3.1. Un-Aged Epoxy Samples Filled with Different Amounts of CaCO3

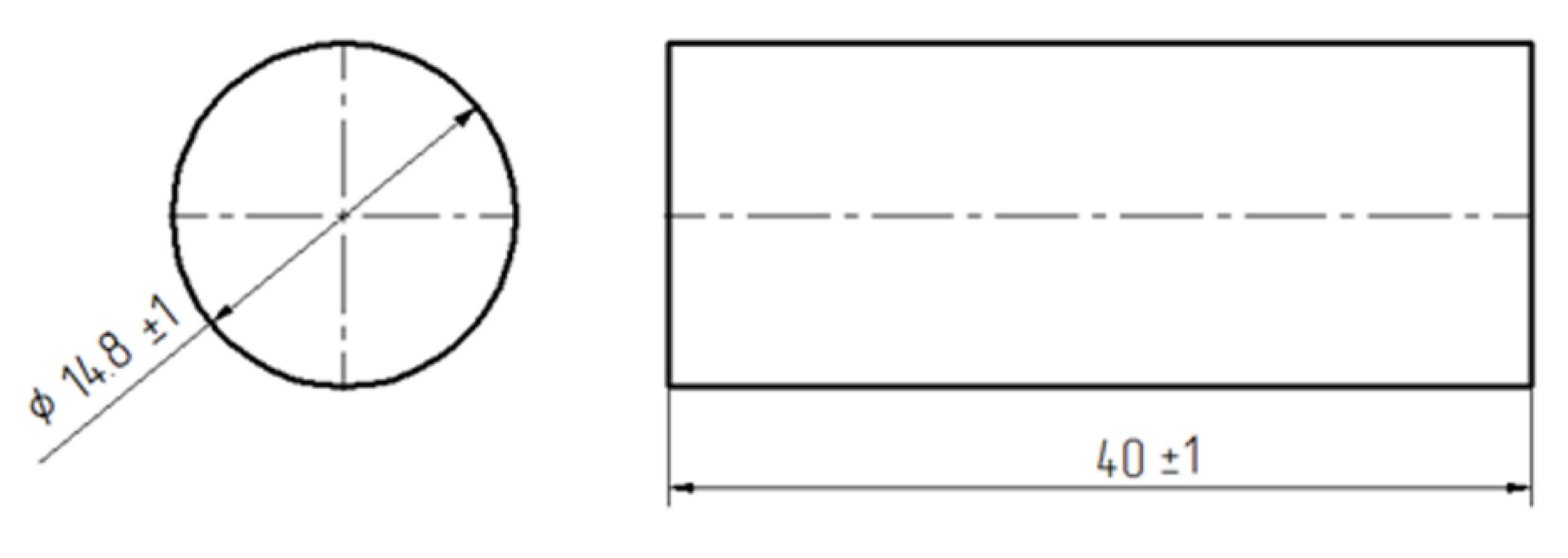

The results, in terms of modulus (

Figure 3a), maximum strength (

Figure 3b) and strain at break (

Figure 3c), of the mechanical (in compression mode) tests performed on un-aged E5/TFF/100:26 and E5/Z-1/100:12 specimens are reported in

Figure 3.

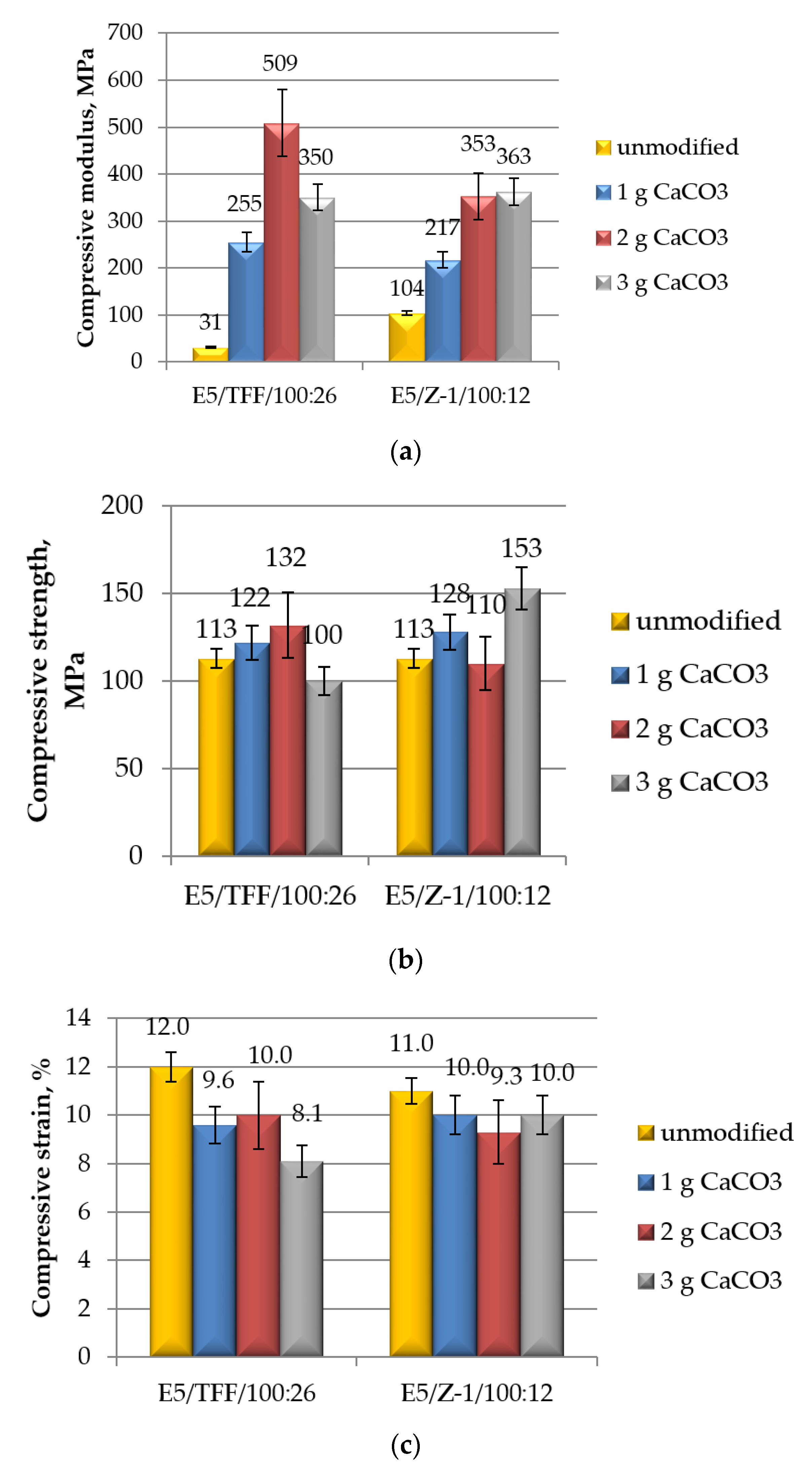

First, we analyse the effect of the curing agent. From the observation of the data reported in

Figure 3, it can be concluded that maximum strength and strain at break measured in compression mode are not substantially influenced by the type of hardener. The selection of the curing agent suitable for the cure at ambient temperature, on the other hand, remarkably affects the compressive modulus of the epoxy. The obtained results are in a good agreement with mechanical properties, measured in compression mode, reported for commercial cold-cured epoxy-based structural adhesives.

The effect of the filler on the mechanical properties of the epoxy resins is analysed next. Generally speaking, the addition of calcium carbonate to the adhesives brings about an increase in both compressive modulus and maximum strength, and a decrease in strain at break, having the CaCO3 content a certain influence on the analysed properties.

In particular, in the systems cured with TFF curing agent, i.e., those displaying the lowest value of compressive modulus, the addition of a limited amount (2 g) of the filler leads to a noticeable increase in this characteristic (

Figure 3a). However, by increasing further the CaCO

3 content, the compressive modulus is reduced, even though it results always much higher than that measured on un-filled resin cured with the same curing agent (i.e., E5/TFF/100:26 system).

The growth in modulus of E5/Z-1/100:12 compound is more regular upon the addition of increasing amounts of calcium carbonate, although the increases measured at 2 and 3 g of CaCO

3 are very close (

Figure 3a). However, the standard deviation value measured for this set of specimens (CaCO

3 content equal to 2g) was slightly higher with respect to the others.

In comparing the two groups of compounds, i.e., cured with TFF, or Z-1 curing agents, respectively, the highest value of compressive modulus (i.e., 509 MPa) was observed for the system E5/TFF/100:26 modified with 2 g calcium carbonate, the lowest (217 MPa) for E5/Z-1/100:12 compound containing the lowest amount (1 g) of this filler. The effect of the filler on this characteristic is similar for both epoxy adhesives at the greatest loads (i.e., 3 g).

The observed appreciable growth in compressive modulus as a result of the addition of small amounts of calcium carbonate reflects what previously found by testing CaCO

3-epoxy specimens in tensile mode [

29,

40,

41,

42]. This result was attributed to the elastic modulus of the filler, which is much higher than that of the epoxy matrix, according to the “rule of mixture” for composite materials [

40,

42].

In the case of E5/TFF/100:26 systems, the addition of 1 and 2 g of CaCO

3 leads to a steady increase in maximum strength (

Figure 3b); at the highest analysed amount of filler (3 g), on the other hand, a decrease in strength is observed, down to a value even lower than that measured on the un-modified resin. A higher spread of values was observed in the case of the compound including 2 g of calcium carbonate.

The addition of small contents (1 and 2 g) of CaCO

3 in E5/Z-1/100:12 compounds produces limited variations in maximum strength (

Figure 3b), considering the variability of results; an appreciable increase in this characteristic was, conversely, measured at the highest content (3 g) of this filler. This latter is the greatest value of compressive strength (153 MPa) found analysing the filled systems based on the two different curing agents.

It has been reported in previous literature [

29,

40,

41,

42] that lower values of tensile and flexural strengths with respect to the pristine resin are obtained upon addition of the same micro-filler to epoxy. This result was mainly attributed to the weak interface strength developed between the matrix and the filler particles [

42]. In the reviewed studies, significantly greater amounts of calcium carbonate were added to epoxy adhesives. Apart from this distinct feature, it is likely that the effect of CaCO

3 filler is unlike when the epoxy is subjected to a compressive load, since the adhesion at the interface filler/matrix probably plays a less primary role.

Finally, the compressive strain of E5/TFF/100:26 systems are reduced upon addition of different amounts of CaCO3, being the reductions of this characteristic similar at 1 and 2 g loads. A greater decrease in strain is observed at the highest amount of filler (3 g). The reductions in compressive strain seem to be almost independent by the content of calcium carbonate in the case of E5/Z-1/100:12 compounds.

Limited reductions in ultimate strain of CaCO

3-epoxy with respect to the unfilled resin measured in tensile mode were reported also elsewhere [

29,

40,

41,

42]. This result, consistent with the increase in elastic modulus, was explained in terms of a stiffening and embrittlement of the epoxy upon addition of the filler [

29]; also the irregular shape of the calcium carbonate particles can affect elongation at break to a certain extent [

41].

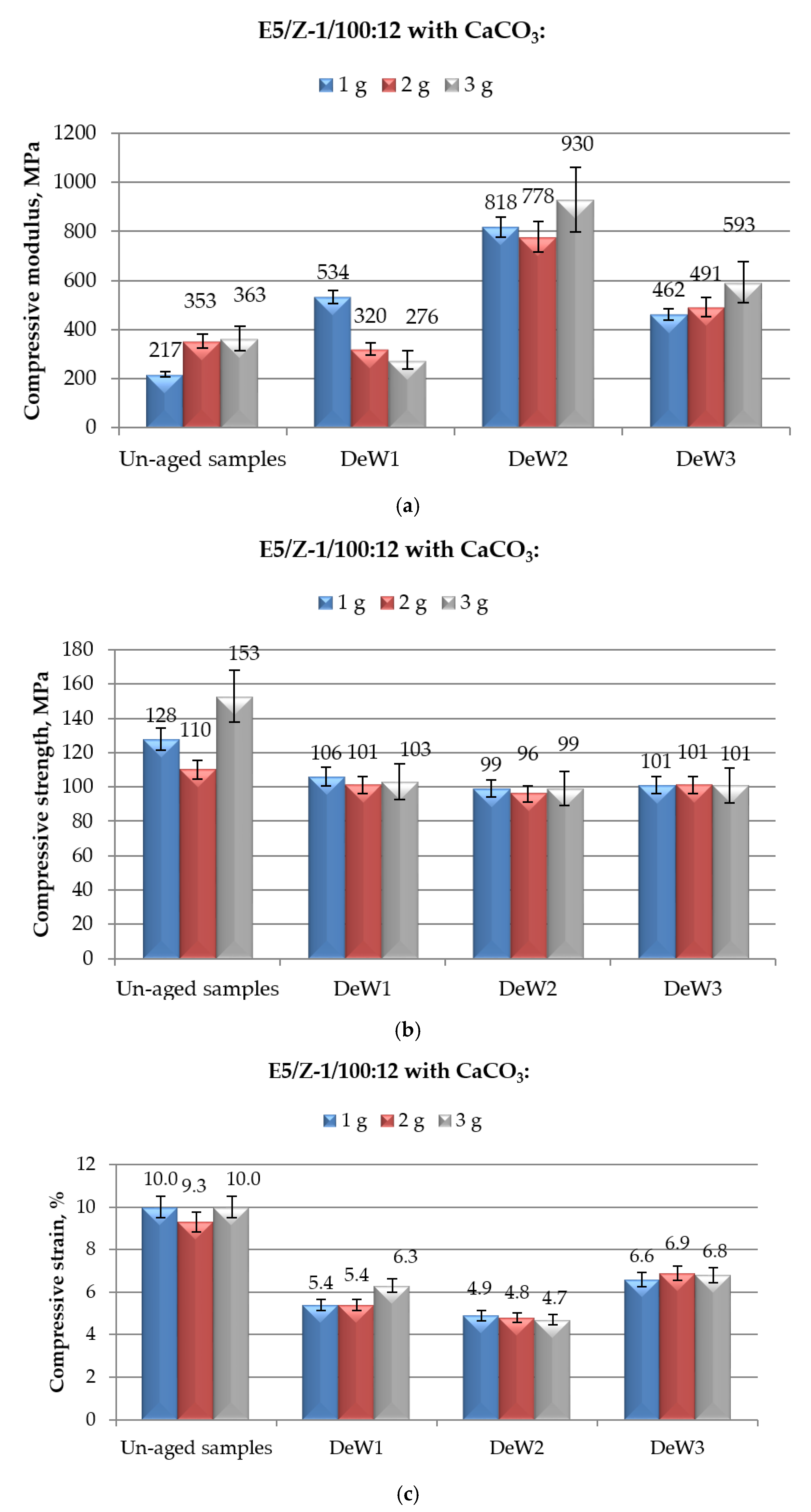

3.2. Epoxy Samples Filled with Different Amounts of CaCO3 and Aged in Demineralised Water

The main aim of the present study was the assessment of the effects of an aqueous environment on the mechanical (measured in compression mode) properties of cold-cured epoxy-based structural adhesives in which different amounts of CaCO

3 filler are added. To this aim, the effect of an immersion in demineralised water was first analysed, and the results are reported in

Figure 4 and

Figure 5 for the systems based on E5/TFF/100:26, and E5/Z-1/100:12, respectively.

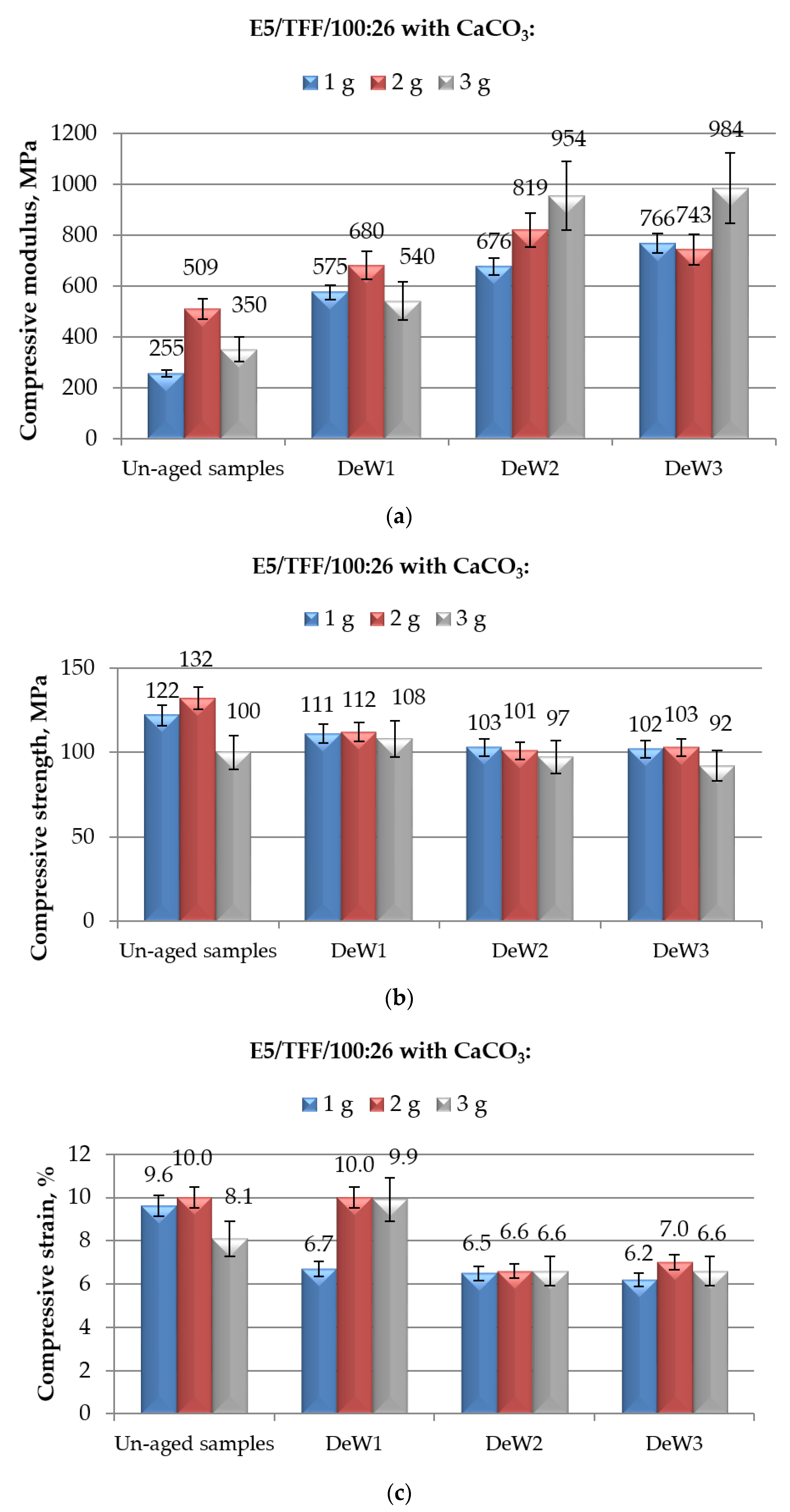

In the case of E5/TFF/100:26 adhesive, filled with different amounts of calcium carbonate, the compressive modulus, that was already greater than that measured on un-filled resin (i.e., 31 MPa), experienced a further increase upon immersion in demineralised water, even if aged for prolonged times, as reported in

Figure 4a. The increase was particularly remarkable (+181% over un-aged specimens with the same composition) at the highest amount of calcium carbonate (i.e., 3 g) when the specimens were aged for 10 months, although a significant spread or results was measured for this system. Nevertheless, the trend of mechanical data is clear, and it represents an important advantage for outdoor exposed structural adhesives that can be frequently exposed to moisture/liquid water, even for prolonged periods of time.

As already described, the exposure to freshwater severely affects the characteristics and the behaviour of epoxy resins due to the plasticization of the resin. Plasticization was found to produce severe reductions in elastic modulus measured in tensile mode of both neat and CaCO

3–filled epoxies [

40,

41,

42]. The detrimental effects of immersion in water on modulus was found to be less severe in the case of calcium carbonate-filled epoxies if compared with neat resin, being attributed to the ability of the micro-particles to hinder the elastic deformation of the matric resin [

40,

41]. The results reported in previous studies, on the other hand, cannot be directly applied to the mechanical characteristics measured in compression mode, due to the different mechanisms taking place in the resin during the application of tensile versus compressive loads. Additionally, we cannot exclude that a concurrent advancement of curing occurs during the immersion in demineralized water; the specimens, in fact, were cold-cured for a week, which is a time far to be sufficient to achieve the completion of curing carried out at ambient temperature [

12,

13,

43]. A further increase of the degree of cure at longer times is likely to produce a growth in compressive modulus, able to counteract the plasticization effect of water, as previously observed for cold-cured unfilled epoxies tested in tensile mode after different immersion times in demineralised water [

44]. These aspects, therefore, deserve further investigation.

Generally speaking, a slight reduction in the compressive strength of CaCO

3-filled epoxy was observed as a consequence of the exposure to demineralised water, as shown in

Figure 4b. The decrease was more evident (up to 23%) for the system E5/TFF/100:26/2CaCO

3, i.e., the compound showing the highest value of maximum strength among unfilled and modified formulations, while it was contained for the other filled systems (around 8–16%). The immersion time in demineralised water had a certain effect on this characteristic up to 6 months of aging; beyond this time, it becomes almost negligible, taking into account the deviation of results. Comparing the results of filled-systems aged for different times in water with those relative to unfilled unaged E5/TFF/100:26, reported in

Figure 3b, it can be concluded that, although aged in demineralised water, the CaCO

3-filled compounds are able to keep values of compressive strength close to those measured on unaged E5/TFF/100:26 control system, especially at 1 and 2 g loads.

Plasticization related to the ingress of water in unfilled and CaCO

3-filled epoxies was found to produce substantial reductions also in the tensile strength [

40,

41,

42,

43]. It is suggested that, in addition to the plasticization of the matrix, in the presence of a micro-filler water, it can also affect the filler-matrix interface, thus further reducing the resistance to a tensile load [

40,

41]. The reductions in compressive strength found in the present study, however, are somewhat limited (never exceeding 25%). Once again, a compensatory effect cannot be excluded, given the continuation of curing during the aging in demineralised water, as observed for the tensile strength measured on cold-cured unfilled epoxy immersed for prolonged times in water [

44].

The behaviour of the strain at break measured in compression mode on epoxy systems loaded with calcium carbonate, reported in

Figure 4c, was strongly dependent on the filler content and on the duration of aging. At the lowest content of CaCO

3, a decrease in strain of about 30% is recorded after only 1 month of immersion; further reductions in strain of this compound due to prolonged aging are limited. On the other hand, the system E5/TFF/100:26/2CaCO

3 kept the same value of strain at break in compression after the shortest immersion time (1 month); this value was appreciably reduced (up to 34%) at longer immersion times, i.e., after 6 and 10 months. Finally, the compound containing the highest amount (3 g) of filler experienced an initial increase (22%) in strain after a 1-month immersion; then a reduction in this property of about 18% with respect to unaged system was measured. Strong reductions in strain can be calculated for filled systems as a consequence of the immersion in water if compared to unaged E5/TFF/100:26 control system.

In contract, the effect of immersion in water on strain at break on CaCO

3-filled epoxies was established, and measured in tensile mode, with increases in this characteristic due to the aqueous aging [

40,

41,

42]. This result was attributed to an enhancement in ductile behaviour, due to the plasticization. Possibly, the aging in water caused an appreciable decrease in the glass transition temperature, even around the aging temperature, shifting the epoxy from a glassy state to a rubbery state [

42]. It was also hypothesized, however, that the calcium carbonated particles, able to hinder to a certain extent the water ingress, limited the deformations of the filled epoxy [

41]. The plasticization, in fact, affected this property to a minor extent than in the case of unfilled resin. In addition, the irregular shape of the CaCO

3 particles also have an influence, contributing to reduce the deformability of the matrix [

41]. As already underlined, the mechanisms taking place in the epoxy during the application of tensile load are likely to be very different from those occurring during a compressive test; this could justify the observed diverse effects on strain at break measured in compression mode of the aging in demineralized water.

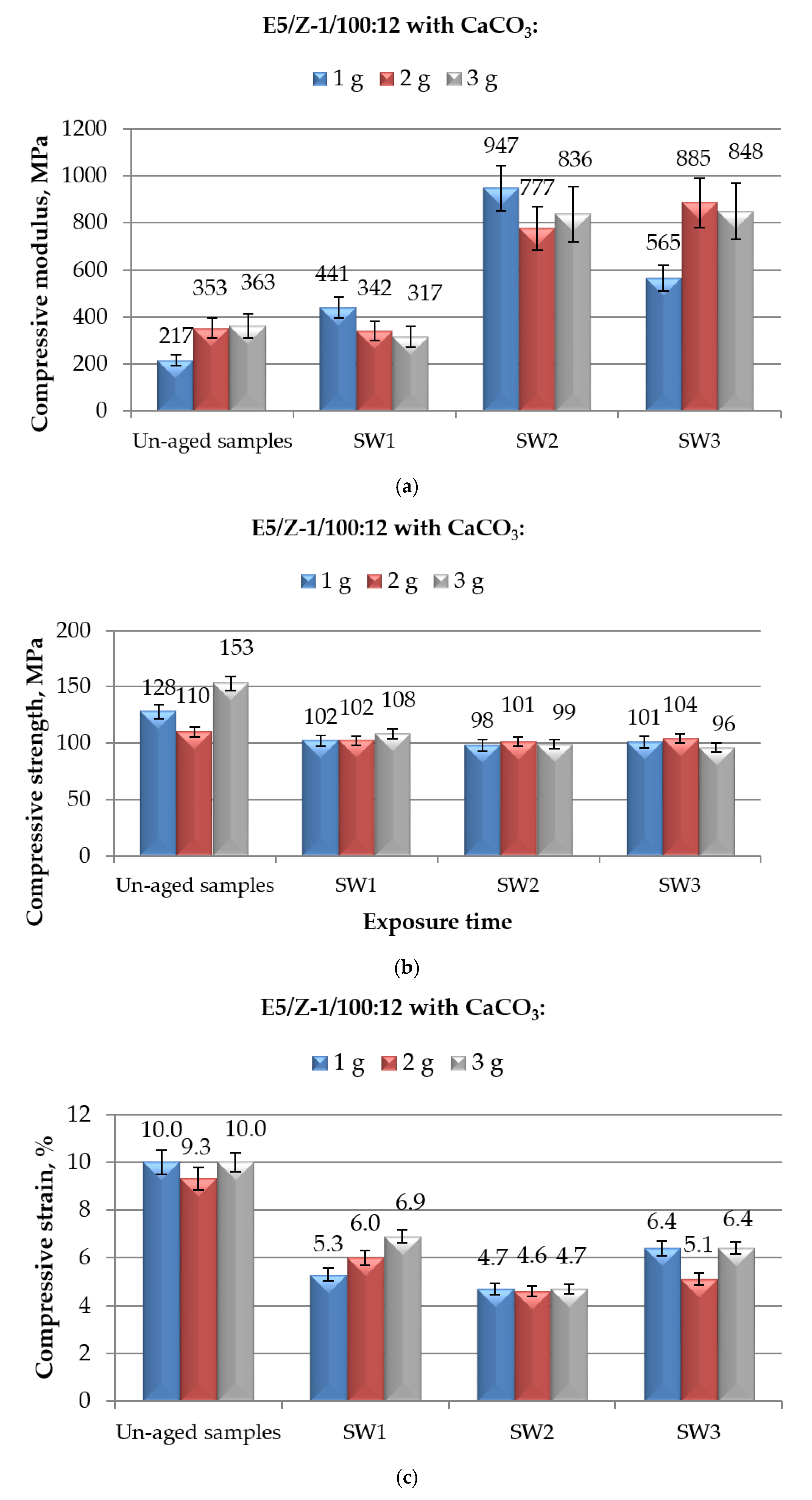

The results of mechanical properties measured in compression mode on CaCO

3-filled E5/Z-1/100:12 compounds aged for different periods in demineralised water are showed in

Figure 5. The reported data are roughly in line with those observed on E5/TFF/100:26, with a certain increase in compressive modulus upon immersion, limited reductions in maximum strength and remarkable drops in strain at break. The same observations reported for the CaCO

3-filled E5/TFF/100:26 can be here repeated to comment the observed results.

Analysing in detail the data relative to compressive modulus, reported in

Figure 5a, the greatest increase in compressive modulus with respect to unaged specimens was observed when the systems were immersed in demineralised water for 6 months, i.e.,: +277%, +120% and +156% for E5/Z-1/100:12/1CaCO

3, E5/Z-1/100:12/2CaCO

3 and E5/Z-1/100:12/3CaCO

3, respectively. At the longest immersion time tested, all the CaCO

3-modified compounds experienced a new decrease in compressive modulus; this property, however, for all the compositions remained well above the values observed for both filled (217 MPa, 353 MPa, and 363 MPa, respectively) and unmodified (104 MPa) un-aged specimens. Comparing these results with those found for filled-compounds cured with the other hardener (reported in

Figure 4a), i.e., CaCO

3-E5/TFF/100:26 systems, it can be noticed that the systems cold-cured with Z-1 keep values of compressive modulus generally lower than those observed for CaCO

3-E5/TFF/100:26 compounds, irrespective to the time of immersion. Furthermore, the effect of a prolonged time in immersion (up to 10 months) is more pronounced for systems cured with Z-1.

The compressive maximum strength of CaCO

3-filled E5/Z-1/100:12 systems appeared to be negatively influenced by the exposure to demineralised water (

Figure 5b); on the other hand, the immersion time has a negligible effect on this property. Starting from 1 month of immersion, the maximum strength achieves and keeps values around 100 MPa, irrespective to the filler content. Once again, this value was not much lower than that measured on unaged E5/Z-1/100:12 control system, i.e., 113 MPa. The behaviour of compressive maximum strength found for CaCO

3-filled E5/Z-1/100:12 systems aged in demineralised water resulted very similar with that observed for filled systems based on E5/TFF/100:26, reported in

Figure 4b, even though for these latter systems the reductions in strength were found to be slightly influenced by the immersion times.

Finally, the strain at break measured during the compressive tests on CaCO

3-modified E5/Z-1/100:12 systems immersed for different times in demineralised water was severely affected by this kind of aging procedure, as can be observed from the data reported in

Figure 5c. This property was appreciably reduced after only 1 month of immersion and more than halved after 6 months, irrespective to the filler content. These reductions were in a certain extent recovered at the longest aging time, i.e., 10 months, although strain at break did not regain the initial (unaged) value for any of the CaCO

3-contents analysed. The addition of filler, therefore, is not able to mitigate the adverse effects of water on compressive strain at break; a decrease of strain more than halved is observed for these systems if compared to the value measured on unaged unfilled E5/Z-1/100:12 (11%). In comparison with the systems cold-cured with the other hardener, i.e., CaCO

3-filled E5/TFF/100:26, subjected to the same aging procedure (

Figure 4c), the reductions in strain at break were found to be slightly lower by increasing the immersion times. However, after a 10-month aging period, very similar strain values were found for both groups of formulations, taking into account the spread of results.

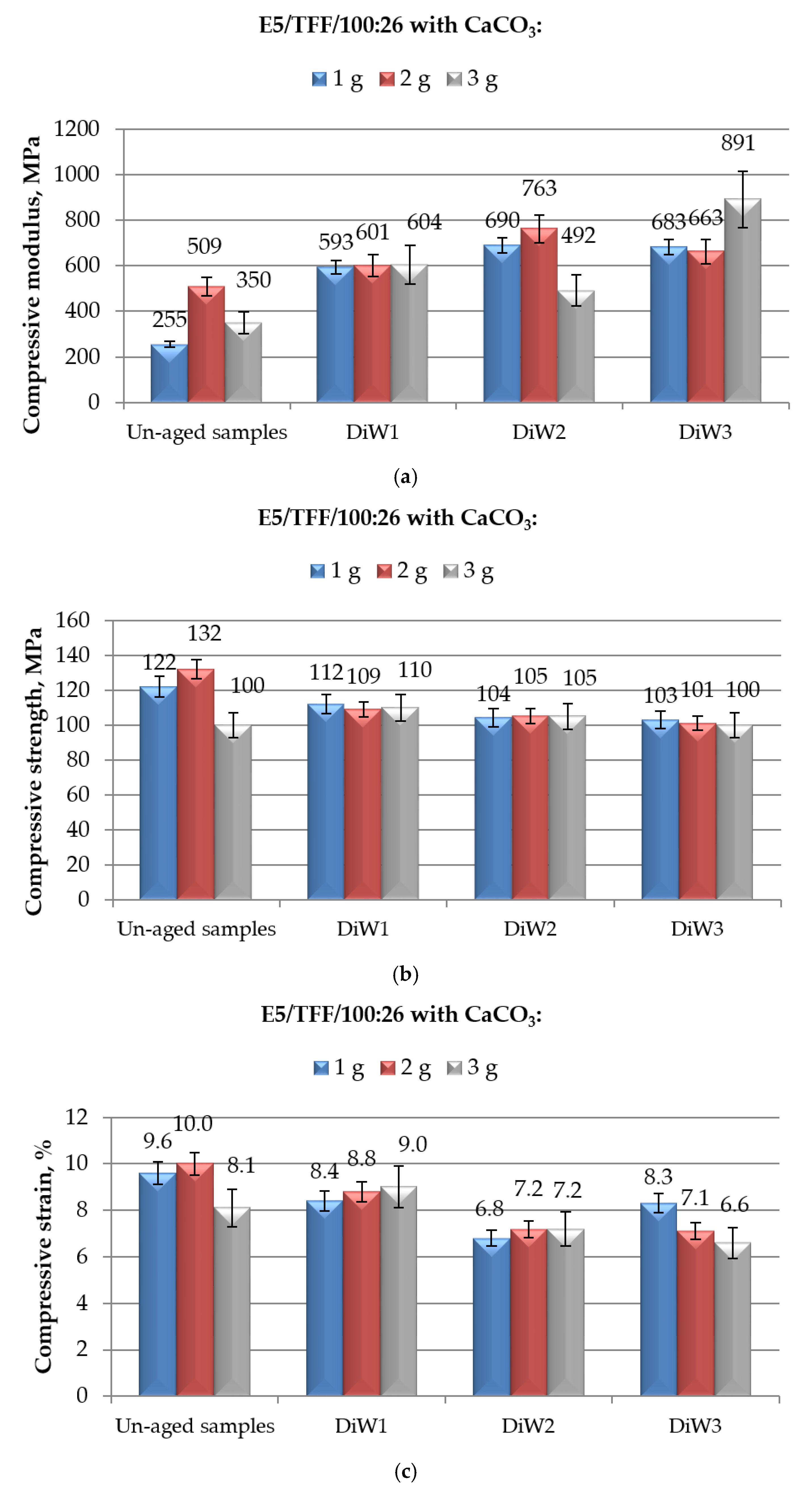

3.3. Epoxy Samples Filled with Different Amounts of CaCO3 and Aged in Distilled Water

The effect of an immersion in distilled water on mechanical properties, measured in compression mode, of CaCO

3-filled E5/TFF/100:26 and E5/Z-1/100:12 systems can be observed in

Figure 6, and

Figure 7, respectively.

Apart from an unavoidable dispersion of experimental results, the general behaviour of all filled systems aged in distilled water follows that of the same compounds aged in demineralised water (reported in

Figure 4 and

Figure 5, respectively), suggesting that the composition of water not containing mineral salts has an irrelevant effect on the mechanical (in compression mode) behaviour of cold-cured CaCO

3-filled epoxy compounds.

Analysing in detail the data reported in

Figure 6a, a substantial increase in compressive modulus was observed as consequence of the aging procedure in distilled water, irrespective to the filler content. Also in this case, the greatest increase (+155% over the same un-aged system) was observed for the system containing the highest amount (3 g) of calcium carbonate and aged for 10 months in distilled water. The growth in compressive modulus upon immersion in distilled water seems to proceed slightly slower with respect to what observed upon immersion in demineralised water (

Figure 4a). However, all the obtained data are substantially greater with respect to the modulus found for unaged unfilled E5/TFF/100:26, i.e., 31 MPa, confirming the positive effect of the addition of calcium carbonate in epoxy adhesives exposed to aqueous environments.

The same slight decrease in the compressive maximum strength observed for CaCO3-filled E5/TFF/100:26 compounds as a consequence of the exposure to demineralised water (

Figure 4b), can be observed when the same systems are aged in distilled water (

Figure 6b), having the immersion time in distilled water a limited effect on the maximum strength only up to six months of aging. Referring to this aqueous environment, however, the effect of the filler content is almost negligible. Finally, also after a prolonged aging in distilled water, the CaCO

3-filled E5/TFF/100:26 systems showed values of mechanical strength not much lower than the compressive strength measured for unaged E5/TFF/100:26 control (113 MPa).

In

Figure 6c, the values of strain at break measured in compression tests on E5/TFF/100:26 systems loaded with different amounts of calcium carbonate are reported as a function of the immersion time in distilled water. By comparing these results with those observed for the same specimens immersed in demineralised water (

Figure 4c), the reductions in strain at break are more gradual by increasing the aging time; moreover, the systems filled with lowest amounts (1 and 2 g) of CaCO

3 experienced smaller reductions in strain after 10 months in distilled water. It is confirmed that the strain of aged CaCO

3-filled E5/TFF/100:26 system is substantially reduced if compared to the value found for unaged E5/TFF/100:26 control system, i.e., 12%.

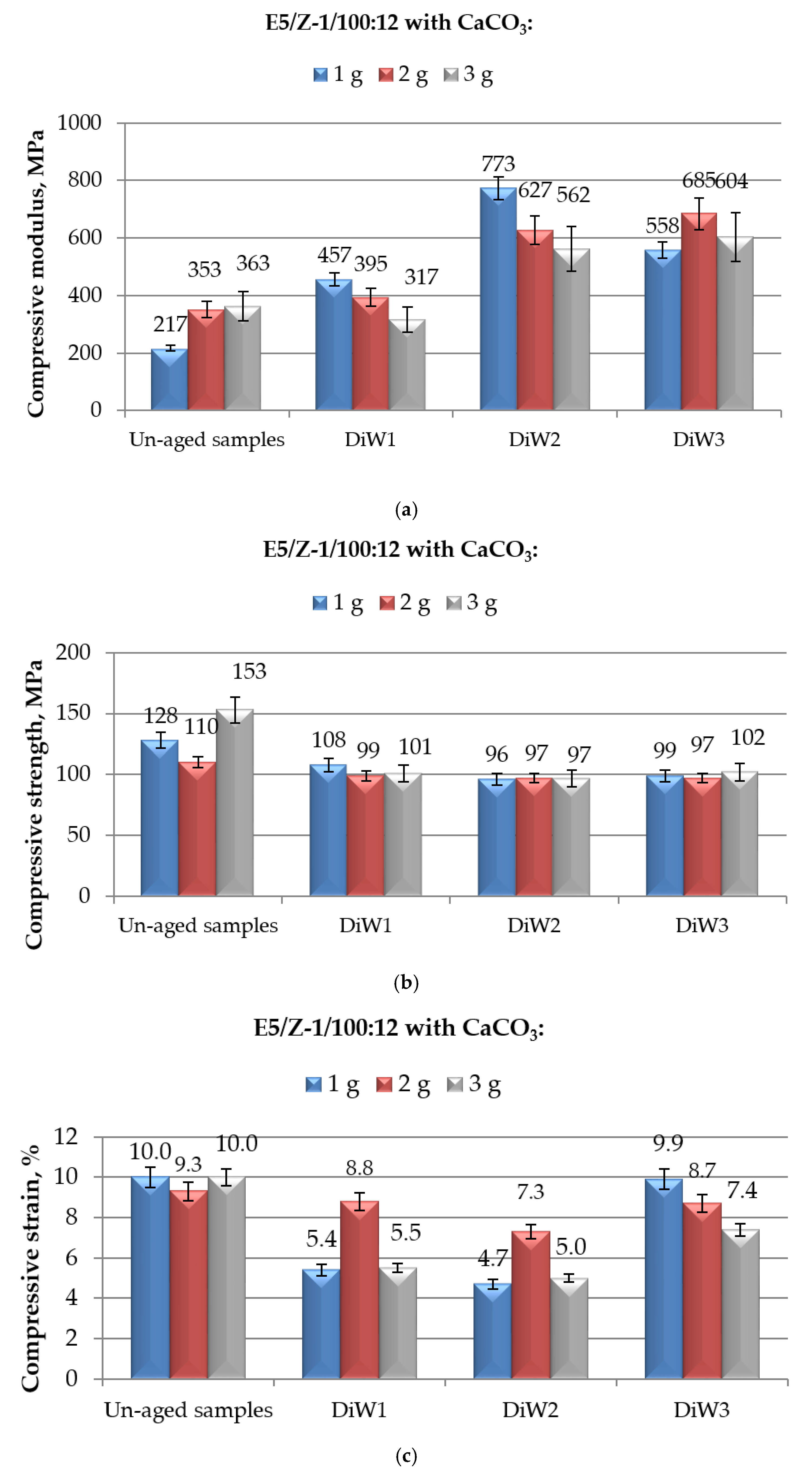

Passing to analyse the results of compression tests performed on CaCO

3-filled E5/Z-1/100:12 systems aged up to 10 months in distilled water, reported in

Figure 7, the general trends of modulus, maximum strength and strain at break are, again, comparable with those observed for the same systems aged in demineralised water (

Figure 5), as well as for the CaCO

3-modified E5/TFF/100:26 compounds exposed for the same periods of time in the same medium, i.e., distilled water (reported in

Figure 6).

The compressive modulus (

Figure 7a) experienced the greatest increase with respect to un-aged specimens at medium/high times of immersion in distilled water, i.e., of 256% for E5/Z-1/100:12/1CaCO

3 exposed for 6 months, 94% and 66% for E5/Z-1/100:12/2CaCO

3 and E5/Z-1/100:12/3CaCO

3, respectively, both immersed up to 10 months. Comparing these results with those reported in

Figure 5a for systems aged in demineralised water, it can be concluded that the reduction of compressive modulus at the longest immersion time (10 months) is much more limited, especially for systems containing 2 and 3 g of CaCO

3. Once again, compressive modulus remained well above the values of this characteristic calculated for both filled (217 MPa, 353 MPa and 363 MPa, respectively) or unmodified (104 MPa) un-aged E5/Z-1/100:12 systems. Finally, comparing these results with those reported in

Figure 6a for CaCO

3-E5/TFF/100:26 systems, no specific trend can be deduced, since the effects of the kind of curing-agent depend on the calcium carbonate content and on the time of immersion in this aqueous medium.

The behaviour and numerical values of compressive maximum strength of CaCO

3-filled E5/Z-1/100:12 systems aged in distilled water up to 10 months, observed in

Figure 7b, are perfectly comparable with those of the same systems immersed in demineralised water (

Figure 5b). The same considerations can be, then, repeated. The negative effects of distilled water on this property, with a negligible effect of the immersion time; a value of compressive maximum strength of aged systems filled with different amounts of calcium carbonate not much lower than that measured on unaged E5/Z-1/100:12 control system, i.e., 113 MPa. Again, the values of compressive maximum strength found for CaCO

3-filled E5/Z-1/100:12 systems and those calculated for filled systems based on E5/TFF/100:26, reported in

Figure 6b, all aged in distilled water, were very similar; the compressive strength values found for the systems cold-cured with Z-1 curing agent appears, again, less sensitive to the immersion times.

The compressive strain at break calculated for CaCO

3-filled E5/Z-1/100:12 systems after different periods of immersion in distilled water are, finally, reported in

Figure 7c. Also in this case, after a first severe reduction of strain upon 1 and 6 months of immersion, a new growth in this property is noted after 10 months, similarly to what can be seen for the same systems aged in demineralised water (

Figure 5c). The only exception is represented by the system E5/Z-1/100:12/2CaCO

3, whose value of compressive strain remained very close to that measured on un-aged system, almost irrespective to the immersion time. It is confirmed, therefore, that the addition of CaCO

3 is able to reduce only to a limited extent the adverse effects of distilled water on compressive strain at break, that remained always much lower than the value measured on unaged unfilled E5/Z-1/100:12 (11%). The comparison of the strain at break values of CaCO

3-filled E5/Z-1/100:12 systems with those found for the CaCO

3-filled E5/TFF/100:26 ones, subjected to the same aging procedure (

Figure 6c), confirms that the strain values of these latter systems are less affected by the permanence in this aqueous environment, especially for low to medium immersion times (1 and 6 months).

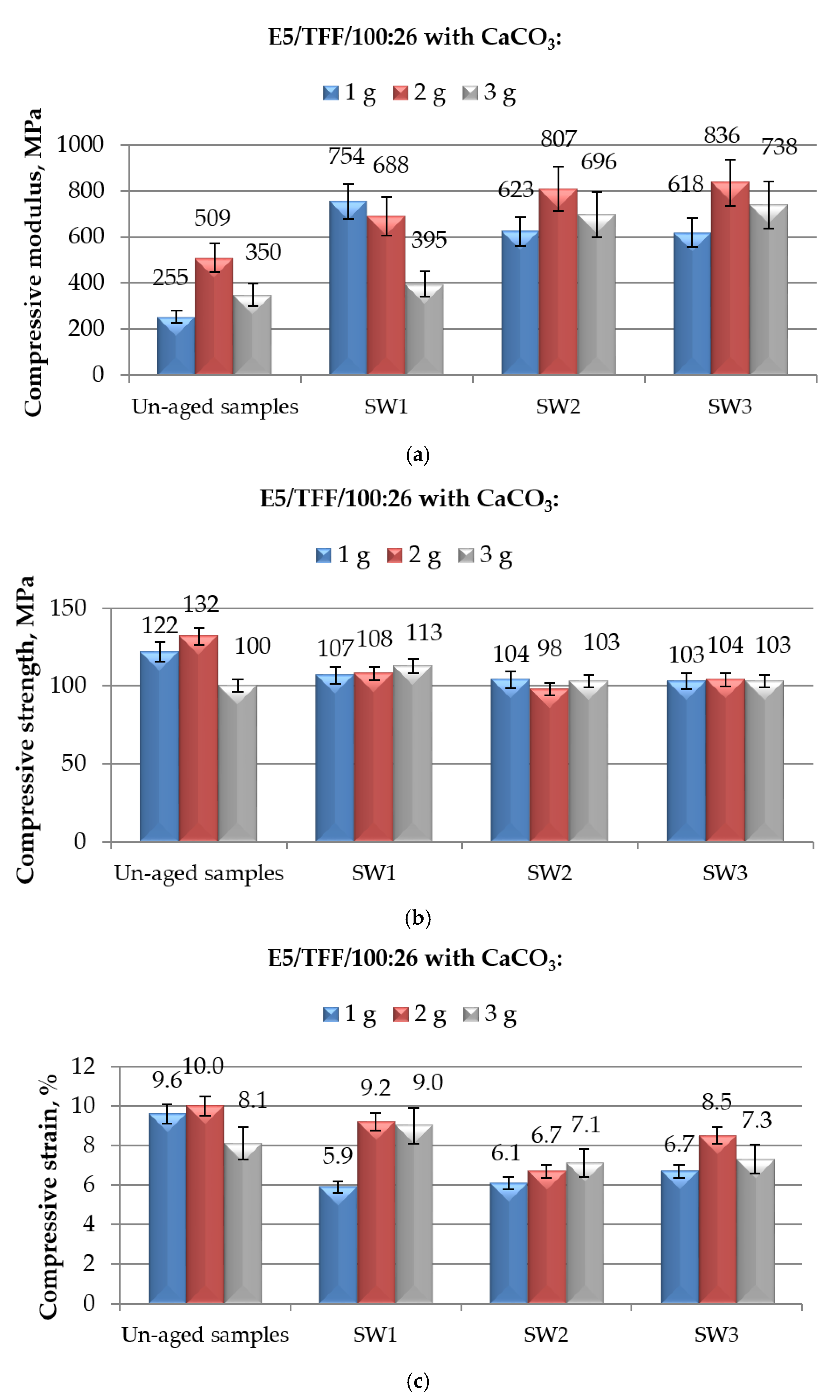

3.4. Epoxy Samples Filled with Different Amounts of CaCO3 and Aged in Spring Water

In the last part of this wide study, the effects of an immersion in spring water on mechanical properties, measured in compression mode, of CaCO

3-filled E5/TFF/100:26 and E5/Z-1/100:12 systems were analysed; the results are presented in

Figure 8, and

Figure 9, respectively.

The general trends of compressive modulus, maximum strength and strain at break observed for CaCO3-filled systems aged in demineralised and distilled water are confirmed when the same compounds were immersed in spring water, with an increase in modulus, a slight decrease in strength and strong reductions in strain values as a consequence of the aging procedure.

A significant growth in compressive modulus of CaCO

3-filled E5/TFF/100:26 system was recorded as consequence of an aging in spring water, as reported in

Figure 8a. The growth was more regular by increasing the immersion time for the compounds containing 2 and 3 g of calcium carbonate, both achieving the highest value of compressive modulus after a 10-month aging procedure, with increases of 64%, and 111%, respectively, with respect to un-aged specimens; the behaviour of E5/TFF/100:26/1CaCO

3 system resulted irregular, with an appreciable increase in modulus after 1 month of immersion and a subsequent slight reduction after 1 and 6 months. Comparing the numerical values of the compressive modulus reported in

Figure 4a and

Figure 6a for the same compounds exposed to demineralised water, and distilled water, respectively, it can be concluded that a prolonged aging (10 months) in spring water caused the lowest increases in this property. We highlight a high dispersion in the experimental results. Once again, the presence of filler was favourable, since the compressive modulus was well above the modulus found for unaged unfilled E5/TFF/100:26, irrespective to the filler content and aging time.

From the analysis of the compressive maximum strength data reported in

Figure 8b, it can be repeated what already observed in the case of immersion in demineralised and distilled water (

Figure 4b and

Figure 6b, respectively), that is, the exposure to spring water brought about a slight decrease in the compressive maximum strength of CaCO

3-filled E5/TFF/100:26 compounds; the exposure time had a limited effect on the maximum strength only up to 6 months of aging; the effect of the filler load is almost insignificant; irrespective to the filler content, the aged CaCO

3-modified E5/TFF/100:26 compounds achieved values of mechanical strength not much lower than that recorded for unaged E5/TFF/100:26 control.

The values of compressive strain at break measured for filled systems aged in spring water, reported in

Figure 8c, closely follow the same trend observed for the samples immersed in demineralised water, shown in

Figure 4c, in terms of effect of filler and of exposure time. The system loaded with lowest (1 g) content of CaCO

3 experienced an appreciable decrease in strain (39%) after 1 month of immersion, while it kept almost the same value at longer immersion times; after the shortest immersion time, the system E5/TFF/100:26/2CaCO

3 display a value of compressive strain very close to that measured in its unaged state, while this value was appreciably reduced at longer immersion times, especially after six months; analysing, finally, the compound containing the highest amount (3 g) of filler, after an initial increase (+11%) in compressive strain upon a 1-month immersion in spring water, a reduction of strain around 10-12% with respect to unaged system was measured at longer aging times. Once again, the aging in spring water caused substantial reductions in compressive strain at break in E5/TFF/100:26 systems filled with small amounts of calcium carbonate.

The last analysed data refer to the results of compression tests performed on CaCO

3-filled E5/Z-1/100:12 systems aged up to 10 months in spring water, reported in

Figure 9. The behaviour observed for compressive modulus (

Figure 9a), maximum strength (

Figure 9b) and strain at break (

Figure 9c) are comparable with that observed for the same systems aged in demineralised water (

Figure 5) and in distilled water (

Figure 7) as well as for the CaCO

3-modified E5/TFF/100:26 compounds immersed in spring water (reported in

Figure 8).

Referring to the compressive modulus (

Figure 9a), it experienced an increase even greater that that observed upon exposure to demineralised (

Figure 5a) and distilled (

Figure 7a) water at the same immersion times, i.e., 6 months. A longer immersion time, i.e., 10 months, caused a reduction in this property, smaller for the filler contents equal to 2 and 3 g of CaCO

3, remaining the compressive modulus also in this case well above the value calculated for unmodified un-aged E5/Z-1/100:12 control.

The values of compressive maximum strength measured on CaCO

3-filled E5/Z-1/100:12 systems aged in spring water up to 10 months (

Figure 9b) again follow what already observed for the same compound aged in the other aqueous environments (

Figure 5b, and

Figure 7b, respectively), with a certain reduction of this property after only 1 month of immersion and a minimal effects of filler content and aging times.

Finally, in

Figure 9c the compressive strain at break data measured on CaCO

3-filled E5/Z-1/100:12 systems after different periods of immersion in spring water are shown. This characteristic was confirmed to be severely reduced by the exposure of an aqueous environment, being the reductions in this property more evident at 6 months of immersion. Also in this case, a new increase in this property was recorded after 10 months of exposure, analogously to what observed for CaCO

3-filled E5/Z-1/100:12 systems immersed in demineralised (

Figure 5c) and distilled (

Figure 7c) water for the same time. Very small appeared the effect of the filler content, irrespective to the aging time. From these latter results it is confirmed that upon addition of small amounts of CaCO

3 it was not possible to appreciably limit the adverse effects of an aqueous environment on compressive strain at break of CaCO

3-filled E5/Z-1/100:12 systems, since this value resulted much lower than that measured on unaged unfilled E5/Z-1/100:12.