Dielectric Measurement Based Deducted Quantities to Track Repetitive, Short-Term Thermal Aging of Polyvinyl Chloride (PVC) Cable Insulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

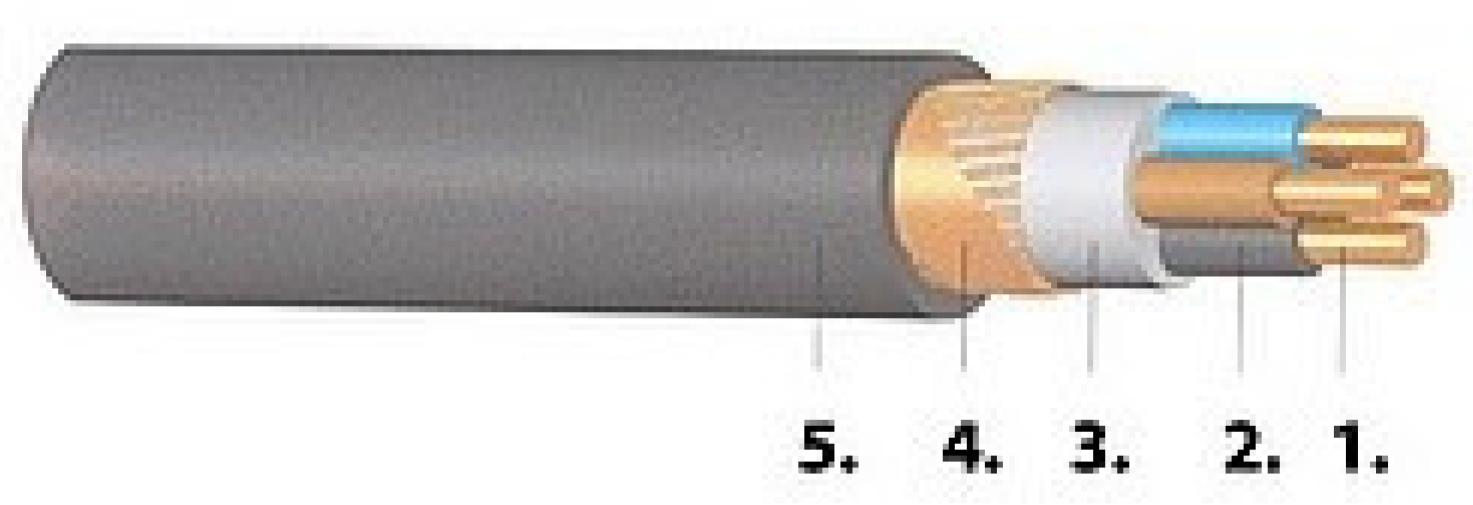

2.1.1. PVC Cable Samples

2.1.2. PVC Films

2.2. Thermal Aging

2.2.1. PVC Cable Samples

- Heating up the heating chamber to the required temperature and letting the temperature stabilize for at least an hour

- Putting the samples into the heating chamber for 3 or 6 h depending on the aging cycle

- Removing the samples from the heating chamber

- Placing the specimens in the laboratory where the temperature was controlled

- Letting the samples rest for at least 8 h

2.2.2. PVC Films

2.3. Measurement Methods

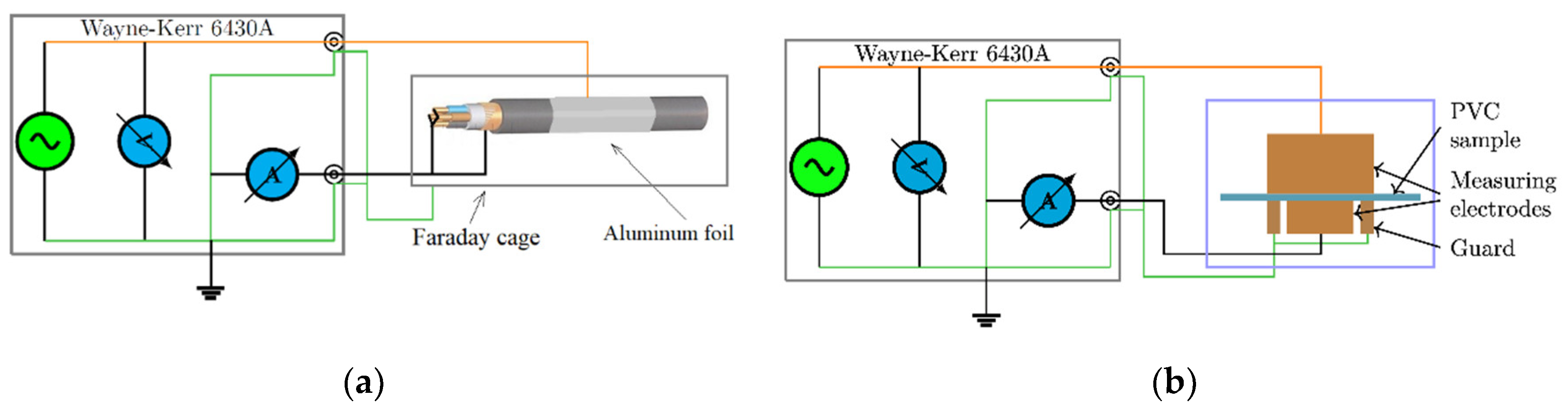

2.3.1. PVC Cable Samples

2.3.2. PVC Films

2.4. Measured and Calculated Deducted Quantities for Following Aging

2.4.1. Central Loss Factor (CLF)

2.4.2. Central Frequency (CF)

2.4.3. Central Capacitance (CC)

2.4.4. Capacitance × Log(Frequency) × tan δ (CxlgFxLF)

2.4.5. Capacitance × Frequency × tan δ (CxFxLF)

2.4.6. Area of Capacitance Times tan δ at Logarithmic Frequencies (Alog)

2.4.7. Multiplication of Available Values: CFxCLFxCC, CFxCLF

2.4.8. VR Measurements

3. Results—PVC Cable Samples

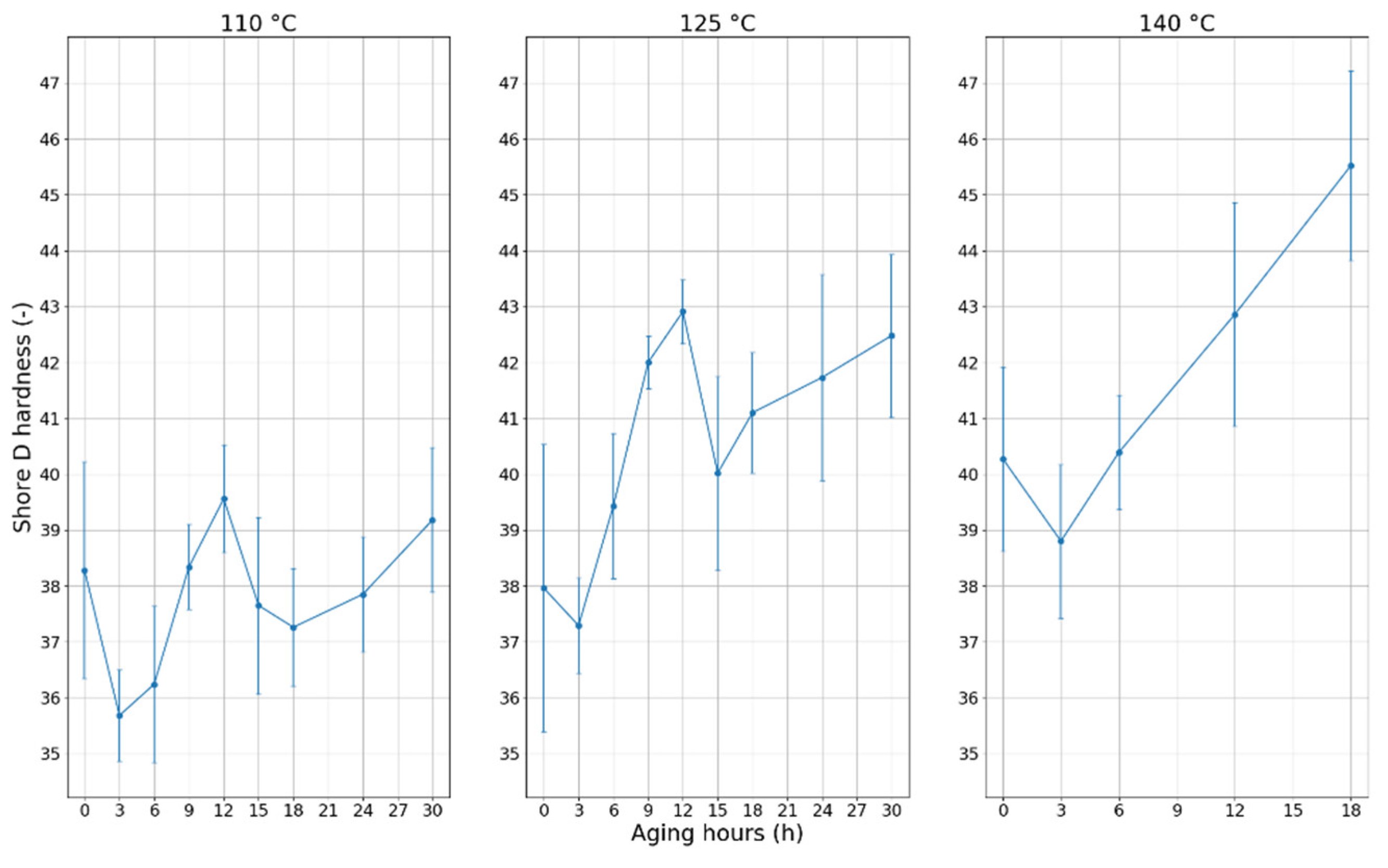

3.1. Shore D vs. Aging

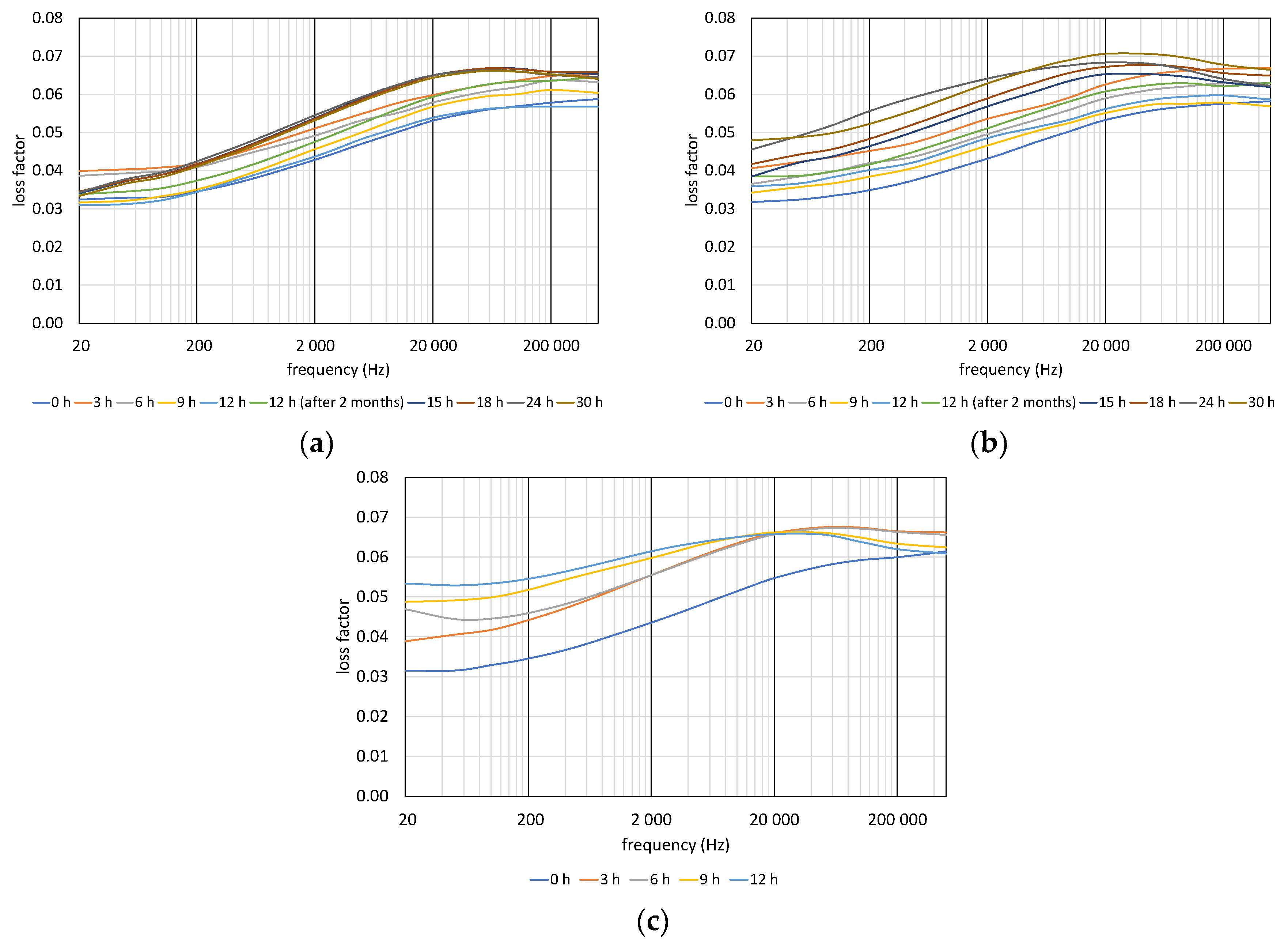

3.2. Loss Factor (Tan Delta) vs. Aging

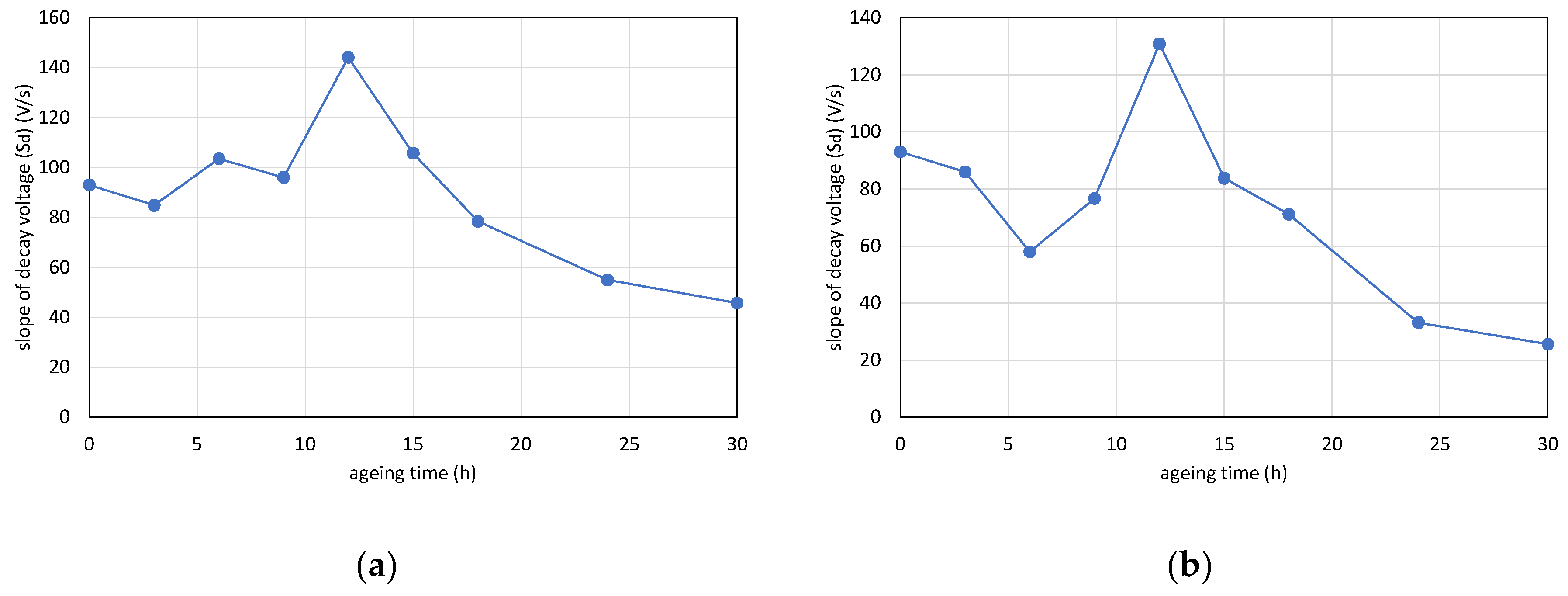

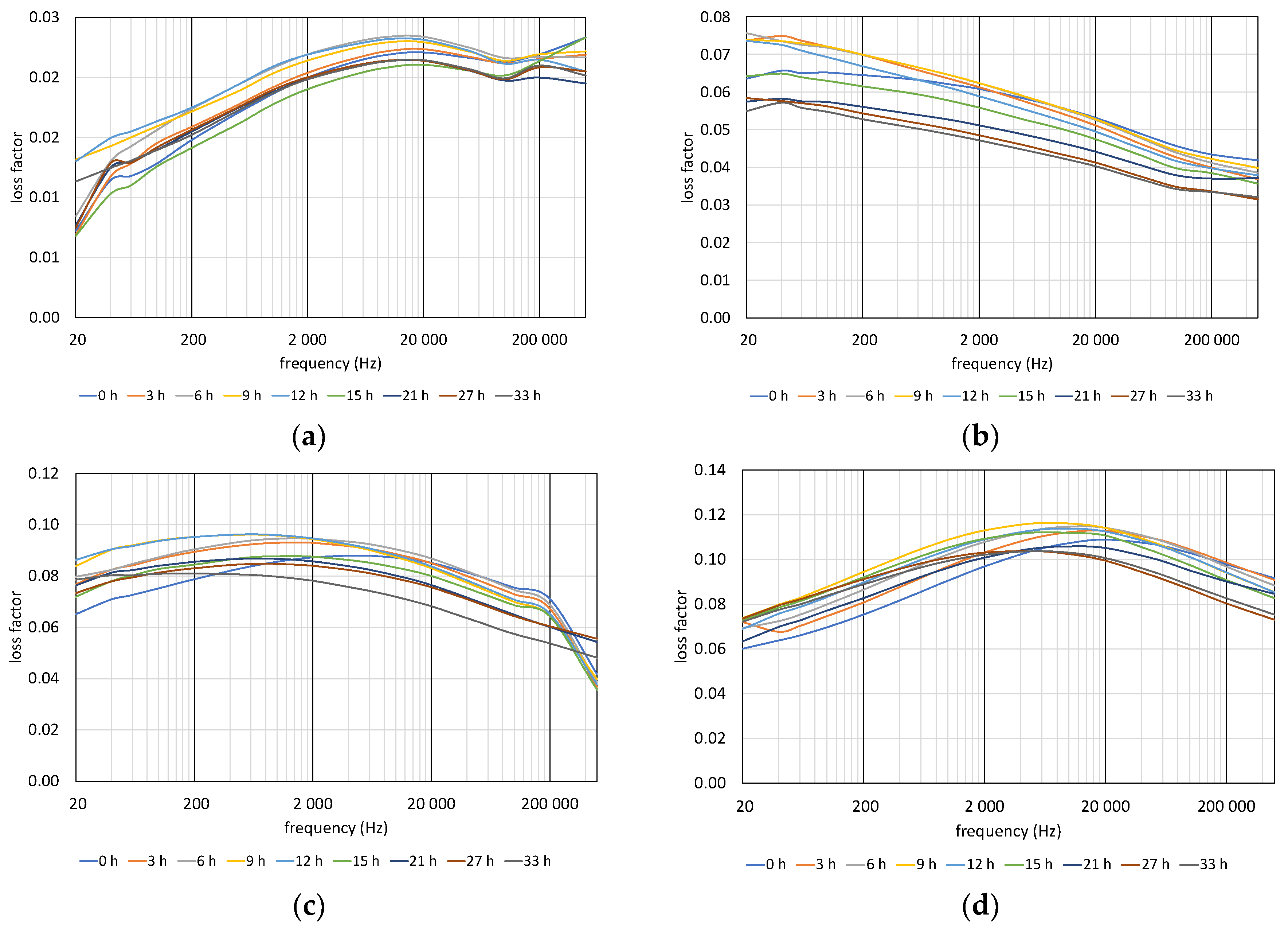

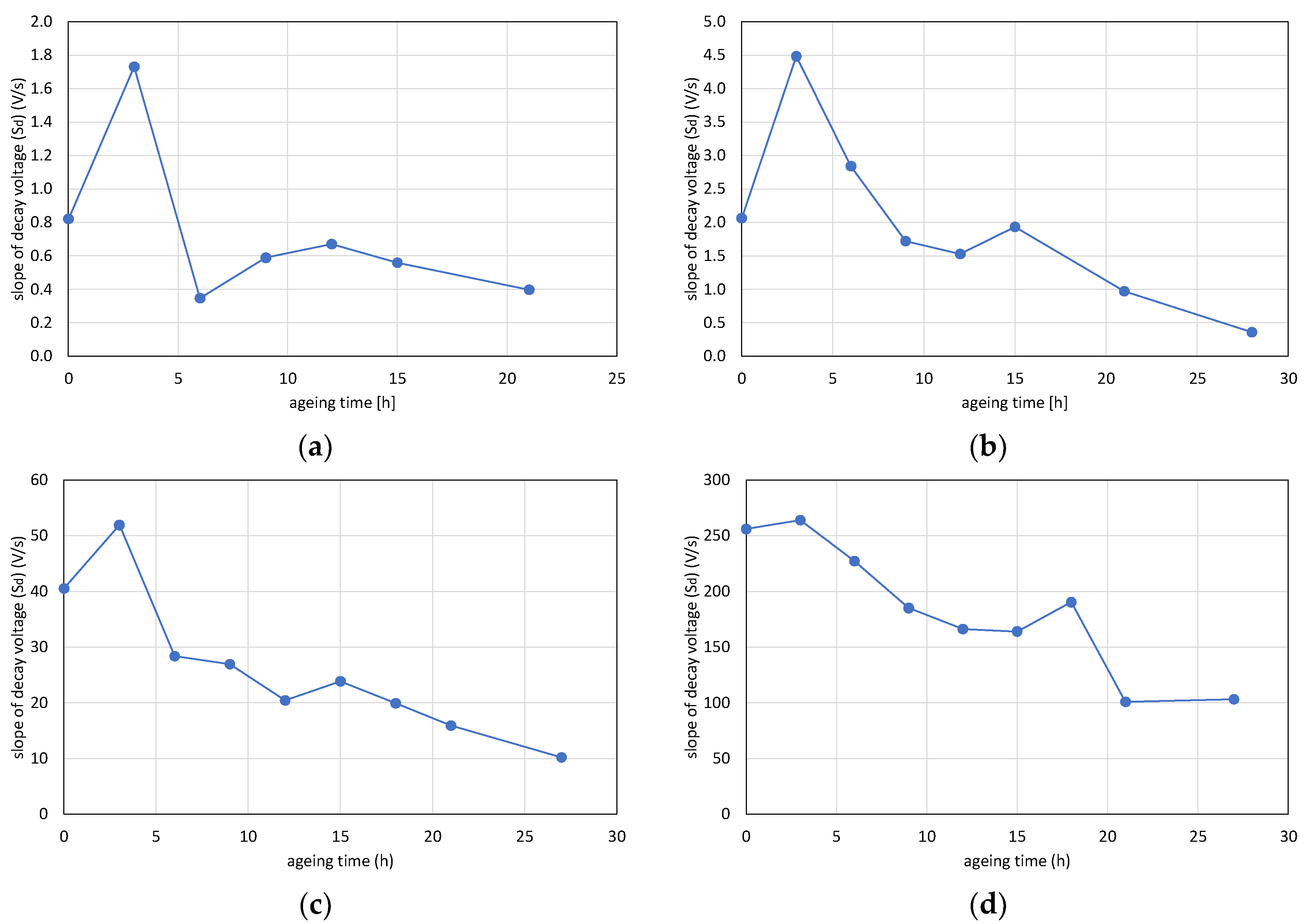

3.3. Slope of Decay Voltage (Sd) vs. Aging Time

3.4. Comparison of Deducted Quantities

3.4.1. All Measurements Converted to Equivalent Aging at 110 °C

3.4.2. Measurements at 110 °C

3.4.3. Measurements at 125 °C

3.4.4. Measurements at 140 °C

4. Results—PVC Films

4.1. Shore D vs. Aging

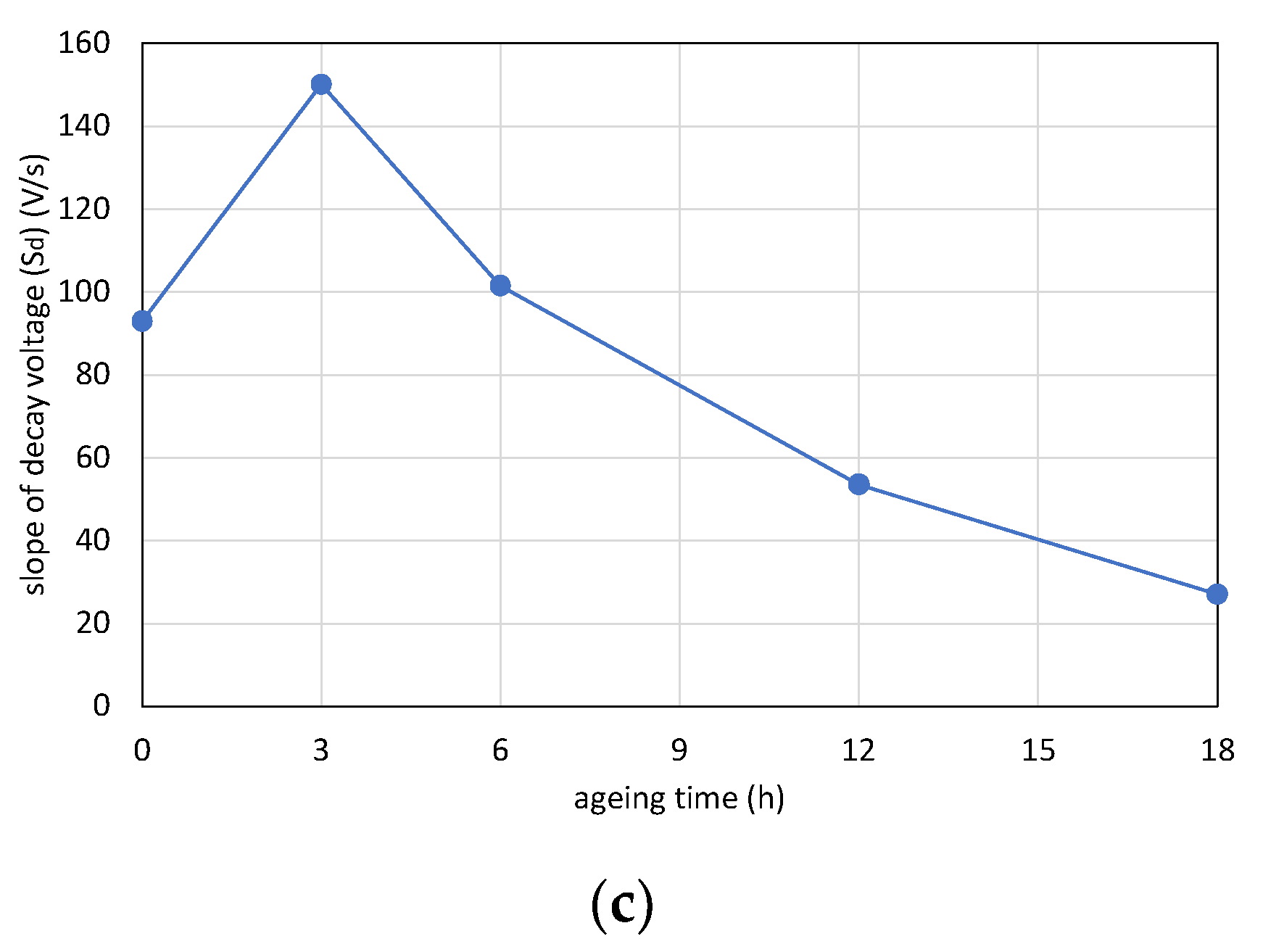

4.2. Loss Factor (tan delta) vs. Aging

4.3. Slope of Decay Voltage (Sd) vs. Aging Time

4.4. Comparison of Deducted Quantities

4.4.1. Nonplasticized Specimens

4.4.2. Plasticized Specimens

5. Discussion

5.1. PVC Cable Samples

5.2. PVC Films

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anandakumaran, K.; Barreca, S.; Seidl, N.; Castaldo, P.V. Nuclear qualification of PVC insulated cables. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 818–825. [Google Scholar] [CrossRef]

- Packa, J.; Váry, M.; Lelák, J.; Šály, V. Degradation of 230/400 V distribution cables with PVC insulation. In Proceedings of the 2017 18th International Scientific Conference on Electric Power Engineering (EPE), Kouty nad Desnou, Czech Republic, 17–19 May 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Kruizinga, B.; Wouters, P.A.A.F.; Steennis, E.F. Fault development on water ingress in damaged underground Low-voltage cables with plastic insulation. In Proceedings of the 2015 IEEE Electrical Insulation Conference (EIC), Seattle, WA, USA, 7–10 June 2015; pp. 309–312. [Google Scholar] [CrossRef]

- Ramteke, P.K.; Ahirwar, A.K.; Shrestha, N.B.; Rao, V.V.S.S.; Vaze, K.K.; Ghosh, A.K. Thermal aging predictions of polymeric insulation cables from Arrhenius plot using short-term test values. In Proceedings of the 2010 2nd International Conference on Reliability, Safety and Hazard-Risk-Based Technologies and Physics-of-Failure Methods (ICRESH), Mumbai, India, 14–16 December 2010; pp. 325–328. [Google Scholar] [CrossRef]

- Konečná, Z. Temperature dependence of electrical parameters of coaxial cables. In Proceedings of the 2016 Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 6–8 September 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Höning, N.; de Jong, E.; Bloemhof, G.; Poutre, H.L. Thermal behavior of low-voltage cables in smart grid—Related environments. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Europe, Istanbul, Turkey, 12–15 October 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Armendariz, M.; Babazadeh, D.; Nordström, L.; Barchiesi, M. A method to place meters in active low-voltage distribution networks using BPSO algorithm. In Proceedings of the 2016 Power Systems Computation Conference (PSCC), Genoa, Italy, 20–24 June 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Kemari, Y.; Mekhaldi, A.; Teguar, M. Investigation into the dissipated energy under accelerated thermal aging in PVC/B used in low-voltage cables insulation. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; pp. 666–669. [Google Scholar] [CrossRef]

- Tamus, Z.Á. Practical consideration of mechanical measurements in cable diagnostics. In Proceedings of the 2011 Electrical Insulation Conference (EIC), Annapolis, MD, USA, 5–8 June 2011; pp. 359–363. [Google Scholar] [CrossRef]

- Nedjar, M.; Beroual, A.; Bournane, M. Thermal aging of polyvinyl chloride. In Proceedings of the CEIDP ‘05. 2005 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, 2005, Nashville, TN, USA, 6–19 October 2005; pp. 261–264. [Google Scholar] [CrossRef]

- Tamus, Z.Á.; Németh, E. Condition assessment of PVC insulated low-voltage cables by voltage response method. In Proceedings of the 2010 International Conference on Condition Monitoring and Diagnosis, CMD 2010, Tokyo, Japan, 11 September 2010; pp. 721–724. [Google Scholar]

- Koga, Y.; Arao, Y.; Kubouchi, M. Application of small punch test to lifetime prediction of plasticized polyvinyl chloride wire. Polym. Degrad. Stab. 2020, 171, 109013. [Google Scholar] [CrossRef]

- Salivon, T.; Colin, X.; Comte, R. Degradation of XLPE and PVC cable insulators. In Proceedings of the 2015 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Ann Arbor, MI, USA, 18–21 October 2015; pp. 656–659. [Google Scholar] [CrossRef]

- Morsy, M.A.; Shwehdi, M.H. A supportive approach into life testing and characterization of PVC and XLPE-insulated cable materials. In Proceedings of the CEIDP ‘05. 2005 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, 2005, Nashville, TN, USA, 16–19 October 2005; pp. 210–213. [Google Scholar] [CrossRef]

- Konečná, Z.; Zavadil, M. Impact of thermal stress on coaxial cable. In Proceedings of the 2017 18th International Scientific Conference on Electric Power Engineering (EPE), Kouty nad Desnou, Czech Republic, 17–19 May 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Marzinotto, M.; Mazzanti, G.; Mazzetti, C.; Pompili, M.; Santulli, C.; Schiaffino, P. Investigation on thermal endurance of PVC compounds for low-voltage cable insulation. In Proceedings of the 2007 Annual Report—Conference on Electrical Insulation and Dielectric Phenomena, Vancouver, BC, Canada, 14–17 October 2007; pp. 49–52. [Google Scholar] [CrossRef]

- Csányi, G.M.; Tamus, Z.Á.; Varga, Á. Impact of Distributed Generation on the Thermal Aging of Low-voltage Distribution Cables. In Technological Innovation for Smart Systems. DoCEIS 2017; Camarinha-Matos, L., Parreira-Rocha, M., Ramezani, J., Eds.; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2017; Volume 499. [Google Scholar] [CrossRef]

- Csányi, G.M.; Tamus, Z.Á.; Kordás, P. Effect of Enhancing Distribution Grid Resilience on Low-voltage Cable Aging. In Technological Innovation for Resilient Systems. DoCEIS 2018; Camarinha-Matos, L., Adu-Kankam, K., Julashokri, M., Eds.; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2018; Volume 521. [Google Scholar] [CrossRef]

- Bal, S.; Tamus, Z.Á. Investigation of Effects of Short-Term Thermal Stress on PVC Insulated Low-voltage Distribution Cables. Period. Polytech. Electr. Eng. Comput. Sci. in press.

- Csányi, G.M.; Tamus, Z.Á. Temperature dependence of conductive and polarization processes of PVC cable. In Proceedings of the 2014 IEEE Electrical Insulation Conference (EIC), Philadelphia, PA, USA, 8–11 June 2014; pp. 299–302. [Google Scholar] [CrossRef]

- Nagy, A.; Tamus, Z.Á. Effect of dioctyl phthalate (DOP) plasticizing agent on the dielectric properties of PVC insulation. In Proceedings of the 2016 Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 16–8 September 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Ekelund, M.; Edin, H.; Gedde, U.W. Long-term performance of poly (vinyl chloride) cables. part 1: Mechanical and electrical performances. Polym. Degrad. Stab. 2007, 92, 617–629. [Google Scholar] [CrossRef]

- Tamus, Z. Ádám; Csábi, D.; Csányi, G.M. Characterization of dielectric materials by the extension of voltage response method. J. Phys. Conf. Ser. 2015, 646, 012043. [Google Scholar] [CrossRef]

- Csányi, G.M.; Tamus, Z.Á.; Iváncsy, T. Investigation of dielectric properties of cable insulation by the extended voltage response method. In Proceedings of the 2016 Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 6–8 September 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Nemeth, E. Some newest results of diagnostics testing of impregnated paper insulated cable. In Proceedings of the 10th International Symposium on High-Voltage Engineering, ISH’97, Montréal, QC, Canada, 25–29 August 1997; Volume 4, pp. 191–194. [Google Scholar]

- Nemeth, E. Measuring voltage response: A non-destructive diagnostic test method of HV insulation. IEEE Proc. Sci. Meas. Technol. 1999, 146, 249–252. [Google Scholar] [CrossRef]

- Csányi, G.M.; Tamus, Z.Á. Effect of short term thermal aging on PVC films by the extended voltage response measurement method. In Proceedings of the 2020 International Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 1–4 September 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Imperatore, M.V.; Fifield, L.S.; Fabiani, D.; Bowler, N. Dielectric spectroscopy on thermally aged, intact, poly-vinyl chloride/ethylene propylene rubber (PVC/EPR) multipolar cables. In Proceedings of the 2017 IEEE Conference on Electrical Insulation and Dielectric Phenomenon (CEIDP), Fort Worth, TX, USA, 20–25 October 2017; pp. 173–176. [Google Scholar] [CrossRef]

- Yoshida, S.; Sato, T.; Kobayashi, Y.; Sato, T.; Shiono, T.; Hirai, S.; Minami, M.; Aida, F.; Nakagawa, M.; Arai, Y. Development of a method to evaluate deterioration degree of low-voltage PVC sheathed cable. In Proceedings of the Conference Record of the 1998 IEEE International Symposium on Electrical Insulation (Cat. No.98CH36239), Piscataway, NJ, USA; 1998; Volume 1, pp. 715–718. [Google Scholar] [CrossRef]

- Nedjar, M.; Béroual, A.; Boubakeur, A. Influence of thermal aging on the electrical properties of poly(vinyl chloride). J. Appl. Polym. Sci. 2006, 102, 4728–4733. [Google Scholar] [CrossRef]

- Audouin, L.; Dalle, B.; Metzger, G.; Verdu, J. Thermal aging of plasticized PVC. II. Effect of plasticizer loss on electrical and mechanical properties. J. Appl. Polym. Sci. 1992, 45, 2097–2103. [Google Scholar] [CrossRef]

- Ito, M.; Nagai, K. Analysis of degradation mechanism of plasticized PVC under artificial aging conditions. Polym. Degrad. Stab. 2007, 92, 260–270. [Google Scholar] [CrossRef]

- Quennehen, P.; Royaud, I.; Seytre, G.; Gain, O.; Rain, P.; Espilit, T.; Francois, S. Determination of the aging mechanism of single core cables with PVC insulation. Polym. Degrad. Stab. 2015, 119, 96–104. [Google Scholar] [CrossRef]

- Wei, X.; Linde, E.; Hedenqvist, M.S. Plasticiser loss from plastic or rubber products through diffusion and evaporation. NPJ Mater. Degrad. 2019, 3, 18. [Google Scholar] [CrossRef]

- Audouin, L.; Verdu, J. Thermal aging of plasticized PVC: Effect of loss kinetics on plasticizer depth distribution. In Proceedings of the 1994 4th International Conference on Properties and Applications of Dielectric Materials (ICPADM), Brisbane, Queensland, Australia, 3–8 July 1994; Volume 1, pp. 262–265. [Google Scholar] [CrossRef]

- Fisch, M.; Bacaloglu, R. Study of additive compatibility with poly(vinyl chloride) (PVC). 2: Dynamic mechanical analysis of PVC lubrication by stearic acid and its derivatives. J. Vinyl. Addit. Technol. 1998, 4, 4–11. [Google Scholar] [CrossRef]

- Al-Malaika, S.; Axtell, F.; Rothon, R.; Gilbert, M. Chapter 7—Additives for plastics. In Brydson’s Plastics Materials, 8th ed.; Marianne, G., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 127–168. [Google Scholar] [CrossRef]

| 125 °C | 140 °C | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aging Time at Different Temperatures (h) | 3 | 6 | 9 | 12 | 15 | 18 | 24 | 30 | 3 | 6 | 12 | 18 |

| Equivalent Aging Time at 110 °C (h) | 8 | 15 | 23 | 31 | 39 | 46 | 62 | 77 | 19 | 37 | 74 | 111 |

| CLF | CF | CFxCLF | CFxCLFxCC | CxFxLF | CC | Alog | ShoreD | CxLFxlgF | Sd | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 110 °C (21 meas.) | Aging t. | 0.687 | −0.853 | −0.676 | 0.077 | −0.354 | 0.874 | 0.875 | 0.853 | 0.849 | −0.636 |

| ShoreD | 0.332 | −0.700 | −0.717 | −0.092 | −0.592 | 0.706 | 0.627 | 1.000 | 0.598 | −0.388 | |

| Diff. | −0.831 | −0.612 | −0.897 | −0.835 | −0.844 | −0.589 | −0.753 | 1.000 | −0.765 | 0.090 | |

| 110 °C (9 meas.) | Aging t. | 0.675 | 0.277 | 0.830 | 0.869 | 0.849 | 0.877 | 0.815 | 0.432 | 0.826 | −0.440 |

| ShoreD | −0.319 | 0.842 | 0.407 | 0.357 | 0.016 | 0.293 | −0.045 | 1.000 | −0.013 | 0.065 | |

| Diff. | −0.941 | 0.781 | −0.025 | −0.174 | −0.896 | −0.389 | −0.869 | 1.000 | −0.862 | 0.306 | |

| 125 °C (9 meas.) | Aging t. | 0.821 | −0.898 | −0.469 | 0.835 | 0.935 | 0.984 | 0.959 | 0.721 | 0.957 | −0.393 |

| ShoreD | 0.281 | −0.519 | −0.609 | 0.464 | 0.524 | 0.677 | 0.529 | 1.000 | 0.531 | 0.076 | |

| Diff. | −0.739 | 0.586 | −0.433 | −0.336 | −0.492 | −0.167 | −0.754 | 1.000 | −0.707 | 0.302 | |

| 140 °C (4 meas.) | Aging t. | 0.700 | −0.962 | −0.980 | −0.769 | 0.601 | 0.848 | 0.860 | 0.932 | 0.811 | −0.980 |

| ShoreD | 0.395 | −0.811 | −0.957 | −0.943 | 0.279 | 0.606 | 0.619 | 1.000 | 0.548 | −0.915 | |

| Diff. | −0.993 | 0.793 | −0.851 | −0.990 | −0.960 | −0.940 | −0.977 | 1.000 | −0.975 | −0.569 | |

| CLF | CF | CFxCLF | CFxCLFxCC | CxFxLF | CC | Alog | ShoreD | CxLFxlgF | Sd | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DOP0 | Aging t. | −0.580 | −0.295 | −0.516 | −0.628 | −0.865 | −0. 15 | −0.569 | 0.122 | −0.686 | −0.535 |

| ShoreD | 0.404 | −0.451 | −0.377 | −0.297 | 0.019 | 0.281 | 0.458 | 1.000 | 0.403 | −0.776 | |

| Diff. | 0.947 | −0.114 | 0.376 | 0.603 | 0.924 | 0.976 | 0.934 | 1.000 | 0.657 | −0.904 | |

| DOP30 | Aging t. | −0.950 | −0.027 | −0.811 | −0.867 | −0.935 | −0.843 | −0.924 | 0.810 | −0.935 | −0.769 |

| ShoreD | −0.838 | 0.418 | −0.398 | −0.468 | −0.675 | −0.660 | −0.832 | 1.000 | −0.816 | −0.880 | |

| Diff. | −0.693 | 0.746 | 0.023 | −0.156 | −0.549 | −0.627 | −0.698 | 1.000 | −0.060 | −0.808 | |

| DOP40 | Aging t. | −0.879 | −0.637 | −0.831 | −0.869 | −0.929 | −0.905 | −0.811 | 0.724 | −0.875 | −0.884 |

| ShoreD | −0.876 | −0.087 | −0.362 | −0.415 | −0.620 | −0.728 | −0.873 | 1.000 | −0.856 | −0.423 | |

| Diff. | −0.456 | 0.605 | 0.514 | 0.489 | 0.255 | −0.066 | −0.518 | 1.000 | −0.414 | −0.131 | |

| DOP50 | Aging t. | −0.690 | −0.829 | −0.918 | −0.936 | −0.958 | −0.950 | −0.591 | 0.836 | −0.771 | −0.925 |

| ShoreD | −0.796 | −0.544 | −0.692 | −0.721 | −0.786 | −0.830 | −0.736 | 1.000 | −0.832 | −0.639 | |

| Diff. | −0.364 | 0.055 | −0.046 | −0.038 | −0.059 | 0.074 | −0.250 | 1.000 | −0.278 | 0.413 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Csányi, G.M.; Bal, S.; Tamus, Z.Á. Dielectric Measurement Based Deducted Quantities to Track Repetitive, Short-Term Thermal Aging of Polyvinyl Chloride (PVC) Cable Insulation. Polymers 2020, 12, 2809. https://doi.org/10.3390/polym12122809

Csányi GM, Bal S, Tamus ZÁ. Dielectric Measurement Based Deducted Quantities to Track Repetitive, Short-Term Thermal Aging of Polyvinyl Chloride (PVC) Cable Insulation. Polymers. 2020; 12(12):2809. https://doi.org/10.3390/polym12122809

Chicago/Turabian StyleCsányi, Gergely Márk, Semih Bal, and Zoltán Ádám Tamus. 2020. "Dielectric Measurement Based Deducted Quantities to Track Repetitive, Short-Term Thermal Aging of Polyvinyl Chloride (PVC) Cable Insulation" Polymers 12, no. 12: 2809. https://doi.org/10.3390/polym12122809

APA StyleCsányi, G. M., Bal, S., & Tamus, Z. Á. (2020). Dielectric Measurement Based Deducted Quantities to Track Repetitive, Short-Term Thermal Aging of Polyvinyl Chloride (PVC) Cable Insulation. Polymers, 12(12), 2809. https://doi.org/10.3390/polym12122809