Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation

- ✓

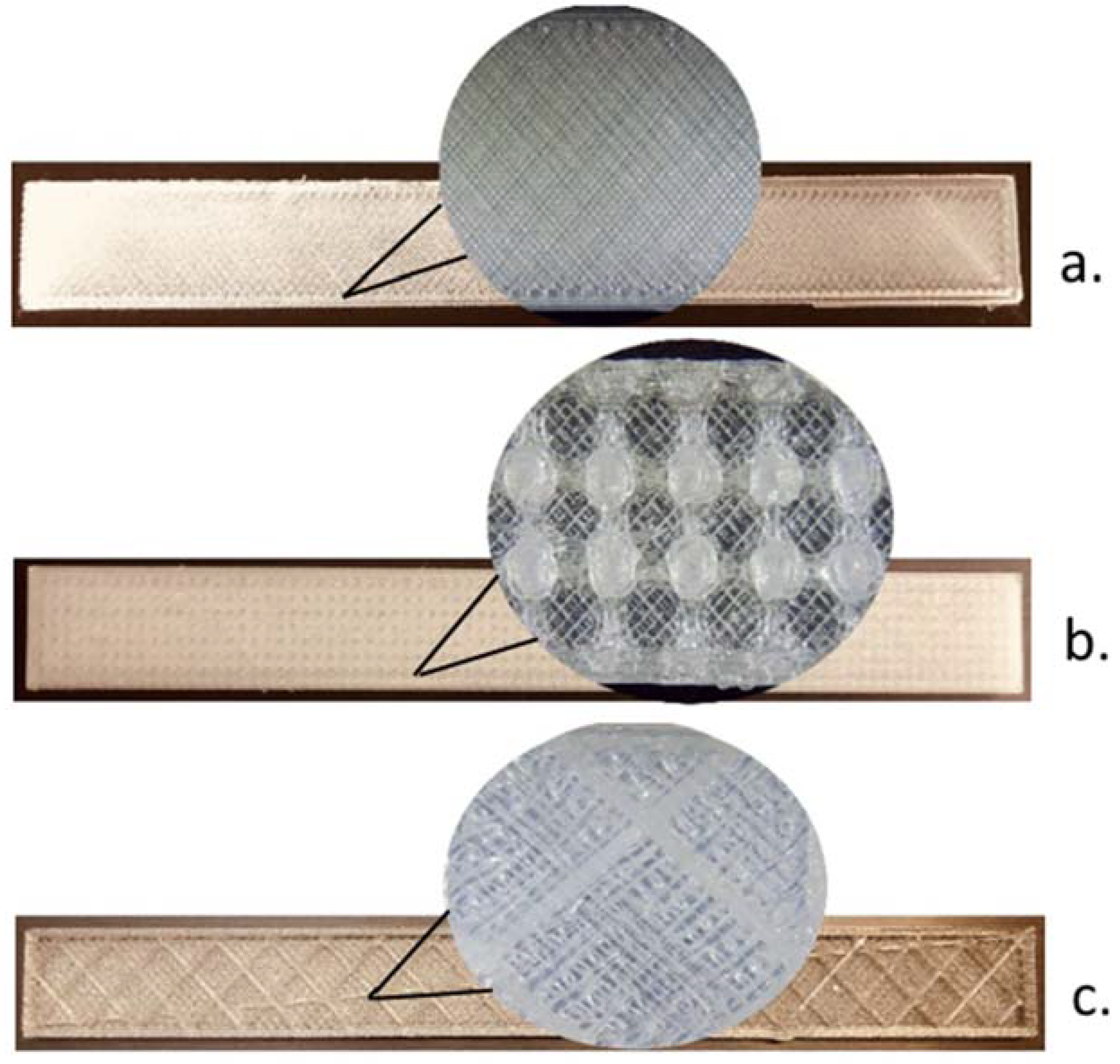

- For a: solid (plainly printed), without holes;

- ✓

- For b: Holes were provided on the x, y and z-axis with a diameter of 1.6 mm and 2 mm distance between the axes.Plain walls with 0.5 mm thickness were printed to encase these samples;

- ✓

- For c: square holes were provided on the z-axis (4 × 4 mm) and a distance between axes of 4.5 mm.Plain walls with 0.5 mm thickness were printed to encase these samples.

- -

- Tensile test samples: total length 160 mm, calibrated length 60 mm, thickness 3 mm, radius between the calibrated section and the fastening sections 76.29 mm, fastening section length 22.5 mm and 20 mm width;

- -

- Cylindrical blocks for compression tests: diameter 10 mm, height 15 mm;

- -

- Three point-bending samples: 160 mm length, 16 mm width and 3 mm height;

- -

- Impact energy (shock resistance) cubic samples: 15 mm in edge.

2.3. Characterization Methods

3. Results

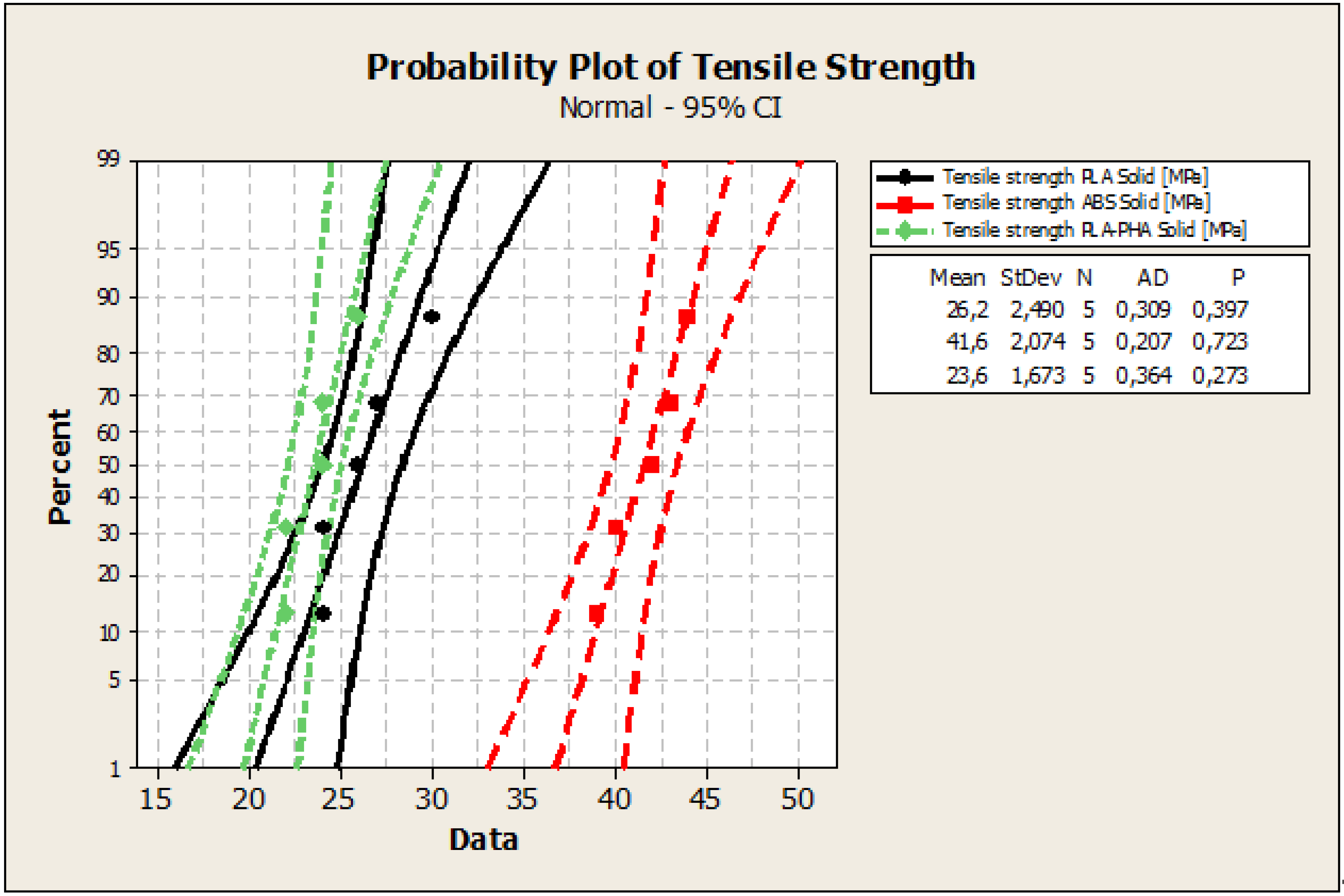

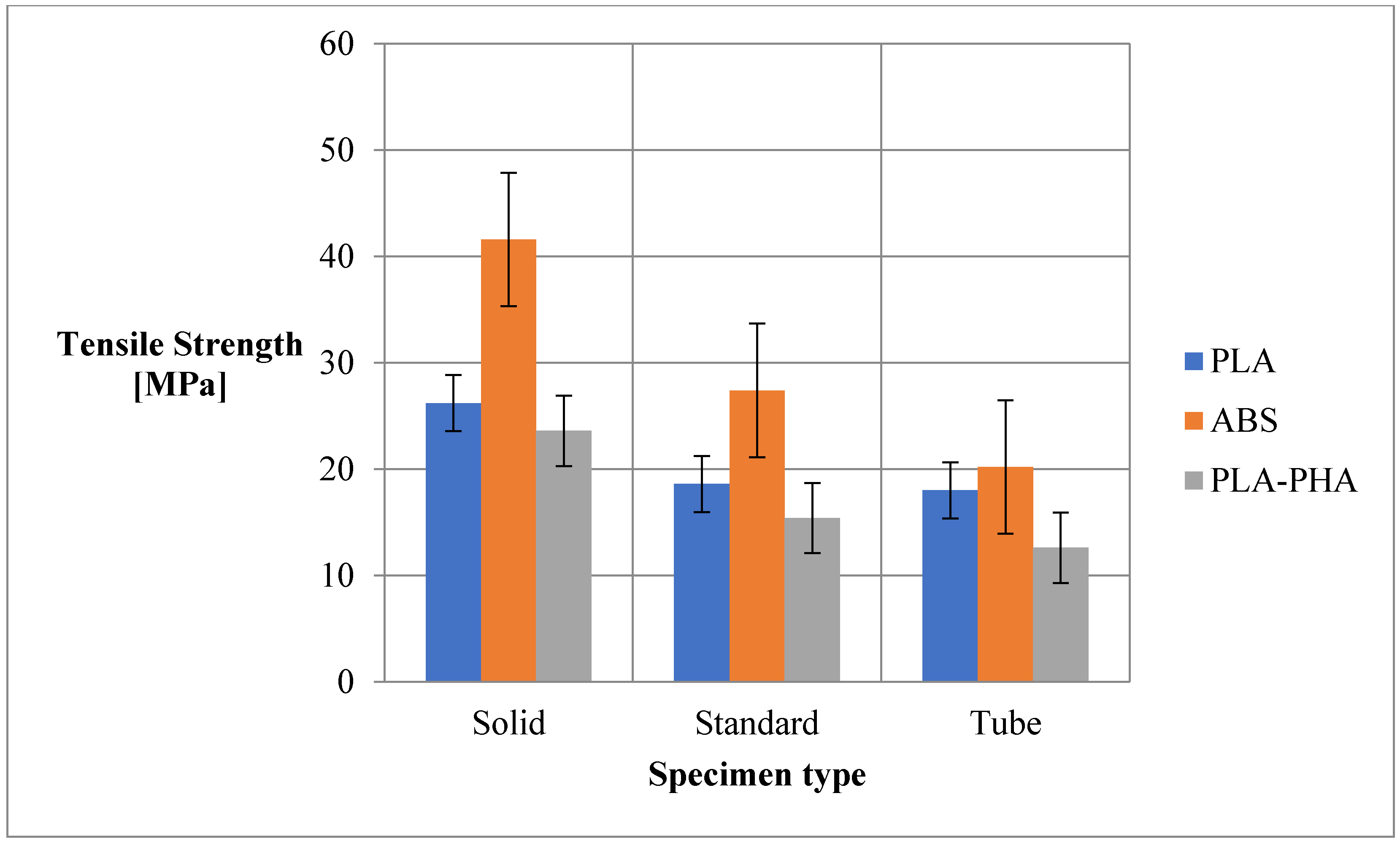

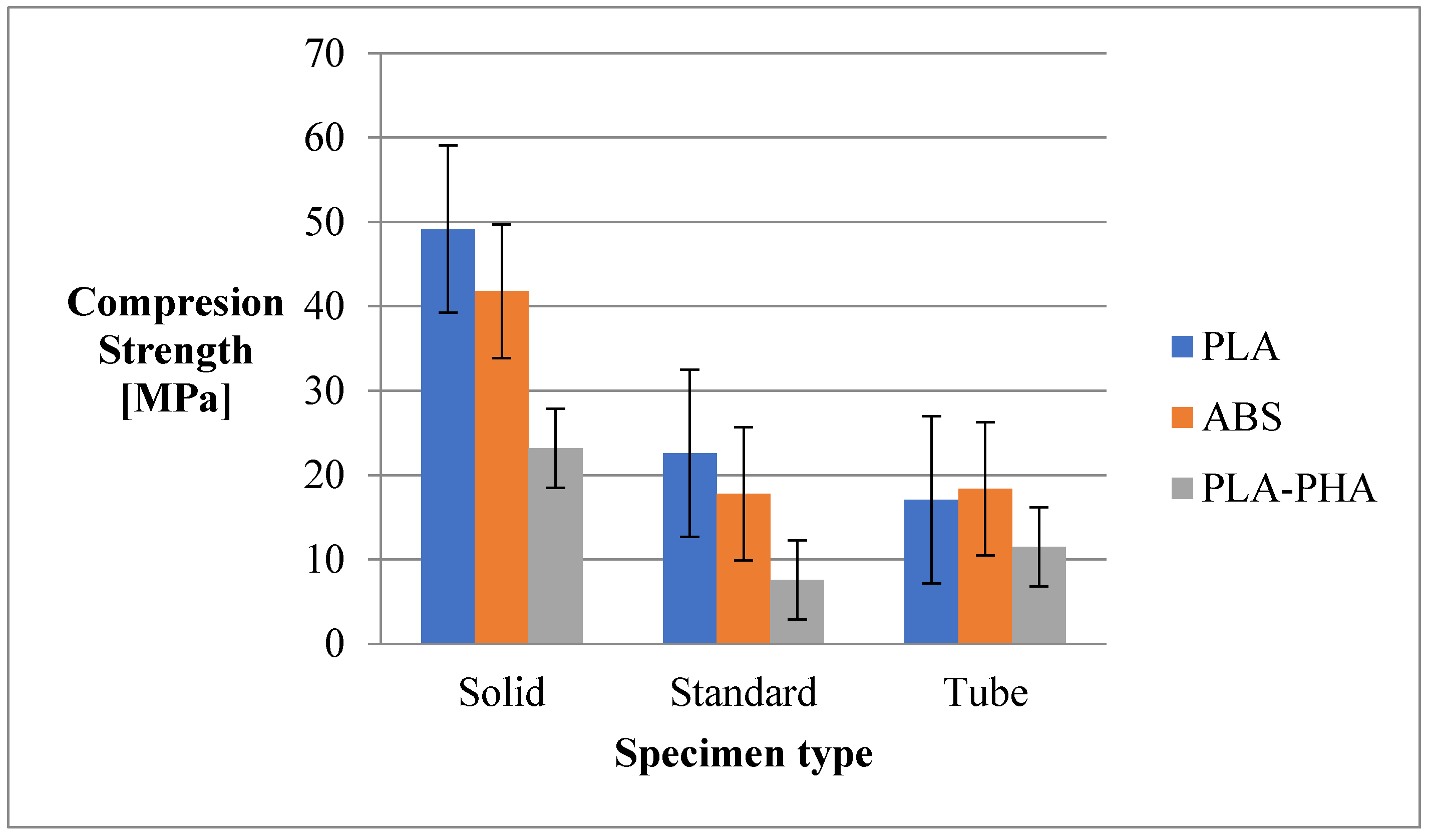

3.1. Mechanical Properties of the Printed Materials

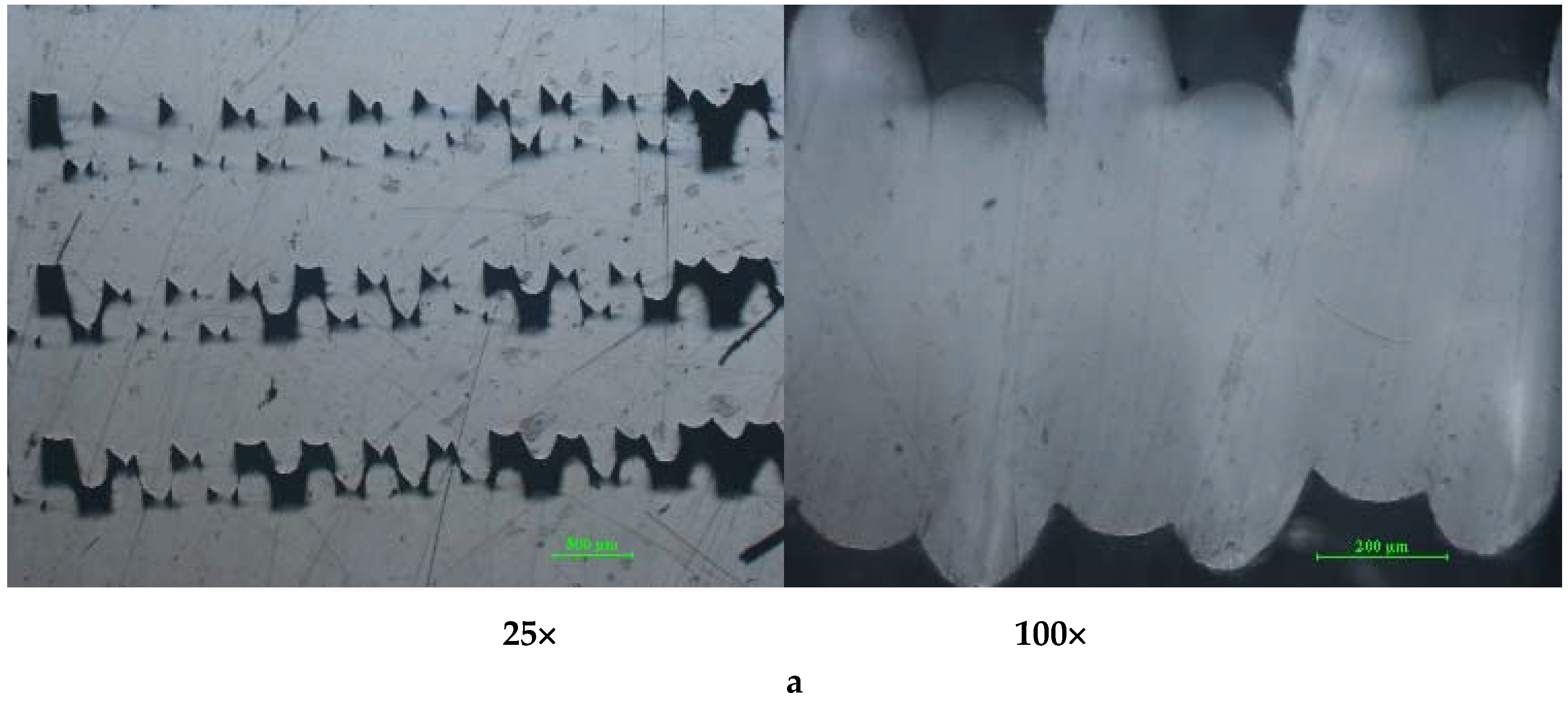

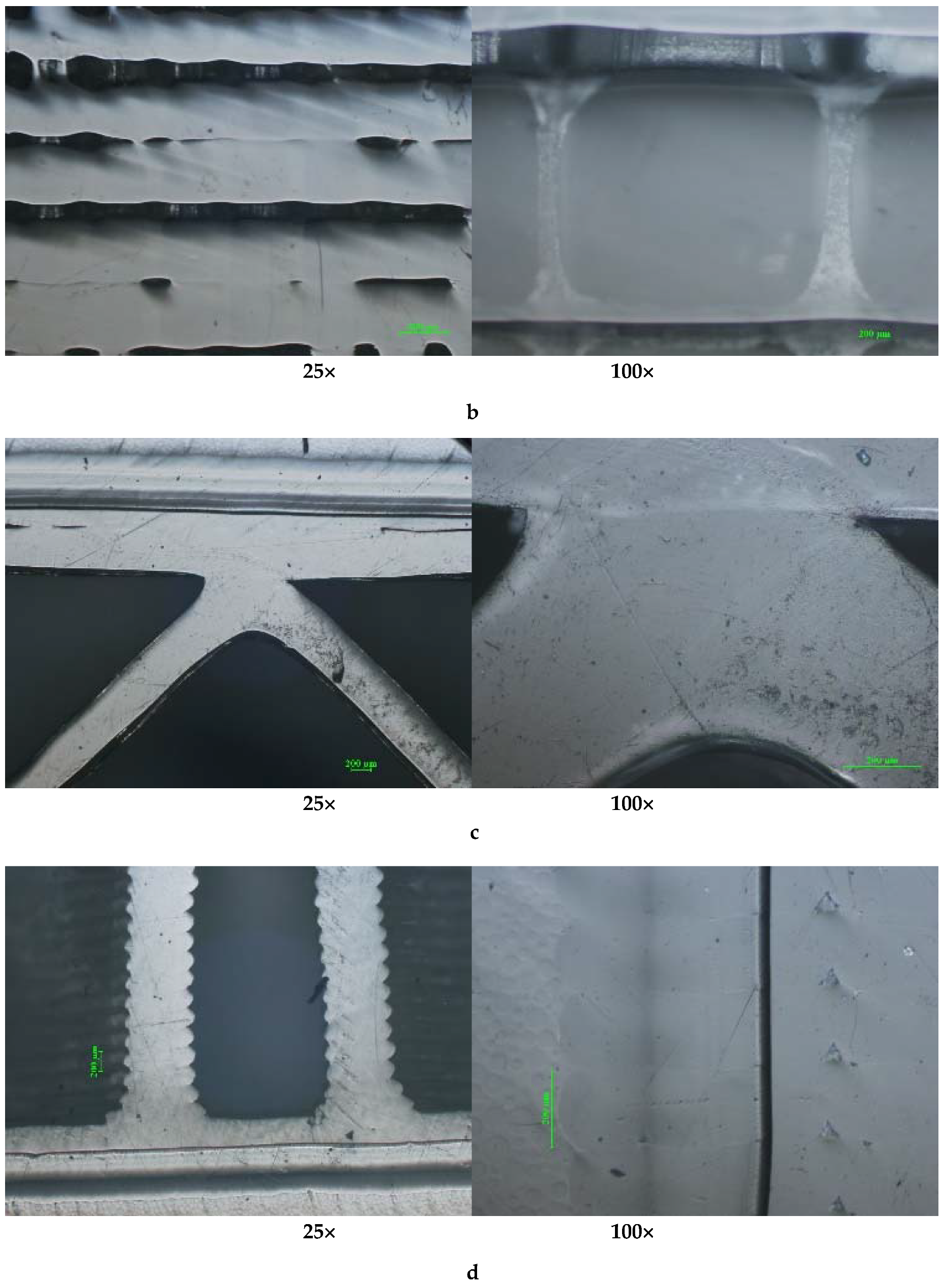

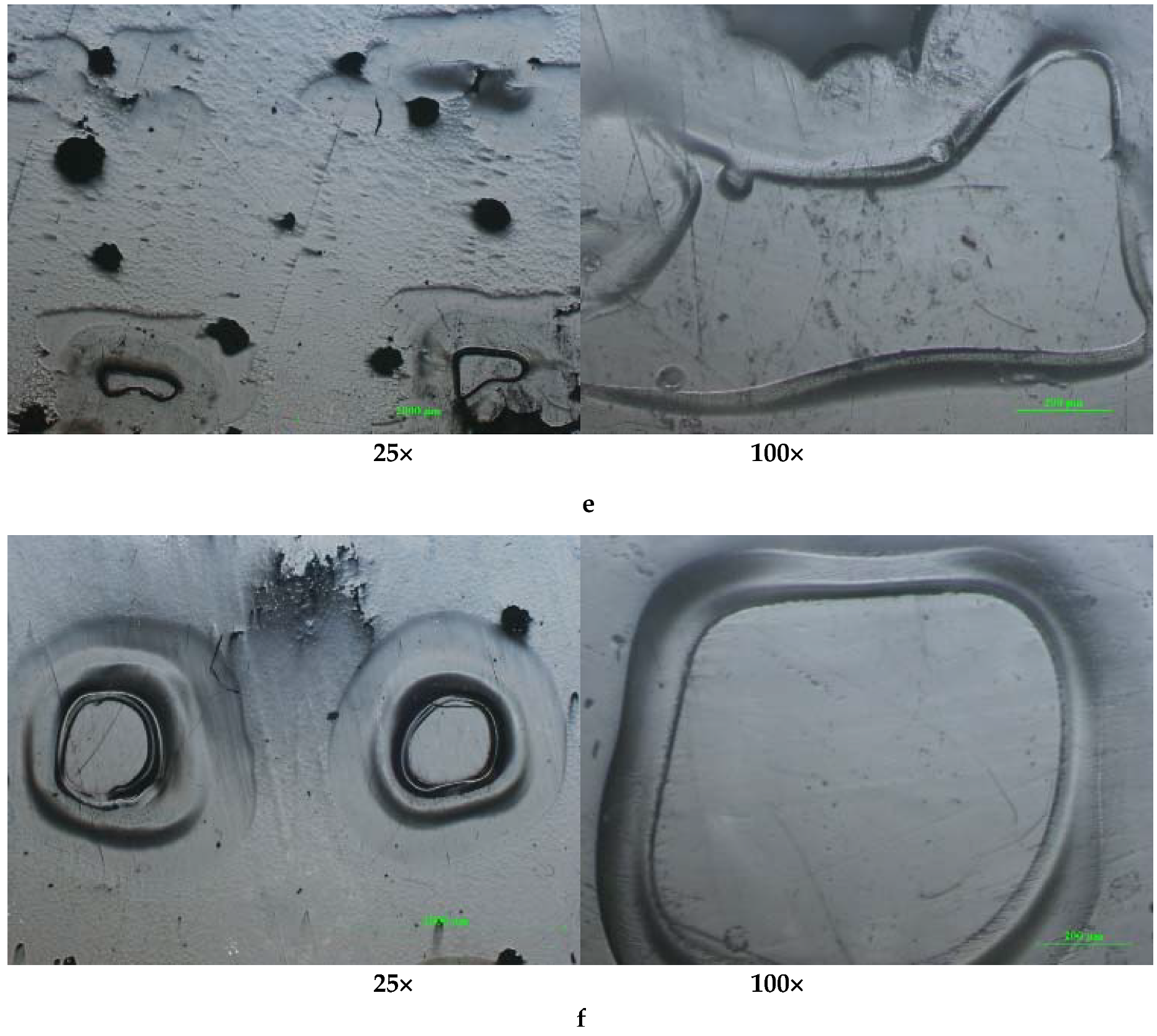

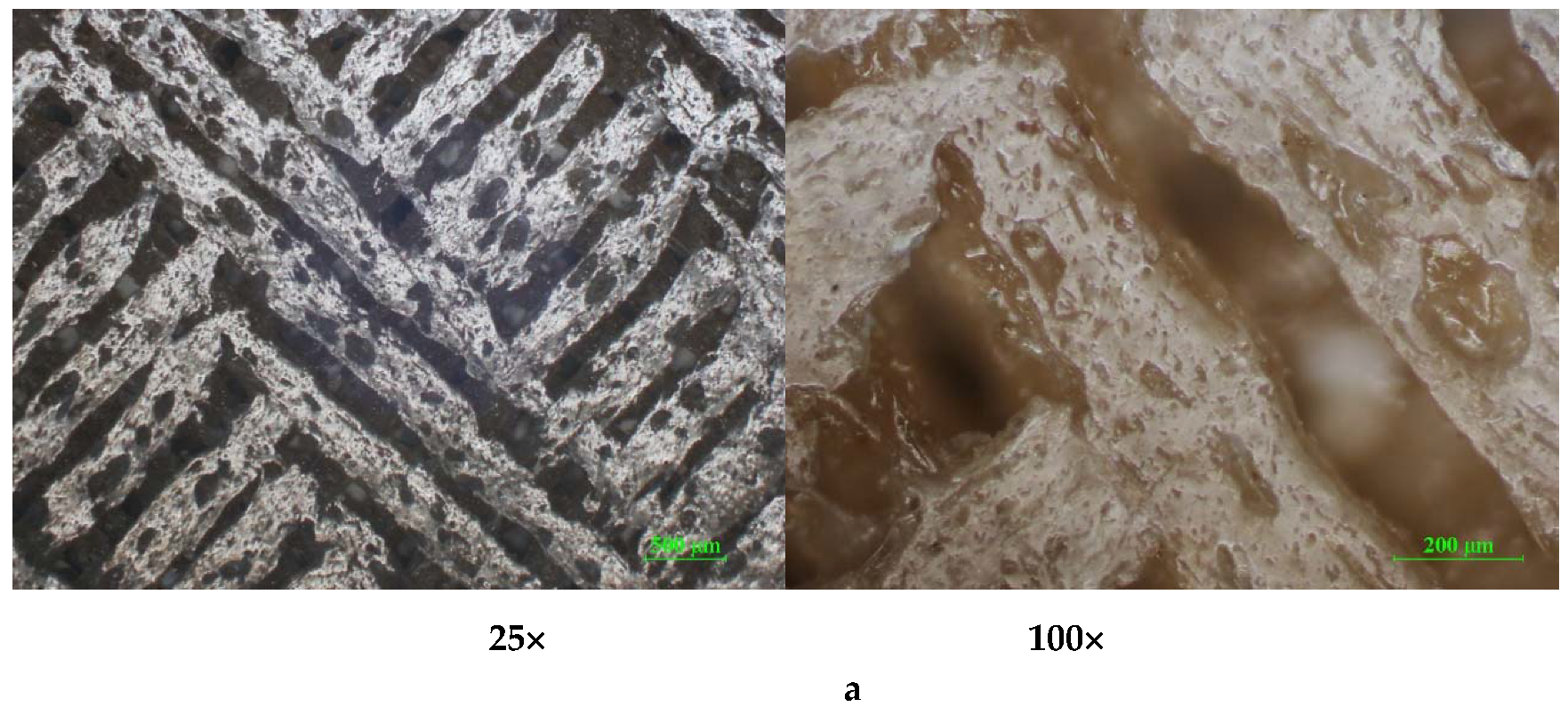

3.2. Metallographic Analysis of the Printed Materials

4. Conclusions

- ✓

- For parts subjected to tensile strain: it is recommended to use ABS, PLA in solid configuration, followed by ABS in standard configuration when high strengths are required. Using the standard configuration and the ABS material, tensile strengths can be obtained, with approximately 20% higher from the point of view of the material consumption ratio / tensile strength;

- ✓

- For parts subjected to compression: it is recommended to use PLA, ABS and PLA/PHA/BambooFill materials in solid configuration. The cylindrical architecture confers a higher compressive strength compared to the standard architecture and a 15% reduction in material (comparing the cylindrical with standard consumption);

- ✓

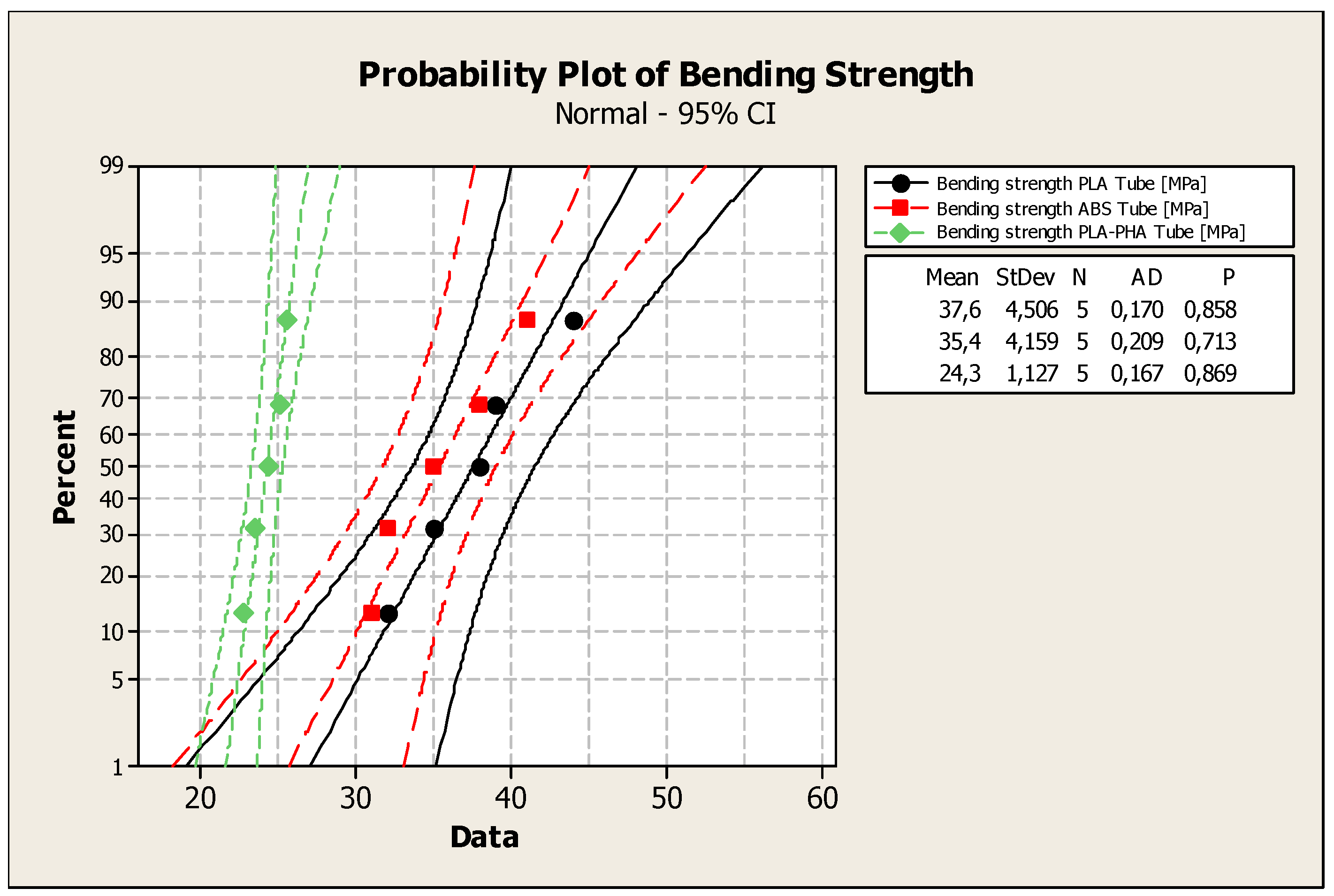

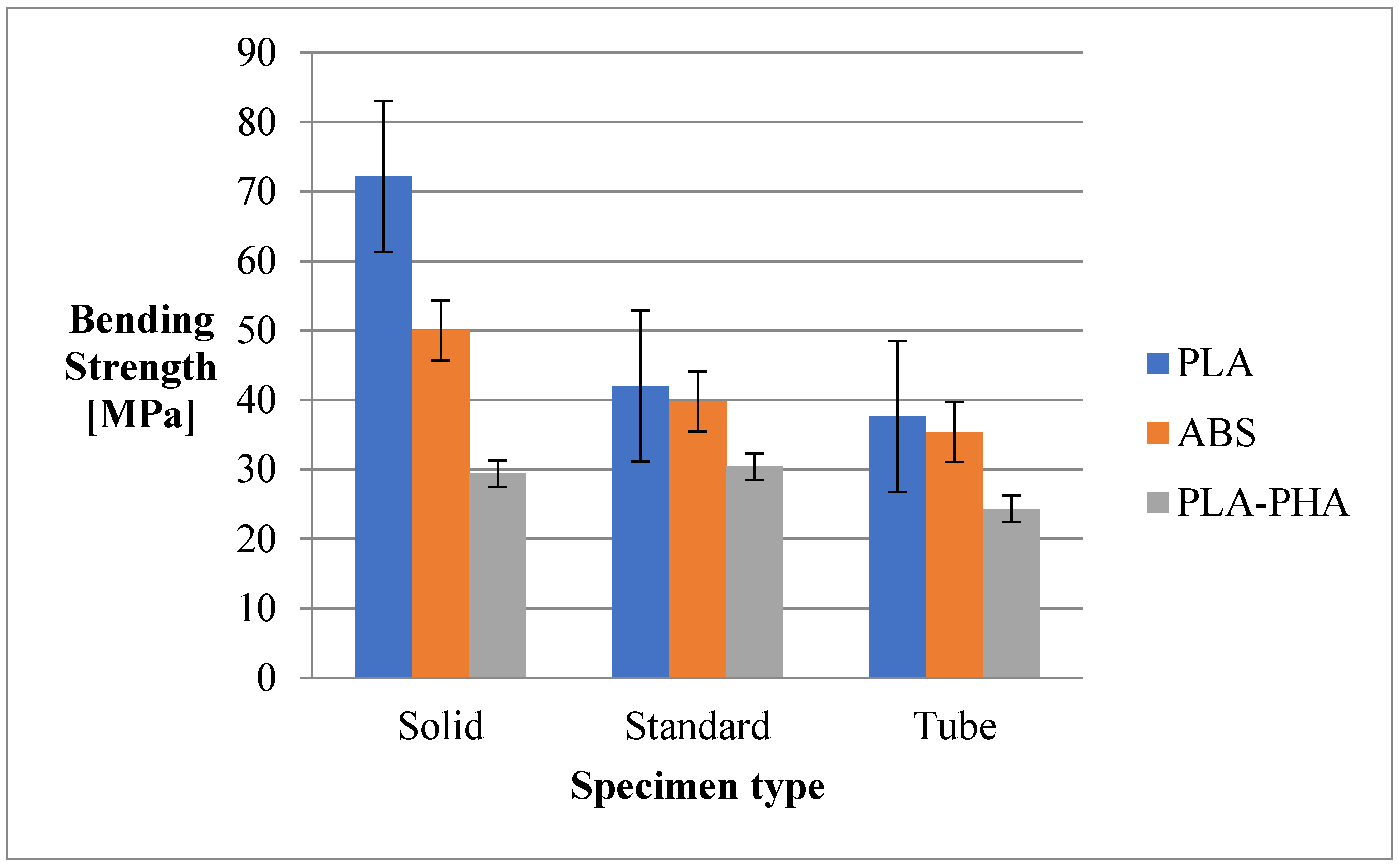

- For parts subjected to flexural stresses: it is recommended to use PLA, ABS materials in solid configuration, followed by PLA in standard configuration. The use of PLA / PHA BambooFill material is not recommended due to its low properties in parts with this type of request;

- ✓

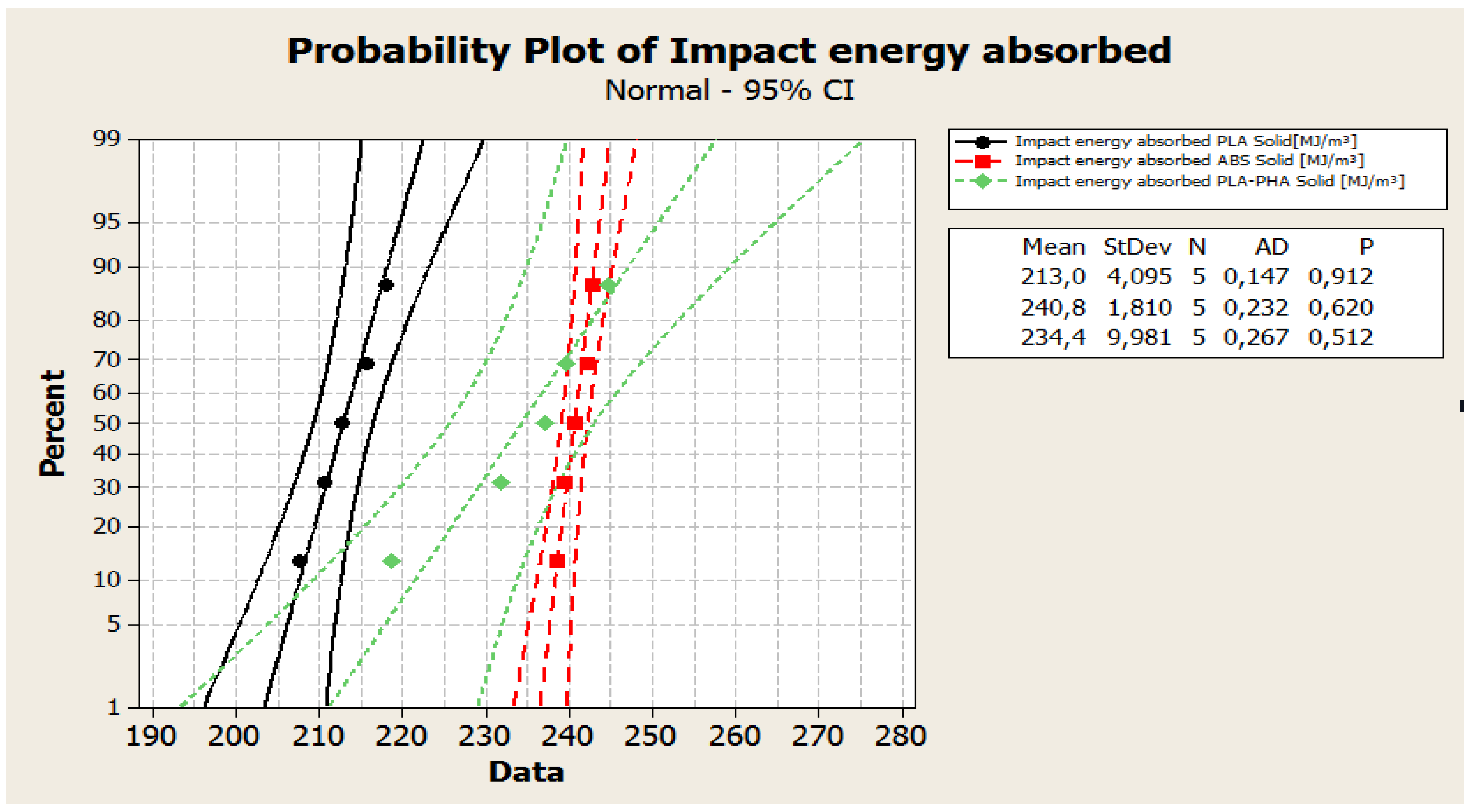

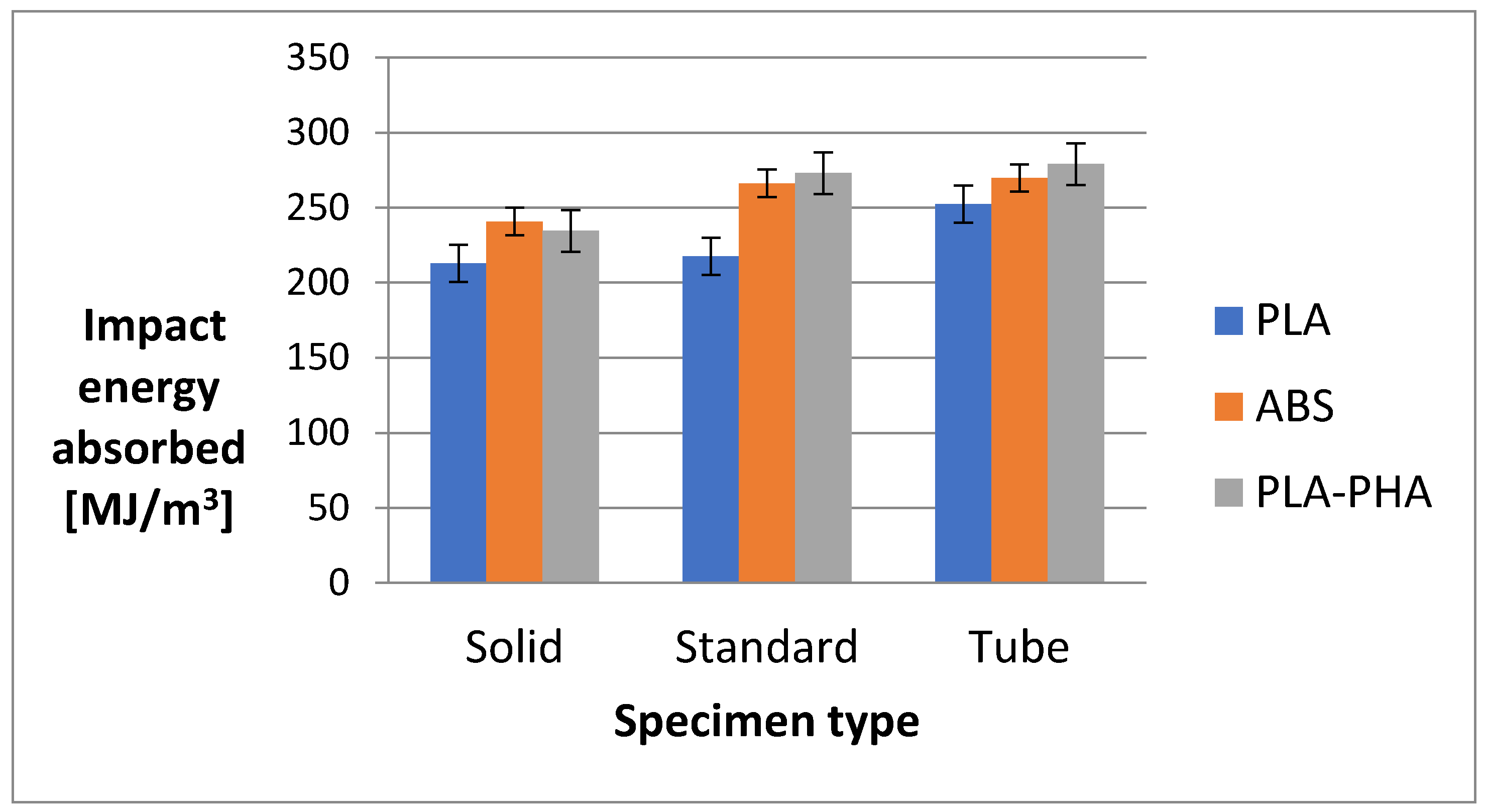

- For excellent impact resistance: it is recommended to use PLA/PHA/BambooFill material in tube configuration, followed by ABS in standard configuration. The internal architecture of the cylindrical type presents the best properties for energy absorption and gives a 65% reduction in material consumption;

- ✓

- The mechanical behavior of FFF parts is primarily determined by the material type and, only after that, the internal architecture.

Author Contributions

Funding

Conflicts of Interest

References

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Lian, Q.; Xiangquan, W.; Dichen, L. Additive manufacturing technology. In Digital Orthopedics; Pei, G., Ed.; Springer: Dordrecht, The Netherlands, 2019; ISBN 9789402410761. [Google Scholar] [CrossRef]

- Bose, S.; Ke, D.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive manufacturing of biomaterials. Prog. Mater. Sci. 2018, 93, 45–111. [Google Scholar] [CrossRef] [PubMed]

- Deckers, J.; Vleugels, J.; Kruth, J.P. Additive manufacturing of ceramics: A review. J. Ceram. Sci. Technol. 2014, 5, 245–260. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Ambrosi, A.; Pumera, M. 3D-printing technologies for electrochemical applications. Chem. Soc. Rev. 2016, 45, 2740–2755. [Google Scholar] [CrossRef]

- Symes, M.D.; Kitson, P.J.; Yan, J.; Richmond, C.J.; Cooper, G.J.T.; Bowman, R.W.; Vilbrandt, T.; Cronin, L. Integrated 3D-printed reactionware for chemical synthesis and analysis. Nat. Chem. 2012, 4, 349–354. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Wang, K.; Li, S.; Rao, Y.; Wu, Y.; Peng, Y.; Yao, S.; Zhang, H.; Ahzi, S. Flexure Behaviors of ABS-based Composites Containing Carbon and Kevlar Fibers by Material Extrusion 3D Printing. Polymers 2019, 11, 1878. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Microstructure and Mechanical Performance of 3D Printed Wood-PLA/PHA Using Fused Deposition Modelling: Effect of Printing Temperature. Polymers 2019, 11, 1778. [Google Scholar] [CrossRef]

- Szuman, K.; Krucińska, I.; Boguń, M.; Draczyński, Z. PLA/PHA-Biodegradable Blends for Pneumothermic Fabrication of Nonwovens. Autex Res. J. 2016, 16, 119–127. [Google Scholar] [CrossRef]

- Pop, M.A.; Croitoru, C.; Bedő, T.; Geamăn, V.; Radomir, I.; Coșniță, M.; Zaharia, S.M.; Chicoș, A.L.; Miloșan, I. Structural changes during 3D printing of bioderived and synthetic thermoplastic materials. J. Appl. Polym. Sci. 2019, 136, 47382. [Google Scholar] [CrossRef]

- Hung, K.C.; Tseng, C.S.; Hsu, S.H. Advanced Healthcare Materials; John Wiley & Sons: Hoboken, NJ, USA, 2014; Volume 3, pp. 1578–1587. [Google Scholar]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; Friedrich, H. 3D printing of CNT-and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Brites, F.; Malça, C.; Gaspar, F.; Horta, J.F.; Franco, M.C.; Biscaia, S.; Mateus, A. Cork Plastic Composite Optimization for 3D Printing Applications. Procedia Manuf. 2017, 12, 156–165. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of porosity and crystallinity on 3D printed PLA properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef]

- Vinyas, M.; Athul, S.J.; Harursampath, D.; Thoi, T.N. Experimental evaluation of the mechanical and thermal properties of 3D printed PLA and its composites. Mater. Res. Express 2019, 6, 115301. [Google Scholar] [CrossRef]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Peng, T. Analysis of Energy Utilization in 3D Printing Processes. Procedia Cirp 2016, 40, 62–67. [Google Scholar] [CrossRef]

- Torrado, A.R.; Roberson, D.A. Failure Analysis and Anisotropy Evaluation of 3D-Printed Tensile Test Specimens of Different Geometries and Print Raster Patterns. J. Fail. Anal. Prev. 2016, 16, 154–164. [Google Scholar] [CrossRef]

- Song, P.; Fu, Z.; Liu, L.; Fu, C.W. Printing 3D objects with interlocking parts. Comput. Aided Geom. Des. 2015, 35, 137–148. [Google Scholar] [CrossRef]

- Umetani, N.; Schmidt, R. Cross-sectional structural analysis for 3D printing optimization. In SIGGRAPH Asia Technical Briefs; Association for Computing Machinery: New York, NY, USA, 2013; pp. 11–20. [Google Scholar] [CrossRef]

- Wang, W.; Wang, T.Y.; Yang, Z.; Liu, L.; Tong, X.; Tong, W.; Deng, J.; Chen, F.; Liu, X. Cost-effective printing of 3D objects with skin-frame structures. ACM Trans. Graph. 2013, 32. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Mathematical modeling and FDM process parameters optimization using response surface methodology based on Q-optimal design. Appl. Math. Model. 2016, 40, 10052–10073. [Google Scholar] [CrossRef]

- Pop, M.A.; Geamăn, V.; Radomir, I.; Bedo, T. Capacity of energy absorption by flick through shock in cooper foams. J. Porous Media 2017, 20, 405–415. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural Fillers: A review of their mechanical properties. Polymer 2019, 11, 1094. [Google Scholar] [CrossRef]

- Alvarez, C.; Kenny, L.; Lagos, C.; Rodrigo, F.; Aizpun, M. Investigating the influence of infill percentage on the mechanical properties of fused deposition modelled ABS parts. Ing. Investig. 2016, 36, 110–116. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

| Specimen Type | Mean [MPa] | Variance [MPa2] | Standard Deviation [MPa] | Coefficient of Variation [%] |

|---|---|---|---|---|

| ABS—Solid | 41.6 | 4.3 | 2.074 | 4.98 |

| ABS—Standard | 27.4 | 0.3 | 0.548 | 2 |

| ABS—Cylindrical Tube | 20 | 4.2 | 2.049 | 10.15 |

| Specimen Type | Mean [MPa] | Variance [MPa2] | Standard Deviation [MPa] | Coefficient of Variation [%] |

|---|---|---|---|---|

| PLA—Solid | 49.2 | 23.71 | 4.87 | 9.9 |

| PLA—Standard | 22.576 | 0.53 | 0.728 | 3.23 |

| ABS—Cylindrical Tube | 18.4 | 3.3 | 1.817 | 9.87 |

| Specimen Type | Mean [MPa] | Variance [MPa2] | Standard Deviation [MPa] | Coefficient of Variation [%] |

|---|---|---|---|---|

| PLA—Solid | 72.2 | 3.2 | 1.789 | 2.48 |

| PLA—Standard | 42 | 4 | 3 | 4.76 |

| PLA—Cylindrical Tube | 37.6 | 20.3 | 4.51 | 11.98 |

| Specimen Type | Mean [MJ/m3] | Variance [MJ/m3] | Standard Deviation [MJ/m3] | Coefficient of Variation [%] |

|---|---|---|---|---|

| PLA—Solid | 240.78 | 3.27 | 1.81 | 0.75 |

| PLA-PHA—Standard | 272.93 | 31,25 | 5.59 | 2.05 |

| PLA-PHA—Cylindrical Tube | 279.01 | 56.42 | 7.51 | 2.69 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pop, M.A.; Croitoru, C.; Bedo, T.; Geamăn, V.; Radomir, I.; Zaharia, S.M.; Chicoș, L.A. Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts. Polymers 2020, 12, 1129. https://doi.org/10.3390/polym12051129

Pop MA, Croitoru C, Bedo T, Geamăn V, Radomir I, Zaharia SM, Chicoș LA. Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts. Polymers. 2020; 12(5):1129. https://doi.org/10.3390/polym12051129

Chicago/Turabian StylePop, Mihai Alin, Cătălin Croitoru, Tibor Bedo, Virgil Geamăn, Irinel Radomir, Sebastian Marian Zaharia, and Lucia Antoaneta Chicoș. 2020. "Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts" Polymers 12, no. 5: 1129. https://doi.org/10.3390/polym12051129

APA StylePop, M. A., Croitoru, C., Bedo, T., Geamăn, V., Radomir, I., Zaharia, S. M., & Chicoș, L. A. (2020). Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts. Polymers, 12(5), 1129. https://doi.org/10.3390/polym12051129