Environmentally Efficient 316L Stainless Steel Feedstocks for Powder Injection Molding

Abstract

1. Introduction

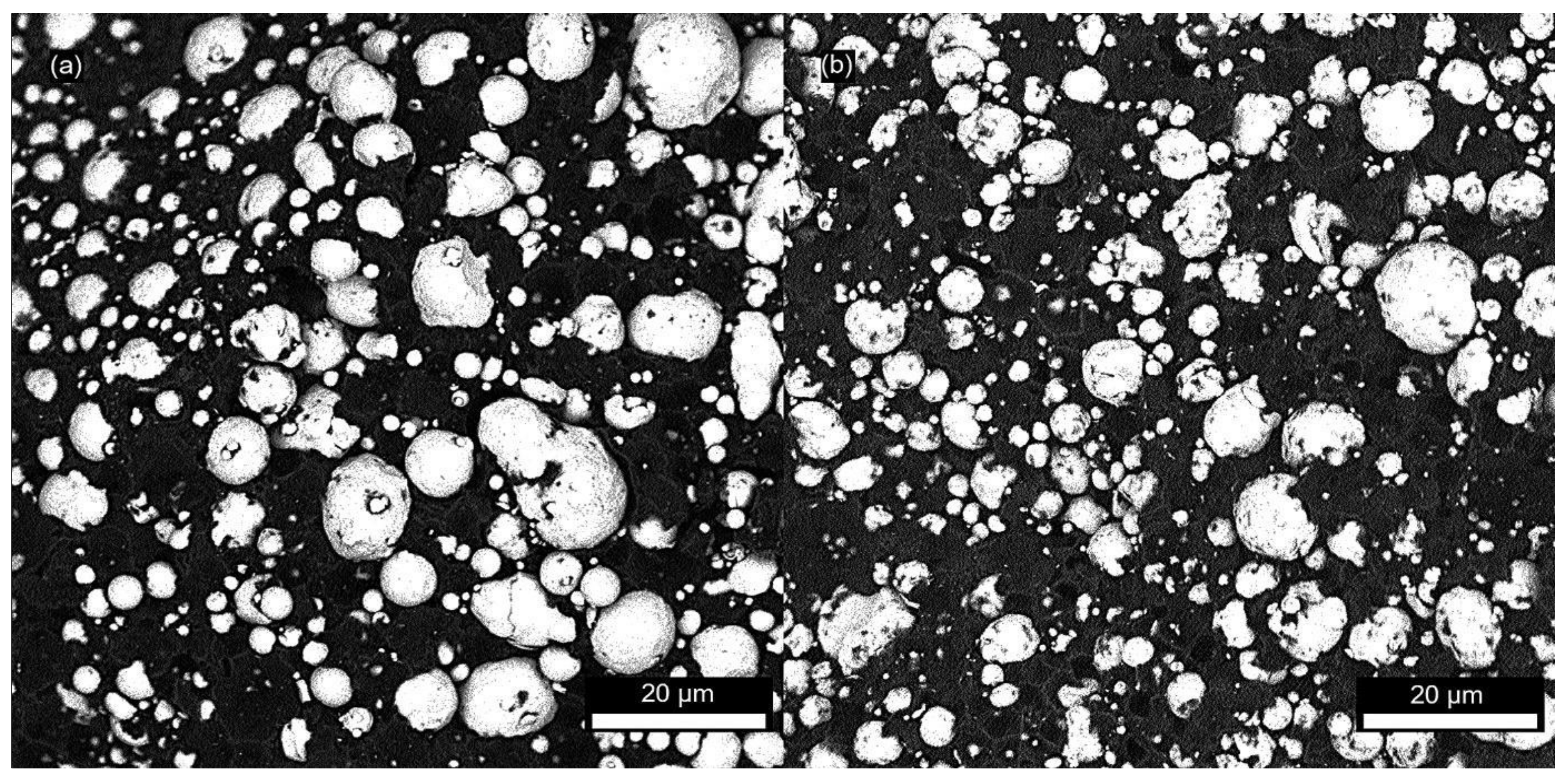

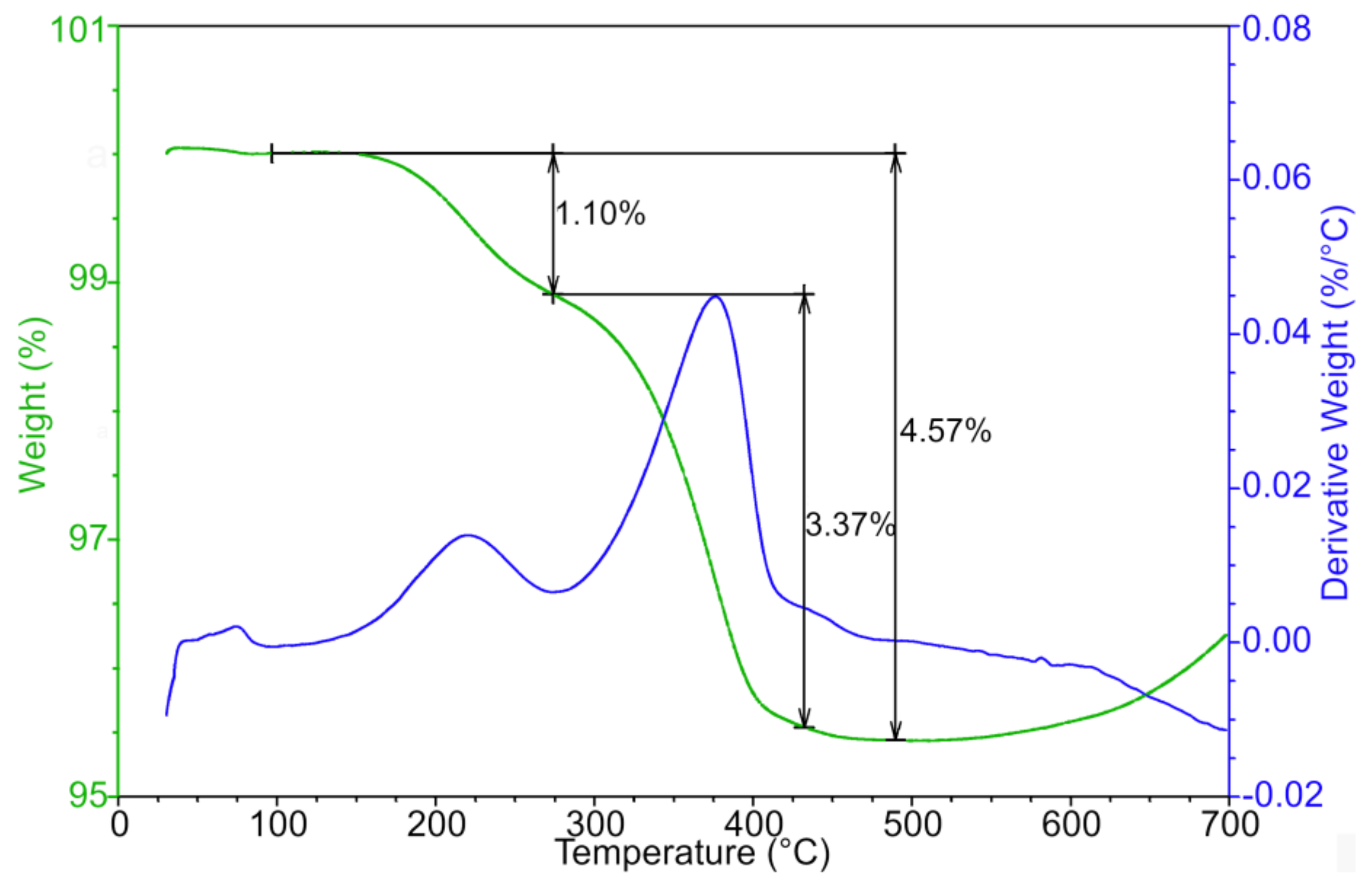

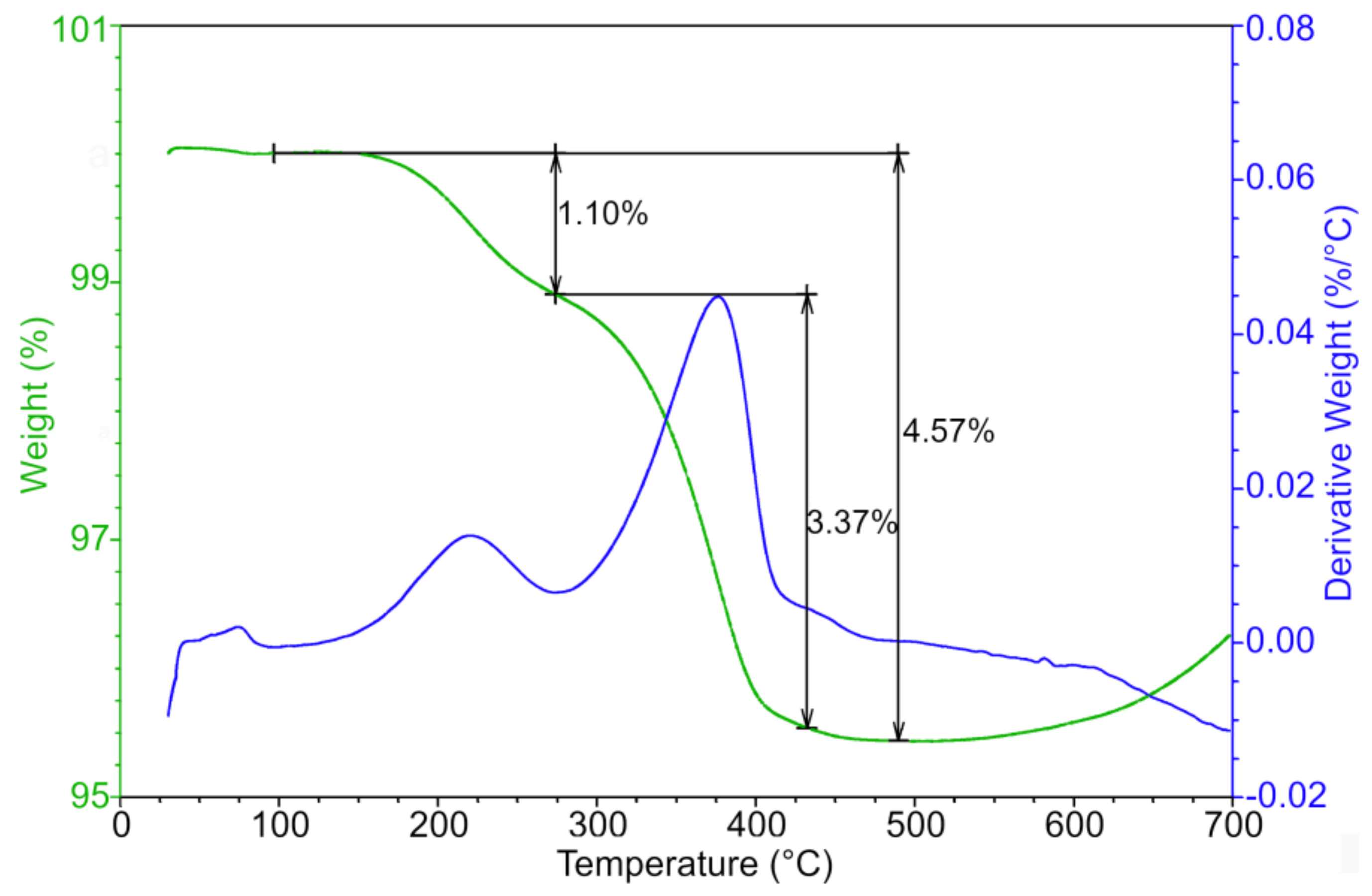

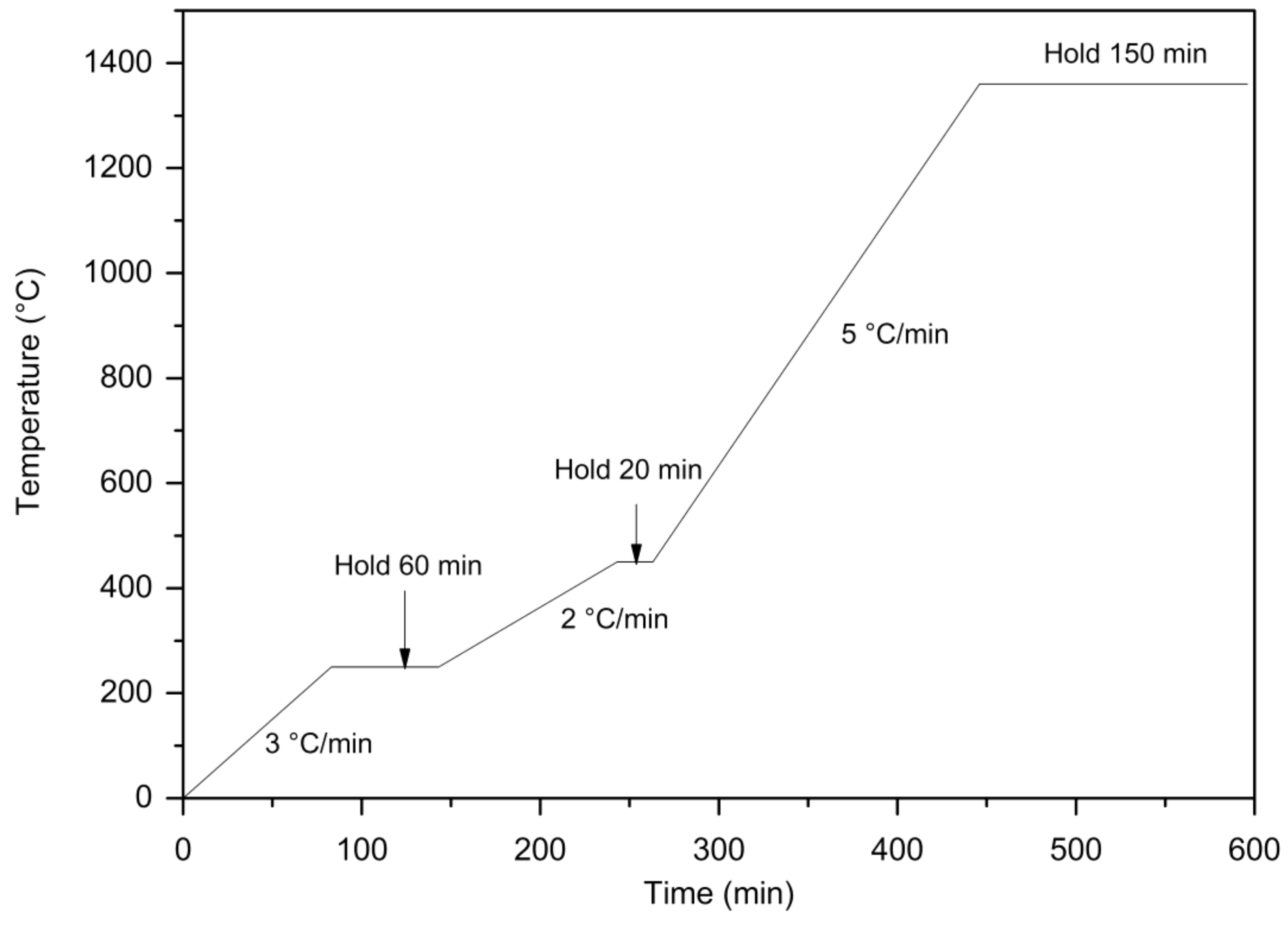

2. Materials and Methods

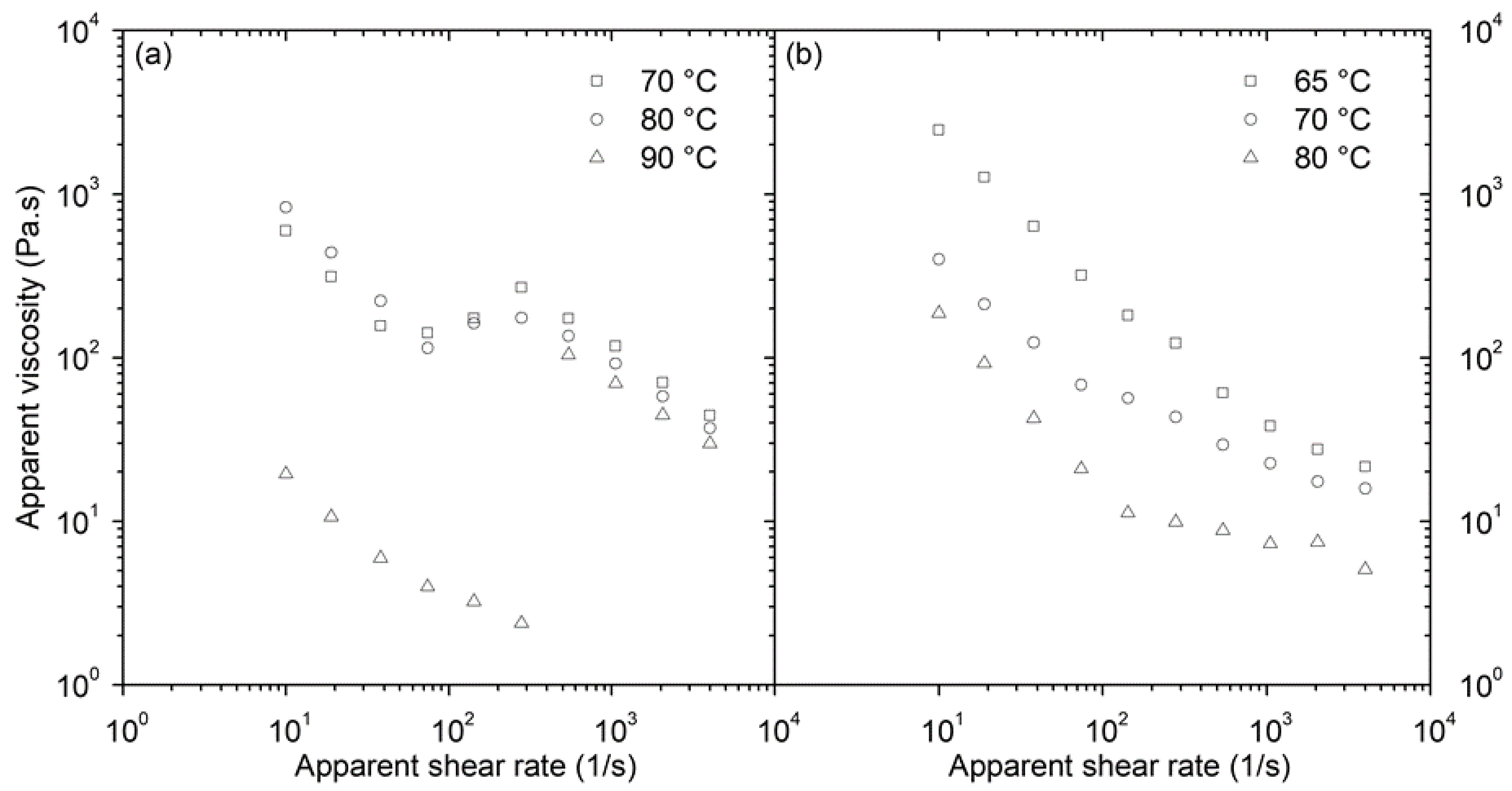

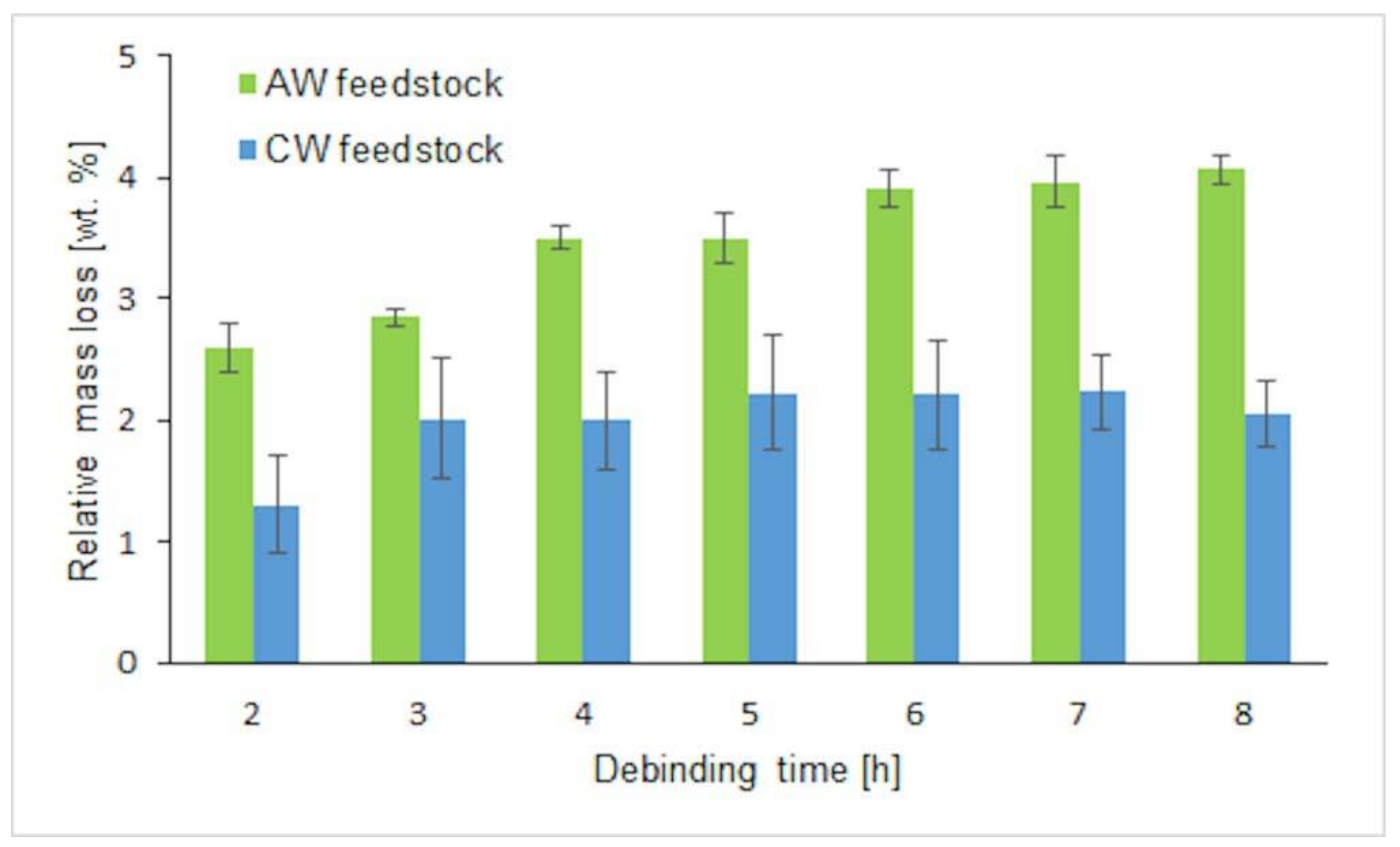

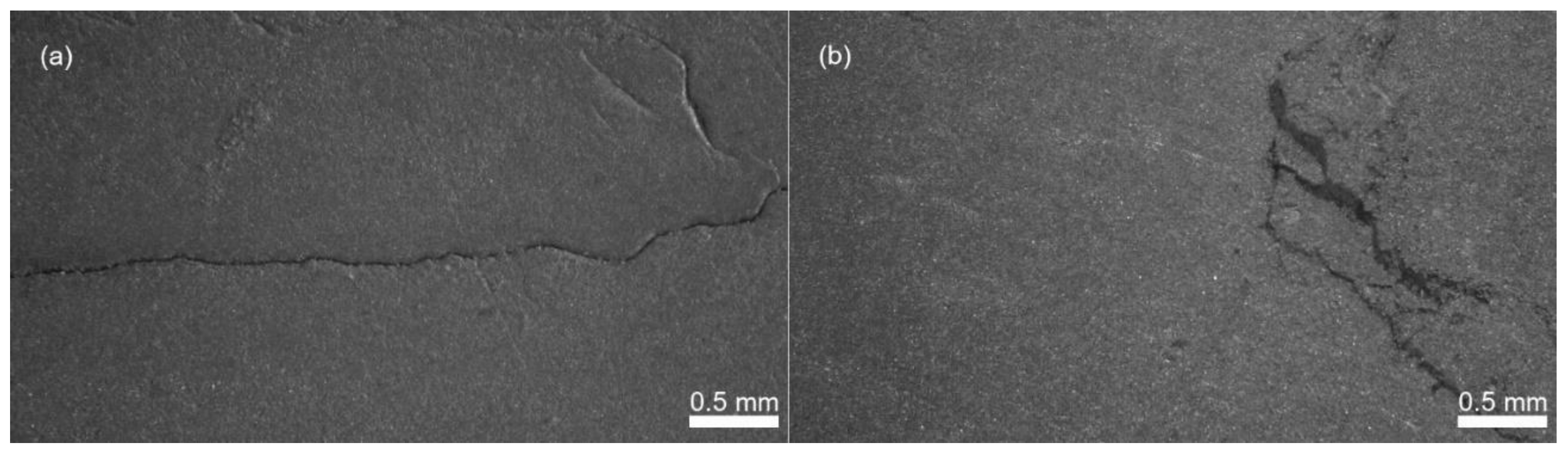

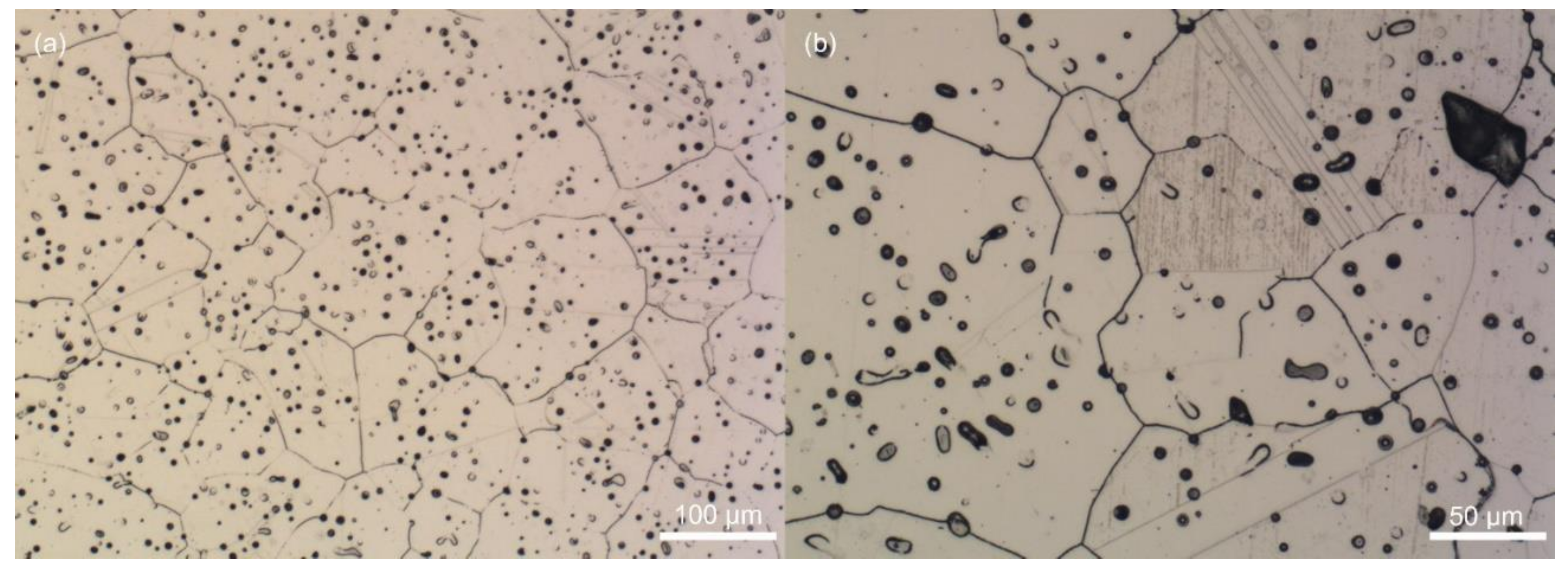

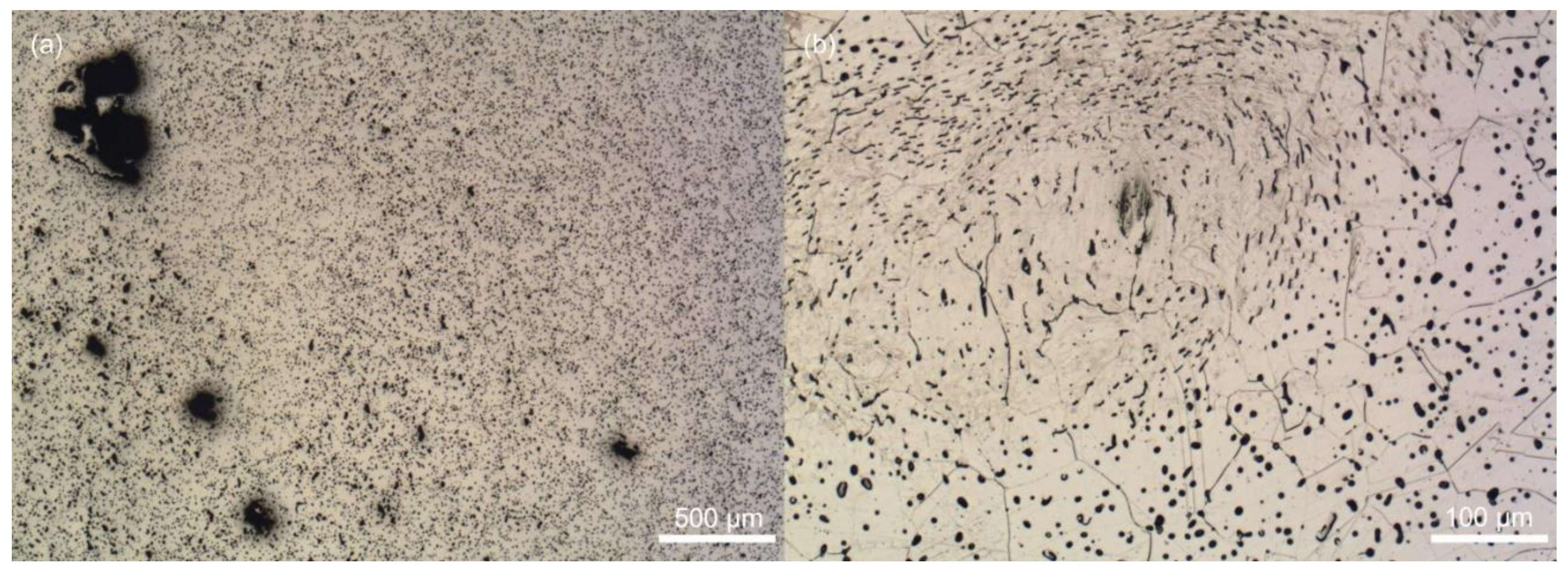

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Metall. Mater. Trans. A 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Guo, P.; Zou, B.; Huang, C.; Gao, H. Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition. J. Mater. Process. Technol. 2017, 240, 12–22. [Google Scholar] [CrossRef]

- Hinojos, A.; Mireles, J.; Reichardt, A.; Frigola, P.; Hosemann, P.; Murr, L.E.; Wicker, R.B. Joining of Inconel 718 and 316 Stainless Steel using electron beam melting additive manufacturing technology. Mater. Des. 2016, 94, 17–27. [Google Scholar] [CrossRef]

- Quinard, C.; Barriere, T.; Gelin, J.C. Development and property identification of 316L stainless steel feedstock for PIM and µPIM. Powder Technol. 2009, 190, 123–128. [Google Scholar] [CrossRef]

- Sotomayor, M.E.; Levenfeld, B.; Várez, A. Powder injection moulding of premixed ferritic and austenitic stainless steel powders. Mater. Sci. Eng. A 2011, 528, 3480–3488. [Google Scholar] [CrossRef]

- Huang, M.-S.; Hsu, H.-C. Effect of backbone polymer on properties of 316L stainless steel MIM compact. J. Mater. Process. Technol. 2009, 209, 5527–5535. [Google Scholar] [CrossRef]

- Hausnerova, B.; Bleyan, D.; Kasparkova, V.; Pata, V. Surface adhesion between ceramic injection molding feedstocks and processing tools. Ceram. Int. 2016, 42, 460–465. [Google Scholar] [CrossRef]

- Checot-Moinard, D.; Rigollet, C.; Lourdin, P. Powder injection moulding PIM of feedstock based on hydrosoluble binder and submicronic powder to manufacture parts having micro-details. Powder Technol. 2011, 208, 472–479. [Google Scholar] [CrossRef]

- Bleyan, D.; Svoboda, P.; Hausnerova, B. Specific interactions of low molecular weight analogues of carnauba wax and polyethylene glycol binders of ceramic injection moulding feedstocks. Ceram. Int. 2015, 41, 3975–3982. [Google Scholar] [CrossRef]

- Hausnerova, B.; Kuritka, I.; Bleyan, D. Polyolefin Backbone Substitution in Binders for Low Temperature Powder Injection Moulding Feedstocks. Molecules 2014, 19, 2748–2760. [Google Scholar] [CrossRef]

- Yang, W.-W.; Yang, K.-Y.; Hon, M.-H. Effects of PEG molecular weights on rheological behavior of alumina injection molding feedstocks. Mater. Chem. Phys. 2003, 78, 416–424. [Google Scholar] [CrossRef]

- Krauss, V.A.; Oliveira, A.A.M.; Klein, A.N.; Al-Qureshi, H.A.; Fredel, M.C. A model for PEG removal from alumina injection moulded parts by solvent debinding. J. Mater. Process. Technol. 2007, 182, 268–273. [Google Scholar] [CrossRef]

- Bernardo, E.; Hidalgo, J.; Jiménez-Morales, A.; Torralba, J.M. Powder Injection Moulding: Feedstock Development: Feedstock Development for Powder Injection Moulding of Zirconium Silicate. In Proceedings of the European Congress and Exhibition on Powder Metallurgy. European PM Conference Proceedings, Barcelona, Spain, 9–12 October 2011; pp. 1–6. [Google Scholar]

- Abajo, C.; Jiménez-Morales, A.; Torralba, J.M. New processing route for ZrSiO4 by powder injection moulding using an eco-friendly binder system. Bol. Soc. Esp. Ceram. Vidrio 2015, 54, 93–100. [Google Scholar] [CrossRef]

- Bleyan, D.; Hausnerova, B.; Svoboda, P. The development of powder injection moulding binders: A quantification of individual components’ interactions. Powder Technol. 2015, 286, 84–89. [Google Scholar] [CrossRef]

- Hauf, G.; Hütter, M. Data Sheet—polyMIM® 316L; Polymer-Chemie GmbH: Bad Sobernheim, Germany, 2009. [Google Scholar]

- Vuluga, Z.; Corobea, M.C.; Elizetxea, C.; Ordonez, M.; Ghiurea, M.; Raditoiu, V.; Nicolae, C.A.; Florea, D.; Iorga, M.; Somoghi, R.; et al. Morphological and Tribological Properties of PMMA/Halloysite Nanocomposites. Polymers 2018, 10, 816. [Google Scholar] [CrossRef] [PubMed]

- MPIF Standard 50. Standard Test Methods for Metal Powders and Powder Metallurgy Products; Metal Powder Industries Federation: Princeton, NJ, USA, 2012; pp. 91–93. ISBN 978-0-9819496-8-0. [Google Scholar]

- Hoffman, R.L. Discontinuous and Dilatant Viscosity Behavior in Concentrated Suspensions. I. Observation of a Flow Instability. Trans. Soc. Rheol. 1972, 16, 155–173. [Google Scholar] [CrossRef]

- Barnes, H.A. A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: Its cause, character, and cure. J. Non-Newtonian Fluid Mech. 1995, 56, 221–251. [Google Scholar] [CrossRef]

- Hausnerova, B.; Kasparkova, V.; Hnatkova, E. Effect of backbone binders on rheological performance of ceramic injection molding feedstocks. Polym. Eng. Sci. 2017, 57, 739–745. [Google Scholar] [CrossRef]

- Hausnerova, B.; Marcanikova, L.; Filip, P.; Saha, P. Optimization of powder injection molding of feedstock based on aluminum oxide and multicomponent water-soluble polymer binder. Polym. Eng. Sci. 2011, 51, 1376–1382. [Google Scholar] [CrossRef]

- Hnatkova, E.; Hausnerova, B.; Filip, P. Evaluation of powder loading and flow properties of Al2O3 ceramic injection molding feedstocks treated with stearic acid. Ceram. Int. 2019, 45, 20084–20090. [Google Scholar] [CrossRef]

- Memon, S.A.; Liao, W.Y.; Yang, S.; Cui, H.; Shah, S.F.A. Development of Composite PCMs by Incorporation of Paraffin into Various Building Materials. Materials 2015, 8, 499–518. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.C.; Al-Kayiem, H.H. Evaluation of copper nanoparticles—Paraffin wax compositions for solar thermal energy storage. Sol. Energy 2016, 132, 267–278. [Google Scholar] [CrossRef]

- Zaky, M.T.; Soliman, F.S.; Farag, A.S. Influence of paraffin wax characteristics on the formulation of wax-based binders and their debinding from green molded parts using two comparative techniques. J. Mater. Process. Technol. 2009, 209, 5981–5989. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, L.; Shan, F.; Fang, G. Preparation and characteristics of microencapsulated stearic acid as composite thermal energy storage material in buildings. Energy Build. 2013, 62, 469–474. [Google Scholar] [CrossRef]

- Oh, M.C.; Seok, H.; Kim, H.-J.; Ahn, B. De-Lubrication Behavior of Novel EBS Based Admixed Lubricant in Aluminum P/M Alloy. Arch. Metall. Mater. 2015, 60, 1427–1431. [Google Scholar] [CrossRef]

- Zhang, J.; Li, H.; Tu, J.; Shi, R.; Luo, Z.; Xiong, C.; Jiang, M. Shape Stability of Polyethylene Glycol/Acetylene Black Phase Change Composites for Latent Heat Storage. Adv. Mater. Sci. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Ni, J.; Yu, M.; Han, K. Debinding and Sintering of an Injection-Moulded Hypereutectic Al–Si Alloy. Materials 2018, 11, 807. [Google Scholar] [CrossRef]

- Craig, R.G.; Powers, J.M.; Peyton, F.A. Thermogravimetric Analysis of Waxes. J. Dent. Res. 1971, 50, 450–454. [Google Scholar] [CrossRef]

- Raza, M.R.; Ahmad, F.; Muhamad, N.; Sulong, A.B.; Omar, M.A.; Akhtar, M.N.; Aslam, M.; Shrazi, I. Effects of Debinding and Sintering Atmosphere on Properties and Corrosion Resistance of Powder Injection Molded 316 L—Stainless Steel. Sains Malays. 2017, 46, 285–293. [Google Scholar] [CrossRef]

- Chinnathaypgal, V.N.; Rangarasaiah, R.M.; Desai, V.; Samanta, S.K. Evaluation of Wear Behaviour of Metal Injection Moulded Nickel Based Metal Matrix Composite. Silicon 2019, 11, 175–185. [Google Scholar] [CrossRef]

- Shang, F.; Qiao, B.; Dong, Y.F.; Cao, Z.-W.; Sun, W.; He, Y.-Q. Simulation on the Two-phase Separation of Powder Injection Molding 316L Stainless Steel. Mater. Sci. 2019, 25, 246–251. [Google Scholar] [CrossRef]

- Natali, S.; Brotzu, A.; Pilone, D. Comparison between Mechanical Properties and Structures of a Rolled and a 3D-Printed Stainless Steel. Materials 2019, 12, 3867. [Google Scholar] [CrossRef] [PubMed]

- Kanchanomai, C.; Saengwichian, B.; Manonukul, A. Delamination wear of metal injection moulded 316L stainless steel. Wear 2009, 267, 1665–1672. [Google Scholar] [CrossRef]

- Sulima, I.; Ratuszek, W.; Zielińska-Lipiec, A.; Jaworska, L. Microstructural Evolution of 316L Austenitic Stainless Steel with 2%TiB2 Addition during the HP-HT Sintering. Steel Res. Int. 2017, 88, 1700047. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Ahn, S.; Lee, J.; Lee, C.S. Effects of Sintering Conditions on the Mechanical Properties of Metal Injection Molded 316L Stainless Steel. ISIJ Int. 2003, 43, 119–126. [Google Scholar] [CrossRef]

| Injection Molding Parameter | Material | |

|---|---|---|

| AW Feedstock | CW Feedstock | |

| Temperature—nozzle [°C] | 75 | 65 |

| Temperature—zone 1 [°C] | 95 | 70 |

| Temperature—zone 2 [°C] | 85 | 90 |

| Temperature—zone 3 [°C] | 80 | 80 |

| Temperature—zone 4 [°C] | 75 | 60 |

| Temperature—zone 5 [°C] | 20 | 30 |

| Screw stroke [mm] | 60 | 70 |

| Cooling time [s] | 30 | 10 |

| Injection pressure [bar] | 1000 | 500 |

| Hold pressure/time 1 [bar]/[s] | 800/5 | 400/5 |

| Hold pressure/time 2 [bar]/[s] | 150/2 | 50/0.5 |

| Mechanical Property | Speed [°C/min] | ||

|---|---|---|---|

| 5 | 10 | 15 | |

| Tensile strength [MPa] | 557 ± 34 | 535 ± 45 | 546 ± 41 |

| Yield strength [MPa] | 264 ± 6 | 267 ± 5 | 264 ± 2 |

| Elongation [%] | 30 ± 8 | 25 ± 11 | 27 ± 9 |

| Sintered density [g/cm3] | 7.27 | 7.16 | 7.22 |

| Vickers Microhardness [HV] | 150 ± 6 | 145 ± 7 | 145 ± 11 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hausnerova, B.; Novak, M. Environmentally Efficient 316L Stainless Steel Feedstocks for Powder Injection Molding. Polymers 2020, 12, 1296. https://doi.org/10.3390/polym12061296

Hausnerova B, Novak M. Environmentally Efficient 316L Stainless Steel Feedstocks for Powder Injection Molding. Polymers. 2020; 12(6):1296. https://doi.org/10.3390/polym12061296

Chicago/Turabian StyleHausnerova, Berenika, and Martin Novak. 2020. "Environmentally Efficient 316L Stainless Steel Feedstocks for Powder Injection Molding" Polymers 12, no. 6: 1296. https://doi.org/10.3390/polym12061296

APA StyleHausnerova, B., & Novak, M. (2020). Environmentally Efficient 316L Stainless Steel Feedstocks for Powder Injection Molding. Polymers, 12(6), 1296. https://doi.org/10.3390/polym12061296