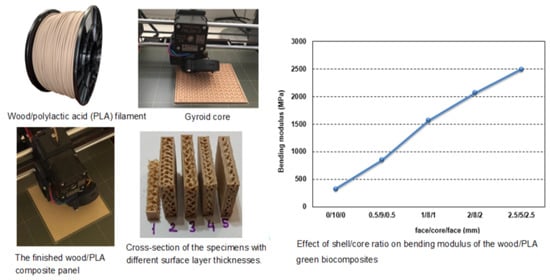

Effects of the Face/Core Layer Ratio on the Mechanical Properties of 3D Printed Wood/Polylactic Acid (PLA) Green Biocomposite Panels with a Gyroid Core

Abstract

:1. Introduction

2. Materials and Methods

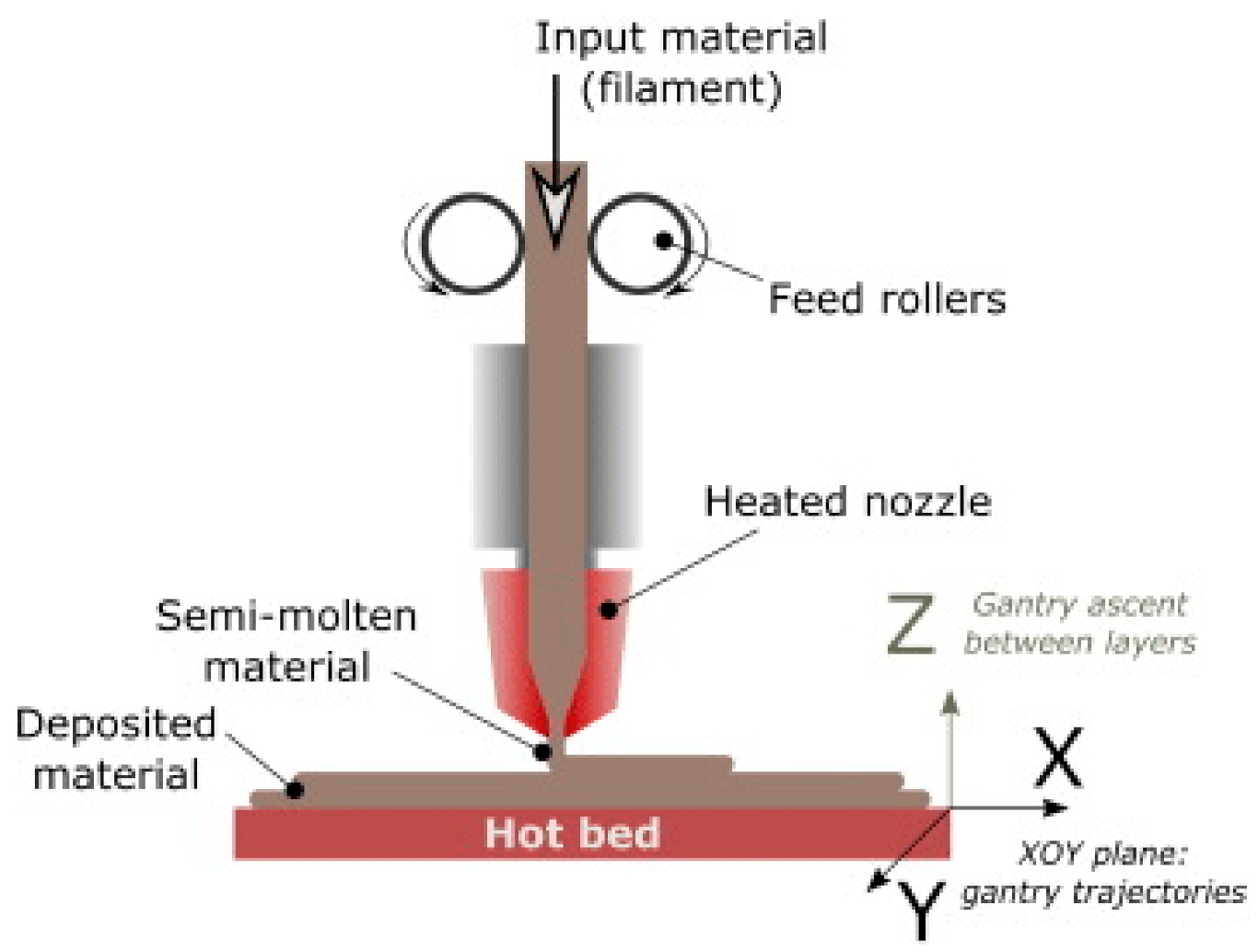

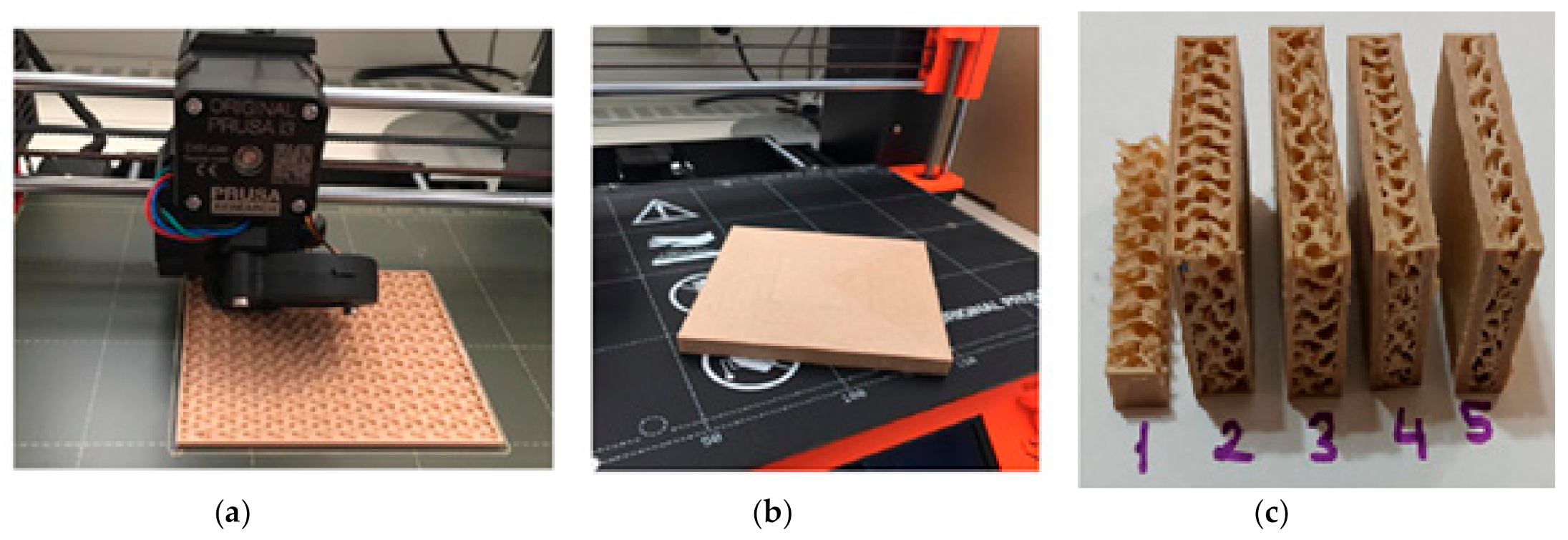

2.1. Manufacture of 3D Printed Wood-PLA Specimens

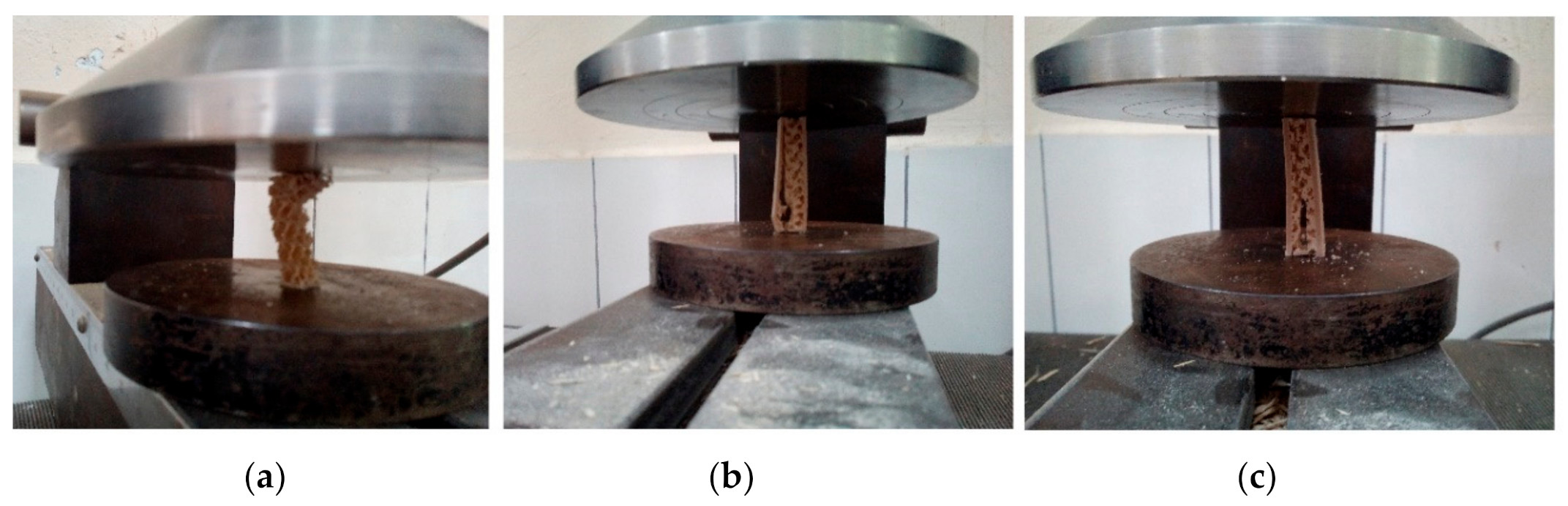

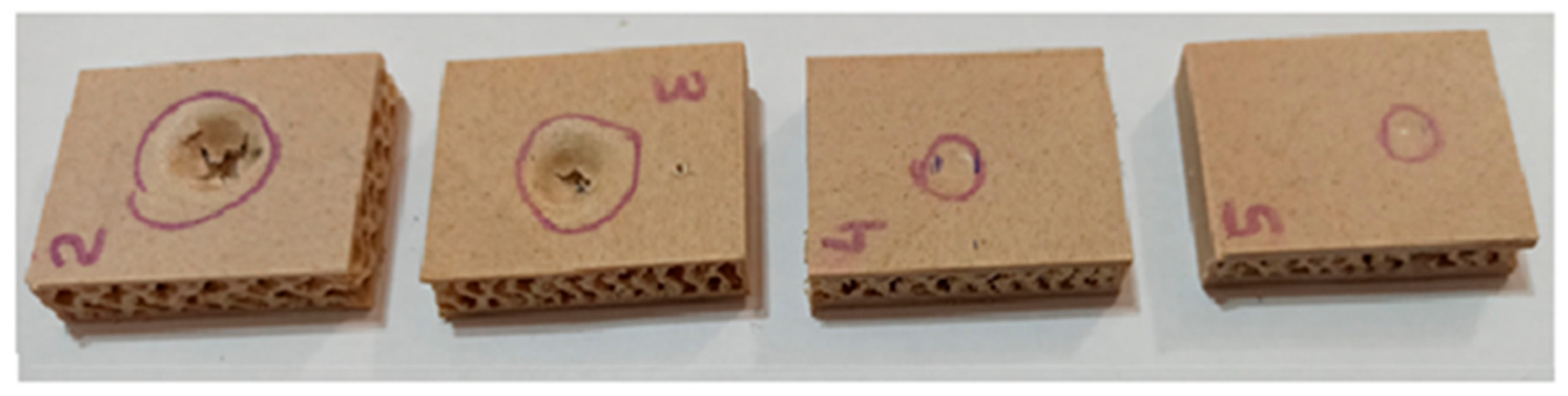

2.2. Determination of Mechanical Properties

2.3. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pranzo, D.; Larizza, P.; Filippini, D.; Percoco, G. extrusion-based 3d printing of microfluidic devices for chemical and biomedical applications: A topical review. Micromachines 2018, 9, 374. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pop, M.A.; Croitoru, C.; Bedo, T.; Geamăn, V.; Radomir, I.; Zaharia, S.M.; Chicoș, L.A. Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts. Polymers 2020, 12, 1129. [Google Scholar] [CrossRef] [PubMed]

- Guessasma, S.; Belhabib, S.; Nouri, H. Microstructure and Mechanical Performance of 3D Printed Wood-PLA/PHA Using Fused Deposition Modelling: Effect of Printing Temperature. Polymers 2019, 11, 1778. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kuznetsov, V.E.; Tavitov, A.G.; Urzhumtsev, O.D.; Mikhalin, M.V.; Moiseev, A.I. Hardware Factors Influencing Strength of Parts Obtained by Fused Filament Fabrication. Polymers 2019, 11, 1870. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.C. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef] [Green Version]

- Singamneni, S.; Smith, D.; LeGuen, M.-J.; Truong, D. Extrusion 3D Printing of Polybutyrate-Adipate-Terephthalate-Polymer Composites in the Pellet Form. Polymers 2018, 10, 922. [Google Scholar] [CrossRef] [Green Version]

- Zaharia, S.M.; Enescu, L.A.; Pop, M.A. Mechanical performances of lightweight sandwich structures produced by material extrusion-based additive manufacturing. Polymers 2020, 12, 1740. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kuzman, M.K. Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials. Int. J. Adv. Manuf. Technol. 2019, 102, 2195–2200. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariž, M.; Kuzman, M.K. Effect of wood flour content on surface properties of 3D printed materials produced from wood flour/PLA filament. Int. J. Polym. Anal. Charac. 2019, 24, 659–666. [Google Scholar] [CrossRef]

- Petras, A. Design of Sandwich Structures. Ph.D. Thesis, Cambridge University, Cambridge, UK, 1988; 100p. [Google Scholar]

- Ayrilmis, N.; Kwon, J.H.; Han, T.H. Improving bending and tensile properties of lignocellulosic filled polypropylene composite panels using aramid fabric. Fiber Polym. 2014, 15, 2410–2415. [Google Scholar] [CrossRef]

- da Silva, C.M.M. 3D Printing of Gyroid Structures for Superior Structural Behaviour. Master’s Thesis, The University of Porto, Porto, Portugal, 2019; 184p. [Google Scholar]

- Khaderi, S.; Deshpande, V.; Fleck, N. The stiffness and strength of the gyroid lattice. Int. J. Solid Struct. 2014, 51, 3866–3877. [Google Scholar] [CrossRef] [Green Version]

- Monkova, K.; Monka, P.; Zetkova, I.; Hanzl, P.; Mandulak, D. Three Approaches to the Gyroid Structure Modelling as a Base of Lightweight Component Produced by Additive Technology. DEStech Trans. Comput. Sci. Eng. CMSAM 2017. [Google Scholar] [CrossRef] [Green Version]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashcroft, I.A. Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Addit. Manuf. 2017, 16, 24–29. [Google Scholar] [CrossRef]

- Jung, G.A.; Yeo, J.; Tian, Z.; Qin, Z.; Buehler, M.J. Unusually low and density-insensitive thermal conductivity of three-dimensional gyroid graphene. Nanoscale 2017, 9, 13477–13484. [Google Scholar] [CrossRef] [PubMed]

- Sparrow, N. 3D Printing. Plastics Today: Community for Plastic Professionals. Available online: https://www.plasticstoday.com/medical/dpi-manufactures-complex-lattice-structures-medical-shipping-technology (accessed on 1 October 2020).

- ISO 291. Plastics—Standard Atmospheres for Conditioning and Testing; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- ISO 178. Plastics-Determination of Flexural Properties; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- ASTM C364/C364M. Standard Test Method for Edgewise Compressive Strength of Sandwich Constructions; American Society for Testing Materials, Volume 04.03; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- EN 1534. Wood Flooring and Parquet—Determination of Resistance to indentation—Test Method; European Committee for Standardization: Brussels, Belgium, 2020. [Google Scholar]

- ISO 27528:2009. Wood-Based Panels-Determination of Resistance to Axial Withdrawal of Screws; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- Wong, E.D.; Yang, P.; Zhang, M.; Wang, Q.; Nakao, T.; Li, K.F.; Kawai, S. Analysis of the effects of density profile on the bending properties of particleboard using finite element method (FEM). Holz Roh Werkst. 2003, 61, 66–72. [Google Scholar] [CrossRef]

- Akbulut, T.; Ayrilmis, N. Some advantages of three-layer medium-density fibreboard as compared to the traditional single-layer one. J. Wood Sci. 2019, 65, 46. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Akbulut, T.; Yurttas, E. Effects of core layer fiber size and face-to-core layer ratio on the properties of three-layered fiberboard. Bioresources 2017, 12, 7964–7974. [Google Scholar]

- Shalbafan, A.; Luedtke, J.; Welling, J.; Thoemen, H. Comparison of foam core materials in innovative lightweight wood-based panels. Eur. J. Wood Prod. 2012, 70, 287–292. [Google Scholar] [CrossRef]

- Gomez-Gras, G.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Lluma-Fuentes, J. Fatigue performance of fused filament fabrication PLA specimens. Mater. Des. 2018, 140, 278–285. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Kang, S.; Ha, Y.; Hong, S.G. Structural behavior of durable composite sandwich panels with high performance expanded polystyrene concrete. Int. J. Concr. Struct. Mater. 2018, 12, 21. [Google Scholar] [CrossRef]

- Hou, Y.; Neville, R.; Scarpa, F.; Remillat, C.; Gu, B.; Ruzzene, M. Graded conventional-auxetic Kirigami sandwich structures: Flatwise compression and edgewise loading. Compos. Part B Eng. 2014, 59, 33–42. [Google Scholar] [CrossRef]

| Specimen Code | Infill Ratio (%) | Sample Thickness (Face/Core/Face) (mm) | Filament Composition | Printing Temperature (°C) | Resolution (mm) | Nozzle Diameter (mm) |

|---|---|---|---|---|---|---|

| 1 | 15 | 0/10/0 | Wood/PLA | 210 | 0.10 | 0.4 |

| 2 | 15 | 0.5/9/0.5 | Wood/PLA | 210 | 0.10 | 0.4 |

| 3 | 15 | 1/8/1 | Wood/PLA | 210 | 0.10 | 0.4 |

| 4 | 15 | 2/6/2 | Wood/PLA | 210 | 0.10 | 0.4 |

| 5 | 15 | 2.5/5/2.5 | Wood/PLA | 210 | 0.10 | 0.4 |

| Specimen Code | Sample Weight 1 (g) | Bending Strength (N/mm2) | Bending Modulus (N/mm2) | Compressive Strength 2 (N/mm2) | Brinell Hardness (N/mm2) | Face Screw Withdrawal Resistance Surface (N) |

|---|---|---|---|---|---|---|

| 1 | 19.4 (0.3) a 3 | 1.76 (0.36) a | 324 (5.28) a | 0.61 (0.06) a | - | - |

| 2 | 41.6 (0.4) b | 8.10 (0.13) b | 847.5 (38) b | 3.52 (0.05) b | 2.12 (06) a | 445 (31) a |

| 3 | 39.7 (0.4) c | 9.74 (0.91) c | 1563 (32) c | 6.61 (0.33) c | 3.35 (0.8) b | 635 (39) b |

| 4 | 56.6 (0.5) d | 9.32 (0.82) c | 2068.3 (49) d | 12.48 (0.51) d | 15.10 (1.9) c | 1032 (28) c |

| 5 | 65.8 (0.3) e | 11.82 (0.11) d | 2492 (41) e | 14.62 (0.30) e | 26.00 (2.3) d | 1475 (54) d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayrilmis, N.; Nagarajan, R.; Kuzman, M.K. Effects of the Face/Core Layer Ratio on the Mechanical Properties of 3D Printed Wood/Polylactic Acid (PLA) Green Biocomposite Panels with a Gyroid Core. Polymers 2020, 12, 2929. https://doi.org/10.3390/polym12122929

Ayrilmis N, Nagarajan R, Kuzman MK. Effects of the Face/Core Layer Ratio on the Mechanical Properties of 3D Printed Wood/Polylactic Acid (PLA) Green Biocomposite Panels with a Gyroid Core. Polymers. 2020; 12(12):2929. https://doi.org/10.3390/polym12122929

Chicago/Turabian StyleAyrilmis, Nadir, Rajini Nagarajan, and Manja Kitek Kuzman. 2020. "Effects of the Face/Core Layer Ratio on the Mechanical Properties of 3D Printed Wood/Polylactic Acid (PLA) Green Biocomposite Panels with a Gyroid Core" Polymers 12, no. 12: 2929. https://doi.org/10.3390/polym12122929

APA StyleAyrilmis, N., Nagarajan, R., & Kuzman, M. K. (2020). Effects of the Face/Core Layer Ratio on the Mechanical Properties of 3D Printed Wood/Polylactic Acid (PLA) Green Biocomposite Panels with a Gyroid Core. Polymers, 12(12), 2929. https://doi.org/10.3390/polym12122929