Impact Strengthening of Laminated Kevlar/Epoxy Composites by Nanoparticle Reinforcement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

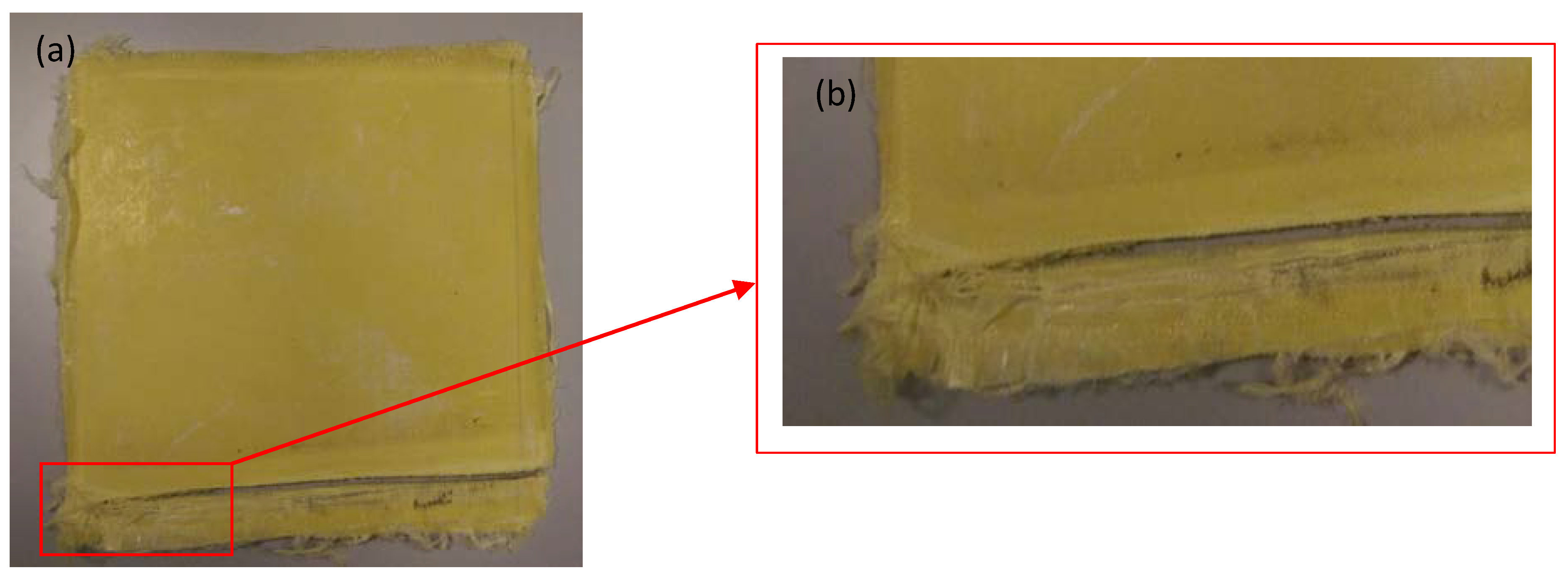

2.2. Method

2.3. Characterization

2.3.1. Differential Scanning Calorimetry (DSC)

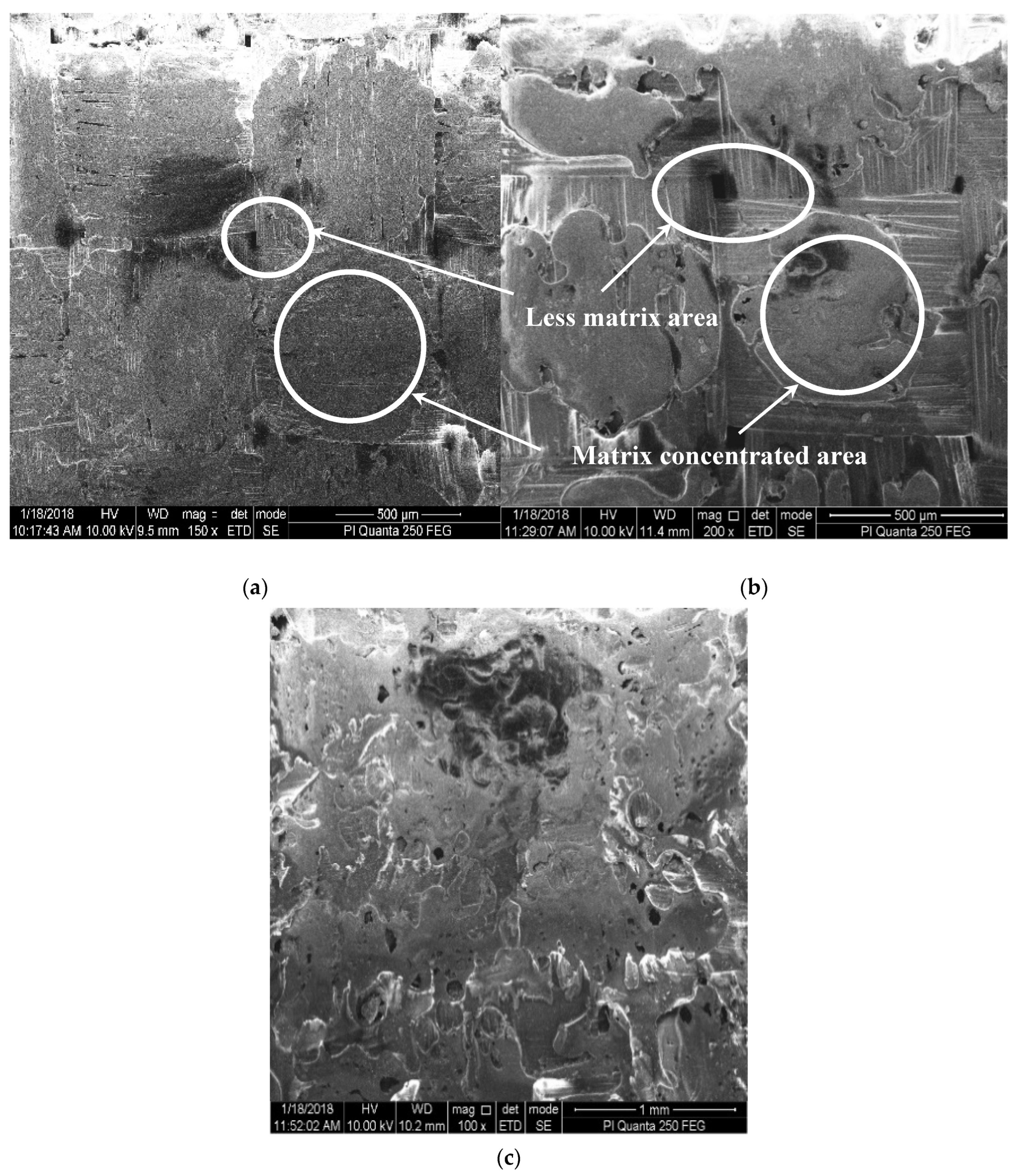

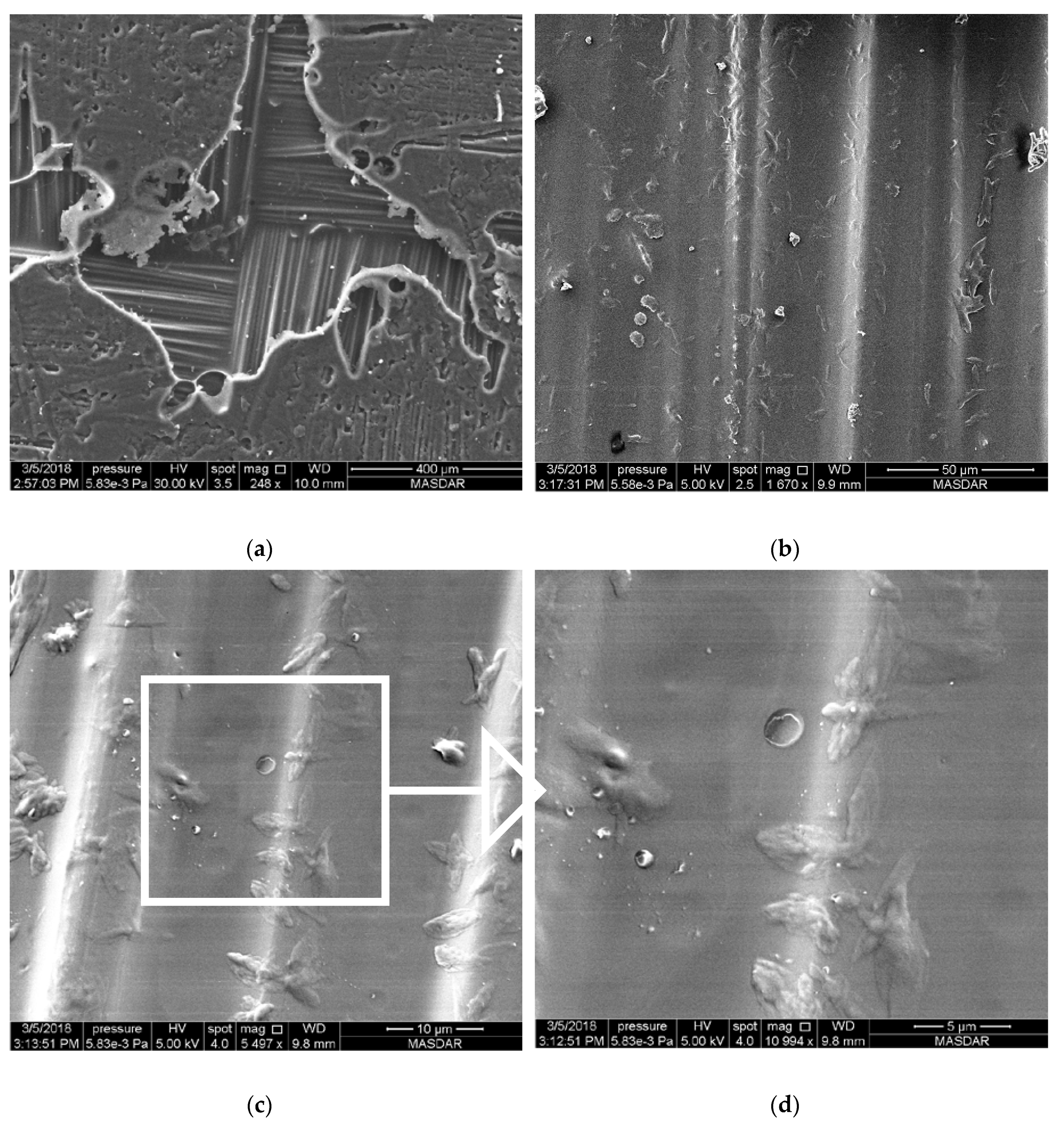

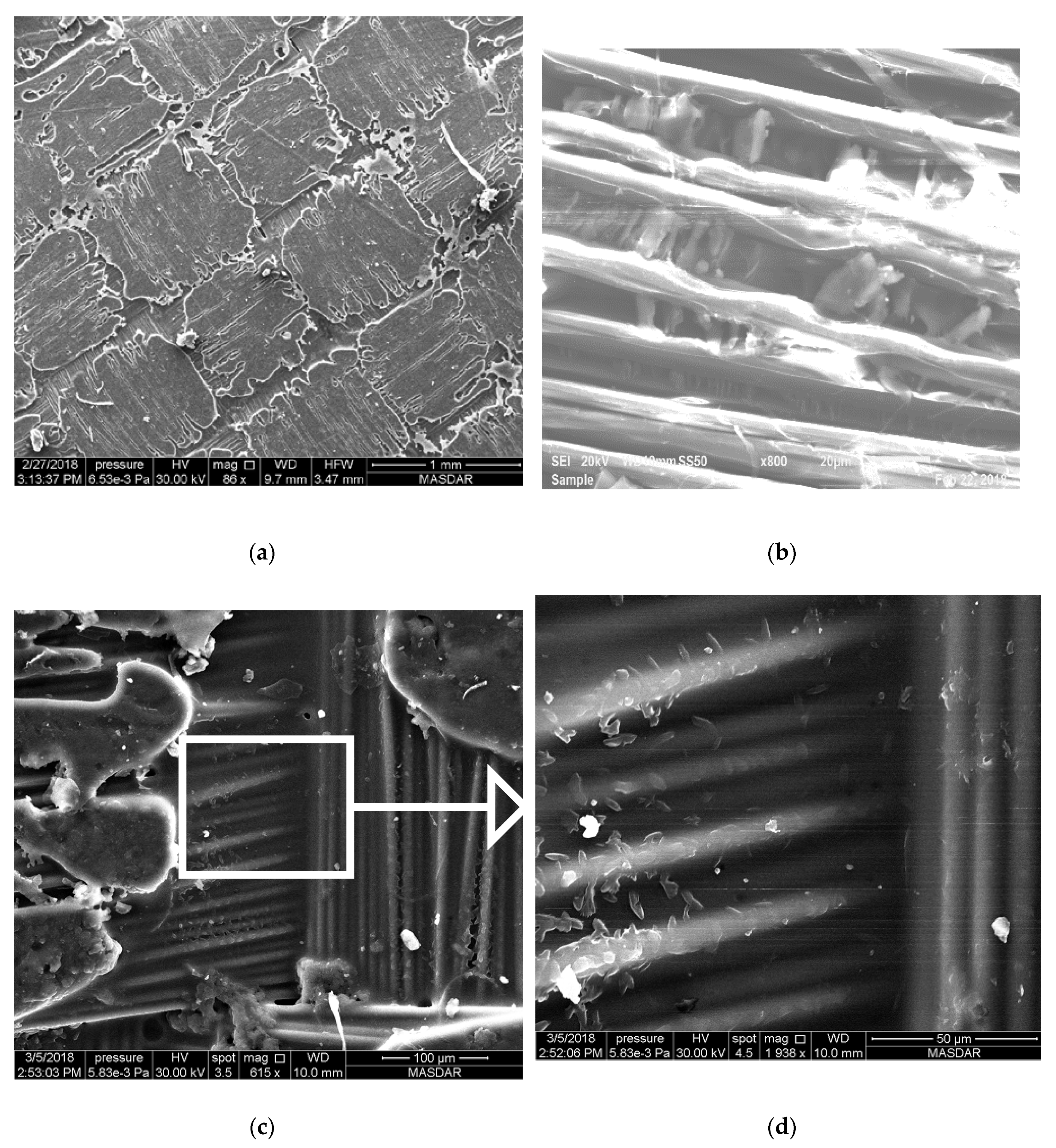

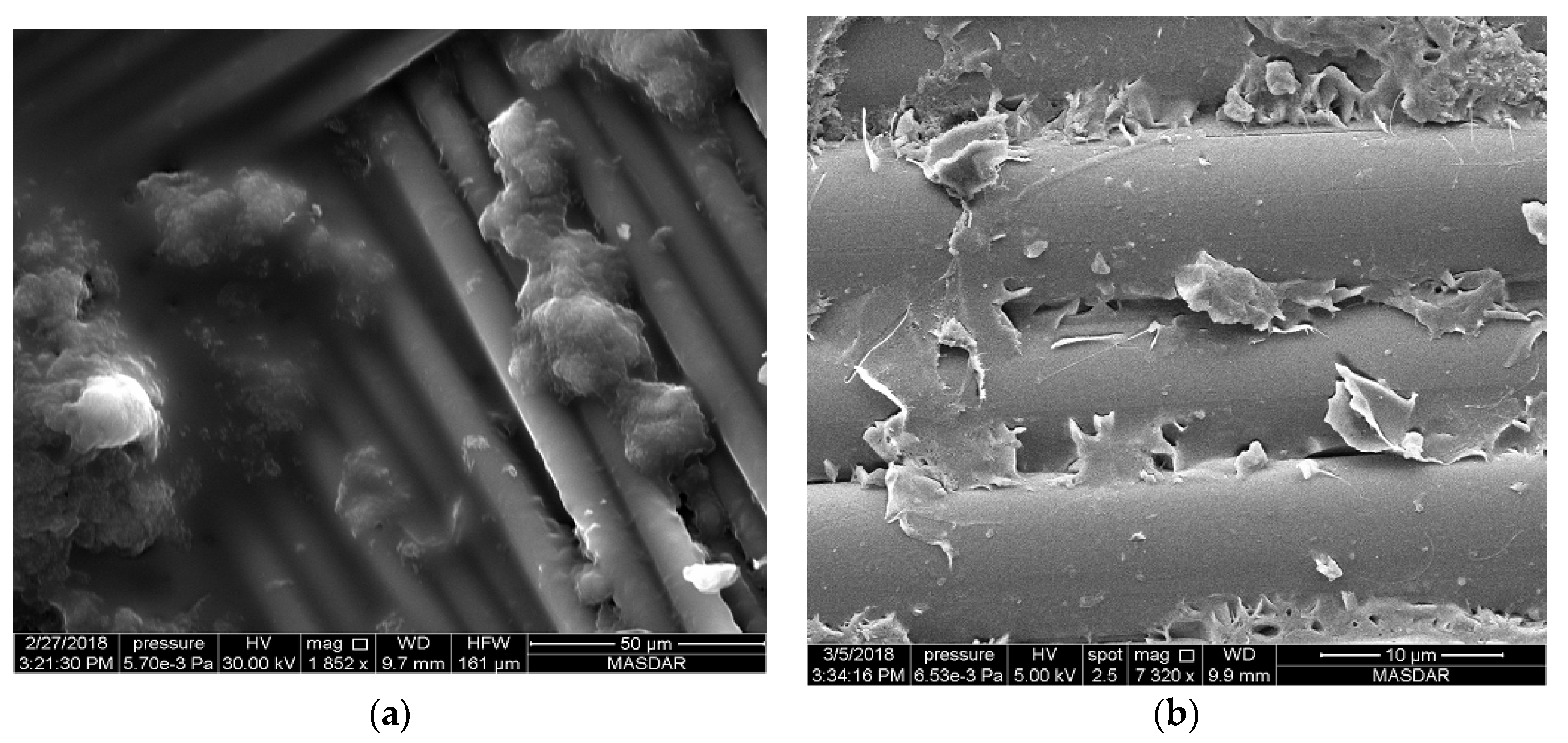

2.3.2. Scanning Electron Microscopy (SEM)

2.3.3. Three-Point Bending Test

2.3.4. Impact Test

3. Results and Discussion

3.1. Differential Scanning Calorimetry (DSC)

3.2. Microstructure (SEM)

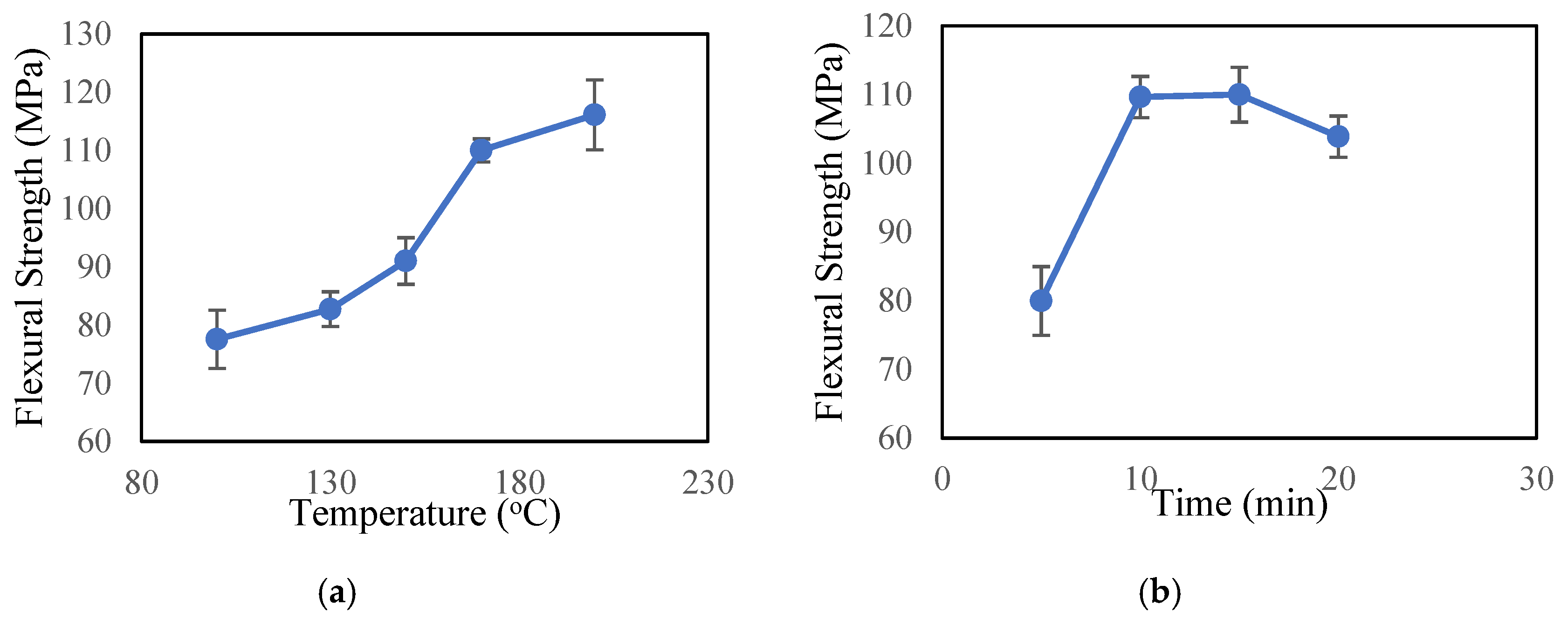

3.3. Three-Point Bending Test

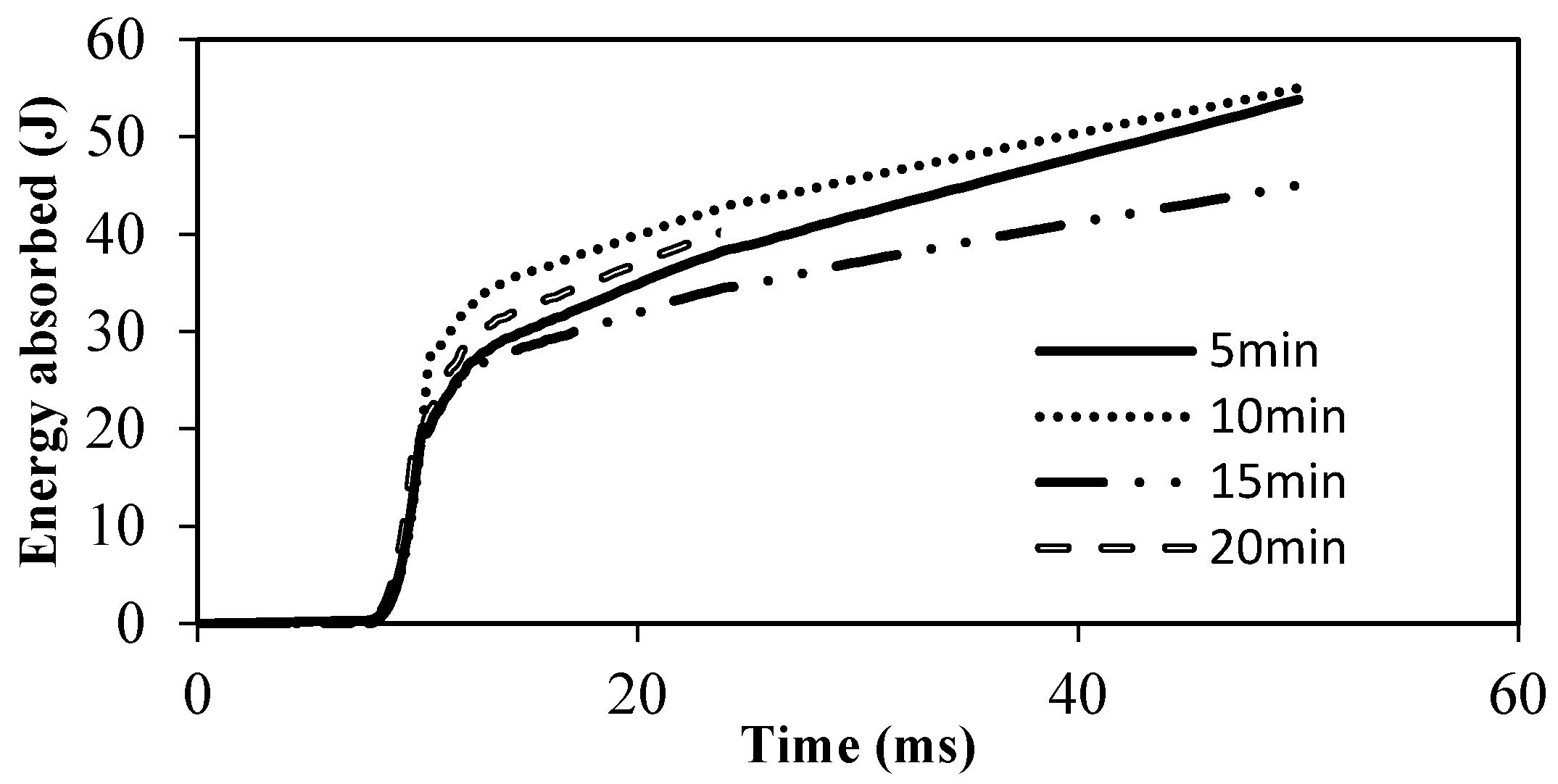

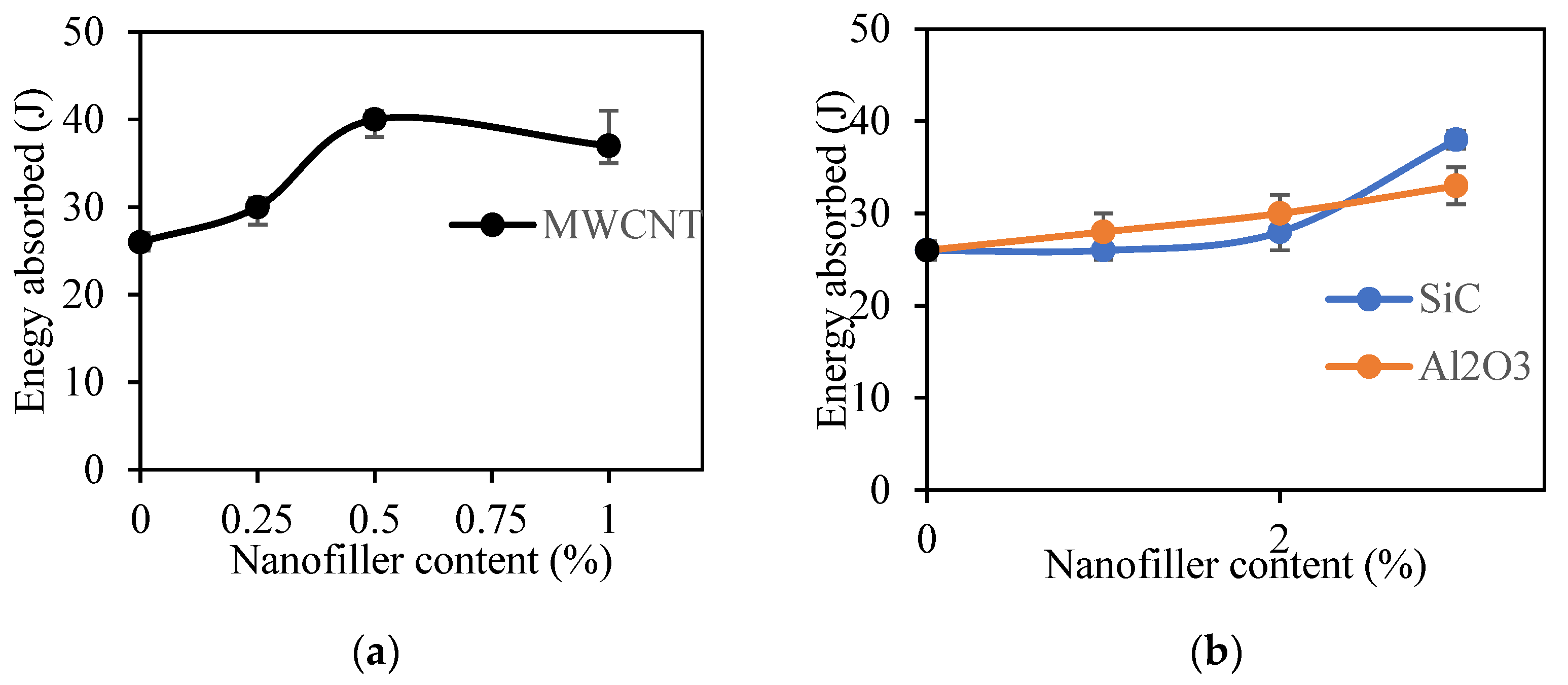

3.4. Impact Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fouad, H.; Mourad, A.-H.I.; ALshammari, B.A.; Hassan, M.K.; Abdallah, M.Y.; Hashem, M. Fracture toughness, vibration modal analysis and viscoelastic behavior of Kevlar, glass, and carbon fiber/epoxy composites for dental-post applications. J. Mech. Behav. Biomed. Mater. 2020, 101, 103456. [Google Scholar] [CrossRef] [PubMed]

- Idrisi, A.H.; Mourad, A.-H.I. Wear performance analysis of aluminum matrix composites and optimization of process parameters using statistical techniques. Metall. Mater. Trans. A 2019, 50, 5395–5409. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Idrisi, A.-H.I.; Wrage, M.C.; Abdel-Magid, B.M. Long-term durability of thermoset composites in seawater environment. Compos. Part B Eng. 2019, 168, 243–253. [Google Scholar] [CrossRef]

- Dehbi, A.; Mourad, A.-H.I. Durability of mono-layer versus tri-layers LDPE films used as greenhouse cover: Comparative study. Arab. J. Chem. 2016, 9, S282–S289. [Google Scholar] [CrossRef] [Green Version]

- Idrisi, A.H.; Ismail Mourad, A.-H.I.; Abdel-Magid, B.; Mozumder, M.; Afifi, Y. Impact of the Harsh Environment on E-Glass Epoxy Composite. In Proceedings of the ASME 2019 Pressure Vessels and Piping Conference, American Society of Mechanical Engineers Digital Collection, San Antonio, TX, USA, 14–19 July 2019. [Google Scholar]

- Idrisi, A.H.; Mourad, A.-H.I. Impact of the harsh environment on GFRE and GFRPol composite. In Proceedings of the OCEANS 2019 MTS/IEEE SEATTLE, Seattle, WA, USA, 27–31 October 2019; pp. 1–5. [Google Scholar]

- Mourad, A.-H.I.; Zaaroura, N. Impact of nanofillers incorporation on laminated nanocomposites performance. J. Mater. Eng. Perform. 2018, 27, 4453–4461. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Zaaroura, N.; Cherupurakal, N. Wet lay-up technique for manufacturing of advanced laminated composites. Karbala Int. J. Mod. Sci. 2019, 5, 5. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Al Mansoori, M.S.; Al Marzooqi, L.A.; Genena, F.A.; Cherupurakal, N. Optimization of curing conditions and nanofiller incorporation for production of high performance laminated Kevlar/epoxy nanocomposites. In American Society of Mechanical Engineers, Pressure Vessels and Piping Division (Publication) PVP; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 51678. [Google Scholar]

- Christy, J.V.; Mourad, A.-H.I.; Arunachalam, R. Sustainable Manufacturing and Optimization of Squeeze Stir Cast Rods Using Recycled Aluminum and Alumina Reinforcements. In Proceedings of the ASME 2020 Pressure Vessels and Piping Conference, Minneapolis, MN, USA, 19–24 July 2020; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2020. [Google Scholar]

- Christy, J.V.; Arunachalam, R.; Mourad, A.-H.I.; Krishnan, P.K.; Piya, S.; Al-Maharbi, M. Processing, Properties, and Microstructure of Recycled Aluminum Alloy Composites Produced Through an Optimized Stir and Squeeze Casting Processes. J. Manuf. Process. 2020, 59, 287–301. [Google Scholar] [CrossRef]

- Kabir, R.B.; Ferdous, N. Kevlar-the super tough fiber. Int. J. Text. Sci. 2012, 1, 78. [Google Scholar] [CrossRef]

- DuPont Website: “Kevlar® Fiber for Military-KM2 Plus”. Available online: https://www.dupont.ae/military-law-enforcement-and-emergency-response/military-body-armor.html (accessed on 24 January 2019).

- Li, M.; Zhu, Y.; Teng, C. Facial fabrication of aramid composite insulating paper with high strength and good thermal conductivity. Compos. Commun. 2020, 21, 100370. [Google Scholar] [CrossRef]

- Clifton, S.; Thimmappa, B.H.S.; Selvam, R.; Shivamurthy, B. Polymer nanocomposites for high-velocity impact applications-A review. Compos. Commun. 2020, 17, 72–86. [Google Scholar] [CrossRef]

- DuPont Website: “Kevlar® for Oil and Gas”. Available online: https://www.dupont.com/personal-protection/oil-and-gas.html (accessed on 24 January 2019).

- Yamasaki, H.; Morita, S. Identification of the epoxy curing mechanism under isothermal conditions by thermal analysis and infrared spectroscopy. J. Mol. Struct. 2014, 1069, 164–170. [Google Scholar] [CrossRef]

- Mravljak, M.; Sernek, M. The influence of curing temperature on rheological properties of epoxy adhesives. Drv. Ind. 2011, 62, 19–25. [Google Scholar] [CrossRef]

- Nakka, J.S. Tailoring of Epoxy Material Properties. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2010. [Google Scholar]

- Suthan, R.; Jayakumar, V.; Madhu, S. Evaluation of mechanical properties of kevlar fibre epoxy composites: An experimental study. Int. J. Veh. Struct. Syst. 2018, 10, 389–394. [Google Scholar] [CrossRef]

- Chinnasamy, V.; Subramani, S.P.; Palaniappan, S.K.; Mylsamy, B.; Aruchamy, K. Characterization on thermal properties of glass fiber and kevlar fiber with modified epoxy hybrid composites. J. Mater. Res. Technol. 2020, 9, 3158–3167. [Google Scholar] [CrossRef]

- Bulut, M.; Alsaadi, M.; Erkliğ, A. A comparative study on the tensile and impact properties of Kevlar, carbon, and S-glass/epoxy composites reinforced with SiC particles. Mater. Res. Express 2018, 5, 25301. [Google Scholar] [CrossRef]

- Derradji, M.; Ramdani, N.; Zhang, T.; Wang, J.; Feng, T.; Wang, H.; Liu, W. Mechanical and thermal properties of phthalonitrile resin reinforced with silicon carbide particles. Mater. Des. 2015, 71, 48–55. [Google Scholar] [CrossRef]

- Chakraborty, D.; Saha, S.; Dey, S.; Pramanik, S. Enhanced mechanical toughness of carbon nanofibrous-coated surface modified Kevlar reinforced polyurethane/epoxy matrix hybrid composites. J. Appl. Polym. Sci. 2020, 137, 48802. [Google Scholar] [CrossRef]

- Pekbey, Y.; Aslantaş, K.; Yumak, N. Ballistic impact response of Kevlar Composites with filled epoxy matrix. Steel Compos. Struct. 2017, 22, 191–200. [Google Scholar]

- Micheli, D.; Vricella, A.; Pastore, R.; Delfini, A.; Giusti, A.; Albano, M.; Marchetti, M.; Moglie, F.; Primiani, V.M. Ballistic and electromagnetic shielding behaviour of multifunctional Kevlar fiber reinforced epoxy composites modified by carbon nanotubes. Carbon N. Y. 2016, 104, 141–156. [Google Scholar] [CrossRef]

- Yang, S.; Chalivendra, V.B.; Kim, Y.K. Impact behaviour of auxetic Kevlar®/epoxy composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 42031. [Google Scholar] [CrossRef]

- Johnsen, B.B.; Frømyr, T.R.; Thorvaldsen, T.; Olsen, T. Preparation and characterisation of epoxy/alumina polymer nanocomposites. Compos. Interfaces 2013, 20, 721–740. [Google Scholar] [CrossRef]

- Mourad, A.-H.I. Thermo-mechanical characteristics of thermally aged polyethylene/polypropylene blends. Mater. Des. 2010, 31, 918–929. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Akkad, R.O.; Soliman, A.A.; Madkour, T.M. Characterisation of thermally treated and untreated polyethylene–polypropylene blends using DSC, TGA and IR techniques. Plast. Rubber Compos. 2009, 38, 265–278. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Fouad, H.; Elleithy, R. Impact of some environmental conditions on the tensile, creep-recovery, relaxation, melting and crystallinity behaviour of UHMWPE-GUR 410-medical grade. Mater. Des. 2009, 30, 4112–4119. [Google Scholar] [CrossRef]

- Mohamed, F.H.; Mourad, A.-H.I.; Barton, D.C. UV irradiation and aging effects on nanoscale mechanical properties of ultra high molecular weight polyethylene for biomedical implants. Plast. Rubber Compos. 2008, 37, 346–352. [Google Scholar] [CrossRef]

- Babaghayou, M.I.; Mourad, A.-H.I.; Lorenzo, V.; Chabira, S.F.; Sebaa, M. Anisotropy evolution of low density polyethylene greenhouse covering films during their service life. Polym. Test. 2018, 66, 146–154. [Google Scholar] [CrossRef]

- Babaghayou, M.I.; Mourad, A.-H.I.; Cherunurakal, N. Anisotropy evaluation of LDPE/LLDPE/PIB trilayer films. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, UAE, 4 February–9 April 2020; pp. 1–3. [Google Scholar]

- Babaghayou, M.I.; Mourad, A.-H.I.; Ochoa, A.; Beltrán, F.; Cherupurakal, N. Study on the thermal stability of stabilized and unstabilized low-density polyethylene films. Polym. Bull. 2020, 1–17. [Google Scholar] [CrossRef]

- Mozumder, M.S.; Mourad, A.-H.I.; Mairpady, A.; Pervez, H.; Haque, M.E. Effect of TiO2 Nanofiller Concentration on the Mechanical, Thermal and Biological Properties of HDPE/TiO2 Nanocomposites. J. Mater. Eng. Perform. 2018, 27, 2166–2181. [Google Scholar] [CrossRef]

- Dehbi, A.; Mourad, A.-H.I.; Djakhdane, K.; Hilal-Alnaqbi, A. Degradation of thermomechanical performance and lifetime estimation of multilayer greenhouse polyethylene films under simulated climatic conditions. Polym. Eng. Sci. 2015, 55, 287–298. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.I.; Hussain, A. Investigation on the mechanical behavior of polyester-scrap tire composites. Constr. Build. Mater. 2016, 127, 896–903. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Abu-Jdayil, B.; Hassan, M. Mechanical behavior of Emirati red shale fillers/unsaturated polyester composite. SN Appl. Sci. 2020, 2, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Pervez, H.; Mozumder, M.S.; Mourad, A.-H.I. Optimization of injection molding parameters for HDPE/TiO2 nanocomposites fabrication with multiple performance characteristics using the Taguchi method and grey relational analysis. Materials 2016, 9, 710. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mourad, A.-H.I.; Elsayed, H.F.; Barton, D.C.; Kenawy, M.; Abdel-Latif, L.A. Ultra high molecular weight polyethylene deformation and fracture behaviour as a function of high strain rate and triaxial state of stress. Int. J. Fract. 2003, 120, 501–515. [Google Scholar] [CrossRef]

- Taraghi, I.; Fereidoon, A.; Taheri-Behrooz, F. Low-velocity impact response of woven Kevlar/epoxy laminated composites reinforced with multi-walled carbon nanotubes at ambient and low temperatures. Mater. Des. 2014, 53, 152–158. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Ferreira, J.A.M.; Santos, P.; Richardson, M.O.W.; Santos, J.B. Impact response of Kevlar composites with filled epoxy matrix. Compos. Struct. 2012, 94, 3520–3528. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Ayad, O.G.; Rahman, A.; Hilal-Alnaqbi, A.; Abu-Jdayil, B.I. Experimental Investigation of Kevlar KM2Plus Nano-Reinforced Laminated Composite Thermo-Mechanical Properties. In ASME 2016 Pressure Vessels and Piping Conference; American Society of Mechanical Engineers: New York, NY, USA, 2016; p. V06AT06A030. [Google Scholar]

- Ciecierska, E.; Boczkowska, A.; Kurzydlowski, K.J.; Rosca, I.D.; Van Hoa, S. The effect of carbon nanotubes on epoxy matrix nanocomposites. J. Therm. Anal. Calorim. 2013, 111, 1019–1024. [Google Scholar] [CrossRef] [Green Version]

- Thostenson, E.T.; Chou, T.-W. Processing-structure-multi-functional property relationship in carbon nanotube/epoxy composites. Carbon N. Y. 2006, 44, 3022–3029. [Google Scholar] [CrossRef]

- Yang, K.; Gu, M.; Guo, Y.; Pan, X.; Mu, G. Effects of carbon nanotube functionalization on the mechanical and thermal properties of epoxy composites. Carbon N. Y. 2009, 47, 1723–1737. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, Y.; Zhou, H.; Zhang, J.; Zou, J. The influence of hydroxylated carbon nanotubes on epoxy resin composites. Adv. Mater. Sci. Eng. 2012, 2012. [Google Scholar] [CrossRef] [Green Version]

- Taraghi, I.; Fereidoon, A.; Mohyeddin, A. The effect of MWCNTs on the mechanical properties of woven Kevlar/epoxy composites. Steel Compos. Struct. 2014, 17, 825–834. [Google Scholar] [CrossRef]

- Wu, A.S.; Chou, T.-W. Carbon nanotube fibers for advanced composites. Mater. Today 2012, 15, 302–310. [Google Scholar] [CrossRef]

- Shivamurthy, B.; Anandhan, S.; Bhat, K.U.; Thimmappa, B.H.S. Structure-property relationship of glass fabric/MWCNT/epoxy multi-layered laminates. Compos. Commun. 2020, 22, 100460. [Google Scholar] [CrossRef]

- Romagnoli, C.; D’Asta, F.; Brandi, M.L. Drug delivery using composite scaffolds in the context of bone tissue engineering. Clin. Cases Miner. Bone Metab. 2013, 10, 155. [Google Scholar] [PubMed]

| Curing Temperature (°C) | Required Time (Minutes) |

|---|---|

| 80 | 25 |

| 100 | 19 |

| 130 | 13 |

| 150 | 10 |

| 170 | 5 |

| 200 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mourad, A.H.I.; Cherupurakal, N.; Hafeez, F.; Barsoum, I.; A. Genena, F.; S. Al Mansoori, M.; A. Al Marzooqi, L. Impact Strengthening of Laminated Kevlar/Epoxy Composites by Nanoparticle Reinforcement. Polymers 2020, 12, 2814. https://doi.org/10.3390/polym12122814

Mourad AHI, Cherupurakal N, Hafeez F, Barsoum I, A. Genena F, S. Al Mansoori M, A. Al Marzooqi L. Impact Strengthening of Laminated Kevlar/Epoxy Composites by Nanoparticle Reinforcement. Polymers. 2020; 12(12):2814. https://doi.org/10.3390/polym12122814

Chicago/Turabian StyleMourad, Abdel Hamid I., Nizamudeen Cherupurakal, Farrukh Hafeez, Imad Barsoum, Farah A. Genena, Mouza S. Al Mansoori, and Lamia A. Al Marzooqi. 2020. "Impact Strengthening of Laminated Kevlar/Epoxy Composites by Nanoparticle Reinforcement" Polymers 12, no. 12: 2814. https://doi.org/10.3390/polym12122814

APA StyleMourad, A. H. I., Cherupurakal, N., Hafeez, F., Barsoum, I., A. Genena, F., S. Al Mansoori, M., & A. Al Marzooqi, L. (2020). Impact Strengthening of Laminated Kevlar/Epoxy Composites by Nanoparticle Reinforcement. Polymers, 12(12), 2814. https://doi.org/10.3390/polym12122814