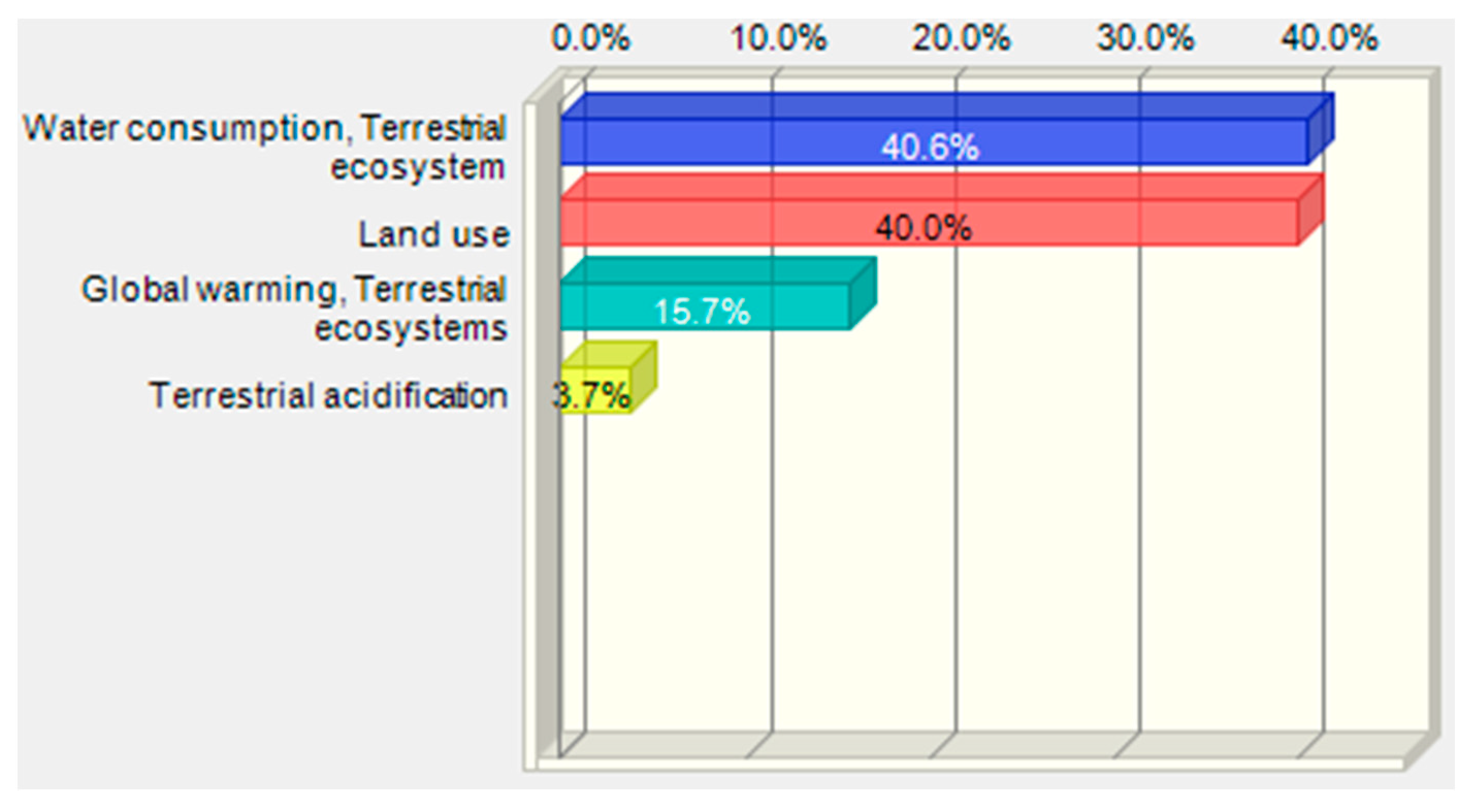

The results distribution characteristics obtained for significant impact categories as a result of the uncertainty analysis (i.e., mean, standard value) were used for performing the key issue analysis using the MC simulation and the CB software. The analysis enabled us to identify the impact categories with the greatest shares in the uncertainty of the final result in the damage category. The fine particulate matter formation category had the greatest share (69.5%) in the human health damage category variance. Depending on changes in this impact category, the total impact in the human health area will be subject to most serious changes. In the ecosystem quality area, water consumption had the greatest share as regards terrestrial ecosystem and land use. As regards these impact categories, the greatest changes should be also expected wherever even a slight decrease in the input parameters value takes place in order to improve the environmental impact of the PLA bottle shaping process. In the group of impact categories referred to above, low quality input data would introduce significant uncertainty of the final impact results in damage categories. The final impact result in the damage category is most sensitive to changes in the impact categories referred to above.

The method proposed for the evaluation of data quality and uncertainty permits to easily identify key parameters that affect the final result of LCA (without the need to calculate complex endpoint coefficients and parameters of the results distribution shape). A single procedure combines three types of analyses: the quality of data, uncertainty of results and sensitivity with respect to input (inventory) data and impact categories, thereby enabling one to determine qualitative and quantitative relationships between input data, impact categories and impact areas, as presented in

Figure 22. Clearly, although some categories show a relatively high uncertainty, they will not have any significant effect on the final result, e.g., the water consumption category, despite its high uncertainty, will not have any serious impact on the human health damage category. But then, in the case of the ecosystem quality damage category, two impact categories will cause the greatest uncertainty of results: water consumption and land use, although they do not represent the greatest shares in this damage category.

In practice, data uncertainty assessment procedures come down to one type of analysis, e.g., the semi-quantitative DQI approach [

20], stochastic modelling with the use of the MC simulation [

22,

48], sensitivity analysis [

10,

65]. Combinations of several methods are not common, due to the significant input of labour and time required and a great number of data than need to be entered and collected [

62,

72]. However, the method proposed here, is based on inventory outcomes and each step produces a set of inputs for the next stage, thereby providing a network of links between input data and impact categories, as well as damage categories (

Figure 22).

The types of variables distribution used in these studies (triangle distribution for input data and lognormal distribution for impact categories), as well as range endpoints, are not without effect on the value of results obtained either. Using other distributions might lead to small differences in the uncertainty results, as shown in [

20,

38,

65,

72]. It should be pointed out that the input data distribution is based on the semi-quantitative DQI approach result and it is largely the quality of data that will determine results of any further stages.