Morphological and Mechanical Properties of Bilayers Wood-Plastic Composites and Foams Obtained by Rotational Molding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fiber Preparation

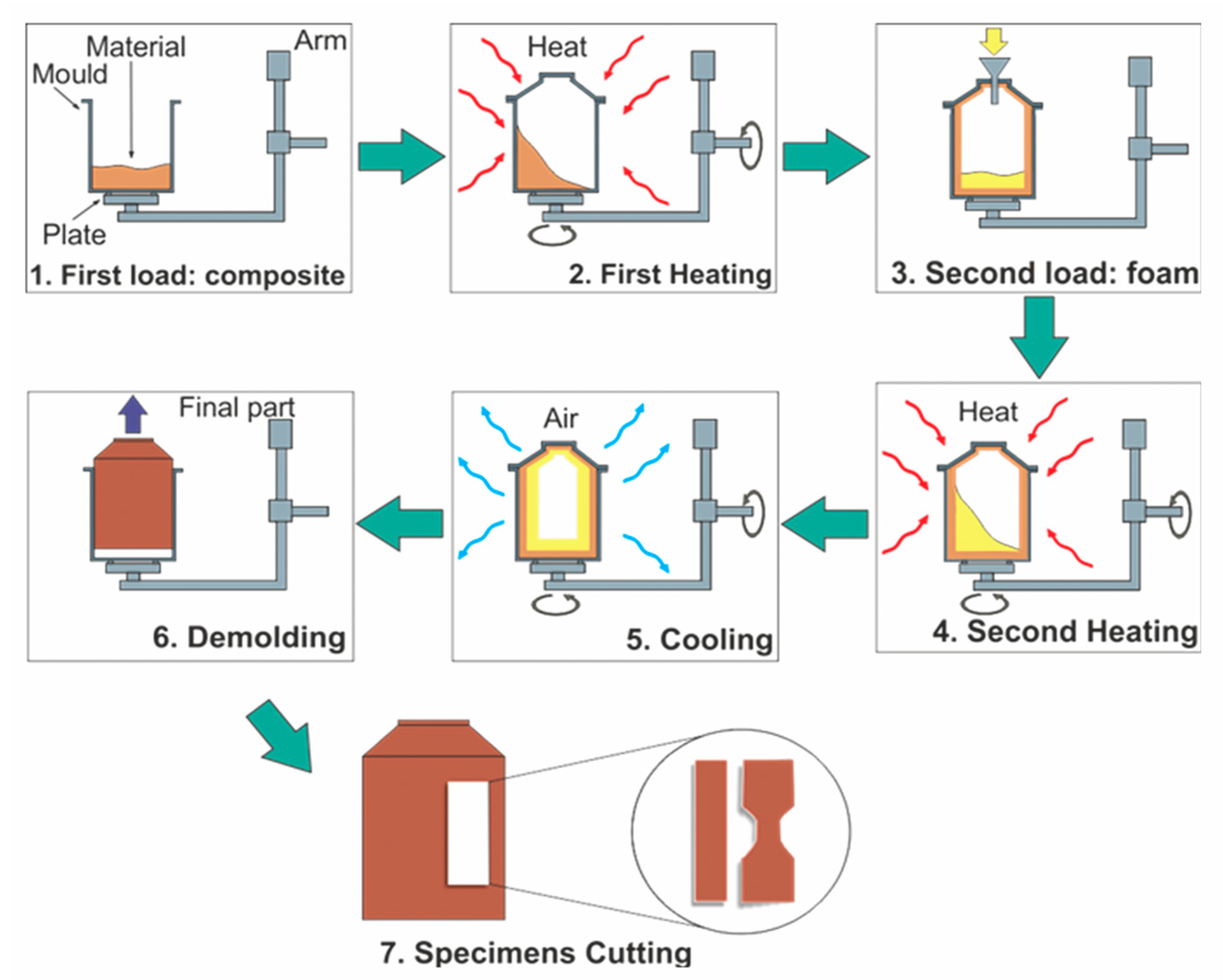

2.3. Rotational Molding

2.4. Characterization

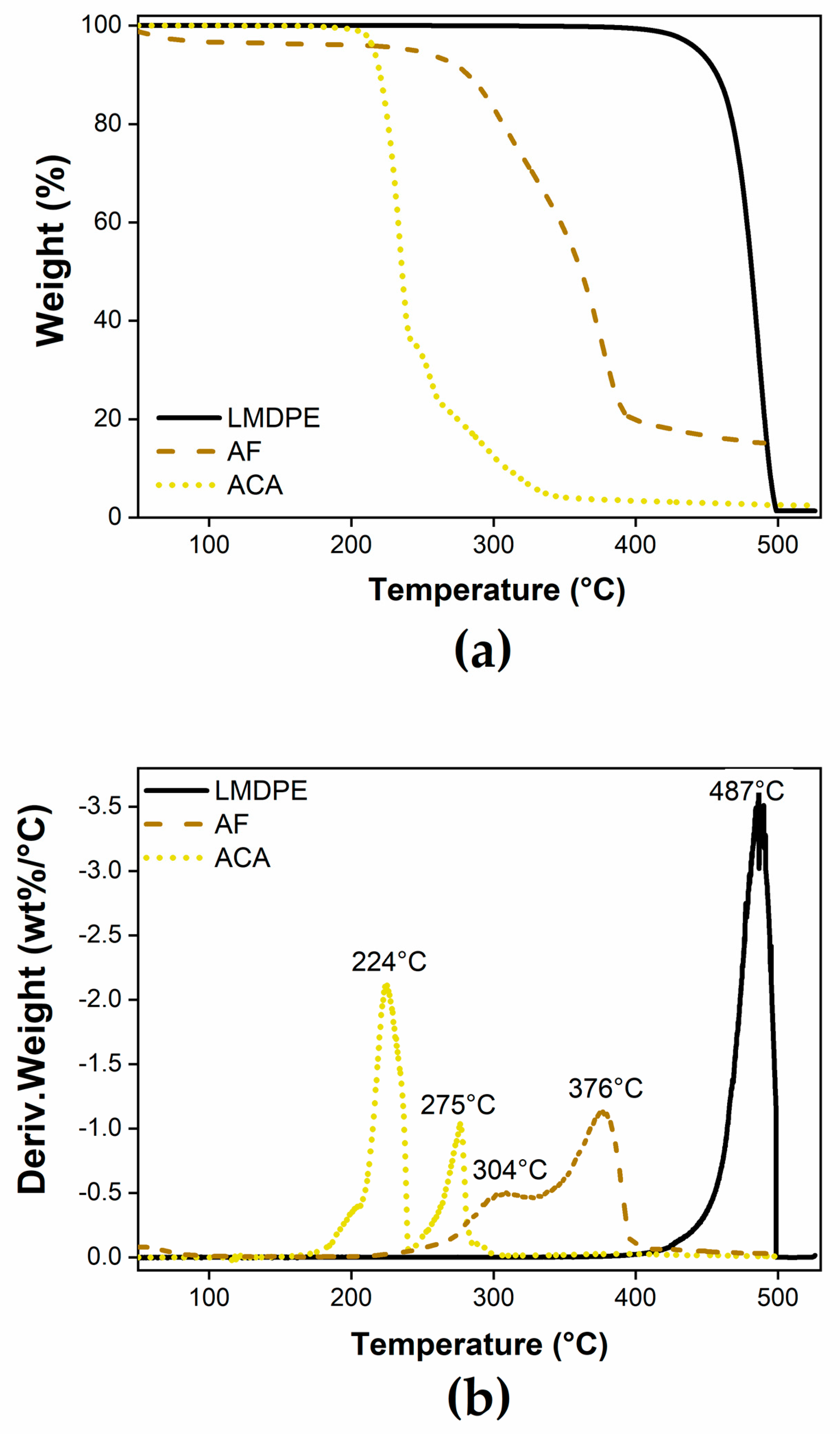

2.4.1. Thermogravimetry (TGA)

2.4.2. Morphology

2.4.3. Density

2.4.4. Mechanical Properties

3. Results and Discussion

3.1. Thermogravimetry Analyzes

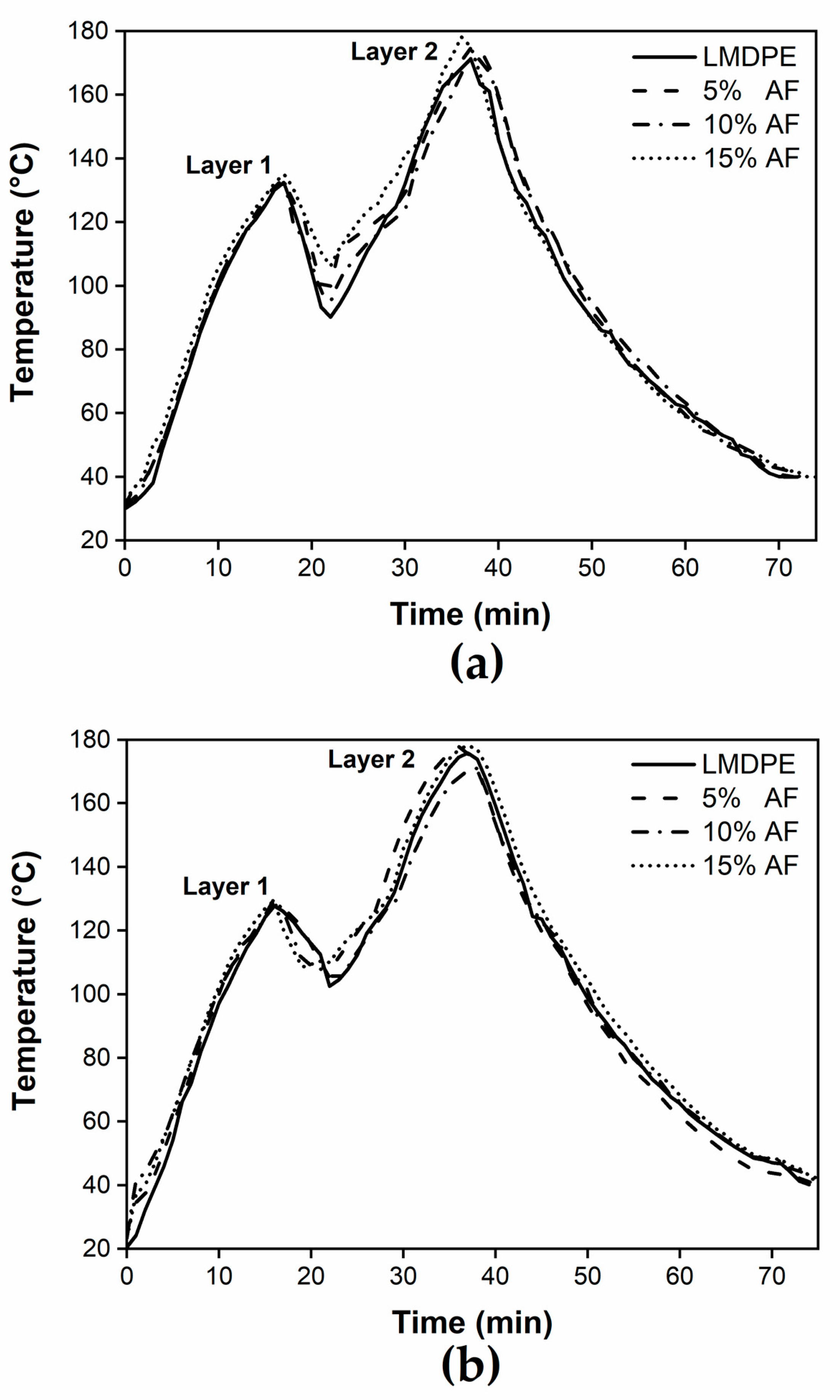

3.2. Processing Cycle Time

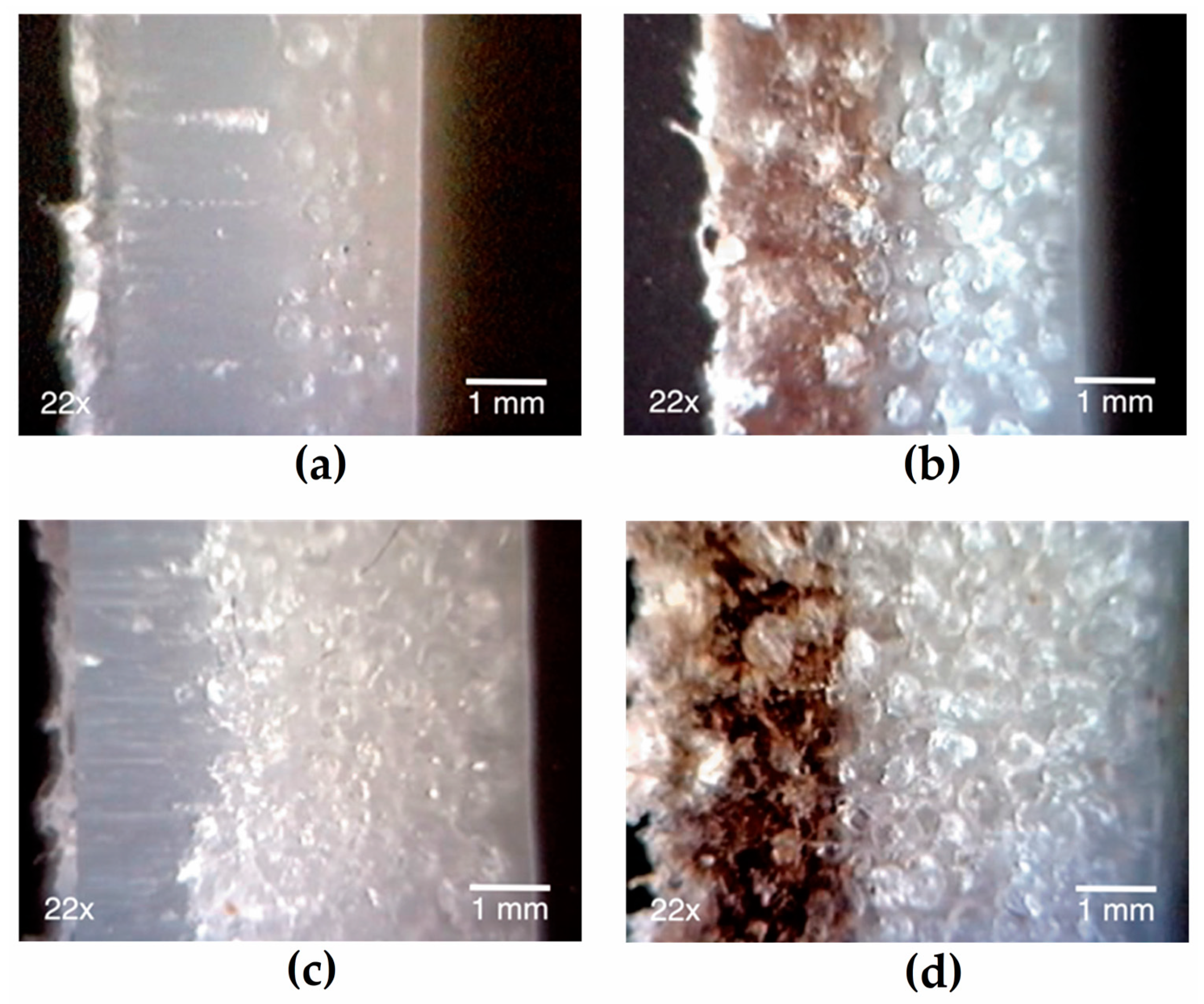

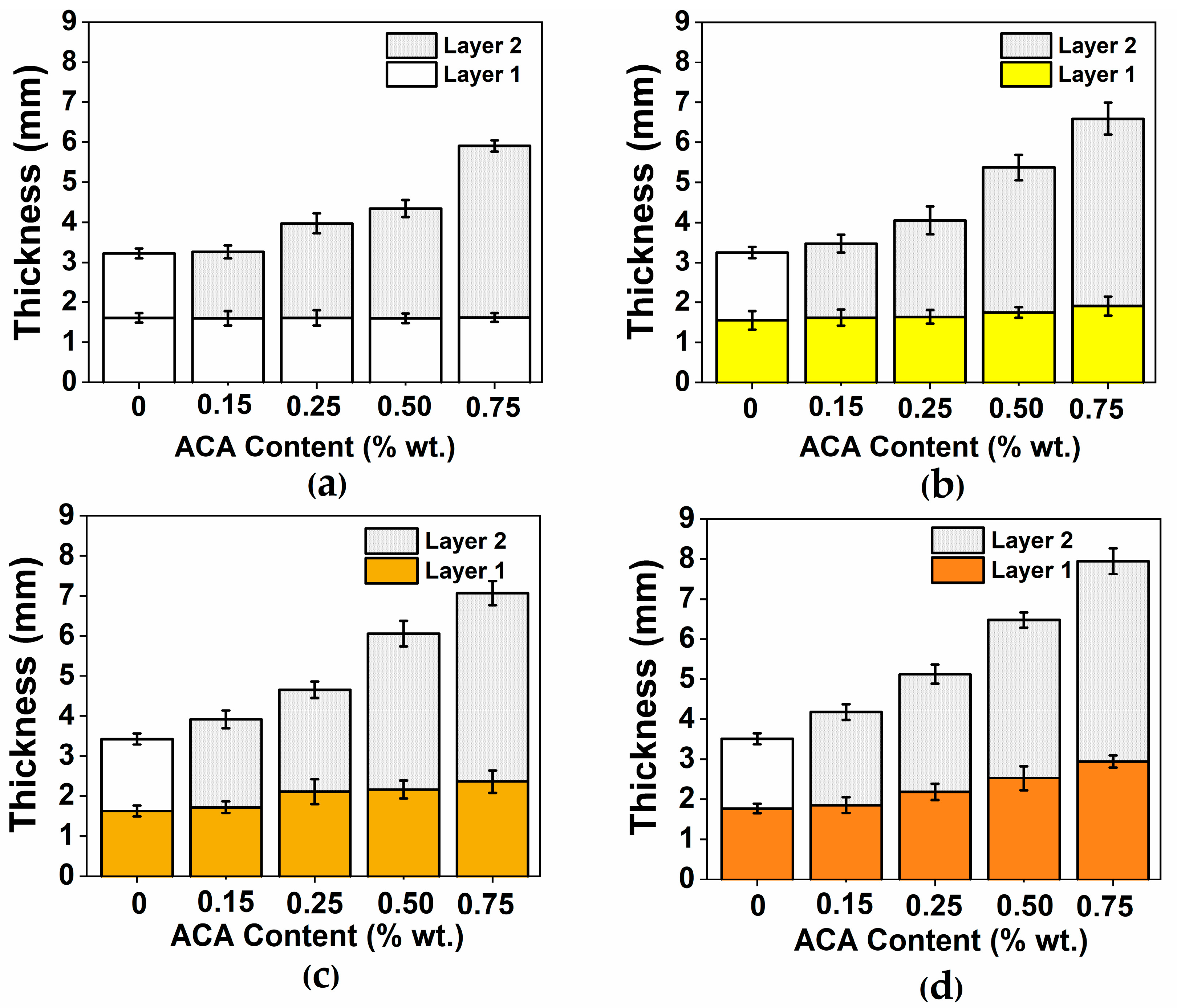

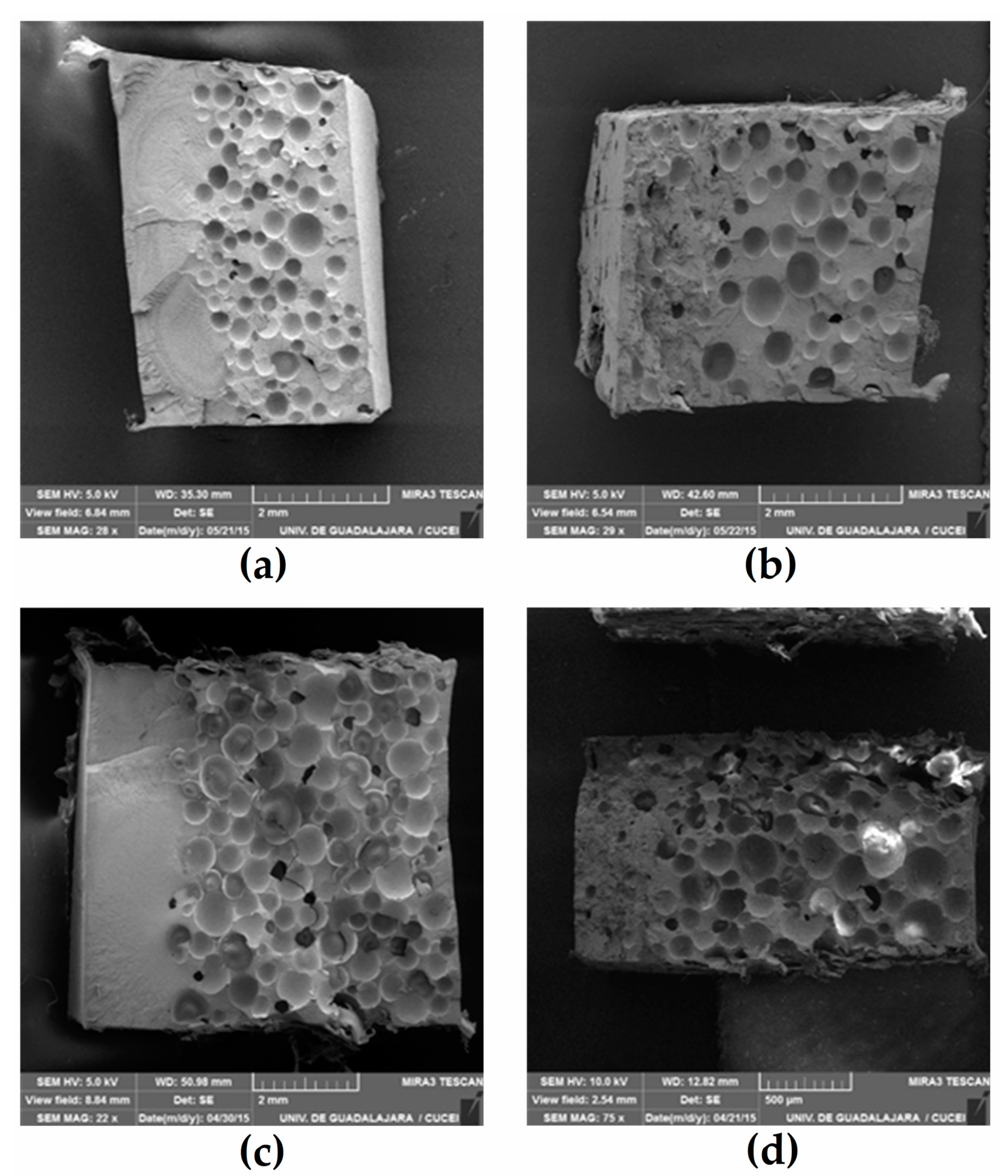

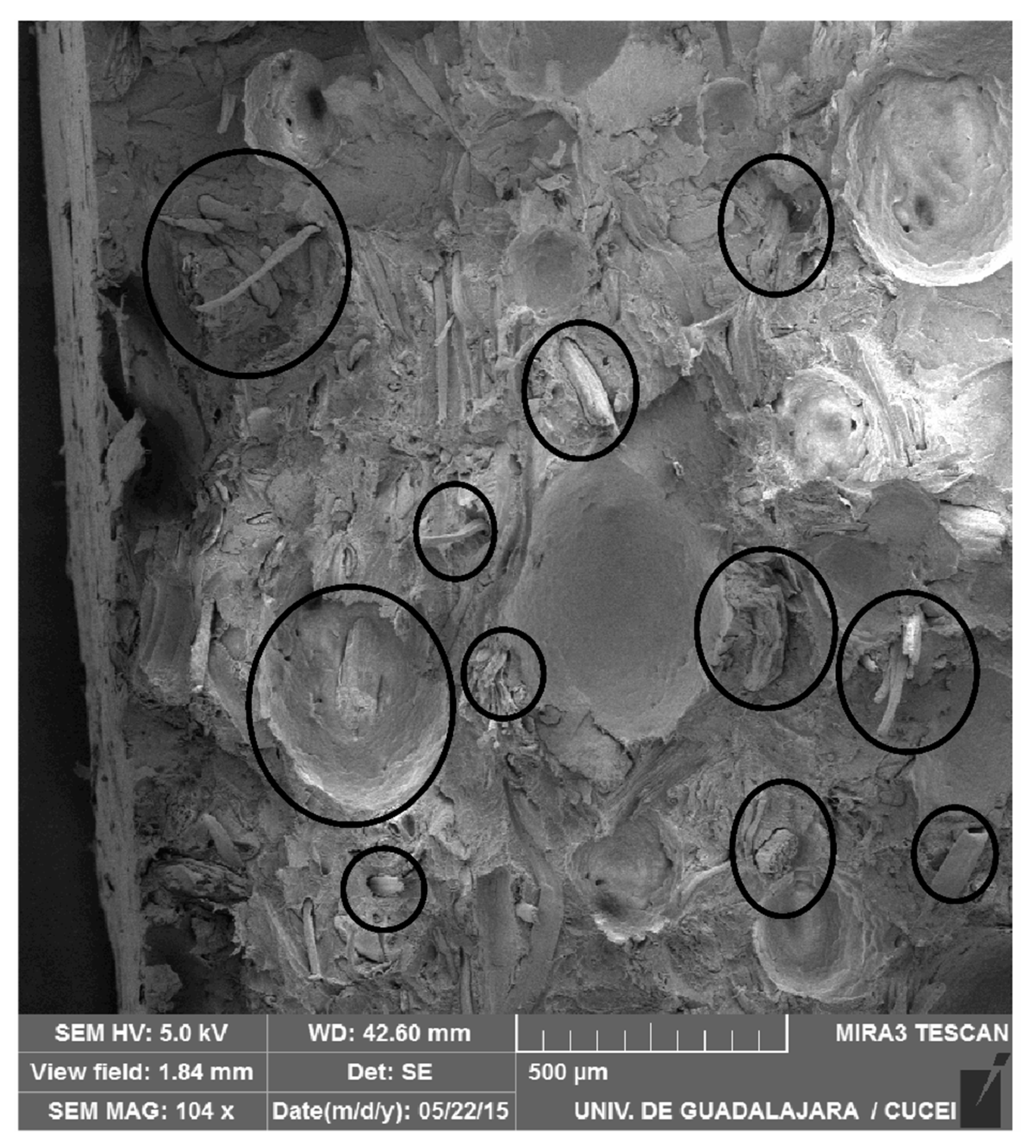

3.3. Morphology

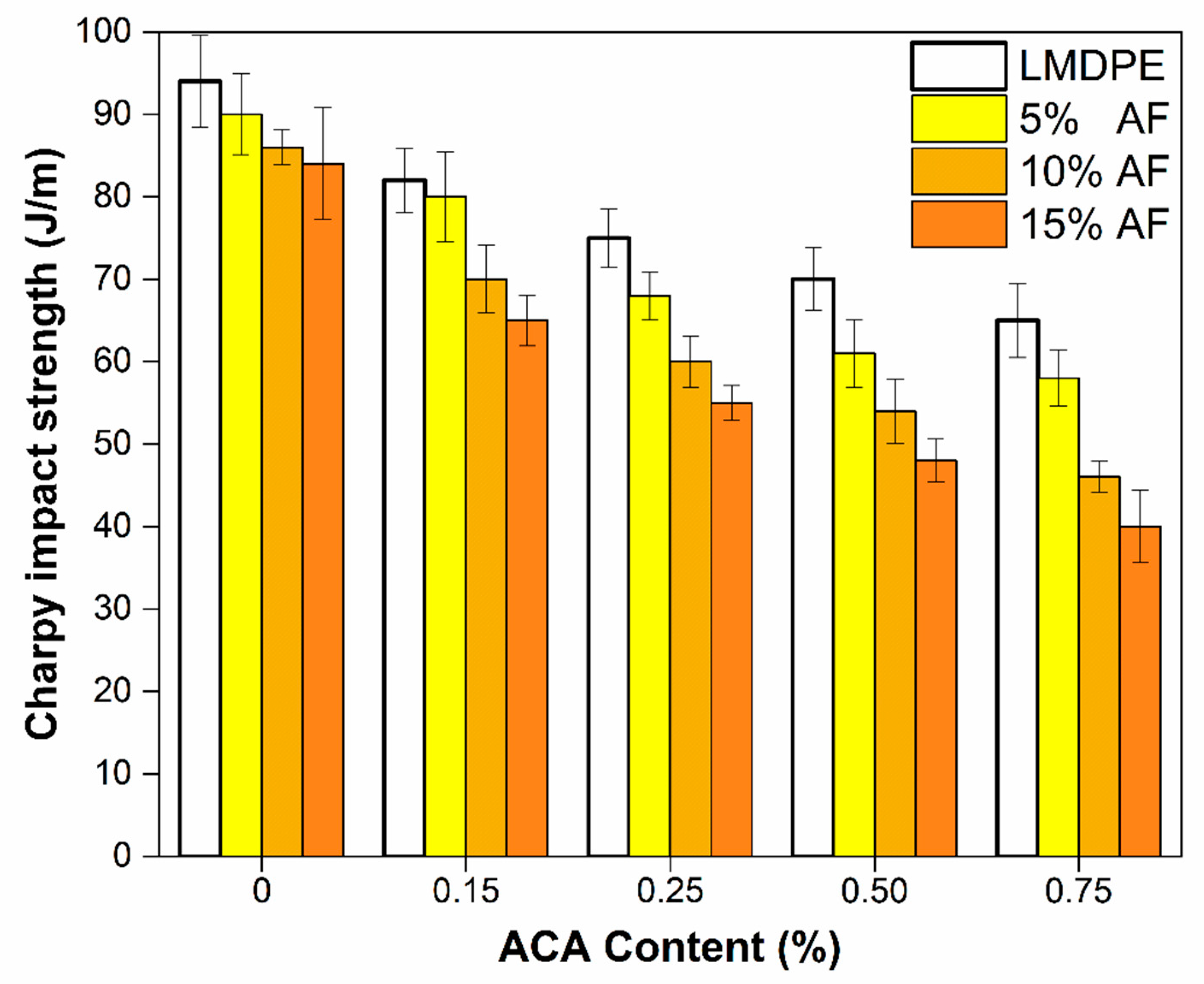

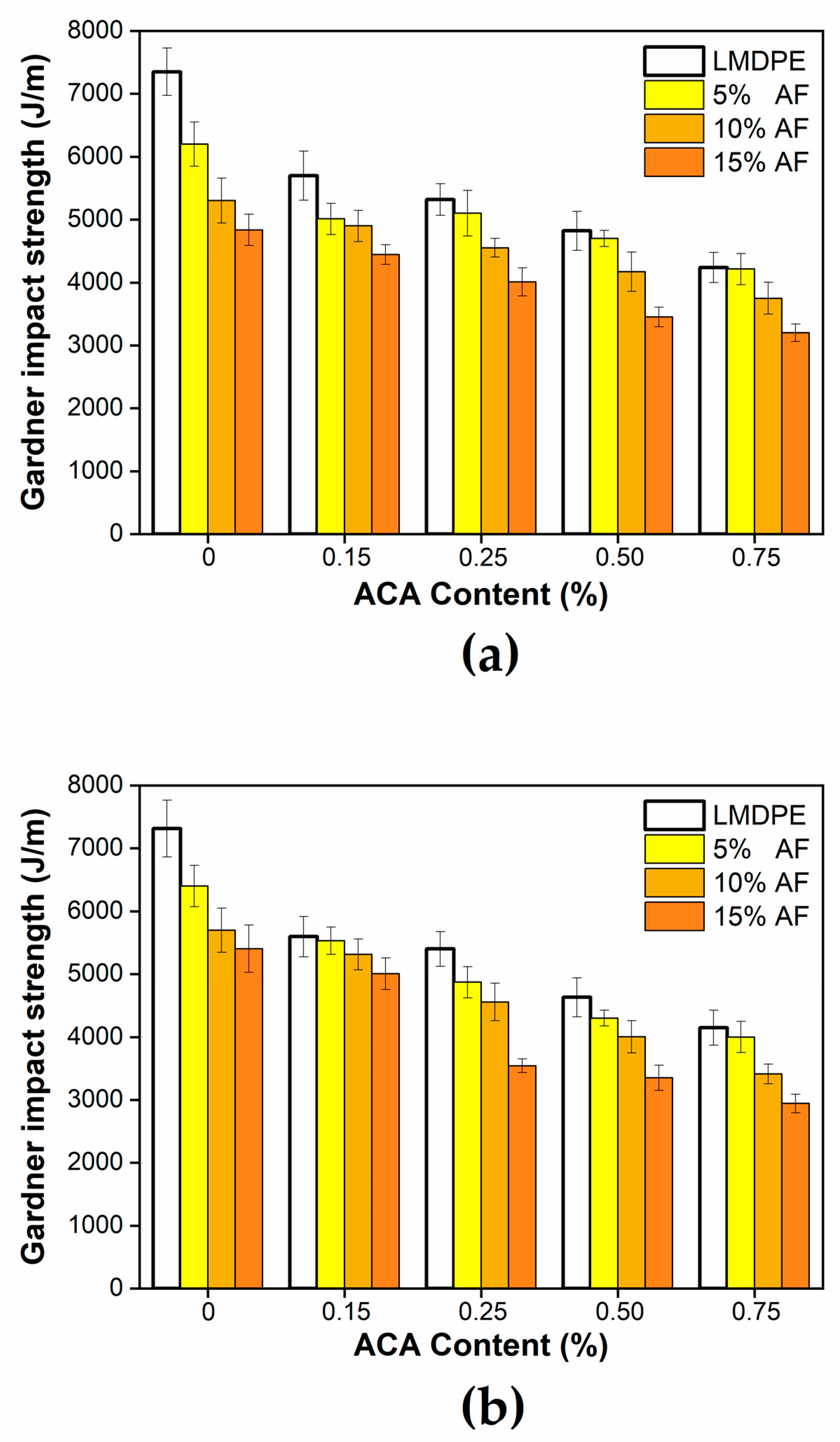

3.4. Impact

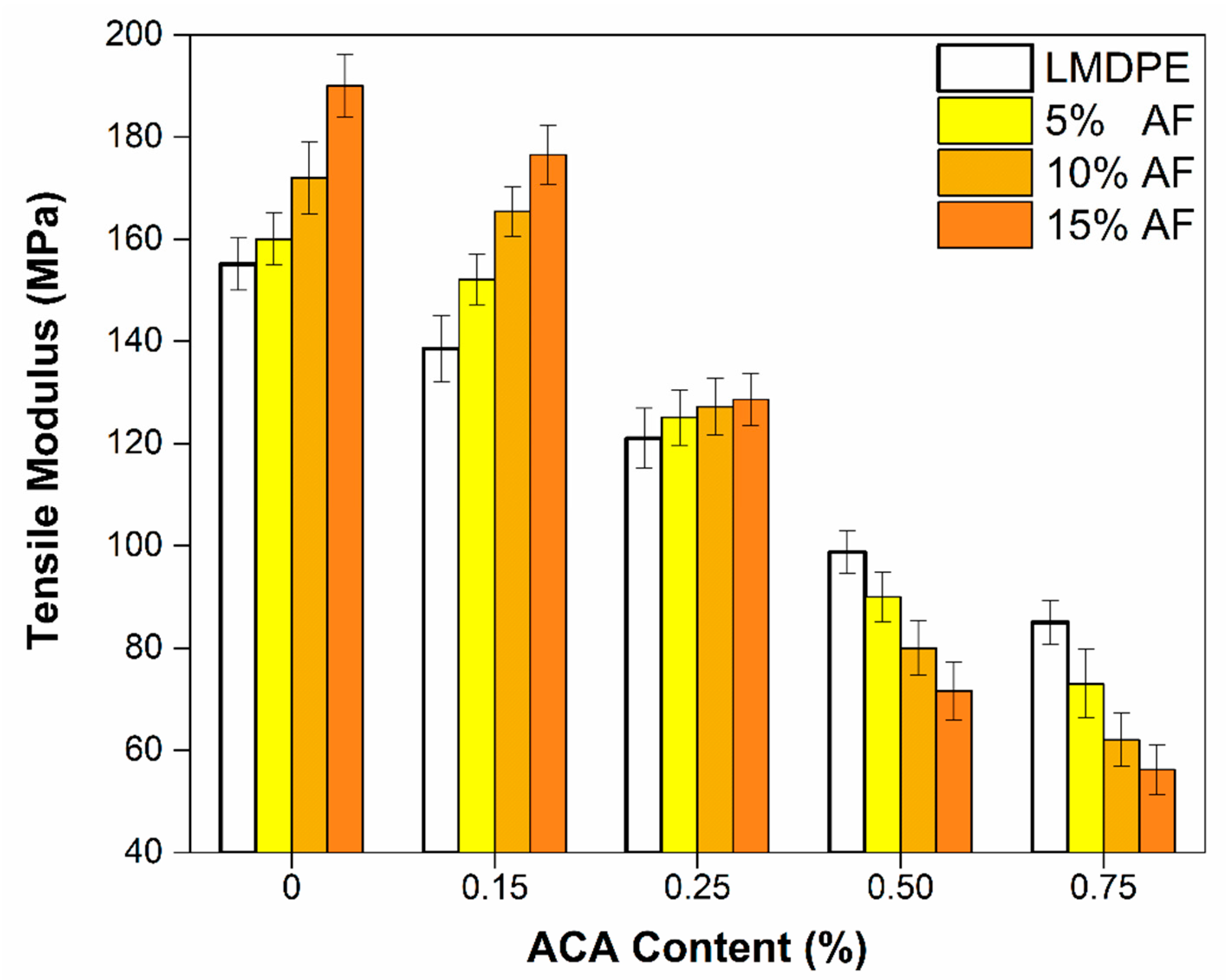

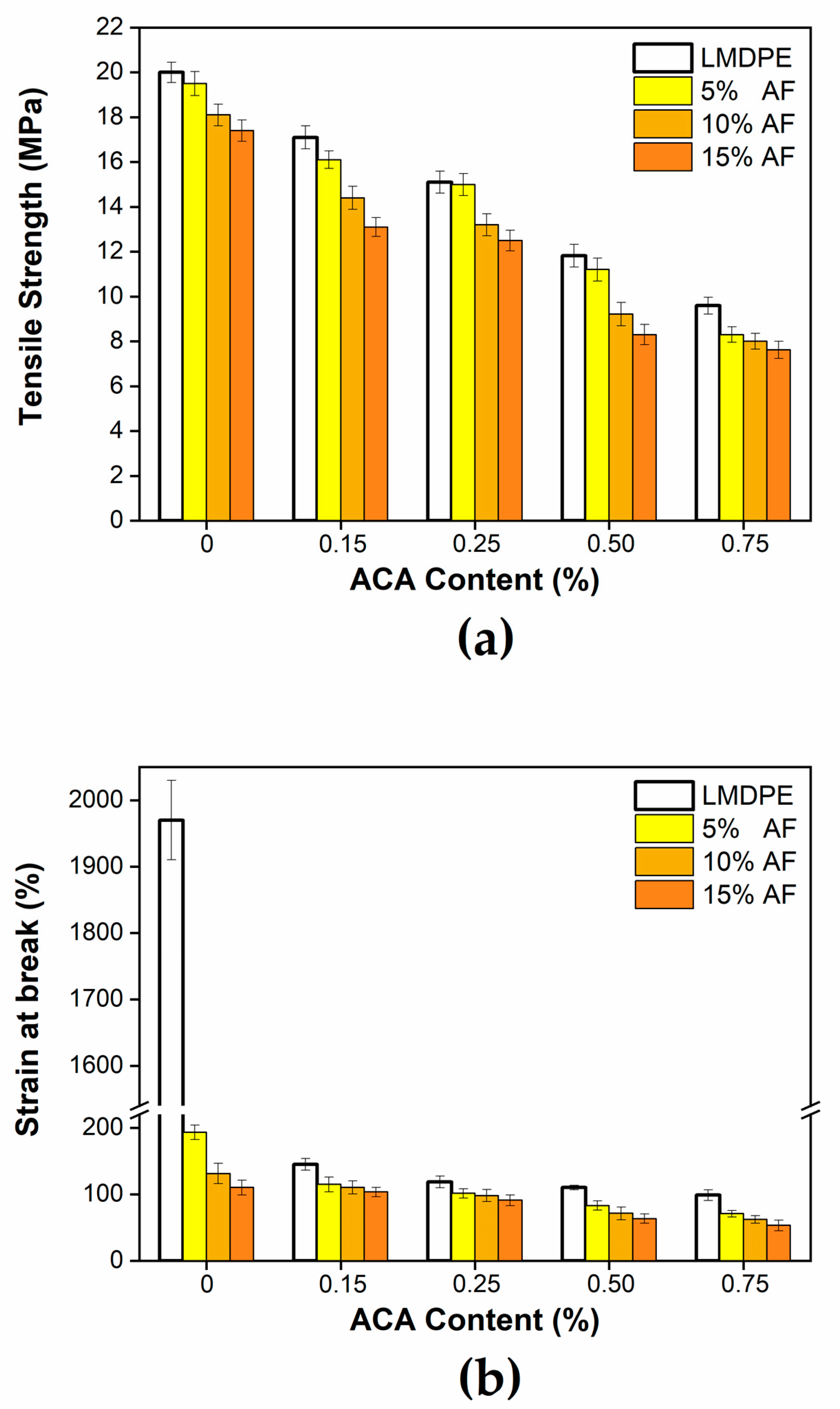

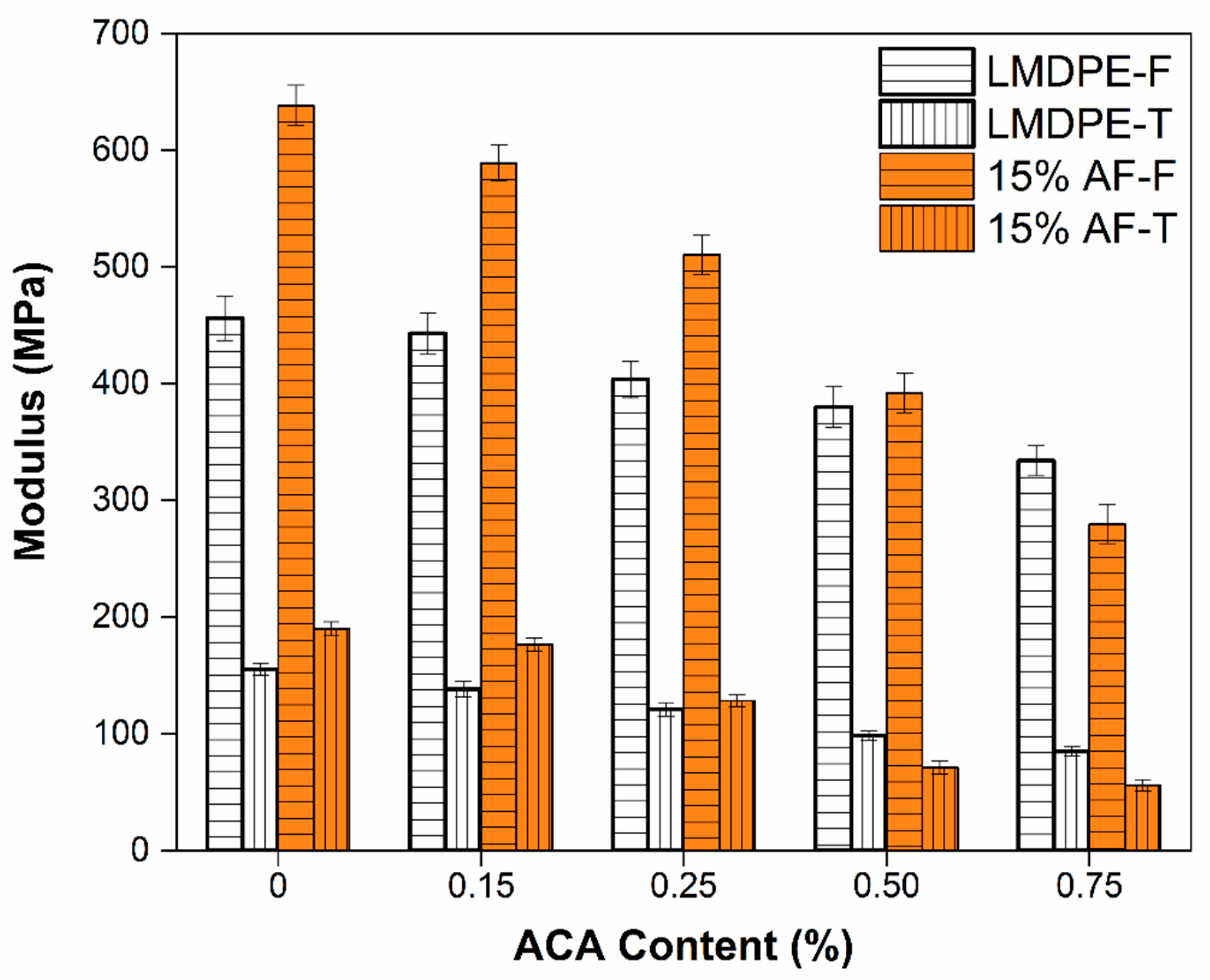

3.5. Tension and Flexion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hamad, K.; Kaseem, M.; Deri, F. Recycling of waste from polymer materials: An overview of the recent works. Polym. Degrad. Stab. 2013, 98, 2801–2812. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Annandarajah, C.; Li, P.; Michel, M.; Chen, Y.; Jamshidi, R.; Kiziltas, A.; Hoch, R.; Grewell, D.; Montazami, R. Study of agave fiber-reinforced biocomposite films. Materials (Basel) 2019, 12, 99. [Google Scholar] [CrossRef] [PubMed]

- Singha, A.S.; Rana, R.K. Natural fiber reinforced polystyrene composites: Effect of fiber loading, fiber dimensions and surface modification on mechanical properties. Mater. Des. 2012, 41, 289–297. [Google Scholar] [CrossRef]

- John, M.J.; Sikampula, N.; Boguslavsky, L. Agave nonwovens in polypropylene composites—Mechanical and thermal studies. J. Compos. Mater. 2015, 49, 669–676. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Fundamental studies on wood-plastic composites: Effects of fiber concentration and mixing temperature on the mechanical properties of poplar/PP composite. Polym. Compos. 2008, 29, 569–573. [Google Scholar] [CrossRef]

- Tissandier, C.; González-Núñez, R.; Rodrigue, D. Asymmetric microcellular composites: Mechanical properties and modulus prediction. J. Cell. Plast. 2016, 52, 365–398. [Google Scholar] [CrossRef]

- Kord, B. Effect of chemical blowing agent on the hygroscopic behavior of HDPE/rice husk flour composites. J. Compos. Mater. 2013, 26, 1114–1126. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; González-López, M.E.; Pérez-Fonseca, A.A.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of fiber content and surface treatment on the mechanical properties of natural fiber composites produced by rotomolding. Compos. Interfaces 2017, 24, 35–53. [Google Scholar] [CrossRef]

- Vignali, A.; Iannace, S.; Falcone, G.; Utzeri, R.; Stagnaro, P.; Bertini, F. Lightweight poly(ε-Caprolactone) composites with surface modified hollow glass microspheres for use in rotational molding: Thermal, rheological and mechanical properties. Polymers (Basel) 2019, 11, 624. [Google Scholar] [CrossRef] [PubMed]

- Greco, A.; Ferrari, F.; Buccoliero, M.G.; Trono, G. Thermal and mechanical analysis of polyethylene homo-composites processed by rotational molding. Polymers (Basel) 2019, 11, 528. [Google Scholar] [CrossRef] [PubMed]

- Cramez, M.C.; Oliveira, M.J.; Crawford, R.J. Optimization of the rotational moulding process for polyolefins. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 323–334. [Google Scholar] [CrossRef]

- Torres, F.; Díaz, R. Morphological characterisation of Natural Fibre Reinforced Thermoplastics (NFRTP) processed by extrusion, compression and rotational moulding. Polym. Polym. Compos. 2004, 12, 705–718. [Google Scholar] [CrossRef]

- Ward-Perron, N.; Rodrigue, D. Natural fiber reinforced thermoplastics (NFRTP) processed by rotomolding. In Proceedings of the 70th Annual Technical Conference of the Society of Plastics Engineers, Orlando, FL, USA, 2–4 April 2012; pp. 2263–2267. [Google Scholar]

- López-Bañuelos, R.H.; Moscoso, F.J.; Ortega-Gudiño, P.; Mendizabal, E.; Rodrigue, D.; González-Núñez, R. Rotational molding of polyethylene composites based on agave fibers. Polym. Eng. Sci. 2012, 52, 2489–2497. [Google Scholar] [CrossRef]

- Torres, F.G.; Aragon, C.L. Final product testing of rotational moulded natural fibre-reinforced polyethylene. Polym. Test. 2006, 25, 568–577. [Google Scholar] [CrossRef]

- Ortega, Z.; Monzón, M.D.; Benítez, N.; Kearns, M.; McCourt, M.; Hornsby, P.R. Banana and abaca fiber-reinforced plastic composites obtained by rotational molding process. Mater. Manuf. Process. 2013, 28, 879–883. [Google Scholar] [CrossRef]

- Barzegari, M.R.; Yao, J.; Rodrigue, D. Compression molding of polyethylene foams under a temperature gradient: Morphology and flexural modulus. Cell. Polym. 2009, 28, 237–248. [Google Scholar] [CrossRef]

- Moscoso-Sánchez, F.J.; Mendizábal, E.; Jasso-Gastinel, C.F.; Ortega-Gudiño, P.; Robledo-Ortíz, J.R.; González-Núñez, R.; Rodrigue, D. Morphological and mechanical characterization of foamed polyethylene via biaxial rotational molding. J. Cell. Plast. 2015, 51, 489–503. [Google Scholar] [CrossRef]

- Liu, S.-J.; Yang, C.-H. Rotational molding of two-layered polyethylene foams. Adv. Polym. Technol. 2001, 20, 108–115. [Google Scholar] [CrossRef]

- Casavola, C.; Moramarco, V.; Pappalettere, C. Impact response of polyethylene sandwich panel obtained by rotational moulding. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1377–1385. [Google Scholar] [CrossRef]

- Vázquez-Fletes, R.C.; Rosales-Rivera, L.C.; Moscoso-Sánchez, F.J.; Mendizábal, E.; Ortega-Gudiño, P.; González-Núñez, R.; Rodrigue, D. Preparation and characterization of multilayer foamed composite by rotational molding. Polym. Eng. Sci. 2016, 56, 278–286. [Google Scholar] [CrossRef]

- González-Núñez, R.; Moscoso-Sánchez, F.J.; Aguilar, J.; López-GonzálezNúñez, R.G.; Robledo-Ortíz, J.R.; Rodrigue, D. Thermal analysis of foamed polyethylene rotational molding followed by internal air temperature profiles. Polym. Eng. Sci. 2018, 58, E235–E241. [Google Scholar] [CrossRef]

- Moscoso, F.J.; Martínez, L.; Canche, G.; Rodrigue, D.; González-Núñez, R. Morphology and properties of polystyrene/agave fiber composites and foams. J. Appl. Polym. Sci. 2013, 127, 599–606. [Google Scholar] [CrossRef]

- Guzmán, R.Z.; Belmontes, F.A.; Romero, S.A.; Monje, A.E. Degradation of blue agave bagasse in low-density polyethylene composites under different processing conditions. J. Compos. Mater. 2014, 48, 3827–3835. [Google Scholar] [CrossRef]

- Mounika, M.; Ramaniah, K.; Ratna-Prasad, A.; Mohana-Rao, K.; Hema, K. Thermal conductivity characterization of bamboo fiber reinforced polyester composite. J. Mater. Environ. Sci. 2012, 3, 1109–1116. [Google Scholar]

- Banerjee, S.; Yan, W.; Bhattacharyya, D. Modeling of heat transfer in rotational molding. Polym. Eng. Sci. 2008, 48, 2188–2197. [Google Scholar] [CrossRef]

- Cramez, M.; Oliveira, M.; Crawford, R. Optimisation of rotational moulding of polyethylene by predicting antioxidant consumption. Polym. Degrad. Stab. 2002, 75, 321–327. [Google Scholar] [CrossRef]

- Ramkumar, P.; Kulkarni, D.; Chaudhari, V. Parametric and mechanical characterization of linear low density polyethylene (LLDPE) using rotational moulding technology. Sadhana 2014, 39, 625–635. [Google Scholar] [CrossRef]

- Emami, M.; Takacs, E.; Vlachopoulos, J. Rotational foam molding of metallocene catalyzed polyethylene: CBA screening and process characteristics. J. Cell. Plast. 2010, 46, 333–351. [Google Scholar] [CrossRef]

- Raymond, A.; Rodrigue, D. Foams and wood composite foams produced by rotomolding. Cell. Polym. 2013, 32, 199–213. [Google Scholar] [CrossRef]

- Kord, B.; Varshoei, A.; Chamany, V. Influence of chemical foaming agent on the physical, mechanical, and morphological properties of HDPE/wood flour/nanoclay composites. J. Reinf. Plast. Compos. 2011, 30, 1115–1124. [Google Scholar] [CrossRef]

- Hooman Hemmasi, A.; Khademi-Eslam, H.; Pourabbasi, S.; Ghasemi, I.; Talaiepour, M. Cell morphology and physico-mechanical properties of HDPE/EVA/Rice hull hybrid foamed composites. BioResources 2011, 6, 2291–2308. [Google Scholar]

- Adhikary, K.B.; Islam, M.R.; Rizvi, G.M.; Park, C.B. Effect of extrusion conditions on the surface quality, mechanical properties, and morphology of cellular wood flour/high-density polyethylene composite profiles. J. Compos. Mater. 2013, 26, 1127–1144. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Rotational molding of self-hybrid composites based on linear low-density polyethylene and maple fibers. Polym. Compos. 2018, 39, 4094–4103. [Google Scholar] [CrossRef]

- Tovar-Cisneros, C.; González-Núñez, R.; Rodrigue, D. Effect of mold temperature on morphology and mechanical properties of injection molded HDPE structural foams. J. Cell. Plast. 2008, 44, 223–237. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pérez-Fonseca, A.A.; Fuentes-Talavera, F.J.; Anzaldo, J.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Rotomolded polyethylene-agave fiber composites: Effect of fiber surface treatment on the mechanical properties. Polym. Eng. Sci. 2016, 56, 856–865. [Google Scholar] [CrossRef]

- Zhang, Y.; Rodrigue, D.; Ait-kadi, A. High density polyethylene foams. II. Elastic modulus. J. Appl. Polym. Sci. 2003, 90, 2120–2129. [Google Scholar] [CrossRef]

- Arrakhiz, F.Z.; El Achaby, M.; Malha, M.; Bensalah, M.O.; Fassi-Fehri, O.; Bouhfid, R.; Benmoussa, K.; Qaiss, A. Mechanical and thermal properties of natural fibers reinforced polymer composites: Doum/low density polyethylene. Mater. Des. 2013, 43, 200–205. [Google Scholar] [CrossRef]

- Archer, E.; Harkin-Jones, E.; Kearns, M.P. Investigation of the processing characteristics and mechanical properties of metallocene-catalysed polyethylene foams for rotational moulding. J. Cell. Plast. 2003, 39, 487–497. [Google Scholar] [CrossRef]

| Fiber Content (wt %) | PIAT (°C) Layer 1 | PIAT (°C) Layer 2 | Total Cycle (min) | ||

|---|---|---|---|---|---|

| Without Foam | Foamed | Without Foam | Foamed | ||

| 0 | 128 | 171 | 174 | 71 | 74 |

| 5 | 129 | 173 | 174 | 72 | 75 |

| 10 | 130 | 171 | 172 | 73 | 76 |

| 15 | 129 | 176 | 178 | 74 | 77 |

| ACA Content (wt %) | Fiber Content (wt %) | |||

|---|---|---|---|---|

| 0 | 5 | 10 | 15 | |

| 0 | 0.93 ± 0.08 | 0.94 ± 0.05 | 0.96 ± 0.07 | 0.98 ± 0.06 |

| 0.15 | 0.80 ± 0.07 | 0.82 ± 0.06 | 0.86 ± 0.08 | 0.90 ± 0.07 |

| 0.25 | 0.71 ± 0.09 | 0.68 ± 0.06 | 0.65 ± 0.05 | 0.64 ± 0.03 |

| 0.50 | 0.64 ± 0.06 | 0.61 ± 0.06 | 0.55 ± 0.06 | 0.51 ± 0.06 |

| 0.75 | 0.55 ± 0.05 | 0.53 ± 0.02 | 0.51 ± 0.09 | 0.44 ± 0.08 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vázquez Fletes, R.C.; Cisneros López, E.O.; Moscoso Sánchez, F.J.; Mendizábal, E.; González Núñez, R.; Rodrigue, D.; Ortega Gudiño, P. Morphological and Mechanical Properties of Bilayers Wood-Plastic Composites and Foams Obtained by Rotational Molding. Polymers 2020, 12, 503. https://doi.org/10.3390/polym12030503

Vázquez Fletes RC, Cisneros López EO, Moscoso Sánchez FJ, Mendizábal E, González Núñez R, Rodrigue D, Ortega Gudiño P. Morphological and Mechanical Properties of Bilayers Wood-Plastic Composites and Foams Obtained by Rotational Molding. Polymers. 2020; 12(3):503. https://doi.org/10.3390/polym12030503

Chicago/Turabian StyleVázquez Fletes, Roberto Carlos, Erick Omar Cisneros López, Francisco Javier Moscoso Sánchez, Eduardo Mendizábal, Rubén González Núñez, Denis Rodrigue, and Pedro Ortega Gudiño. 2020. "Morphological and Mechanical Properties of Bilayers Wood-Plastic Composites and Foams Obtained by Rotational Molding" Polymers 12, no. 3: 503. https://doi.org/10.3390/polym12030503

APA StyleVázquez Fletes, R. C., Cisneros López, E. O., Moscoso Sánchez, F. J., Mendizábal, E., González Núñez, R., Rodrigue, D., & Ortega Gudiño, P. (2020). Morphological and Mechanical Properties of Bilayers Wood-Plastic Composites and Foams Obtained by Rotational Molding. Polymers, 12(3), 503. https://doi.org/10.3390/polym12030503