Effect of MWCNT Surface Functionalisation and Distribution on Compressive Properties of Kenaf and Hybrid Kenaf/Glass Fibres Reinforced Polymer Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Surface Modification of MWCNT

2.3. Fabrication of Unidirectional (UD) Kenaf and Hybrid UD Kenaf/Glass Fibres Reinforced Polymer Composites

2.4. Designation of Kenaf and Hybrid Kenaf/Glass Fibres Reinforced Polymer Composites

2.5. Characterization

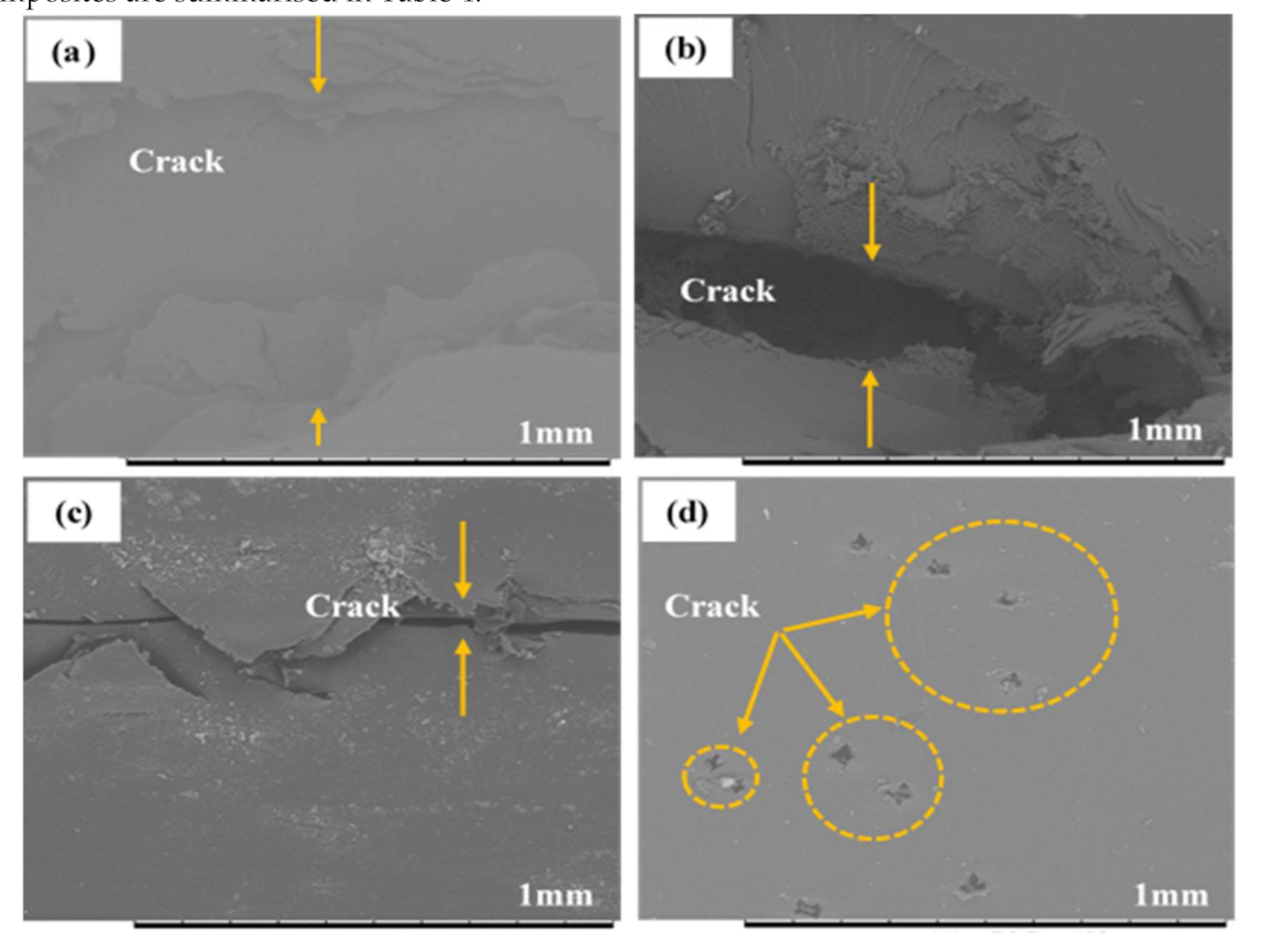

2.5.1. Dispersion Evaluation and Microstructure Characterization

2.5.2. Compression Test

3. Results and Discussion

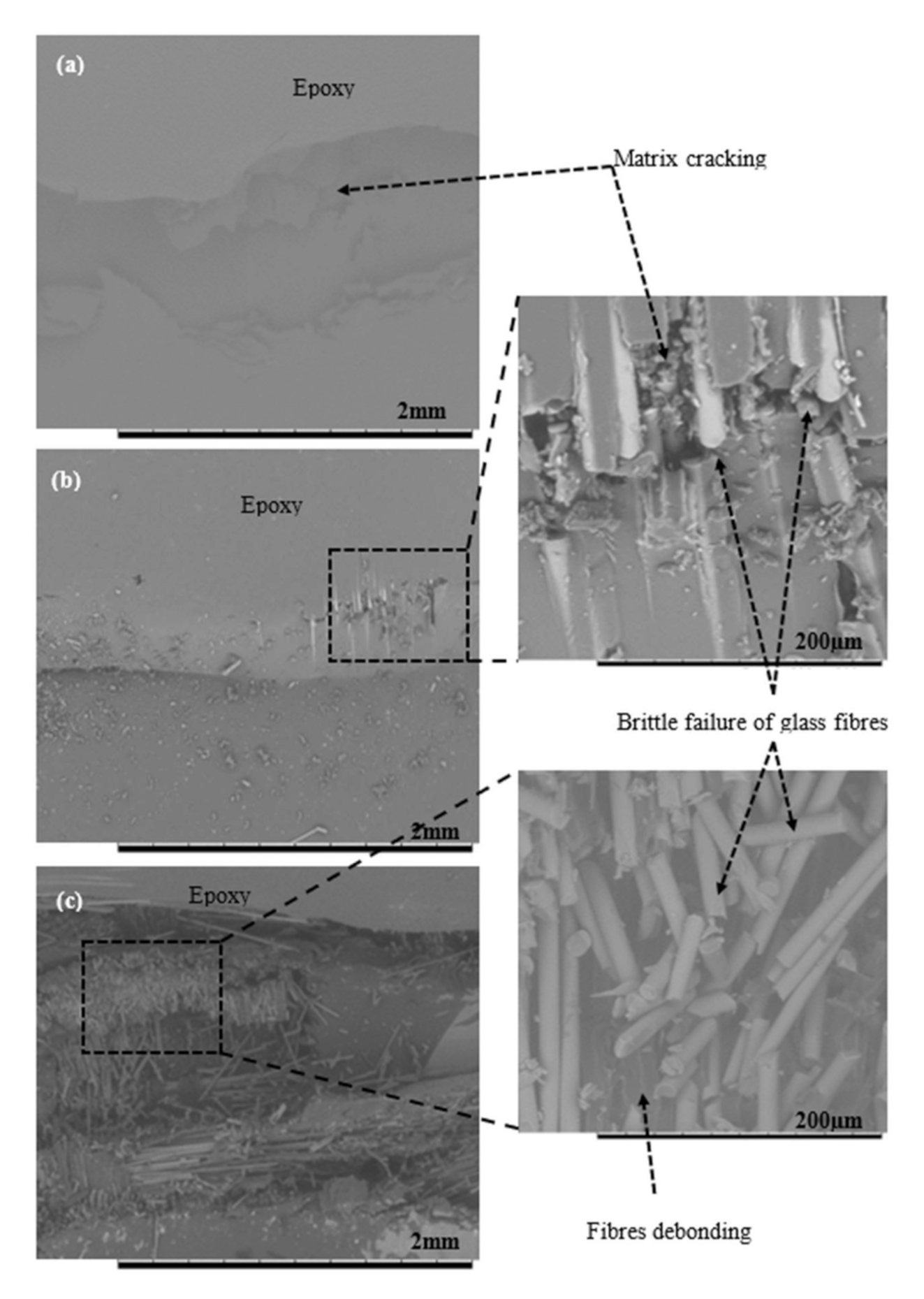

3.1. TEM Evaluation for Dispersion of MWCNT (PCNT/ACNT/SCNT) within Epoxy Matrix

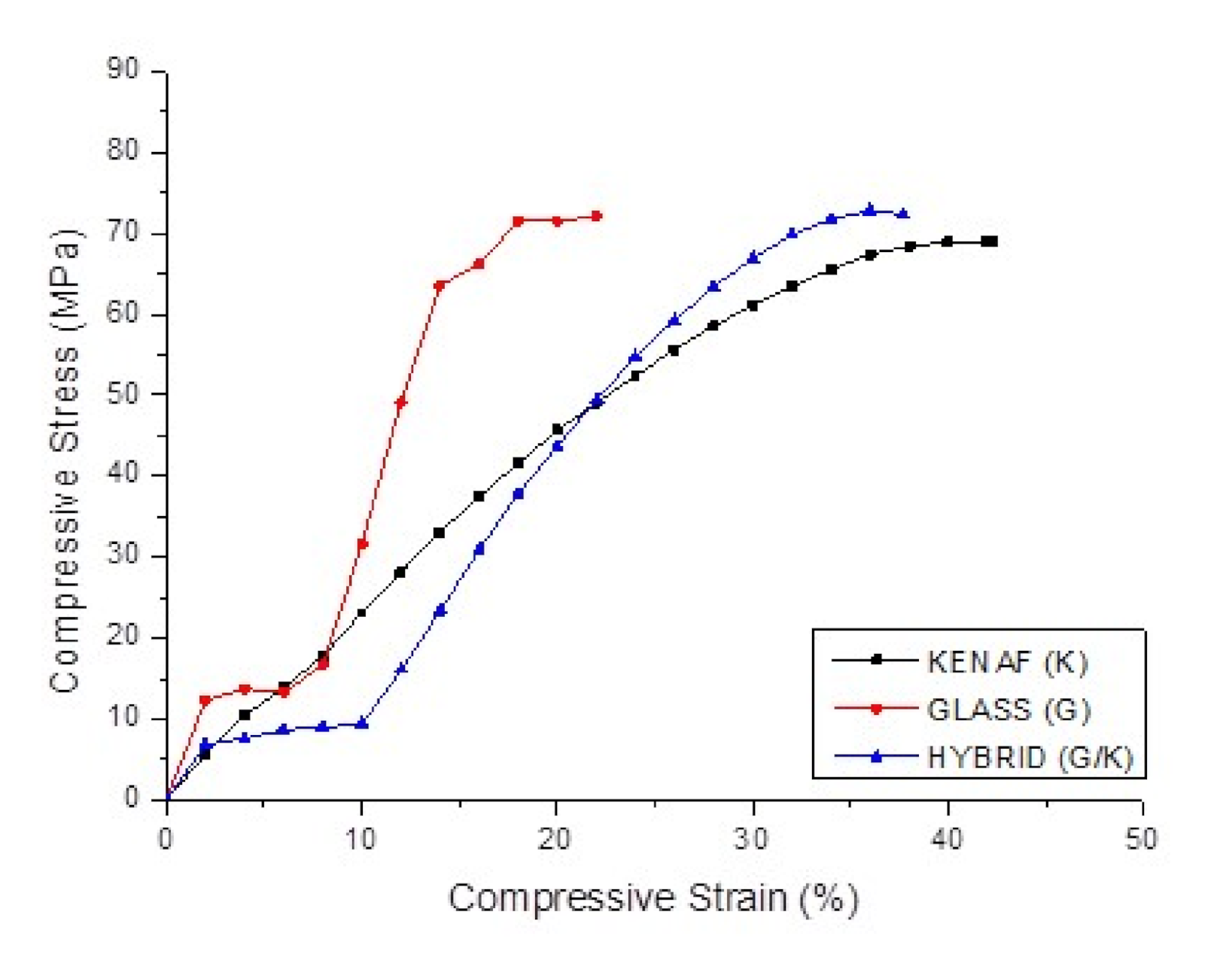

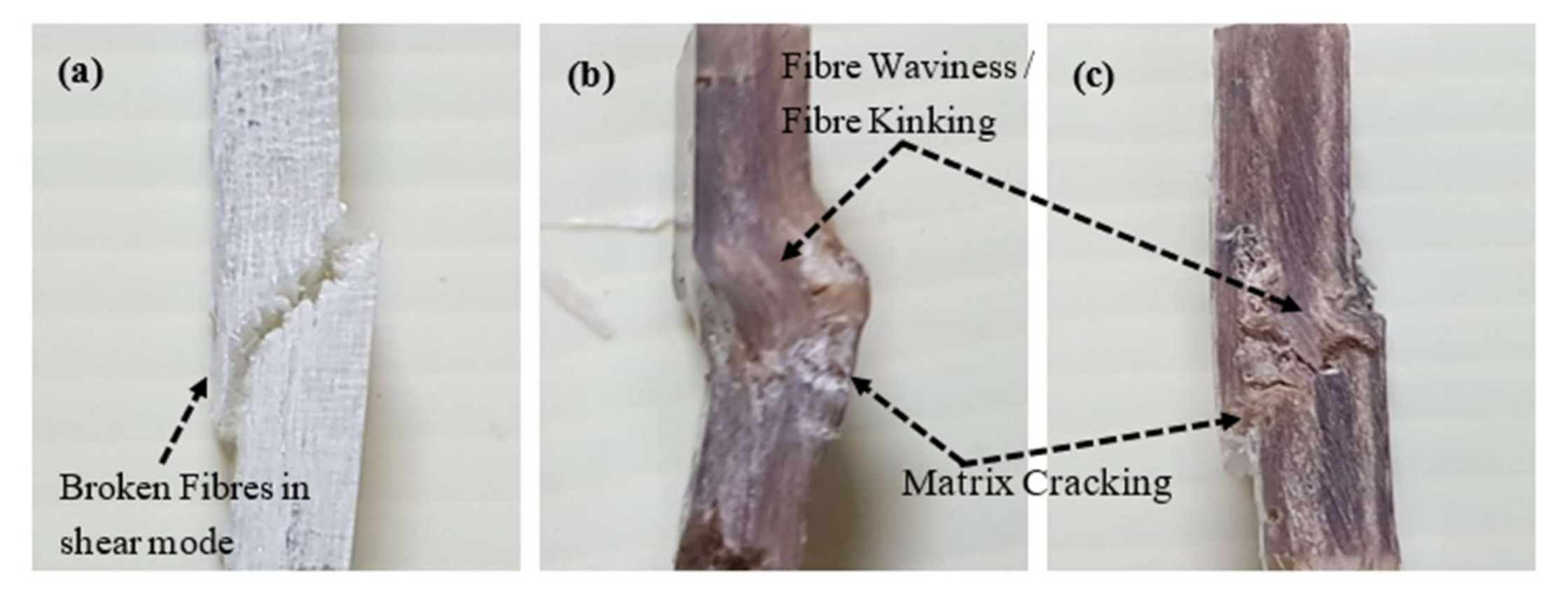

3.2. Effect of Hybridization on Compressive Properties of Kenaf Fibres Reinforced Polymer Composites and Kenaf/Glass Hybrid Composites

3.3. Effect of Surface Functionalisation MWCNT on Compressive Properties of Kenaf Fibres Reinforced Polymer Composites

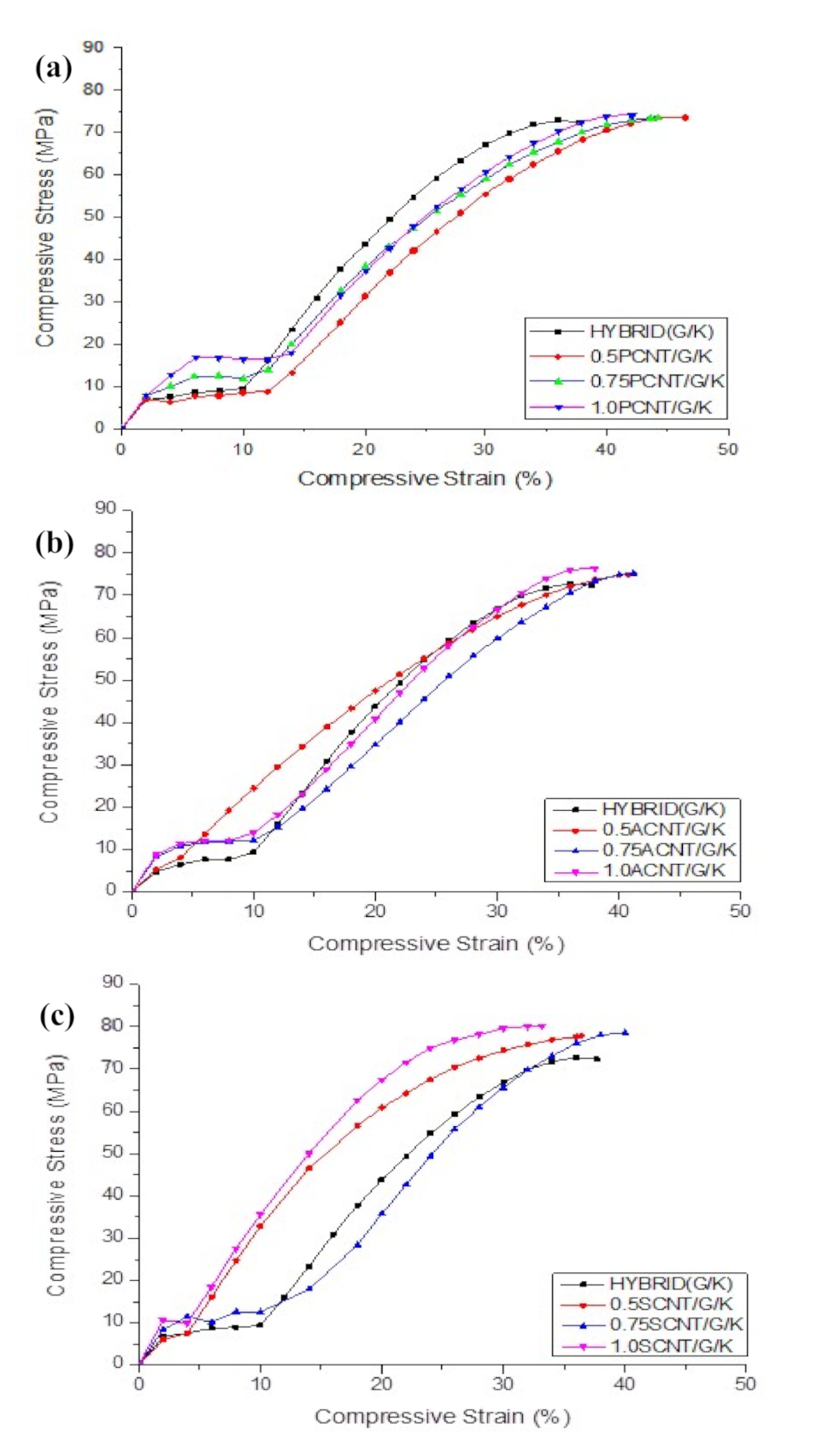

3.4. Effect of Surface Functionalization MWCNT on Compressive Properties of Hybrid Kenaf/Glass Fibres Reinforced Polymer Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Basri, M.H.A.; Abdu, A.; Junejo, N.; Hamid, H.A.; Ahmed, K. Journey of kenaf in Malaysia: A Review. Sci. Res. Essays 2014, 9, 458–470. [Google Scholar]

- Yahaya, R.; Sapuan, S.; Jawaid, M.; Leman, Z.; Zainudin, E. Effect of layering sequence and chemical treatment on the mechanical properties of woven kenaf-aramid hybrid laminated composites. Mater. Des. 2015, 67, 173–179. [Google Scholar] [CrossRef]

- Asumani, O.; Reid, R.; Paskaramoorthy, R. The effects of alkali-silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos. Part A 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M. Effect of Alkali and Silane Treatments on Mechanical and Fibre-matrix Bond Strength of Kenaf and Pineapple Leaf Fibres. J. Bionic Eng. 2016, 13, 426–435. [Google Scholar] [CrossRef]

- Davoodi, M.; Sapuan, S.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Majid, R.A.; Ismail, H.; Taib, R.M. Benzoyl Chloride Treatment of Kenaf Core Powder: The Effects on Mechanical and Morphological Properties of PVC/ENR / kenaf Core Powder Composites. Procedia Chem. 2016, 19, 803–809. [Google Scholar] [CrossRef]

- Shuhimi, F.F.; Bin Abdollah, M.F.; Kalam, A.; Hassan, M.; Mustafa, A.; Amiruddin, H. Tribological characteristics comparison for oil palm fibre/epoxy and kenaf fibre/epoxy composites under dry sliding conditions. Tribol. Int. 2016, 101, 247–254. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Tholibon, D.; Sulong, A.B.; Muhamad, N.; Haron, C. Effects of High-Temperature Exposure on the Mechanical Properties of Kenaf Composites. Polymers 2020, 12, 1643. [Google Scholar] [CrossRef]

- Azam, F.; Atiqah, A.; Razak, Z.; Radzi, M.K.F.M.; Muhamad, N.; Haron, C.; Sulong, A.B. Influence of Multiwalled Carbon Nanotubes on the Rheological Behavior and Physical Properties of Kenaf Fiber-Reinforced Polypropylene Composites. Polymers 2020, 12, 2083. [Google Scholar] [CrossRef]

- Manap, N.; Jumahat, A.; Sapiai, N. Effect of Nanosilica Content on Longitudinal and Transverse Tensile Properties of Unidirectional Kenaf Composite. J. Teknol. 2015, 76, 123–130. [Google Scholar] [CrossRef][Green Version]

- Saba, N.; Jawaid, M.; Hakeem, K.R.; Paridah, M.; Khalina, A.; Alothman, O.Y. Potential of bioenergy production from industrial kenaf (Hibiscus cannabinus L.) based on Malaysian perspective. Renew. Sustain. Energy Rev. 2015, 42, 446–459. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Jauhari, N.; Mishra, R.; Thakur, H. Natural Fibre Reinforced Composite Laminates—A Review. Mater. Today Proc. 2015, 2, 2868–2877. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Aji, I.S.; Sapuan, S.M.; Zainudin, E.S.; Abdan, K. Kenaf fibres as reinforcement for polymeric composites: A review. Int. J. Mech. Mater. Eng. 2009, 4, 239–248. [Google Scholar]

- Silva, G.G.; Ribeiro, H.; Neves, J.C.; Calado, H.D.R.; García, F.G.; Silva, G.G. Multi-walled carbon nanotubes functionalized with triethylenetetramine as fillers to enhance epoxy dimensional thermal stability. J. Therm. Anal. Calorim. 2013, 115, 1021–1027. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Mahmud, J. Flexural and Tensile Properties of Kenaf/Glass Fibres Hybrid composites filled with Carbon Nanotubes. J. Teknol. 2015, 76, 115–120. [Google Scholar] [CrossRef][Green Version]

- Shokrieh, M.; Kefayati, A.R.; Chitsazzadeh, M. Fabrication and mechanical properties of clay/epoxy nanocomposite and its polymer concrete. Mater. Des. 2012, 40, 443–452. [Google Scholar] [CrossRef]

- Ma, P.C.; Mo, S.Y.; Tang, B.Z.; Kim, J.K. Dispersion, interfacial interaction and re-agglomeration of functionalized carbon nanotubes in epoxy composites. Carbon 2010, 48, 1824–1834. [Google Scholar] [CrossRef]

- Wetzel, B.; Rosso, P.; Haupert, F.; Friedrich, K. Epoxy nanocomposites—fracture and toughening mechanisms. Eng. Fract. Mech. 2006, 73, 2375–2398. [Google Scholar] [CrossRef]

- Khare, K.S.; Khabaz, F.; Khare, R. Effect of Carbon Nanotube Functionalization on Mechanical and Thermal Properties of Cross-Linked Epoxy-Carbon Nanotube Nanocomposites: Role of Strengthening the Interfacial Interactions. ACS Appl. Mater. Interfaces 2014, 6, 6098–6110. [Google Scholar] [CrossRef]

- Li, B.; Zhong, W. Review on polymer/graphite nanoplatelet nanocomposites. J. Mater. Sci. 2011, 46, 5595–5614. [Google Scholar] [CrossRef]

- Jumahat, A.; Kasolang, S.; Bahari, M.T. Wear properties of nanosilica filled epoxy polymers and FRP composites. J. Tribol. 2015, 6, 24–36. [Google Scholar]

- Sapiai, N.; Jumahat, A.; Mahmud, J. Mechanical properties of functionalised CNT filled kenaf reinforced epoxy composites. Mater. Res. Express 2018, 5, 045034. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Manap, N.; Usoff, M.A.I. Effect of nanofillers dispersion on mechanical properties of clay/epoxy and silica/epoxy nanocomposites. J. Teknol. 2015, 76, 107–111. [Google Scholar] [CrossRef]

- Ma, P.C.; Kim, J.K.; Tang, B.Z. Effects of silane functionalization on the properties of carbon nanotube/epoxy nanocomposites. Compos. Sci. Technol. 2007, 67, 2965–2972. [Google Scholar] [CrossRef]

- Liew, K.; Lei, Z.; Zhang, L. Mechanical analysis of functionally graded carbon nanotube reinforced composites: A review. Compos. Struct. 2015, 120, 90–97. [Google Scholar] [CrossRef]

- Lavorgna, M.; Romeo, V.; Martone, A.; Caputo, F.; Giordano, M.; Buonocore, G.; Qu, M.; Fei, G.; Xia, H. Silanization and silica enrichment of multiwalled carbon nanotubes: Synergistic effects on the thermal-mechanical properties of epoxy nanocomposites. Eur. Polym. J. 2013, 49, 428–438. [Google Scholar] [CrossRef]

- Park, O.K.; Kim, N.H.; Yoo, G.H.; Rhee, K.Y.; Lee, J.H. Effects of the surface treatment on the properties of polyaniline coated carbon nanotubes/epoxy composites. Compos. Part B 2010, 41, 2–7. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Pitchan, M.K.; Bhowmik, S.; Balachandran, M.; Abraham, M. Effect of surface functionalization on mechanical properties and decomposition kinetics of high performance polyetherimide/MWCNT nano composites. Compos. Part A 2016, 90, 147–160. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, X.; Liu, X.H.; Lai, J.Z. Effect of silane treatment of carboxylic-functionalized multi-walled carbon nanotubes on the thermal properties of epoxy nanocomposites. Express Polym. Lett. 2010, 4, 217–226. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functionalized carbon nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Kim, M.; Rhee, K.Y.; Park, S.J.; Hui, D. Effects of silane-modified carbon nanotubes on flexural and fracture behaviors of carbon nanotube-modified epoxy/basalt composites. Compos. Part B 2012, 43, 2298–2302. [Google Scholar] [CrossRef]

- Lee, J.H.; Rhee, K.Y.; Park, S.J. Silane modification of carbon nanotubes and its effects on the material properties of carbon/CNT/epoxy three-phase composites. Compos. Part A 2011, 42, 478–483. [Google Scholar] [CrossRef]

- Nadler, M.; Werner, J.; Mahrholz, T.; Riedel, U.; Hufenbach, W. Effect of CNT surface functionalisation on the mechanical properties of multi-walled carbon nanotube/epoxy-composites. Compos. Part A 2009, 40, 932–937. [Google Scholar] [CrossRef]

- Shaari, N.S.; Sapiai, N.; Jumahat, A.; Ismail, M.H. Functionalization of multi-wall carbon nanotubes in chemical solution of H2SO4/HNO3 and its dispersion in different media. Mater. Sci. Forum 2016, 882, 103–107. [Google Scholar] [CrossRef]

- Ma, P.C.; Kim, J.K.; Tang, B.Z. Functionalization of carbon nanotubes using a silane coupling agent. Carbon 2006, 44, 3232–3238. [Google Scholar] [CrossRef]

- Sanjay, M.; Arpitha, G.; Yogesha, B. Study on Mechanical Properties of Natural—Glass Fibre Reinforced Polymer Hybrid Composites: A Review. Mater. Today Proc. 2015, 2, 2959–2967. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Natural FRP tube confined fibre reinforced concrete under pure axial compression: A comparison with glass/carbon FRP. Thin Walled Struct. 2014, 82, 159–169. [Google Scholar] [CrossRef]

- Atiqah, A.; Maleque, M.; Jawaid, M.; Iqbal, M. Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos. Part B 2014, 56, 68–73. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Assarar, M.; Sabhi, H.; Ayad, R. Hybridisation effect on diffusion kinetic and tensile mechanical behaviour of epoxy based flax–glass composites. Compos. Part A 2016, 87, 153–160. [Google Scholar] [CrossRef]

- Muhammad, Y.H.; Ahmad, S.; Abu Bakar, M.A.; Mamun, A.A.; Heim, H.P. Mechanical properties of hybrid glass/kenaf fibre-reinforced epoxy composite with matrix modification using liquid epoxidised natural rubber. J. Reinf. Plast. Compos. 2015, 34, 896–906. [Google Scholar] [CrossRef]

- Bhoopathi, R.; Ramesh, M.; Deepa, C. Fabrication and Property Evaluation of Banana-Hemp-Glass Fiber Reinforced Composites. Procedia Eng. 2014, 97, 2032–2041. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Koradiya, S.B.; Patel, J.P.; Parsania, P.H. The Preparation and PhysicoChemical Study of Glass, Jute and Hybrid Glass-Jute Bisphenol-C-Based Epoxy Resin Composites. Polym. Technol. Eng. 2010, 49, 1445–1449. [Google Scholar] [CrossRef]

- Vennerberg, D.; Rueger, Z.; Kessler, M.R. Effect of silane structure on the properties of silanized multiwalled carbon nanotube-epoxy nanocomposites. Polymers 2014, 55, 1854–1865. [Google Scholar] [CrossRef]

- Garg, M.; Sharma, S.; Mehta, R. Pristine and amino functionalized carbon nanotubes reinforced glass fiber epoxy composites. Compos. Part A 2015, 76, 92–101. [Google Scholar] [CrossRef]

- Zamfirova, G.; Gaydarov, V.; Faraguna, F.; Vidović, E.; Jukić, A. Influence of carbon nanotubes functionalization on the mechanical properties of polymethacrylate nanocomposites. Colloids Surf. A 2016, 510, 169–175. [Google Scholar] [CrossRef]

- Cui, L.J.; Wang, Y.; Xiu, W.J.; Wang, W.Y.; Xu, L.H.; Xu, X.B.; Meng, Y.; Li, L.Y.; Gao, J.; Chen, L.T.; et al. Effect of functionalization of multi-walled carbon nanotube on the curing behavior and mechanical property of multi-walled carbon nanotube/epoxy composites. Mater. Des. 2013, 49, 279–284. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, Z.; Hu, Y.; Li, J.; Fan, X. Multiple functionalization of multi-walled carbon nanotubes with carboxyl and amino groups. Appl. Surf. Sci. 2013, 276, 476–481. [Google Scholar] [CrossRef]

- Cha, J.; Jin, S.; Shim, J.H.; Park, C.S.; Ryu, H.J.; Hong, S.H. Functionalization of carbon nanotubes for fabrication of CNT/epoxy nanocomposites. Mater. Des. 2016, 95, 1–8. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber Reinforced Composites: Materials, Manufacturing and Design, Third Edition; CRC Press, Taylor & Francis Inc.: Boca Raton, FL, USA, 2007. [Google Scholar]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.; Jawaid, M.; Leman, Z.; Zainudin, E. Effect of fibre orientations on the mechanical properties of kenaf-aramid hybrid composites for spall-liner application. Def. Technol. 2016, 12, 52–58. [Google Scholar] [CrossRef]

| Composite Systems | Designation |

|---|---|

| Unidirectional (UD) Kenaf Fibre Reinforced Polymer Composite | UD Kenaf (K) |

| Woven Glass Fibre Reinforced Polymer Composite | Woven Glass (G) |

| Hybrid Kenaf/Glass Fibre Reinforced Polymer Composite | Hybrid G/K |

| 0.5 wt % PCNT modified Kenaf FRP Composite | 0.5PCNT/K |

| 0.75 wt % PCNT modified Kenaf FRP Composite | 0.75PCNT/K |

| 1.0 wt % PCNT modified Kenaf FRP Composite | 1.0PCNT/K |

| 0.5 wt % ACNT modified Kenaf FRP Composite | 0.5ACNT/K |

| 0.75 wt % ACNT modified Kenaf FRP Composite | 0.75ACNT/K |

| 1.0 wt % ACNT modified Kenaf FRP Composite | 1.0ACNT/K |

| 0.5 wt % SCNT modified Kenaf FRP Composite | 0.5SCNT/K |

| 0.75 wt % SCNT modified Kenaf FRP Composite | 0.7SCNT/K |

| 1.0 wt % SCNT modified Kenaf FRP Composite | 1.0SCNT/K |

| 0.5 wt % PCNT modified Hybrid Glass/Kenaf FRP Composite | 0.5PCNT/G/K |

| 0.75 wt % PCNT modified Hybrid Glass/Kenaf FRP Composite | 0.75PCNT/G/K |

| 1.0 wt % PCNT modified Hybrid Glass/Kenaf FRP Composite | 1.0PCNT/ G/K |

| 0.5 wt % ACNT modified Hybrid Glass/Kenaf FRP Composite | 0.5ACNT/G/K |

| 0.75 wt % ACNT modified Hybrid Glass/Kenaf FRP Composite | 0.75ACNT/G/K |

| 1.0 wt % ACNT modified Hybrid Glass/Kenaf FRP Composite | 1.0ACNT/G/K |

| 0.5 wt % SCNT modified Hybrid Glass/Kenaf FRP Composite | 0.5SCNT/G/K |

| 0.75 wt % SCNT modified Hybrid Glass/Kenaf FRP Composite | 0.75SCNT/G/K |

| 1.0 wt % SCNT modified Hybrid Glass/Kenaf FRP Composite | 1.0SCNT/G/K |

| Fibres Orientation | Width (mm) | Gage Length (mm) | Tab Length (mm) | Overall Length (mm) | Tab Thickness (mm) |

|---|---|---|---|---|---|

| 0° unidirectional (UD) | 10 | 10 | 50 | 110 | 1.5 |

| |||||

| Composites | Compressive Modulus (GPa) | Compressive Strength (MPa) | Compressive Strain at Break (%) |

|---|---|---|---|

| KENAF (K) | 2.43 ± 0.17 | 68.78 ± 1.08 | 38.6 ± 4.91 |

| GLASS (G) | 6.06 ± 0.16 | 74.34 ± 0.41 | 19.92 ± 1.12 |

| HYBRID (G/K) | 3.57 ± 0.14 | 73.24 ± 0.77 | 37.13 ± 10.49 |

| Composites | Compressive Modulus (GPa) | Compressive Strength (MPa) | Compressive Strain at Break (%) |

|---|---|---|---|

| KENAF (K) | 2.43 ± 0.17 | 68.78 ± 1.08 | 38.6 ± 4.91 |

| 0.5PCNT/K | 2.45 ± 0.09 | 73.44 ± 2.18 | 41.84 ± 5.58 |

| 0.75PCNT/K | 2.74 ± 0.20 | 75.17 ± 2.81 | 45.15 ± 3.71 |

| 1.0PCNT/K | 2.89 ± 0.17 | 73.06 ± 2.20 | 48.20 ± 2.92 |

| 0.5ACNT/K | 3.28 ± 0.19 | 74.66 ± 5.59 | 35.11 ± 3.11 |

| 0.75ACNT/K | 3.69 ± 0.19 | 77.12 ± 1.29 | 40.39 ± 2.31 |

| 1.0ACNT/K | 3.80 ± 0.06 | 78.48 ± 1.79 | 39.34 ± 3.02 |

| 0.5SCNT/K | 3.85 ± 0.05 | 77.51 ± 2.54 | 47.54 ± 7.06 |

| 0.75SCNT/K | 4.07 ± 0.14 | 80.09 ± 3.03 | 43.61 ± 5.66 |

| 1.0SCNT/K | 4.21 ± 0.10 | 82.64 ± 2.16 | 38.12 ± 1.75 |

| Composites | Compressive Modulus (GPa) | Compressive Strength (MPa) | Compressive Strain at Break (%) |

|---|---|---|---|

| HYBRID (G/K) | 3.57 ± 0.14 | 73.24 ± 0.77 | 37.13 ± 10.49 |

| 0.5PCNT/G/K | 3.80 ± 0.20 | 73.55 ± 2.07 | 47.66 ± 8.95 |

| 0.75PCNT/G/K | 4.08 ± 0.11 | 73.60 ± 1.87 | 44.59 ± 9.63 |

| 1.0PCNT/G/K | 4.09 ± 0.07 | 74.26 ± 1.87 | 45.47± 3.65 |

| 0.5ACNT/G/K | 3.95 ± 0.09 | 75.05 ± 0.59 | 41.21 ± 8.64 |

| 0.75ACNT/G/K | 4.21 ± 0.04 | 75.23 ± 0.82 | 42.61 ± 6.98 |

| 1.0ACNT/G/K | 4.23 ± 0.11 | 76.06 ± 1.41 | 39.22 ± 4.23 |

| 0.5SCNT/G/K | 4.18 ± 0.10 | 75.76 ± 1.98 | 35.05 ± 2.38 |

| 0.75SCNT/G/K | 4.26 ± 0.11 | 76.97 ± 2.56 | 44.46 ± 5.29 |

| 1.0SCNT/G/K | 4.35 ± 0.05 | 78.90 ± 1.15 | 36.60 ± 3.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sapiai, N.; Jumahat, A.; Jawaid, M.; Khan, A. Effect of MWCNT Surface Functionalisation and Distribution on Compressive Properties of Kenaf and Hybrid Kenaf/Glass Fibres Reinforced Polymer Composites. Polymers 2020, 12, 2522. https://doi.org/10.3390/polym12112522

Sapiai N, Jumahat A, Jawaid M, Khan A. Effect of MWCNT Surface Functionalisation and Distribution on Compressive Properties of Kenaf and Hybrid Kenaf/Glass Fibres Reinforced Polymer Composites. Polymers. 2020; 12(11):2522. https://doi.org/10.3390/polym12112522

Chicago/Turabian StyleSapiai, Napisah, Aidah Jumahat, Mohammad Jawaid, and Anish Khan. 2020. "Effect of MWCNT Surface Functionalisation and Distribution on Compressive Properties of Kenaf and Hybrid Kenaf/Glass Fibres Reinforced Polymer Composites" Polymers 12, no. 11: 2522. https://doi.org/10.3390/polym12112522

APA StyleSapiai, N., Jumahat, A., Jawaid, M., & Khan, A. (2020). Effect of MWCNT Surface Functionalisation and Distribution on Compressive Properties of Kenaf and Hybrid Kenaf/Glass Fibres Reinforced Polymer Composites. Polymers, 12(11), 2522. https://doi.org/10.3390/polym12112522