Fracture Toughness Analysis of Epoxy-Recycled Rubber-Based Composite Reinforced with Graphene Nanoplatelets for Structural Applications in Automotive and Aeronautics

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

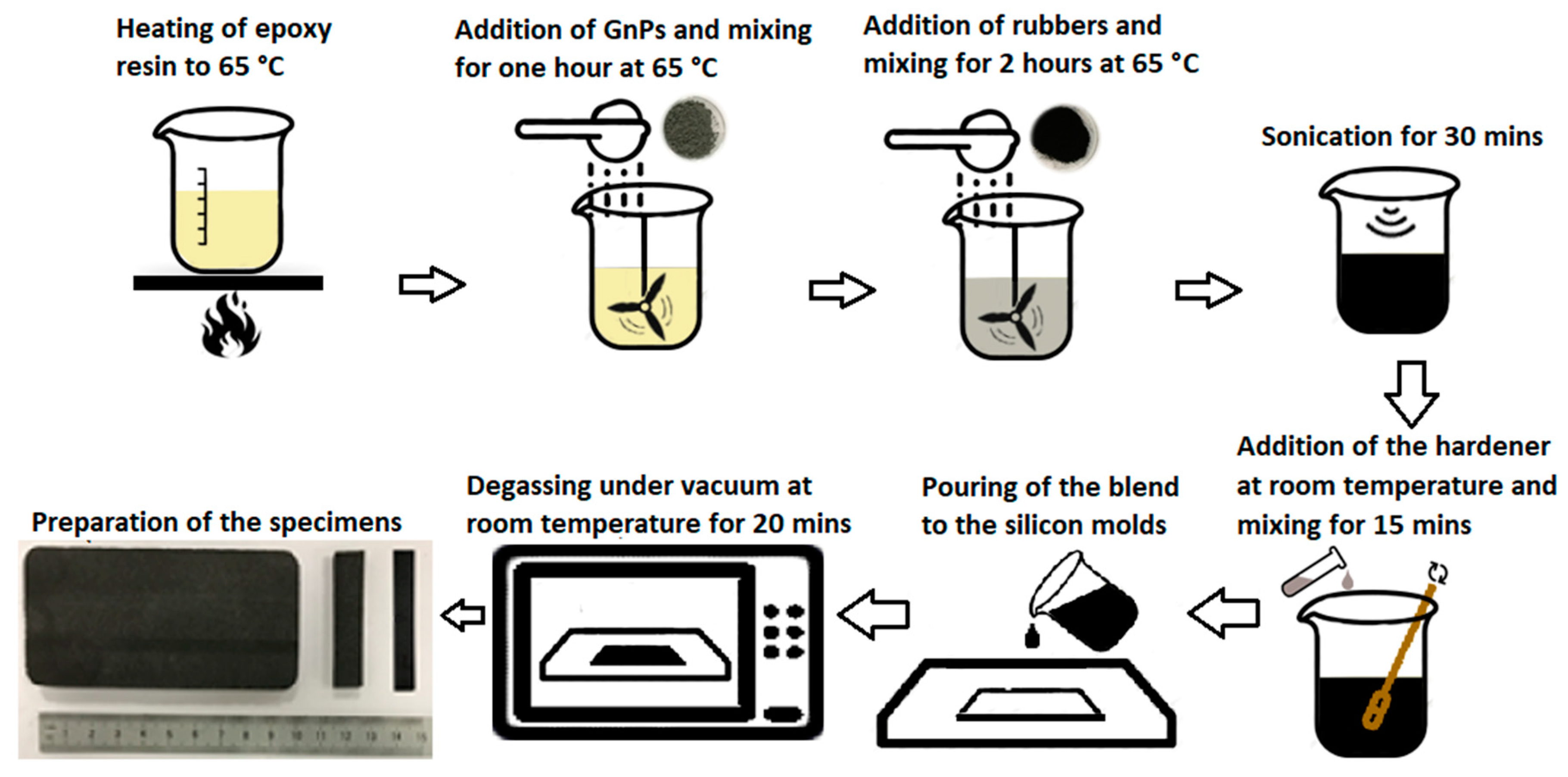

2.2. Materials Processing and Experimental Characterization

3. Results and Discussion

3.1. Physical Characteristics of the Manufactured Composites

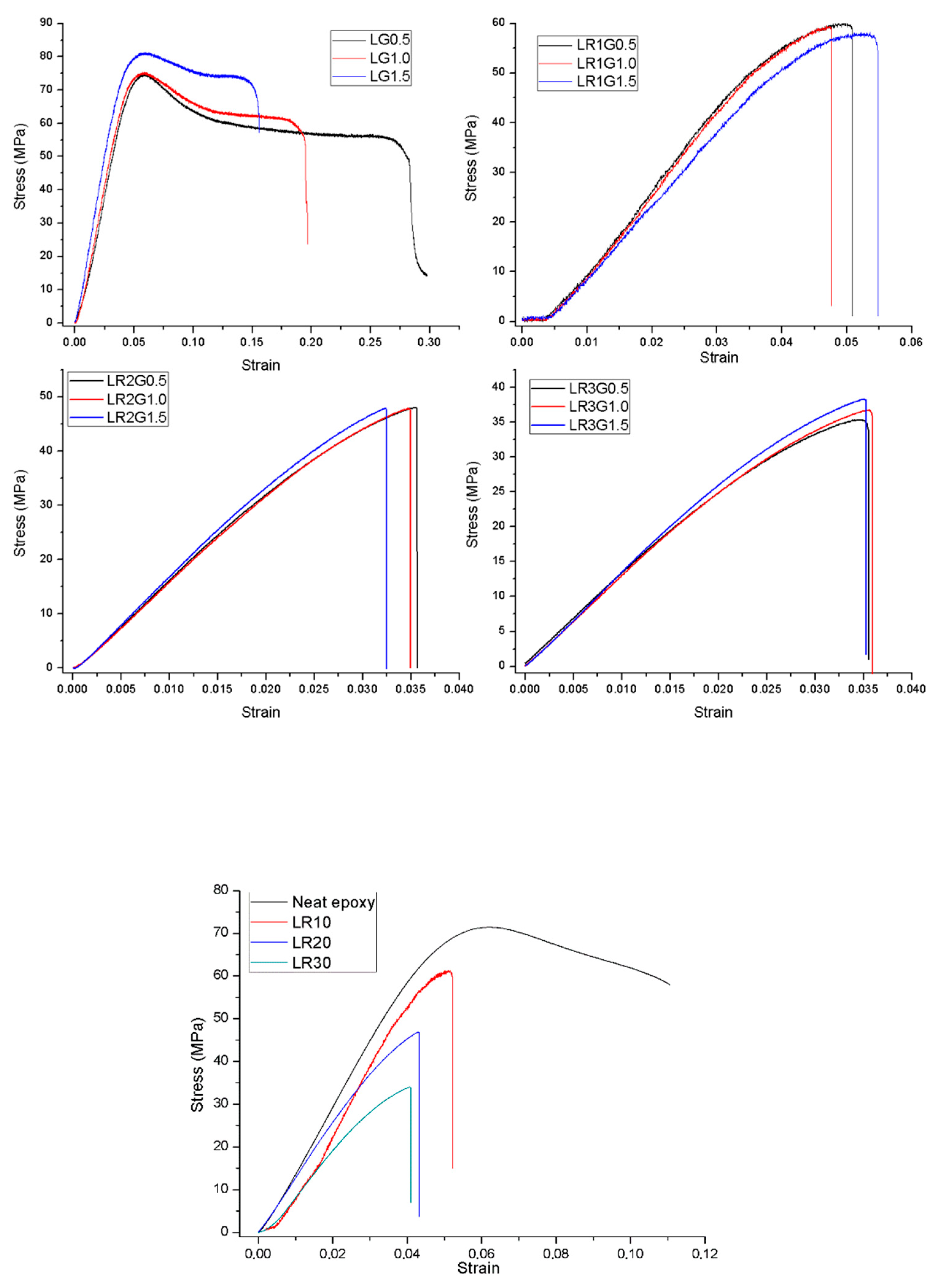

3.2. Mechanical Characterization of the Manufactured Composites by Means of 3PB Tests

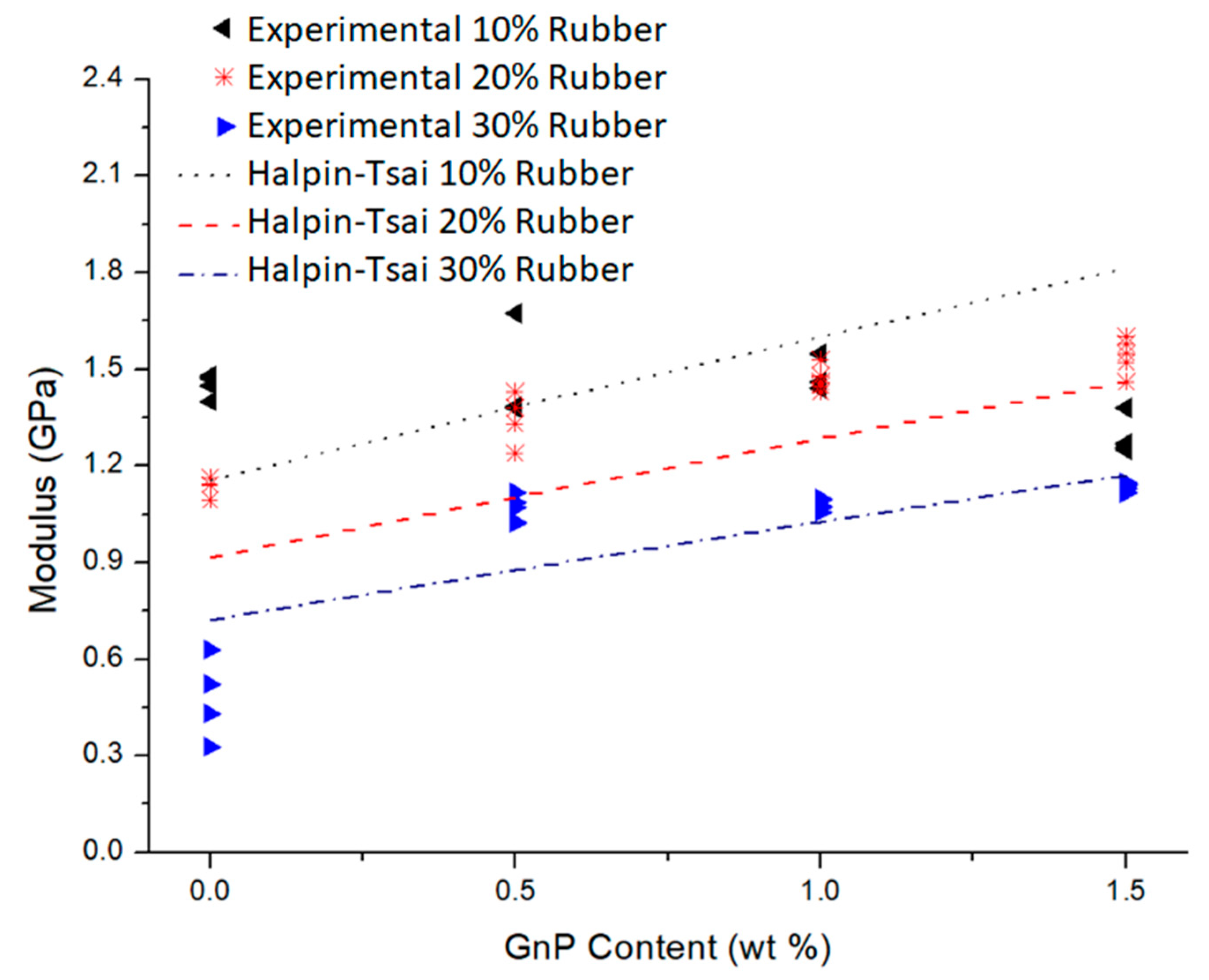

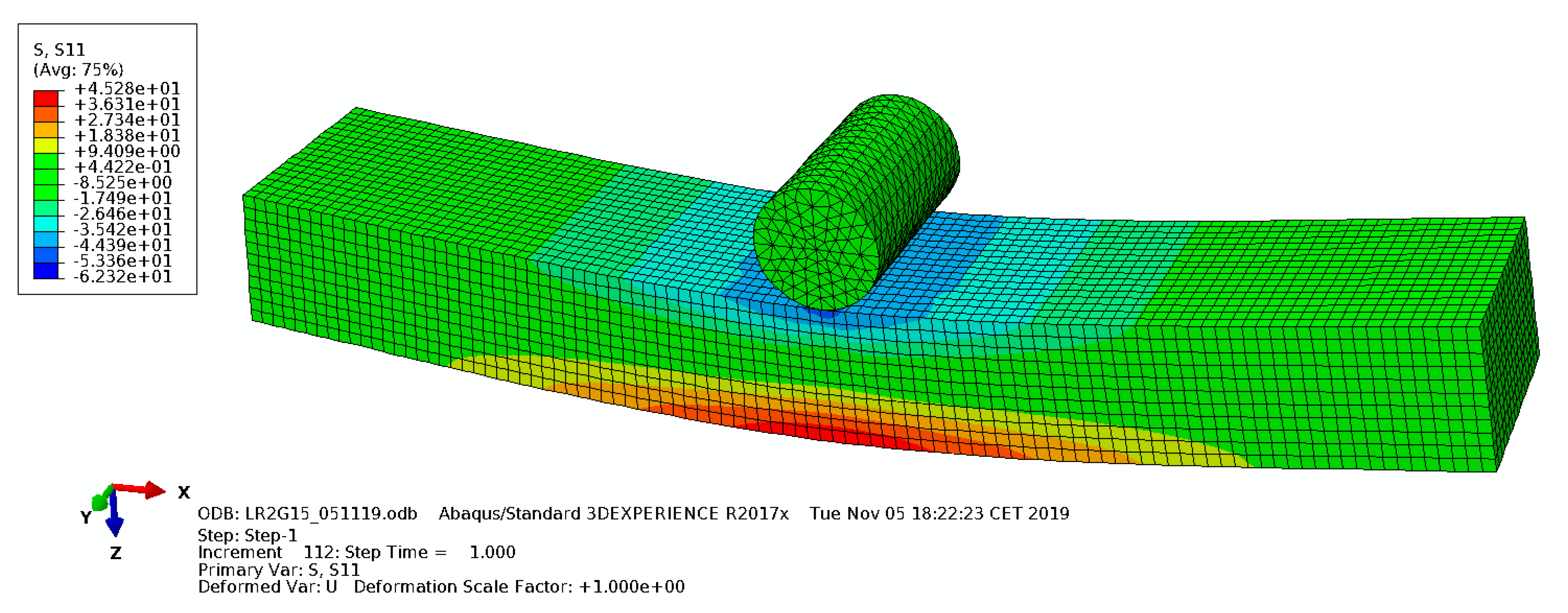

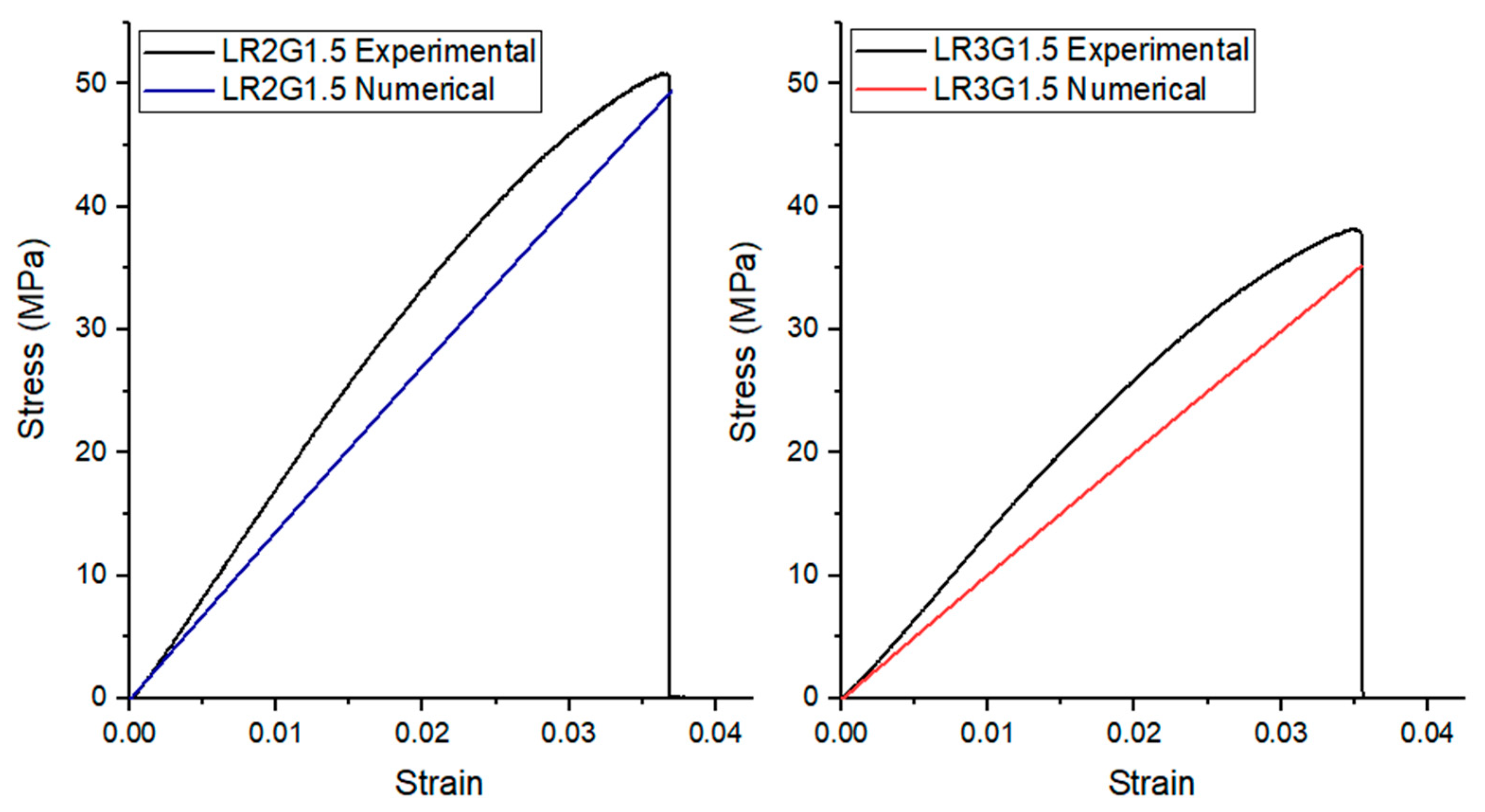

3.3. Numerical Verification of the 3PB Tests

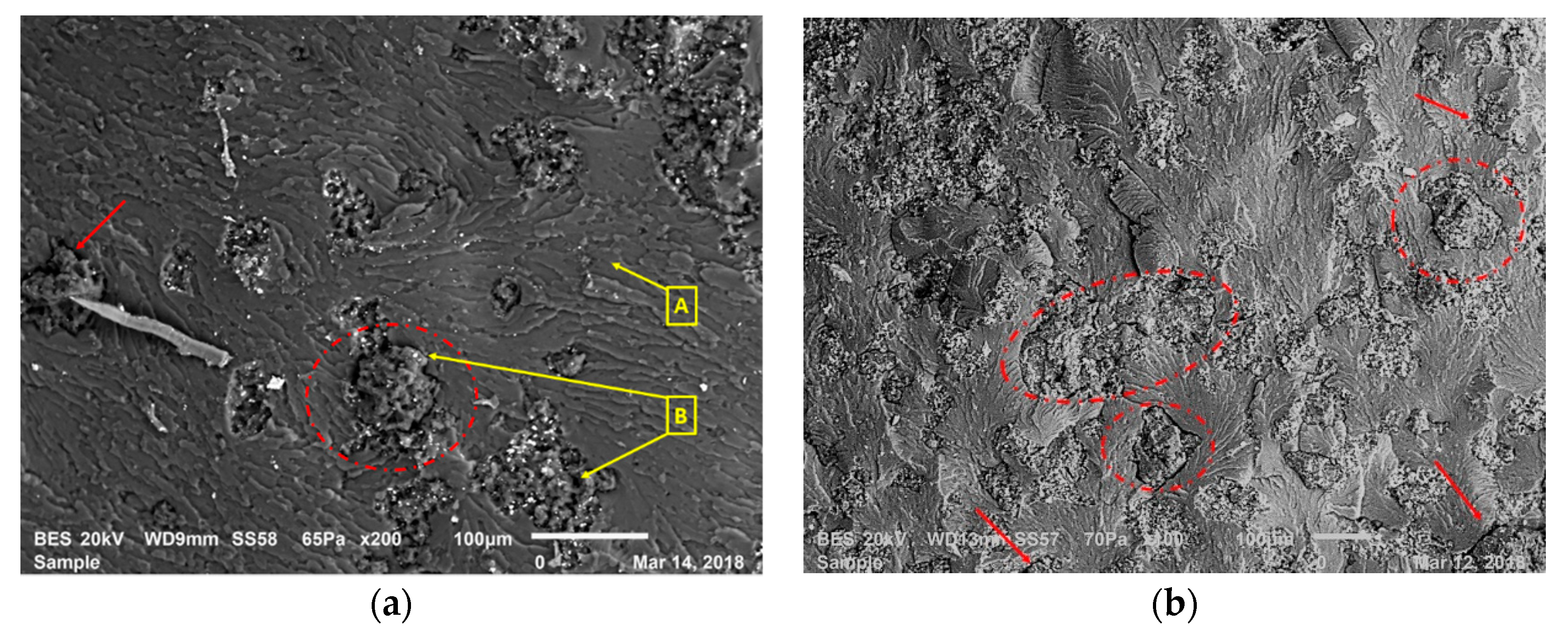

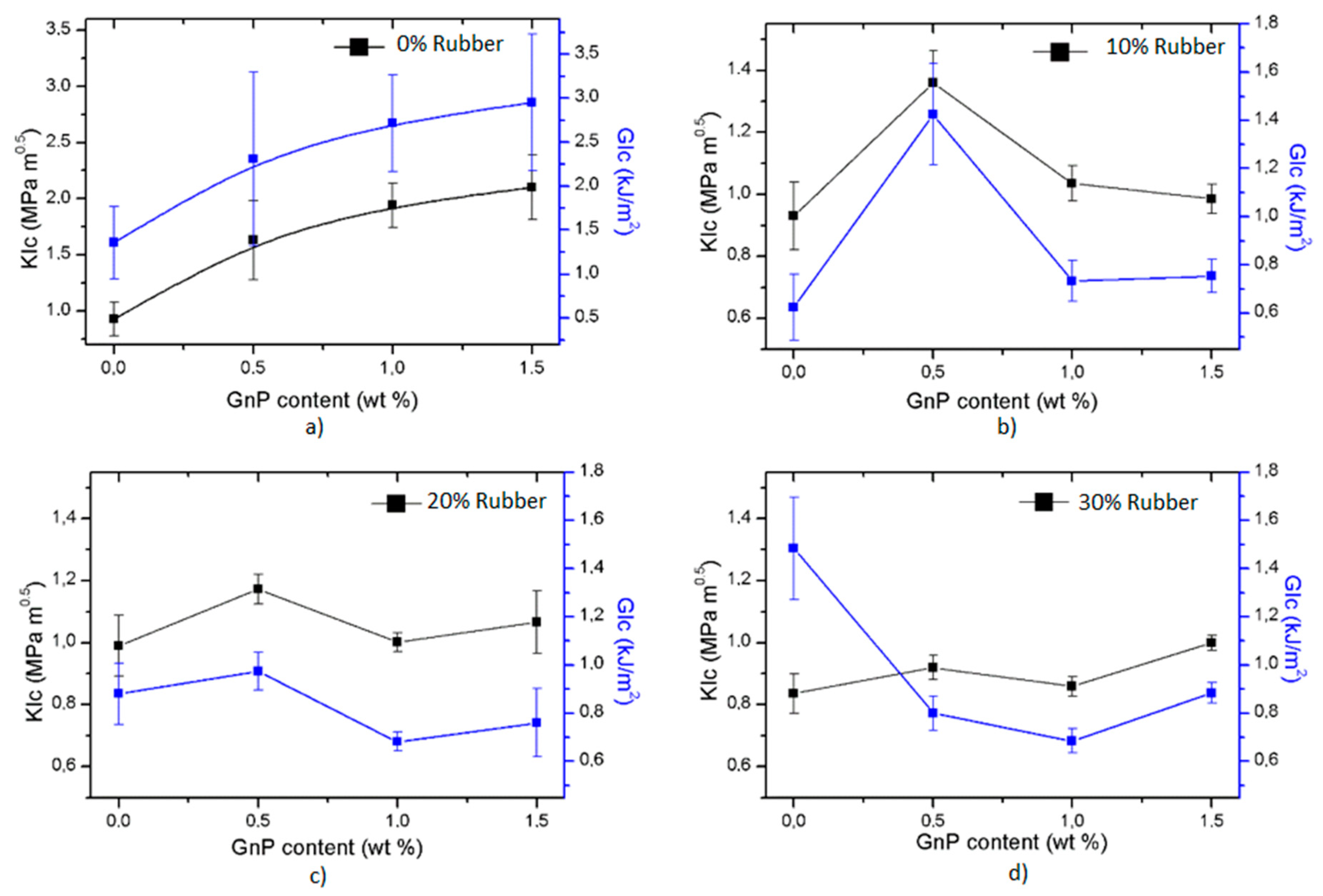

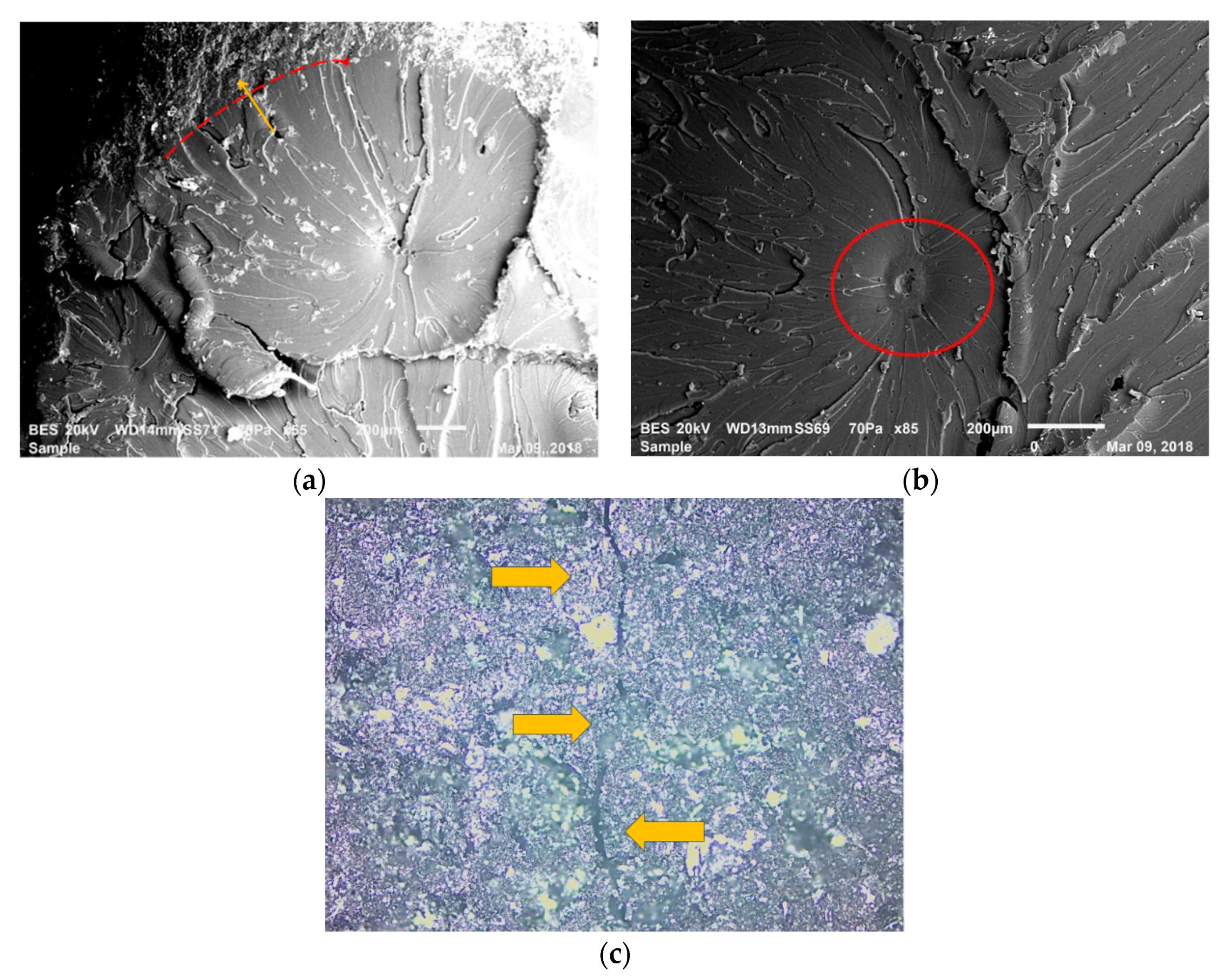

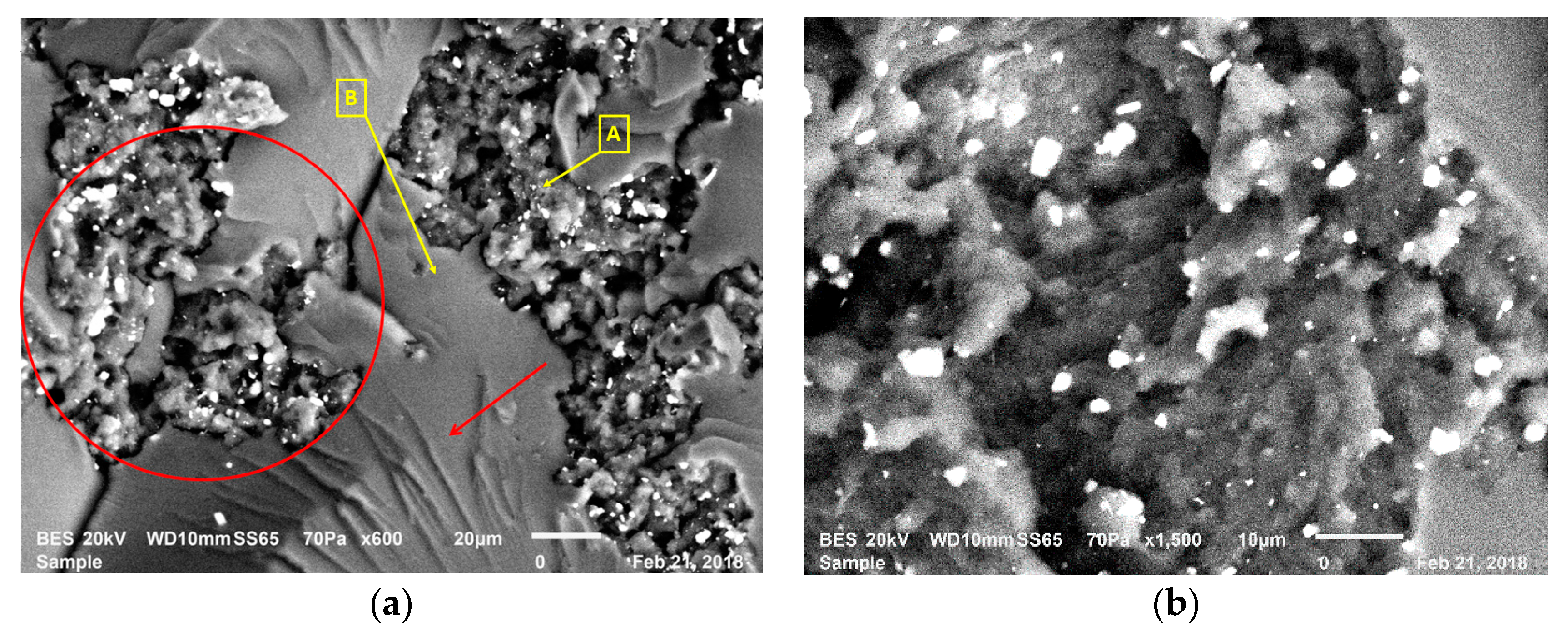

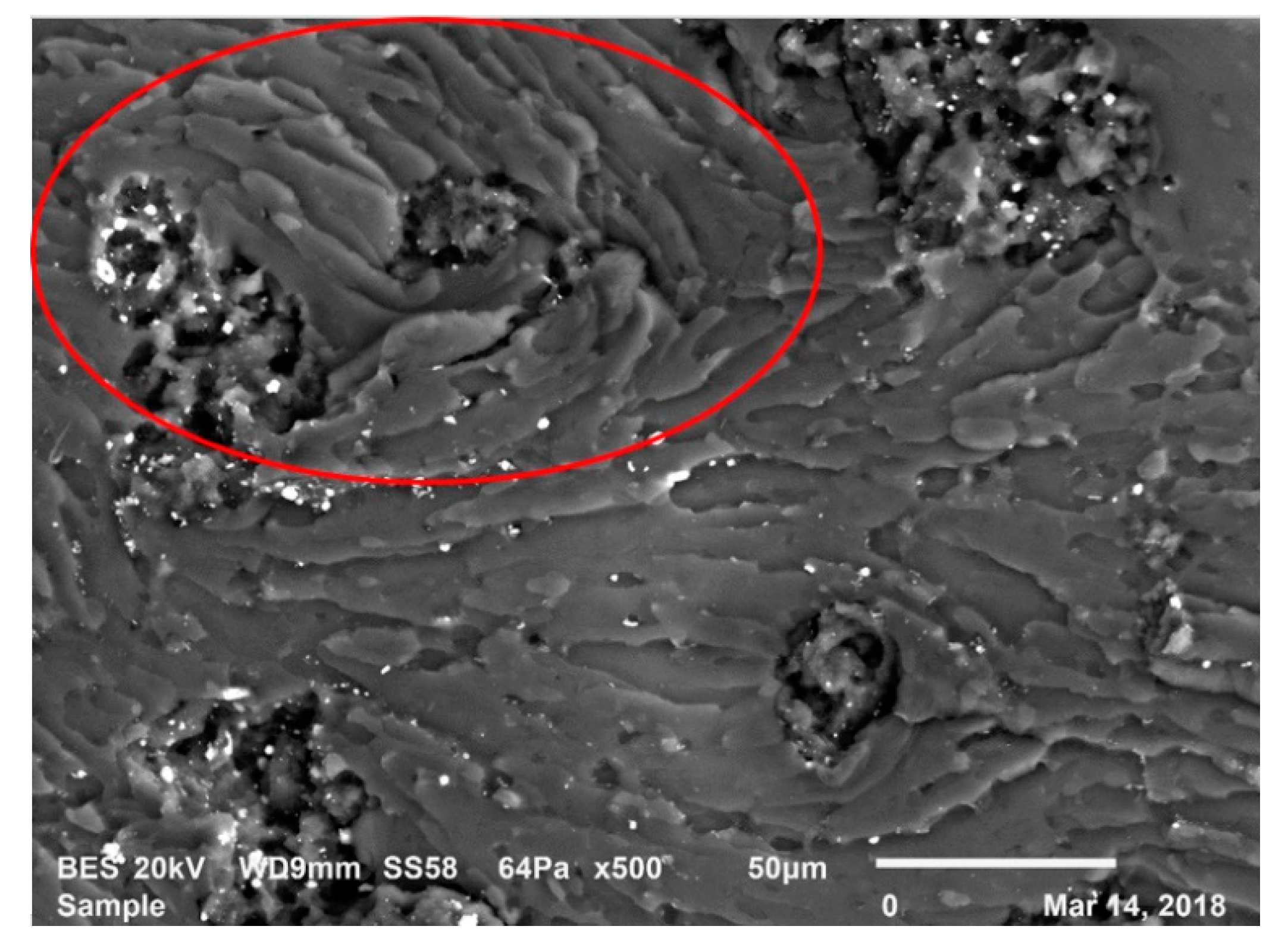

3.4. Determination of the Fracture Toughness and Toughening Mechanisms Identification by Means of SEM

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- May, C. Epoxy Resins: Chemistry and Technology, 2nd ed.; CRC Press: London, UK, 1987; pp. 46–121. [Google Scholar]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Liang, Y.L.; Pearson, R.A. The toughening mechanism in hybrid epoxy-silica-rubber nanocomposites (HESRNs). Polymer 2010, 51, 4880–4890. [Google Scholar] [CrossRef]

- Irez, A.B.; Miskioglu, I.; Bayraktar, E. Toughening Mechanisms on Recycled Rubber Modified Epoxy Based Composites Reinforced with Graphene Nanoplatelets. In Mechanics of Composite, Hybrid and Multifunctional Materials, 1st ed.; Thakre, P.R., Singh, P.R., Slipher, G., Eds.; Springer International Publishing: Cham, Switzerland, 2019; Volume 5, pp. 283–290. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Fiksel, J.; Bakshi, B.R.; Baral, A.; Guerra, E.; De Quervain, B. Comparative life cycle assessment of beneficial applications for scrap tires. Clean Technol. Environ. Policy 2011, 13, 19–35. [Google Scholar] [CrossRef]

- Fang, Y.; Zhan, M.; Wang, Y. The status of recycling of waste rubber. Mater. Des. 2001, 22, 123–128. [Google Scholar] [CrossRef]

- Isayev, A.I. Recycling of Rubbers. In Science and Technology of Rubber, 3rd ed.; Mark, J., Erman, B., Eirich, F., Eds.; Academic Press: Cambridge, MA, USA, 2005; pp. 663–701. [Google Scholar]

- Myhre, M.; MacKillop, D.A. Rubber Recycling. Rubber Chem. Technol. 2002, 75, 429–474. [Google Scholar] [CrossRef]

- Caldona, E.B.; De Leon, A.C.C.; Pajarito, B.B.; Advincula, R.C. A Review on Rubber-Enhanced Polymeric Materials. Polym. Rev. 2017, 57, 311–338. [Google Scholar] [CrossRef]

- Mangaraj, D. Rubber recycling by blending with plastics. In Rubber Recycling, 1st ed.; De, S.K., Isayev, A., Khait, K., Eds.; CRC Press: Boca Raton, FL, USA, 2005; pp. 272–324. [Google Scholar]

- Valášek, P.; Müller, M. EPDM rubber material utilization in epoxy composite systems. Agron. Res. 2014, 12, 291–298. [Google Scholar]

- Al-Aqeeli, N. Fabrication and Assessment of Crumb-Rubber-Modified Coatings with Anticorrosive Properties. Materials 2015, 8, 181–192. [Google Scholar] [CrossRef]

- Roche, N.; Ichchou, M.N.; Salvia, M.; Chettah, A. Dynamic Damping Properties of Thermoplastic Elastomers Based on EVA and Recycled Ground Tire Rubber. J. Elastomers Plast. 2011, 43, 317–340. [Google Scholar] [CrossRef]

- Zhu, S.-H.; Penlidis, A.; Tzoganakis, C.; Ginzel, E. Ultrasonic properties and morphology of devulcanized rubber blends. J. Appl. Polym. Sci. 2012, 124, 2062–2070. [Google Scholar] [CrossRef]

- Li, B.; Zhou, H.; Huang, G. A novel impedance matching material derived from polymer micro-particles. J. Mater. Sci. 2007, 42, 199–206. [Google Scholar] [CrossRef]

- Xue, Q.-J.; Wang, Q.-H. Wear mechanisms of polyetheretherketone composites filled with various kinds of SiC. Wear 1997, 213, 54–58. [Google Scholar] [CrossRef]

- Bagheri, R.; Marouf, B.T.; Pearson, R.A. Rubber-Toughened Epoxies: A Critical Review. Polym. Rev. 2009, 49, 201–225. [Google Scholar] [CrossRef]

- Gong, L.-X.; Zhao, L.; Tang, L.-C.; Liu, H.-Y.; Mai, Y.-W. Balanced electrical, thermal and mechanical properties of epoxy composites filled with chemically reduced graphene oxide and rubber nanoparticles. Compos. Sci. Technol. 2015, 121, 104–114. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Scarpa, F.; Adhikari, S.; Srikantha Phani, A. Effective elastic mechanical properties of single layer graphene sheets. Nanotechnology 2009, 20, 065709. [Google Scholar] [CrossRef]

- Wichmann, M.H.G.; Schulte, K.; Wagner, H.D. On nanocomposite toughness. Compos. Sci. Technol. 2008, 68, 329–331. [Google Scholar] [CrossRef]

- Srivastava, I.; Koratkar, N. Fatigue and fracture toughness of epoxy nanocomposites. JOM J. Miner. Met. Mater. Soc. 2010, 62, 50–57. [Google Scholar] [CrossRef]

- Liang, Y.L.; Pearson, R.A. Toughening mechanisms in epoxy–silica nanocomposites (ESNs). Polymer 2009, 50, 4895–4905. [Google Scholar] [CrossRef]

- Moghaddamzadeh, S.; Rodrigue, D. The effect of polyester recycled tire fibers mixed with ground tire rubber on polyethylene composites. Part II: Physico-mechanical analysis. Prog. Rubber Plast. Recycl. Technol. 2018, 34, 128–142. [Google Scholar] [CrossRef]

- Medina, N.F.; Garcia, R.; Hajirasouliha, I.; Pilakoutas, K.; Guadagnini, M.; Raffoul, S. Composites with recycled rubber aggregates: Properties and opportunities in construction. Constr. Build. Mater. 2018, 188, 884–897. [Google Scholar] [CrossRef]

- Li, W.; Dichiara, A.; Bai, J. Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos. Sci. Technol. 2013, 74, 221–227. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Q.; Chen, D.; Lu, P. Enhanced Mechanical Properties of Graphene-Based Poly(vinyl alcohol) Composites. Macromolecules 2010, 43, 2357–2363. [Google Scholar] [CrossRef]

- Dwaikat, M.M.S.; Spitas, C.; Spitas, V. Predicting nonlinear stress–strain curves of unidirectional fibrous composites in consideration of stick–slip. Compos. Part B Eng. 2013, 44, 501–507. [Google Scholar] [CrossRef]

- Yalcin, D. Fracture Characterization of Knitting Fabric Reinforced Laminated Composites. Master’s Thesis, Usak University, Usak, Turkey, 2016. [Google Scholar]

- Quan, D.; Ivankovic, A. Effect of core–shell rubber (CSR) nano-particles on mechanical properties and fracture toughness of an epoxy polymer. Polymer 2015, 66, 16–28. [Google Scholar] [CrossRef]

- Irez, A.B.; Bayraktar, E.; Miskioglu, I. Flexural fatigue damage analyses of recycled rubber—Modified epoxy-based composites reinforced with alumina fibres. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 959–971. [Google Scholar] [CrossRef]

- Irez, A.B. Conception, Élaboration et Caractérisation des Composites Modifiées par Incorporation de Particules de Caoutchouc Recyclées et Devulcanisées à Base D’époxy: Une Approche Expérimentale Pour des Mécanismes de Renforcement. Ph.D. Thesis, Université-Paris Saclay, Paris, France, 2018. [Google Scholar]

- Chandrasekaran, S.; Seidel, C.; Schulte, K. Preparation and characterization of graphite nano-platelet (GNP)/epoxy nano-composite: Mechanical, electrical and thermal properties. Eur. Polym. J. 2013, 49, 3878–3888. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Zhang, J.; Mouritz, A.P.; Wang, C.H. Multifunctional properties of epoxy nanocomposites reinforced by aligned nanoscale carbon. Mater. Des. 2016, 94, 554–564. [Google Scholar] [CrossRef]

- Park, Y.T.; Qian, Y.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy Toughening with Low Graphene Loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Enhancement of fracture toughness, mechanical and thermal properties of rubber/epoxy composites by incorporation of graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2016, 87, 10–22. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Young, R.J. Fracture Behaviour of Polymers, 1st ed.; Springer: Dordrecht, The Netherlands, 1995; pp. 107–146. [Google Scholar]

- Manjunatha, C.M.; Taylor, A.C.; Kinloch, A.J.; Sprenger, S. The cyclic-fatigue behaviour of an epoxy polymer modified with micron-rubber and nano-silica particles. J. Mater. Sci. 2009, 44, 4487–4490. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wu, S.; Kinloch, A.J.; Wang, C.H.; Mouritz, A.P. Multi-scale toughening of epoxy composites via electric field alignment of carbon nanofibres and short carbon fibres. Compos. Sci. Technol. 2018, 167, 115–125. [Google Scholar] [CrossRef]

- Huang, Y.; Kinloch, A.J. The role of plastic void growth in the fracture of rubber-toughened epoxy polymers. J. Mater. Sci. Lett. 1992, 11, 484–487. [Google Scholar] [CrossRef]

- Williams, J.G. Particle toughening of polymers by plastic void growth. Compos. Sci. Technol. 2010, 70, 885–891. [Google Scholar] [CrossRef]

- Singh, K.; Nanda, T.; Mehta, R. Addition of nanoclay and compatibilized EPDM rubber for improved impact strength of epoxy glass fiber composites. Compos. Part A Appl. Sci. Manuf. 2017, 103, 263–271. [Google Scholar] [CrossRef]

- Krishnan, P. Rheology of Epoxy/Rubber Blends. In Handbook of Epoxy Blends, 1st ed.; Parameswaranpillai, J., Hameed, N., Pionteck, J., Woo, E., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 1, pp. 185–210. [Google Scholar] [CrossRef]

- Irez, A.B.; Zambelis, G.; Bayraktar, E. A New Design of Recycled Ethylene Propylene Diene Monomer Rubber Modified Epoxy Based Composites Reinforced with Alumina Fiber: Fracture Behavior and Damage Analyses. Materials 2019, 12, 2729. [Google Scholar] [CrossRef]

| LRG Composites | GnP Content (wt. %) | |||

|---|---|---|---|---|

| Rubber content (wt. %) | 0% | 0.5% | 1.0% | 1.5% |

| 0% | LG0.5 | LG1.0 | LG1.5 | |

| 10% | LR10 | LR1G0.5 | LR1G1.0 | LR1G1.5 |

| 20% | LR20 | LR2G0.5 | LR2G1.0 | LR2G1.5 |

| 30% | LR30 | LR3G0.5 | LR3G1.0 | LR3G1.5 |

| Composition Name | Density (g/cm3) | Composition Name | Density (g/cm3) | Composition Name | Density (g/cm3) |

|---|---|---|---|---|---|

| LR10 | 1.120 | LR20 | 1.115 | LR30 | 1.035 |

| LG0.5 | 1.145 | LG1.0 | 1.154 | LG1.5 | 1.160 |

| LR1G0.5 | 1.130 | LR2G0.5 | 1.125 | LR3G0.5 | 1.047 |

| LR1G1.0 | 1.155 | LR2G1.0 | 1.130 | LR3G1.0 | 1.076 |

| LR1G1.5 | 1.159 | LR2G1.5 | 1.142 | LR3G1.5 | 1.113 |

| Composition Name | Shore D | Composition Name | Shore D | Composition Name | Shore D |

|---|---|---|---|---|---|

| LR10 | 74.8 ± 0.3 | LR20 | 72.8 ± 0.3 | LR30 | 64.4 ± 0.4 |

| LG0.5 | 70.6 ± 0.5 | LG1.0 | 76.2 ± 0.4 | LG1.5 | 75.6 ± 0.2 |

| LR1G0.5 | 74.2 ± 0.4 | LR2G0.5 | 75.8 ± 0.1 | LR3G0.5 | 72.4 ± 0.1 |

| LR1G1.0 | 72.6 ± 0.2 | LR2G1.0 | 75.0 ± 0.2 | LR3G1.0 | 71.6 ± 0.5 |

| LR1G1.5 | 74.0 ± 0.5 | LR2G1.5 | 75.8 ± 0.2 | LR3G1.5 | 70.2 ± 0.1 |

| Composition Name | Ultimate Flexural Stress (MPa) | Flexural Modulus (MPa) | Strain at Break |

|---|---|---|---|

| Neat epoxy | 78.96 ± 1.22 | 1465.83 ± 145.05 | 0.13 ± 0.017 |

| LG0.5 | 63.05 ± 11.58 | 1297.28 ± 193.76 | 0.064 ± 0.004 |

| LG1.0 | 74.11 ± 1.78 | 1439.75 ± 101.60 | 0.061 ± 0.003 |

| LG1.5 | 78.97 ± 2.49 | 1582.23 ± 111.73 | 0.057 ± 0.004 |

| LR10 | 61.58 ± 1.64 | 1454.71 ± 16.28 | 0.049 ± 0.002 |

| LR20 | 48.33 ± 1.02 | 1149.64 ± 20.74 | 0.045 ± 0.001 |

| LR30 | 34.27 ± 3.77 | 478.25 ± 64.13 | 0.037 ± 0.001 |

| LR1G0.5 | 59.65 ± 0.54 | 1478.84 ± 84.15 | 0.055 ± 0.004 |

| LR1G1.0 | 59.18 ± 0.20 | 1475.10 ± 25.70 | 0.046 ± 0.001 |

| LR1G1.5 | 59.08 ± 0.67 | 1294.78 ± 29.11 | 0.057 ± 0.002 |

| LR2G0.5 | 47.94 ± 0.25 | 1417.84 ± 13.69 | 0.035 ± 0.001 |

| LR2G1.0 | 48.49 ± 1.01 | 1474.58 ± 19.79 | 0.034 ± 0.001 |

| LR2G1.5 | 48.61 ± 0.74 | 1537.54 ± 28.97 | 0.033 ± 0.001 |

| LR3G0.5 | 35.53 ± 0.55 | 1064.35 ± 20.10 | 0.035 ± 0.001 |

| LR3G1.0 | 36.71 ± 0.42 | 1079.57 ± 8.66 | 0.035 ± 0.001 |

| LR3G1.5 | 38.68 ± 0.24 | 1135.30 ± 6.65 | 0.030 ± 0.001 |

| FEM Parameters | |

|---|---|

| Contact properties | Loading tip—specimen: Frictionless, Hard contact |

| Mesh properties | C3D8R: A 8-node linear brick |

| Stress dependence | Isotropic |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irez, A.B.; Bayraktar, E.; Miskioglu, I. Fracture Toughness Analysis of Epoxy-Recycled Rubber-Based Composite Reinforced with Graphene Nanoplatelets for Structural Applications in Automotive and Aeronautics. Polymers 2020, 12, 448. https://doi.org/10.3390/polym12020448

Irez AB, Bayraktar E, Miskioglu I. Fracture Toughness Analysis of Epoxy-Recycled Rubber-Based Composite Reinforced with Graphene Nanoplatelets for Structural Applications in Automotive and Aeronautics. Polymers. 2020; 12(2):448. https://doi.org/10.3390/polym12020448

Chicago/Turabian StyleIrez, Alaeddin Burak, Emin Bayraktar, and Ibrahim Miskioglu. 2020. "Fracture Toughness Analysis of Epoxy-Recycled Rubber-Based Composite Reinforced with Graphene Nanoplatelets for Structural Applications in Automotive and Aeronautics" Polymers 12, no. 2: 448. https://doi.org/10.3390/polym12020448

APA StyleIrez, A. B., Bayraktar, E., & Miskioglu, I. (2020). Fracture Toughness Analysis of Epoxy-Recycled Rubber-Based Composite Reinforced with Graphene Nanoplatelets for Structural Applications in Automotive and Aeronautics. Polymers, 12(2), 448. https://doi.org/10.3390/polym12020448