Urethane-Acrylate/Aramid Nanocomposites Based on Graphenic Materials. A Comparative Study of Their Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

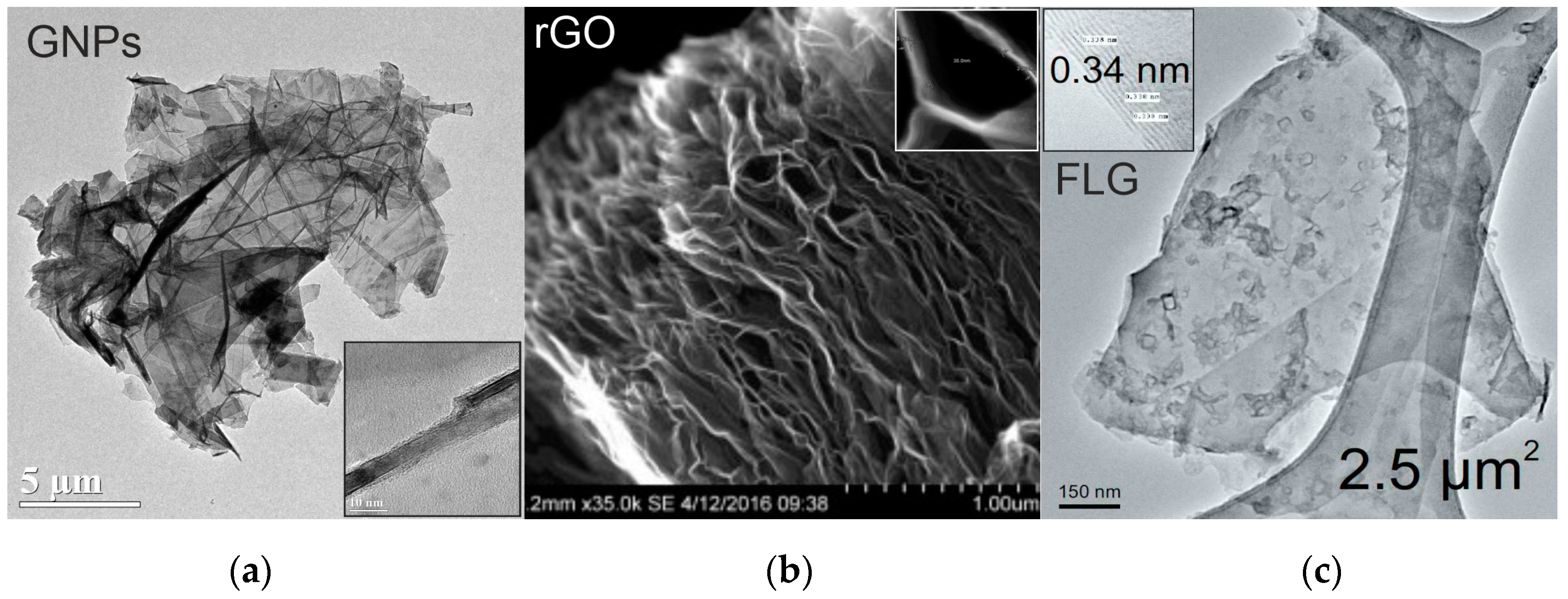

2.1. Materials

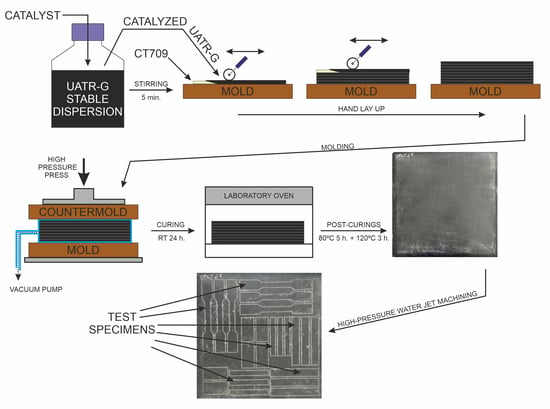

2.2. Methods

3. Results and Discussion

3.1. Laminated Plates

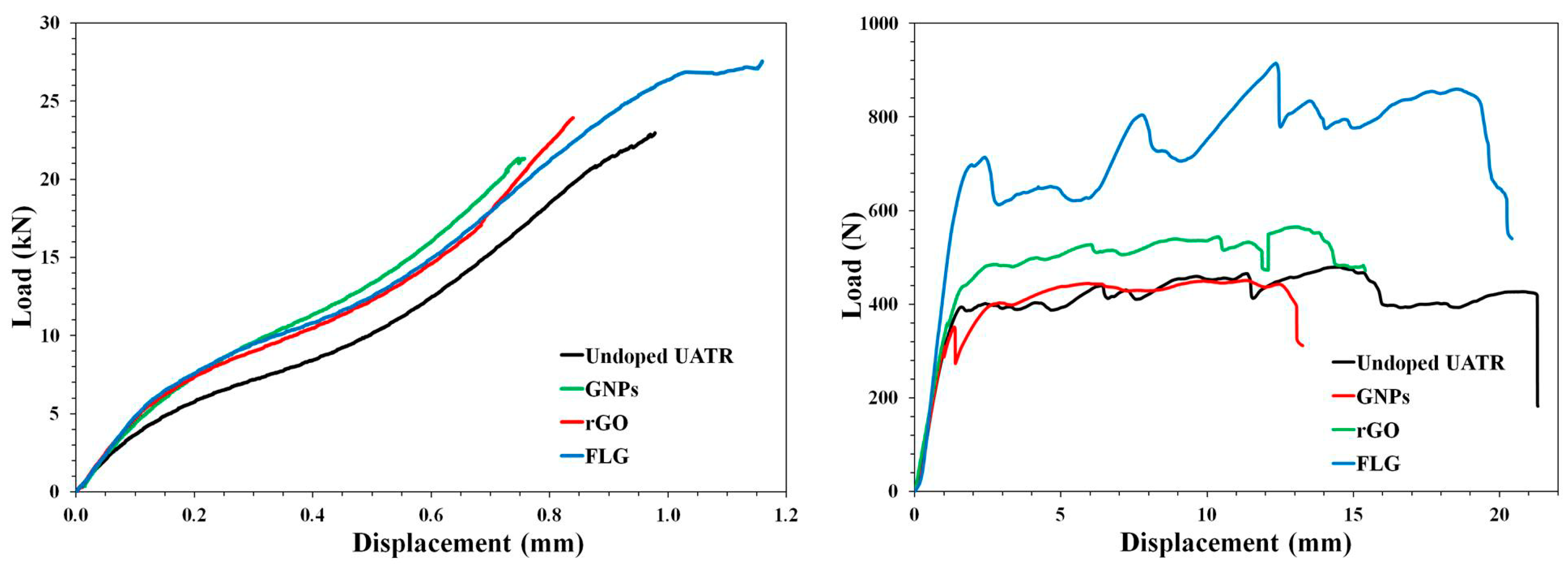

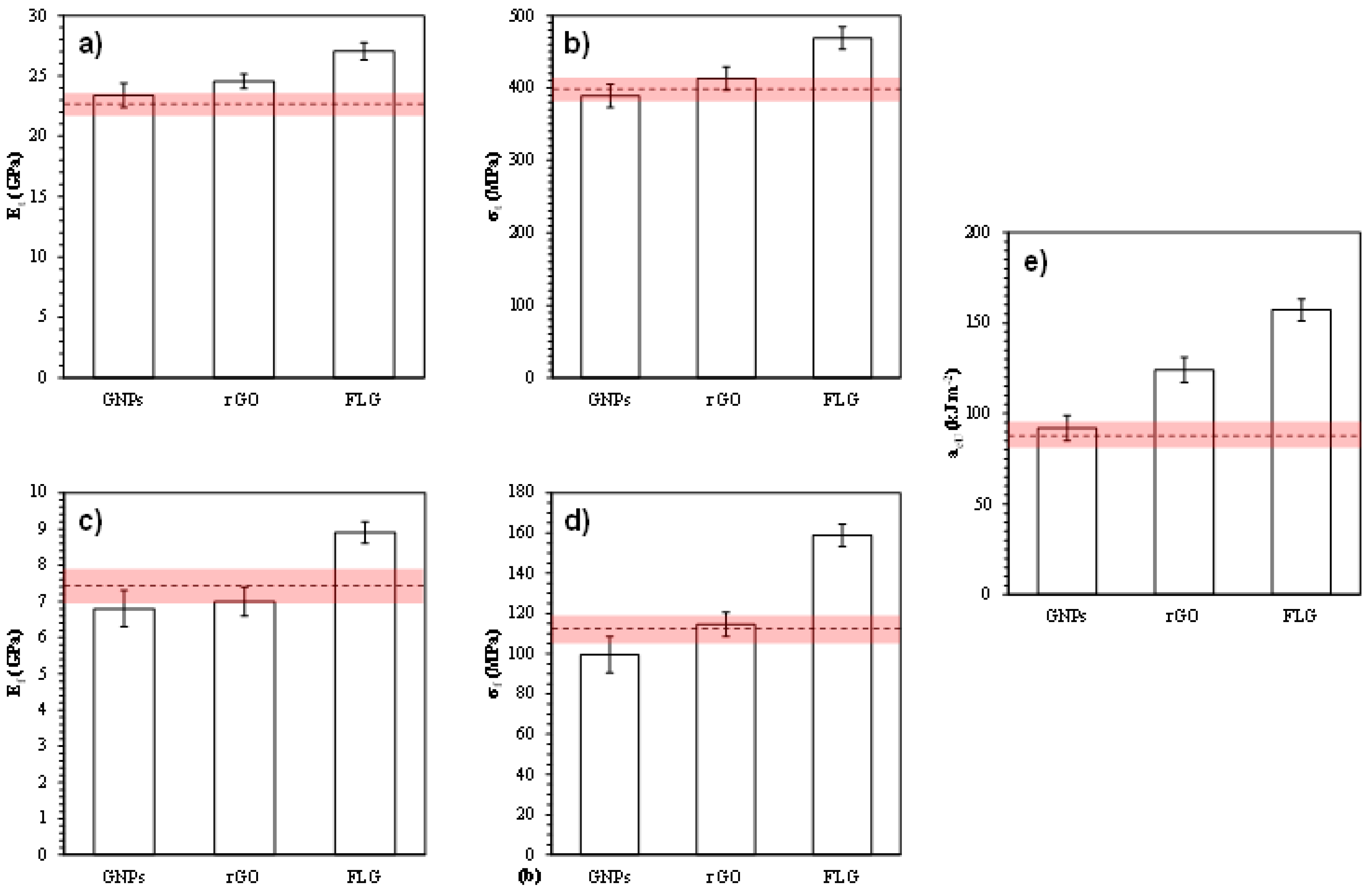

3.2. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Åström, B.T. Manufacturing of Polymer Composites, 1st ed.; Chapman Hall: Cheltenham, UK, 1997; pp. 1–46. [Google Scholar]

- May, C. Epoxy Resins: Chemistry and Technology, 2nd ed.; Marcel Dekker Inc.: New York, NY, USA, 1988; pp. 1–8. [Google Scholar]

- Gago, I.; Del Río, M.; Carretero, J.; León, G.; Ibarra, I.; Miguel, B. Graphene-Based Nanocomposites with Improved Mechanical and Ballistic Protection Properties. In Advanced Materials for Defense. Development, Analysis and Applications; Raul, F., Rana, S., Eds.; Springer: Cham, Switzerland, 2020; Volume 4, pp. 45–54. [Google Scholar]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.; Koratkar, N. Enhanced Mechanical Properties of Nanocomposites at Low Graphene Content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/Polymer Nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- King, J.A.; Klimek, D.R.; Miskioglu, I.; Odegard, G.M. Mechanical properties of graphene nanoplatelet/epoxy composites. J. Compos. Mater. 2015, 49, 659–668. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, H.; Chen, G. Enhanced mechanical properties of nanocomposites at low graphene content based onin situball milling. Polym. Compos. 2016, 37, 1190–1197. [Google Scholar] [CrossRef]

- Atif, R.; Shyha, I.; Inam, F. Mechanical, Thermal, and Electrical Properties of Graphene-Epoxy Nanocomposites—A Review. Polymers 2016, 8, 281. [Google Scholar] [CrossRef]

- Du, X.; Zhou, H.; Sun, W.; Liu, H.Y.; Zhou, G.; Zhou, H.; Mai, Y.-W. Graphene/epoxy interleaves for delamination toughening and monitoring of crack damage in carbon fibre/epoxy composite laminates. Compos. Sci. Technol. 2017, 140, 123–133. [Google Scholar] [CrossRef]

- Gago, I.; Ibarra, I.; León, G.; Miguel, B. Preparación de ABS Dopado Con Grafeno, Patent B2. Publication Number ES 2 570 391, 25 August 2016. [Google Scholar]

- Gago, I.; del Río, M.; Carretero, J.; Ibarra, I.; León, G.; Miguel, B. Nanocomposites Reforzados Con Grafeno y Nanocerámicas de Carburo de Silicio Para Blindajes Personales. In Premios Isdefe I+D+i Los Diez Artículos Finalistas del DESEi+d 2018; Ministerio de Defensa, Subdirección General de Publicaciones y Patrimonio Cultural: Madrid, Spain, 2019; pp. 81–89. [Google Scholar]

- Hassan, M.H.; Othman, A.R.; Kamaruddin, S. The use of response surface methodology (RSM) to optimize the acid digestion parameters in fiber volume fraction test of aircraft composite structures. Int. J. Adv. Manuf. Technol. 2017, 90, 3739–3748. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, B.-M.; Wang, D.-F.; Wu, Z.-J. Effects of cure cycles on void content and mechanical properties of composite laminates. Compos. Struct. 2006, 73, 303–309. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Jiménez-Suárez, A.; Moriche, R.; Ureña, A. Graphene nanoplatelets thickness and lateral size influence on the morphology and behavior of epoxy composites. Eur. Polym. J. 2014, 53, 292–301. [Google Scholar] [CrossRef]

- Chatterjee, S.; Nafezarefi, F.; Tai, N.H.; Schlagenhauf, L.; Nüesch, F.A.; Chu, B.T.T. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon N. Y. 2012, 50, 5380–5386. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, Y. Mechanical properties of graphene: Effects of layer number, temperature and isotope. Comput. Mater. Sci. 2013, 71, 197–200. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Z.; Liu, Y.; Li, N.; Wang, W.; Gao, J. Preparation of reduced graphene oxide/gelatin composite films with reinforced mechanical strength. Mater. Res. Bull. 2012, 47, 2245–2251. [Google Scholar] [CrossRef]

- Das, B.; Prasad, K.E.; Ramamurty, U.; Rao, C.N.R. Nano-indentation studies on polymer matrix composites reinforced by few-layer graphene. Nanotechnology 2009, 20, 125705. [Google Scholar] [CrossRef]

- Anagnostopoulos, G.; Androulidakis, C.; Koukaras, E.N.; Tsoukleri, G.; Polyzos, I.; Parthenios, J.; Papagelis, K.; Galiotis, C. Stress Transfer Mechanisms at the Submicron Level for Graphene/Polymer Systems. ACS Appl. Mater. Interfaces 2015, 7, 4216–4223. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Wajid, A.S.; Ahmed, H.T.; Das, S.; Irin, F.; Jankowski, A.F.; Green, M.J. High-performance pristine graphene/epoxy composites with enhanced mechanical and electrical properties. Macromol. Mater. Eng. 2013, 298, 339–347. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Terrones, M.; Martind, O.; González, M.; Pozuelo, J.; Serrano, B.; Cabanelas, J.C.; Vega-Diaz, S.M.; Baselga, J. Interphases in Graphene Polymer-based Nanocomposites: Achievements and Challenges. Adv. Mater. 2011, 23, 5302–5310. [Google Scholar] [CrossRef] [PubMed]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Zhou, W.; Zhi, E.; Zhang, W.; Ji, J. Graphene-reinforced biodegradable poly(ethylene succinate) nanocomposites prepared by in situ polymerization. J. Appl. Polym. Sci. 2013, 130, 3212–3220. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Taylor, A.C.; Kinloch, I.A. The effect of carbon nanotubes on the fracture toughness and fatigue performance of a thermosetting epoxy polymer. J. Mater. Sci. 2011, 46, 7525–7535. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial Microstructure and Properties of Carbon Fiber Composites Modified with Graphene Oxide. ACS Appl. Mater. Interfaces 2012, 4, 1543–1552. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, L.; Fan, F.; Zeng, Z.; Peng, C.; Loya, P.E.; Liu, Z.; Gong, Y.; Zhang, J.; Zhang, X.; et al. Fracture toughness of graphene. Nat. Commun. 2014, 5, 3782. [Google Scholar] [CrossRef]

- Tripathi, S.N.; Rao, G.S.S.; Mathur, A.B.; Jasra, R. Polyolefin/graphene nanocomposites: A review. RSC Adv. 2017, 7, 23615–23632. [Google Scholar] [CrossRef]

- Seyedin, M.Z.; Razal, J.M.; Innis, P.C.; Jalili, R.; Wallace, G.G. Achieving Outstanding Mechanical Performance in Reinforced Elastomeric Composite Fibers Using Large Sheets of Graphene Oxide. Adv. Funct. Mater. 2015, 25, 94–104. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Graphene/elastomer nanocomposites. Carbon 2015, 95, 460–484. [Google Scholar] [CrossRef]

| Property | GNPs | rGO | FLG |

|---|---|---|---|

| Chemical composition: Carbon (C) Oxygen (O) Impurities (I) | C > 99% | C 81%; O 17%; I 2% | C > 99% |

| C/O atomic ratio | Na | 6.5 | Na |

| Average layers (sheets type) | 30 (isolated sheets) | 8 (in sheet stacks) | 7 (isolated sheets) |

| D50 | 7 µm | Na | 1 µm |

| Specific Surface Area | 40 m2·g−1 | 400 m2·g−1 | 1000 m2·g−1 |

| Functional groups | - | -OH; -COOH; -O- | - |

| Density (25 °C) | Viscosity (25 °C) | Barcol Hardness | Ultimate Tensile Strength | Tensile Modulus |

|---|---|---|---|---|

| 1.04 g·cm−3 | 2 poise | 38 a.u. | 76 MPa | 3.28 GPa |

| Property | Specimen Dimensions | Specimens Tested | ||

|---|---|---|---|---|

| Length (mm) | Width (mm) | Thickness (mm) | ||

| Tensile (Et, σt) | 150 | 10 | 5 | 20 |

| Flexural (Et, σt) | 100 | 15 | 5 | 20 |

| Charpy impact (aCU) | 80 | 10 | 5 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gago, I.; del Río, M.; León, G.; Miguel, B. Urethane-Acrylate/Aramid Nanocomposites Based on Graphenic Materials. A Comparative Study of Their Mechanical Properties. Polymers 2020, 12, 2388. https://doi.org/10.3390/polym12102388

Gago I, del Río M, León G, Miguel B. Urethane-Acrylate/Aramid Nanocomposites Based on Graphenic Materials. A Comparative Study of Their Mechanical Properties. Polymers. 2020; 12(10):2388. https://doi.org/10.3390/polym12102388

Chicago/Turabian StyleGago, Israel, Manuel del Río, Gerardo León, and Beatriz Miguel. 2020. "Urethane-Acrylate/Aramid Nanocomposites Based on Graphenic Materials. A Comparative Study of Their Mechanical Properties" Polymers 12, no. 10: 2388. https://doi.org/10.3390/polym12102388

APA StyleGago, I., del Río, M., León, G., & Miguel, B. (2020). Urethane-Acrylate/Aramid Nanocomposites Based on Graphenic Materials. A Comparative Study of Their Mechanical Properties. Polymers, 12(10), 2388. https://doi.org/10.3390/polym12102388