Robust Polymer Planar Bragg Grating Sensors Embedded in Commercial-Grade Composites

Abstract

1. Introduction

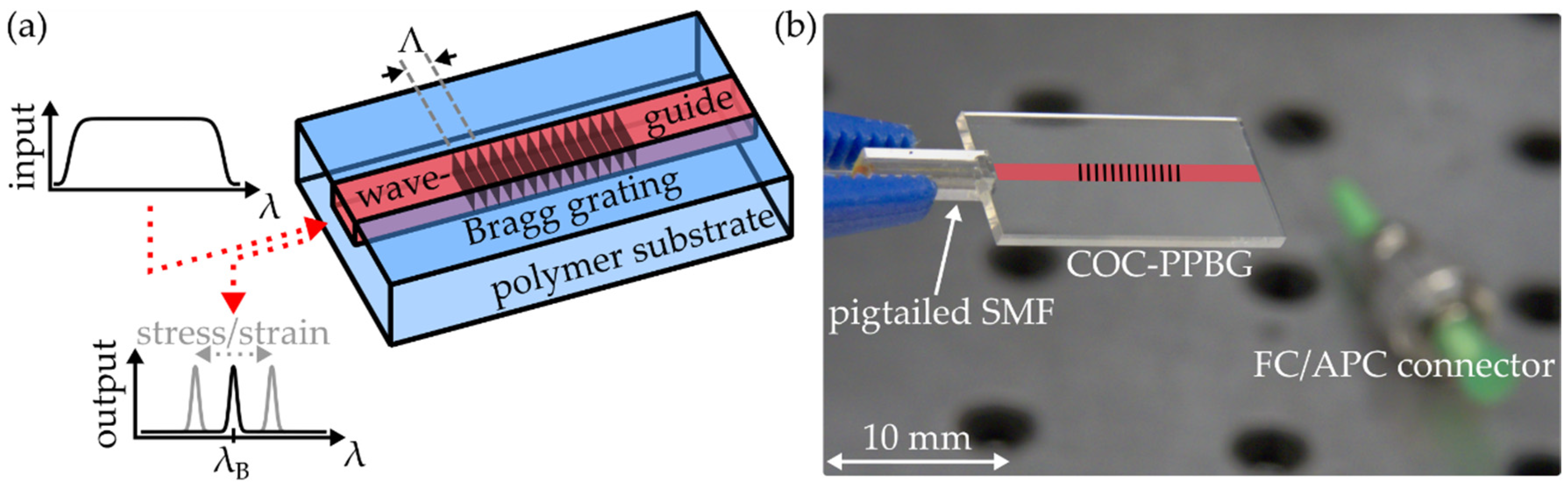

2. Materials and Methods

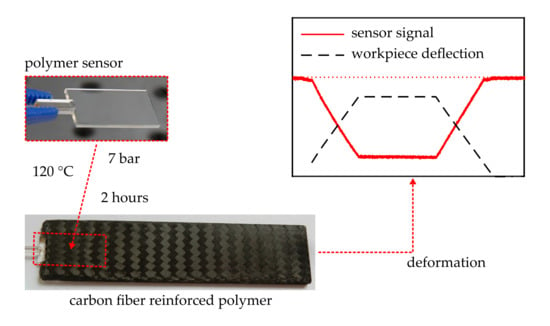

3. Sample Preparation and Sensor Integration

4. Results and Discussion

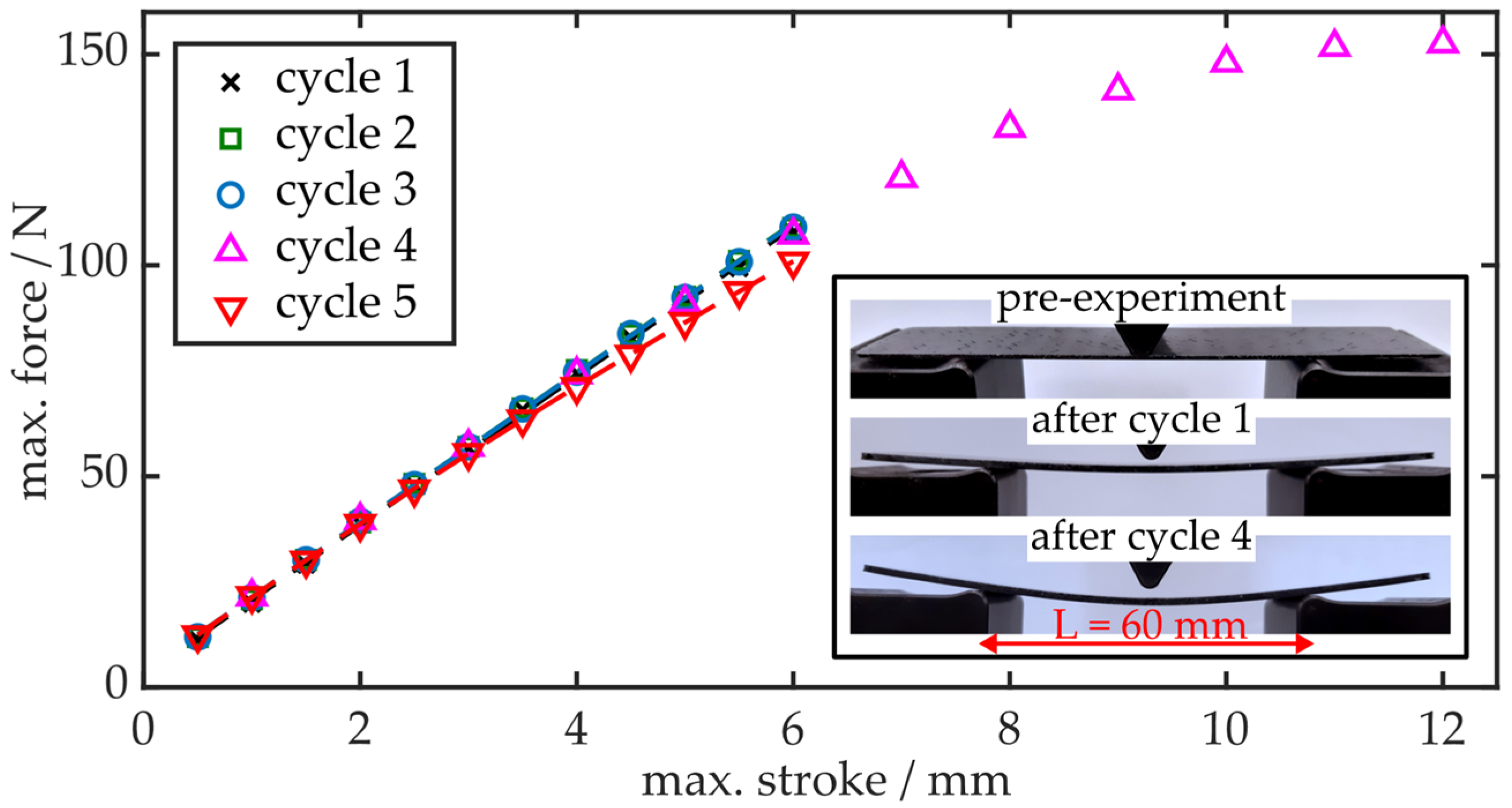

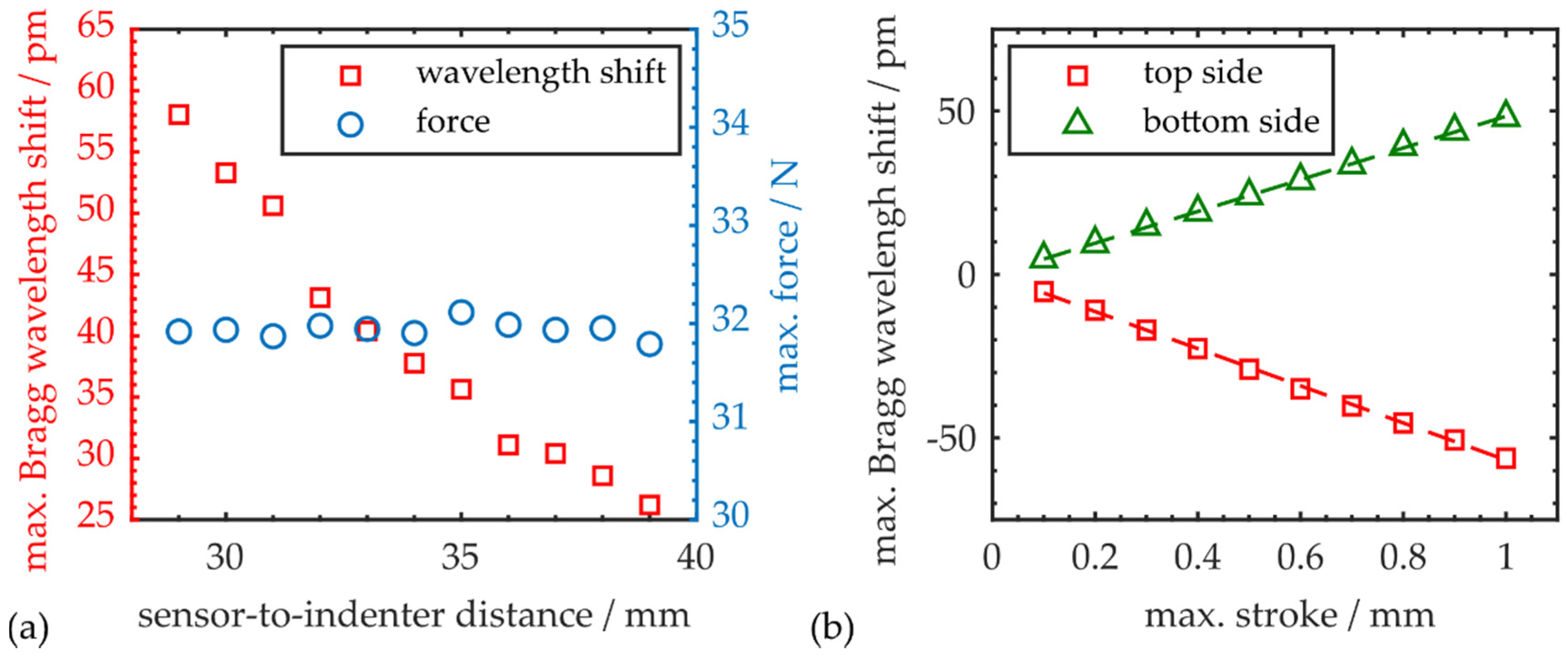

4.1. Specimen A: Flexural Behaviour of Bulk CFRP Specimen

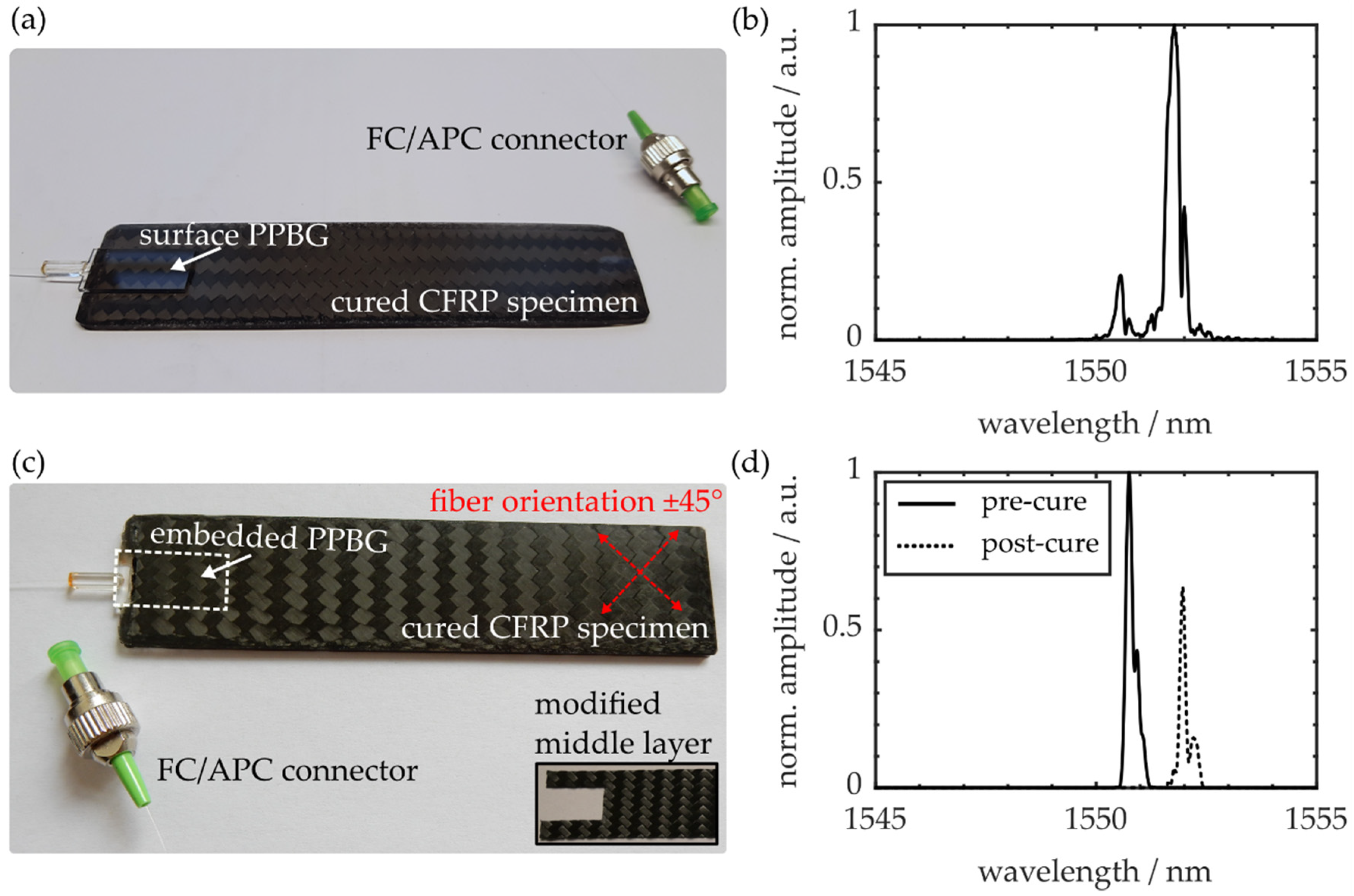

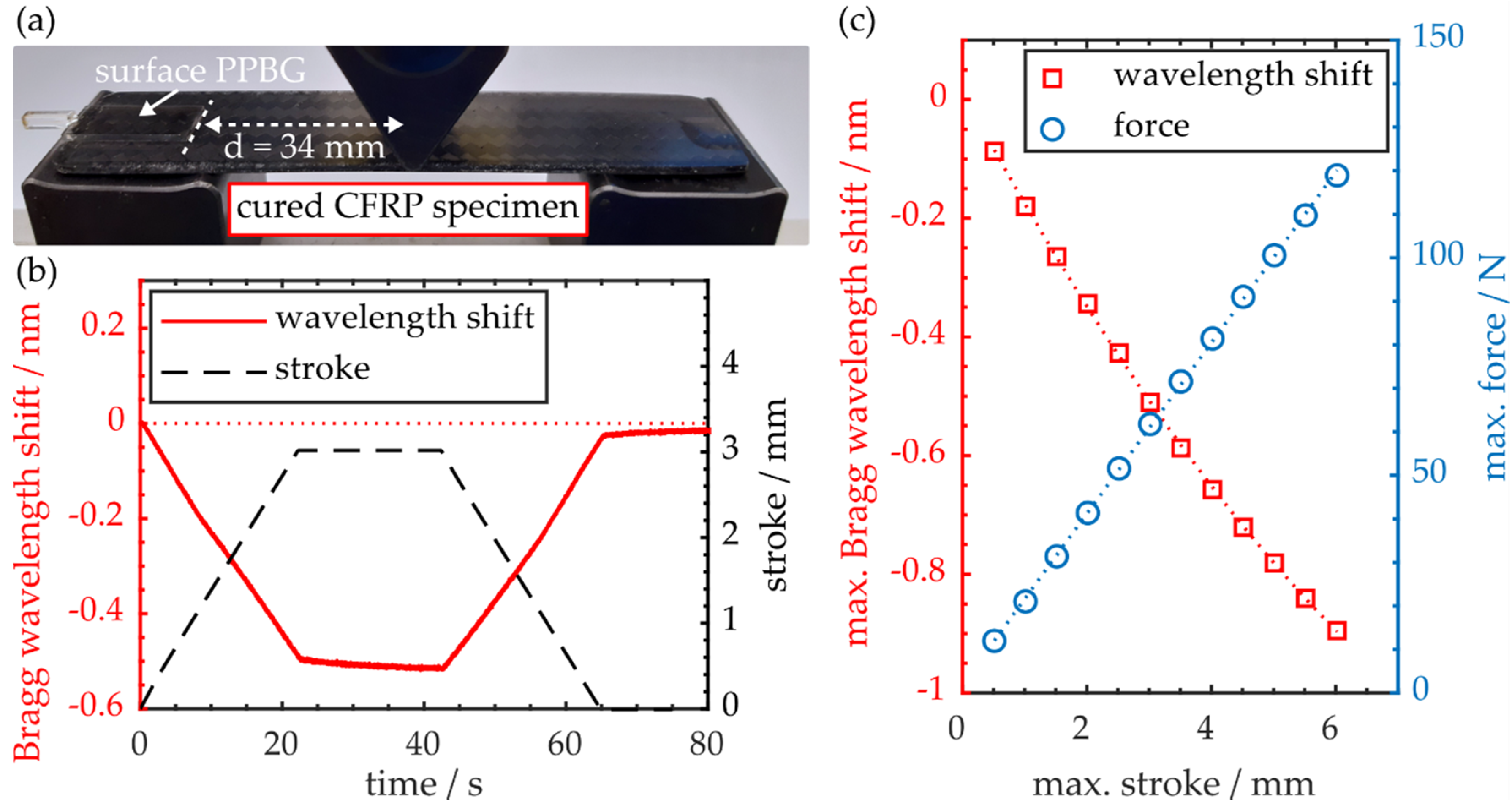

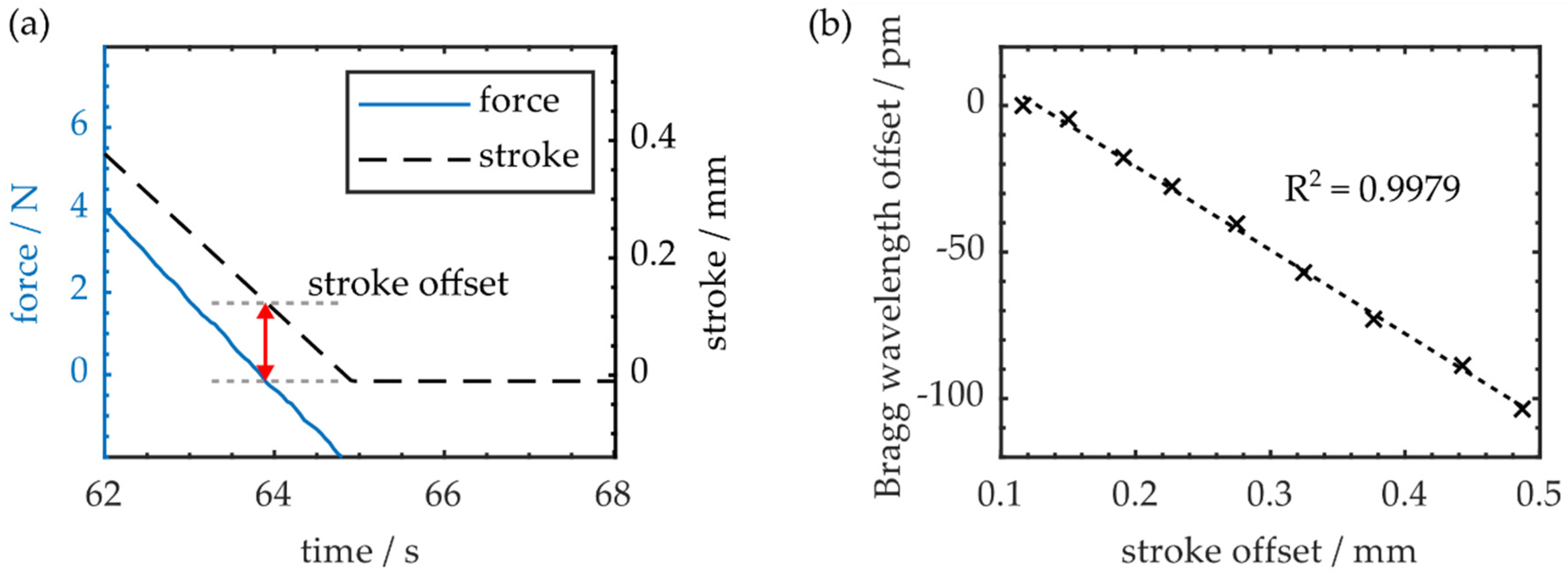

4.2. Specimen B: Polymer Optical Sensor Affixed to Workpiece Surface

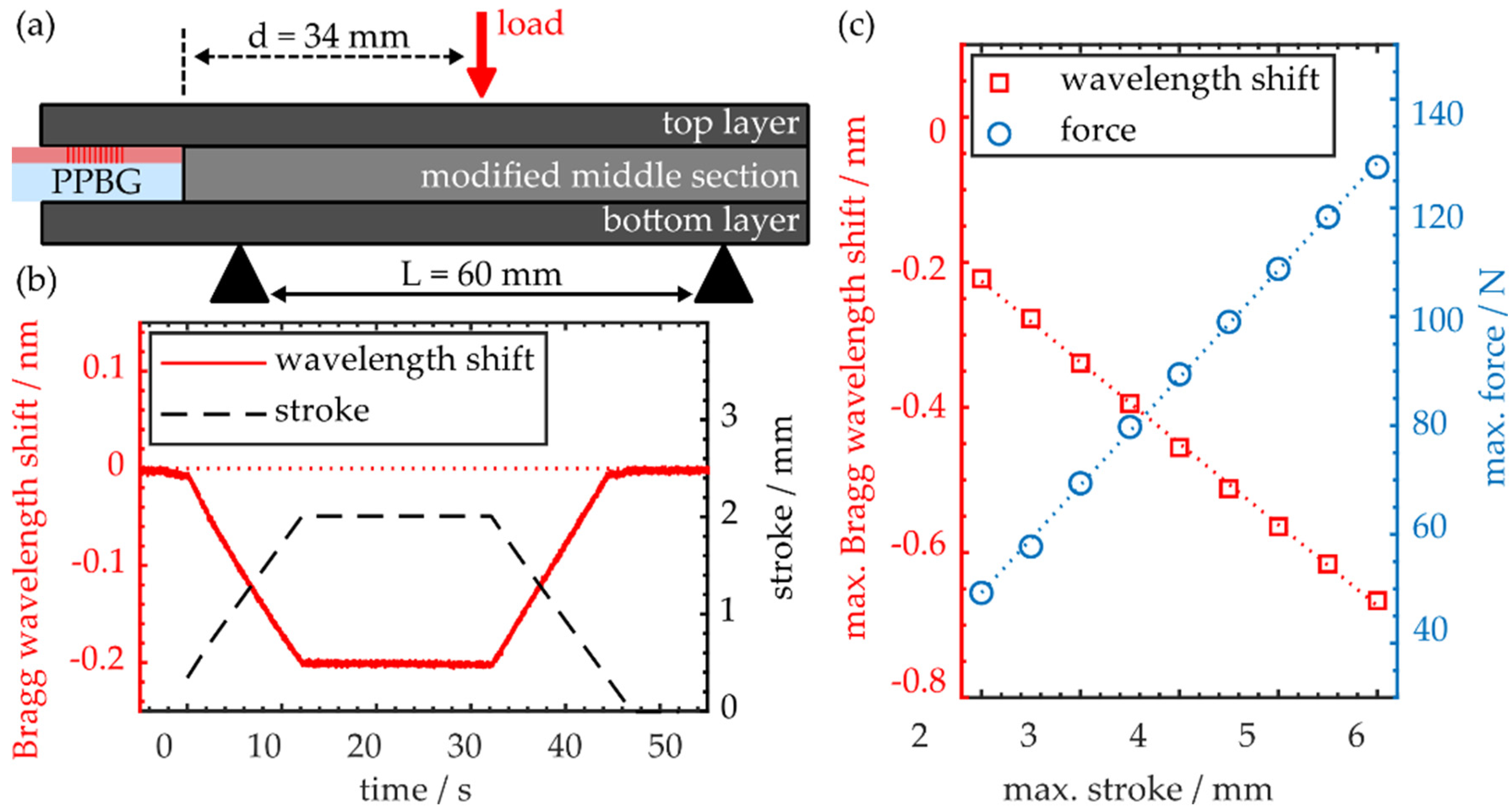

4.3. Specimen C: Functionality of Integrated Polymer Optical Sensor

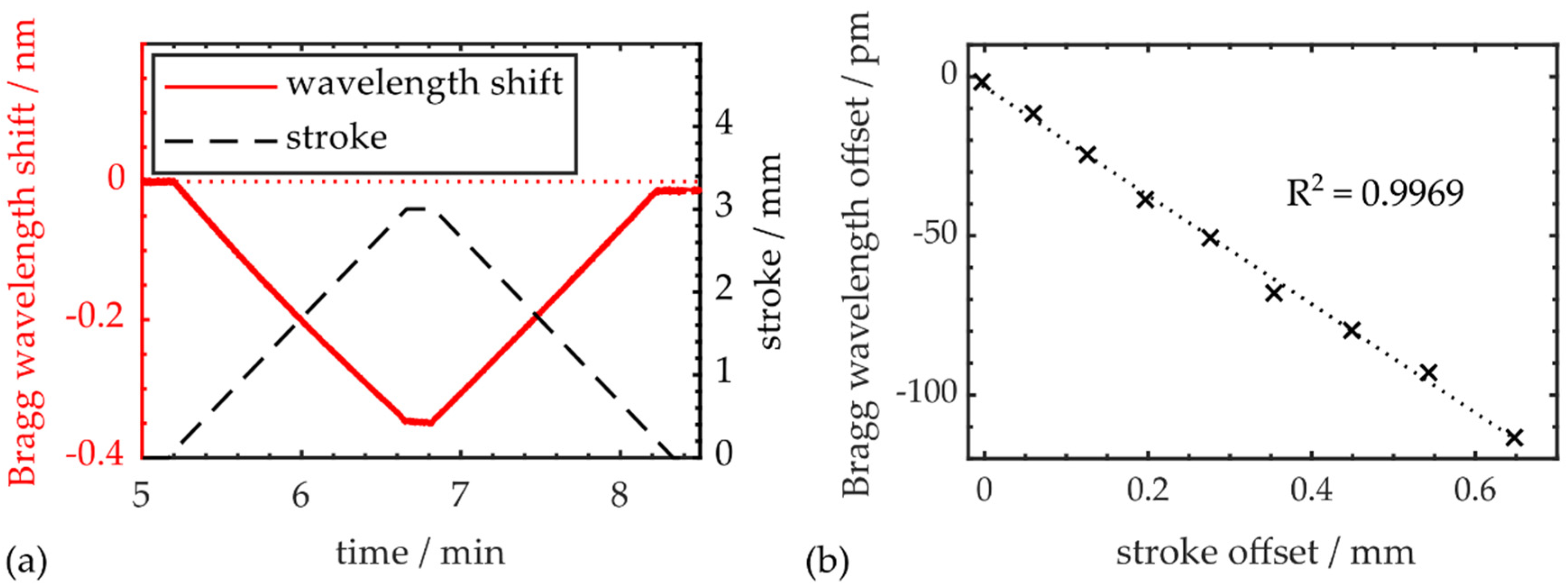

4.4. Specimen D: Influence of Workpiece Orientation and Sensor Positioning

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg grating sensors toward structural health monitoring in composite materials: Challenges and solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef] [PubMed]

- Breuer, U.P. COMMERCIAL Aircraft Composite Technology; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-31918-6. [Google Scholar]

- Adams, D.F.; Carlsson, L.A.; Pipes, R.B. Experimental Characterization of Advanced Composite Materials, 3th ed.; CRC Press: Boca Raton, FL, USA, 2003; ISBN 1-58716-100-1. [Google Scholar]

- Rakočević, M. Bending of Laminated Composite Plates in Layerwise Theory. In Lamination—Theory and Application; Osheku, C.A., Ed.; InTech: London, UK, 2018; ISBN 978-953-51-3925-6. [Google Scholar]

- Wang, Q.; Ri, S.; Tsuda, H.; Takashita, Y.; Kitamura, R.; Ogihara, S. Interlaminar Shear Behavior of Laminated Carbon Fiber Reinforced Plastic from Microscale Strain Distributions Measured by Sampling Moiré Technique. Materials 2018, 11, 1684. [Google Scholar] [CrossRef] [PubMed]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A review on FRP composites applications and durability concerns in the construction sector. J. Reinf. Plast. Comp. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- Goidescu, C.; Welemane, H.; Garnier, C.; Fazzini, M.; Brault, R.; Péronnet, E.; Mistou, S. Damage investigation in CFRP composites using full-field measurement techniques: Combination of digital image stereo-correlation, infrared thermography and X-ray tomography. Compos. Part B Eng. 2013, 48, 95–105. [Google Scholar] [CrossRef]

- Kovalovs, A.; Rucevskis, S.; Kulakov, V.; Wesołowski, M. Damage Detection in Carbon Fibre Reinforced Composites Using Electric Resistance Change Method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 102014. [Google Scholar] [CrossRef]

- Rajan, G.; Prusty, B.G.; Iniewski, K. Structural Health Monitoring of Composite Structures Using Fiber Optic Methods; Taylor & Francis Group: New York, NY, USA, 2017; ISBN 9781315369815. [Google Scholar]

- Kuang, K.S.C.; Cantwell, W.J. Use of conventional optical fibers and fiber Bragg gratings for damage detection in advanced composite structures: A review. Smart Mater. Struct. 2003, 56, 493. [Google Scholar] [CrossRef]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain measurements of composite laminates with embedded fibre bragg gratings: Criticism and opportunities for research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef]

- Zhou, G.; Sim, L.M. Damage detection and assessment in fibre-reinforced composite structures with embedded fibre optic sensors-review. Smart Mater. Struct. 2002, 11, 925–939. [Google Scholar] [CrossRef]

- Khan, F.; Denasi, A.; Barrera, D.; Madrigal, J.; Sales, S.; Misra, S. Multi-core Optical Fibers with Bragg Gratings as Shape Sensor for Flexible Medical Instruments. IEEE Sens. J. 2019, 1. [Google Scholar] [CrossRef]

- Rosenberger, M.; Eisenbeil, W.; Schmauss, B.; Hellmann, R. Simultaneous 2D strain sensing using polymer planar Bragg gratings. Sensors 2015, 15, 4264–4272. [Google Scholar] [CrossRef] [PubMed]

- Rosenberger, M.; Pauer, H.; Girschikofsky, M.; Woern, H.; Schmauss, B.; Hellmann, R. Flexible Polymer Shape Sensor Based on Planar Waveguide Bragg Gratings. IEEE Photonics Technol. Lett. 2016, 28, 1898–1901. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings, 2nd ed.; Academic: London, UK, 2010; ISBN 978-0-12-372579-0. [Google Scholar]

- Luo, Y.; Yan, B.; Zhang, Q.; Peng, G.-D.; Wen, J.; Zhang, J. Fabrication of Polymer Optical Fibre (POF) Gratings. Sensors 2017, 17, 511. [Google Scholar] [CrossRef] [PubMed]

- Peters, K. Polymer optical fiber sensors—A review. Smart Mater. Struct. 2011, 20, 13002. [Google Scholar] [CrossRef]

- Missinne, J.; Teigell Benéitez, N.; Chiesura, G.; Luyckx, G.; Degrieck, J.; van Steenberge, G. Flexible thin polymer waveguide Bragg grating sensor foils for strain sensing. In Proceedings of the Organic Photonic Materials and Devices XIX, San Francisco, CA, USA, 28 January 2017; Tabor, C.E., Kajzar, F., Kaino, T., Koike, Y., Eds.; SPIE: Bellingham, WA, USA, 2017; p. 101010X. [Google Scholar]

- Summerscales, J.; Searle, T.J. Low-pressure (vacuum infusion) techniques for moulding large composite structures. Proc. IMechE 2005, 219, 45–58. [Google Scholar] [CrossRef]

- Jones, R.M. Mechanics of Composite Materials, 2nd ed.; Taylor & Francis Group: New York, NY, USA, 2018; ISBN 9781315272986. [Google Scholar]

- Khanarian, G. Optical properties of cyclic olefin copolymers. Opt. Eng. 2001, 40, 1024. [Google Scholar] [CrossRef]

- Rosenberger, M.; Kefer, S.; Girschikofsky, M.; Roth, G.-L.; Hessler, S.; Belle, S.; Schmauss, B.; Hellmann, R. High-temperature stable and sterilizable waveguide Bragg grating in planar cyclo-olefin copolymer. Opt. Lett. 2018, 43, 3321–3324. [Google Scholar] [CrossRef]

- Yuan, W.; Khan, L.; Webb, D.J.; Kalli, K.; Rasmussen, H.K.; Stefani, A.; Bang, O. Humidity insensitive TOPAS polymer fiber Bragg grating sensor. Opt. Express 2011, 19, 19731–19739. [Google Scholar] [CrossRef]

- Rosenberger, M.; Hessler, S.; Belle, S.; Schmauss, B.; Hellmann, R. Fabrication and characterization of planar Bragg gratings in TOPAS polymer substrates. Sens. Actuators A Phys. 2015, 221, 148–153. [Google Scholar] [CrossRef]

- Rosenberger, M.; Koller, G.; Belle, S.; Schmauss, B.; Hellmann, R. Planar Bragg grating in bulk polymethylmethacrylate. Opt. Express 2012, 20, 27288–27296. [Google Scholar] [CrossRef]

- Rosenberger, M.; Schmauss, B.; Hellmann, R. Influence of the UV dosage on planar Bragg gratings in cyclo-olefin copolymer substrates. Opt. Mater. Express 2016, 6, 2118. [Google Scholar] [CrossRef]

- Hessler, S.; Rosenberger, M.; Schmauss, B.; Hellmann, R. Two-dimensional interferometric characterization of laser-induced refractive index profiles in bulk Topas polymer. Opt. Mater. 2018, 75, 230–235. [Google Scholar] [CrossRef]

- ASTM D7264/D7264M-15. Test Method for Flexural Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Allen, D.H. Damage evolution in laminates. In Damage Mechanics of Composite Materials; Talreja, R., Ed.; Elsevier: Amsterdam, The Netherlands, 1994; ISBN 9780444888525. [Google Scholar]

- Schuecker, C.; Pettermann, H.E. Fiber Reinforced Laminates: Progressive Damage Modeling Based on Failure Mechanisms. Arch. Computat. Methods Eng. 2008, 15, 163–184. [Google Scholar] [CrossRef]

- Koloor, S.S.R.; Ayatollahi, M.R.; Tamin, M.N. Elastic-damage deformation response of fiber-reinforced polymer composite laminates with lamina interfaces. J. Reinf. Plast. Comp. 2017, 36, 832–849. [Google Scholar] [CrossRef]

- Lu, X.; Liu, D. Interlayer shear slip theory for cross-ply laminates with nonrigid interfaces. AIAA J. 1992, 30, 1063–1073. [Google Scholar] [CrossRef]

- Tan, C.W.; Chan, Y.C.; Chan, H.P.; Leung, N.W.; So, C.K. Investigation on bondability and reliability of UV-curable adhesive joints for stable mechanical properties in photonic device packaging. Microelectron. Reliab. 2004, 44, 823–831. [Google Scholar] [CrossRef]

| Specimen | A | B | C | D |

|---|---|---|---|---|

| overall layers | 9 | 11 | ||

| modified middle layers | / | / | 7 | 7 |

| COC-PPBG | / | surface | integrated | integrated |

| length/mm | 106.8 | 106.2 | 100.0 | 100.0 |

| width/mm | 23.5 | 24.4 | 22.8 | 24.1 |

| thickness/mm | 1.35 | 1.41 | 1.40 | 1.71 |

| stiffness/N·mm−1 | 17.7 | 21.6 | 19.4 | 27.1 |

| flexural modulus/GPa | 16.5 | 17.1 | 16.7 | 12.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kefer, S.; Sauer, T.; Hessler, S.; Kaloudis, M.; Schmauss, B.; Hellmann, R. Robust Polymer Planar Bragg Grating Sensors Embedded in Commercial-Grade Composites. Polymers 2020, 12, 715. https://doi.org/10.3390/polym12030715

Kefer S, Sauer T, Hessler S, Kaloudis M, Schmauss B, Hellmann R. Robust Polymer Planar Bragg Grating Sensors Embedded in Commercial-Grade Composites. Polymers. 2020; 12(3):715. https://doi.org/10.3390/polym12030715

Chicago/Turabian StyleKefer, Stefan, Theresia Sauer, Steffen Hessler, Michael Kaloudis, Bernhard Schmauss, and Ralf Hellmann. 2020. "Robust Polymer Planar Bragg Grating Sensors Embedded in Commercial-Grade Composites" Polymers 12, no. 3: 715. https://doi.org/10.3390/polym12030715

APA StyleKefer, S., Sauer, T., Hessler, S., Kaloudis, M., Schmauss, B., & Hellmann, R. (2020). Robust Polymer Planar Bragg Grating Sensors Embedded in Commercial-Grade Composites. Polymers, 12(3), 715. https://doi.org/10.3390/polym12030715