Effects of Micro-Braiding and Co-Wrapping Techniques on Characteristics of Flax/Polypropylene-Based Hybrid Yarn: A Comparative Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

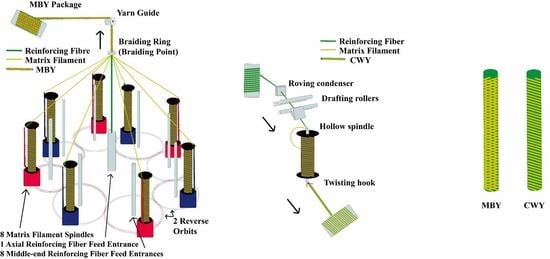

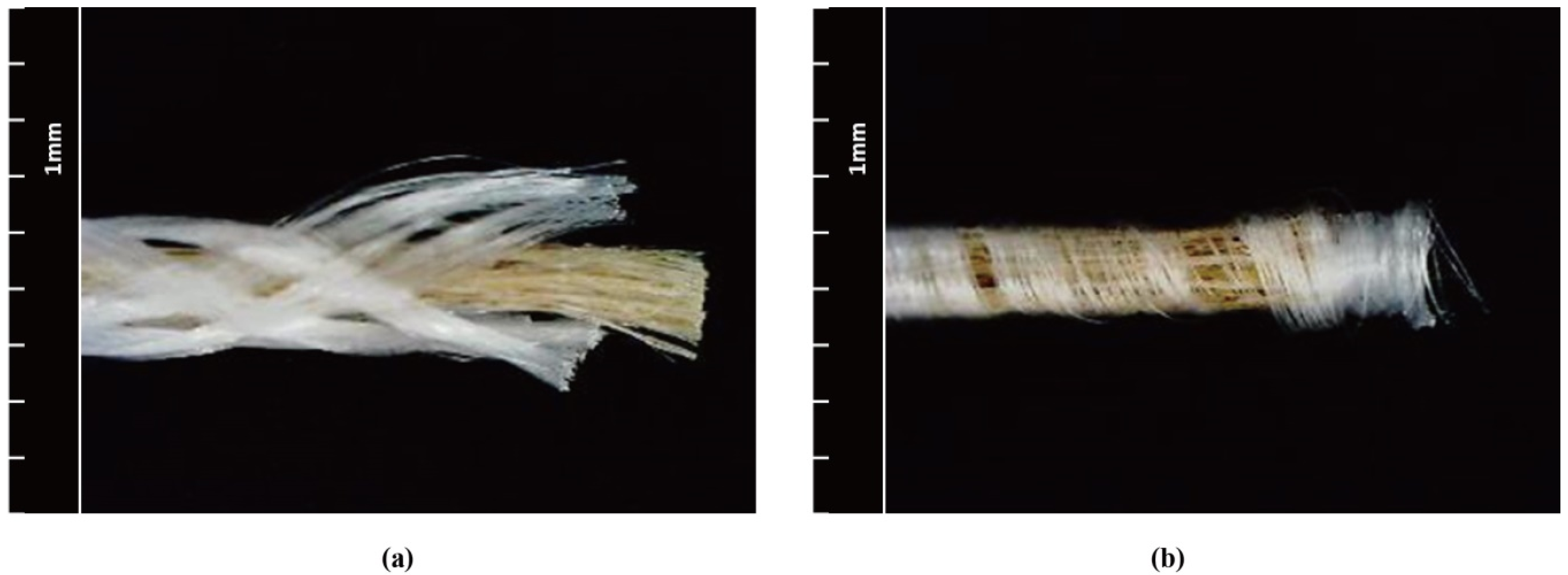

2.2. Preparation of the Flax/PP Hybrid Yarns

2.3. Textile Properties Testing

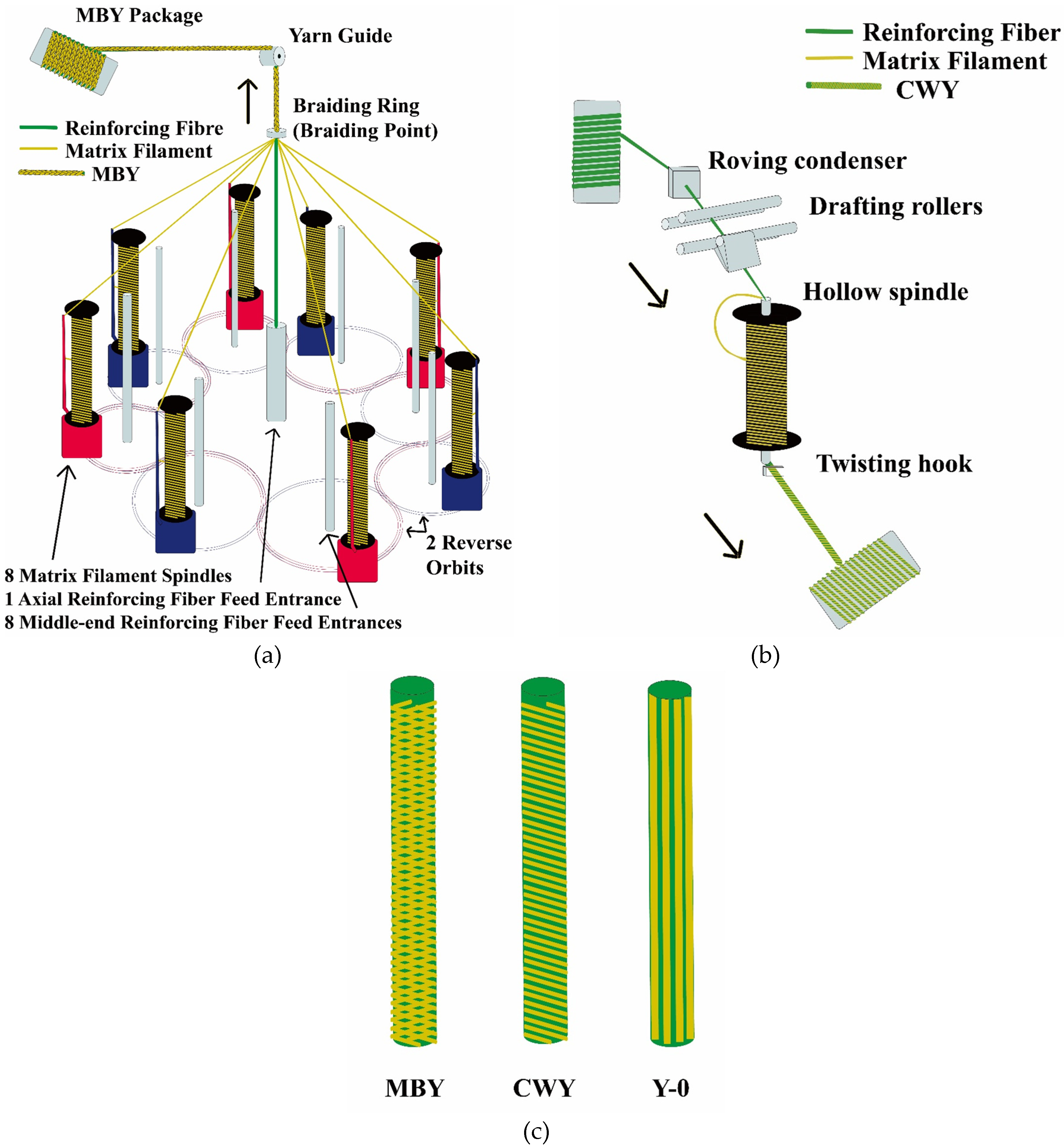

2.4. Tensile Characterization

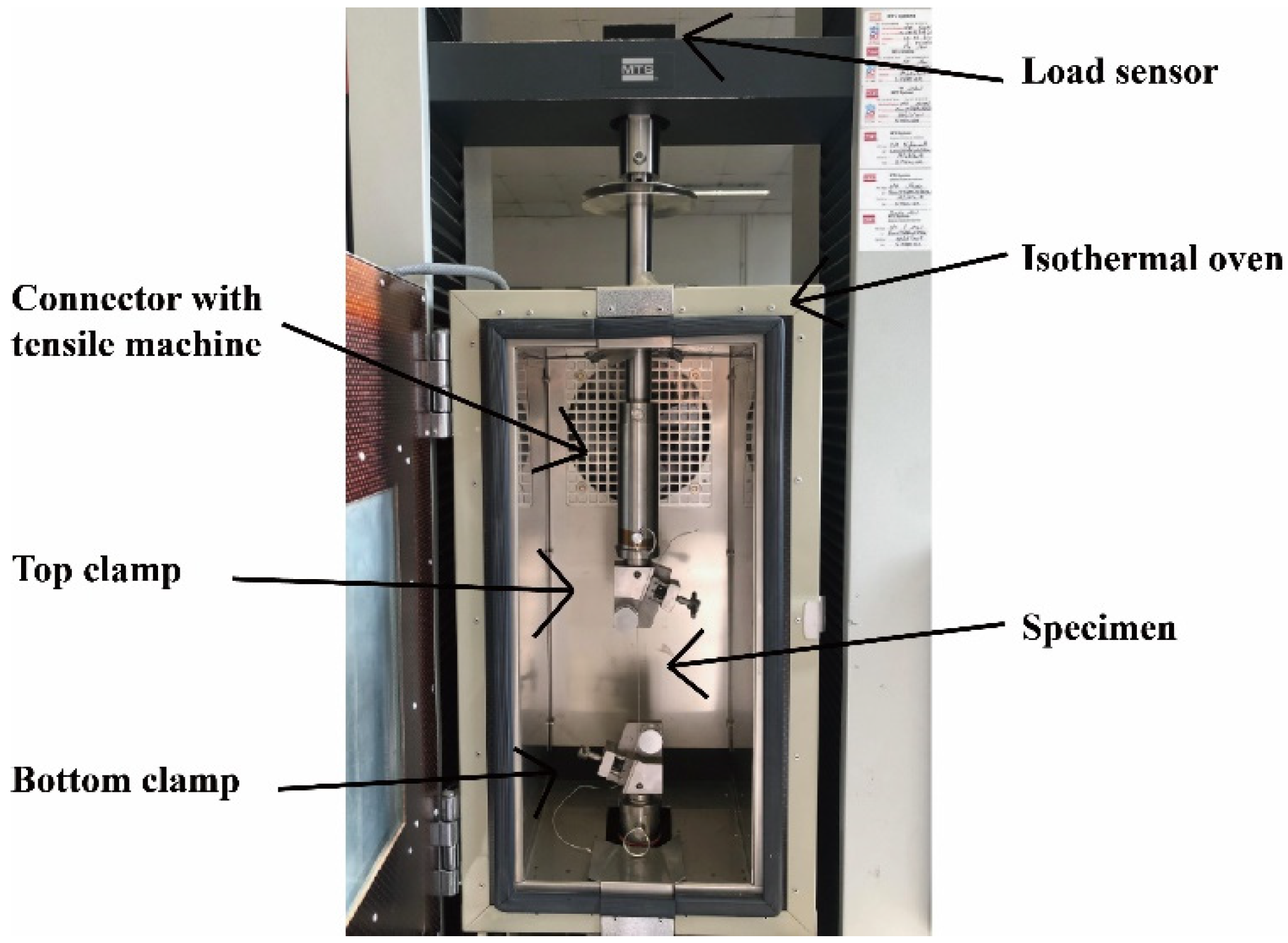

2.5. Braidability Testing

3. Results and Discussion

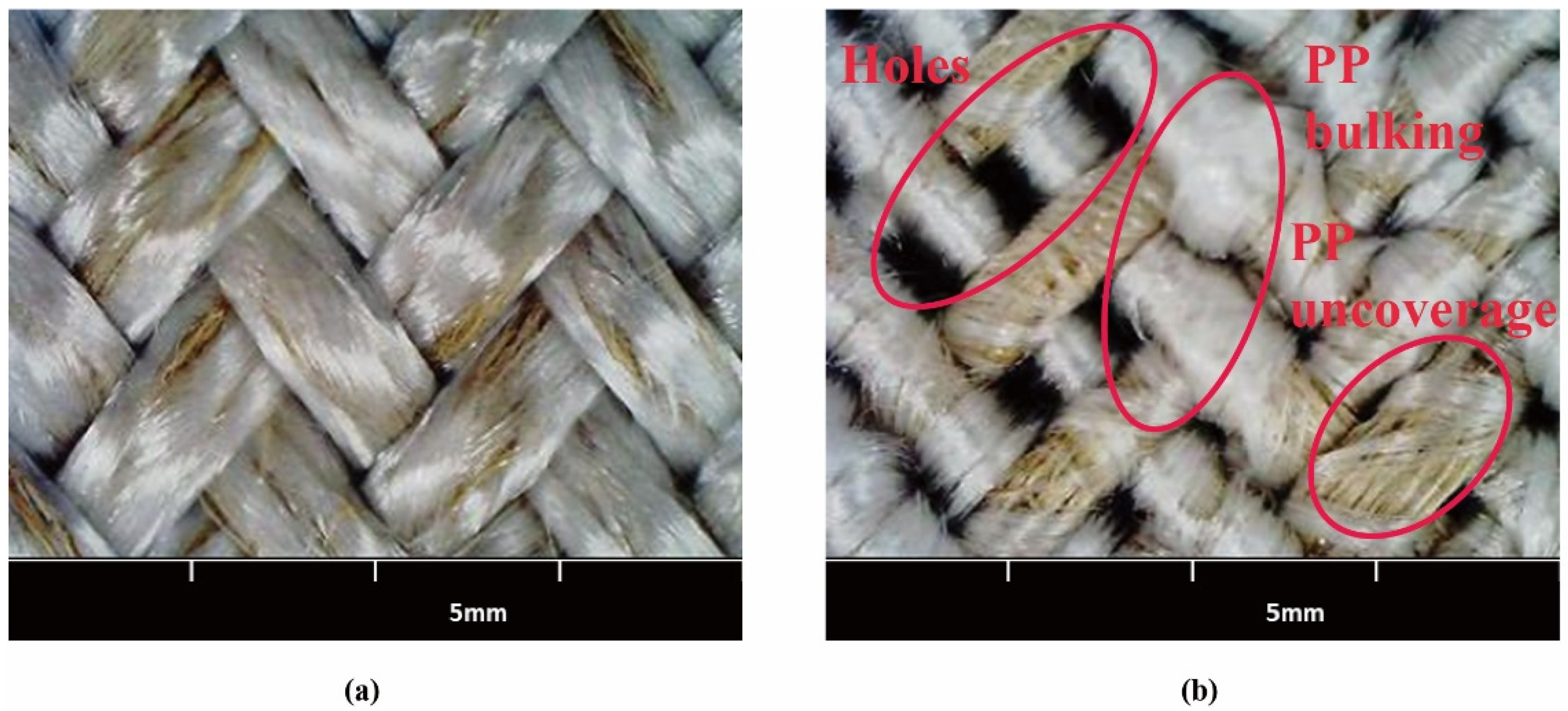

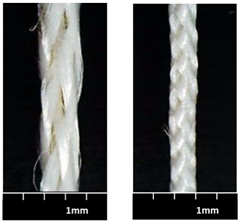

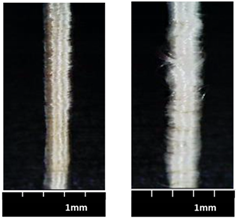

3.1. Textile Properties of the Flax/PP MBYs and CWYs

3.2. Tensile Results

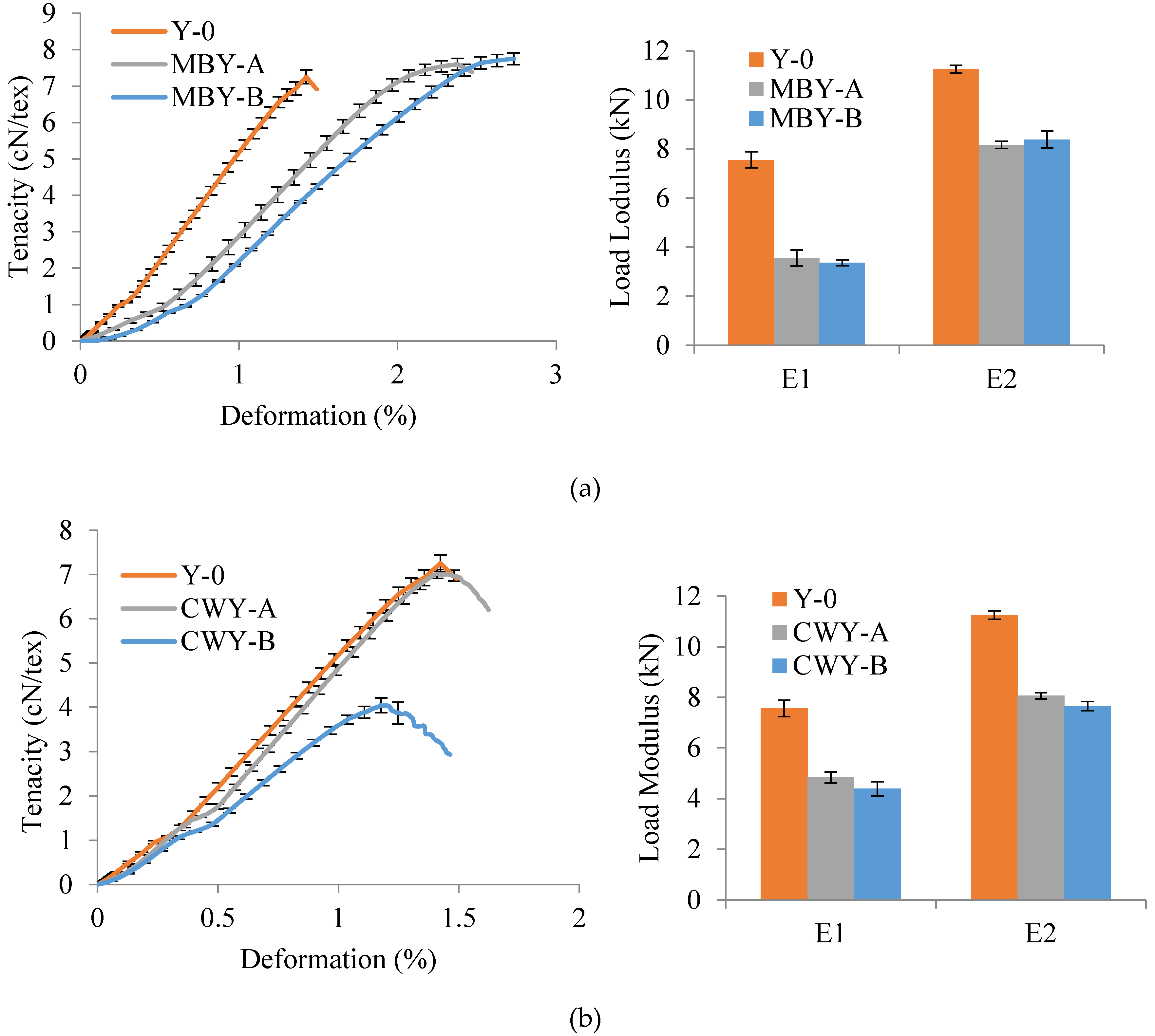

3.2.1. Dry-State Tensile Properties

3.2.2. Thermo-State Tensile Properties

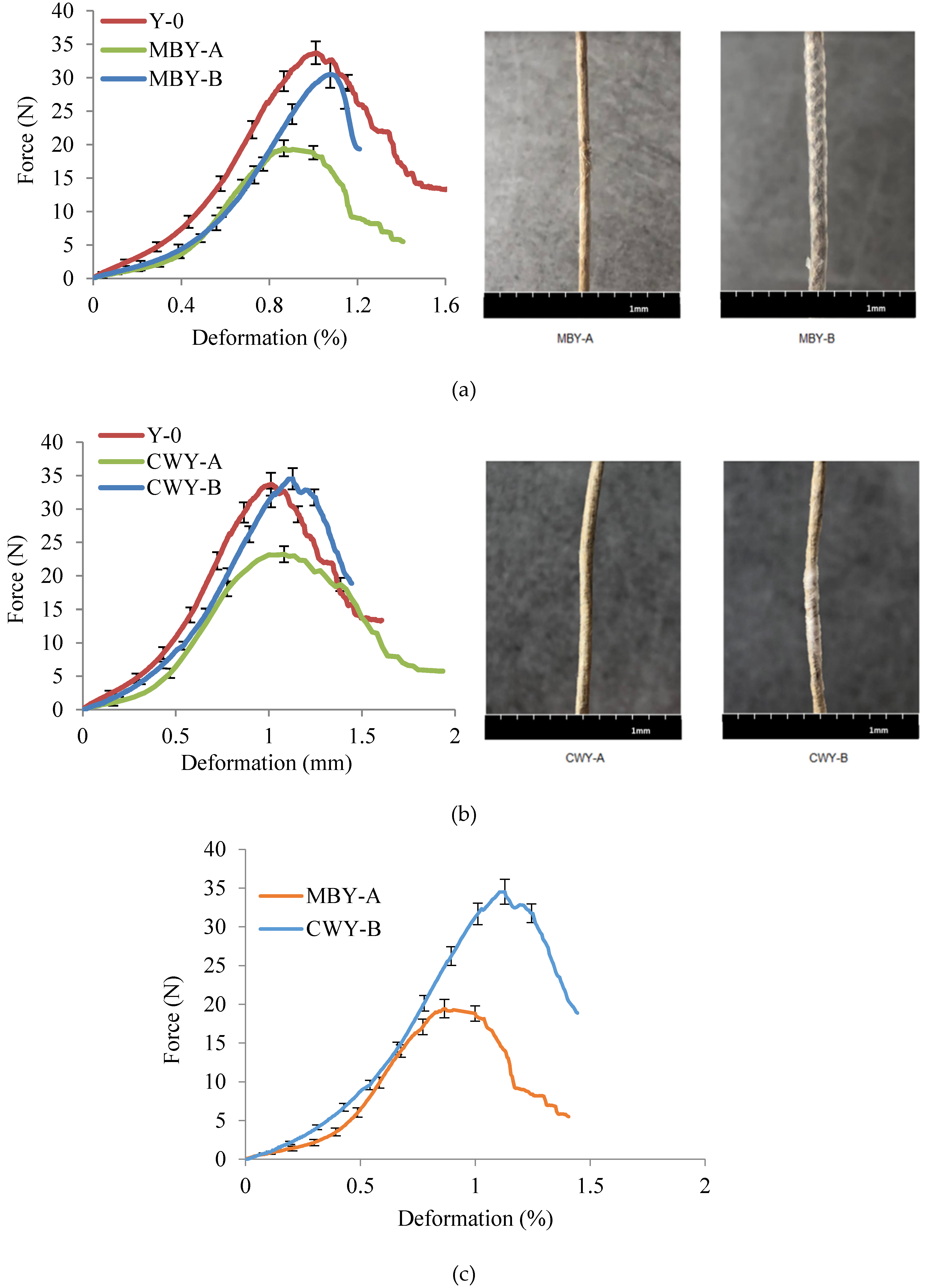

3.3. Braidability of the MBY and CWY

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Omrani, F.; Wang, P.; Soulat, D.; Ferreira, M. Mechanical properties of flax-fibre-reinforced preforms and composites: Influence of the type of yarns on multi-scale characterisations. Compos. Part A 2017, 93, 72–81. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Naveen, J.A.; Satheeshkumar, S. Hybrid fiber reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Lozada, P.T. Perspectivas del tratamiento anaerobio de aguas residuales domésticas en países en desarrollo. Rev. Eia 2012, 9, 115–129. [Google Scholar]

- Svensson, N.; Shishoo, R.; Gilchrist, M. Manufacturing of thermoplastic composites from commingled yarns—A review. J. Thermoplast. Compos. Mater. 1998, 11, 22–56. [Google Scholar] [CrossRef]

- Bar, M.; Das, A.; Alagirusamy, R. Studies on flax-polypropylene based low-twist hybrid yarns for thermoplastic composite reinforcement. J. Reinforced Plastics Composites. 2017, 36, 818–831. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, N. Preforms and composites manufactured by novel flax/polypropylene cowrap spinning method. J. Compos. Mater. 2012, 46, 2097–2109. [Google Scholar] [CrossRef]

- Alagirusamy, R.; Fangueiro, R.; Ogale, V.; Padaki, N. Hybrid yarns and textile preforming for thermoplastic composites. Text. Prog. 2006, 38, 1–71. [Google Scholar] [CrossRef]

- Khondker, O.A.; Ishiaku, U.S.; Nakai, A.; Hamada, H. A novel processing technique for thermoplastic manufacturing of unidirectional composites reinforced with jute yarns. Compos. Part A 2006, 37, 2274–2284. [Google Scholar] [CrossRef]

- Kobayashi, S.; Takada, K. Processing of unidirectional hemp fiber reinforced composites with micro-braiding technique. Compos. Part A 2013, 46, 173–179. [Google Scholar] [CrossRef]

- Zhang, L.; Miao, M. Commingled natural fibre/polypropylene wrap spun yarns for structured thermoplastic composites. Compos. Sci. Technol. 2010, 70, 130–135. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanen, M.; Nousiainen, P. Novel aligned hemp fibre reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part A 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Corbin, A.C.; Ferreira, M.; Labanieh, A.R.; Soulat, D. Natural fiber composite manufacture using wrapped hemp roving with PA12. Mater. Today Proc. 2020, 31, 329–334. [Google Scholar] [CrossRef]

- Potluri, P. Braiding. Wiley Encycl. Compos. 2011, 2, 1–15. [Google Scholar]

- Pil, L.; Bensadoun, F.; Pariset, J.; Verpoest, I. Why are designers fascinated by flax and hemp fibre composites? Compos. Part A 2016, 83, 193–205. [Google Scholar] [CrossRef]

- Kobayashi, S.; Takada, K.; Song, D.Y. Effect of molding condition on the mechanical properties of bamboo-rayon continuous fiber/poly(lactic acid) composites. Adv. Compos. Mater. 2012, 21, 79–90. [Google Scholar] [CrossRef]

- Sakaguchi, M.; Nakai, A.; Hamada, H.; Takeda, N. The mechanical properties of unidirectional thermoplastic composites manufactured by a micro-braiding technique. Compos. Sci. Technol. 2000, 60, 717–722. [Google Scholar] [CrossRef]

- Corbin, A.C.; Soulat, D.; Ferreira, M.; Labanieh, A.R.; Gabrion, X.; Placet, V. Multi-scale analysis of flax fibres woven fabrics for composite applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 1–11.A. [Google Scholar] [CrossRef]

- Boris, D.; Xavier, L.; Damien, S. The tensile behaviour of biaxial and triaxial braided fabrics. J. Ind. Text. 2018, 47, 2184–2204. [Google Scholar] [CrossRef]

- Potluri, P.; Rawal, A.; Rivaldi, M.; Porat, I. Geometrical modelling and control of a triaxial braiding machine for producing 3D preforms. Compos. Part A 2003, 34, 481–492. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, P.; Soulat, D.; Gao, H. Thermo-Mechanical Characterisations of Flax Fibre and Thermoplastic Resin Composites during Manufacturing. Polymers 2018, 10, 1139. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Hamila, N.; Boisse, P.; Chaudet, P.; Lesueur, D. Thermo-mechanical behavior of stretch-broken carbon fiber and thermoplastic resin composites during manufacturing. Polym. Compos. 2015, 36, 694–703. [Google Scholar] [CrossRef]

| Density (g/cm3) | Linear Density (Tex) | Thermodynamic Temperature (C°) | Tenacity (cN/tex) | Deformation (%) | |

|---|---|---|---|---|---|

| Flax Roving | 1.45 [16] | 1000 | 325–360 1 | 13.64 ± 0.42 | 1.42 ± 0.03 |

| PP Filament | 0.91 | 97.50 | 165 2 | 18.98 ± 0.23 | 30.25 ± 0.05 |

|  | |||

| Hybrid yarn ID | MBY-A | MBY-B | CWY-A | CWY-B |

| PP Parameter | PP Braiding Angle (°) | PP Wrapping Turns (tpm) | ||

| 20 | 50 | 800 | 1000 | |

| Linear Density (tex) | 1936 ± 27 | 2219 ± 17 | 1450 ± 14 | 1838 ± 28 |

| PP Mass Ratio (%) | 45.5 | 49.5 | 32.0 | 44.6 |

| CVm (%) | 11.87 | 10.12 | 14.86 | 16.79 |

| Hairiness (H) | 9.35 | 8.05 | 11.74 | 13.25 |

| sH (%) | 3.48 | 3.11 | 3.80 | 5.37 |

| Cover Factor (%) | 98.05 | N/A | 73 | 84 |

| Hybrid Yarn ID | Force-Max (N) | Deformation at Fmax (%) | Tenacity (cN/tex) | Load Modulus E1 (kN) | Load Modulus E2 (kN) |

|---|---|---|---|---|---|

| Y-0 | 136.46 ± 3.53 | 1.42 ± 0.03 | 7.25 ± 0.19 | 7.56 ± 0.33 | 11.25 ± 0.17 |

| MBY-A | 147.15 ± 3.11 | 2.38 ± 0.05 | 7.60 ± 0.16 | 3.56 ± 0.33 | 8.17 ± 0.14 |

| MBY-B | 172.04 ± 3.54 | 2.73 ± 0.12 | 7.75 ± 0.16 | 3.37 ± 0.12 | 8.39 ± 0.34 |

| CWY-A | 101.68 ± 1.47 | 1.41 ± 0.03 | 7.01 ± 0.10 | 4.83 ± 0.21 | 8.06 ± 0.13 |

| CWY-B | 74.36 ± 3.09 | 1.18 ± 0.07 | 4.05 ± 0.17 | 4.39 ± 0.28 | 7.65 ± 0.18 |

| Hybrid Yarn ID | Tenacity before Braiding (cN/tex) | Tenacity after Braiding (cN/tex) | Percentage Decrease of Yarn Tenacity after Braiding (%) |

|---|---|---|---|

| MBY-A | 7.60 ± 0.16 | 7.27 ± 0.31 | 4.34 |

| CWY-B | 4.05 ± 0.17 | 2.70 ± 0.24 | 33 |

| Hybrid Yarn ID | Load Modulus before Braiding (kN) | Load Modulus after Braiding (kN) | Percentage Decrease of Yarn Modulus after Braiding | |||

|---|---|---|---|---|---|---|

| E1 | E2 | E1 | E2 | E1 (%) | E2 (%) | |

| MBY-A | 3.56 ± 0.33 | 8.17 ± 0.14 | 1.57 ± 0.31 | 7.59 ± 0.11 | 56 | 7 |

| CWY-B | 4.39 ± 0.28 | 7.65 ± 0.18 | 2.56 ± 0.24 | 6.13 ± 0.14 | 42 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, W.; Wang, P.; Legrand, X.; Soulat, D.; Ferreira, M. Effects of Micro-Braiding and Co-Wrapping Techniques on Characteristics of Flax/Polypropylene-Based Hybrid Yarn: A Comparative Study. Polymers 2020, 12, 2559. https://doi.org/10.3390/polym12112559

Zhai W, Wang P, Legrand X, Soulat D, Ferreira M. Effects of Micro-Braiding and Co-Wrapping Techniques on Characteristics of Flax/Polypropylene-Based Hybrid Yarn: A Comparative Study. Polymers. 2020; 12(11):2559. https://doi.org/10.3390/polym12112559

Chicago/Turabian StyleZhai, Wenqian, Peng Wang, Xavier Legrand, Damien Soulat, and Manuela Ferreira. 2020. "Effects of Micro-Braiding and Co-Wrapping Techniques on Characteristics of Flax/Polypropylene-Based Hybrid Yarn: A Comparative Study" Polymers 12, no. 11: 2559. https://doi.org/10.3390/polym12112559

APA StyleZhai, W., Wang, P., Legrand, X., Soulat, D., & Ferreira, M. (2020). Effects of Micro-Braiding and Co-Wrapping Techniques on Characteristics of Flax/Polypropylene-Based Hybrid Yarn: A Comparative Study. Polymers, 12(11), 2559. https://doi.org/10.3390/polym12112559