Dog Wool Microparticles/Polyurethane Composite for Thermal Insulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

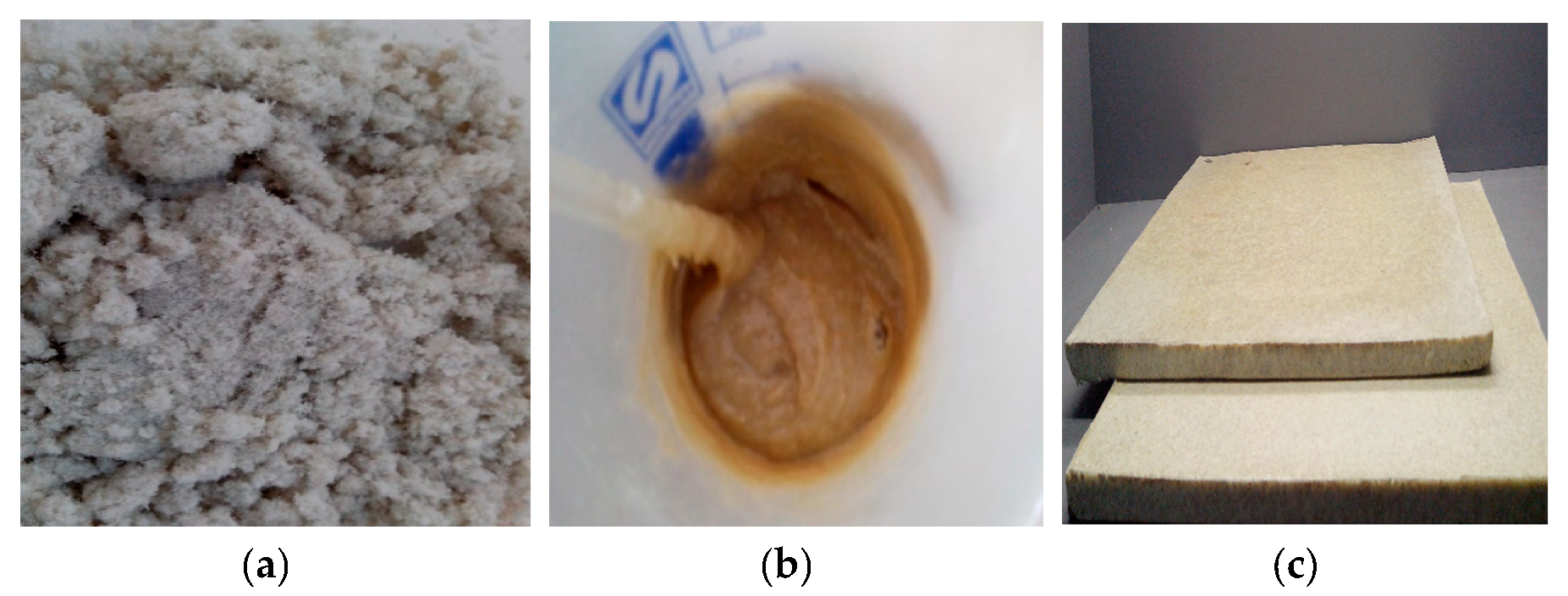

2.2. Treatment of Dog Wool Fibers

2.3. Preparation of Eco-Composites

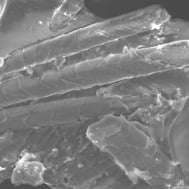

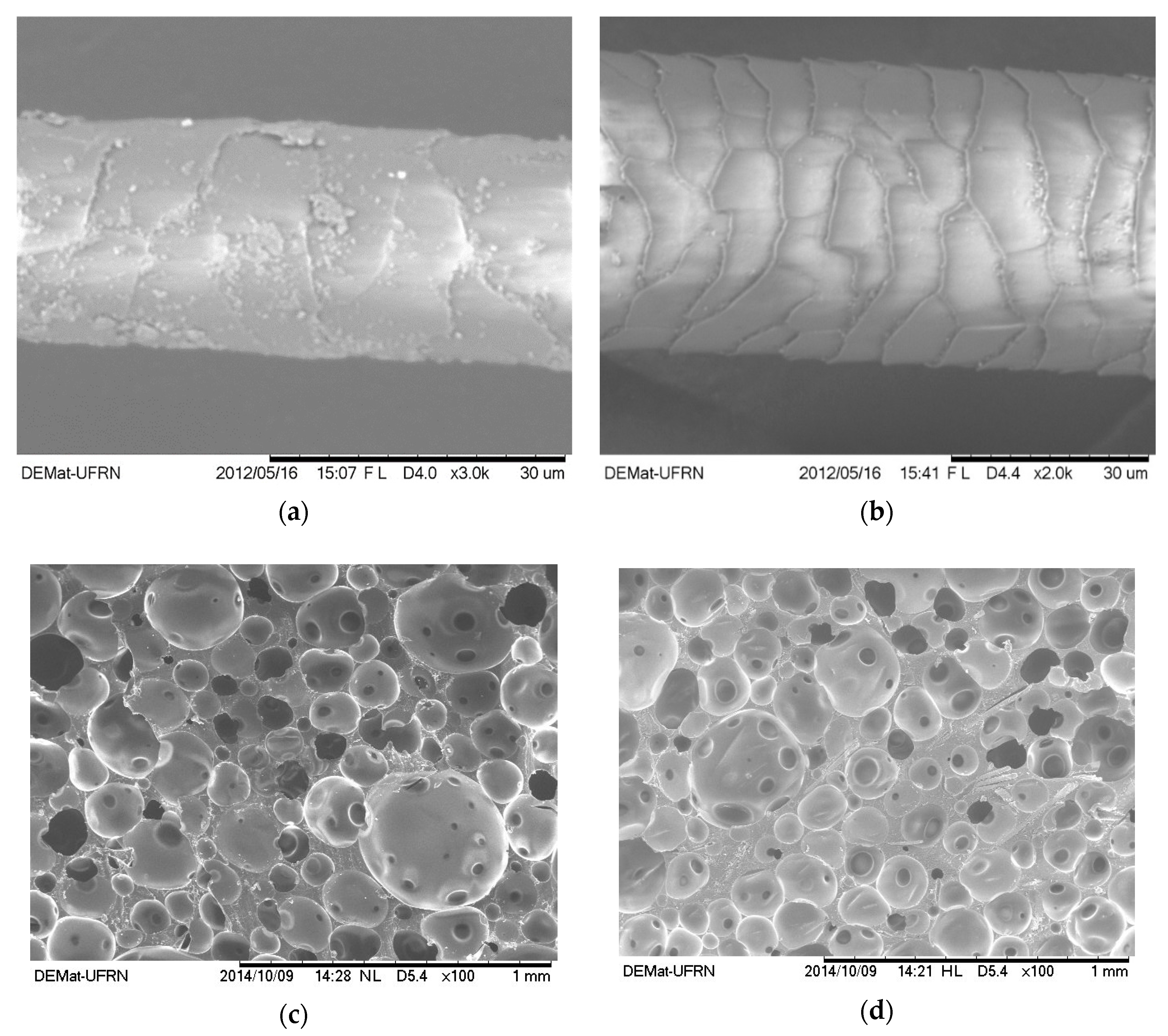

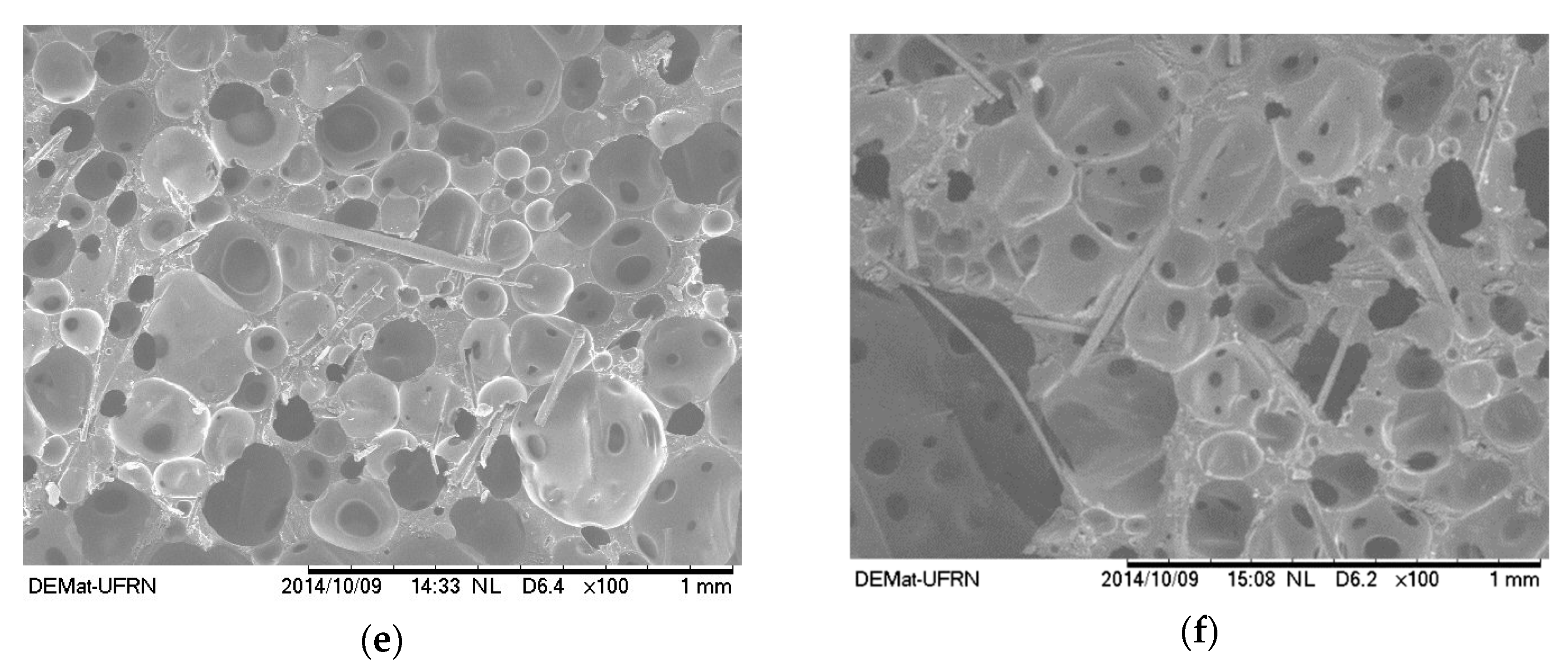

2.4. Scanning Electron Microscopy (SEM)

2.5. Particle Size Distribution

2.6. Fourier-Transformed Infrared (FTIR)

2.7. Thermal Properties

2.8. Mechanical Properties

2.9. Hydration Capacity

2.10. Dilatometry

3. Results and Discussion

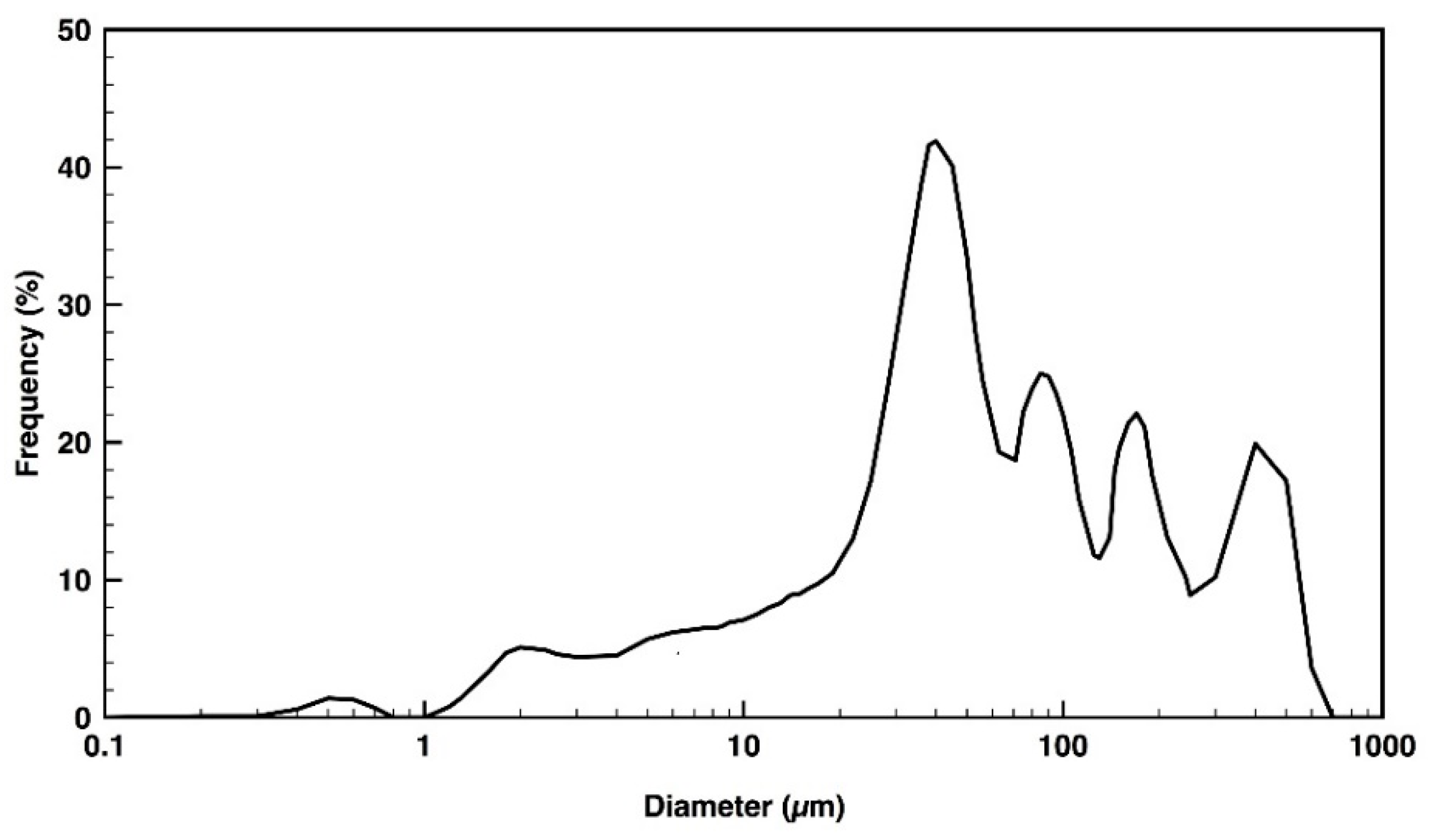

3.1. Particle Size and Eco-Composites’ Morphology

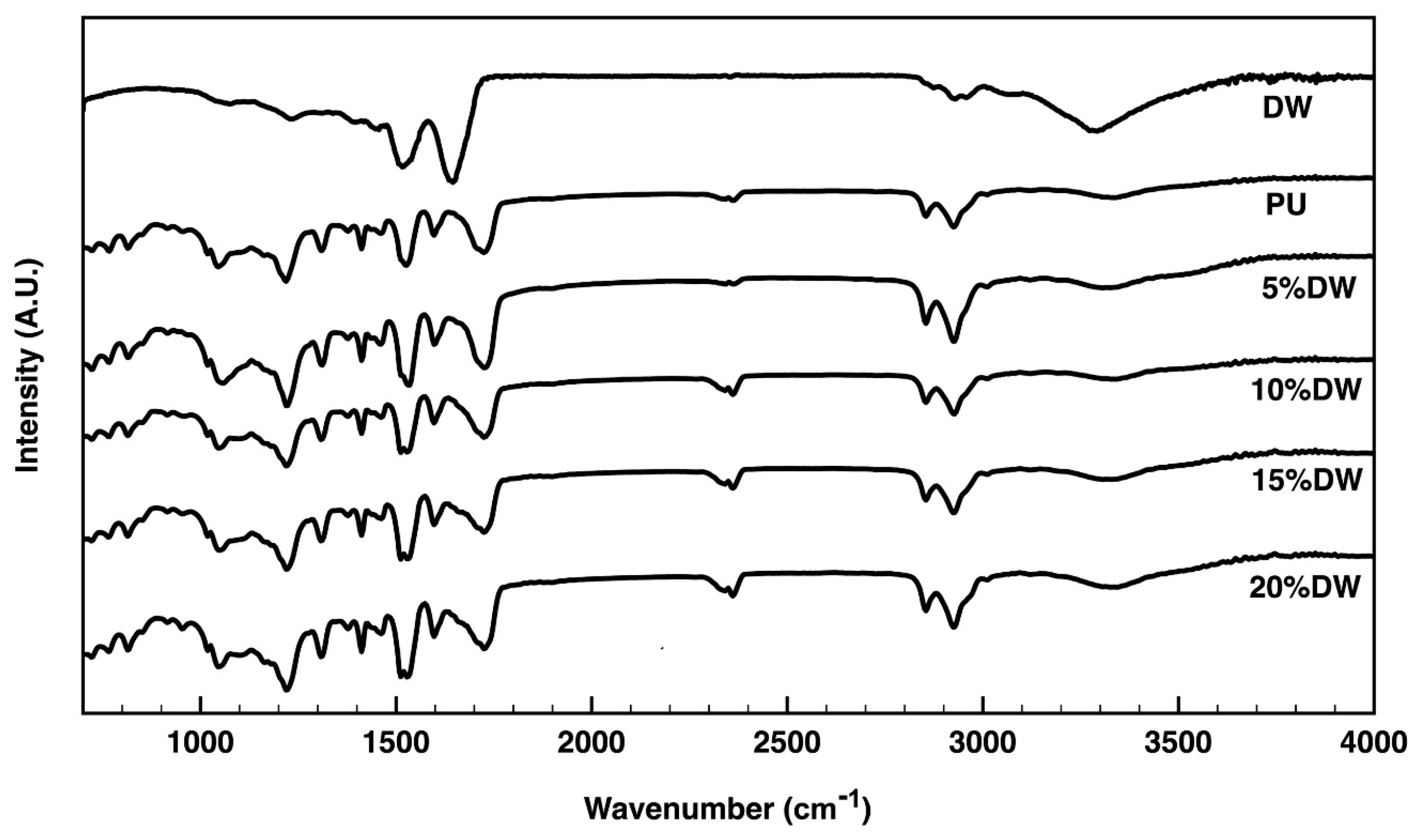

3.2. ATR-FTIR Spectra

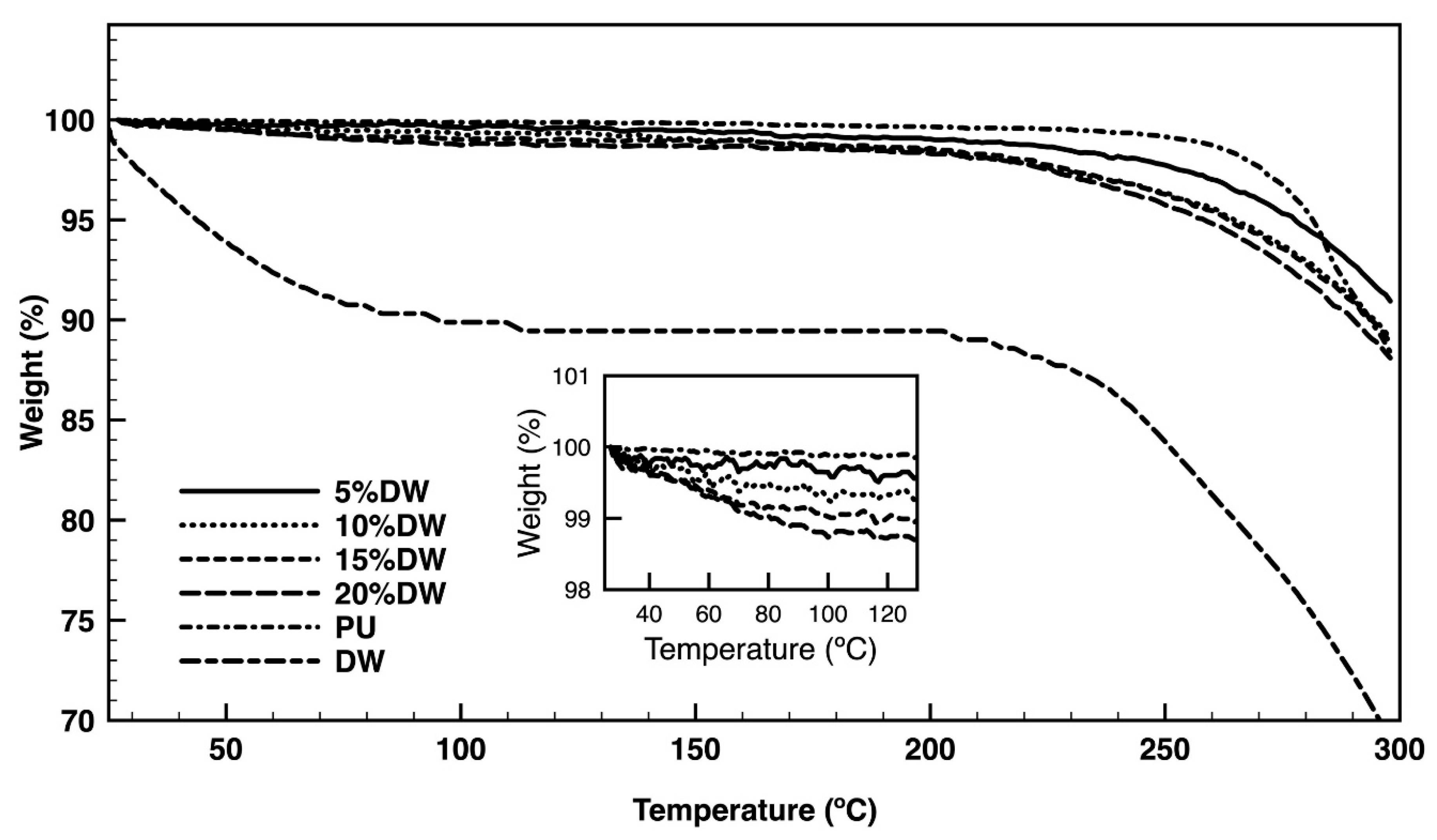

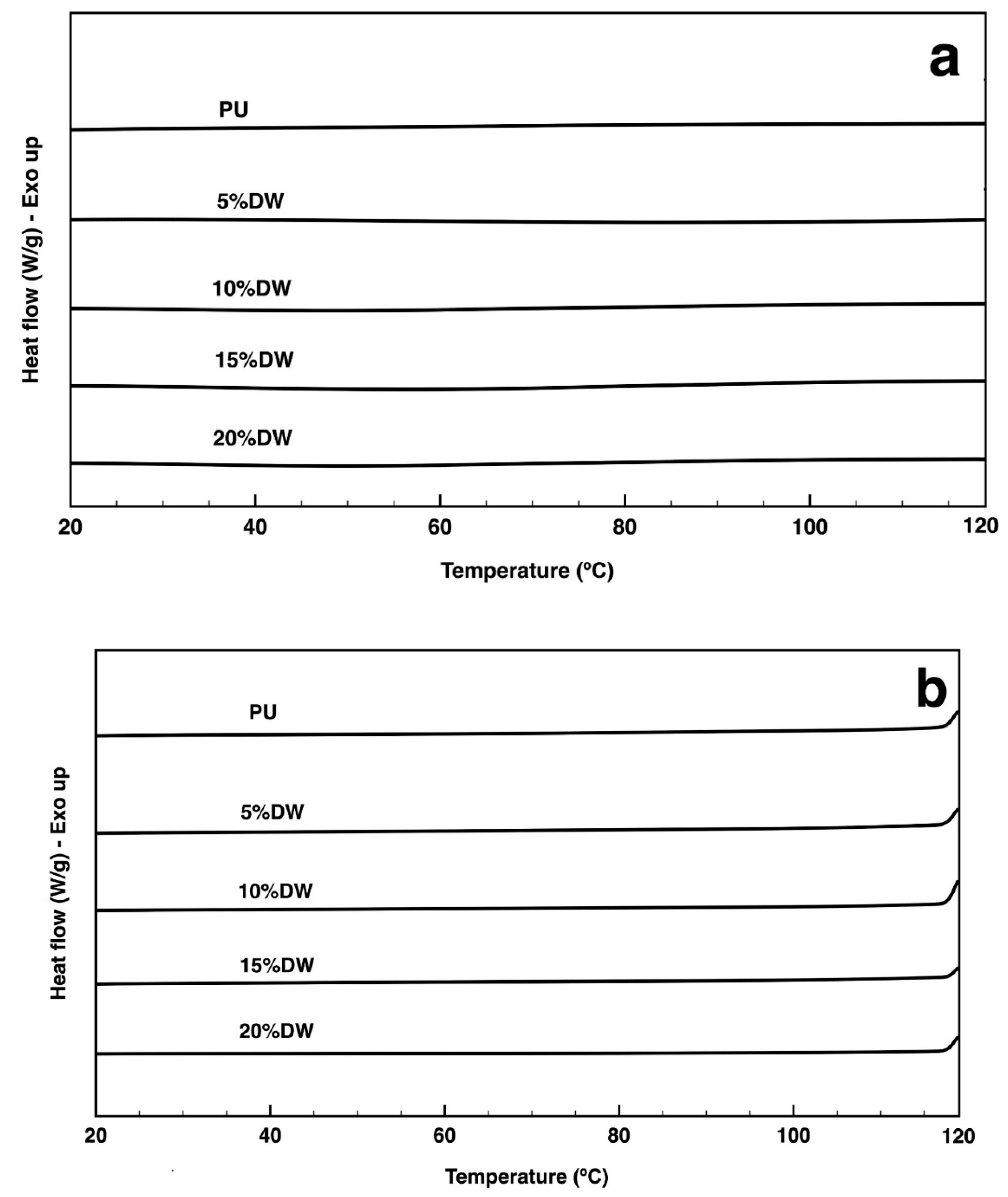

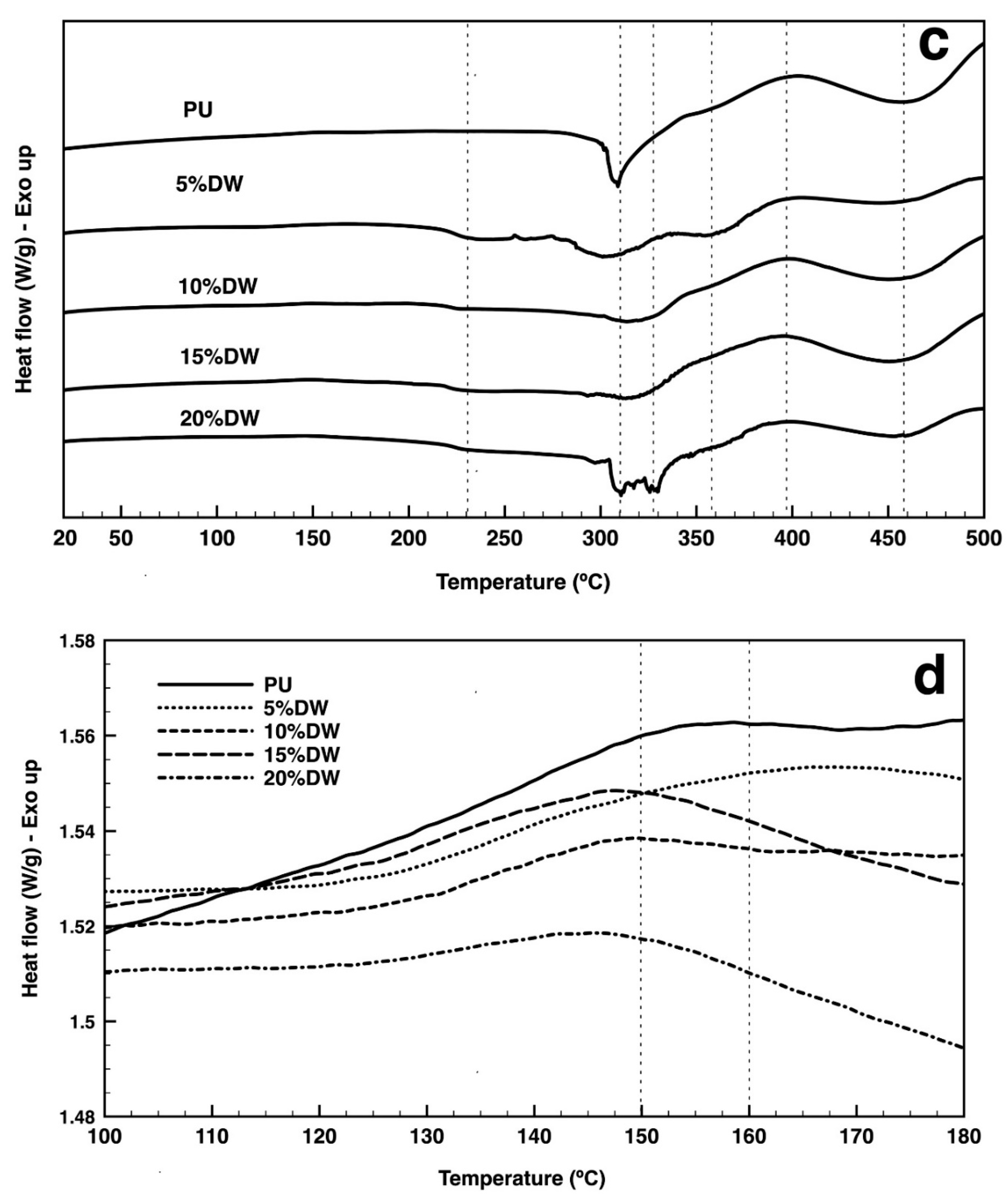

3.3. Thermal Properties

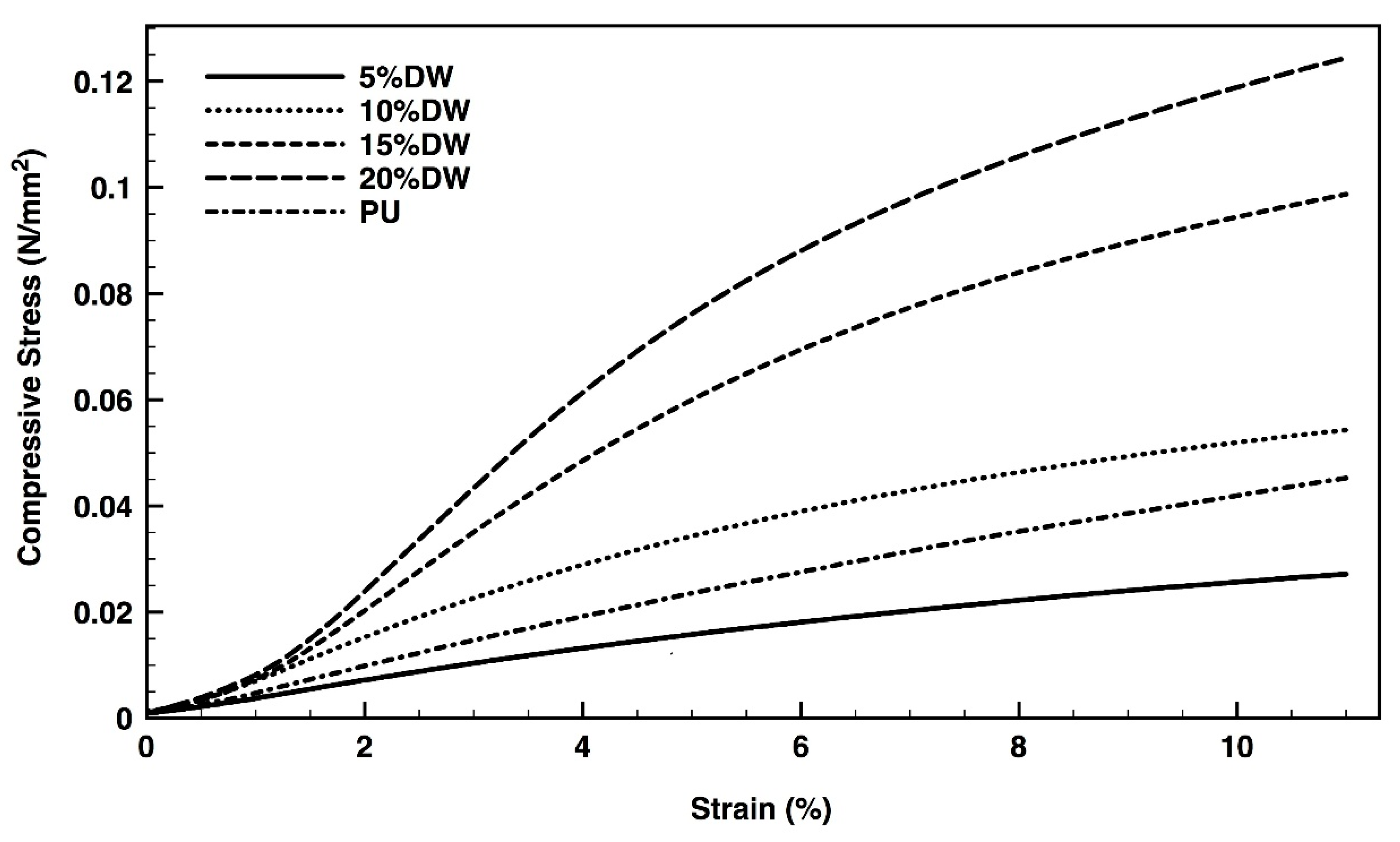

3.4. Mechanical Properties

3.5. Hydration Capacity

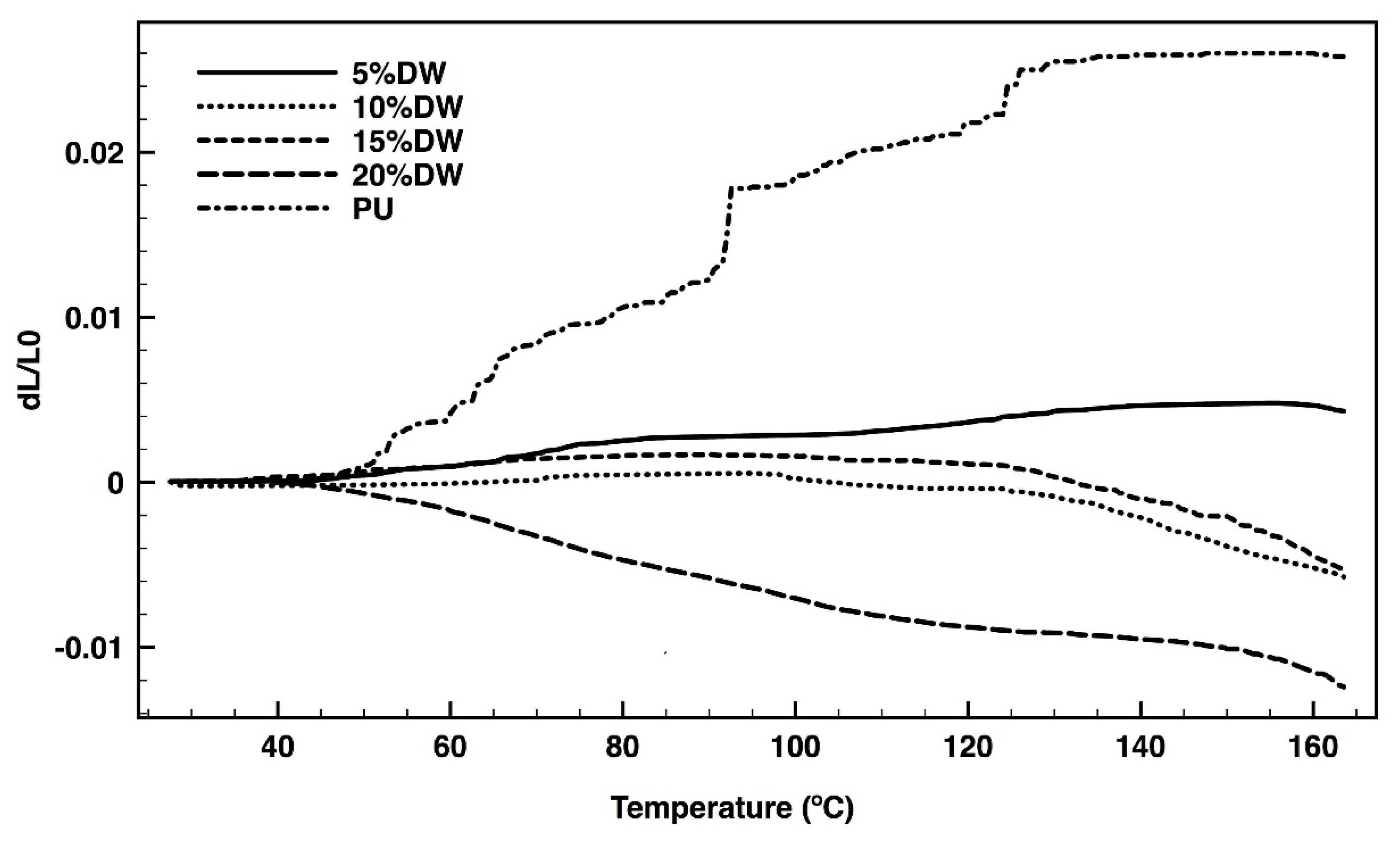

3.6. Dilatometry

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aditya, L.; Mahlia, T.; Rismanchi, B.; Ng, H.; Hasan, M.; Metselaar, H.; Muraza, O.; Aditiya, H. A review on insulation materials for energy conservation in buildings. Renew. Sust. Energy. Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Bozsaky, D. The historical development of thermal insulation materials. Period. Polytech. Archit. 2010, 41, 49–56. [Google Scholar] [CrossRef]

- Willoughby, J. Insulation. In Plant Engineer’s Reference Book (Second Edition); Snow, D.A., Ed.; Butterworth-Heinemann: Oxford, UK, 2002; pp. 301–3018. [Google Scholar]

- Xue, B.-L.; Wen, J.-L.; Sun, R.-C. Lignin-based rigid polyurethane foam reinforced with pulp fiber: Synthesis and characterization. ACS Sustain. Chem. Eng. 2014, 2, 1474–1480. [Google Scholar] [CrossRef]

- Silva, M.; Takahashi, J.; Chaussy, D.; Belgacem, M.; Silva, G. Composites of rigid polyurethane foam and cellulose fiber residue. J. Appl. Polym. Sci. 2010, 117, 3665–3672. [Google Scholar] [CrossRef]

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Kowalski, M.; Krauze, S.; Lewandowska, M. The influence of carbon fillers on the thermal properties of polyurethane foam. J. Therm. Anal. Calorim. 2016, 123, 283–291. [Google Scholar] [CrossRef]

- Rasheed, A.K.; Marhoon, I.I. Mechanical and physical properties of glass wool-rigid polyurethane foam composites. Al-Nahrain J. Eng. Sci. 2015, 18, 41–49. [Google Scholar]

- Schuetz, M.; Glicksman, L.R. A basic study of heat transfer through foam insulation. J. Cell. Plast. 1984, 20, 114–121. [Google Scholar] [CrossRef]

- Ashida, K. Polyurethane and Related Foams: Chemistry and Technology; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Adamus-Włodarczyk, A.; Kairytė, A.; Vaitkus, S. Composites of Rigid Polyurethane Foams Reinforced with POSS. Polymers 2019, 11, 336. [Google Scholar] [CrossRef]

- Rajkumar, G.; Srinivasan, J.; Suvitha, L. Natural protein fiber hybrid composites: Effects of fiber content and fiber orientation on mechanical, thermal conductivity and water absorption properties. J. Ind. Text. 2015, 44, 709–724. [Google Scholar] [CrossRef]

- Gutiérrez, M.C.; De Paoli, M.-A.; Felisberti, M.I. Cellulose acetate and short curauá fibers biocomposites prepared by large scale processing: Reinforcing and thermal insulating properties. Ind. Crop. Prod. 2014, 52, 363–372. [Google Scholar] [CrossRef]

- Zhao, Q.; Yam, R.C.; Zhang, B.; Yang, Y.; Cheng, X.; Li, R.K. Novel all-cellulose ecocomposites prepared in ionic liquids. Cellulose 2009, 16, 217–226. [Google Scholar] [CrossRef]

- Dicker, M.P.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green composites: An overview. Polym. Compos 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Briga-Sa, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Hong, C.K.; Wool, R.P. Development of a bio-based composite material from soybean oil and keratin fibers. J. Appl. Polym. Sci. 2005, 95, 1524–1538. [Google Scholar] [CrossRef]

- Cheng, S.; Lau, K.-T.; Liu, T.; Zhao, Y.; Lam, P.-M.; Yin, Y. Mechanical and thermal properties of chicken feather fiber/PLA green composites. Compos. Part B-Eng. 2009, 40, 650–654. [Google Scholar] [CrossRef]

- Cheung, H.-Y.; Ho, M.-P.; Lau, K.-T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Aluigi, A.; Vineis, C.; Ceria, A.; Tonin, C. Composite biomaterials from fibre wastes: Characterization of wool–cellulose acetate blends. Compos. Part A Appl. Sci. Manuf. 2008, 39, 126–132. [Google Scholar] [CrossRef]

- Gama, N.V.; Soares, B.; Freire, C.S.R.; Silva, R.; Neto, C.P.; Barros-Timmons, A.; Ferreira, A. Bio-based polyurethane foams toward applications beyond thermal insulation. Mater. Des. 2015, 76, 77–85. [Google Scholar] [CrossRef]

- Pielesz, A.; Freeman, H.S.; Wesełucha-Birczyńska, A.; Wysocki, M.; Włochowicz, A. Assessing secondary structure of a dyed wool fibre by means of FTIR and FTR spectroscopies. J. Mol. Struct. 2003, 651–653, 405–418. [Google Scholar] [CrossRef]

- Moody, V.; Needles, H.L. Major Fibers and Their Properties. In Tufted Carpet; William Andrew Publishing: Norwich, NY, USA, 2004; pp. 35–59. [Google Scholar]

- Cruz-Lopes, L.P.; Rodrigues, L.; Domingos, I.; Ferreira, J.; Lemos, L.T.d.; Esteves, B. Production of Polyurethane Foams from Bark Wastes. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2016, 10, 1056–1059. [Google Scholar]

- Idris, A.; Vijayaraghavan, R.; Rana, U.A.; Patti, A.F.; MacFarlane, D.R. Dissolution and regeneration of wool keratin in ionic liquids. Green. Chem. 2014, 16, 2857–2864. [Google Scholar] [CrossRef]

- Aluigi, A.; Zoccola, M.; Vineis, C.; Tonin, C.; Ferrero, F.; Canetti, M. Study on the structure and properties of wool keratin regenerated from formic acid. Int. J. Biol. Macromol. 2007, 41, 266–273. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Nie, Y.; Meng, X.; Zhang, Z.; Zhang, X.; Zhang, S. DBN-based ionic liquids with high capability for the dissolution of wool keratin. RSC. Adv. 2017, 7, 1981–1988. [Google Scholar] [CrossRef]

- Yavuz, G.; Felgueiras, H.P.; Ribeiro, A.I.; Seventekin, N.; Zille, A.; Souto, A.P. Dyed poly (styrene-methyl methacrylate-acrylic acid) photonic nanocrystals for enhanced structural color. ACS Appl. Mater. Interfaces 2018, 10, 23285–23294. [Google Scholar] [CrossRef]

- Felgueiras, H.P.; Teixeira, M.A.; Tavares, T.D.; Homem, N.C.; Zille, A.; Amorim, M.T.P. Antimicrobial action and clotting time of thin, hydrated poly (vinyl alcohol)/cellulose acetate films functionalized with LL37 for prospective wound-healing applications. J. Appl. Polym. Sci. 2019. [Google Scholar] [CrossRef]

- Sakabe, H.; Ito, H.; Miyamoto, T.; Inagaki, H. States of water sorbed on wool as studied by differential scanning calorimetry. Text. Res. J. 1987, 57, 66–72. [Google Scholar] [CrossRef]

- Zhang, Y.; Shang, S.; Zhang, X.; Wang, D.; Hourston, D. Influence of structure of hydroxyl-terminated maleopimaric acid ester on thermal stability of rigid polyurethane foams. J. Appl. Polym. Sci. 1995, 58, 1803–1809. [Google Scholar] [CrossRef]

- Mosiewicki, M.A.; Dell’Arciprete, G.; Aranguren, M.I.; Marcovich, N.E. Polyurethane foams obtained from castor oil-based polyol and filled with wood flour. J. Compos. Mater. 2009, 43, 3057–3072. [Google Scholar] [CrossRef]

- Ma, B.; Qiao, X.; Hou, X.; Yang, Y. Pure keratin membrane and fibers from chicken feather. Int. J. Biol. Macromol. 2016, 89, 614–621. [Google Scholar] [CrossRef] [PubMed]

- Cuvé, L.; Pascault, J.P.; Boiteux, G.; Seytre, G. Synthesis and properties of polyurethanes based on polyolefine: 1. Rigid polyurethanes and amorphous segmented polyurethanes prepared in polar solvents under homogeneous conditions. Polymer 1991, 32, 343–352. [Google Scholar] [CrossRef]

- Zia, F.; Zia, K.M.; Zuber, M.; Kamal, S.; Aslam, N. Starch based polyurethanes: A critical review updating recent literature. Carbohydr. Polym. 2015, 134, 784–798. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Fang, W.-Z.; Li, Y.-M.; Tao, W.-Q. Experimental study of the thermal conductivity of polyurethane foams. Appl. Therm. Eng. 2017, 115, 528–538. [Google Scholar] [CrossRef]

- Wu, G.; Wang, Y.; Wang, K.; Feng, A. The effect of modified AlN on the thermal conductivity, mechanical and thermal properties of AlN/polystyrene composites. RSC Advanc. 2016, 6, 102542–102548. [Google Scholar] [CrossRef]

- Pau, D.S.W.; Fleischmann, C.M.; Spearpoint, M.J.; Li, K.Y. Thermophysical properties of polyurethane foams and their melts. Fire. Mater. 2014, 38, 433–450. [Google Scholar] [CrossRef]

- Prociak, A.; Pielichowski, J.; Sterzynski, T. Thermal diffusivity of rigid polyurethane foams blown with different hydrocarbons. Polym. Test. 2000, 19, 705–712. [Google Scholar] [CrossRef]

- Hawkins, M.C.; O’Toole, B.; Jackovich, D. Cell morphology and mechanical properties of rigid polyurethane foam. J. Cell. Plast. 2005, 41, 267–285. [Google Scholar] [CrossRef]

- Banik, I.; Sain, M.M. Role of refined paper fiber on structure of water blown soy polyol based polyurethane foams. J. Reinf. Plast. Comp. 2008, 27, 1515–1524. [Google Scholar] [CrossRef]

- Lo Nostro, P.; Fratoni, L.; Ninham, B.W.; Baglioni, P. Water absorbency by wool fibers: Hofmeister effect. Biomacromolecules 2002, 3, 1217–1224. [Google Scholar] [CrossRef]

- Ormondroyd, G.A.; Curling, S.F.; Mansour, E.; Hill, C.A. The water vapour sorption characteristics and kinetics of different wool types. J. Text. Inst. 2017, 108, 1198–1210. [Google Scholar] [CrossRef]

| Eco-Composite (%) | Dog Wool (g) | PU (g) |

|---|---|---|

| 5 | 12.5 | 237.5 |

| 10 | 25.0 | 225.0 |

| 15 | 37.5 | 212.5 |

| 20 | 50.0 | 200.0 |

| Samples | Thermal Conductivity (W/mk) | Thermal Capacity (MJ/m3k) | Thermal Diffusivity (m2/s) | Thermal Resistance (°C cm/W) |

|---|---|---|---|---|

| PU | 0.053 ± 0.004 | 0.561 ± 0.045 | 0.091 ± 0.003 | 1878.5 ± 153.3 |

| 5% DW | 0.064 ± 0.006 | 0.454 ± 0.015 | 0.141 ± 0.016 | 1576.0 ± 153.3 |

| 10% DW | 0.070 ± 0.002 | 0.603 ± 0.048 | 0.122 ± 0.006 | 1411.5 ± 61.7 |

| 15% DW | 0.063 ± 0.002 | 0.530 ± 0.046 | 0.120 ± 0.009 | 1590.0 ± 38.2 |

| 20% DW | 0.061 ± 0.002 | 0.615 ± 0.053 | 0.098 ± 0.012 | 1647.5 ± 45.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Claudivan da Silva, F.; Felgueiras, H.P.; Ladchumananandasivam, R.; Ubiragi L. Mendes, J.; de O. Souto Silva, K.K.; Zille, A. Dog Wool Microparticles/Polyurethane Composite for Thermal Insulation. Polymers 2020, 12, 1098. https://doi.org/10.3390/polym12051098

Claudivan da Silva F, Felgueiras HP, Ladchumananandasivam R, Ubiragi L. Mendes J, de O. Souto Silva KK, Zille A. Dog Wool Microparticles/Polyurethane Composite for Thermal Insulation. Polymers. 2020; 12(5):1098. https://doi.org/10.3390/polym12051098

Chicago/Turabian StyleClaudivan da Silva, Francisco, Helena P. Felgueiras, Rasiah Ladchumananandasivam, José Ubiragi L. Mendes, Késia Karina de O. Souto Silva, and Andrea Zille. 2020. "Dog Wool Microparticles/Polyurethane Composite for Thermal Insulation" Polymers 12, no. 5: 1098. https://doi.org/10.3390/polym12051098

APA StyleClaudivan da Silva, F., Felgueiras, H. P., Ladchumananandasivam, R., Ubiragi L. Mendes, J., de O. Souto Silva, K. K., & Zille, A. (2020). Dog Wool Microparticles/Polyurethane Composite for Thermal Insulation. Polymers, 12(5), 1098. https://doi.org/10.3390/polym12051098