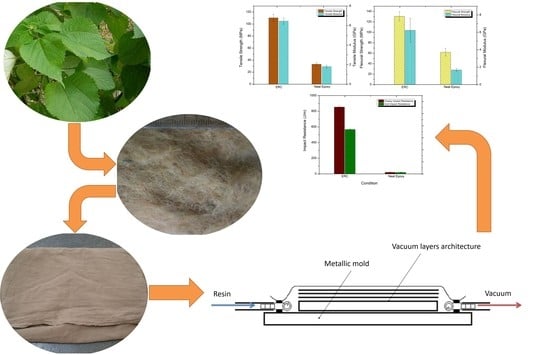

Mechanical Properties of Boehmeria nivea Natural Fabric Reinforced Epoxy Matrix Composite Prepared by Vacuum-Assisted Resin Infusion Molding

Abstract

1. Introduction

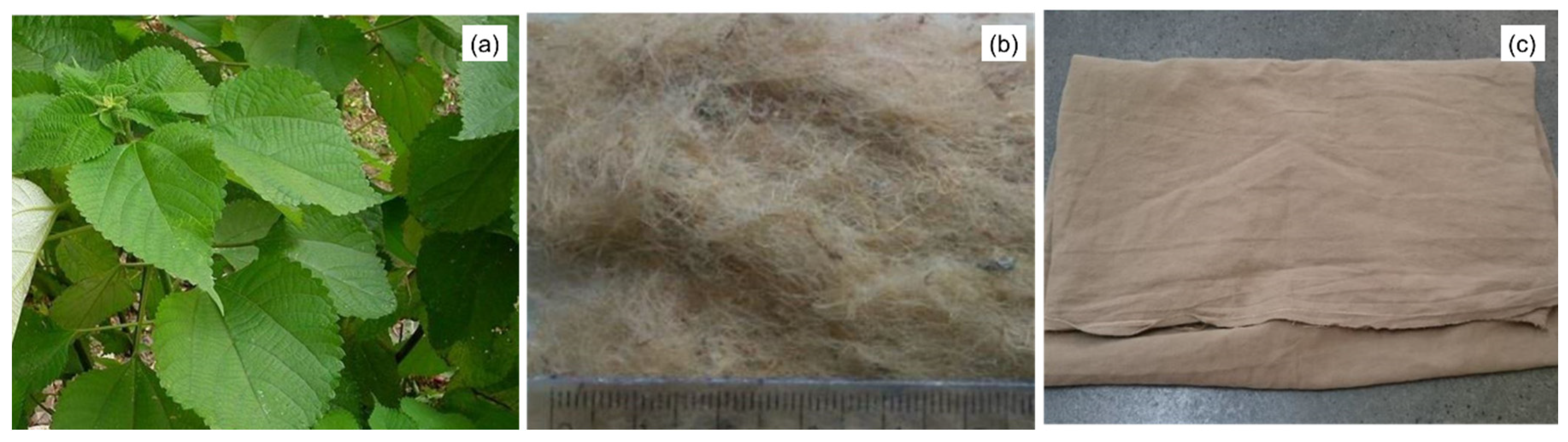

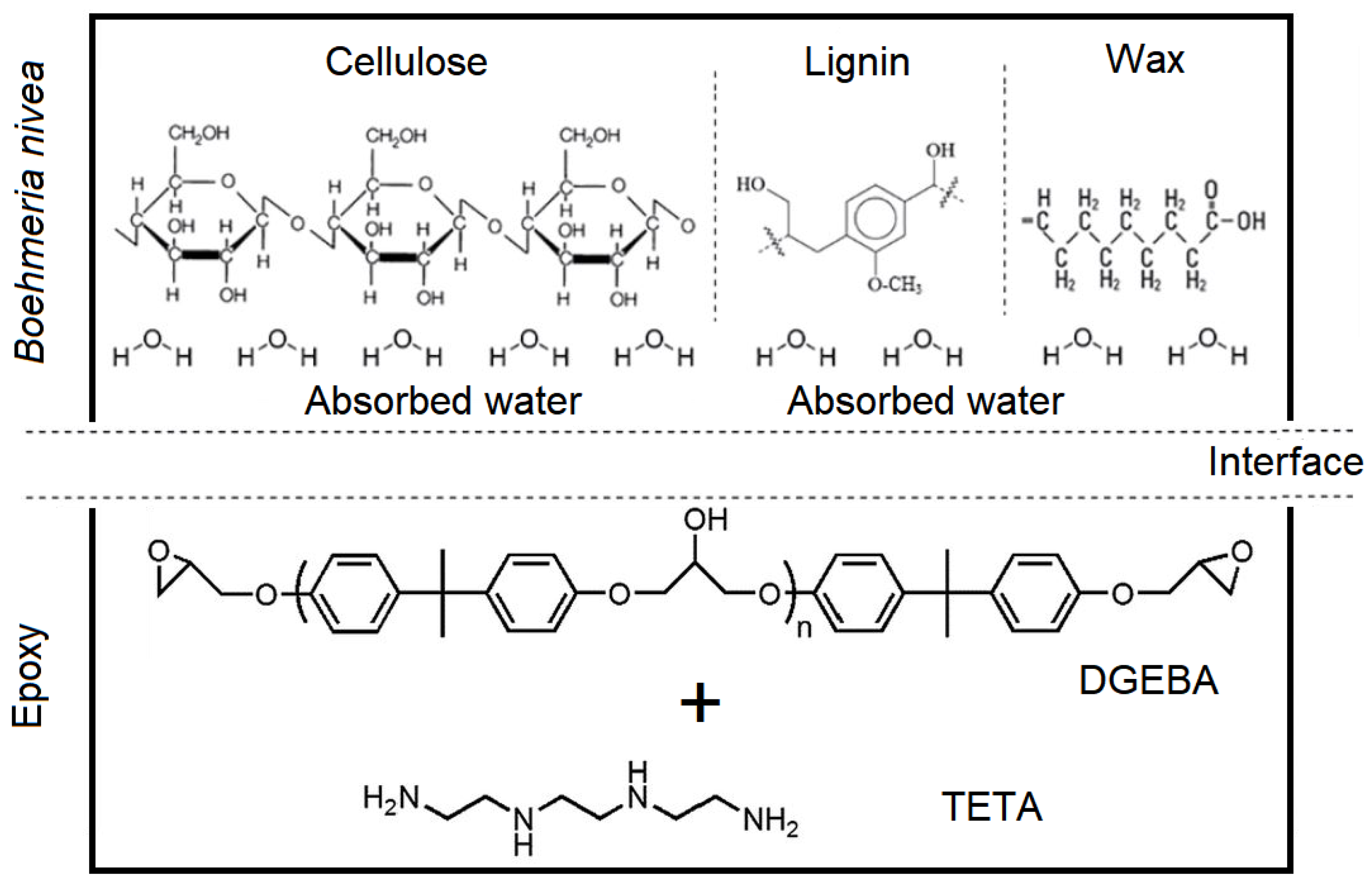

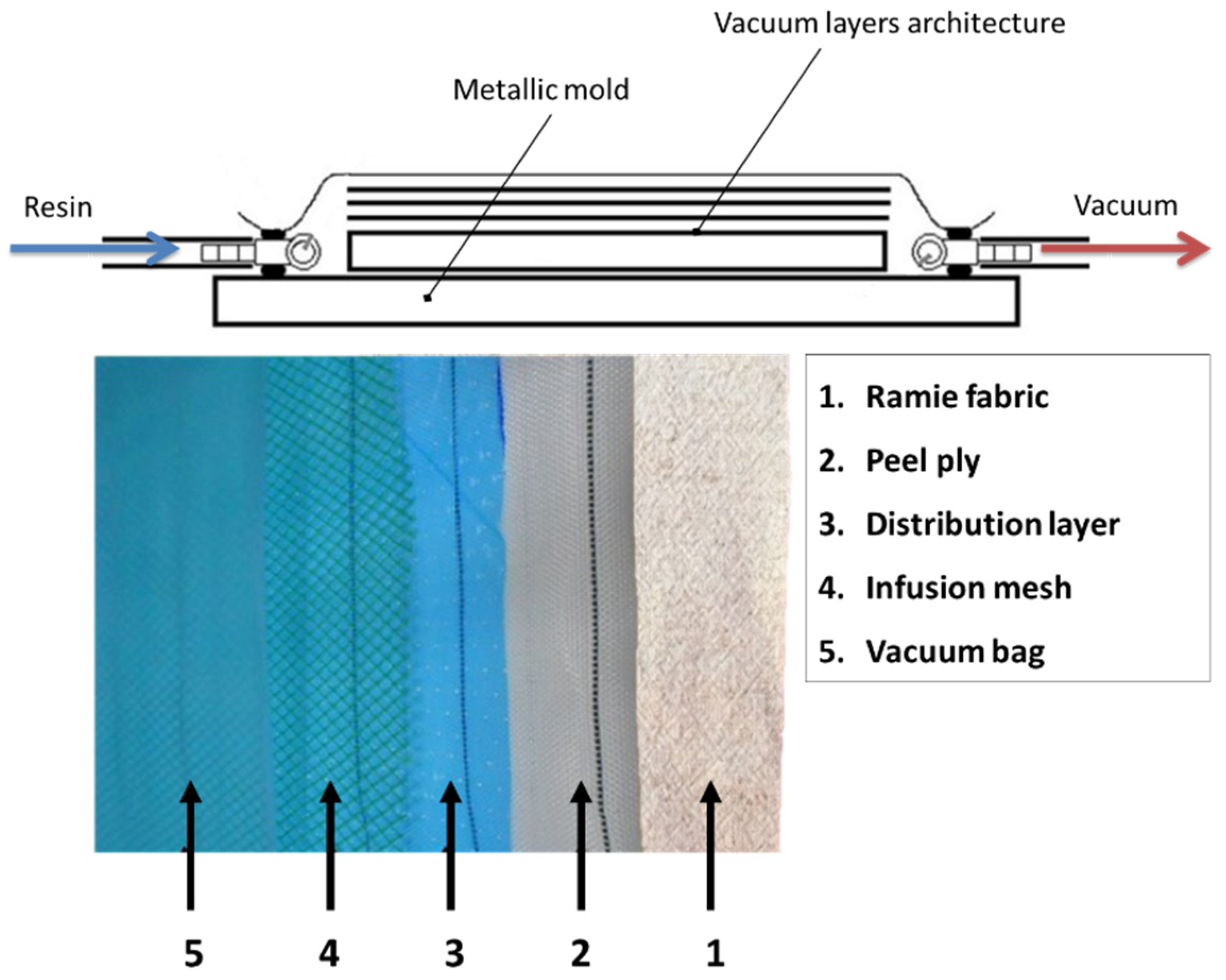

2. Experimental Procedure

3. Results and Discussion

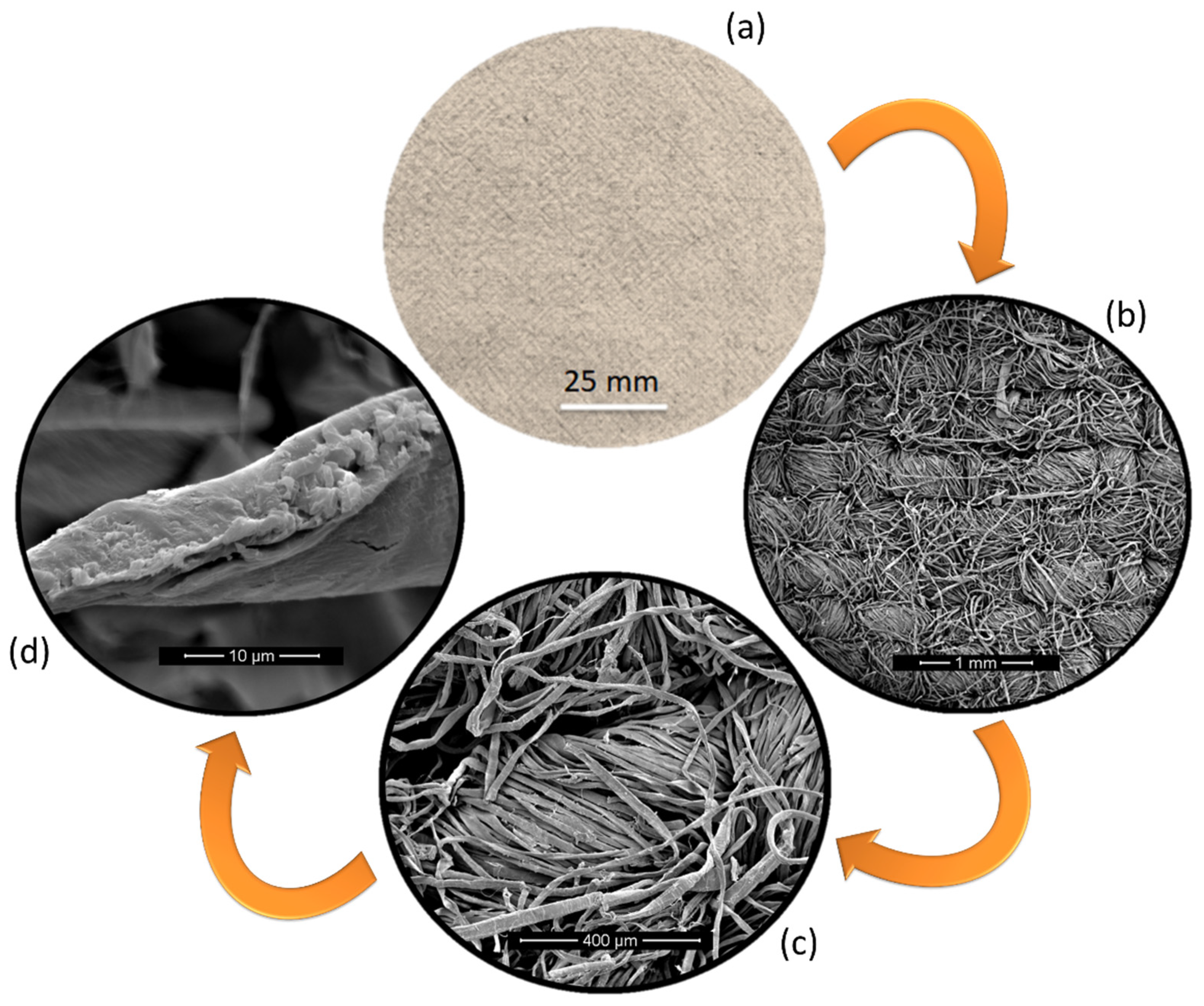

3.1. Ramie Fabric Characterization

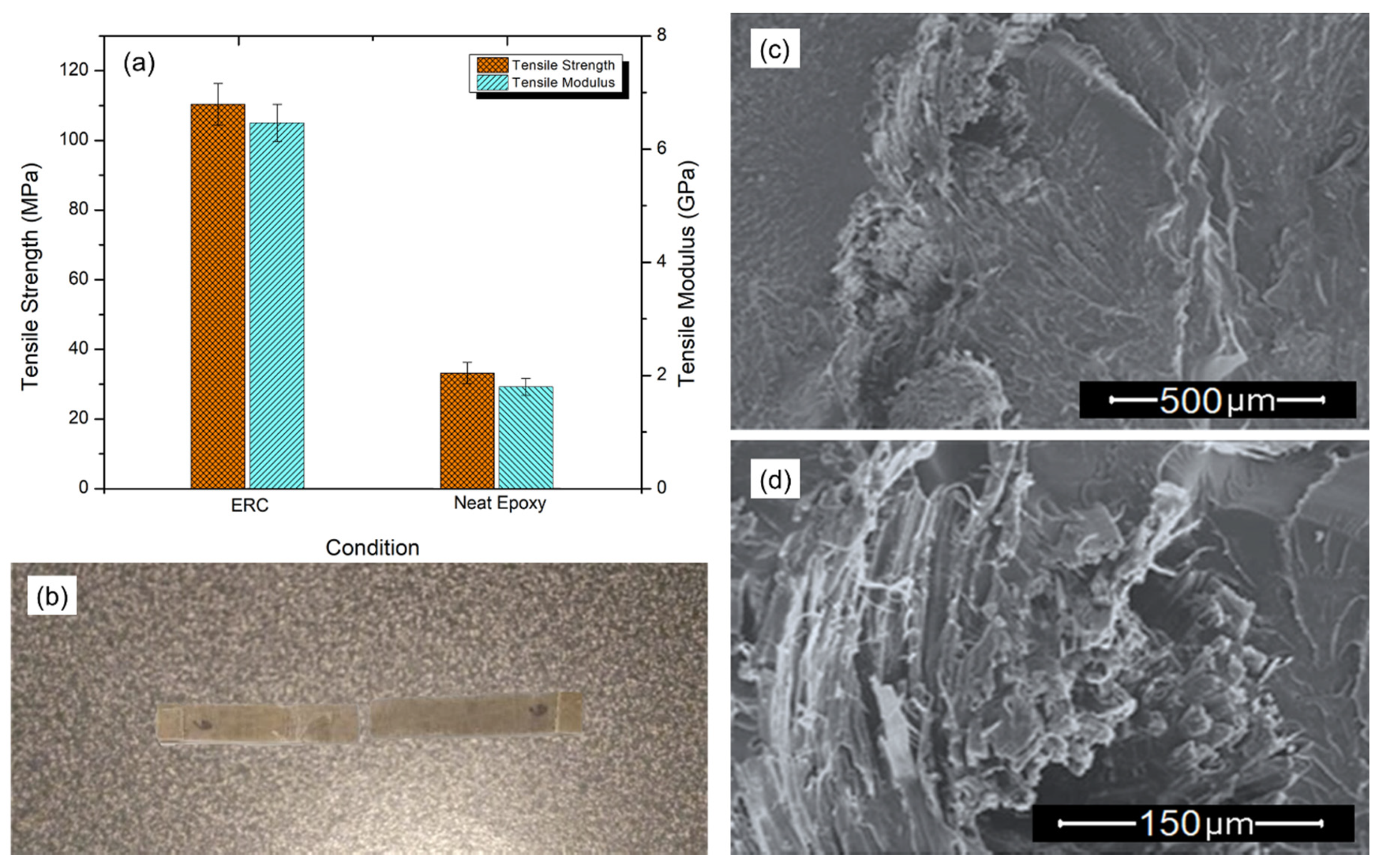

3.2. Tensile Properties

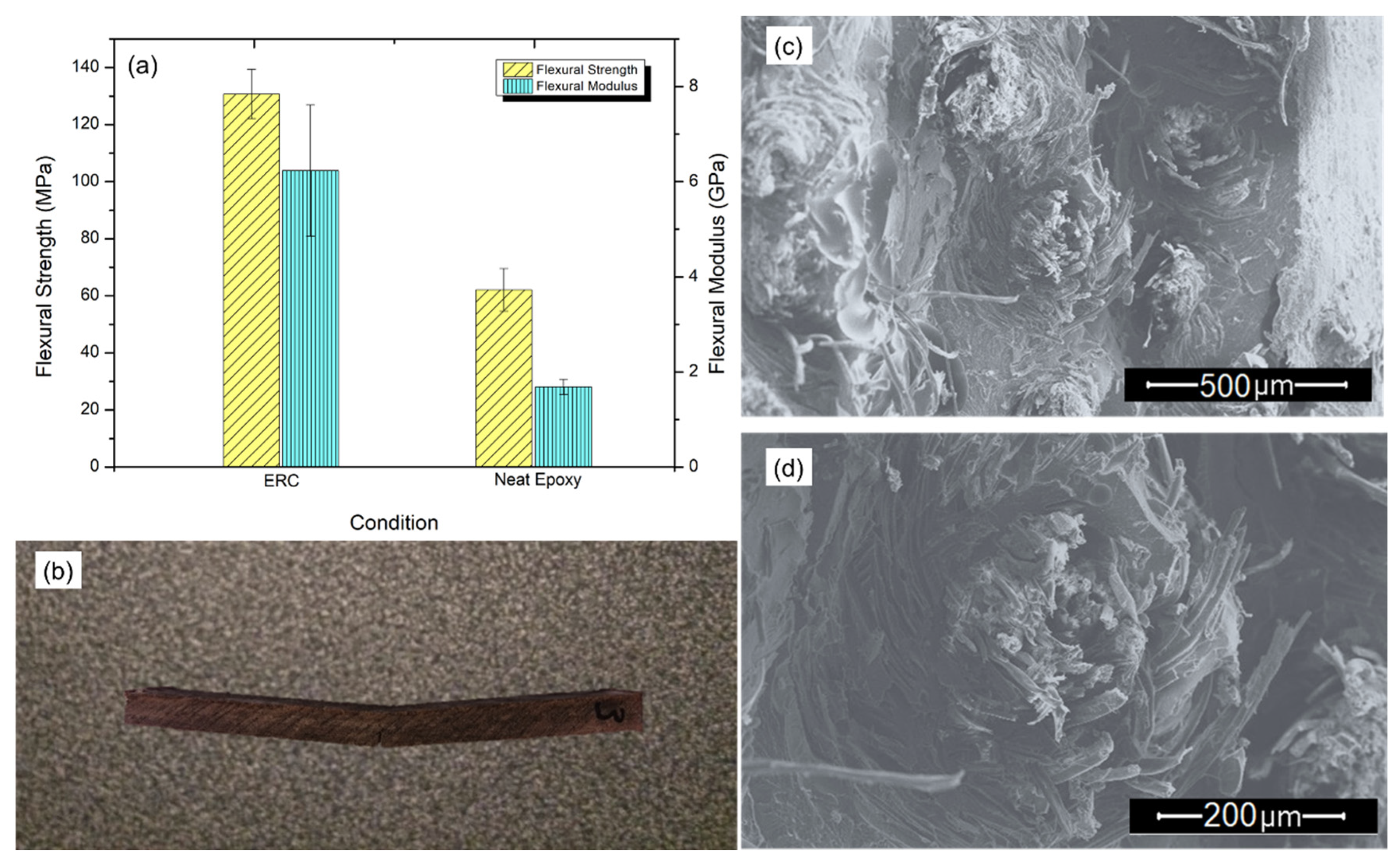

3.3. Flexural Properties

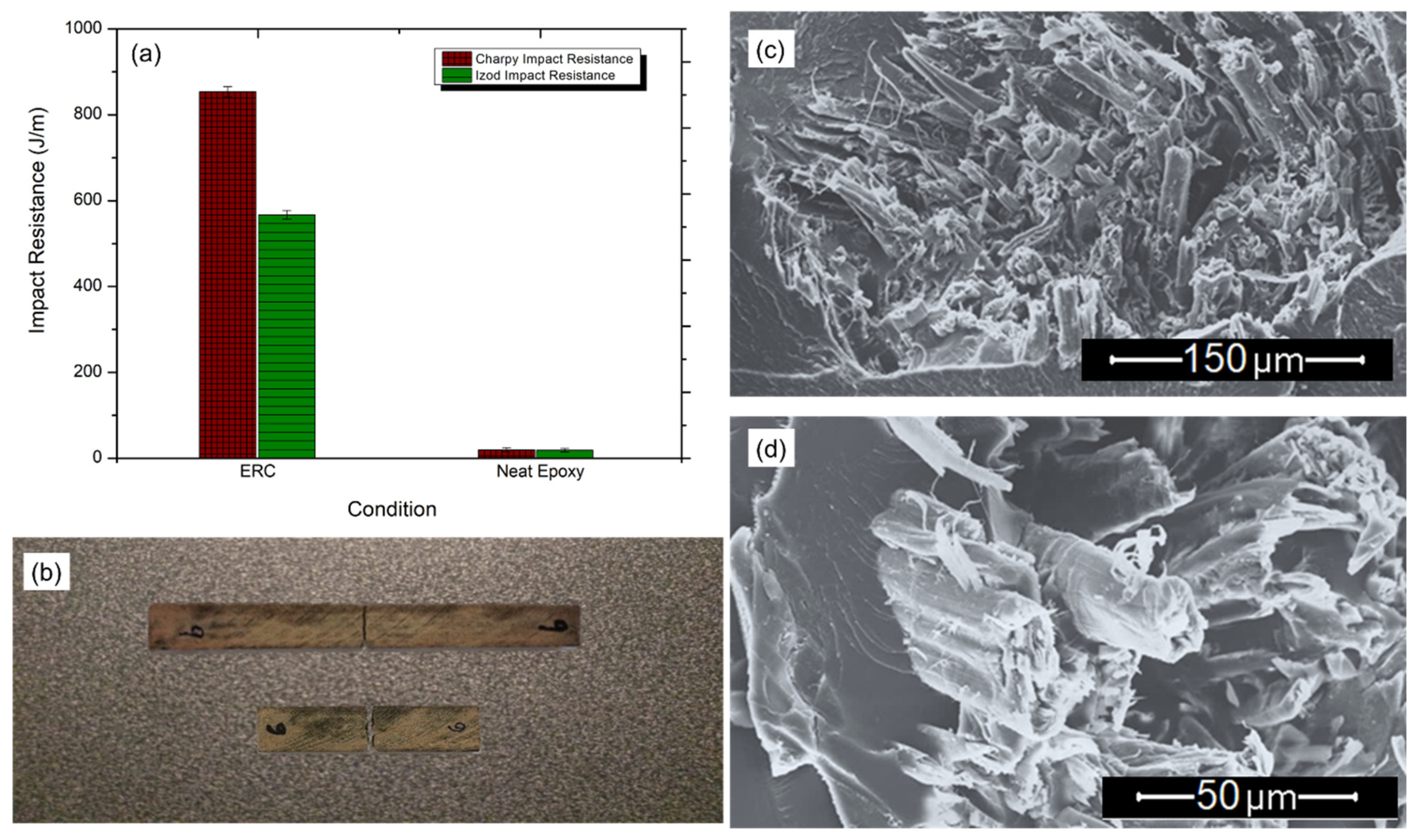

3.4. Impact Resistance

3.5. Comparison with Other NLFs Composites

4. Conclusions

- Tensile tested composites exhibit a significant increase in both the strength and tensile modulus. Ductility is almost not affected by the introduction of fabric into the epoxy matrix, but other tensile properties, such as modulus of resilience and toughness, also displayed a significant increase in comparison to the neat epoxy.

- A flexural strength of over 130 MPa and a higher flexural modulus (over 6 GPa) were observed for the ERC, corresponding to more than two times those for the neat epoxy reference condition.

- The general improvement found in the impact resistance contributes to justifying the effectiveness of the use of ERC composites for ballistic protection applications. Charpy and Izod impact resistances of ~850 and ~550 J/m were obtained.

- Comparison of three mechanical properties of prepared composite (ERC) with those of epoxy resin containing other NLFs revealed that the properties obtained in the present study are the best and highest reported so far for epoxy resin containing various NLFs. Furthermore, the above also suggests that, to achieve superior mechanical properties, it would be better to have the load transfer from the matrix to the reinforcing fibers in the fabric.

- Fractography studies of the ERC composites carried out using scanning electron microscopy suggested that pre-processing of the fabric and the VARIM technique enhanced the adhesion between the natural fiber fabric and the polymeric matrix.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bledzki, A.K.; Gassam, J. Composites reinforced with cellulose based fibers. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Mohanty, A.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Ferreira, A.S.; Nascimento, D.C.O. Natural fiber polymer matrix composites: Heaper, tougher and environmentally friendly. JOM 2009, 61, 17–22. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Thakur, V.; Thakur, M.K.; Gupta, R.K. Review: Raw Natural Fiber–Based Polymer Composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress repost on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar]

- Güven, O.; Monteiro, S.N.; Moura, E.A.B.; Drelich, J. Re-Emerging Field of Lignocellulosic Fiber—Polymer Composites and Ionizing Radiation Technology in their Formulation. Polym. Rev. 2016, 56, 702–736. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fiber composites and their mechanical performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Sanjay, M.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Drelich, J.W.; Lopera, H.A.C.; Nascimento, L.F.C.; Da Luz, F.S.; Da Silva, L.C.; Dos Santos, J.L.; Garcia Filho, F.D.C.; De Assis, F.S.; Édio, P.L.; et al. Natural Fibers Reinforced Polymer Composites Applied in Ballistic Multilayered Armor for Personal Protection—An Overview. In Green Materials Engineering; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019; pp. 33–47. [Google Scholar]

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performance of plant fiber reinforced composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 194, 108151. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Silva, I.L.; Costa, L.L. Natural lignocellulosic fibers as engineering materials—An overview. Metall. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 8th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Wambua, P.; Ivens, I.; Verpoest, I. Natural fibers: Can they replace glass in fiber reinforced plastics. Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Maciel, N.D.O.R.; Ferreira, J.B.; Vieira, J.D.S.; Ribeiro, C.G.D.; Lopes, F.P.D.; Margem, F.M.; Monteiro, S.N.; Vieira, C.M.F.; Da Silva, L.C. Comparative tensile strength analysis between epoxy composites reinforced with curaua fiber and glass fiber. J. Mater. Res. Technol. 2018, 7, 561–565. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Krishna, N.K.; Prasanth, M.; Gowtham, R.; Karthic, S.; Madhavan, M.K. Enhancement of properties of concrete using natural fibers. Mater. Today Proc. 2018, 5, 23816–23823. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Sayed, M. Bionanocomposites materials for food packing applications: Concepts and future outlook. Carbohydr. Polym. 2018, 193, 19–27. [Google Scholar] [CrossRef]

- Potluri, R.; Krishna, N.C. Potential and Applications of Green Composites in Industrial Space. Mater. Today Proc. 2020, 22, 2041–2048. [Google Scholar] [CrossRef]

- Garcia Filho, F.D.C.; Monteiro, S.N. Piassava Fiber as an Epoxy Matrix Composite Reinforcement for Ballistic Armor Applications. JOM 2018, 71, 801–808. [Google Scholar] [CrossRef]

- Pereira, A.C.; De Assis, F.S.; Garcia Filho, F.D.C.; Oliveira, M.S.; Demosthenes, L.C.D.C.; Lopera, H.A.C.; Monteiro, S.N. Ballistic performance of multilayered armor with intermediate polyester composite reinforced with fique natural fabric and fibers. J. Mater. Res. Technol. 2019, 8, 4221–4226. [Google Scholar] [CrossRef]

- Garcia Filho, F.D.C.; Oliveira, M.S.; Pereira, A.C.; Nascimento, L.F.C.; Matheus, J.R.G.; Monteiro, S.N. Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition. J. Mater. Res. Technol. 2020, 9, 1734–1741. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.; Monteiro, S.N.; Da Luz, F.S.; Pinheiro, W.A.; Garcia Filho, F.D.C. Effect of Graphene Oxide Coating on Natural Fiber Composite for Multilayered Ballistic Armor. Polymer 2019, 11, 1356. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Guimarães, J.; Wypych, F. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- Zhandarov, S. Characterization of fiber/matrix interface strength: Applicability of different tests, approaches and parameters. Compos. Sci. Technol. 2005, 65, 149–160. [Google Scholar] [CrossRef]

- Jacob, M.; Joseph, S.; Pothen, L.A.; Thomas, S. A study of advances in characterization of interfaces and fiber surfaces in lignocellulosic fiber-reinforced composites. Compos. Interfaces 2005, 12, 95–124. [Google Scholar] [CrossRef]

- Garcia Filho, F.D.C.; Da Luz, F.S.; Oliveira, M.S.; Pereira, A.C.; Costa, U.O.; Monteiro, S.N. Thermal behavior of graphene oxide-coated piassava fiber and their epoxy composites. J. Mater. Res. Technol. 2020, 9, 5343–5351. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2019, 55, 829–892. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Lu, H.R. Bast-Fiber Crops Cultivation Science in China; Agriculture Press: Beijing, China, 1992. [Google Scholar]

- International Natural Fiber Organization: Annual Production of Natural Fibers. Available online: http://www.naturalfibersinfo.org (accessed on 28 April 2020).

- Ni, J.-L.; Zhu, A.-G.; Wang, X.-F.; Xu, Y.; Sun, Z.-M.; Chen, J.-H.; Luan, M.-B. Genetic diversity and population structure of ramie (Boehmeria nivea L.). Ind. Crop. Prod. 2018, 115, 340–347. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.D.C.; Da Luz, F.S.; Pereira, A.C.; Demosthenes, L.C.D.C.; Nascimento, L.F.C.; Lopera, H.A.C.; Monteiro, S.N. Statistical analysis of notch toughness of epoxy matrix composites reinforced with fique fabric. J. Mater. Res. Technol. 2019, 8, 6051–6057. [Google Scholar] [CrossRef]

- Mishra, V.; Biswas, S. Physical and Mechanical Properties of Bi-directional Jute Fiber Epoxy Composites. Procedia Eng. 2013, 51, 561–566. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Effect of water, seawater and alcaline solution ageing on mechanical properties of flax fabric/epoxy composites used for civil engineering applications. Constr. Build. Mater. 2015, 99, 118–127. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvalho, J.P.; Vieira, C.M.F.; Lopes, F.P.; Simonassi, N.T.; Da Luz, F.S.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2020, 9, 1296–1304. [Google Scholar] [CrossRef]

- Nascimento, L.F.C.; Monteiro, S.N.; Louro, L.H.L.; Luz, F.S.; Santos, J.L.; Braga, F.O.; Marçal, R.L.S.B. Charpy impact testo f epoxy composites reinforced with untreated and mercerized mallow fibers. J. Mater. Res. Technol. 2018, 7, 520–527. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.; Bezerra, W.B.A.; Monteiro, S.N. Evaluation of Izod impact and bend properties of epoxy composites reinforced with mallow fibers. J. Mater. Res. Technol. 2020, 9, 373–382. [Google Scholar] [CrossRef]

- Simonassi, N.T.; Pereira, A.C.; Monteiro, S.N.; Margem, F.M.; Rodríguez, R.J.S.; De Deus, J.F.; Vieira, C.M.F.; Drelich, J. Reinforcement of Polyester with Renewable Ramie Fibers. Mater. Res. 2017, 20, 51–59. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17, Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D790-17, Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D6110-18, Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics; ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- ASTM D256-10, Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics; ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- ASTM D3776/D3776M-09a, Standard Test Methods for Mass Per Unit Area (Weight) of Fabric; ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Ma, H.; Li, Y.; Shen, Y.; Xie, L.; Wang, D. Effect of linear density and yarn structure on the mechanical properties of ramie fiber yarn reinforced composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 98–108. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; Oliveira, M.S.; Junior, V.F.D.V.; Garcia Filho, F.D.C.; Pinheiro, M.A.; Candido, V.S.; Monteiro, S.N.; De Veiga, V.F.; Da Silva, A.C.R. Guaruman fiber: Another possible reinforcement in composites. J. Mater. Res. Technol. 2020, 9, 622–628. [Google Scholar] [CrossRef]

- Gu, Y.; Tan, X.; Yang, Z.; Li, M.; Zhang, Z. Hot compaction and mechanical properties of ramie fabric/epoxy composite fabricated using vacuum assisted resin infusion molding. Mater. Des. 2014, 56, 852–861. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Milanezi, T.L.; Louro, L.H.L.; Édio, P.L.; Braga, F.D.O.; Gomes, A.; Drelich, J. Novel ballistic ramie fabric composite competing with Kevlar™ fabric in multilayered armor. Mater. Des. 2016, 96, 263–269. [Google Scholar] [CrossRef]

- Andrew, J.J.; Srinivasan, S.M.; Arockiarajan, A.; Dhakal, H.N.; Arokiarajan, A. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Compos. Struct. 2019, 224, 111007. [Google Scholar] [CrossRef]

| Properties | Neat Epoxy | ERC |

|---|---|---|

| Toughness | 87.8 ± 14.5 MJ/m3 | 184.7 ± 16.8 MJ/m3 |

| Modulus of Resilience | 12.5 ± 1.1 MJ/m3 | 21.5 ± 5.7 MJ/m3 |

| Ductility | 3.18 ± 0.31%EL [in 57 mm] | 4.71 ± 1.26%EL [in 57 mm] |

| Elongation at fracture | 0.81 ± 0.023 mm | 0.88 ± 0.015 mm |

| Composite (0.3NLFs/0.7polymer) | Fiber Design/Manufacture Method | Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Resistance (J/m) | Reference |

|---|---|---|---|---|---|

| ERC | Bidirectional fabric/VARIM | 110 ± 6 | 131 ± 9 | (C) 854 ± 12 (I) 567 ± 10 | *PW |

| Fique/epoxy | Bidirectional fabric/Press molding | 47 | X | (C) 480 ± 180 (I) 222 ± 50 | 35 |

| Jute/epoxy | Bidirectional fabric/Hand lay-up | 90 | 34 | (I) 426 | 36 |

| Flax/epoxy | Bidirectional fabric/Hand lay-up | 118 | 131 | X | 37 |

| Hemp/epoxy | Unidirectional and long/Press molding | 50 ± 4 | 77 ± 6 | X | 38 |

| Mallow/epoxy | Unidirectional and long/Press molding | 178 ± 18 | 191 ± 24 | (C) 905 ± 95 (I) 499 ± 35 | 39, 40 |

| Ramie/polyester | Unidirectional and long/Press molding | 89 ± 9 | 212 ± 12 | (C) 1000 (I) 594 | 41 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia Filho, F.d.C.; Luz, F.S.d.; Nascimento, L.F.C.; Gundappa Satyanarayana, K.; Wieslaw Drelich, J.; Neves Monteiro, S. Mechanical Properties of Boehmeria nivea Natural Fabric Reinforced Epoxy Matrix Composite Prepared by Vacuum-Assisted Resin Infusion Molding. Polymers 2020, 12, 1311. https://doi.org/10.3390/polym12061311

Garcia Filho FdC, Luz FSd, Nascimento LFC, Gundappa Satyanarayana K, Wieslaw Drelich J, Neves Monteiro S. Mechanical Properties of Boehmeria nivea Natural Fabric Reinforced Epoxy Matrix Composite Prepared by Vacuum-Assisted Resin Infusion Molding. Polymers. 2020; 12(6):1311. https://doi.org/10.3390/polym12061311

Chicago/Turabian StyleGarcia Filho, Fabio da Costa, Fernanda Santos da Luz, Lucio Fabio Cassiano Nascimento, Kestur Gundappa Satyanarayana, Jaroslaw Wieslaw Drelich, and Sergio Neves Monteiro. 2020. "Mechanical Properties of Boehmeria nivea Natural Fabric Reinforced Epoxy Matrix Composite Prepared by Vacuum-Assisted Resin Infusion Molding" Polymers 12, no. 6: 1311. https://doi.org/10.3390/polym12061311

APA StyleGarcia Filho, F. d. C., Luz, F. S. d., Nascimento, L. F. C., Gundappa Satyanarayana, K., Wieslaw Drelich, J., & Neves Monteiro, S. (2020). Mechanical Properties of Boehmeria nivea Natural Fabric Reinforced Epoxy Matrix Composite Prepared by Vacuum-Assisted Resin Infusion Molding. Polymers, 12(6), 1311. https://doi.org/10.3390/polym12061311