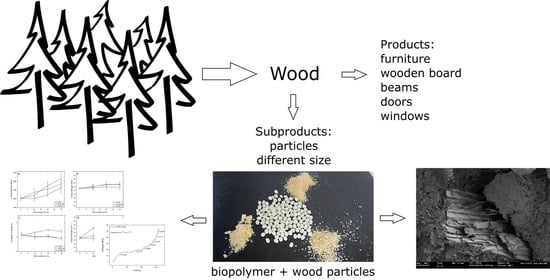

Study of the Properties of a Biodegradable Polymer Filled with Different Wood Flour Particles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Granulometric Analysis

- d is the sieve size (in mm) being considered (32, 16, 8, 4, 2, 1, 0.5, 0.25, 0.125, 0.063). d value is always minor or equal to D value.

- D is maximum particle size (in mm). D value is equal to size mesh with cumulative retained less to 15%

- e is the parameter that adjusts the curve. e value is 0.5 to Fuller and Thompson method.

2.3. Optical Measurements

2.4. Sample Preparation

2.5. Rheological Characterization

2.6. Mechanical Properties Measurement

2.7. Scanning Electron Microscopy (SEM) Measurements

2.8. Thermal Characterization

- is the degree of crystallinity in %

- is the melting enthalpy in J g−1

- is the cold crystallization enthalpy in J g−1

- is the calculated melting enthalpy of purely crystalline PLA, 93.7 J g−1

- is the weight fraction of the PLA sample.

3. Results

3.1. Wood Flour Particles Characterization

3.2. Biocomposites Characterization

3.2.1. Rheological Characterization

3.2.2. Mechanical Properties

3.2.3. SEM Studies

3.2.4. Thermal Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- Plastics Europe Market Research Group (PEMRG). Plastics-the Facts 2019 An Analysis of European Plastics Production, Demand and Waste Data. Plast. Facts 2019, 1, 1–42. [Google Scholar]

- Aldas, M.; Paladines, A.; Valle, V.; Pazmiño, M.; Quiroz, F. Effect of the Prodegradant-Additive Plastics Incorporated on the Polyethylene Recycling. Int. J. Polym. Sci. 2018, 2018, 1–10. [Google Scholar] [CrossRef]

- Kolek, Z. Recycled Polymers from Food Packaging in Relation to Environmental Protection. Polish J. Environ. Stud. 2001, 10, 73–76. [Google Scholar]

- Aldas, M.; Valle, V.; Aguilar, J.; Pavon, C.; Santos, R.; Luna, M. Ionizing Radiation as Adjuvant for the Abiotic Degradation of Plastic Bags Containing Pro-oxidant Additives. J. Appl. Polym. Sci. 2021, 138, 49664. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef] [PubMed]

- Pavon, C.; Aldas, M.; De La Rosa-Ramírez, H.; López-Martínez, J.; Arrieta, M.P. Improvement of PBAT Processability and Mechanical Performance by Blending with Pine Resin Derivatives for Injection Moulding Rigid Packaging with Enhanced Hydrophobicity. Polymers 2020, 12, 2891. [Google Scholar] [CrossRef]

- Owen, A.J.; Jones, R.A.L. Rheology of a Simultaneously Phase-Separating and Gelling Biopolymer Mixture. Macromolecules 1998, 31, 7336–7339. [Google Scholar] [CrossRef]

- What is Solanyl Biopolymers? Available online: https://www.solanylbiopolymers.com/about-solanyl.html (accessed on 27 November 2020).

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Villegas, C.; Arrieta, M.P.; Rojas, A.; Torres, A.; Faba, S.; Toledo, M.J.; Gutierrez, M.A.; Zavalla, E.; Romero, J.; Galotto, M.J.; et al. PLA/Organoclay Bionanocomposites Impregnated with Thymol and Cinnamaldehyde by Supercritical Impregnation for Active and Sustainable Food Packaging. Compos. Part B Eng. 2019, 176, 107336. [Google Scholar] [CrossRef]

- De La Rosa-Ramírez, H.; Aldas, M.; Ferri, J.M.; López-Martínez, J.; Samper, M.D. Modification of Poly (Lactic Acid) through the Incorporation of Gum Rosin and Gum Rosin Derivative: Mechanical Performance and Hydrophobicity. J. Appl. Polym. Sci. 2020, 137, 1–15. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Jiménez-López, M.; Aldas, M.; López, J. Combined Effect of Linseed Oil and Gum Rosin as Natural Additives for PVC. Ind. Crops Prod. 2017, 99, 196–204. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Park, H.-M.; Ha, C.-S. Bio-Nanocomposites for Food Packaging Applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Sessini, V.; Navarro-Baena, I.; Arrieta, M.P.; Dominici, F.; López, D.; Torre, L.; Kenny, J.M.; Dubois, P.; Raquez, J.-M.; Peponi, L. Effect of the Addition of Polyester-Grafted-Cellulose Nanocrystals on the Shape Memory Properties of Biodegradable PLA/PCL Nanocomposites. Polym. Degrad. Stab. 2018, 152, 126–138. [Google Scholar] [CrossRef]

- Fortunati, E.; Peltzer, M.; Armentano, I.; Torre, L.; Jimenez, A.; Kenny, J.M. Effects of Modified Cellulose Nanocrystals on the Barrier and Migration Properties of PLA Nano-Biocomposites. Carbohydr. Polym. 2012, 90, 948–956. [Google Scholar] [CrossRef] [PubMed]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; López, J.; Kenny, J.M.M. Bionanocomposite Films Based on Plasticized PLA–PHB/Cellulose Nanocrystal Blends. Carbohydr. Polym. 2015, 121, 265–275. [Google Scholar] [CrossRef] [PubMed]

- Bouakaz, B.S.; Pillin, I.; Habi, A.; Grohens, Y. Synergy between Fillers in Organomontmorillonite/Graphene-PLA Nanocomposites. Appl. Clay Sci. 2015, 116, 69–77. [Google Scholar] [CrossRef]

- Gordobil, O.; Delucis, R.; Eguees, I.; Labidi, J. Kraft Lignin as Filler in PLA to Improve Ductility and Thermal Properties. Ind. Crops Prod. 2015, 72, 46–53. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S. Morphology and Thermal Degradation Studies of Melt-Mixed Poly(Lactic Acid) (PLA)/Poly(Epsilon-Caprolactone) (PCL) Biodegradable Polymer Blend Nanocomposites with TiO2 as Filler. Polym. Test. 2015, 45, 93–100. [Google Scholar] [CrossRef]

- Aguilar, R.; Nakamatsu, J.; Ramírez, E.; Elgegren, M.; Ayarza, J.; Kim, S.; Pando, M.A.; Ortega-San-Martin, L. The Potential Use of Chitosan as a Biopolymer Additive for Enhanced Mechanical Properties and Water Resistance of Earthen Construction. Constr. Build. Mater. 2016, 114, 625–637. [Google Scholar] [CrossRef]

- Bagheriasl, D.; Carreau, P.J.; Riedl, B.; Dubois, C.; Hamad, W.Y. Shear Rheology of Polylactide (PLA)-Cellulose Nanocrystal (CNC) Nanocomposites. Cellulose 2016, 23, 1885–1897. [Google Scholar] [CrossRef]

- John, M.J. Biopolymer Blends Based on Polylactic Acid and Polyhydroxy Butyrate-Co-Valerate: Effect of Clay on Mechanical and Thermal Properties. Polym. Compos. 2015, 36, 2042–2050. [Google Scholar] [CrossRef]

- Vanamudan, A.; Sudhakar, P.P. Biopolymer Capped Silver Nanoparticles with Potential for Multifaceted Applications. Int. J. Biol. Macromol. 2016, 86, 262–268. [Google Scholar] [CrossRef] [PubMed]

- Chamieh, J.; Biron, J.P.; Cipelletti, L.; Cottet, H. Monitoring Biopolymer Degradation by Taylor Dispersion Analysis. Biomacromolecules 2015, 16, 3945–3951. [Google Scholar] [CrossRef] [PubMed]

- Arrieta, M.P.; Peponi, L.; López, D.; Fernández-García, M. Recovery of Yerba Mate (Ilex Paraguariensis) Residue for the Development of PLA-Based Bionanocomposite Films. Ind. Crops Prod. 2018, 111, 317–328. [Google Scholar] [CrossRef]

- Luzi, F.; Puglia, D.; Sarasini, F.; Tirillo, J.; Maffei, G.; Zuorro, A.; Lavecchia, R.; Kenny, J.M.; Torre, L. Valorization and Extraction of Cellulose Nanocrystals from North African Grass: Ampelodesmos Mauritanicus (Diss). Carbohydr. Polym. 2019, 209, 328–337. [Google Scholar] [CrossRef]

- Berglund, L.; Noel, M.; Aitomaki, Y.; Oman, T.; Oksman, K. Production Potential of Cellulose Nanofibers from Industrial Residues: Efficiency and Nanofiber Characteristics. Ind. Crops Prod. 2016, 92, 84–92. [Google Scholar] [CrossRef]

- Nosek, R.; Holubcik, M.; Jandacka, J. The Impact of Bark Content of Wood Biomass on Biofuel Properties. Bioresources 2016, 11, 44–53. [Google Scholar] [CrossRef]

- Kuzmina, I. Influence the Food Additive of Fermented Cedar Elfin Wood on Biochemical Indices of Cows Blood in Magadan Region. Zootekhniya 2015, 6, 6–8. [Google Scholar]

- Rollinson, A.N.; Williams, O. Experiments on Torrefied Wood Pellet: Study by Gasification and Characterization for Waste Biomass to Energy Applications. R. Soc. Open Sci. 2016, 3, 150578. [Google Scholar] [CrossRef]

- Samarzija-Jovanovic, S.; Jovanovic, V.; Petkovic, B.; Dekic, V.; Markovic, G.; Zekovic, I.; Marinovic-Cincovic, M. Nanosilica and Wood Flour-Modified Urea-Formaldehyde Composites. J. Thermoplast. Compos. Mater. 2016, 29, 656–669. [Google Scholar] [CrossRef]

- Pawlak, F.; Aldas, M.; López-Martínez, J.; Samper, M.D. Effect of Different Compatibilizers on Injection-Molded Green Fiber-Reinforced Polymers Based on Poly(Lactic Acid)-Maleinized Linseed Oil System and Sheep Wool. Polymers 2019, 11, 1514. [Google Scholar] [CrossRef] [PubMed]

- Aldas, M.; Pavon, C.; López-Martínez, J.; Arrieta, M.P. Pine Resin Derivatives as Sustainable Additives to Improve the Mechanical and Thermal Properties of Injected Moulded Thermoplastic Starch. Appl. Sci. 2020, 10, 2561. [Google Scholar] [CrossRef]

- Sarasini, F.; Puglia, D.; Fortunati, E.; Kenny, J.M.; Santulli, C. Effect of Fiber Surface Treatments on Thermo-Mechanical Behavior of Poly(Lactic Acid)/Phormium Tenax Composites. J. Polym. Environ. 2013, 21, 881–891. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Diez Garcia, A.; Lopez, D.; Fiori, S.; Peponi, L. Antioxidant Bilayers Based on PHBV and Plasticized Electrospun PLA-PHB Fibers Encapsulating Catechin. Nanomaterials 2019, 9, 346. [Google Scholar] [CrossRef]

- Lewandowski, K.; Piszczek, K.; Zajchowski, S.; Mirowski, J. Rheological Properties of Wood Polymer Composites at High Shear Rates. Polym. Test. 2016, 51, 58–62. [Google Scholar] [CrossRef]

- Nitz, H.; Semke, H.; Landers, R.; Mulhaupt, R. Reactive Extrusion of Polycaprolactone Compounds Containing Wood Flour and Lignin. J. Appl. Polym. Sci. 2001, 81, 1972–1984. [Google Scholar] [CrossRef]

- Pavon, C.; Aldas, M.; López-Martínez, J.; Ferrándiz, S. New Materials for 3D-Printing Based on Polycaprolactone with Gum Rosin and Beeswax as Additives. Polymers 2020, 12, 334. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Kelnar, I.; Luyt, A.S. Effect of Layered Silicates on the Thermal Stability of PCL/PLA Microfibrillar Composites. Polym. Test. 2016, 50, 9–14. [Google Scholar] [CrossRef]

- Bulatović, V.O.; Mandić, V.; Kučić Grgić, D.; Ivančić, A. Biodegradable Polymer Blends Based on Thermoplastic Starch. J. Polym. Environ. 2020, 1–17. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Sánchez-Nacher, L.; Fenollar, O.; Balart, R. The Effect of Maleinized Linseed Oil (MLO) on Mechanical Performance of Poly(Lactic Acid)-Thermoplastic Starch (PLA-TPS) Blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef]

- Aldas, M.; Ferri, J.M.; Lopez-Martinez, J.; Samper, M.D.; Arrieta, M.P. Effect of Pine Resin Derivatives on the Structural, Thermal, and Mechanical Properties of Mater-Bi Type Bioplastic. J. Appl. Polym. Sci. 2020, 137, 48236. [Google Scholar] [CrossRef]

- Aldas, M.; Rayón, E.; López-Martínez, J.; Arrieta, M.P. A Deeper Microscopic Study of the Interaction between Gum Rosin Derivatives and a Mater-Bi Type Bioplastic. Polymer 2020, 12, 226. [Google Scholar] [CrossRef] [PubMed]

- Kelnar, I.; Kratochvil, J.; Kapralkova, L. Crystallization and Thermal Properties of Melt-Drawn PCL/PLA Microfibrillar Composites. J. Therm. Anal. Calorim. 2016, 124, 799–805. [Google Scholar] [CrossRef]

- Pilla, S.; Gong, S.; O’Neill, E.; Rowell, R.M.; Krzysik, A.M. Polylactide-Pine Wood Flour Composites. Polym. Eng. Sci. 2008, 48, 578–587. [Google Scholar] [CrossRef]

- Chuayjuljit, S.; Kongthan, J.; Chaiwutthinan, P.; Boonmahitthisud, A. Poly(Vinyl Chloride)/Poly(Butylene Succinate)/Wood Flour Composites: Physical Properties and Biodegradability. Polym. Compos. 2018, 39, 1543–1552. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, C.; Chu, P.K.; Lv, F.; Zhang, C.; Ji, J.; Zhang, R.; Wang, H. Mechanical and Thermal Properties of Basalt Fiber Reinforced Poly(Butylene Succinate) Composites. Mater. Chem. Phys. 2012, 133, 845–849. [Google Scholar] [CrossRef]

| CB120 | BK 40-90 | Grade 9 | |

|---|---|---|---|

| Color | Yellow | yellow | yellow |

| Structure | Fibrous | cubic | cubic |

| Particle range (mm) | 0.07–0.15 | 0.30–0.50 | 0.80–1.10 |

| CB 120 | BK 40-90 | Grade 9 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mesh Size | Weight Retained | Cumulative Retained | Total % Passing | Weight Retained | Cumulative Retained | Total % Passing | Weight Retained | Cumulative Retained | Total % Passing | |||

| mm | g | g | % | % | g | g | % | % | G | g | % | % |

| 32 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 |

| 16 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 |

| 8 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 |

| 4 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 |

| 2 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 |

| 1 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 100 | 55.5 | 55.5 | 27.75 | 72.25 |

| 0.5 | 0 | 0 | 0 | 100 | 76.5 | 76.5 | 38.15 | 61.85 | 129 | 184.5 | 92.25 | 7.75 |

| 0.25 | 31 | 31 | 15.12 | 84.88 | 103.5 | 180 | 89.77 | 10.23 | 12.5 | 197 | 98.5 | 1.5 |

| 0.125 | 112 | 143 | 69.75 | 30.25 | 18.5 | 198.5 | 99.00 | 1 | 3 | 200 | 100 | 0 |

| 0.063 | 50 | 193 | 94.14 | 5.86 | 2 | 200.5 | 100 | 0 | 0 | 200 | 100 | 0 |

| bottom | 12 | 205 | 100 | 0 | 0 | 200.5 | 100 | 0 | 0 | 200 | 100 | 0 |

| Total | 205 | 200.5 | 200 | |||||||||

| Viscosity, Pa s | ||||||||

|---|---|---|---|---|---|---|---|---|

| Shear rate (s−1) | 100 | 200 | 500 | 1000 | 2000 | 5000 | 10,000 | |

| Material | % of filler | |||||||

| Virgin | 0 | 3061.25 | 1730.12 | 815.25 | 463.87 | 236.75 | 90.38 | 49.92 |

| CB 120 | 10 | 3244.37 | 1900.46 | 842.38 | 500.87 | 250.78 | 95.31 | 52.85 |

| 20 | 3300.25 | 2000.65 | 974.27 | 520.51 | 251.09 | 95.91 | 59.22 | |

| 30 | 3492.52 | 2101.56 | 985.37 | 543.18 | 280.06 | 103.15 | 63.23 | |

| BK 40-90 | 10 | 3408.25 | 2109.37 | 1022.62 | 532.46 | 256.84 | 110.56 | 60.87 |

| 20 | 3662.51 | 2271.56 | 1095.25 | 587.18 | 295.46 | 120.87 | 70.23 | |

| 30 | 3720.21 | 2500.32 | 1200.54 | 610.87 | 306.43 | 126.32 | 75.98 | |

| Grade 9 | 10 | 3304.37 | 2036.87 | 1021.62 | 565.87 | 291.90 | 110.28 | 60.67 |

| 20 | 3400.25 | 2286.56 | 1109.62 | 598.56 | 309.81 | 118.95 | 65.99 | |

| 30 | 3563.12 | 2500.65 | 1200.87 | 620.15 | 325.46 | 120.38 | 70.15 | |

| First Heating at 5 °C min−1 | |||||

|---|---|---|---|---|---|

| Mixture | Tcc, °C | Tm, °C | Normalized Enthalpy | Crystallinity , (%) | |

| Cold (J g−1) | Hot (J g−1) | ||||

| PLA-PCL | 78.85 | 160.17 | 6.43 | 14.31 | 10.51 |

| 10—CB 120 | 78.77 | 161.86 | 6.40 | 14.70 | 12.31 |

| 20—CB 120 | 79.72 | 161.91 | 4.70 | 15.43 | 17.90 |

| 30—CB 120 | 79.83 | 160.58 | 4.42 | 16.80 | 23.61 |

| 10—BK 40-90 | 79.94 | 161.28 | 3.60 | 12.15 | 12.67 |

| 20—BK 40-90 | 80.35 | 163.03 | 5.84 | 14.18 | 13.90 |

| 30—BK 40-90 | 80.36 | 162.74 | 5.17 | 14.85 | 18.45 |

| 10—Grade 9 | 82.50 | 161.64 | 5.92 | 13.27 | 10.89 |

| 20—Grade 9 | 79.77 | 162.23 | 4.77 | 13.61 | 14.73 |

| 30—Grade 9 | 79.39 | 160.28 | 4.23 | 12.56 | 15.88 |

| Second Heating at 5 °C min−1 | |||||

| Mixture | Tcc, °C | Tm, °C | Normalized Cold (J g−1) | Enthalpy Hot (J g−1) | Crystallinity , (%) |

| PLA-PCL | - | 156.86 | - | 12.62 | 16.84 |

| 10—CB 120 | - | 158.21 | - | 12.17 | 18.04 |

| 20—CB 120 | - | 158.19 | - | 12.62 | 21.05 |

| 30—CB 120 | - | 158.35 | - | 14.11 | 26.89 |

| 10—BK 40-90 | - | 157.71 | - | 12.43 | 18.43 |

| 20—BK 40-90 | - | 159.88 | - | 13.66 | 22.78 |

| 30—BK 40-90 | - | 159.42 | - | 14.28 | 27.22 |

| 10—Grade 9 | - | 158.16 | - | 10.66 | 15.80 |

| 20—Grade 9 | - | 158.58 | - | 12.16 | 20.28 |

| 30—Grade 9 | - | 157.23 | - | 11.12 | 21.19 |

| Filler Content | CB 120 | BK 40-90 | Grade 9 |

|---|---|---|---|

| wt.% | |||

| 0 | 53.8 | 53.8 | 53.8 |

| 10 | 53.8 | 54.2 | 54.4 |

| 20 | 54.4 | 54.6 | 54.8 |

| 30 | 54.8 | 55.0 | 55.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parres, F.; Peydro, M.A.; Juarez, D.; Arrieta, M.P.; Aldas, M. Study of the Properties of a Biodegradable Polymer Filled with Different Wood Flour Particles. Polymers 2020, 12, 2974. https://doi.org/10.3390/polym12122974

Parres F, Peydro MA, Juarez D, Arrieta MP, Aldas M. Study of the Properties of a Biodegradable Polymer Filled with Different Wood Flour Particles. Polymers. 2020; 12(12):2974. https://doi.org/10.3390/polym12122974

Chicago/Turabian StyleParres, Francisco, Miguel Angel Peydro, David Juarez, Marina P. Arrieta, and Miguel Aldas. 2020. "Study of the Properties of a Biodegradable Polymer Filled with Different Wood Flour Particles" Polymers 12, no. 12: 2974. https://doi.org/10.3390/polym12122974

APA StyleParres, F., Peydro, M. A., Juarez, D., Arrieta, M. P., & Aldas, M. (2020). Study of the Properties of a Biodegradable Polymer Filled with Different Wood Flour Particles. Polymers, 12(12), 2974. https://doi.org/10.3390/polym12122974