Optimization of Preparation Conditions for Side-Emitting Polymer Optical Fibers Using Response Surface Methodology

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Central Composite Design (CCD)

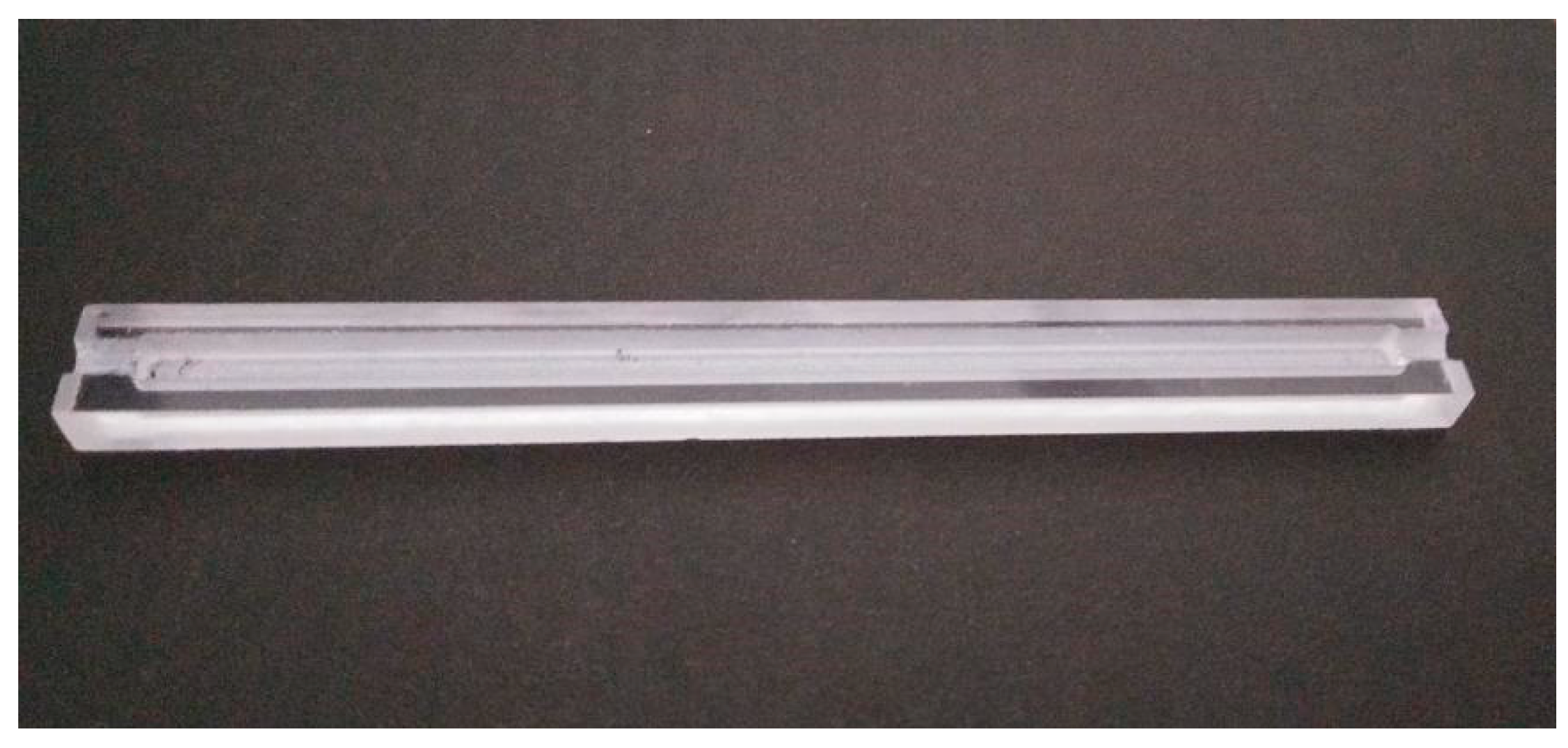

2.3. Preparation of SPOFs

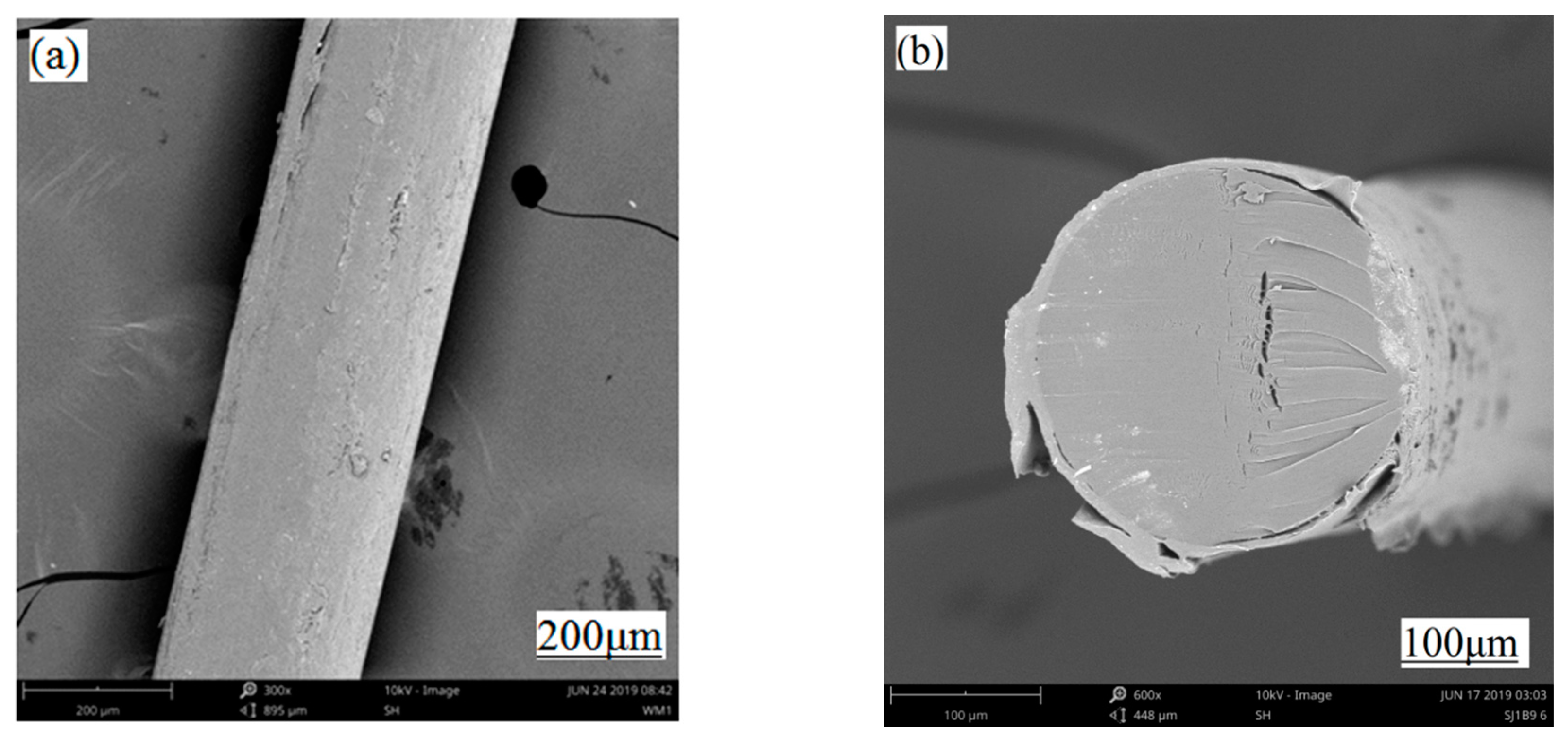

2.4. SEM Text of SPOFs

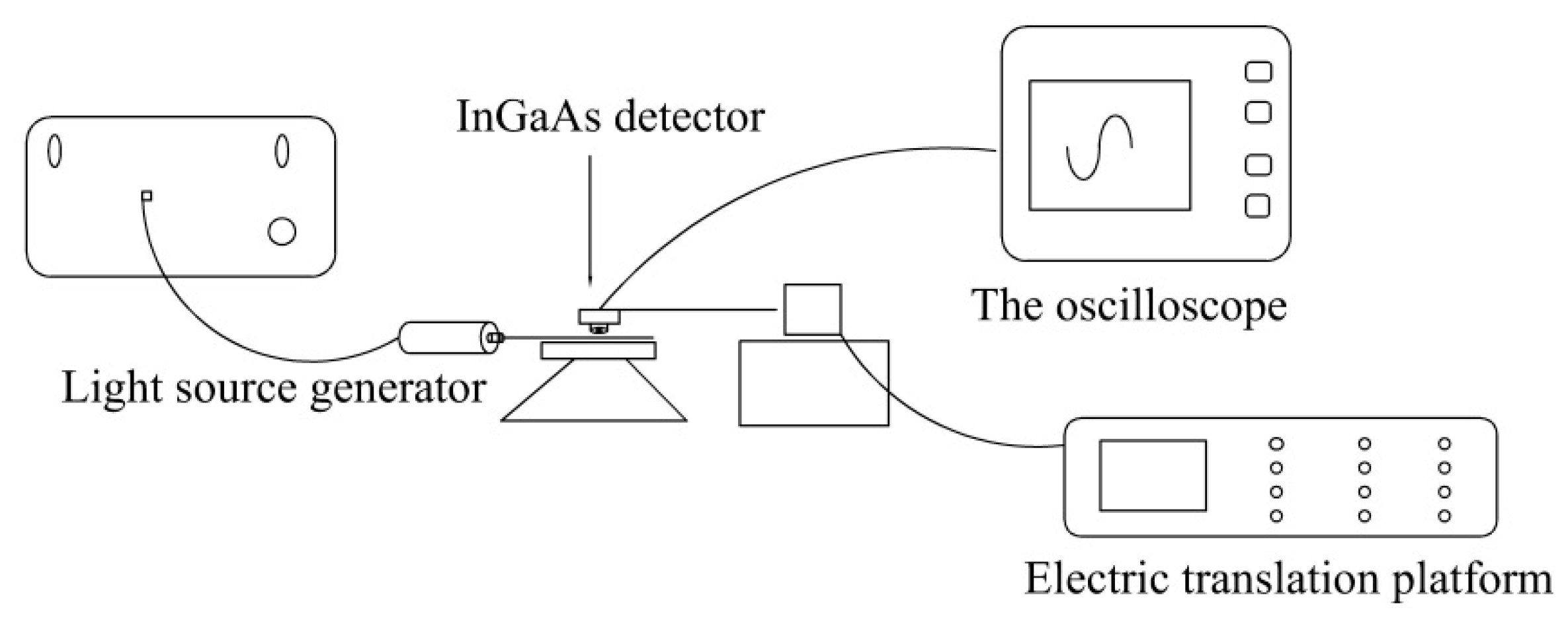

2.5. Illumination Intensity Test

2.6. Breaking Strength Test

2.7. Rigidity Test

3. Results and Discussion

3.1. Model Fitting and Statistical Analysis

3.2. Data Processing

3.3. Application of Central Composite Model

3.4. Statistical Analysis

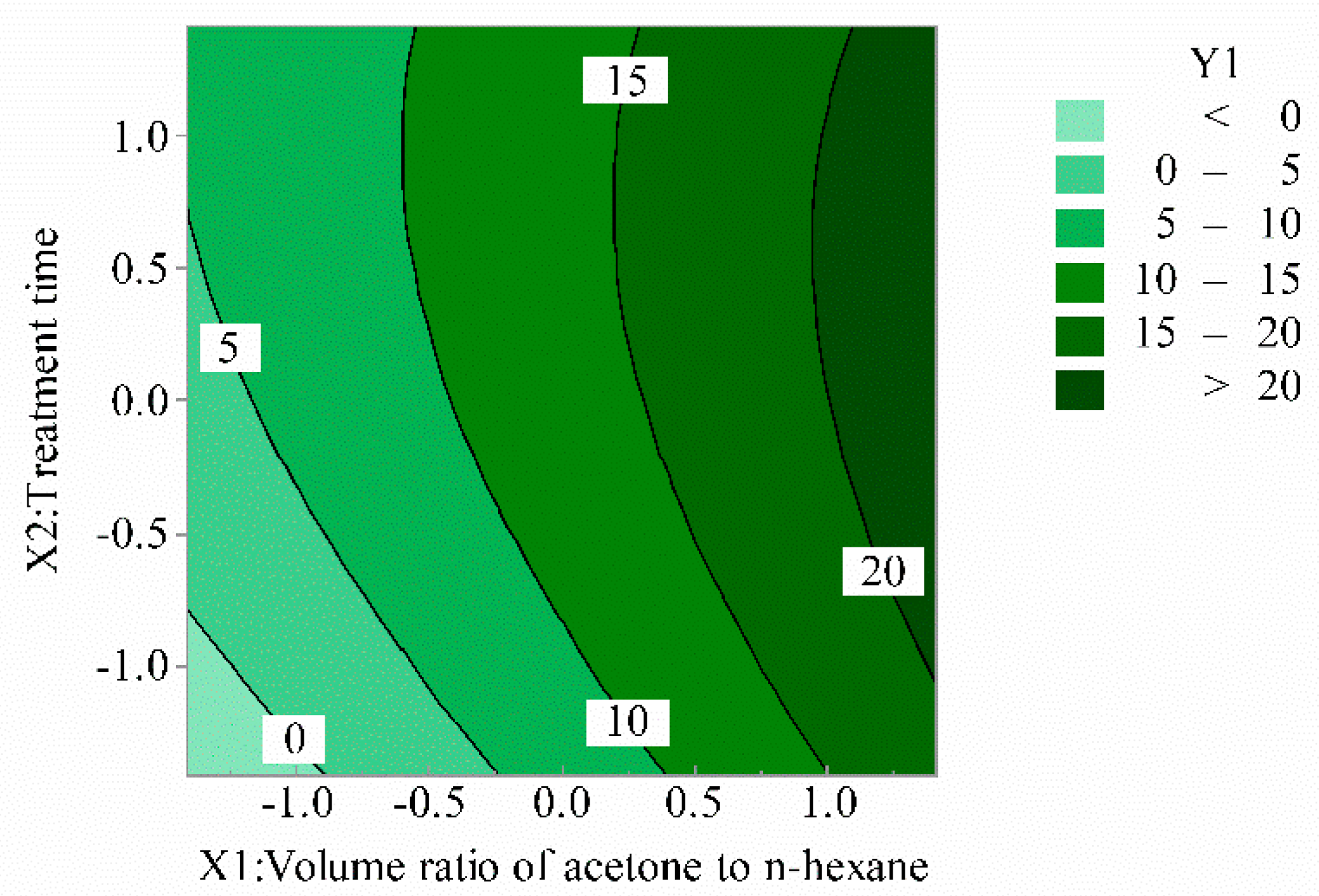

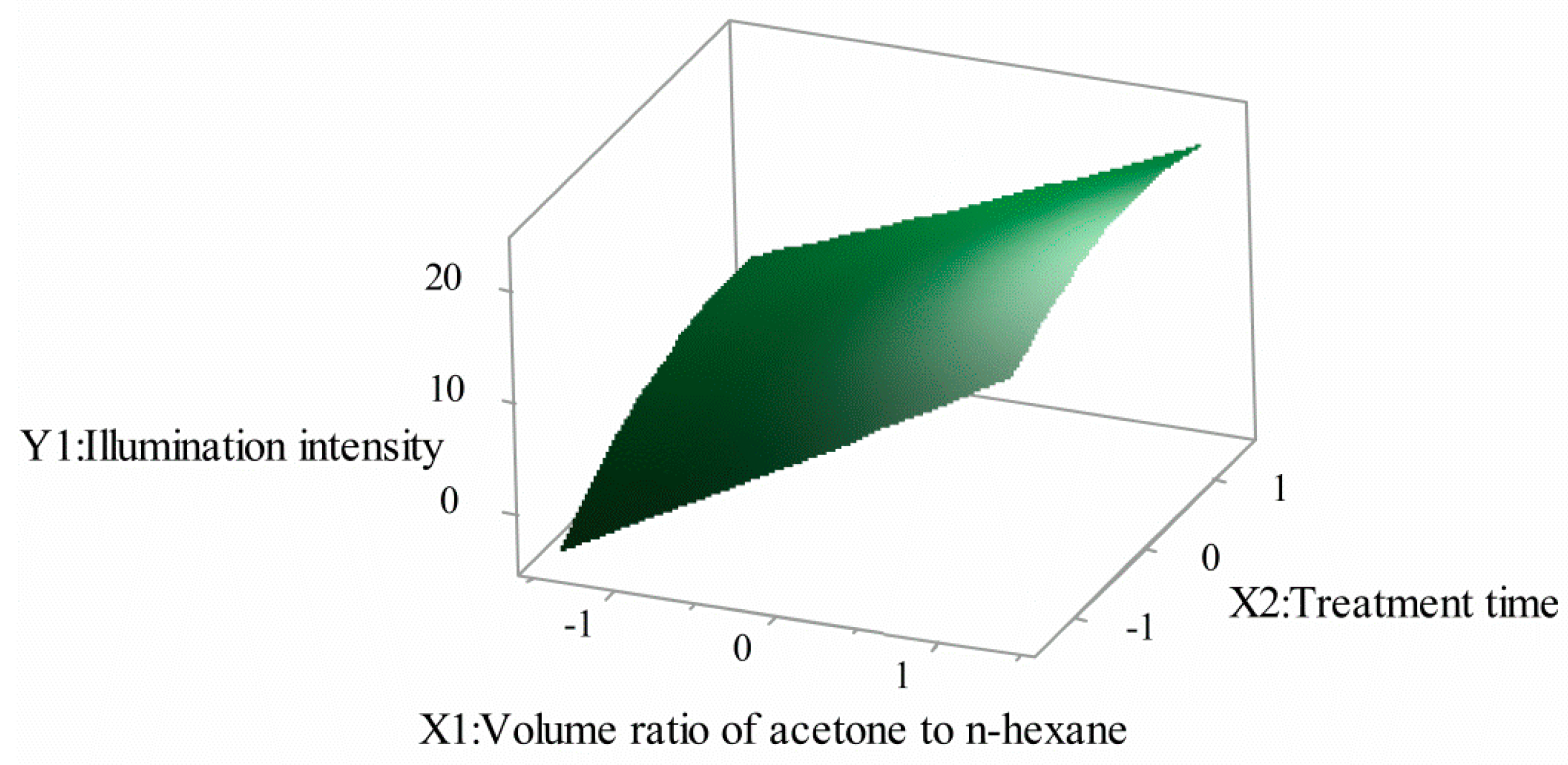

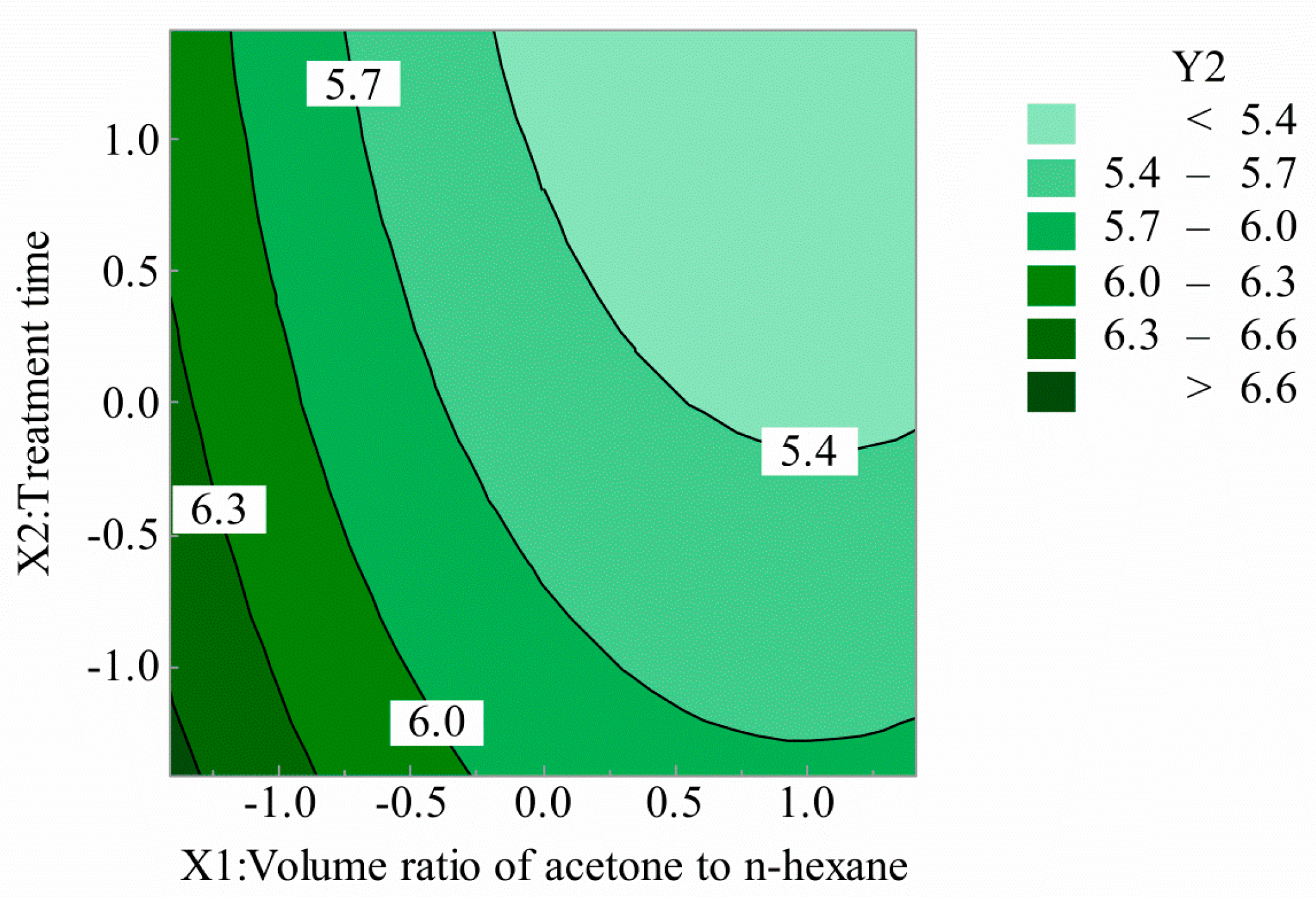

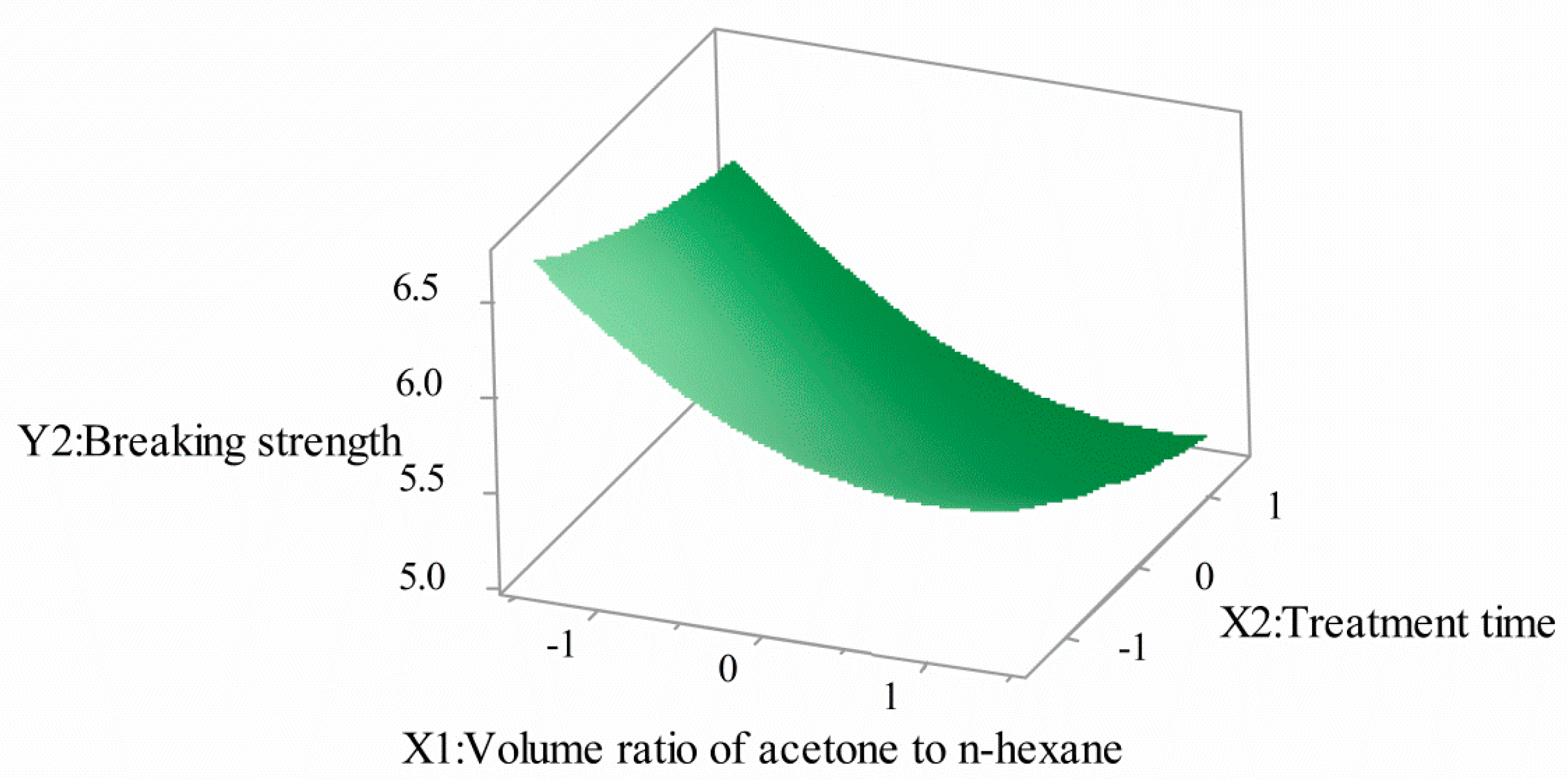

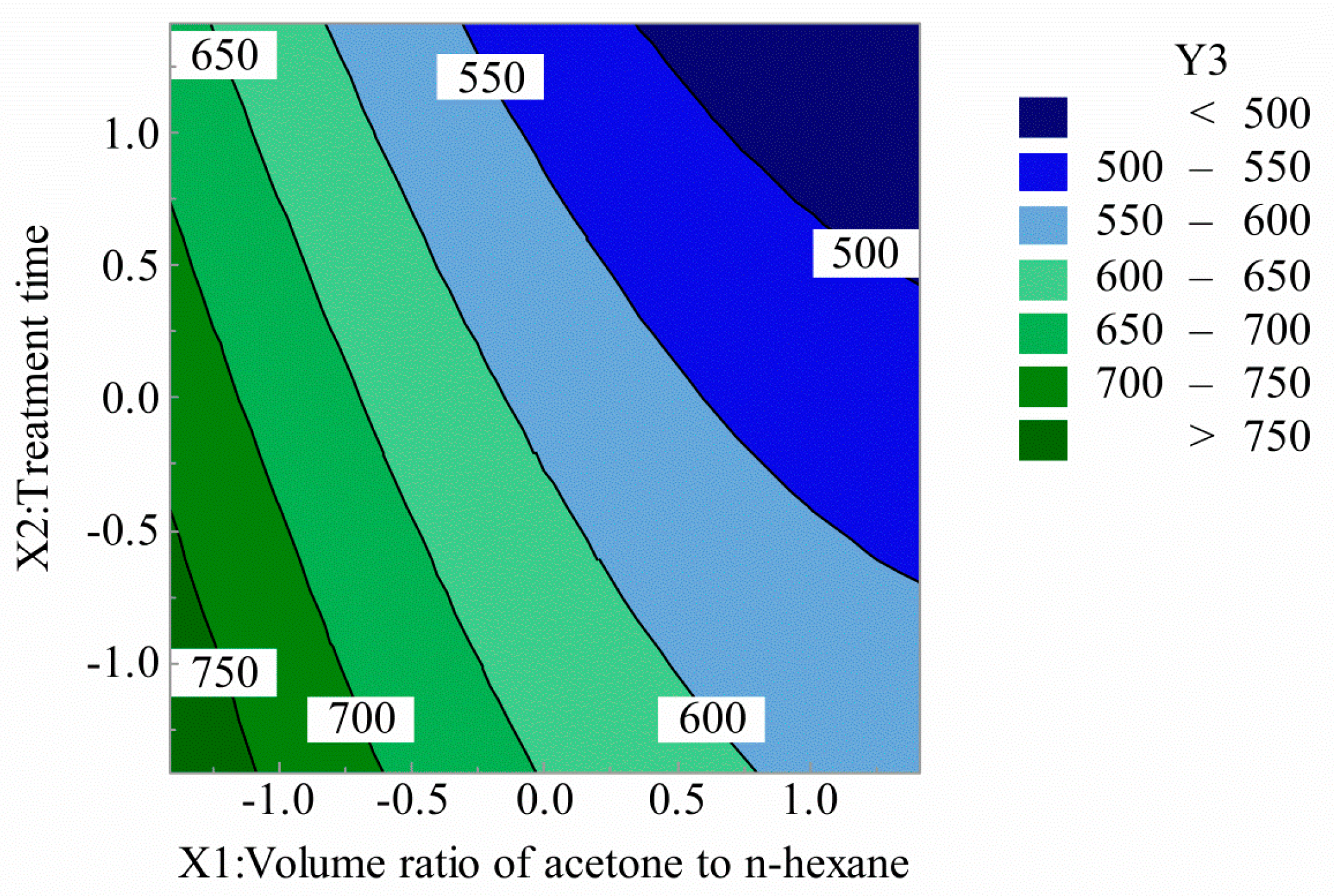

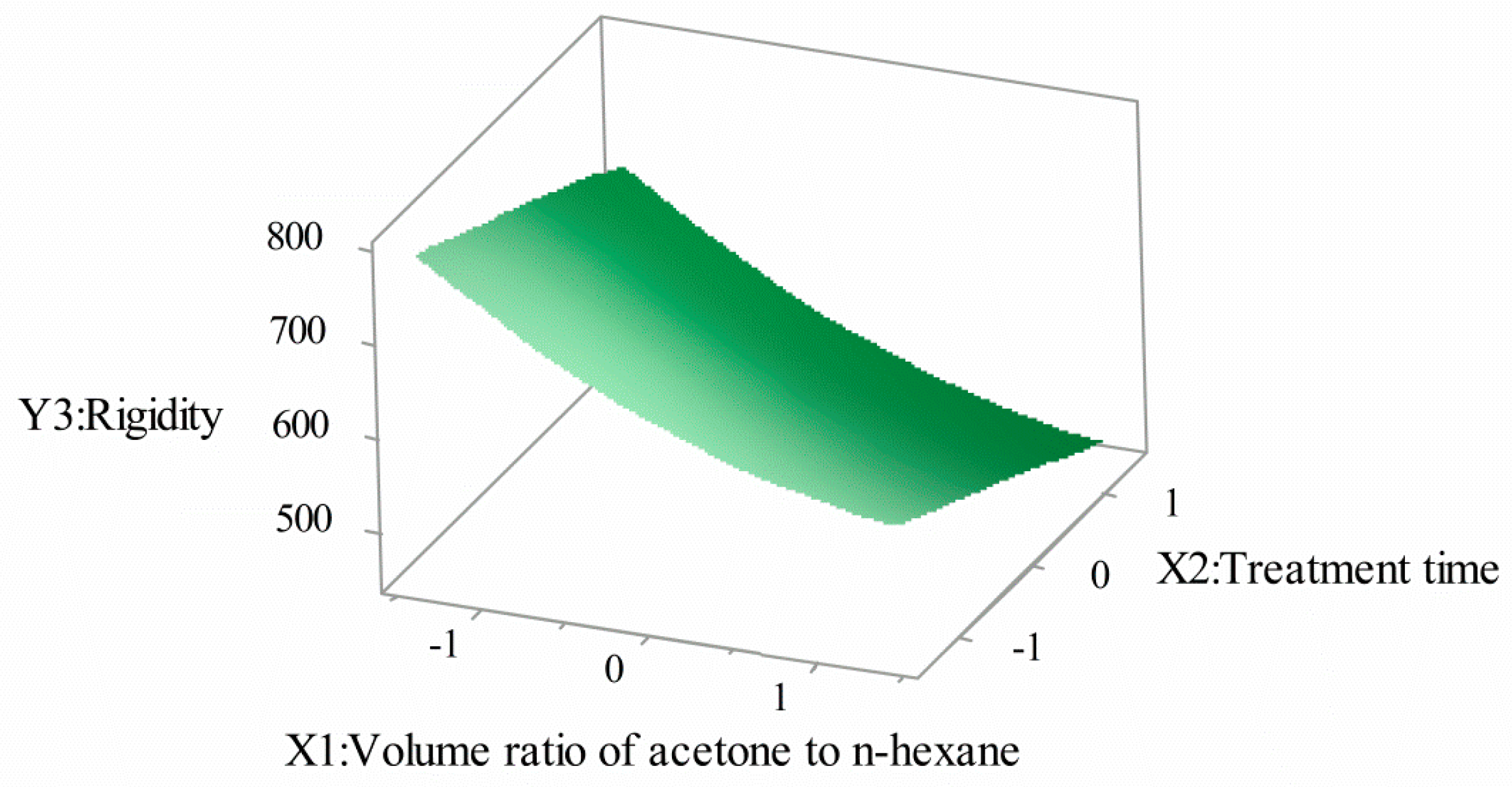

3.5. Effects of Model Parameters and Their Interactions

3.6. Optimal Conditions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Leal-Junior, A.; Avellar, L.; Frizera, A.; Marques, C. Smart textiles for multimodal wearable sensing using highly stretchable multiplexed optical fiber system. Sci. Rep. 2020, 10, 13867. [Google Scholar] [CrossRef] [PubMed]

- Vicentini, C.; Carpentier, O.; Tylcz, J.-B.; Mortier, L.; Betrouni, N.; Mordon, S. Treatment of a vulvar Paget disease by photodynamic therapy with a new light emitting fabric based device. Photodiagn. Photodyn. 2017, 17, A64. [Google Scholar] [CrossRef] [Green Version]

- Costa-Almeida, R.; Bogas, D.; José, R.F. Near-Infrared Radiation-Based Mild Photohyperthermia Therapy of Non-Melanoma Skin Cancer with PEGylated Reduced Nanographene Oxide. Polymers 2020, 12, 1840. [Google Scholar] [CrossRef] [PubMed]

- Journot, C.; Nicolle, L.; Lavanchy, Y.; Gerber-Lemaire, S. Selection of Water-Soluble Chitosan by Microwave-Assisted Degradation and pH-Controlled Precipitation. Polymers 2020, 12, 1274. [Google Scholar] [CrossRef]

- Zhou, W.; Yang, G.; Ni, X. Recent Advances in Crosslinked Nanogel for Multimodal Imaging and Cancer Therapy. Polymers 2020, 12, 1902. [Google Scholar] [CrossRef]

- Wang, D.; Sheng, B.; Peng, L. Flexible and Optical Fiber Sensors Composited by Graphene and PDMS for Motion Detection. Polymers 2019, 11, 1433. [Google Scholar] [CrossRef] [Green Version]

- Mishra, R.; Shukla, A.; Kremenakova, D.; Militky, J. Surface modification of polymer optical fibers for enhanced side emission behavior. Fiber. Polym. 2013, 14, 1468. [Google Scholar] [CrossRef]

- Yuan, J.; Hua, L.G.; Dong, Y.Z. Preparing principle and applications of side glowing optical fiber. Opt. Fiber. Technol. 2000, 8, 185. [Google Scholar]

- Rukhlenko, I.D.; Farajikhah, S.; Lilley, C.; Georgis, A.; Large, M.; Fleming, S. Performance Optimization of Polymer Fibre Actuators for Soft Robotics. Polymers 2020, 12, 454. [Google Scholar] [CrossRef] [Green Version]

- Merchant, D.F.; Scully, P.J.; Schmit, N.F. Chemical tapering of polymer optical fibre. Sens. Actuat. B Chem. 1999, 76, 365. [Google Scholar] [CrossRef]

- Batumalay, M.; Harun, S.W.; Ahmad, F. Tapered Plastic Optical Fiber Coated with Graphene for Uric Acid Detection. IEEE. Sens. J. 2014, 14, 1704. [Google Scholar] [CrossRef]

- Rajan, G.; Liu, B.; Luo, Y. High Sensitivity Force and Pressure Measurements Using Etched Singlemode Polymer Fiber Bragg Gratings. IEEE Sens. J. 2013, 13, 1794. [Google Scholar] [CrossRef]

- Bhowmik, K.; Peng, G.D.; Luo, Y. High Intrinsic Sensitivity Etched Polymer Fiber Bragg Grating Pair for Simultaneous Strain and Temperature Measurements. IEEE. Sens. J. 2016, 16, 2453. [Google Scholar] [CrossRef] [Green Version]

- Vijayan, A.; Gawli, S.; Kulkarni, A. An optical fiber weighing sensor based on bending. Meas. Sci. Technol. 2008, 19, 105302. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, F.; Dong, L.; Li, Z.; Chen, L.; He, X.; Gong, J.; Zhang, J.; Li, Q. Design and Optimization of Flexible Polypyrrole/Bacterial Cellulose Conductive Nanocomposites Using Response Surface Methodology. Polymers 2019, 11, 960. [Google Scholar] [CrossRef] [Green Version]

- Karacan, F.; Ozden, U.; Karacan, S. Optimization of manufacturing conditions for activated carbon from Turkish lignite by chemical activation using response surface methodology. Appl. Therm. Eng. 2007, 27, 1212. [Google Scholar] [CrossRef]

- Kunnan Singh, J.S.; Ching, Y.C.; Abdullah, L.C.; Ching, K.Y.; Razali, S.; Gan, S.N. Optimization of Mechanical Properties for Polyoxymethylene/Glass Fiber/Polytetrafluoroethylene Composites Using Response Surface Methodology. Polymers 2018, 10, 338. [Google Scholar] [CrossRef] [Green Version]

- Montgomery, D.C. Design and analysis of experiments, 8th edition. Environ. Prog. Sustain. 2013, 32, 8. [Google Scholar]

- Azargohar, R.; Dalai, A.K. Production of activated carbon from Luscar char: Experimental and modeling studies. Micropor. Mesopor. Mat. 2005, 85, 219. [Google Scholar] [CrossRef]

- Mousavi, S.J.; Parvini, M.; Ghorbani, M. Experimental design data for the zinc ions adsorption based on mesoporous modified chitosan using central composite design method. Carbohydr. Polym. 2018, 188, 197. [Google Scholar] [CrossRef]

- Beckers, M.; Vad, T.; Mohr, B.; Weise, B.A.; Steinmann, W.; Gries, T.; Seide, G.; Kentzinger, E.; Bunge, C.-A. Novel Melt-Spun Polymer-Optical Poly (methyl methacrylate) Fibers Studied by Small-Angle X-ray Scattering. Polymers 2017, 9, 60. [Google Scholar] [CrossRef] [Green Version]

- Ayesta, I.; Zubia, J.; Arrue, J.; Illarramendi, M.A.; Azkune, M. Characterization of Chromatic Dispersion and Refractive Index of Polymer Optical Fibers. Polymers 2017, 9, 730. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharifi, H.; Zabihzadeh, S.M.; Ghorbani, M. The application of response surface methodology on the synthesis of conductive polyaniline/cellulosic fiber nanocomposites. Carbohydr. Polym. 2018, 194, 384. [Google Scholar] [CrossRef] [PubMed]

- Torrades, F.; García-Montaño, J. Using central composite experimental design to optimize the degradation of real dye wastewater by Fenton and photo-Fenton reactions. Dyes. Pigment. 2014, 100, 184. [Google Scholar] [CrossRef] [Green Version]

- Tripathi, P.; Srivastava, V.C.; Kumar, A. Optimization of an azo dye batch adsorption parameters using Box–Behnken design. Desalination 2009, 249, 1273. [Google Scholar] [CrossRef]

- Bowerman, B.L. Statistical Design and Analysis of Experiments with Applications to Engineering and Science. J. Am. Stat. Assoc. 2012, 33, 105. [Google Scholar]

- Krzysztof, W.; Narowski, P. A Strategy for Problem Solving of Filling Imbalance in Geometrically Balanced Injection Molds. Polymers 2020, 12, 805. [Google Scholar]

- Abd, S.; Salah, H.; Nachida, M. Using Central Composite Experimental Design to Optimize the Degradation of Tylosin from Aqueous Solution by Photo-Fenton Reaction. Materials 2016, 9, 428. [Google Scholar]

- Ayesta, I.; Illarramendi, M.A.; Arrue, J.; Parola, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Optical Characterization of Doped Thermoplastic and Thermosetting Polymer-Optical-Fibers. Polymers 2017, 9, 90. [Google Scholar] [CrossRef]

| Project | Parameter |

|---|---|

| Fiber diameter (mm) | 0.250 |

| Fiber cladding thickness (mm) | 0.025 |

| Numerical aperture | 0.5 |

| Maximum transmission loss (dB/km) | 250 |

| Working temperature (℃) | −50–(+70) |

| Factor | Range and Levels | ||||

|---|---|---|---|---|---|

| Independent variable | −α | −1 | 0 | 1 | α |

| Volume ratio of acetone to n-hexane (X1) | 0.3 | 0.5 | 1 | 1.5 | 1.7 |

| Treatment time (X2, s) | 1.5 | 4 | 10 | 16 | 18.5 |

| Run | Volume Ratio of Acetone to n-hexane, X1 | Treatment Time, X2(s) | Illumination Intensity, Y1(mV) | Breaking Strength, Y2(N) | Rigidity, Y3(N·mm2) |

|---|---|---|---|---|---|

| 1 | 1(0) | 10(0) | 7.064 | 5.481 | 582.512 |

| 2 | 0.5(−1) | 16(1) | 4.374 | 5.876 | 659.076 |

| 3 | 1.5(1) | 4(−1) | 6.869 | 5.584 | 568.832 |

| 4 | 0.3(−1.414) | 10(0) | 2.775 | 6.396 | 726.526 |

| 5 | 1(0) | 10(0) | 6.938 | 5.601 | 596.322 |

| 6 | 1(0) | 10(0) | 6.670 | 5.510 | 590.384 |

| 7 | 1(0) | 18.5(1.414) | 7.190 | 5.355 | 496.218 |

| 8 | 0.5(−1) | 4(−1) | 2.670 | 6.249 | 715.862 |

| 9 | 1.5(1) | 16(1) | 7.615 | 5.133 | 508.738 |

| 10 | 1(0) | 1.5(−1.414) | 4.281 | 5.930 | 660.651 |

| 11 | 1(0) | 10(0) | 7.159 | 5.593 | 590.010 |

| 12 | 1.7(1.414) | 10(0) | 9.238 | 5.409 | 510.682 |

| 13 | 10(0) | 10(0) | 7.000 | 5.536 | 582.214 |

| Source | Y1 | Y2 | Y3 | |||

|---|---|---|---|---|---|---|

| Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | |

| X1 | 6.922 | <0.001 | −0.351 | <0.001 | −75.331 | <0.001 |

| X2 | 2.251 | <0.001 | −0.205 | <0.001 | −43.683 | <0.001 |

| X12 | 0.163 | 0.568 | 0.164 | <0.001 | 18.812 | 0.028 |

| X22 | −1.400 | 0.001 | 0.034 | 0.128 | −1.270 | 0.857 |

| X1X2 | −0.680 | 0.101 | −0.020 | 0.474 | −0.847 | 0.929 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | Prob > F |

|---|---|---|---|---|---|

| Y1 (Illumination intensity, mV) | |||||

| Model | 5 | 440.246 | 88.049 | 169.832 | <0.001 |

| Linear | 2 | 423.909 | 211.955 | 408.807 | <0.001 |

| Square | 2 | 14.484 | 7.242 | 13.972 | 0.004 |

| Two-Way Interaction | 1 | 1.852 | 1.852 | 3.574 | 0.101 |

| R2 = 0.992 | |||||

| R2(adj) = 0.986 | |||||

| Y2 (Breaking strength, N) | |||||

| Model | 5 | 1.507 | 0.301 | 113.648 | <0.001 |

| Linear | 2 | 1.318 | 0.659 | 248.487 | <0.001 |

| Square | 2 | 0.187 | 0.094 | 35.340 | <0.001 |

| Two-Way Interaction | 1 | 0.002 | 0.002 | 0.573 | 0.474 |

| R2 = 0.988 | |||||

| R2(adj) = 0.979 | |||||

| Y3 (Rigidity, N·mm2) | |||||

| Model | 5 | 63,218.912 | 12,643.836 | 39.346 | <0.001 |

| Linear | 2 | 60,655.943 | 30,327.872 | 94.382 | <0.001 |

| Square | 2 | 2560.324 | 1280.137 | 3.982 | 0.070 |

| Two-Way Interaction | 1 | 2.800 | 2.800 | 0.001 | 0.929 |

| R2 = 0.966 | |||||

| R2(adj) = 0.941 |

| Variable | Setting | Response | Fit | SE Fit | 95% CI | 95% PI |

|---|---|---|---|---|---|---|

| Y1 | 19.339 | 0.932 | (17.135, 21.542) | (16.554, 22.123) | ||

| Y2 | 5.707 | 0.067 | (5.550, 5.865) | (5.508, 5.907) | ||

| Y3 | 572.013 | 23.218 | (517.132, 626.841) | (502.557, 641.326) | ||

| X1 | 1.703 | |||||

| X2 | 2.716 |

| Parameter | Optimum Value | Response | Predictive | Experimental |

|---|---|---|---|---|

| X1 | 1.703 | Y1 | 19.339 | 18.862 |

| X2 | 2.716 | Y2 | 5.707 | 5.736 |

| Y3 | 572.013 | 563.647 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Yang, K.; Zhang, C. Optimization of Preparation Conditions for Side-Emitting Polymer Optical Fibers Using Response Surface Methodology. Polymers 2020, 12, 3062. https://doi.org/10.3390/polym12123062

Hu X, Yang K, Zhang C. Optimization of Preparation Conditions for Side-Emitting Polymer Optical Fibers Using Response Surface Methodology. Polymers. 2020; 12(12):3062. https://doi.org/10.3390/polym12123062

Chicago/Turabian StyleHu, Xianjin, Kun Yang, and Cheng Zhang. 2020. "Optimization of Preparation Conditions for Side-Emitting Polymer Optical Fibers Using Response Surface Methodology" Polymers 12, no. 12: 3062. https://doi.org/10.3390/polym12123062

APA StyleHu, X., Yang, K., & Zhang, C. (2020). Optimization of Preparation Conditions for Side-Emitting Polymer Optical Fibers Using Response Surface Methodology. Polymers, 12(12), 3062. https://doi.org/10.3390/polym12123062