Investigation on the Continuous Wave Mode and the ms Pulse Mode Fiber Laser Drilling Mechanisms of the Carbon Fiber Reinforced Composite

Abstract

1. Introduction

2. Experimental Methods

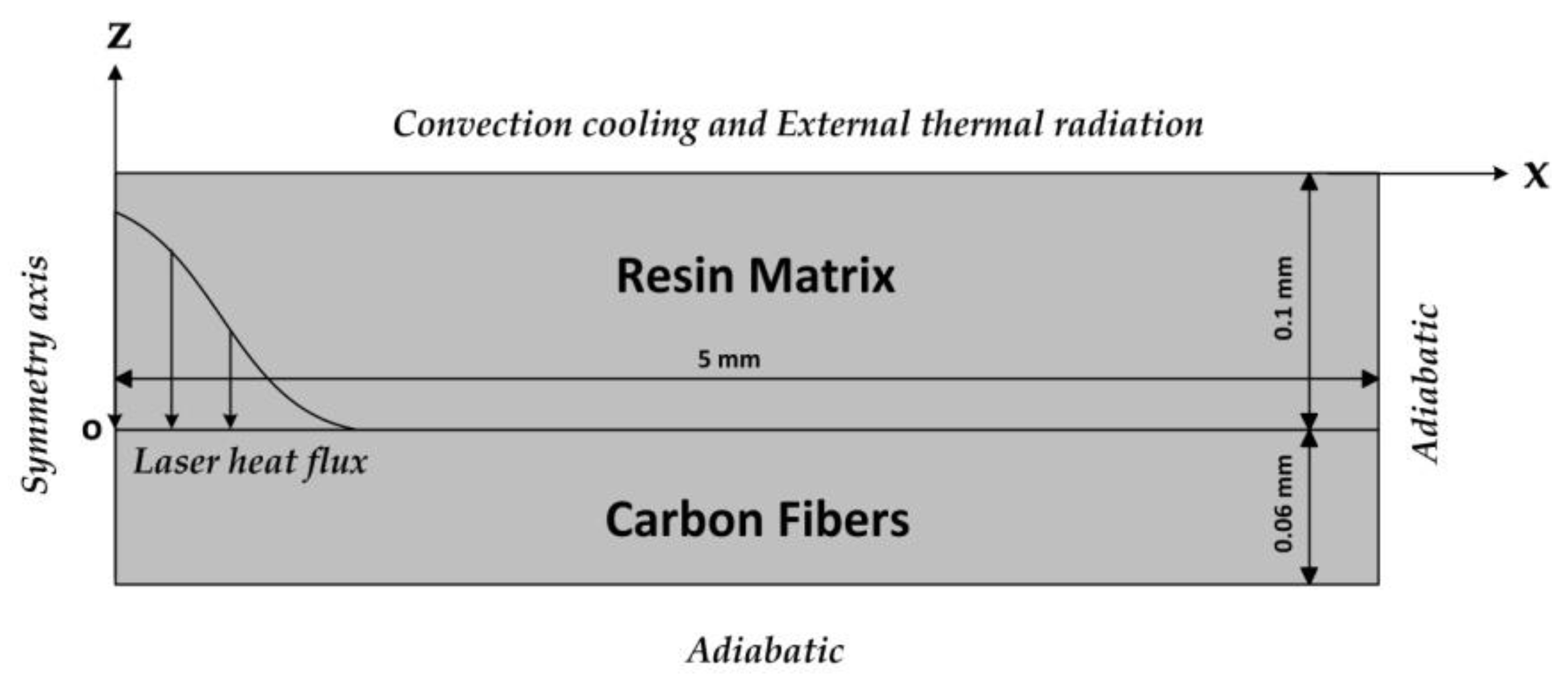

2.1. Material Specification

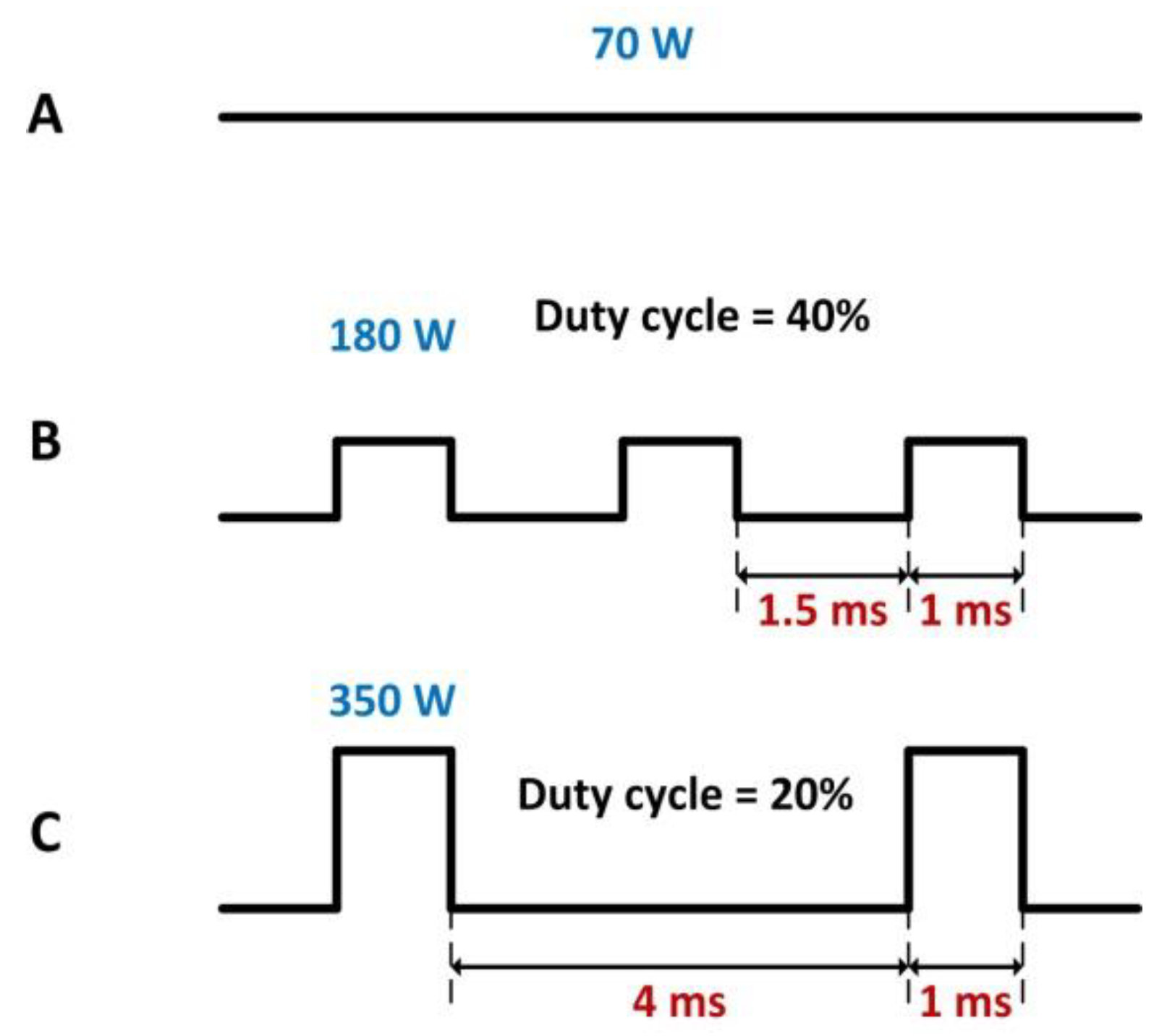

2.2. Laser Setup

2.3. Time Measurement of the Laser Penetrating Target

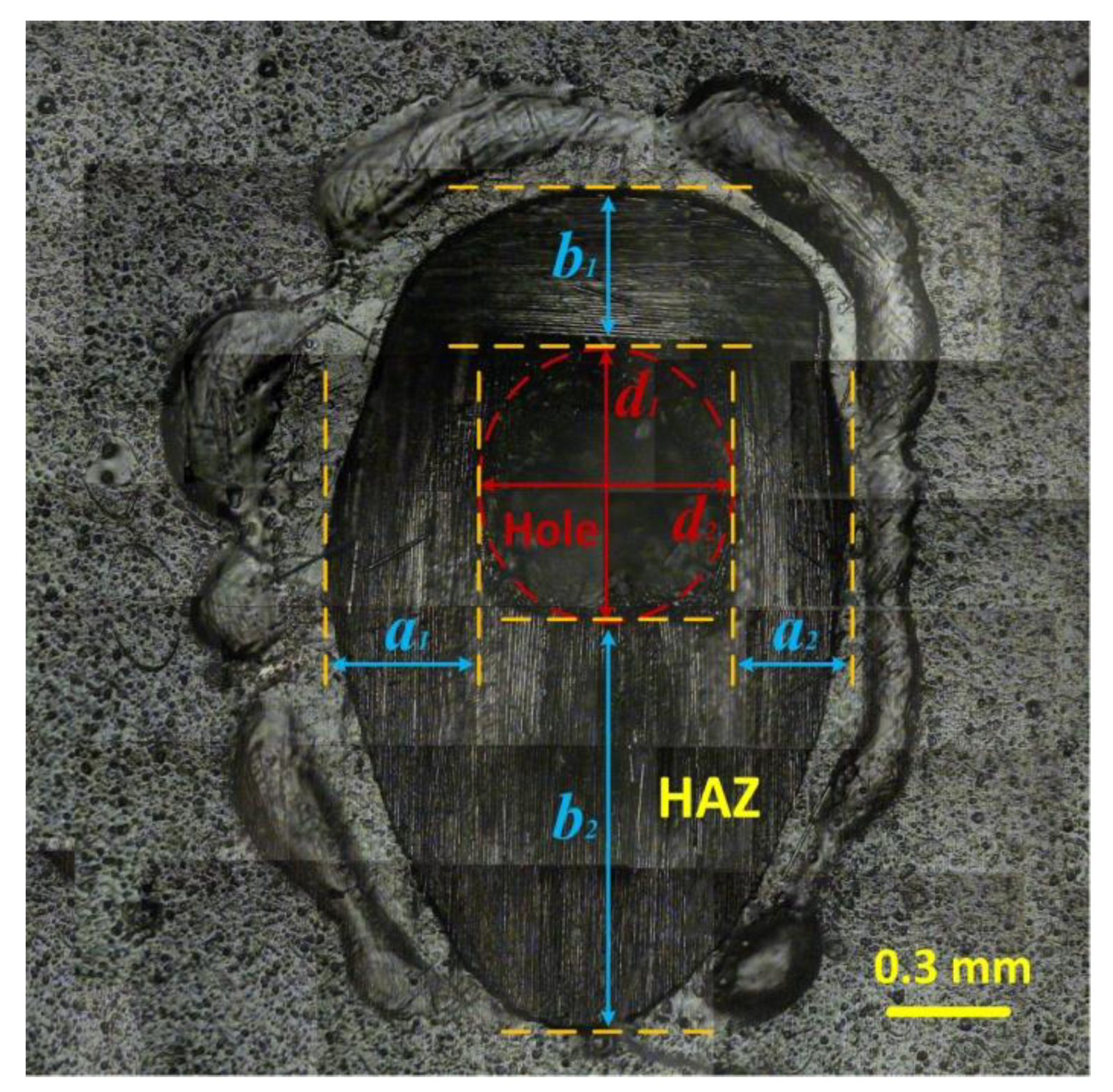

2.4. Measurement of the Entrance Hole Diameter and the Surface HAZ Width

2.5. Mass Measurement of the Ablated Material

3. Experimental Results and Discussion

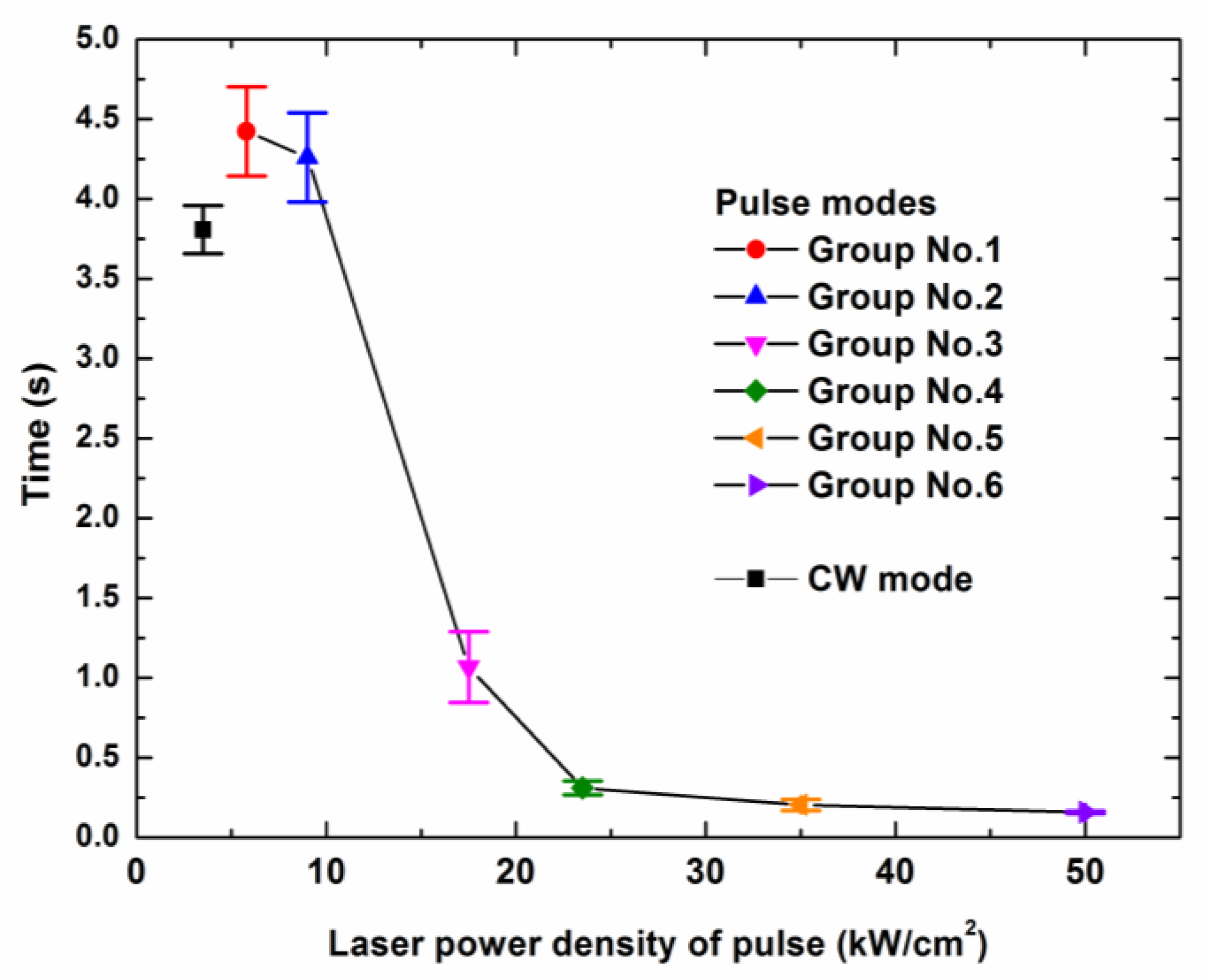

3.1. Laser Penetrating Time

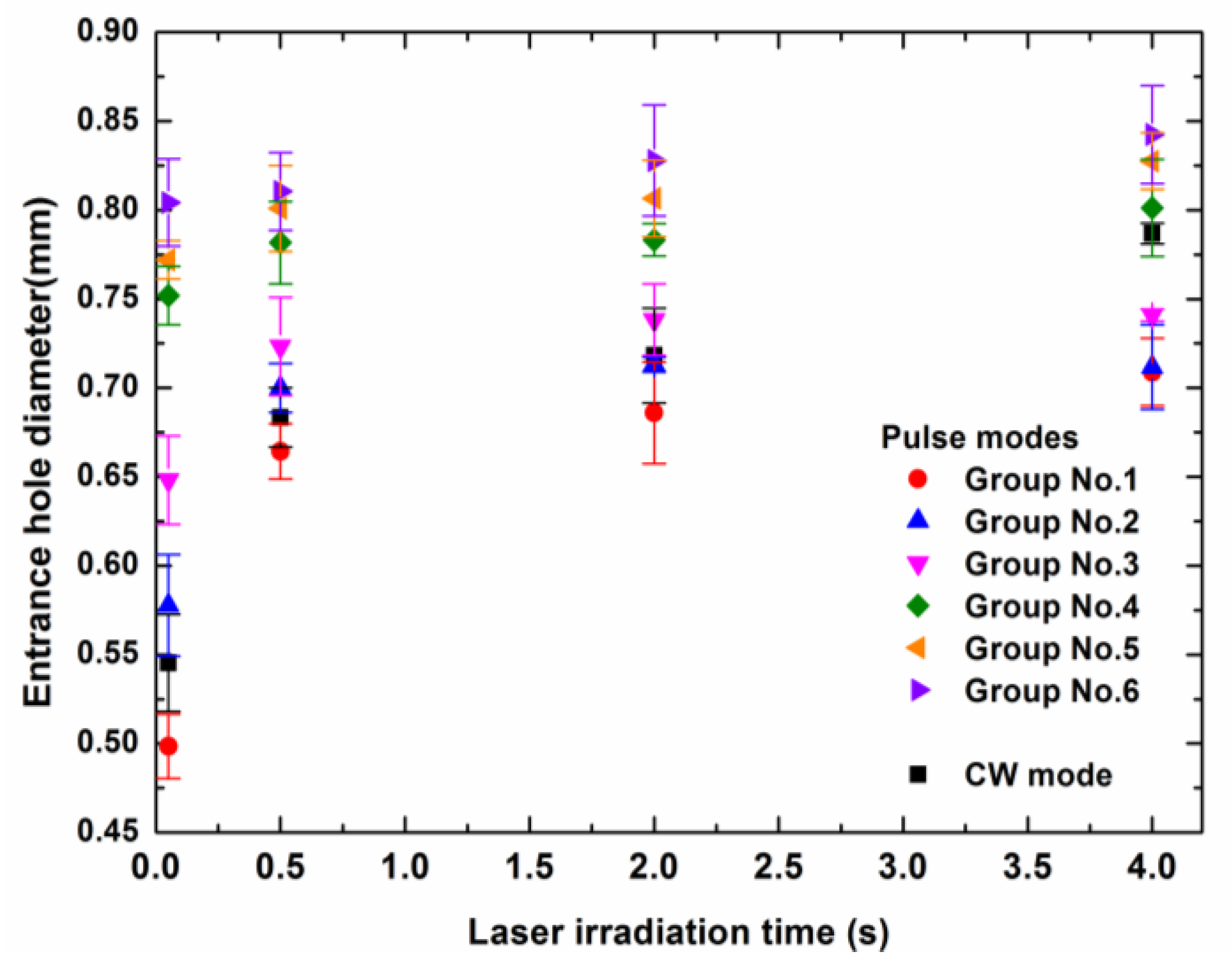

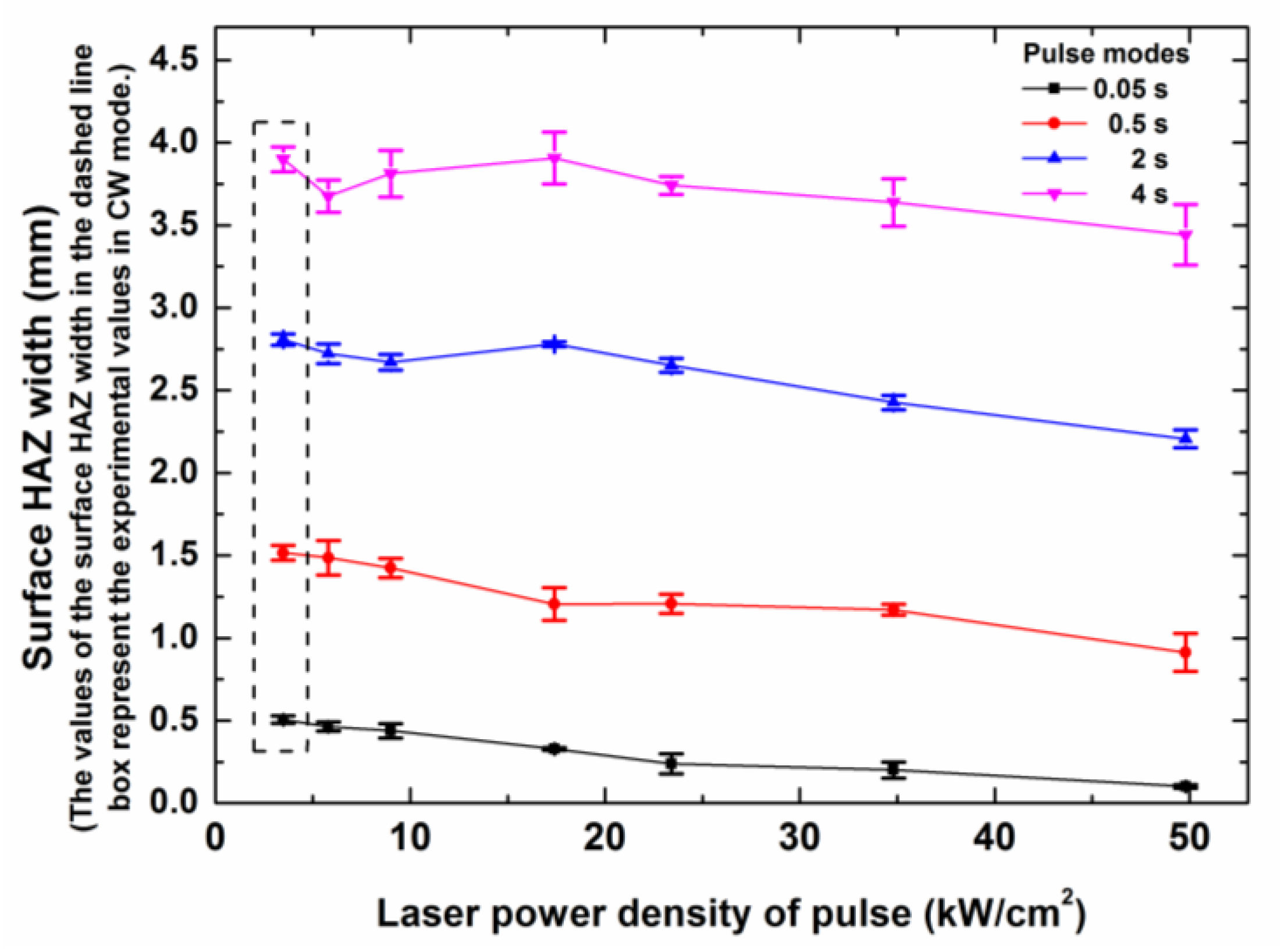

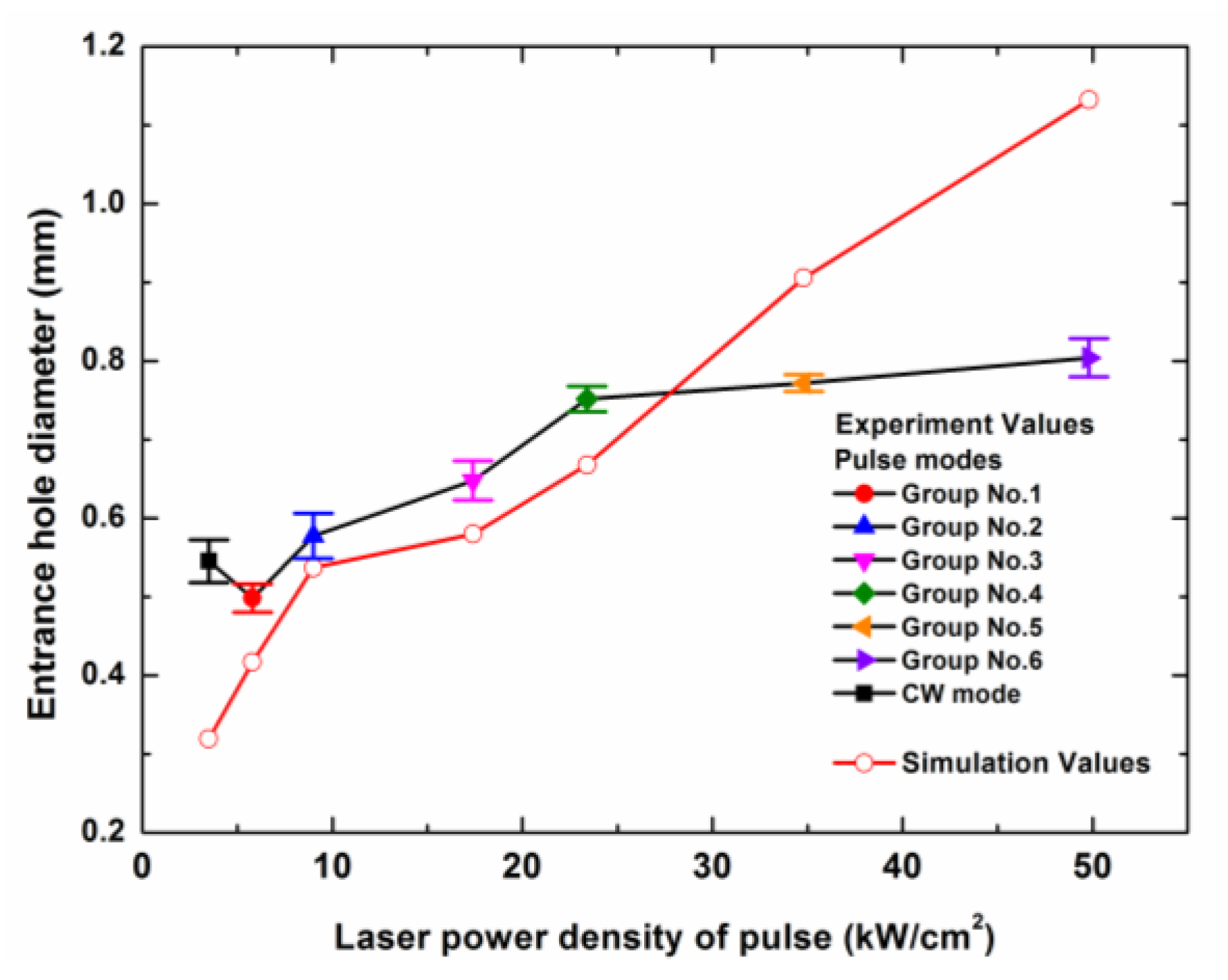

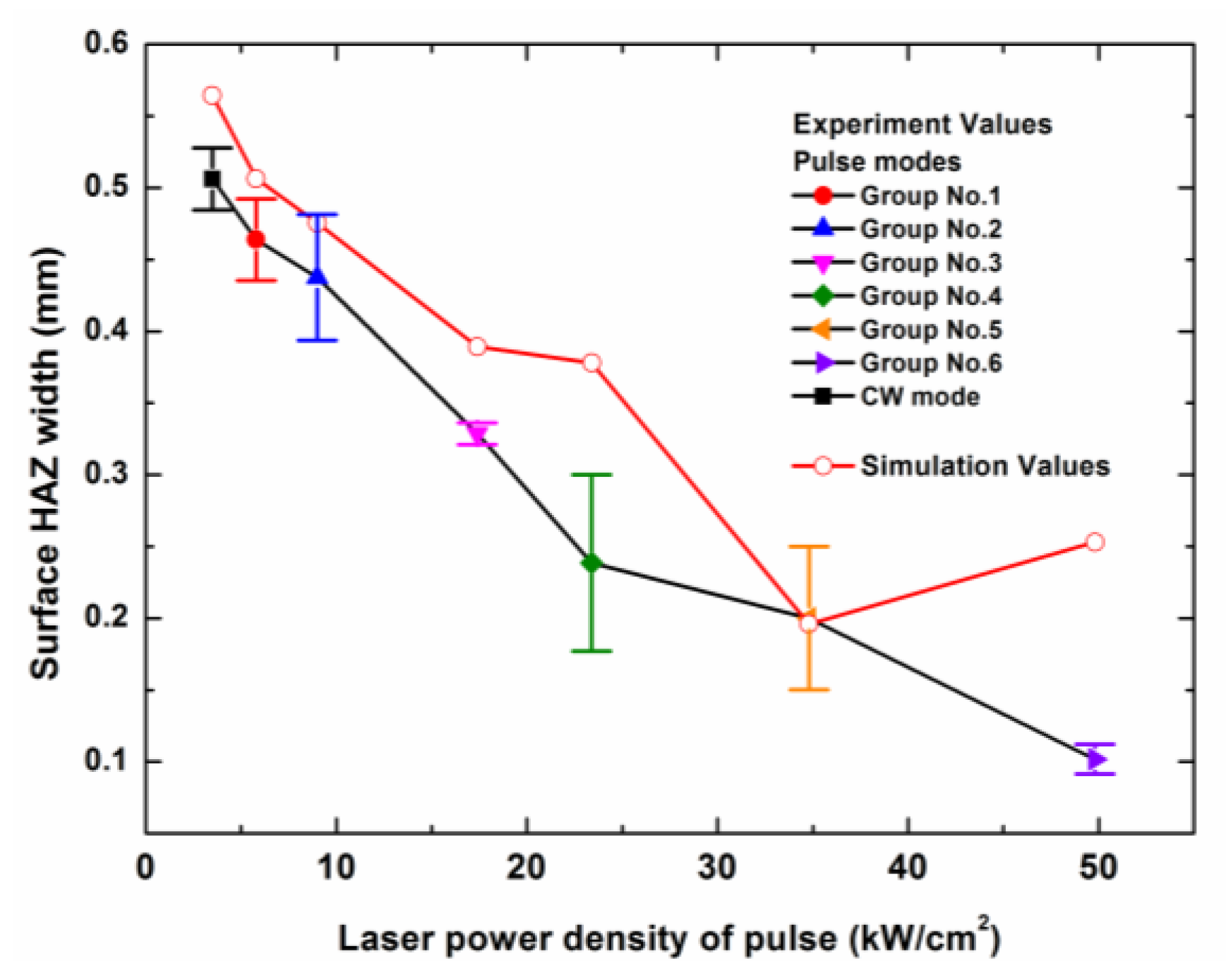

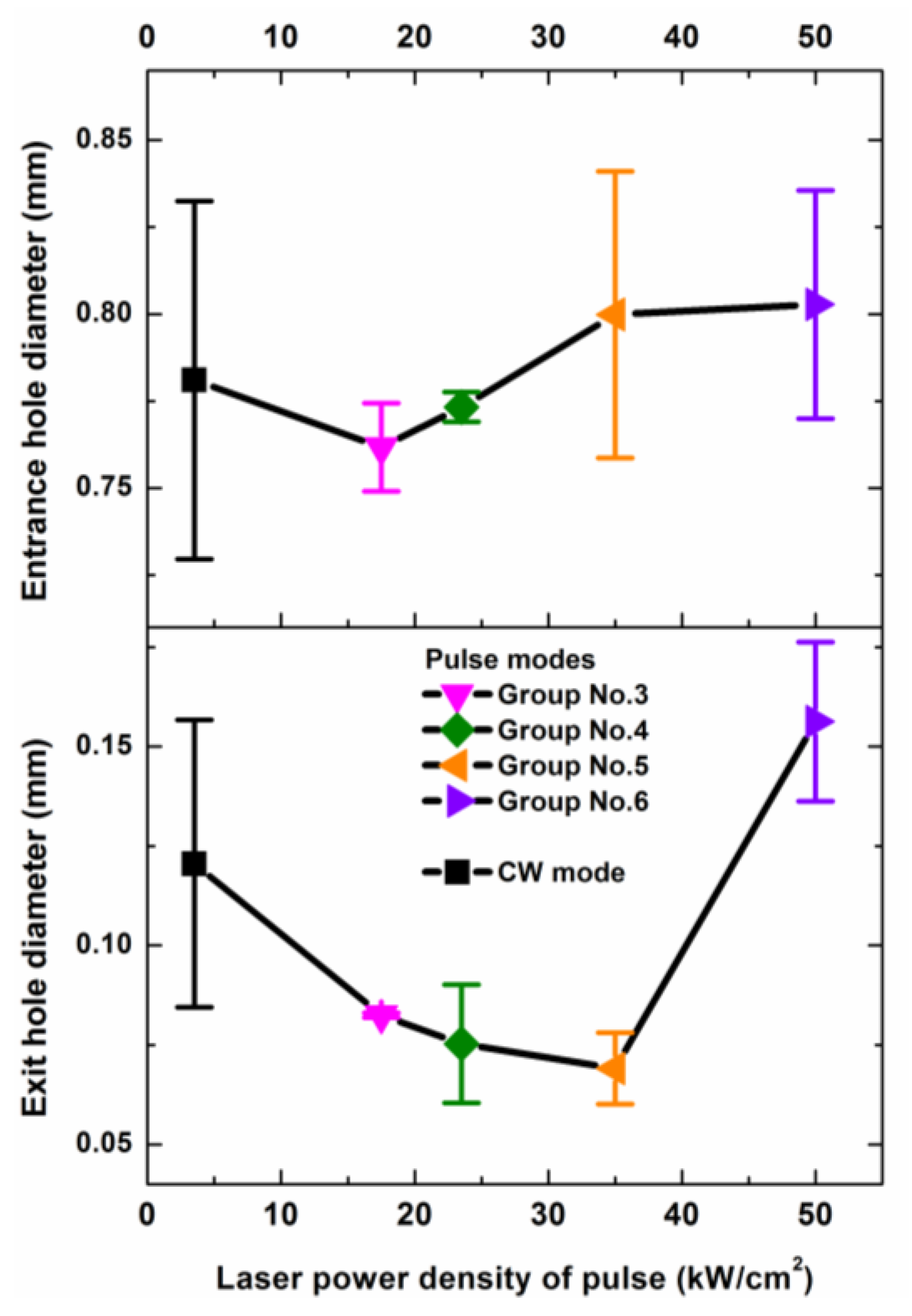

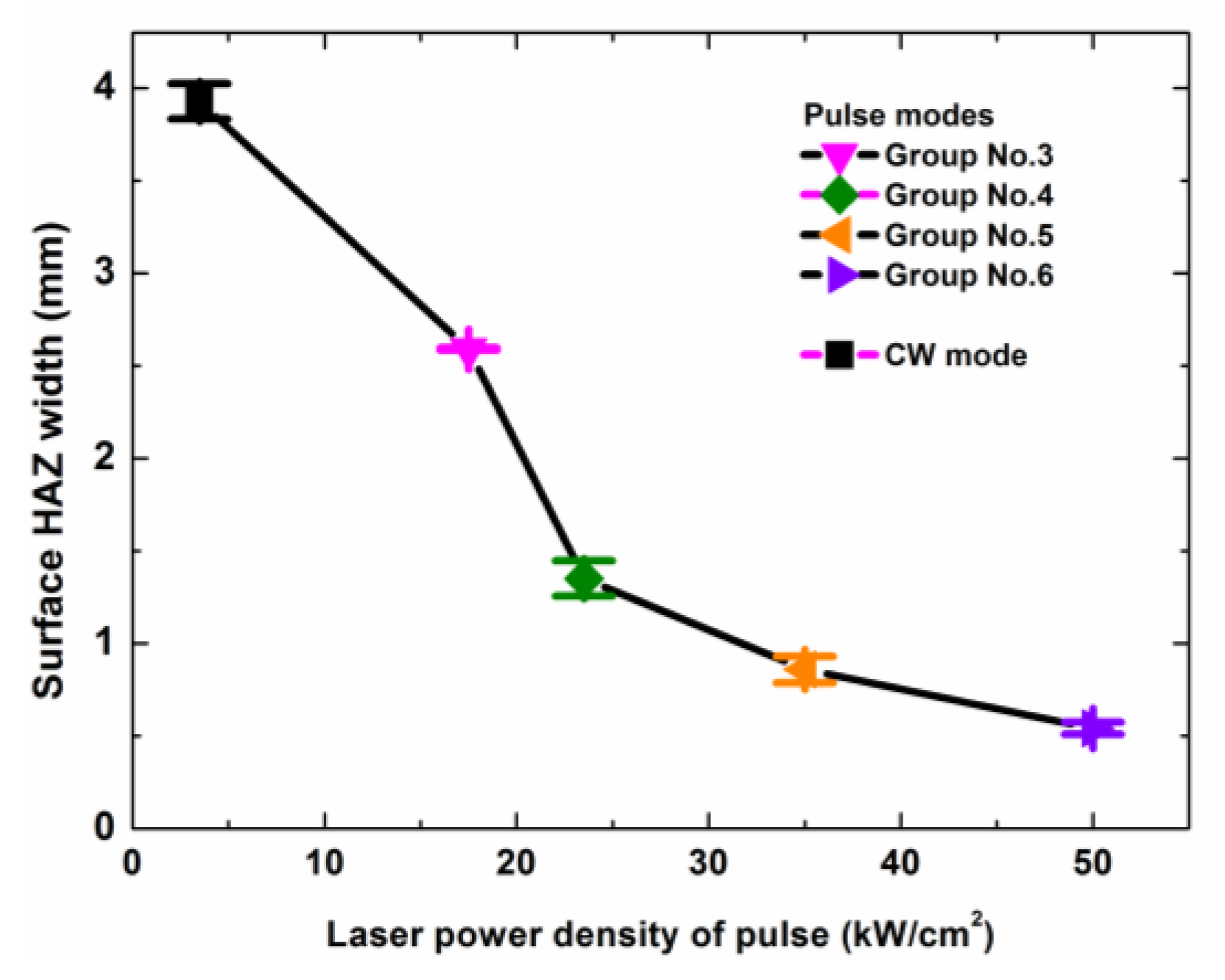

3.2. Entrance Hole Diameter and Surface HAZ Width

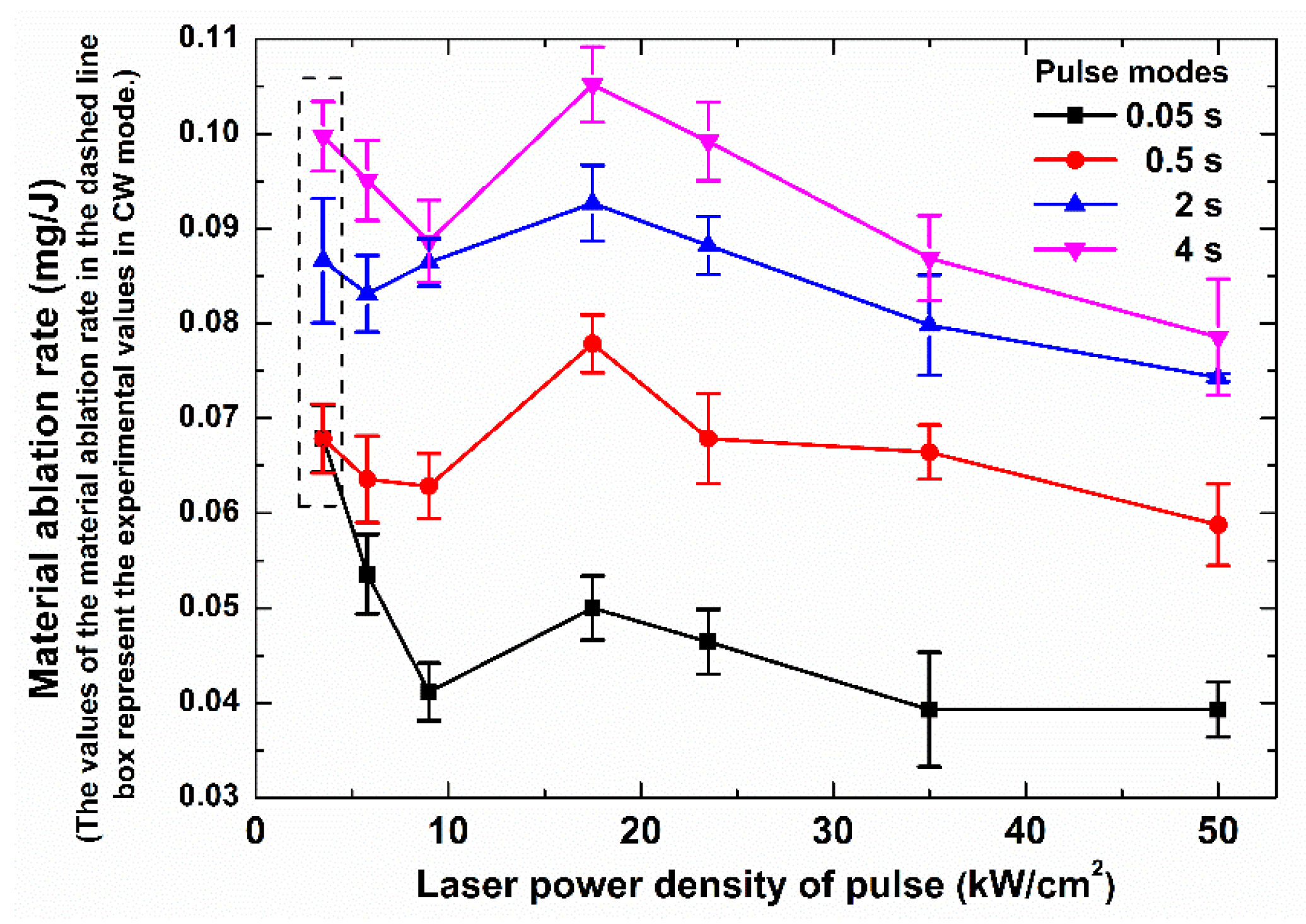

3.3. Material Ablation Rate

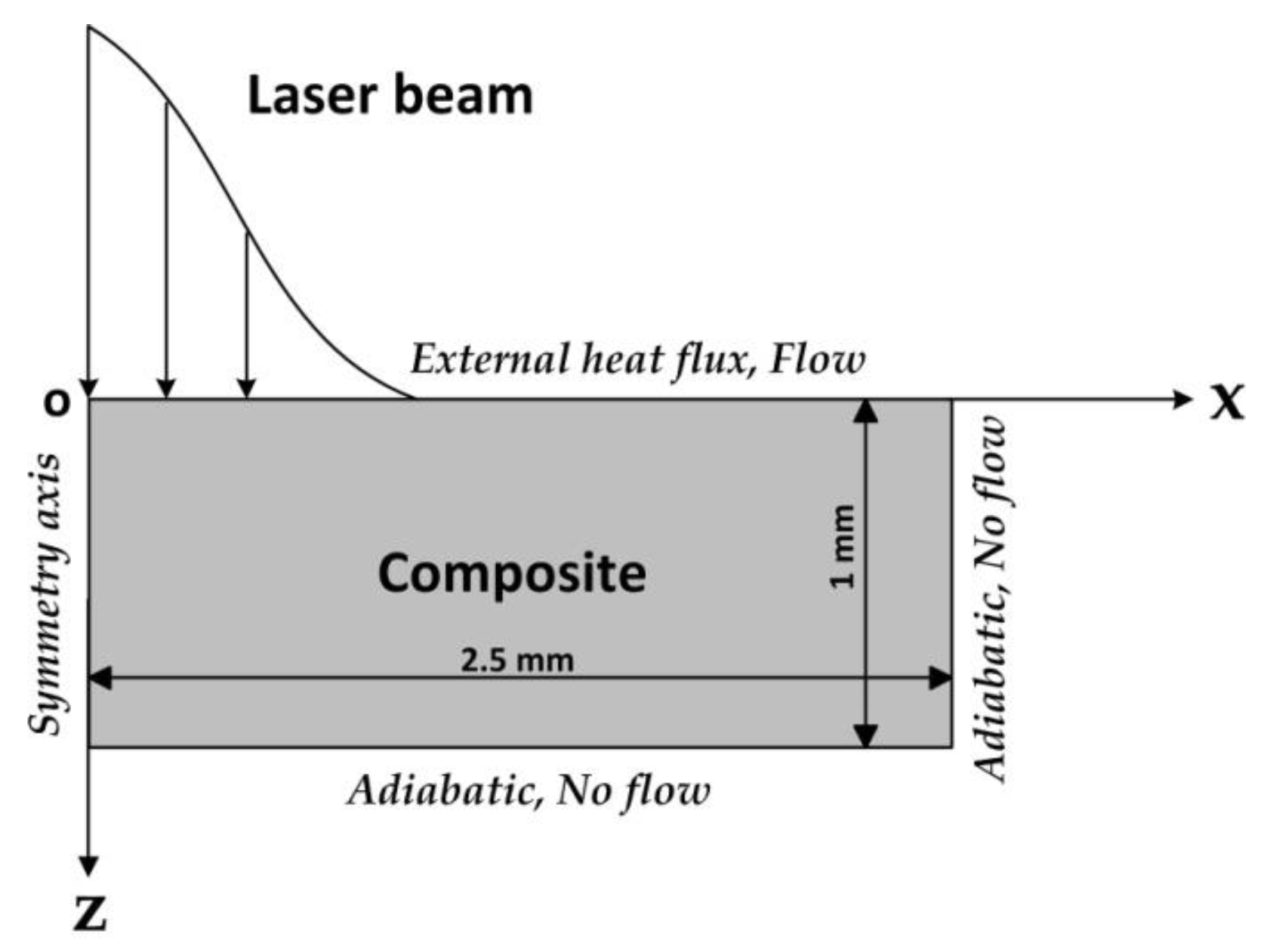

4. Numerical Simulation and Discussion

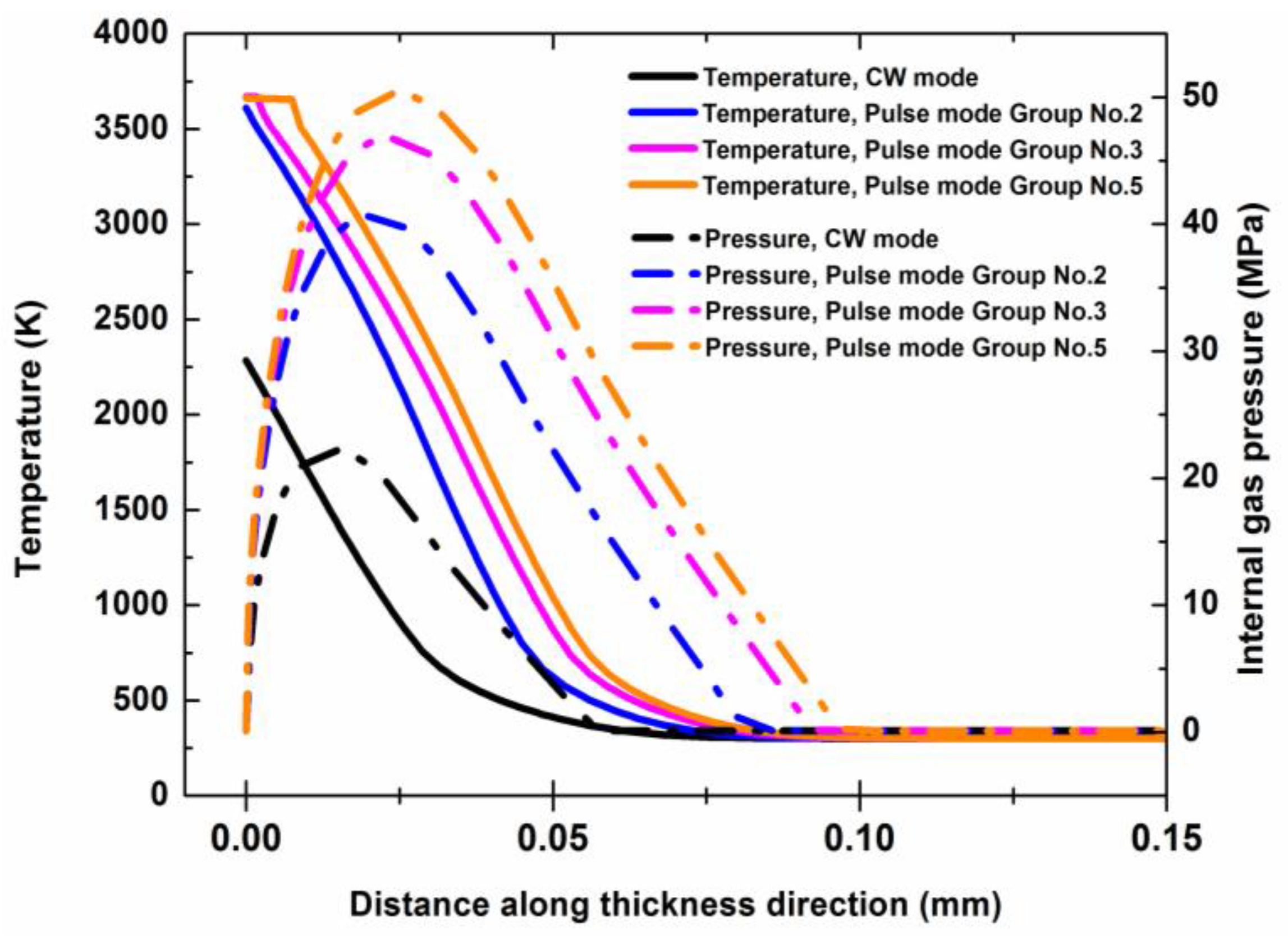

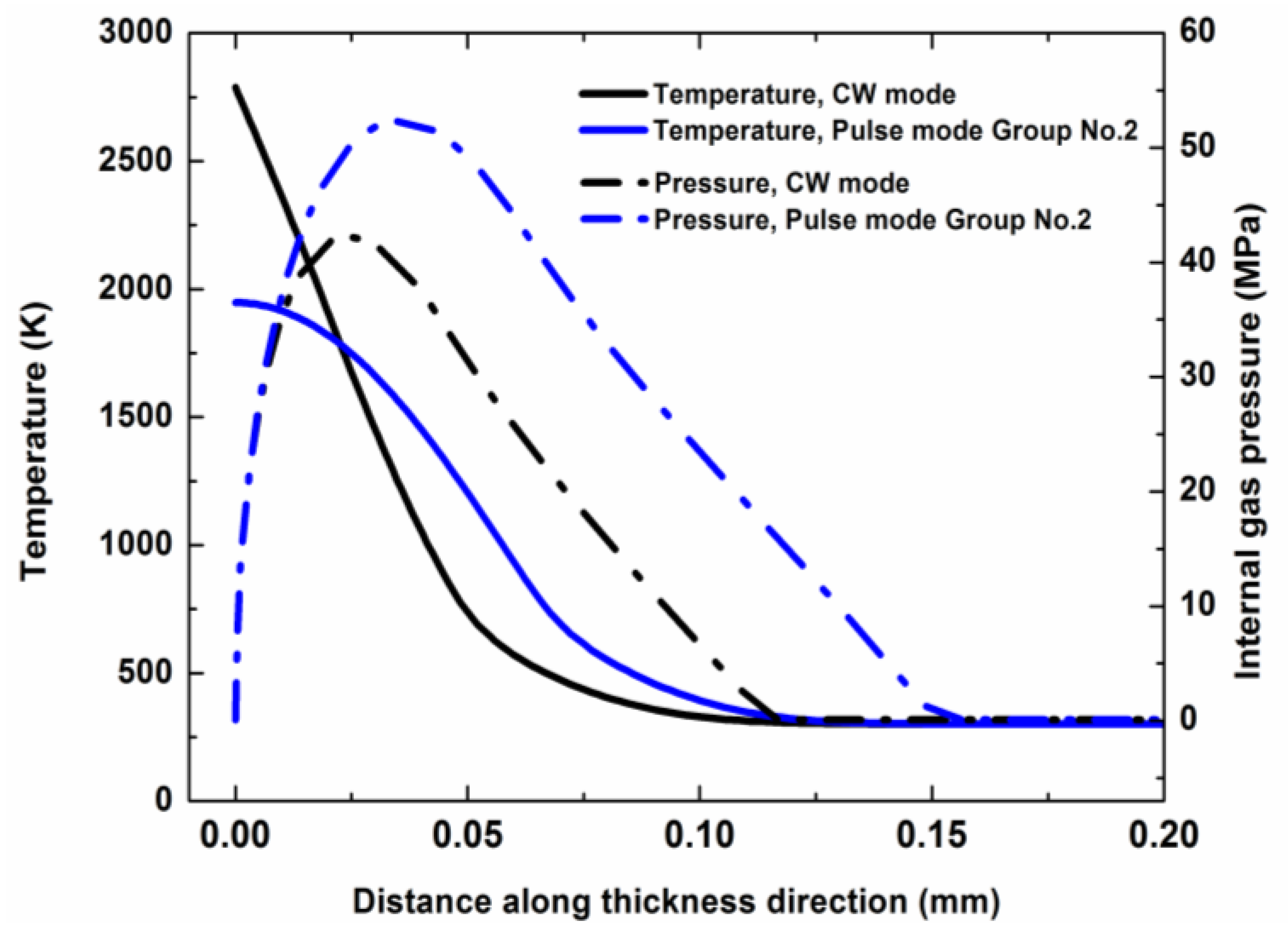

4.1. Simulation of the Internal Gas Pressure

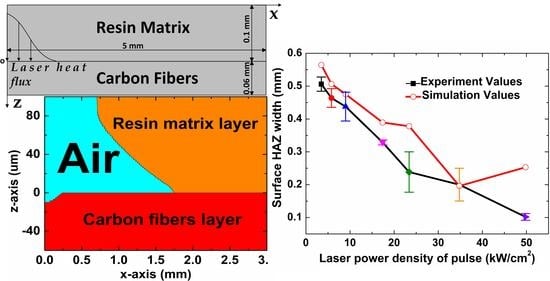

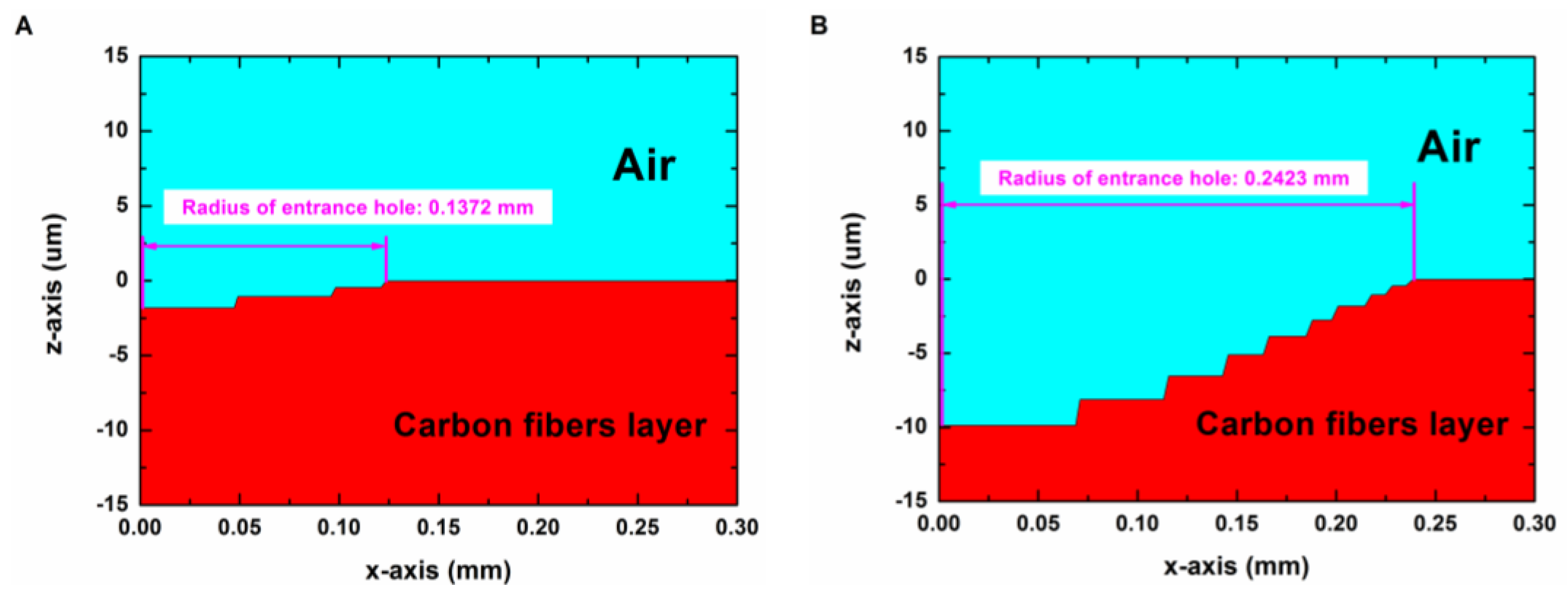

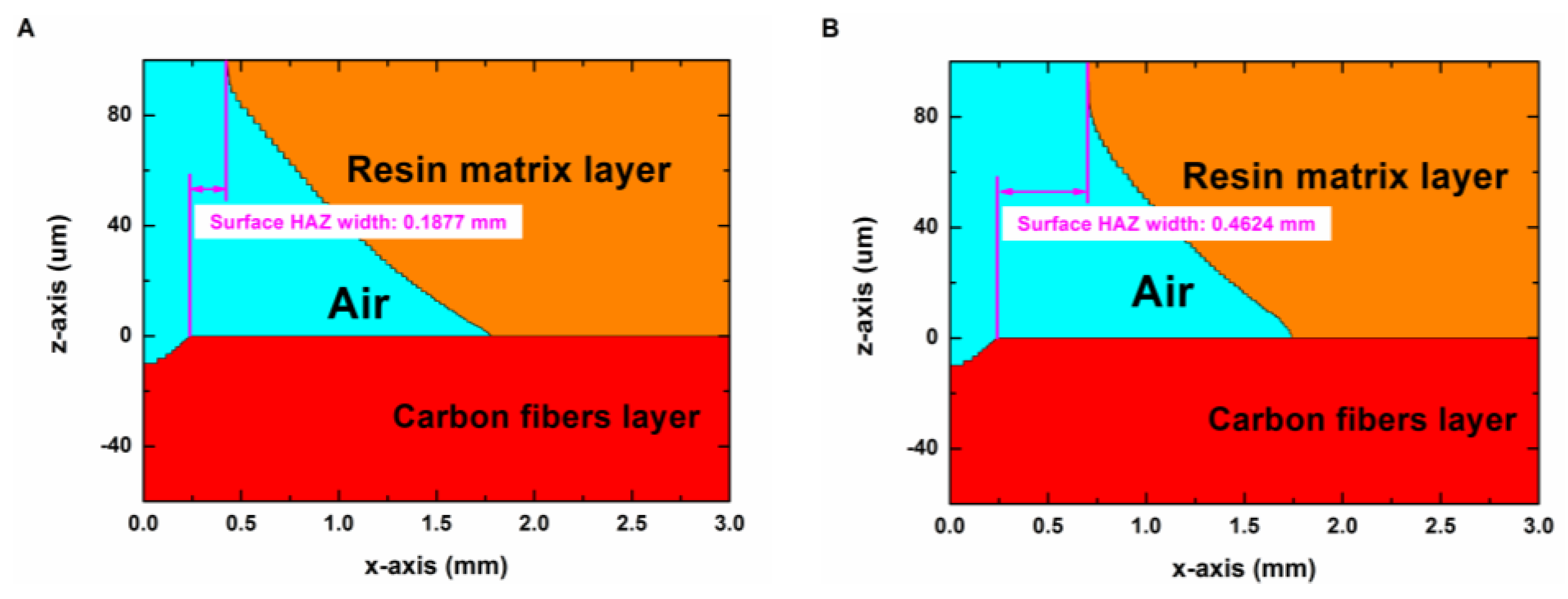

4.2. Simulation of the Entrance Hole Diameter and the Surface HAZ Width

5. Discussion of the CW Mode and the ms Pulse Modes Laser Drilling Efficiencies

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Glossary of symbols | |||

| Pre-exponential factor, s−1 | Greek symbols | ||

| Heat capacity, J/(kg·K) | Heat of pyrolysis reaction, J/kg | ||

| Entrance hole diameter, m | Temperature transition zone half width of gasification process, K | ||

| Exit hole diameter, m | Emissivity of carbon-phenolic | ||

| Diameter of carbon fiber, m | Taper of drilled hole | ||

| Temperature transition zone half width of latent heat of gasification, K | Permeability, m2 | ||

| Activation energy, J/mol | Gas kinematic viscosity, Pa·s | ||

| Transition function | Gas velocity, m/s | ||

| Thickness of composite, m | Density, Kg/m3 | ||

| Surface convection coefficient, | Stefan-Boltzman constant, W/(m2·K4) | ||

| Laser peak power density, W/cm2 | Duty cycle | ||

| Laser heat fluence with Gauss distribution in space, W/cm2 | |||

| Thermal conductivity, W/(m·K) | Superscripts | ||

| Thermal conductivity of composite parallel to fiber axis, W/(m·K) | air | Air | |

| Thermal conductivity of composite perpendicular to fiber axis, W/(m·K) | char | Carbon residue | |

| Latent heat of mass gasification, J/kg | fiber | Carbon fiber | |

| Molecular weight of pyrolysis gas, g/mol | gas | Pyrolysis gas | |

| Mass, kg | poly | Polymer resin | |

| Number of laser pulses | |||

| n | Zero or positive integer | ||

| Reaction order | |||

| Gas pressure, Pa | |||

| Initial internal gas pressure, Pa | |||

| Ambient pressure, Pa | Subscripts | ||

| Ideal gas constant, J/(mol·K) | |||

| Spot radius, m | e | End state after reaction | |

| Temperature, K | eff | Effective parameter | |

| Initial temperature, K | Original state before reaction | ||

| Ambient temperature, K | sim | Simulation value | |

| Gasification temperature of carbon, K | |||

| Temperature of the upper surface, K | |||

| Laser penetration time, s | |||

| Pulse duration, s | |||

| Volume fraction | |||

| Surface HAZ width, m | |||

| x, y, z | Cartesian coordinate system | ||

Appendix A

Appendix A.1. Estimation of the Laser Penetration Time

Appendix A.2. Model Formulation for the Internal Gas Pressure

- (1)

- The laser energy was completely absorbed on the surface of the composite.

- (2)

- The possible oxidation reaction and the material erosion on the composite surface were neglected.

- (3)

- The polymer matrix degraded into the carbon residue and pyrolysis gas directly via heating.

- (4)

- The pyrolysis gas was chemically non-reactive and the ideal gas equation of state could be used.

- (5)

- The pyrolysis gas was always in thermal equilibrium with the nearby solid.

- (6)

- The volume change and the thermal expansion of the material were neglected.

| 300 | 0.0056 |

| 422 | 0.0076 |

| 533 | 0.0085 |

| 811 | 0.0054 |

| 1367 | 0.0077 |

| 1922 | 0.0099 |

| 3500 | 0.0222 |

| Parameter | Symbol | Value | Units |

|---|---|---|---|

| Thermal conductivity of the polymer resin [18] | 0.2 | W/(m·K) | |

| Density of the polymer resin [24] | 900 | kg/m3 | |

| Heat capacity of the polymer resin [24] | 2500 | J/(kg·K) | |

| Thermal conductivity of the carbon residue [24] | 0.2 | W/(m·K) | |

| Density of the carbon residue [24] | 1300 | kg/m3 | |

| Heat capacity of the carbon residue [24] | 1589 | J/(kg·K) | |

| Thermal conductivity of the pyrolysis gas [24] | 0.025 | W/(m·K) | |

| Density of the pyrolysis gas [24] | 1.997 | kg/m3 | |

| Heat capacity of the pyrolysis gas [24] | 720 | J/(kg·K) | |

| The heat of decomposition [24] | 9 × 105 | J/kg | |

| Thermal conductivity of the carbon fiber parallel to the fiber axis [18] | 50 | W/(m·K) | |

| Thermal conductivity of the carbon fiber perpendicular to the fiber axis [18] | 5 | W/(m·K) | |

| Density of the carbon fiber [18] | 1850 | kg/m3 | |

| Heat capacity of the carbon fiber [18] | 710 | J/(kg·K) |

Appendix A.3. Model Formulation for the Entrance Hole Diameter and the Surface HAZ Width

References

- Lacalle, N.L.D.; Lamikiz, A.; Campa, F.J.; Valdivielso, A.F.; Etxeberria, I. Design and test of a multitooth tool for CFRP milling. J. Compos. Mater. 2009, 43, 3275–3290. [Google Scholar] [CrossRef]

- Liu, D.F.; Tang, Y.J.; Cong, W.L. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Voisey, K.T.; Fouquet, S.; Roy, D.; Clyne, T.W. Fibre swelling during laser drilling of carbon fibre composites. Opt. Lasers Eng. 2006, 44, 1185–1197. [Google Scholar] [CrossRef]

- Prieß, T.; Sause, M.G.; Fischer, D.; Middendorf, P. Detection of delamination onset in laser-cut carbon fiber transverse crack tension specimens using acoustic emission. J. Compos. Mater. 2015, 49, 2639–2647. [Google Scholar] [CrossRef]

- Harada, Y.; Muramatsu, M.; Suzuki, T.; Nishino, M.; Niino, H. Influence of laser process on mechanical behavior during cutting of carbon fiber reinforced plastic composites. Mater. Sci. Forum 2014, 783, 1518–1523. [Google Scholar] [CrossRef]

- Negarestani, R.; Li, L.; Sezer, H.; Whitehead, D.; Methven, J. Nano-second pulsed DPSS Nd: YAG laser cutting of CFRP composites with mixed reactive and inert gases. Int. J. Adv. Manuf. 2010, 49, 553–566. [Google Scholar] [CrossRef]

- Herzog, D.; Jaeschke, P.; Meier, O.; Haferkamp, H. Investigations on the thermal effect caused by laser cutting with respect to static strength of CFRP. Int. J. Mach. Tools Manu. 2008, 48, 1464–1473. [Google Scholar] [CrossRef]

- Romoli, L.; Fischer, F.; Kling, R. A study on UV laser drilling of PEEK reinforced with carbon fibers. Opt. Lasers Eng. 2012, 50, 449–457. [Google Scholar] [CrossRef]

- Takahashi, K.; Tsukamoto, M.; Masuno, S.; Sato, Y. Heat conduction analysis of laser CFRP processing with IR and UV laser light. Compos. Part A Appl. Sci. Manuf. 2016, 84, 114–122. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S.; Tagliaferri, V. Fibre laser cutting of CFRP thin sheets by multi-passes scan technique. Opt. Lases Eng. 2014, 53, 43–50. [Google Scholar] [CrossRef]

- Moreno, P.; Méndez, C.; García, A.; Arias, I.; Roso, L. Femtosecond laser ablation of carbon reinforced polymers. Appl. Surf. Sci. 2006, 252, 4110–4119. [Google Scholar] [CrossRef]

- Mathew, J.; Goswami, G.L.; Ramakrishnan, N.; Naik, N.K. Parametric studies on pulsed Nd:YAG laser cutting of carbon fibre reinforced plastic composites. J. Mater. Process. Technol. 1999, 89, 198–203. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Lusquiños, F.; Val, J.; Comesaña, R.; Boutinguiza, M.; Pou, J. Experimental study on the CO2 laser cutting of carbon fiber reinforced plastic composite. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1400–1409. [Google Scholar] [CrossRef]

- Herzog, D.; Schmidt-Lehr, M.; Canisius, M.; Oberlander, M.; Tasche, J.P.; Emmelmann, C. Laser cutting of carbon fiber reinforced plastic using a 30 kW fiber laser. J. Laser Appl. 2015, 27, S28001. [Google Scholar] [CrossRef]

- Li, Z.L.; Zheng, H.Y.; Lim, G.C.; Chu, P.L.; Li, L. Study on UV laser machining quality of carbon fibre reinforced composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1403–1408. [Google Scholar] [CrossRef]

- Li, Z.; Chu, P.; Zheng, H.; Lim, G. Process development of laser machining of carbon fibre reinforced plastic composites. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Temecula, CA, USA, 20–23 October 2008; p. 406. [Google Scholar]

- Liu, Y.; Wang, C.; Li, W.; Zhang, L.; Yang, X.; Cheng, G.; Zhang, Q. Effect of energy density and feeding speed on micro-hole drilling in C/SiC composites by picosecond laser. J. Mater. Process. Technol. 2014, 214, 3131–3140. [Google Scholar] [CrossRef]

- Sheng, P.; Chryssolouris, G. Theoretical model of laser grooving for composite materials. J. Compos. Mater. 1995, 29, 96–112. [Google Scholar] [CrossRef]

- Young, T.; O’Driscoll, D. Impact of Nd-YAG laser drilled holes on the strength and stiffness of laminar flow carbon fibre reinforced composite panels. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1–9. [Google Scholar] [CrossRef]

- Weber, R.; Hafner, M.; Michalowski, A.; Graf, T. Minimum damage in CFRP laser pro cessing. Phys. Procedia 2011, 12, 302–307. [Google Scholar] [CrossRef]

- Xu, H.; Hu, J. Study of polymer matrix degradation behavior in CFRP short pulsed laser processing. Polymers 2016, 8, 299. [Google Scholar] [CrossRef]

- Leone, C.; Papa, I.; Tagliaferri, F.; Lopresto, V. Investigation of CFRP laser milling using a 30W Q-switched Yb: YAG fiber laser: Effect of process parameters on removal mechanisms and HAZ formation. Compos. Part A Appl. Sci. Manuf. 2013, 55, 129–142. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S. Effects of surface laser treatment on direct co-bonding strength of CFRP laminates. Compos. Struct. 2018, 194, 240–251. [Google Scholar] [CrossRef]

- Chippendale, R.; Golosnoy, I.; Lewin, P. Numerical modelling of thermal decomposition processes and associated damage in carbon fibre composites. J. Phys. D Appl. Phys. 2014, 47, 385301. [Google Scholar] [CrossRef]

- Henderson, J.; Wiecek, T. A mathematical model to predict the thermal response of decomposing, expanding polymer composites. J. Compos. Mater. 1987, 21, 373–393. [Google Scholar] [CrossRef]

- Dimitrienko, Y.I. Thermomechanical behaviour of composite materials and structures under high temperatures: 1. Materials. Compos. Part A Appl. Sci. Manuf. 1997, 28, 453–461. [Google Scholar] [CrossRef]

- McGurn, M.T.; DesJardin, P.E.; Dodd, A.B. Numerical simulation of expansion and charring of carbon-epoxy laminates in fire environments. Int. J. Heat Mass Transf. 2012, 55, 272–281. [Google Scholar] [CrossRef]

- Potts, R.L. Application of integral methods to ablation charring erosion-A review. J. Spacecr. Rocket. 1995, 32, 200–209. [Google Scholar] [CrossRef]

- Potts, R.L. Hybrid integral/quasi-steady solution of charring ablation. In Proceedings of the AIAA and ASME, 5th Joint Thermophysics and Heat Transfer Conference, Seattle, WA, USA, 18–20 June 1990; p. 1677. [Google Scholar]

- Shi, S.; Li, L.; Liang, J.; Tang, S. Surface and volumetric ablation behaviors of SiFRP composites at high heating rates for thermal protection applications. Int. J. Heat Mass. Transf. 2016, 102, 1190–1198. [Google Scholar] [CrossRef]

- Kuwahara, F.; Kameyama, Y.; Yamashita, S.; Nakayama, A. Numerical modeling of turbulent flow in porous media using a spatially periodic array. J. Porous Media 1998, 1, 47–55. [Google Scholar] [CrossRef]

- Voller, V.R.; Prakash, C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass. Transf. 1987, 30, 1709–1719. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Z.; Ni, X. Modeling and simulation on long pulse laser drilling processing. Int. J. Heat Mass Transf. 2014, 73, 429–437. [Google Scholar] [CrossRef]

- Li, W.; Huang, H.; Tian, Y.; Zhao, Z. Nonlinear analysis on thermal behavior of charring materials with surface ablation. Int. J. Heat Mass Transf. 2015, 84, 245–252. [Google Scholar] [CrossRef]

- Lachaud, J.; Van, E.T.; Scoggins, J.B.; Magin, T.E.; Mansour, N.N. Detailed chemical equilibrium model for porous ablative materials. Int. J. Heat Mass Transf. 2015, 90, 1034–1045. [Google Scholar] [CrossRef]

- Shi, S.; Liang, J.; Yi, F.; Fang, G. Modeling of one-dimensional thermal response of silica-phenolic composites with volume ablation. J. Compos. Mater. 2013, 47, 2219–2235. [Google Scholar] [CrossRef]

- Dimitrienko, Y.I. Thermomechanics of Composites under High Temperatures, 1st ed.; Springer Science & Business Media: Heidelberg, Germany, 1999; pp. 73–106. [Google Scholar]

- Fischer, F.; Kreling, S.; Jäschke, P.; Frauenhofer, M.; Kracht, D.; Dilger, K. Laser surface pre-treatment of cfrp for adhesive bonding in consideration of the absorption behaviour. J. Adhes. 2012, 88, 350–363. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids II, 1st ed.; Academic Press: New York, NY, USA, 1991; pp. 77–135. [Google Scholar]

- Smausz, T.; Kondász, B.; Gera, T.; Ajtai, T.; Utry, N.; Pintér, M.; Kiss-Albert, G.; Budai, J.; Bozóki, Z.; Szabó, G. Determination of UV-visible-NIR absorption coefficient of graphite bulk using direct and indirect methods. Appl. Phys. A Mater. 2017, 123, 633. [Google Scholar] [CrossRef]

| Physical Data | Matrix | Carbon Fiber Parallel to the Fiber Axis (p) | Carbon Fiber Perpendicular to the Fiber Axis (s) |

|---|---|---|---|

| Density (kg/m3) | 1250 | 1850 | |

| Heat conductivity (W/m/K) | 0.2 | 50 | 5 |

| Heat capacity (J/kg/K) | 1200 | 710 | |

| Sublimation temperature (K) | 800 | 3600 | |

| Latent heat (kJ/kg) | 1000 | 43,000 |

| Pulse Mode Group No. | Pulse Peak Power (W) | Pulse Peak Power Density (kW/cm2) | Pulse Frequency (Hz) | Duty Cycle |

|---|---|---|---|---|

| 1 | 116 | 5.8 | 600 | 60% |

| 2 | 180 | 9.0 | 400 | 40% |

| 3 | 350 | 17.4 | 200 | 20% |

| 4 | 470 | 23.4 | 150 | 15% |

| 5 | 700 | 34.8 | 100 | 10% |

| 6 | 1000 | 49.8 | 70 | 7% |

| Continuous wave (CW) mode | Mean power (W) | Mean power density (kW/cm2) | ||

| 70 | 3.5 | |||

| Pulse Mode Group No. | Laser Irradiation Time (s) |

|---|---|

| 3 | 1.9 |

| 4 | 0.6 |

| 5 | 0.31 |

| 6 | 0.23 |

| Continuous wave (CW) mode | Laser irradiation time (s) |

| 3.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Hou, W.; Han, B.; Xu, L.; Li, Z.; Nan, P.; Ni, X. Investigation on the Continuous Wave Mode and the ms Pulse Mode Fiber Laser Drilling Mechanisms of the Carbon Fiber Reinforced Composite. Polymers 2020, 12, 706. https://doi.org/10.3390/polym12030706

Li X, Hou W, Han B, Xu L, Li Z, Nan P, Ni X. Investigation on the Continuous Wave Mode and the ms Pulse Mode Fiber Laser Drilling Mechanisms of the Carbon Fiber Reinforced Composite. Polymers. 2020; 12(3):706. https://doi.org/10.3390/polym12030706

Chicago/Turabian StyleLi, Xiao, Wentao Hou, Bing Han, Lingfei Xu, Zewen Li, Pengyu Nan, and Xiaowu Ni. 2020. "Investigation on the Continuous Wave Mode and the ms Pulse Mode Fiber Laser Drilling Mechanisms of the Carbon Fiber Reinforced Composite" Polymers 12, no. 3: 706. https://doi.org/10.3390/polym12030706

APA StyleLi, X., Hou, W., Han, B., Xu, L., Li, Z., Nan, P., & Ni, X. (2020). Investigation on the Continuous Wave Mode and the ms Pulse Mode Fiber Laser Drilling Mechanisms of the Carbon Fiber Reinforced Composite. Polymers, 12(3), 706. https://doi.org/10.3390/polym12030706