Effect of the Strain Rate on Damage in Filled EPDM during Single and Cyclic Loadings

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Composition and Processing

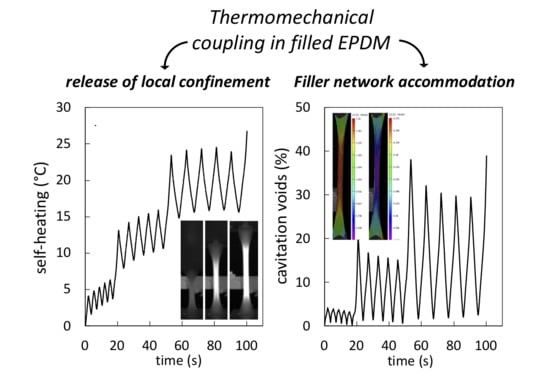

2.2. Thermomechanical Set-up by Infrared Spectroscopy (IR) and Digital Image Correlation (DIC)

2.3. Swelling

3. Results and Discussion

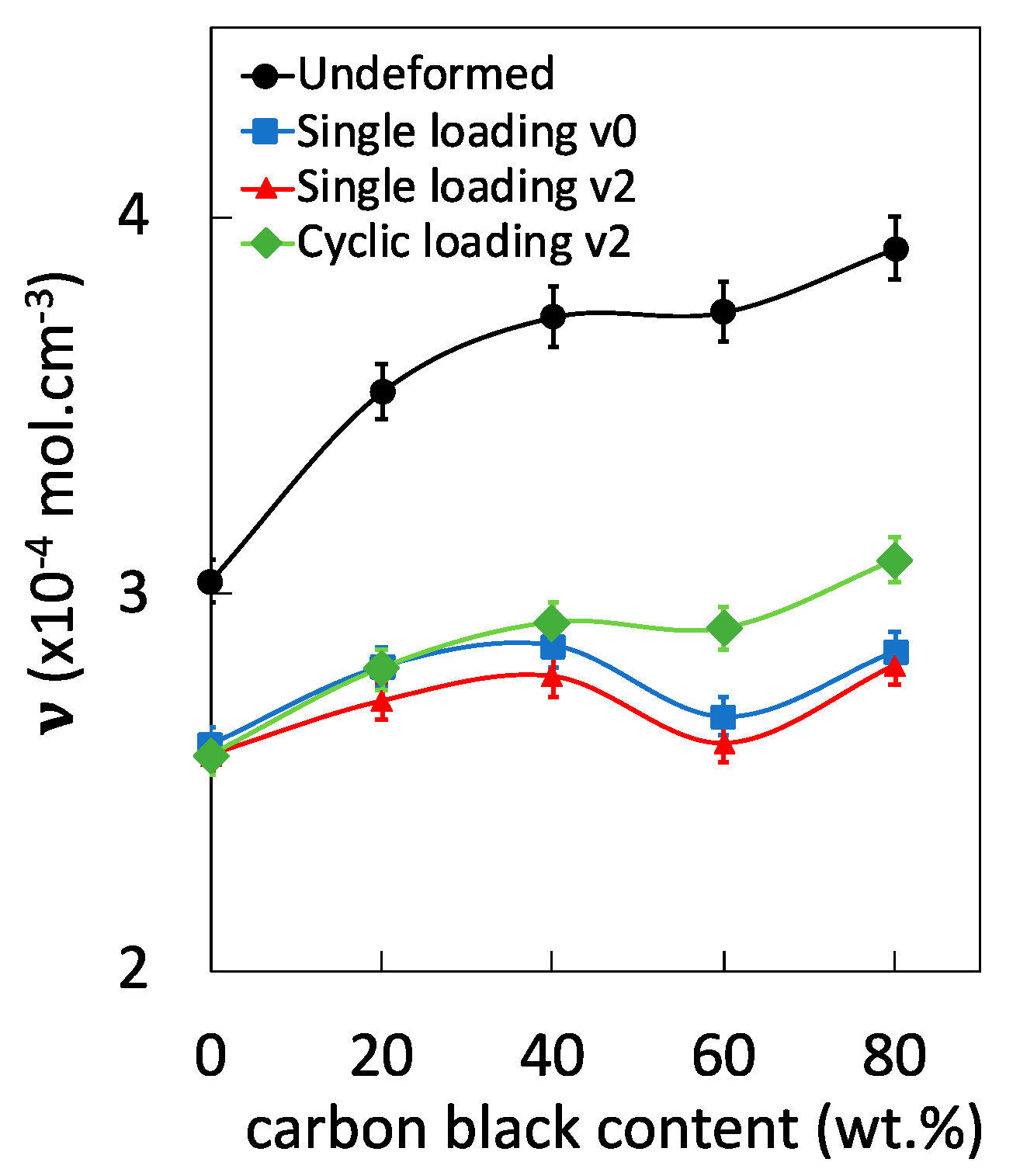

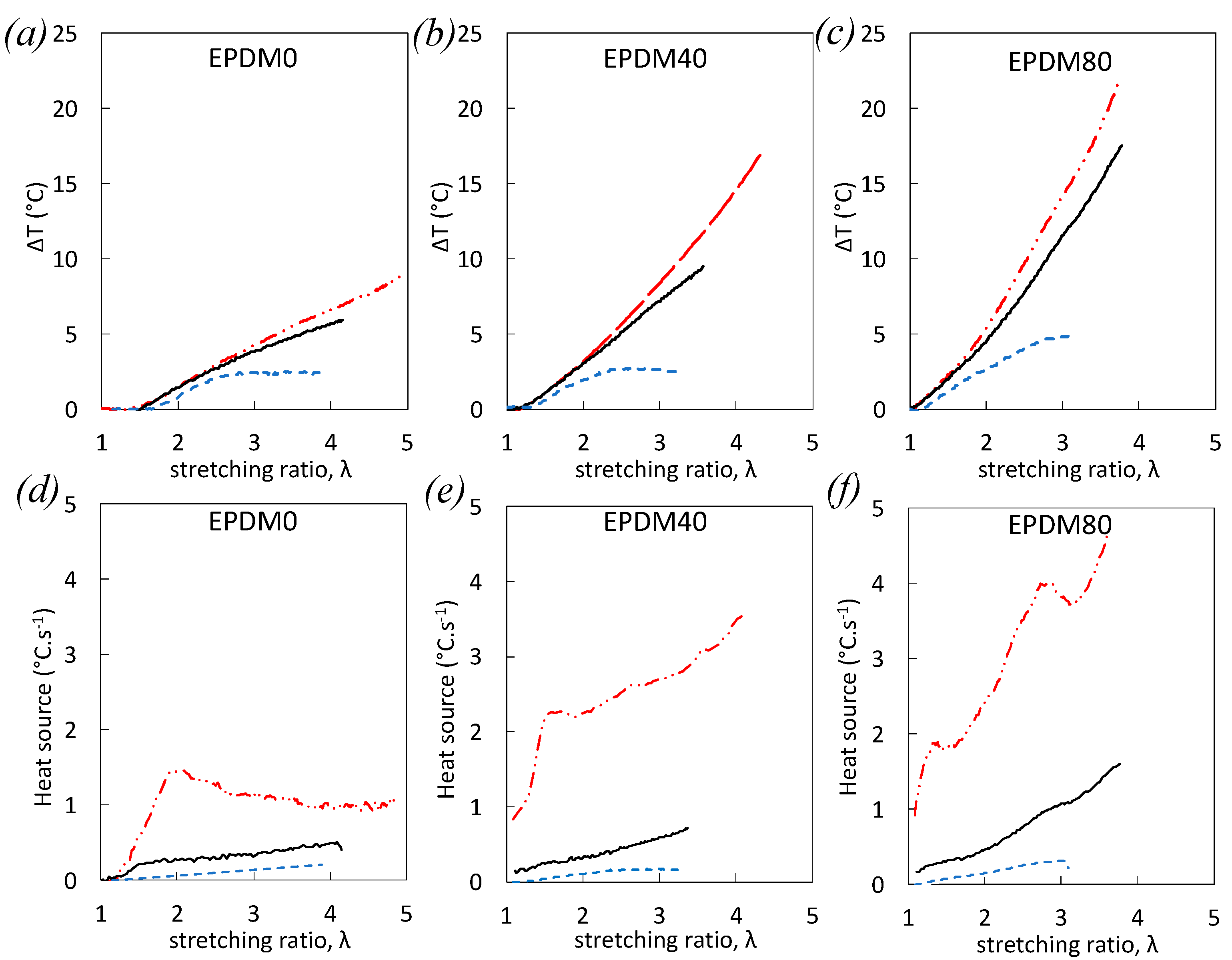

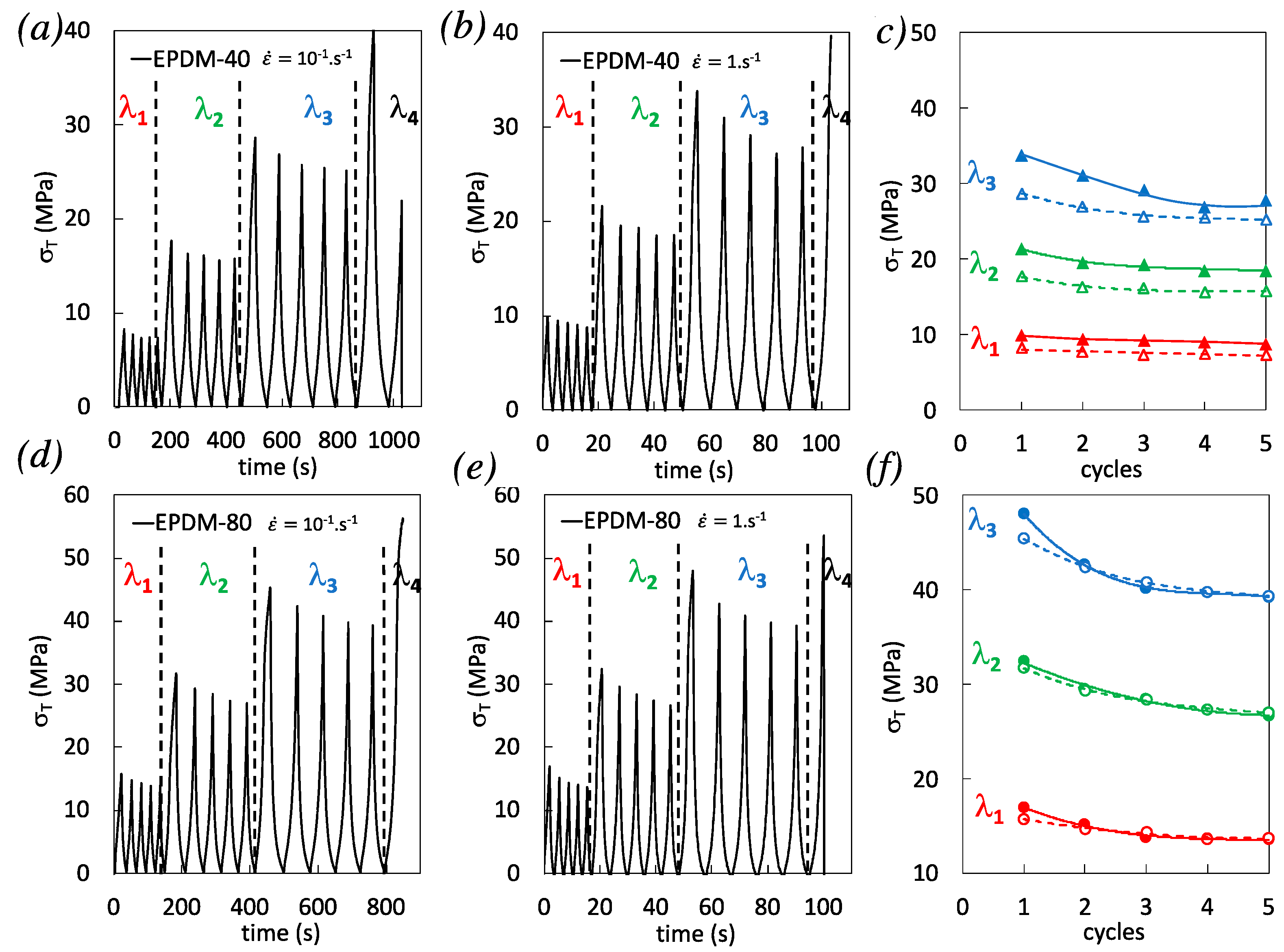

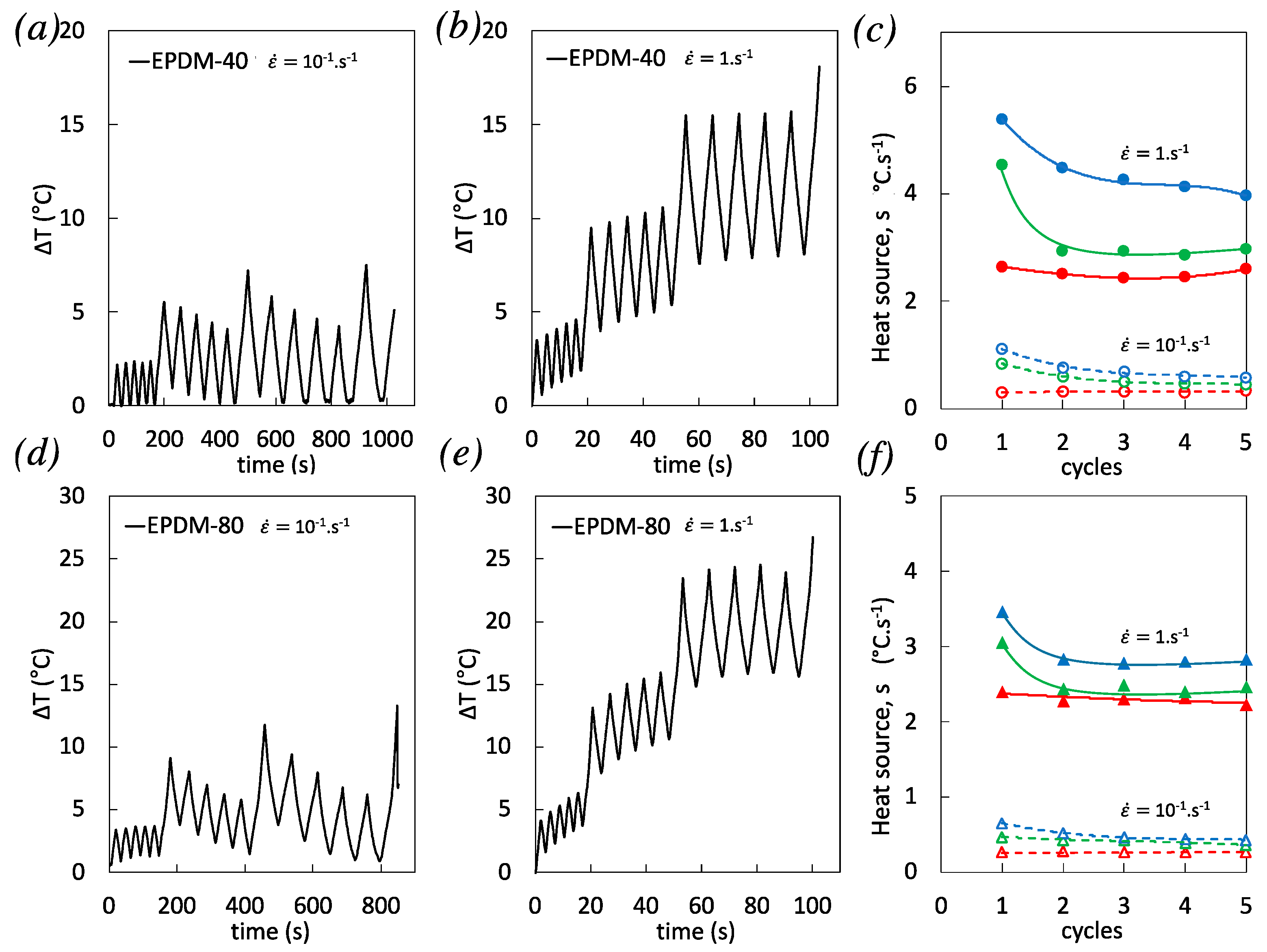

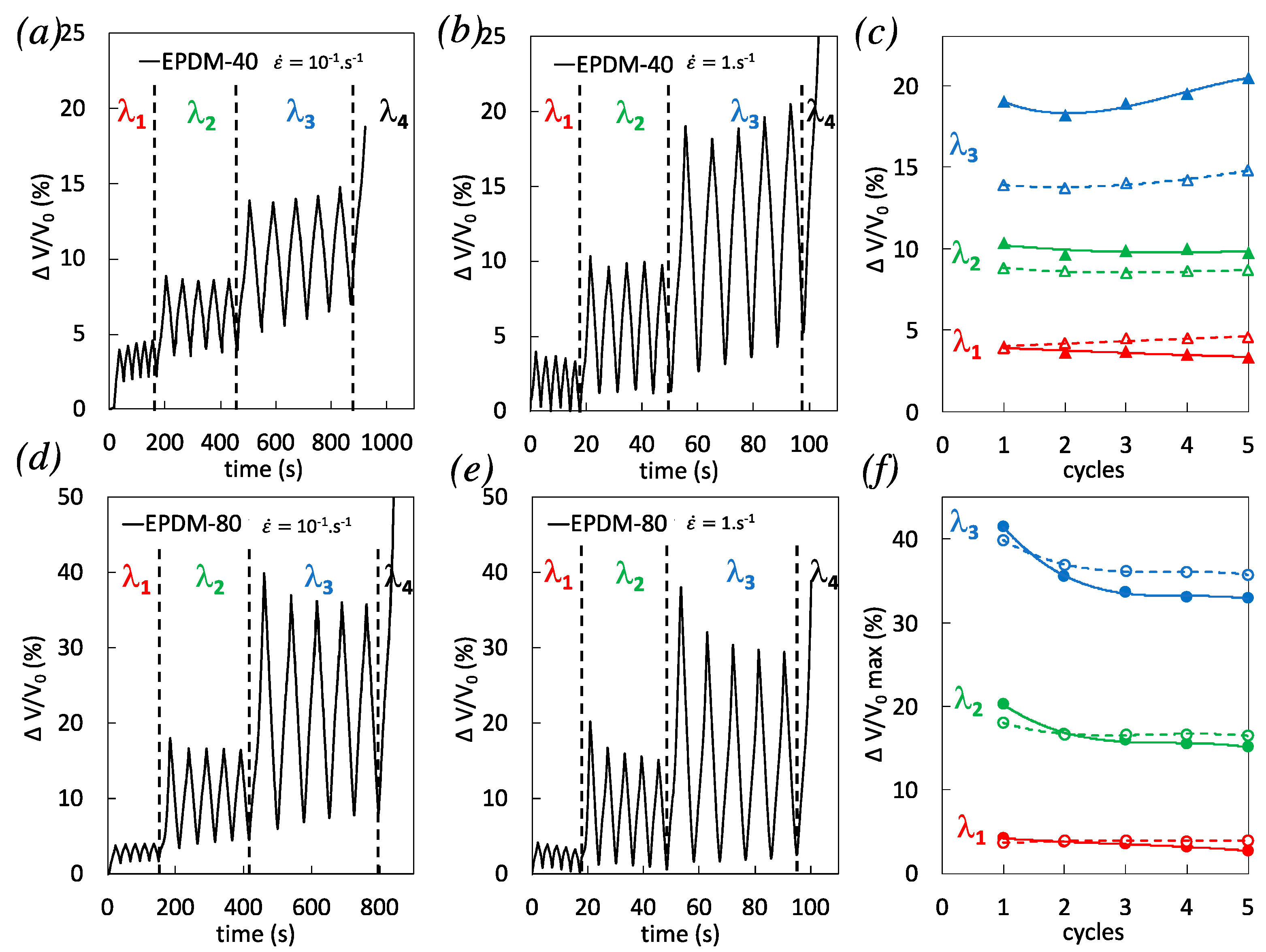

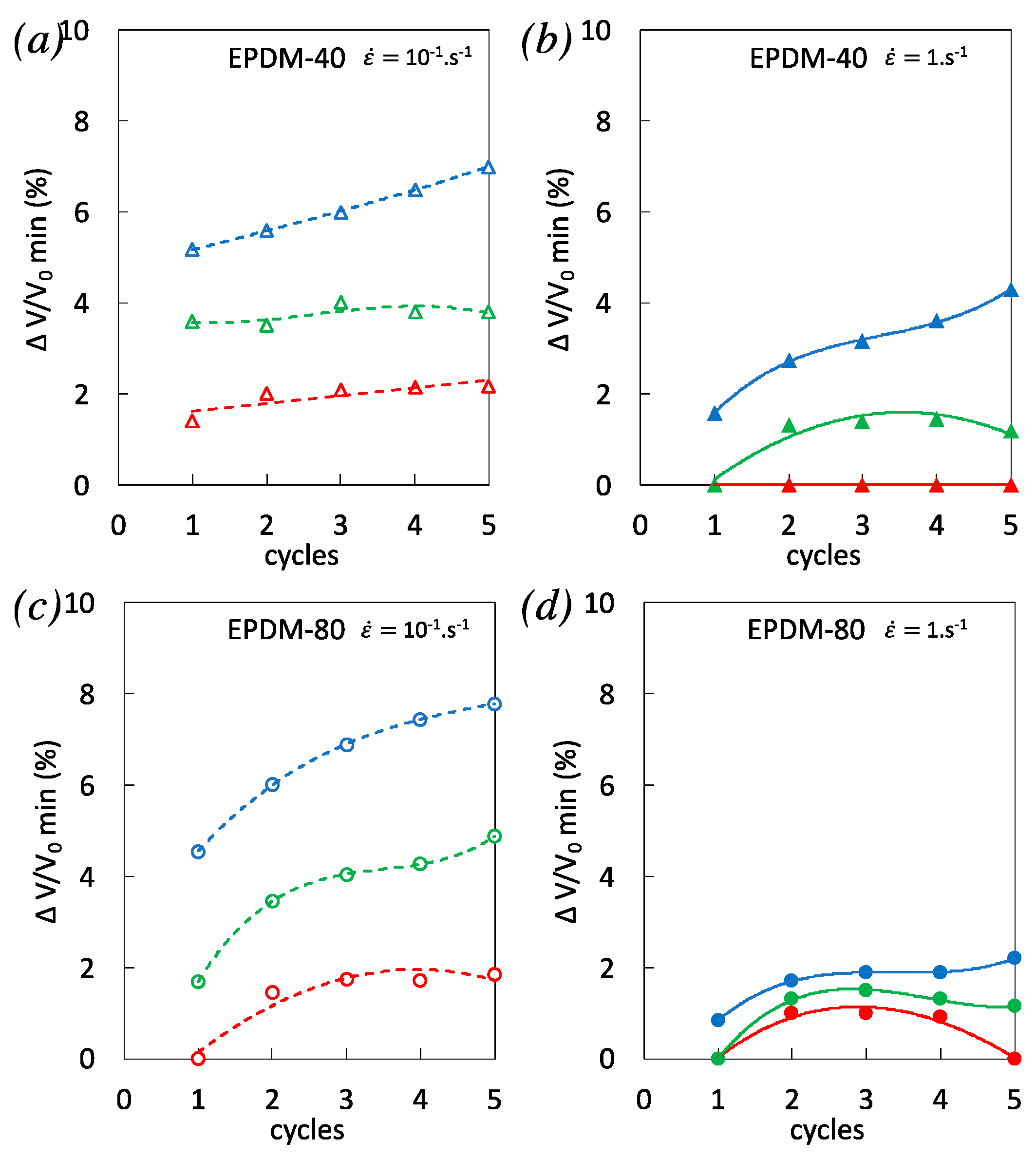

3.1. Effect of the Strain Rate and Type of Loading on Chains Network Damage

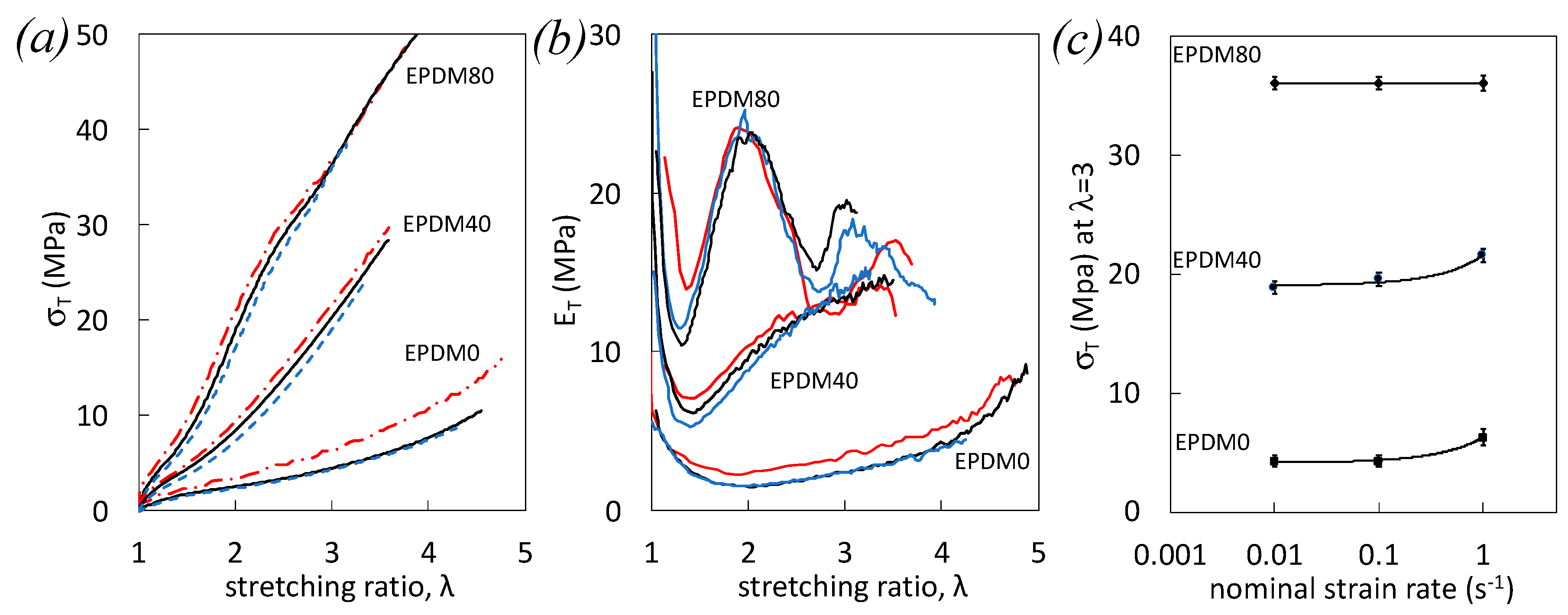

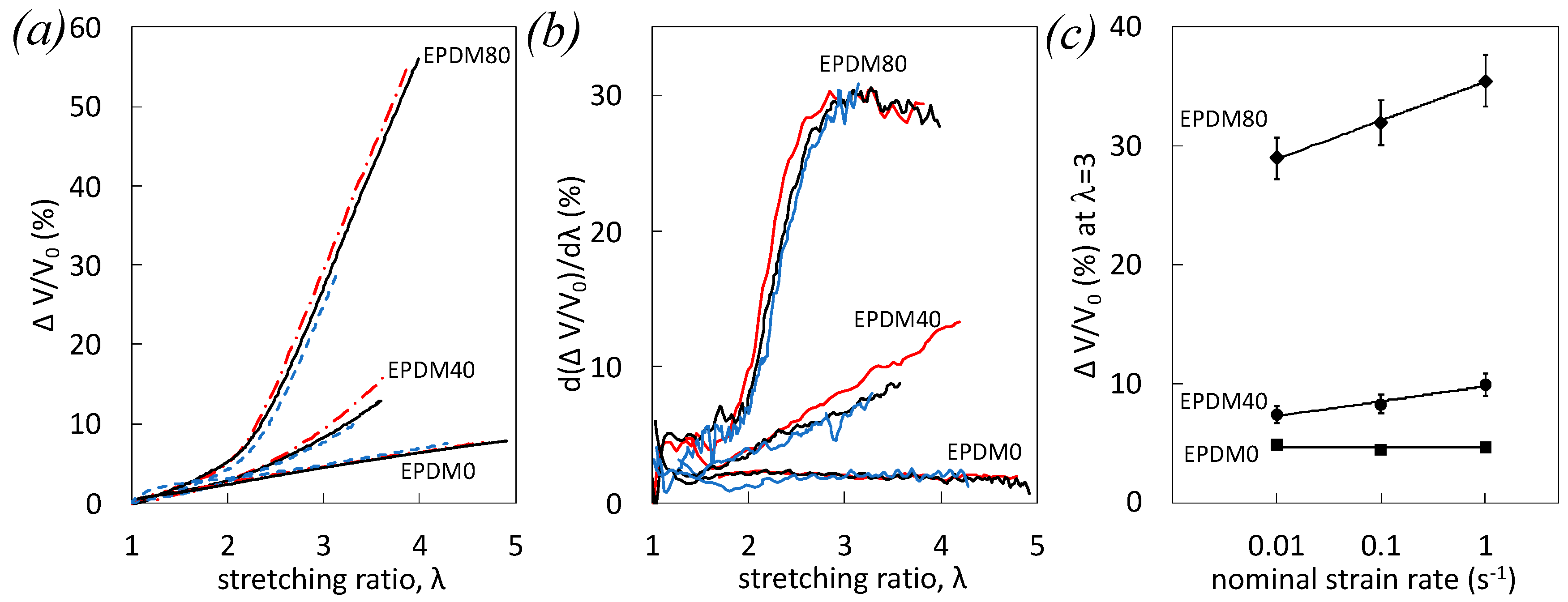

3.2. Effect of the Strain Rate on Damage during Single Loading

3.3. Effect of the Strain Rate on Damage During Cyclic Loading

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sridharan, H.; Chanda, J.; Ghosh, P.; Mukhopadhyay, R. Rubber Blend and Filler Effects on Damage Mechanisms under Monotonic and Fatigue Loading. Rubber Chem. Technol. 2019, 92, 415–430. [Google Scholar] [CrossRef]

- Lake, G.J.; Lindley, P.B. The mechanical fatigue limit for rubber. J. Appl. Polym. Sci. 1965, 9, 1233–1251. [Google Scholar] [CrossRef]

- Diaz, R.; Colomines, G.; Peuvrel-Disdier, E.; Deterre, R. Thermo-mechanical recycling of rubber: Relationship between material properties and specific mechanical energy. J. Mater. Process. Technol. 2018, 252, 454–468. [Google Scholar] [CrossRef]

- Oguz, O.; Candau, N.; Citak, M.K.; Cetin, F.N.; Mokkapati, V.R.; Menceloglu, Y.Z. A Sustainable Approach to Produce Stiff, Super-Tough, and Heat-Resistant Poly (lactic acid)-Based Green Materials. ACS Sustain. Chem. Eng. 2019, 7, 7869–7877. [Google Scholar] [CrossRef]

- Mahapatra, S.P.; Tripathy, D.K. Compressive Deformation and Energy Absorption Characteristics of Conductive Carbon Black Reinforced Microcellular EPDM Vulcanizates. Cell. Polym. 2005, 24, 209–222. [Google Scholar] [CrossRef]

- Banić, M.; Stamenkovic, D.; Miltenovic, V.; Milosevic, M.; Miltenovic, A.; Djekic, P.; Rackov, M. Prediction of heat generation in rubber or rubber-metal springs. Therm. Sci. 2012, 16, 527–539. [Google Scholar] [CrossRef]

- Siviour, C.R.; Jordan, J. High Strain Rate Mechanics of Polymers: A Review. J. Dyn. Behav. Mater. 2016, 2, 15–32. [Google Scholar] [CrossRef]

- Eiamnipon, N.; Nimdum, P.; Renard, J.; Kolitawong, C. Experimental investigation on high strain rate tensile behaviors of steel cord–rubber composite. Compos. Struct. 2013, 99, 1–7. [Google Scholar] [CrossRef]

- Kraus, G.; Childers, C.W.; Rollmann, K.W. Stress softening in carbon black-reinforced vulcanizates. Strain rate and temperature effects. J. Appl. Polym. Sci. 1966, 10, 229–244. [Google Scholar] [CrossRef]

- Tomita, Y.; Azuma, K.; Naito, M. Computational evaluation of strain-rate-dependent deformation behavior of rubber and carbon-black-filled rubber under monotonic and cyclic straining. Int. J. Mech. Sci. 2008, 50, 856–868. [Google Scholar] [CrossRef]

- Suzuki, N.; Ito, M. Chain Scissions of Rubber Molecules by a Tensile Force in Filled Rubber Systems. e-J. Soft Mater. 2005, 1, 1–7. [Google Scholar] [CrossRef][Green Version]

- Dinari, A.; Chaabane, M.; Benameur, T.; Guo, Q.; Gloaguen, J.; Zaïri, F. Multiscale Observation of the Fatigue-Induced Damage Mechanisms in Carbon-Black Filled Styrene-Butadiene Rubber. Macromol. Mater. Eng. 2020, 305, 2000227. [Google Scholar] [CrossRef]

- Weng, G.; Huang, G.; Lei, H.; Qu, L.; Nie, Y.; Wu, J. Crack initiation and evolution in vulcanized natural rubber under high temperature fatigue. Polym. Degrad. Stab. 2011, 96, 2221–2228. [Google Scholar] [CrossRef]

- Le Cam, J.-B.; Huneau, B.; Verron, E. Fatigue damage in carbon black filled natural rubber under uni- and multiaxial loading conditions. Int. J. Fatigue 2013, 52, 82–94. [Google Scholar] [CrossRef]

- Le Cam, J.-B. A Review of Volume Changes in Rubbers: The Effect of Stretching. Rubber Chem. Technol. 2010, 83, 247–269. [Google Scholar] [CrossRef]

- De Crevoisier, J.; Besnard, G.; Merckel, Y.; Zhang, H.; Vion-Loisel, F.; Caillard, J.; Berghezan, D.; Creton, C.; Diani, J.; Brieu, M.; et al. Volume changes in a filled elastomer studied via digital image correlation. Polym. Test. 2012, 31, 663–670. [Google Scholar] [CrossRef]

- Merckel, Y.; Julie, D.; Brieu, M.; Caillard, J. Effects of the amount of fillers and of the crosslink density on the mechanical behavior of carbon-black filled styrene butadiene rubbers. J. Appl. Polym. Sci. 2013, 129, 2086–2091. [Google Scholar] [CrossRef]

- Le Cam, J.-B.; Toussaint, E. Volume Variation in Stretched Natural Rubber: Competition between Cavitation and Stress-Induced Crystallization. Macromolecules 2008, 41, 7579–7583. [Google Scholar] [CrossRef]

- Cantournet, S.; Layouni, K.; Laiarinandrasana, L.; Piques, R. Experimental investigation and modelling of compressibility induced by damage in carbon black-reinforced natural rubber. C. R. Méc. 2014, 342, 299–310. [Google Scholar] [CrossRef]

- Martinez, J.R.S.; Le Cam, J.-B.; Balandraud, X.; Toussaint, E.; Caillard, J. Filler effects on the thermomechanical response of stretched rubbers. Polym. Test. 2013, 32, 835–841. [Google Scholar] [CrossRef]

- Le Cam, J.-B.; Martinez, J.R.S.; Balandraud, X.; Toussaint, E.; Caillard, J. Thermomechanical Analysis of the Singular Behavior of Rubber: Entropic Elasticity, Reinforcement by Fillers, Strain-Induced Crystallization and the Mullins Effect. Exp. Mech. 2015, 55, 771–782. [Google Scholar] [CrossRef]

- Candau, N.; Chazeau, L.; Chenal, J.-M.; Gauthier, C.; Munch, E. Compared abilities of filled and unfilled natural rubbers to crystallize in a large strain rate domain. Compos. Sci. Technol. 2015, 108, 9–15. [Google Scholar] [CrossRef]

- Ruellan, B.; Le Cam, J.-B.; Robin, E.; Jeanneau, I.; Canévet, F.; Mortier, F. Influence of the Temperature on Lifetime Reinforcement of a Filled NR. In Fracture, Fatigue, Failure and Damage Evolution; Springer: Cham, Switzerland, 2019; Volume 6, pp. 45–50. [Google Scholar] [CrossRef]

- La Rosa, G.; Risitano, A. Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components. Int. J. Fatigue 2000, 22, 65–73. [Google Scholar] [CrossRef]

- Le Saux, V.; Marco, Y.; Calloch, S.; Doudard, C.; Charrier, P. Fast evaluation of the fatigue lifetime of rubber-like materials based on a heat build-up protocol and micro-tomography measurements. Int. J. Fatigue 2010, 32, 1582–1590. [Google Scholar] [CrossRef]

- Raghunath, R.; Juhre, D.; Kluppel, M. A physically motivated model for filled elastomers including strain rate and amplitude dependency in finite viscoelasticity. Int. J. Plast. 2016, 78, 223–241. [Google Scholar] [CrossRef]

- Candau, N.; Pradille, C.; Bouvard, J.-L.; Billon, N. On the use of a four-cameras stereovision system to characterize large 3D deformation in elastomers. Polym. Test. 2016, 56, 314–320. [Google Scholar] [CrossRef]

- Candau, N.; Bouvard, J.-L.; Peuvrel-Disdier, E.; Valette, R.; Pradille, C.; Billon, N. Coupled thermal and volume change measurements during stretching of filled EPDM rubbers. In Proceedings of the 10th International Conference on Mechanics of Time-Dependent Materials (MTDM2016), Paris, France, May 2016; Available online: https://hal-mines-paristech.archives-ouvertes.fr/hal-01499444 (accessed on 11 December 2020).

- Candau, N.; Oguz, O.; Peuvrel-Disdier, E.; Bouvard, J.-L.; Pradille, C.; Billon, N. Strain-induced network chains damage in carbon black filled EPDM. Polymer 2019, 175, 329–338. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical Mechanics of Cross-Linked Polymer Networks, I. Rubberlike Elasticity. J. Chem. Phys. 1943, 11, 512–520. [Google Scholar] [CrossRef]

- Kraus, G. Swelling of filler-reinforced vulcanizates. J. Appl. Polym. Sci. 1963, 7, 861–871. [Google Scholar] [CrossRef]

- Candau, N. Compréhension des Mécanismes de Cristallisation sous Tension des Elastomères en Conditions Quasi-Statiques et Dynamiques. Ph.D. Thesis, The Institut National des Sciences Appliquées, Lyon, France, 2014. [Google Scholar]

- Candau, N.; Chazeau, L.; Chenal, J.-M.; Gauthier, C.; Munch, E. Complex dependence on the elastically active chains density of the strain induced crystallization of vulcanized natural rubbers, from low to high strain rate. Polymer 2016, 97, 158–166. [Google Scholar] [CrossRef]

- Suzuki, N.; Ito, M.; Yatsuyanagi, F. Effects of rubber/filler interactions on deformation behavior of silica filled SBR systems. Polymer 2005, 46, 193–201. [Google Scholar] [CrossRef]

- Candau, N.; Oguz, O.; Peuvrel-Disdier, E.; Bouvard, J.-L.; Pradille, C.; Billon, N. Strain and filler ratio transitions from chains network to filler network damage in EPDM during single and cyclic loadings. Polymer 2020, 197, 122435. [Google Scholar] [CrossRef]

- Pramanik, P.K.; Khastagir, D.; Saha, T.N. Effect of extensional strain on the resistivity of electrically conductive nitrile-rubber composites filled with carbon filler. J. Mater. Sci. 1993, 28, 3539–3546. [Google Scholar] [CrossRef]

- Song, B.; Cheng, W.; Cheng, M. Novel model for uniaxial strain-rate-dependent stress-strain behavior of ethylene-propylene-diene monomer rubber in compression or tension. J. Appl. Polym. Sci. 2004, 92, 1553–1558. [Google Scholar] [CrossRef]

- Plagge, J.; Klüppel, M. A physically based model of stress softening and hysteresis of filled rubber including rate- and temperature dependency. Int. J. Plast. 2017, 89, 173–196. [Google Scholar] [CrossRef]

- Das, N.C.; Chaki, T.K.; Khastgir, D. Effect of axial stretching on electrical resistivity of short carbon fibre and carbon black filled conductive rubber composites. Polym. Int. 2002, 51, 156–163. [Google Scholar] [CrossRef]

- Martinez, J.R.S.; Le Cam, J.-B.; Balandraud, X.; Toussaint, E.; Caillard, J. New elements concerning the Mullins effect: A thermomechanical analysis. Eur. Polym. J. 2014, 55, 98–107. [Google Scholar] [CrossRef]

- Benaarbia, A.; Chrysochoos, A.; Robert, G. Kinetics of stored and dissipated energies associated with cyclic loadings of dry polyamide 6.6 specimens. Polym. Test. 2014, 34, 155–167. [Google Scholar] [CrossRef]

- Martinez, J.R.S.; Le Cam, J.-B.; Balandraud, X.; Toussaint, E.; Caillard, J. Mechanisms of deformation in crystallizable natural rubber. Part 2: Quantitative calorimetric analysis. Polymer 2013, 54, 2727–2736. [Google Scholar] [CrossRef]

- Candau, N.; Oguz, O.; Peuvrel-Disdier, E.; Bouvard, J.-L.; Maspoch, M.L.; Corvec, G.; Pradille, C.; Billon, N. Heat source and voiding signatures of Mullins damage in filled EPDM. Polym. Test. 2020, 91, 106838. [Google Scholar] [CrossRef]

- Mullins, L. Softening of Rubber by Deformation. Rubber Chem. Technol. 1969, 42, 339–362. [Google Scholar] [CrossRef]

- Rosca, I.D.; Vergnaud, J.M. Study of process of cure of EPDM rubbers in moving die rheometer. Plast. Rubber Compos. 2001, 30, 275–281. [Google Scholar] [CrossRef]

- Cheremisinoff, N.P. Spotlight on EPDM Elastomers. Polym. Plast. Technol. Eng. 1992, 31, 713–744. [Google Scholar] [CrossRef]

- Hamed, G.R. Molecular Aspects of the Fatigue and Fracture of Rubber. Rubber Chem. Technol. 1994, 67, 529–536. [Google Scholar] [CrossRef]

- Cho, J.K.; Sun, H.; Seo, H.W.; Chung, J.-Y.; Seol, M.; Kim, S.-H.; Kim, R.-S.; Park, I.-K.; Suhr, J.; Park, J.C.; et al. Heat dissipative mechanical damping properties of EPDM rubber composites including hybrid fillers of aluminium nitride and boron nitride. Soft Matter 2020, 16, 6812–6818. [Google Scholar] [CrossRef]

- Medalia, A.I. Heat Generation in Elastomer Compounds: Causes and Effects. Rubber Chem. Technol. 1991, 64, 481–492. [Google Scholar] [CrossRef]

- Picquart, M.; Poirey, G.; Puel, G.; Aubry, D. An original experimental approach showing that most nonlinearities expressed by filled elastomers relate to microscopic friction and cavitation. J. Appl. Polym. Sci. 2020, 138, 49941. [Google Scholar] [CrossRef]

- Qian, D.; Meng, F. Modelling Mullins Effect Induced by Chain Delamination and Reattachment. arXiv 2020, arXiv:2009.14055. [Google Scholar]

- Demassieux, Q.; Berghezan, D.; Cantournet, S.; Proudhon, H.; Creton, C. Temperature and aging dependence of strain-induced crystallization and cavitation in highly crosslinked and filled natural rubber. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 780–793. [Google Scholar] [CrossRef]

| Components | Content (phr) | ρ * (mol·cm−3) |

|---|---|---|

| EPDM | 100 | 0.87 |

| Carbon black (N550) | 0, 40, 80 | 2.00 |

| Calcium Oxide | 4 | 3.34 |

| Zinc Oxide | 5 | 5.61 |

| Stearin | 1 | 0.94 |

| Polyethylene Glycol (PEG) | 2 | 1.12 |

| Sulfur | 1.2 | 2.00 |

| Mercaptobenzothiazole (MBT 75%) | 1 | 1.46 |

| Mercaptobenzothiazole disulfide (MBTS 75%) | 0.8 | 1.50 |

| N-cyclohexyl-2-benzothiazolesulfenamide (CBS 75%) | 1.2 | 1.30 |

| Zinc dialkyl dithiophosphate (ZDTP 70%) | 1.5 | 1.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candau, N.; Oguz, O.; Peuvrel-Disdier, E.; Bouvard, J.-L.; Maspoch, M.L.; Corvec, G.; Pradille, C.; Billon, N. Effect of the Strain Rate on Damage in Filled EPDM during Single and Cyclic Loadings. Polymers 2020, 12, 3021. https://doi.org/10.3390/polym12123021

Candau N, Oguz O, Peuvrel-Disdier E, Bouvard J-L, Maspoch ML, Corvec G, Pradille C, Billon N. Effect of the Strain Rate on Damage in Filled EPDM during Single and Cyclic Loadings. Polymers. 2020; 12(12):3021. https://doi.org/10.3390/polym12123021

Chicago/Turabian StyleCandau, Nicolas, Oguzhan Oguz, Edith Peuvrel-Disdier, Jean-Luc Bouvard, María Lluïsa Maspoch, Guillaume Corvec, Christophe Pradille, and Noëlle Billon. 2020. "Effect of the Strain Rate on Damage in Filled EPDM during Single and Cyclic Loadings" Polymers 12, no. 12: 3021. https://doi.org/10.3390/polym12123021

APA StyleCandau, N., Oguz, O., Peuvrel-Disdier, E., Bouvard, J.-L., Maspoch, M. L., Corvec, G., Pradille, C., & Billon, N. (2020). Effect of the Strain Rate on Damage in Filled EPDM during Single and Cyclic Loadings. Polymers, 12(12), 3021. https://doi.org/10.3390/polym12123021