The Investigation of the Silica-Reinforced Rubber Polymers with the Methoxy Type Silane Coupling Agents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

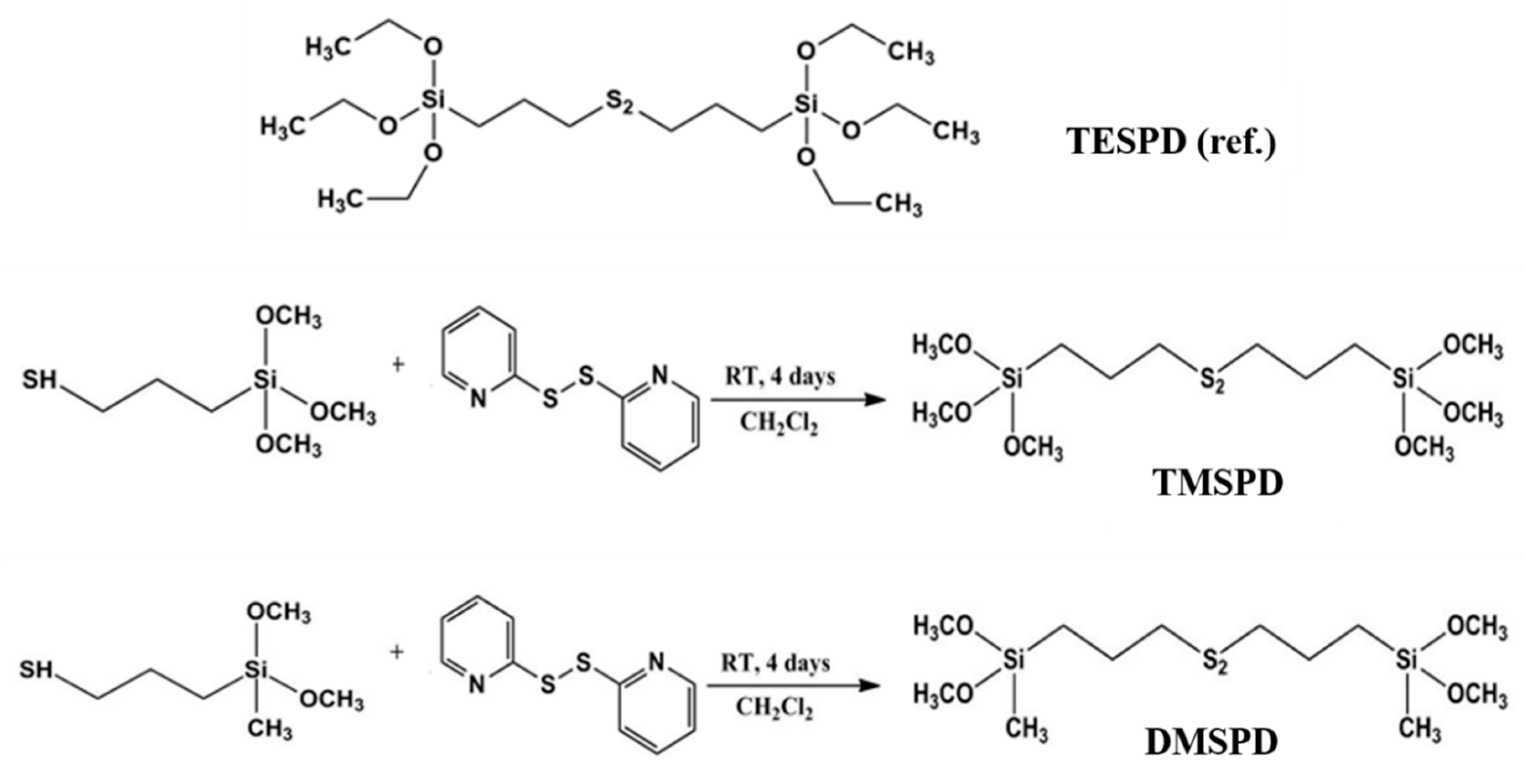

2.2. Synthesis of SCAs

2.2.1. Synthesis of 3,3’-Bis(trimethoxysilylpropyl) Disulfide (TMSPD)

2.2.2. Synthesis of 3,3’-Bis(dimethoxymethylsilylpropyl) Disulfide (DMSPD)

2.3. Preparation of Silica/SBR Composites

2.3.1. Preparation of the Materials

2.3.2. Preparation of WMB Silica/SBR Composites

2.3.3. Preparation of DMB Silica/SBR Composites

2.4. Measurement

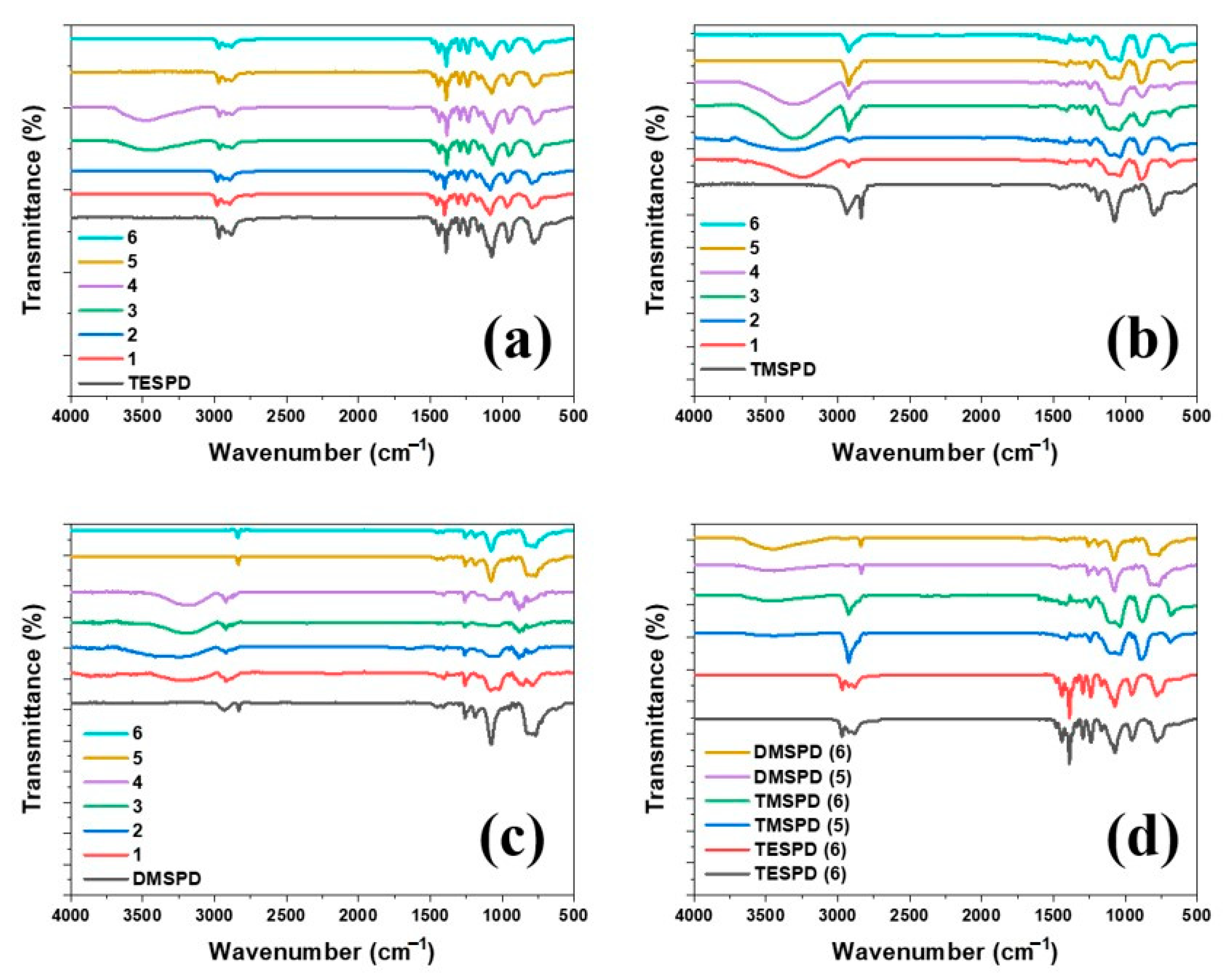

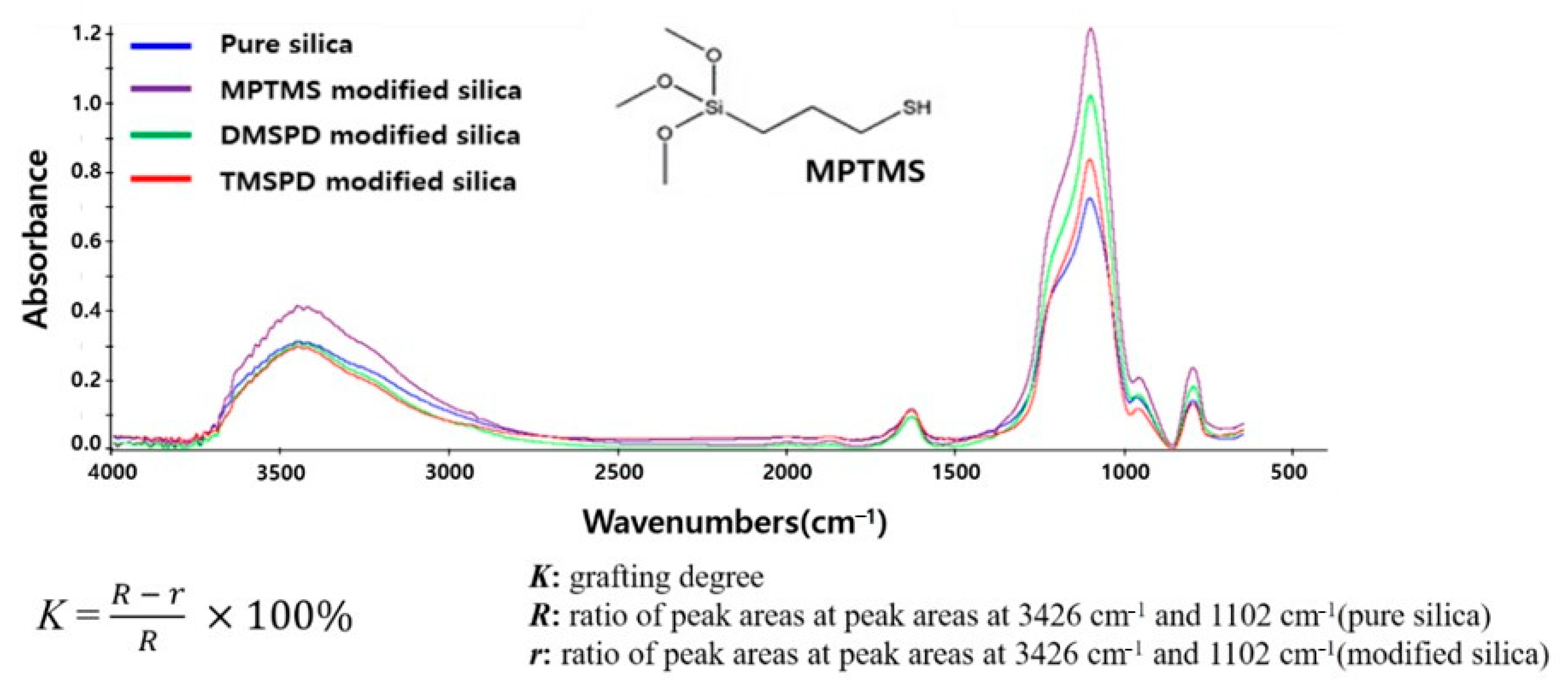

2.4.1. FTIR Spectroscopic Analysis

2.4.2. Gel Permeation Chromatography (GPC)

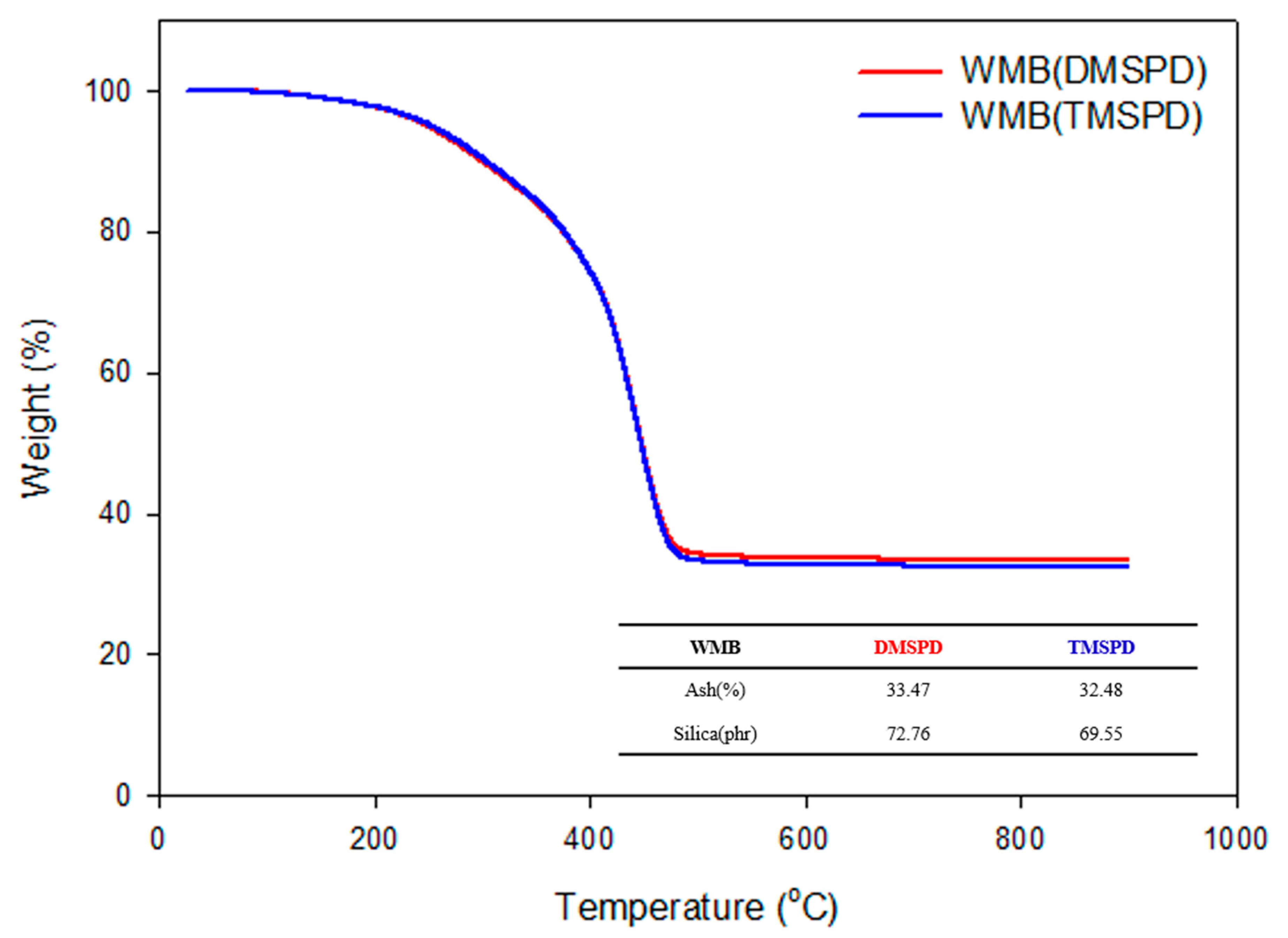

2.4.3. Thermogravimetric Analysis (TGA)

2.4.4. Deutsches Institut für Normung (DIN) Abrasion Test

2.4.5. Mechanical Properties

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ko, J.Y.; Prakashan, K.; Kim, J.K. New silane coupling agents for silica tire tread compounds. J. Elastomers Plast. 2012, 44, 549–562. [Google Scholar] [CrossRef]

- Zafarmehrabian, R.; Gangali, S.T.; Ghoreishy, M.H.R.; Davallu, M. The Effects of Silica/Carbon Black Ratio on the Dynamic Properties of the Tread compounds in Truck Tires. E-J. Chem. 2012, 9, 1102–1112. [Google Scholar] [CrossRef]

- Hao, P.T.; Ismail, H.; Hashim, A.S. Study of two types of styrene butadiene rubber in tire tread compounds. Polym. Test. 2001, 20, 539–544. [Google Scholar] [CrossRef]

- Ikeda, Y.; Katoh, A.; Shimanuki, J.; Kohjiya, S. Nano-Structural Observation of in situ Silica in Natural Rubber Matrix by Three Dimensional Transmission Electron Microscopy. Macromol. Rapid Commun. 2004, 25, 1186–1190. [Google Scholar] [CrossRef]

- Park, S.-J.; Jin, S.-Y.; Kaang, S. Influence of thermal treatment of nano-scaled silica on interfacial adhesion properties of the silica/rubber compounding. Mater. Sci. Eng. A 2005, 398, 137–141. [Google Scholar] [CrossRef]

- Tomita, Y.; Nakata, S.; Honma, T.; Yashiro, K. Deformation behavior of silica-filled rubber with coupling agents under monotonic and cyclic straining. Int. J. Mech. Sci. 2014, 86, 7–17. [Google Scholar] [CrossRef]

- Sarkawi, S.; Dierkes, W.K.; Noordermeer, J.W. Elucidation of filler-to-filler and filler-to-rubber interactions in silica-reinforced natural rubber by TEM Network Visualization. Eur. Polym. J. 2014, 54, 118–127. [Google Scholar] [CrossRef]

- Rattanasom, N.; Saowapark, T.; Deeprasertkul, C. Reinforcement of natural rubber with silica/carbon black hybrid filler. Polym. Test. 2007, 26, 369–377. [Google Scholar] [CrossRef]

- Reuvekamp, L.A.E.M.; Brinke, J.W.T.; Van Swaaij, P.J.; Noordermeer, J.W. Effects of Time and Temperature on the Reaction of Tespt Silane Coupling Agent During Mixing with Silica Filler and Tire Rubber. Rubber Chem. Technol. 2002, 75, 187–198. [Google Scholar] [CrossRef]

- Sengloyluan, K.; Sahakaro, K.; Dierkes, W.K.; Noordermeer, J.W. Silica-reinforced tire tread compounds compatibilized by using epoxidized natural rubber. Eur. Polym. J. 2014, 51, 69–79. [Google Scholar] [CrossRef]

- Prasertsri, S.; Rattanasom, N. Mechanical and damping properties of silica/natural rubber composites prepared from latex system. Polym. Test. 2011, 30, 515–526. [Google Scholar] [CrossRef]

- Zou, H.; Wu, S.; Shen, J. Polymer/Silica Nanocomposites: Preparation, Characterization, Properties, and Applications. Chem. Rev. 2008, 108, 3893–3957. [Google Scholar] [CrossRef] [PubMed]

- Bukleski, M.; Ivanovski, V.; Hey-Hawkins, E. A direct method of quantification of maximal chemisorption of 3-aminopropylsilyl groups on silica gel using DRIFT spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 149, 69–74. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Hill, C.A.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Sae-Oui, P.; Sirisinha, C.; Thepsuwan, U.; Hatthapanit, K. Comparison of reinforcing efficiency between Si-69 and Si-264 in a conventional vulcanization system. Polym. Test. 2004, 23, 871–879. [Google Scholar] [CrossRef]

- Pere, E.; Cardy, H.; Latour, V.; Lacombe, S. Low-temperature reaction of trialkoxysilanes on silica gel: A mild and controlled method for modifying silica surfaces. J. Colloid Interface Sci. 2005, 281, 410–416. [Google Scholar] [CrossRef]

- Chen, Z.R.; Araki, S.; Cole, W.M.; Hergenrother, W.; Warren, S. U.S. Patent 7312271, 25 December 2007. Available online: https://patents.google.com/patent/US7312271B2/en (accessed on 19 December 2019).

- Wallen, P.J.; Bowman, G.C.; Colvin, H.A.; Hardiman, C.J.; Reyna, J.E.R. U.S. Patent 8357733, 22 January 2013. Available online: https://patents.google.com/patent/US8357733B2/en (accessed on 19 December 2019).

- Mun, H.; Hwang, K.; Yu, E.; Kim, W.; Kim, W. Glycidyl Methacrylate-Emulsion Styrene Butadiene Rubber (GMA-ESBR)/Silica Wet Masterbatch Compound. Polymers 2019, 11, 1000. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Han, B.; Liu, L.; Zhang, F.; Zhang, L.; Wen, S.; Lu, Y.; Yang, H.; Shen, J. Surface modification of silica by two-step method and properties of solution styrene butadiene rubber (SSBR) nanocomposites filled with modified silica. Compos. Sci. Technol. 2013, 88, 69–75. [Google Scholar] [CrossRef]

- Li, Y.; Han, B.; Wen, S.; Lu, Y.; Yang, H.; Zhang, L.; Liu, L. Effect of the temperature on surface modification of silica and properties of modified silica filled rubber composites. Compos. Part A Appl. Sci. Manuf. 2014, 62, 52–59. [Google Scholar] [CrossRef]

- Park, J.; Kim, K.; Lim, S.-H.; Hong, Y.; Paik, H.-J.; Kim, W. Functionalized Emulsion Styrene-Butadiene Rubber Containing Diethylaminoethyl Methacrylate for Silica Filled Compounds. Elastomers Compos. 2015, 50, 110–118. [Google Scholar] [CrossRef] [Green Version]

- Rooj, S.; Das, A.; Stöckelhuber, K.W.; Mukhopadhyay, N.; Bhattacharyya, A.R.; Jehnichen, D.; Heinrich, G. Pre-intercalation of long chain fatty acid in the interlayer space of layered silicates and preparation of montmorillonite/natural rubber nanocomposites. Appl. Clay Sci. 2012, 67, 50–56. [Google Scholar] [CrossRef]

- Kim, D.-W.; Kim, C.-H.; Jung, H.-K.; Kang, Y.-G. The Effect of Glyceride Modified by Fatty Acid on Mechanical Properties of Silica filled Rubber Compounds. Elastomers Compos. 2013, 48, 114–124. [Google Scholar] [CrossRef]

- Cichomski, E.M. Silica-Silane Reinforced Passenger Car Tire Treads: Effect of Silica Morphology, Silica-Polymer Interface Structure and Rubber Matrix Network on Tire-Performance Indicators. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, May 2015. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, Y.; Honda, H.; Harada, A.; Fujii, S.; Nagata, K. Mechanical properties of silane-treated, silica-particle-filled polyisoprene rubber composites: Effects of the loading amount and alkoxy group numbers of a silane coupling agent containing mercapto groups. J. Appl. Polym. Sci. 2009, 113, 1507–1514. [Google Scholar] [CrossRef]

| * Phr | T-1 (DMB-TESPD) | T-2 (DMB-DMSPD) | T-3 (DMB-TMSPD) | T-4 (WMB-DMSPD) | T-5 (WMB-TMSPD) |

|---|---|---|---|---|---|

| Styrene-butadiene rubber (SBR)-1723 | 100 | 100 | 100 | 100 | 100 |

| TDAE oil | 37.5 | 37.5 | 37.5 | 37.5 | 37.5 |

| Dried silica cake | 70 | 70 | 70 | ||

| SCA | SI-75: 7 | DMSPD: 7 | TMSPD: 7 | ||

| DMSPD -modified silica | 77 | ||||

| TMSPD -modified silica | - | 77 | |||

| ZnO | 3 | 3 | 3 | 3 | 3 |

| S/A | 2 | 2 | 2 | 2 | 2 |

| 6PPD | 1 | 1 | 1 | 1 | 1 |

| FMB | |||||

| Sulfur | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| CBS | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| DPG | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Sample | SCA (g) | IPA (g) | H2O (g) | Acetic acid (g) |

|---|---|---|---|---|

| 1 | 0.5 | 4 | 96 | 0.7 |

| 2 | 20 | 80 | 0.7 | |

| 3 | 80 | 20 | 0.7 | |

| 4 | 96 | 4 | 0.7 | |

| 5 | 20 | 80 | 0 | |

| 6 | 80 | 20 | 0 |

| Pure | MPTMS | DMSPD | TMSPD | |

|---|---|---|---|---|

| R | 0.390 | |||

| r | 0.329 | 0.283 | 0.314 | |

| K (grafting degree) | 0 | 15.6 | 27.4 | 19.5 |

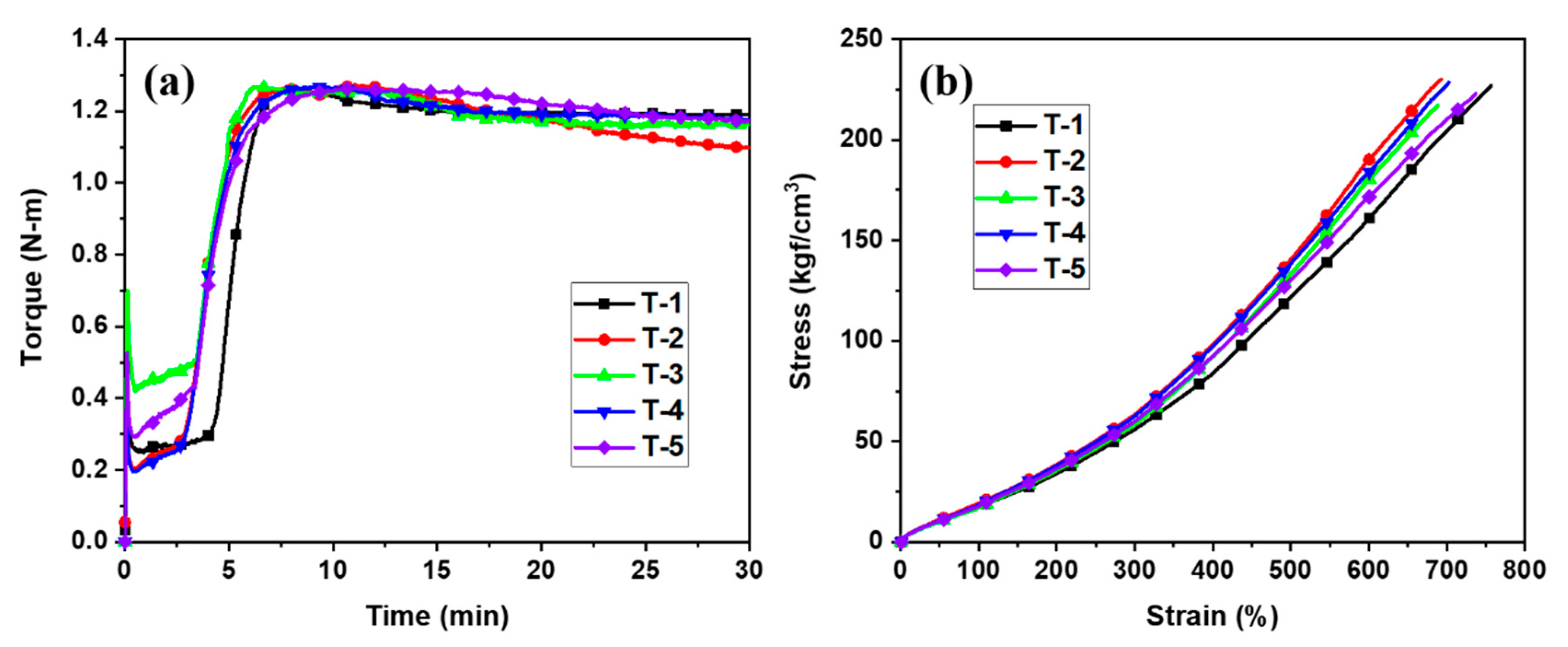

| Unit | T-1 | T-2 | T-3 | T-4 | T-5 | |

|---|---|---|---|---|---|---|

| t10 | min:s | 3:36 | 3:07 | 2:50 | 3:34 | 3:36 |

| t90 | min:s | 6:12 | 5:17 | 4:59 | 5:33 | 5:55 |

| Cure rate * | N-m/min | 0.445 | 0.528 | 0.495 | 0.529 | 0.513 |

| Tmin | N-m | 0.272 | 0.291 | 0.341 | 0.199 | 0.207 |

| Tmax | N-m | 1.260 | 1.267 | 1.266 | 1.266 | 1.265 |

| Tmax –Tmin | N-m | 0.988 | 0.976 | 0.925 | 1.067 | 1.058 |

| ML1+4 | - | 98.3 | 89.9 | 97.2 | 86.2 | 84.5 |

| Unit | T-1 | T-2 | T-3 | T-4 | T-5 | |

|---|---|---|---|---|---|---|

| Hardness | Shore A | 57 | 58 | 57 | 57 | 56 |

| M100% | kgf/cm2 | 17.8 | 19.3 | 17.1 | 18.5 | 17.9 |

| M300% | kgf/cm2 | 56.2 | 63.5 | 58.4 | 62.8 | 60.2 |

| Elongation at break | % | 756 | 692 | 688 | 702 | 736 |

| Tensile strength | kgf/cm2 | 227 | 230 | 217 | 228 | 223 |

| DIN abrasion | mg | 155 | 129 | 151 | 131 | 137 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.Y.; Kim, J.S.; Lim, S.H.; Jang, S.H.; Kim, D.H.; Park, N.-H.; Jung, J.W.; Choi, J. The Investigation of the Silica-Reinforced Rubber Polymers with the Methoxy Type Silane Coupling Agents. Polymers 2020, 12, 3058. https://doi.org/10.3390/polym12123058

Lee SY, Kim JS, Lim SH, Jang SH, Kim DH, Park N-H, Jung JW, Choi J. The Investigation of the Silica-Reinforced Rubber Polymers with the Methoxy Type Silane Coupling Agents. Polymers. 2020; 12(12):3058. https://doi.org/10.3390/polym12123058

Chicago/Turabian StyleLee, Sang Yoon, Jung Soo Kim, Seung Ho Lim, Seong Hyun Jang, Dong Hyun Kim, No-Hyung Park, Jae Woong Jung, and Jun Choi. 2020. "The Investigation of the Silica-Reinforced Rubber Polymers with the Methoxy Type Silane Coupling Agents" Polymers 12, no. 12: 3058. https://doi.org/10.3390/polym12123058

APA StyleLee, S. Y., Kim, J. S., Lim, S. H., Jang, S. H., Kim, D. H., Park, N.-H., Jung, J. W., & Choi, J. (2020). The Investigation of the Silica-Reinforced Rubber Polymers with the Methoxy Type Silane Coupling Agents. Polymers, 12(12), 3058. https://doi.org/10.3390/polym12123058