The prediction of material behavior can lead to immense savings, monetary and time wise, in various industrial processes. A commonly chosen method for such predictions is the analysis of rheological material properties. The subsequent modelling of generated data can potentially further expand its predictability exceeding the underlying experimental range. Due to the advances in computational engineering and technology, many researches focus on constitutive modeling, based on linear and nonlinear continuum mechanics [

1,

2] and computational modeling using a variety of finite element approaches [

3,

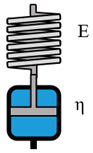

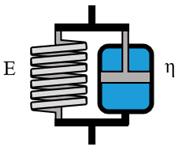

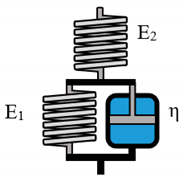

4]. Computational simulations are often highly specific due to the chosen boundary conditions, while continuum mechanical approaches require a deep knowledge of the underlying physical and mathematical tools. A more accessible approach for rheological modelling is based on classic mechanics following Hooks law (springs) and Newtonian behavior (dashpot). Examples of this approach can be found in the literature since the 1960s [

5], where already correlations of rheological properties and asphalt mixtures have been investigated. Since this time, the application of rheological model systems has continued, covering a wide range of industrial related research fields. Dey et al. [

6] used the Burgers model parameters, derived from stress relaxation tests for further characterizing the response of soil beds to viscoelastic loads. He concluded the Burgers model as suitable for describing a majority of occurring time dependent visco-elastic effects and explicitly suggests its use for geotechnical engineering. Mazurek et al. [

7] modelled the stiffness of asphalt concrete within the linear viscoelastic regime. He also compared the applicability of different higher order model systems, such as Burgers model, Huet–Sayegh, and generalized Maxwell model and concluded the Huet–Sayegh model was the most suitable one. While they deemed the Burgers model as not suitable for modelling the asphalt concrete behavior, they also included a table that shows an adequate R

2 and mean normalized error while fitting the obtained complex modulus data. Xu et al. [

8] took this approach even further and used mathematical functions, derived from rheological models, in order to generate a master curve for the measured dynamic moduli. Mahiuddin et al. [

9] displayed a completely different use for rheological modelling. He dedicated his research to the characterization of mechanical properties of fruits and vegetables in order to optimize transportation, storage and handling of harvested goods. Therefore, he compared the applicability of three elements generalized Maxwell model with a fractional power-law model, solved using Caputos’ fractional derivate. By using the fractional power-law model he could reduce the amount of fit parameters from seven to four, while still guaranteeing an adequate description of the measured stress–relaxation data. In the eyes of the authors, a reevaluation of the showcased data using the Burgers model, which uses four fitting parameters as well, should yield an adequate description as well. Shi et al. [

10] and Meng et al. [

11] used the three and four parameter Burgers model to predict stress relaxation properties of starch films and rice flour. An accurate description of the stress–strain relation and creep properties was achieved. Kundera et al. used a generalized Maxwell approach to describe the visco-elastic stress recovery behavior of O-rings, produced by an additive manufacturing approach [

12]. A generalized Maxwell model, using five fitting parameters, was used to describe the stress–relaxation properties of the sealings. However, only the mechanical properties were correlated with the rheological model parameters. A direct correlation of sealing properties and model parameters did not take place. The here shown examples are representative for a wide field of rheological modelling. The majority of modelling approaches is based on the stress–relaxation test procedure [

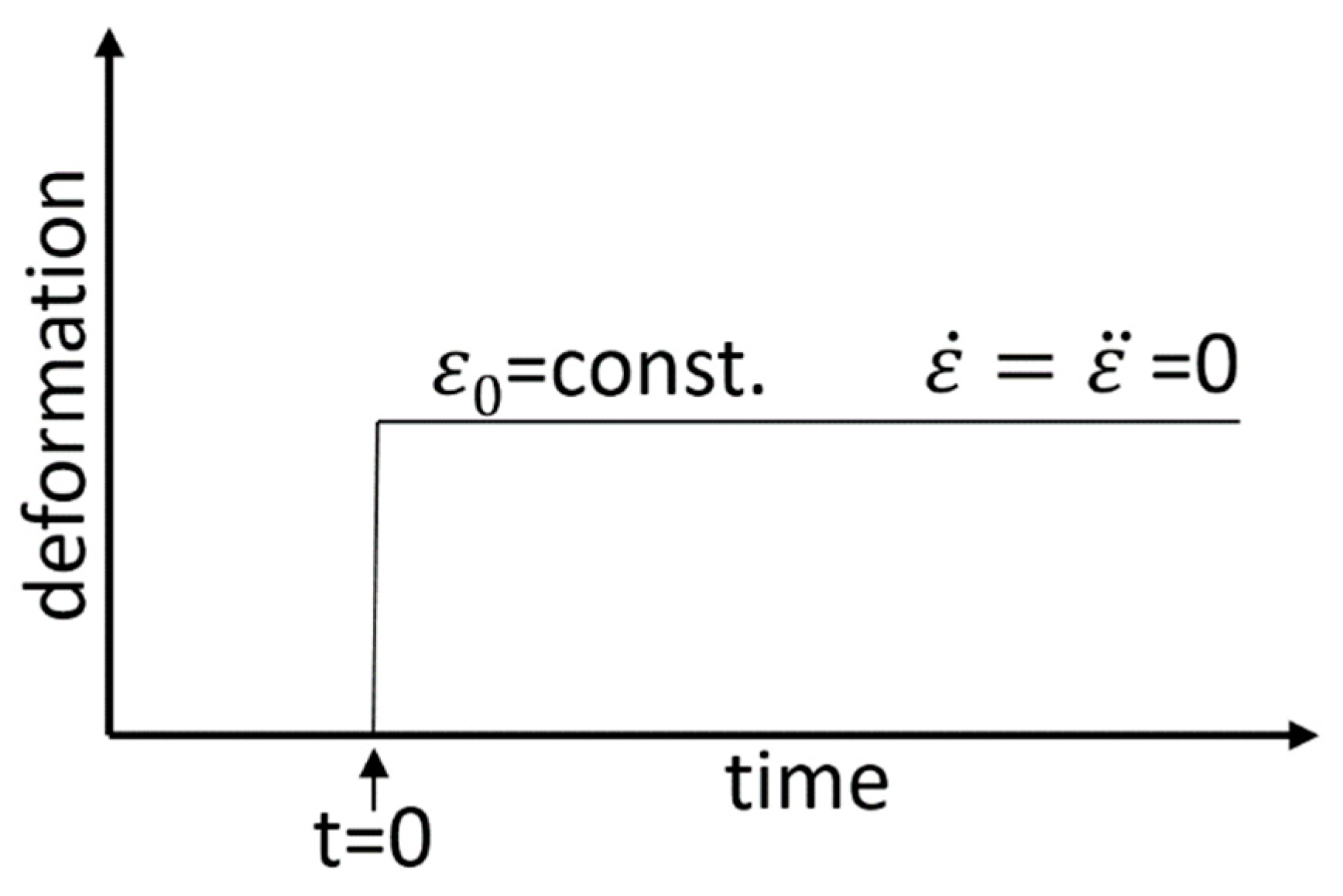

13]. While this is of major interest for the characterization of product properties, a lot of information affecting the production process is neglected. For nozzle and extrusion based processes, which play a major role in polymer processing and its correlated industrial fields, an analysis of frequency depended material properties is mandatory. However, research covering the classic rheological modelling of frequency dependent measurements is rarely conducted. Bhattacharyya et al. [

14] derived a predictive function from an augmented Jeffreys model, where a friction element is added, for the dampening properties of shape memory polymers. He also derived such functions for various mechanical loading types, covering constant stress and stress rate as well as constant and periodic strain and constant strain rate. Sun et al. [

15] used the Burgers model in a similar way to the presented approach. After a rheological characterization via frequency sweep, two fit functions for G’ and G″ were derived and fitted to the resulting data. However, they concluded that the Burgers model is not suitable for describing frequency dependent measurement data of dough. Our own experience shows that fit functions, as used in the publication, can lead to falsified conclusions due to the use of too many fit parameters. The data presented was subsequently fitted by a two parameter power-law function. However, shear rate or frequency dependent properties were not described by rheological model systems.

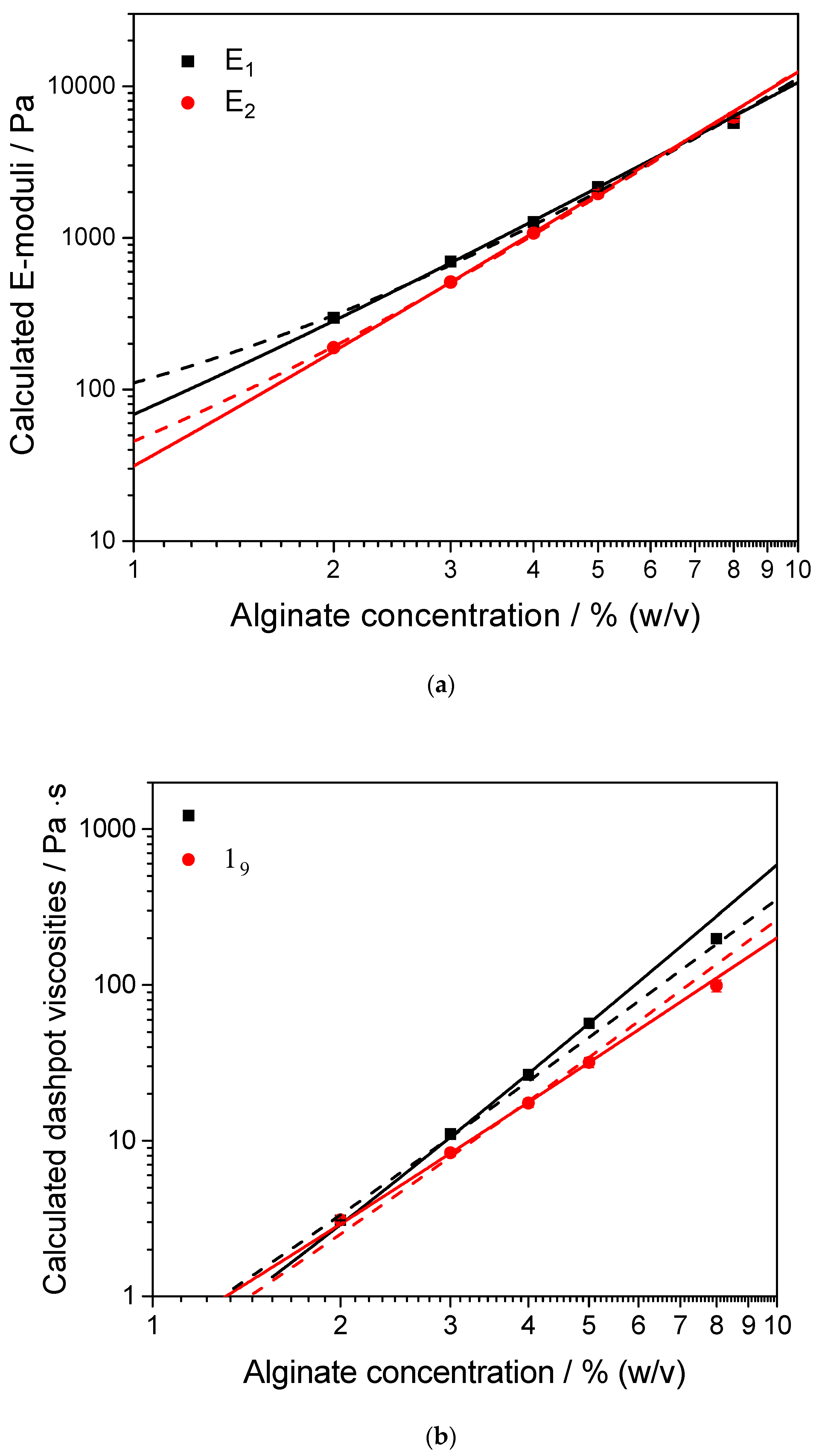

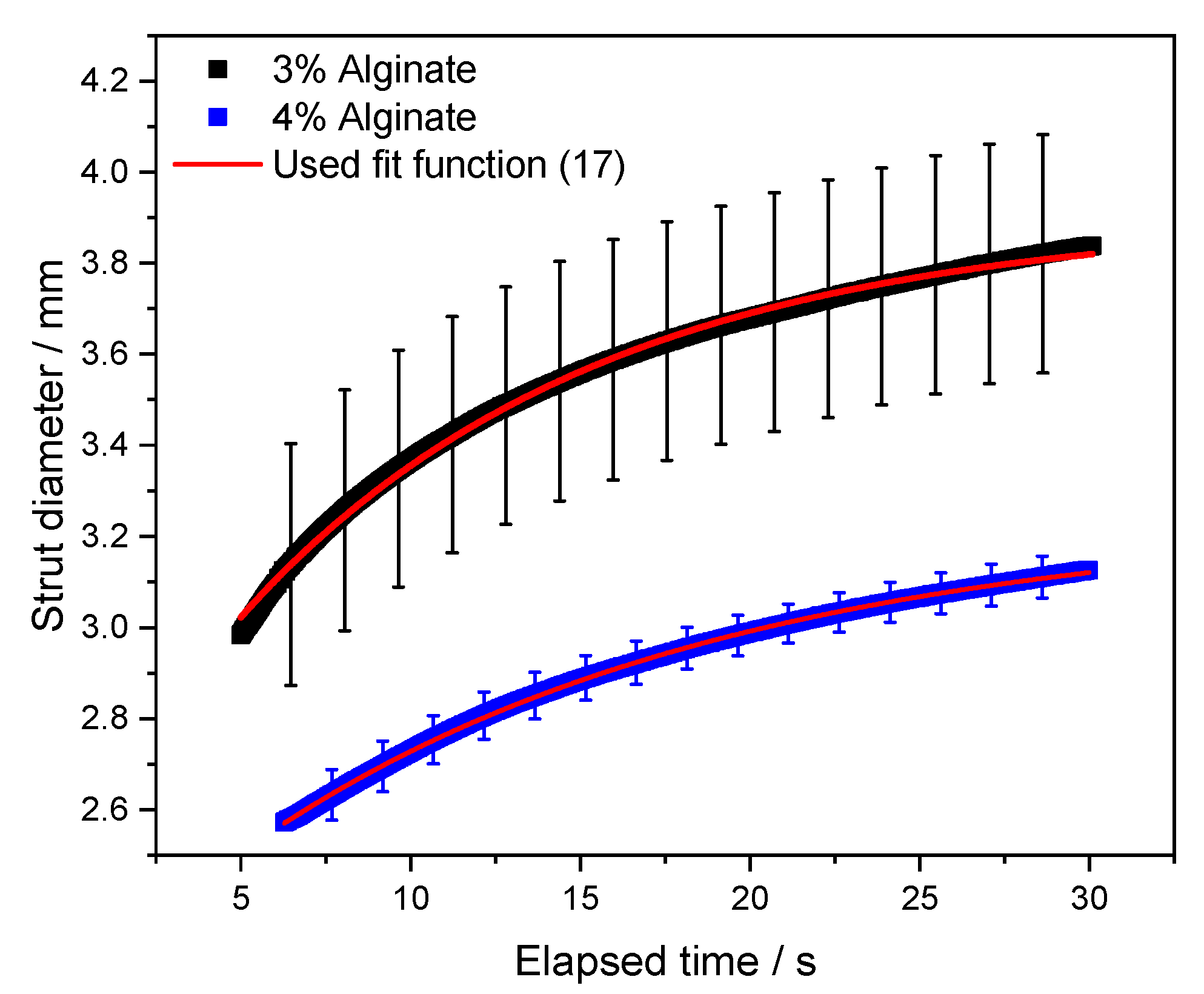

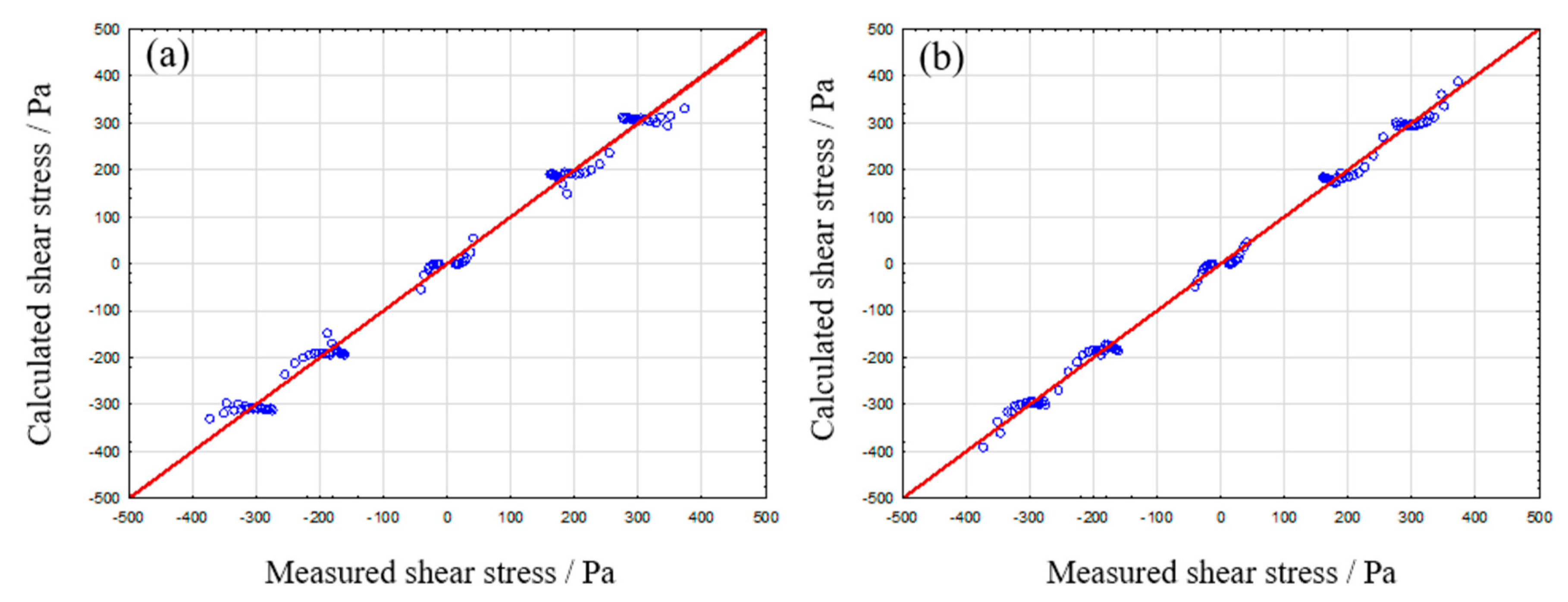

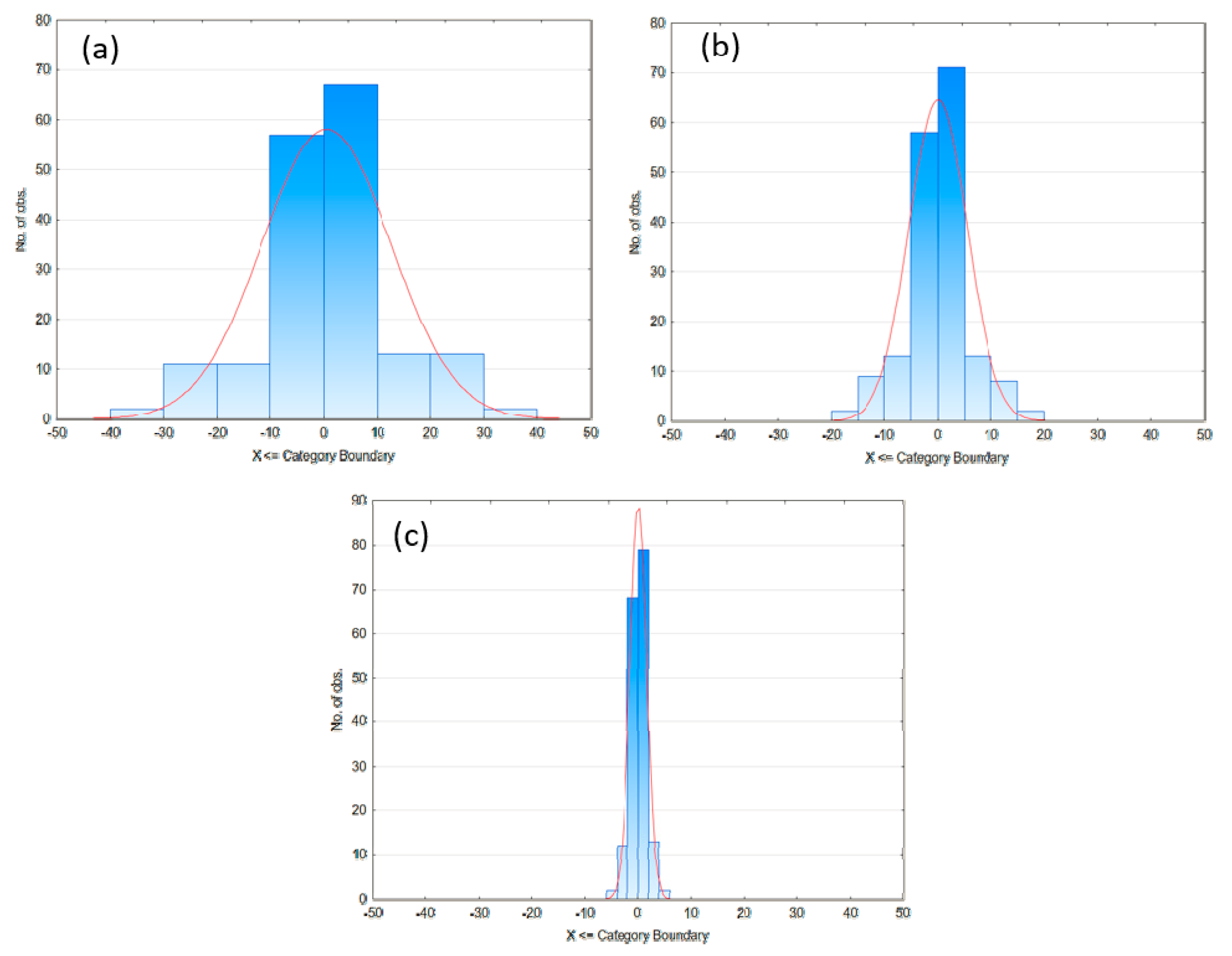

The here presented approach is meant to close the gap between commonly performed rheological measurements for polymer characterization and rheological modelling. We based the here presented method on frequency sweep measurements, where the material is subjected to an oscillatory strain with fixed amplitude and varied frequency. Due to the well-known phenomena during such measurements it is easy to find pertinent literature for benchmarking own findings. Additionally, the amount of data that is already openly accessible enables wide-ranging conclusions, exceeding the scope of self-performed experiments. In order to proof the applicability of our approach we investigated different types of common polymer materials. Uncrosslinked alginate solutions with various concentrations are chosen as representative for rheological liquid behavior [

16]. Due to their properties, alginates are used for a variety of applications, which range from seemingly simple products, such as thickeners for the food industry [

17], to complex drug delivery systems [

18] and wound dressings [

19]. The ability to store water, transport important components for cell proliferation, such as nutrients and growth factors, and to provide a mechanically stable surrounding for cell transport also makes alginate usable as bio-ink for 3D-printing processes [

20,

21]. An emerging research field, namely biofabrication, uses alginates and comparable hydrogels for the fabrication of tissue and organ replacement. Due to the connection of the 3D printing process and the rheological properties of bioinks one can find a variety of rheological characterization protocols and their results [

22,

23,

24,

25]. Additionally, one can potentially reevaluate studies such as Gao et al. [

26], which correlates frequency dependent material properties and the resulting printing quality for better comparability of various printed materials. A possible approach on the correlation of rheological model parameters and bio-printing of alginate is presented, as follows.

For the sake of completeness, we furthermore characterized a liquid silicone rubber system (LSR). This highly crosslinked rubber is chosen as representative for rheological solids. Such LSR materials are commonly combined with conductive filler materials, often carbon particles and carbon nanotubes, in order to generate sensor systems [

31,

32,

33] or artificial actuators for a variety of applications [

34,

35,

36]. However, a correlation of rheological measurements and process or product performance is rarely conducted. Thus, an approach to further evaluate rheological measurements is presented. This method can be used to determine a suitable rheological model system as well as revealing model parameter values. As highlighted before, a variety of materials has already been analyzed with respect to their creep recovery behavior. However, to the knowledge of the authors, the only description of frequency dependent material behavior is based on the derivation of fit-functions from rheological model systems, which can be error-prone and inapplicable. Therefore, the novelty of the presented work can be concluded in three main aspects: