PVDF-BaTiO3 Nanocomposite Inkjet Inks with Enhanced β-Phase Crystallinity for Printed Electronics

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

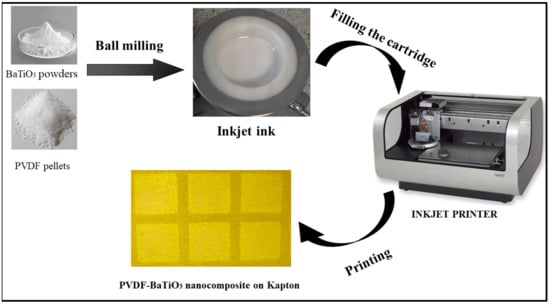

2.2. Ink Preparation

2.3. Characterization

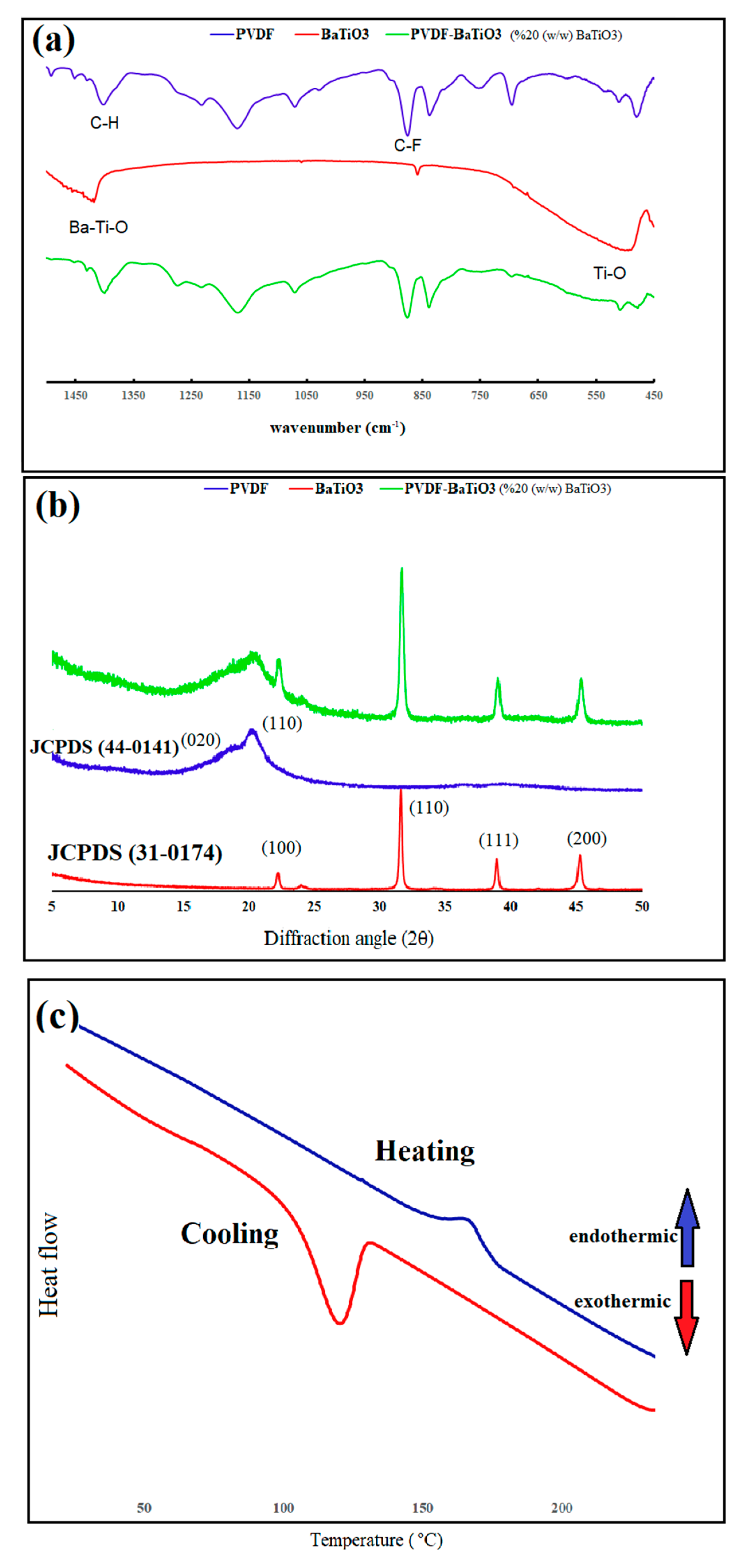

3. Results and Discussion

3.1. Determining Inkjet Printable Region

3.2. Influence of BaTiO3 Content on β-Phase Crystallinity

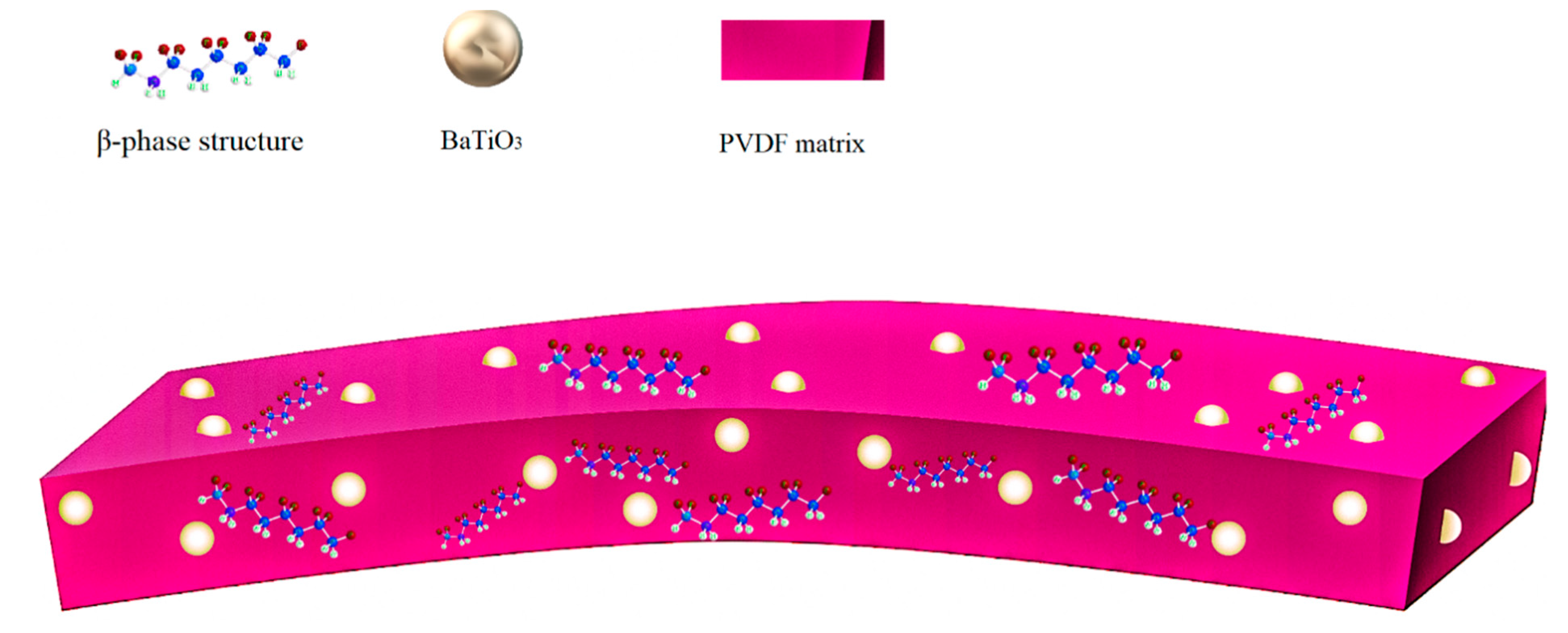

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, Y.; Wu, X.; Guo, X.; Kong, B.; Zhang, M.; Qian, X.; Mi, S.; Sun, W. The boom in 3D-printed sensor technology. Sensors 2017, 17, 1166. [Google Scholar] [CrossRef] [PubMed]

- Zolfagharian, A.; Kouzani, A.Z.; Khoo, S.Y.; Moghadam, A.A.A.; Gibson, I.; Kaynak, A. Evolution of 3D printed soft actuators. Sens. Actuators A Phys. 2016, 250, 258–272. [Google Scholar] [CrossRef]

- Pang, Y.; Cao, Y.; Chu, Y.; Liu, M.; Snyder, K.; MacKenzie, D.; Cao, C. Additive manufacturing of batteries. Adv. Funct. Mater. 2020, 30, 1906244. [Google Scholar] [CrossRef]

- Li, H.; Liang, J. Recent development of printed micro-supercapacitors: Printable materials, printing technologies and perspectives. Adv. Mater. 2020, 32, 1805864. [Google Scholar] [CrossRef]

- Conti, S.; Pimpolari, L.; Calabrese, G.; Worsley, R.; Majee, S.; Polyushkin, D.K.; Paur, M.; Pace, S.; Keum, D.H.; Fabbri, F.; et al. Low-voltage 2D materials-based printed field-effect transistors for integrated digital and analog electronics on paper. Nat. Commun. 2020, 11, 1–9. [Google Scholar] [CrossRef]

- Fromm, J.E. Numerical calculation of the fluid dynamics of drop-on-demand jets. IBM J. Res. Dev. 1984, 28, 322–333. [Google Scholar] [CrossRef]

- Reis, N.; Derby, B. Ink jet deposition of ceramic suspensions: Modeling and experiments of droplet formation. Mater. Res. Soc. 2000, 625, 117–122. [Google Scholar] [CrossRef]

- Jang, D.; Kim, D.; Moon, J. Influence of fluid physical properties on ink-jet printability. Langmuir 2009, 25, 2629–2635. [Google Scholar] [CrossRef]

- Ruan, L.; Yao, X.; Chang, Y.; Zhou, L.; Qin, G.; Zhang, X. Properties and applications of the β Phase Poly (vinylidene fluoride). Polymers 2018, 10, 228. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, X.; Ellingford, C.; Zhang, Y.; Chen, S.; Zhou, K.; Zhang, D.; Bowen, C.R.; Wan, C. Interface design for high energy density polymer nanocomposites. Chem. Soc. Rev. 2019, 48, 4424–4465. [Google Scholar] [CrossRef]

- Chen, S.; Yan, X.; Liu, W.; Qiao, R.; Chen, S.; Luo, H.; Zhang, D. Polymer-based dielectric nanocomposites with high energy density via using natural sepiolite nanofibers. Chem. Eng. J. 2020, 401, 126095. [Google Scholar] [CrossRef]

- Shaik, H.; Rachith, S.N.; Rudresh, K.J.; Sheik, A.S.; Thulasi Raman, K.H.; Kondaiah, P.; Mohan Rao, G. Towards β-phase formation probability in spin coated PVDF thin films. J. Polym. Res. 2017, 24, 35. [Google Scholar] [CrossRef]

- Li, L.; Zhang, M.; Rong, M.; Ruan, W. Studies on the transformation process of PVDF from α to β phase by stretching. RSC Adv. 2014, 4, 3938–3943. [Google Scholar] [CrossRef]

- Senthil Kumar, R.; Sarathi, T.; Venkataraman, K.K.; Bhattacharyya, A. Enhanced piezoelectric properties of polyvinylidene fluoride nanofibers using carbon nanofiber and electrical poling. Mater. Lett. 2019, 255, 126515. [Google Scholar] [CrossRef]

- Lei, T.; Zhu, P.; Cai, X.; Yang, L.; Yang, F. Electrospinning of PVDF nanofibrous membranes with controllable crystalline phases. Appl. Phys. A 2015, 120, 5–10. [Google Scholar] [CrossRef]

- Mahato, P.; Seal, A.; Garain, S.; Sen, S. Effect of fabrication technique on the crystalline phase and electrical properties of PVDF films. Mater. Sci. Pol. 2015, 33, 157–162. [Google Scholar] [CrossRef]

- Tienne, L.G.P.; de Abreu, T.B.; Gondim, F.F.; da Cruz, B.D.S.M.; Martins, G.R.; Simão, R.A.; Marques, M.D.F.V. Low contents of graphite improving general properties of poly(vinylidene fluoride). Polym. Test. 2020, 91, 106790. [Google Scholar] [CrossRef]

- Maity, N.; Mandal, A.; Nandi, A.K. High dielectric poly(vinylidene fluoride) nanocomposite films with MoS2 using polyaniline interlinker via interfacial interaction. J. Mater. Chem. C 2017, 5, 12121–12133. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.; Liu, W.; Fu, R.; Tu, S.; Zhao, Y.; Dong, L.; Yan, B.; Gu, Y. High performance piezoelectric nanogenerators based on electrospun ZnO Nanorods/Poly(vinylidene fluoride) composite membranes. J. Phys. Chem. C 2019, 123, 11378–11387. [Google Scholar] [CrossRef]

- Pariy, I.O.; Ivanova, A.A.; Shvartsman, V.V.; Lupascu, D.C.; Sukhorukov, G.B.; Ludwig, T.; Bartasyte, A.; Mathur, S.; Surmeneva, M.A.; Surmenev, R.A. Piezoelectric response in hybrid micropillar arrays of poly (vinylidene fluoride) and reduced graphene oxide. Polymers 2019, 11, 1065. [Google Scholar] [CrossRef]

- Gong, X.; Chen, Y.; Tang, C.Y.; Law, W.C.; Chen, L.; Wu, C.; Hu, T.; Tsui, G.C.P. Crystallinity and morphology of barium titanate filled poly (vinylidene fluoride) nanocomposites. J. Appl. Polym. Sci. 2018, 135, 46877. [Google Scholar] [CrossRef]

- Bai, H.; Wang, X.; Zhou, Y.; Zhang, L. Preparation and characterization of poly(vinylidene fluoride) composite membranes blended with nano-crystalline cellulose. Prog. Nat. Sci. Mater. Int. 2012, 22, 250–257. [Google Scholar] [CrossRef]

- Rahimpour, A.; Madaeni, S.S.; Zereshki, S.; Mansourpanah, Y. Preparation and characterization of modified nano-porous PVDF membrane with high antifouling property using UV photo-grafting. Appl. Surf. Sci. 2009, 255, 7455–7461. [Google Scholar] [CrossRef]

- Gu, S.; He, G.; Wu, X.; Hu, Z.; Wang, L.; Xiao, G.; Peng, L. Preparation and characterization of poly(vinylidene fluoride)/sulfonated poly(phthalazinone ether sulfone ketone) blends for proton exchange membrane. J. Appl. Polym. Sci. 2010, 116, 852–860. [Google Scholar] [CrossRef]

- Gomes, J.; Nunes, J.S.; Sencadas, V.; Lanceros-Méndez, S. Influence of the β-phase content and degree of crystallinity on the piezo-and ferroelectric properties of poly (vinylidene fluoride). Smart Mater. Struct. 2010, 19, 065010. [Google Scholar] [CrossRef]

- Salimi, A.; Yousefi, A.A. FTIR studies of b-phase crystal formation in stretched PVDF films. Polym. Test. 2003, 22, 699–704. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, Y.; Zhang, W.; Yan, X.; Huang, B. Improved battery performance contributed by the optimized phase ratio of β and α of PVDF. RSC Adv. 2019, 9, 29760–29764. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef]

- Kappadan, S.; Gebreab, T.W.; Thomas, S.; Kalarikkal, N. Tetragonal BaTiO3 nanoparticles: An efficient photocatalyst for the degradation of organic pollutants. Mater. Sci. Semicond. Process. 2016, 51, 42–47. [Google Scholar] [CrossRef]

- Muniz, F.T.L.; Miranda, M.A.R.; Morilla dos Santos, C.; Sasaki, J.M. The Scherrer equation and the dynamical theory of X-ray diffraction. Acta Crystallogr. Sect. A Found. Adv. 2016, 72, 385–390. [Google Scholar] [CrossRef]

- Chen, C.; Cai, F.; Zhu, Y.; Liao, L.; Qian, J.; Yuan, F.-G.; Zhang, N. 3D printing of electroactive PVDF thin films with high β-phase content. Smart Mater. Struct. 2019, 28, 065017. [Google Scholar] [CrossRef]

- Shanks, R.A.; Tiganis, B.E. Nucleating agents for thermoplastics. In Plastics Additives: An A–Z Reference; Pritchard, G., Ed.; Springer: Dordrecht, The Netherlands, 1998; pp. 464–471. [Google Scholar]

- Sebastian, M.; Larrea, A.; Gonçalves, R.; Alejo, T.; Vilas, J.; Sebastian, V.; Martins, P.; Lanceros-Mendez, S. Understanding nucleation of the electroactive β-phase of poly (vinylidene fluoride) by nanostructures. RSC Adv. 2016, 6, 113007–113015. [Google Scholar] [CrossRef]

| Sample Name | PVDF Concentration (mg mL−1) | BaTiO3 Concentration (mg mL−1) | Density (kg m−3) | Viscosity (cP) (at Room Temperature) | Surface Tension (mN m−1) | Printhead Temperature(s) (°C) | Z Value | Jetting Behavior |

|---|---|---|---|---|---|---|---|---|

| PB1 | 40 | 8.0 | 972 | 13.6 | 30.2 | 30, 40, 50 | 1.17 | No ejection |

| PB2 | 32 | 6.4 | 967 | 9.7 | 31.7 | 30, 40, 50 | 1.72 | No ejection |

| PB3 | 24 | 4.8 | 963 | 6.0 | 32.4 | 30, 40, 50 | 2.79 | Chaotic jet |

| PB4 | 16 | 3.2 | 959 | 3.7 | 33.5 | 30 | 4.59 | Chaotic jet |

| PB4 | 16 | 3.2 | 959 | 3.7 | 33.5 | 40, 50 | 4.59 | Ideal jet |

| PB5 | 8 | 1.6 | 955 | 2.1 | 34.8 | 30, 40, 50 | 8.23 | Ideal jet |

| PB6 | 1 | 0.2 | 959 | 1.3 | 36.0 | 30, 40, 50 | 13.56 | Satellite drop |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdolmaleki, H.; Agarwala, S. PVDF-BaTiO3 Nanocomposite Inkjet Inks with Enhanced β-Phase Crystallinity for Printed Electronics. Polymers 2020, 12, 2430. https://doi.org/10.3390/polym12102430

Abdolmaleki H, Agarwala S. PVDF-BaTiO3 Nanocomposite Inkjet Inks with Enhanced β-Phase Crystallinity for Printed Electronics. Polymers. 2020; 12(10):2430. https://doi.org/10.3390/polym12102430

Chicago/Turabian StyleAbdolmaleki, Hamed, and Shweta Agarwala. 2020. "PVDF-BaTiO3 Nanocomposite Inkjet Inks with Enhanced β-Phase Crystallinity for Printed Electronics" Polymers 12, no. 10: 2430. https://doi.org/10.3390/polym12102430

APA StyleAbdolmaleki, H., & Agarwala, S. (2020). PVDF-BaTiO3 Nanocomposite Inkjet Inks with Enhanced β-Phase Crystallinity for Printed Electronics. Polymers, 12(10), 2430. https://doi.org/10.3390/polym12102430