Evaluation of Grinding of Unfilled and Glass Fiber Reinforced Polyamide 6,6

Abstract

:1. Introduction

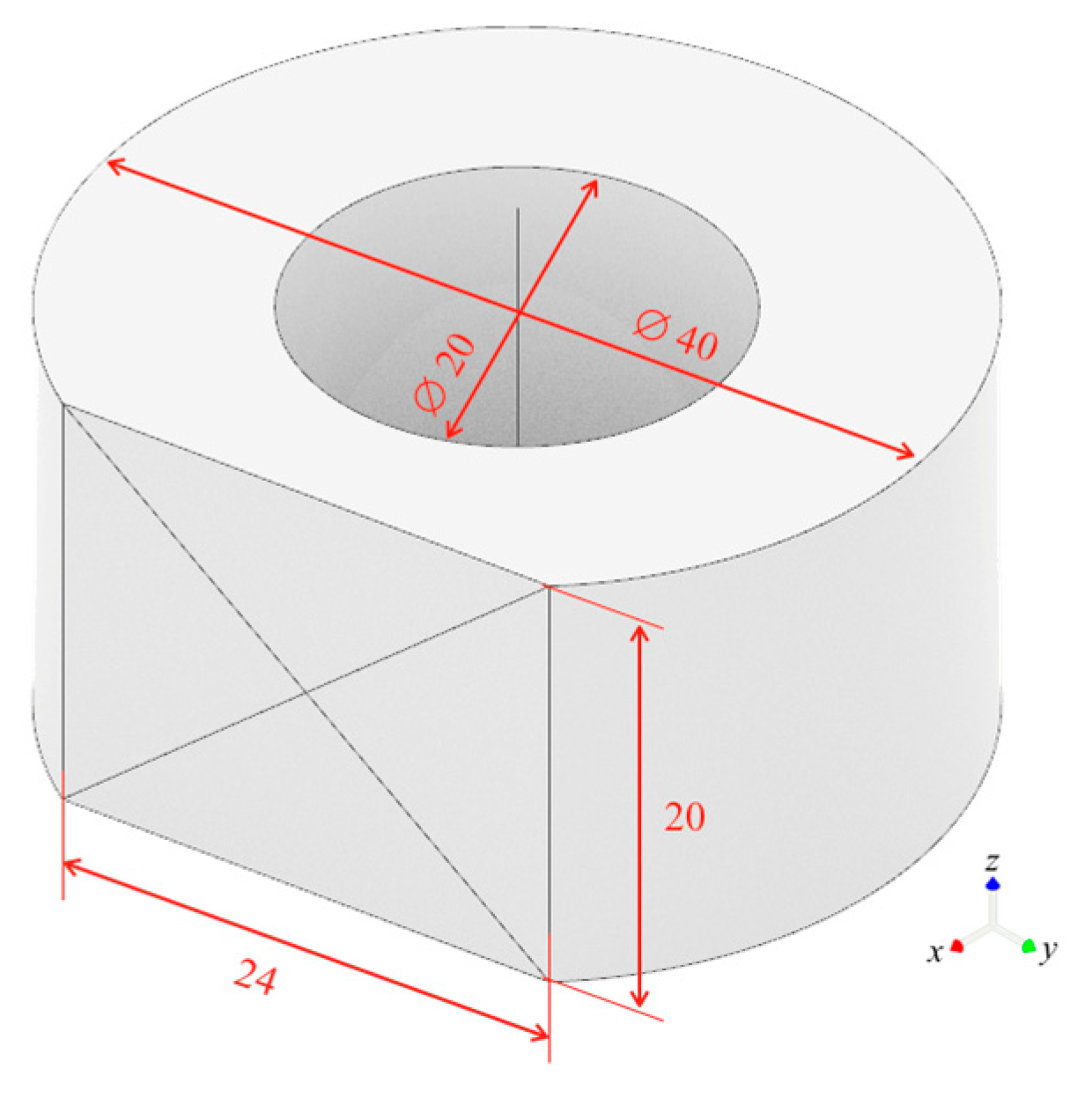

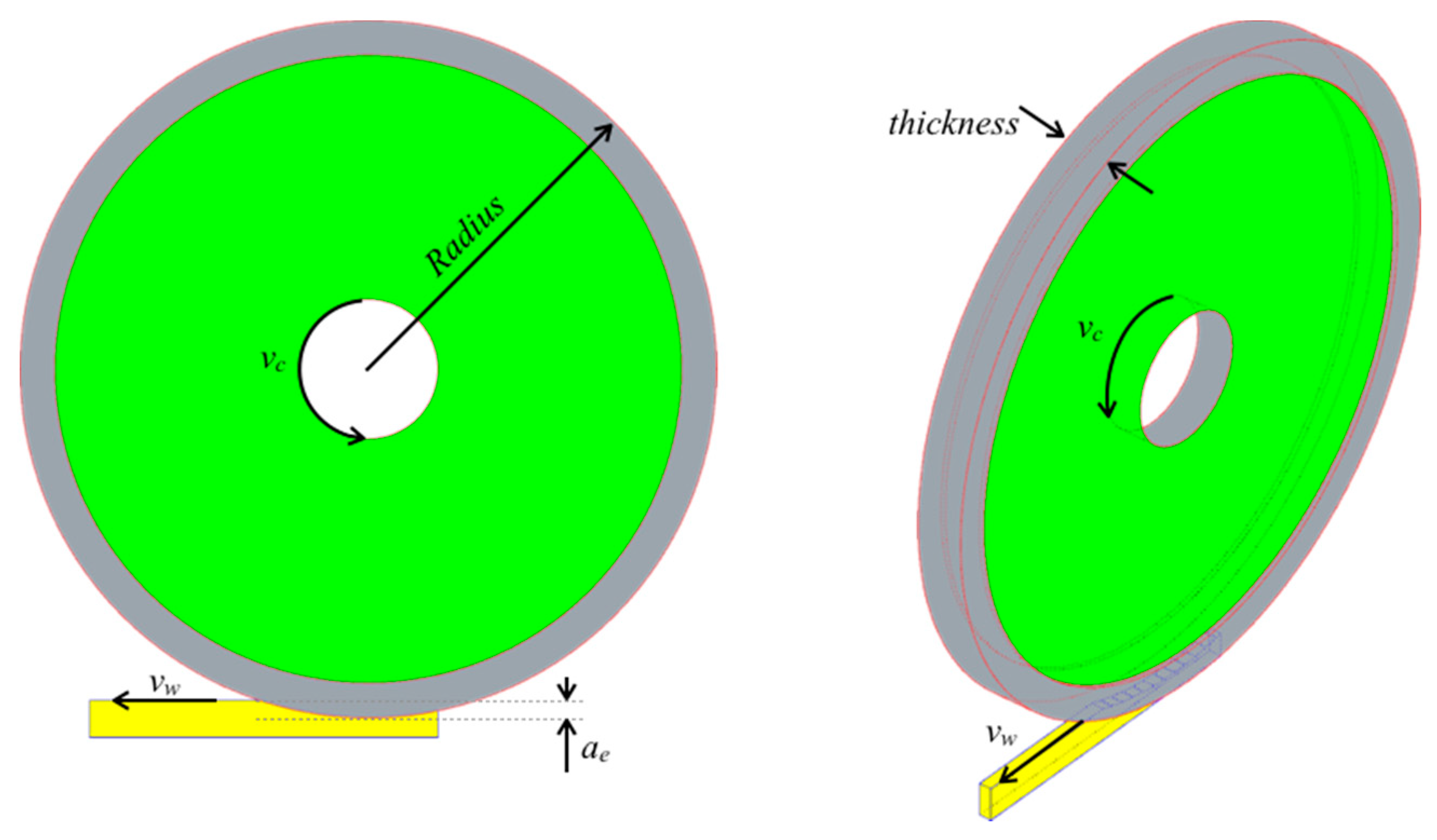

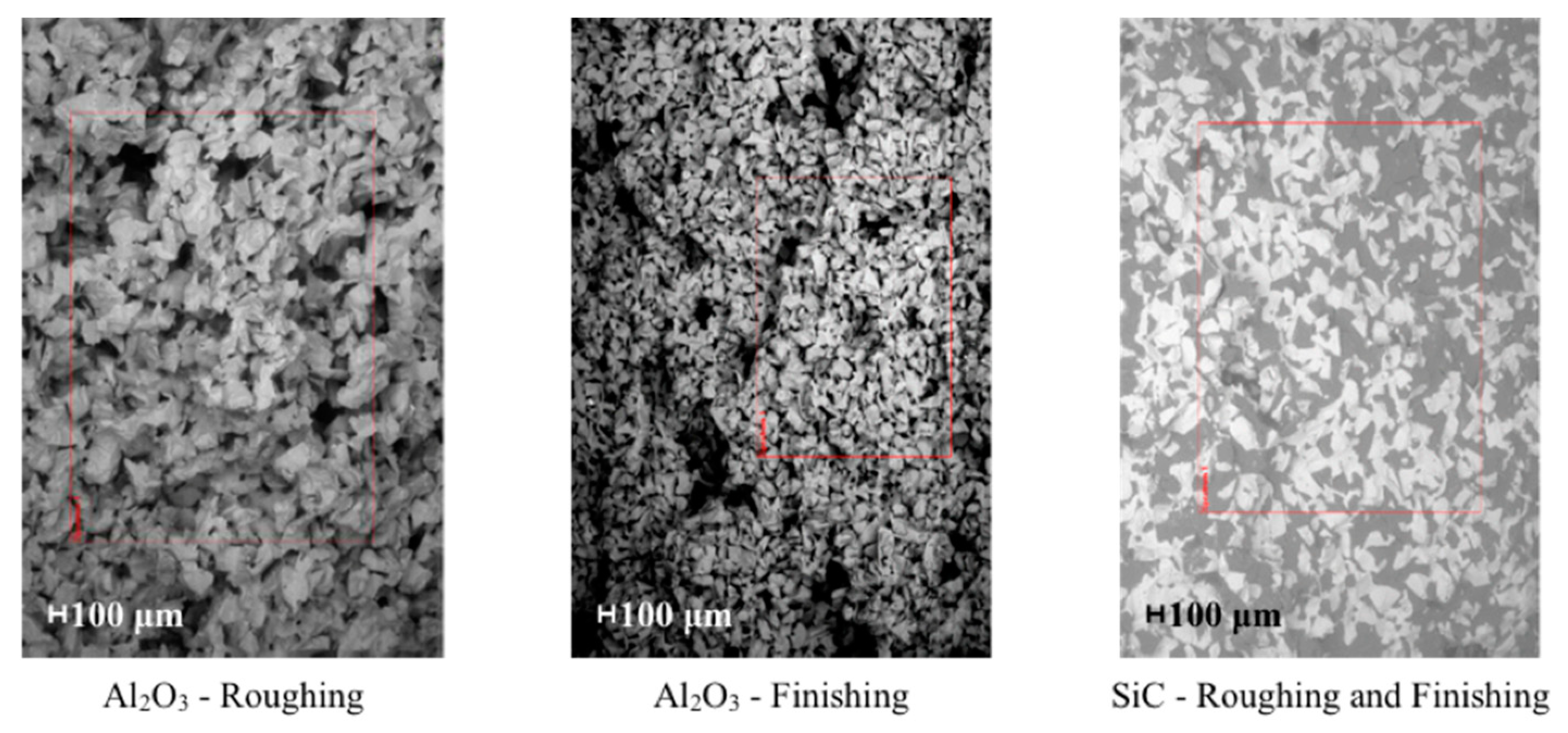

2. Materials and Methods

2.1. Machining Process

2.2. Setup of the Grinding Process

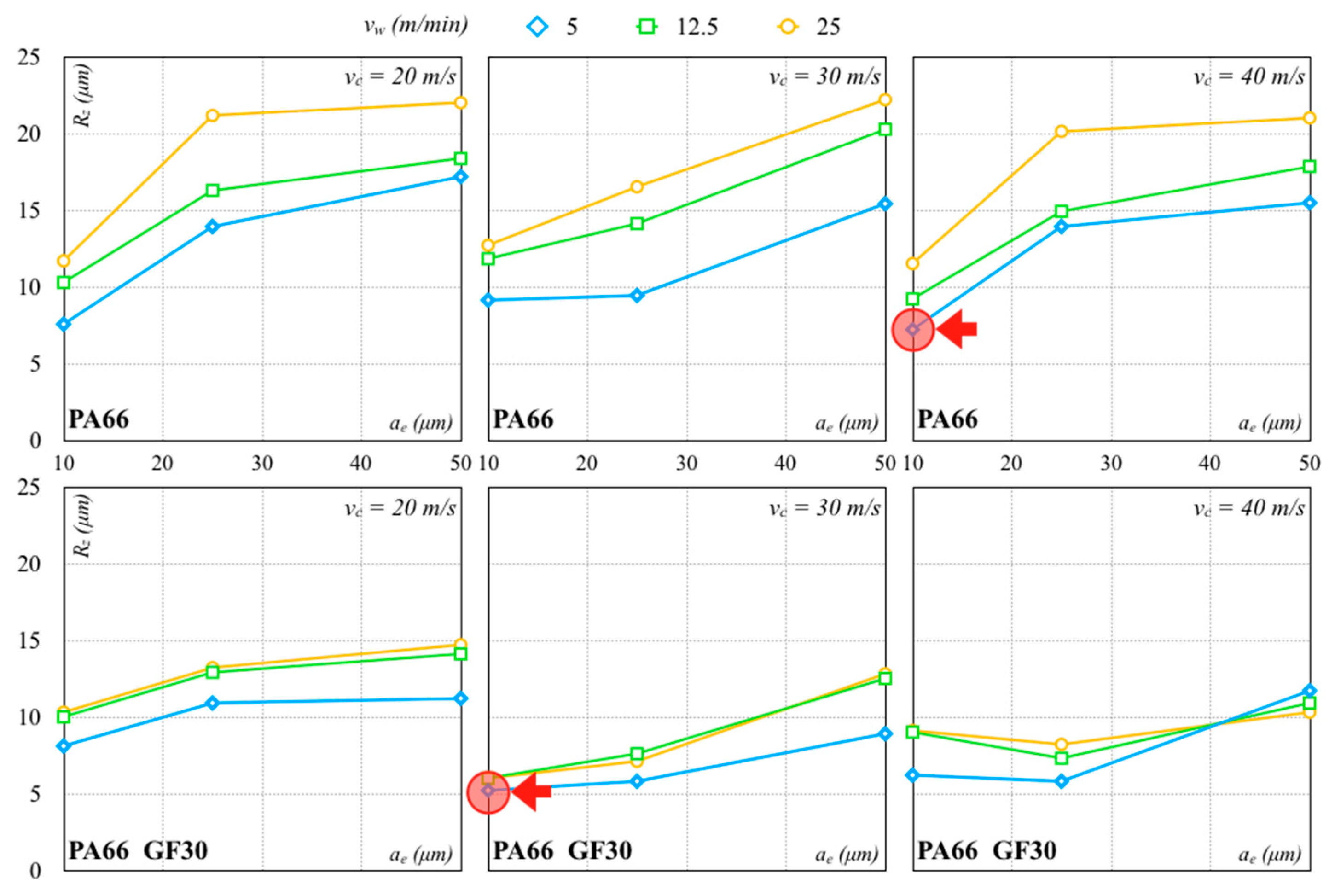

3. Results

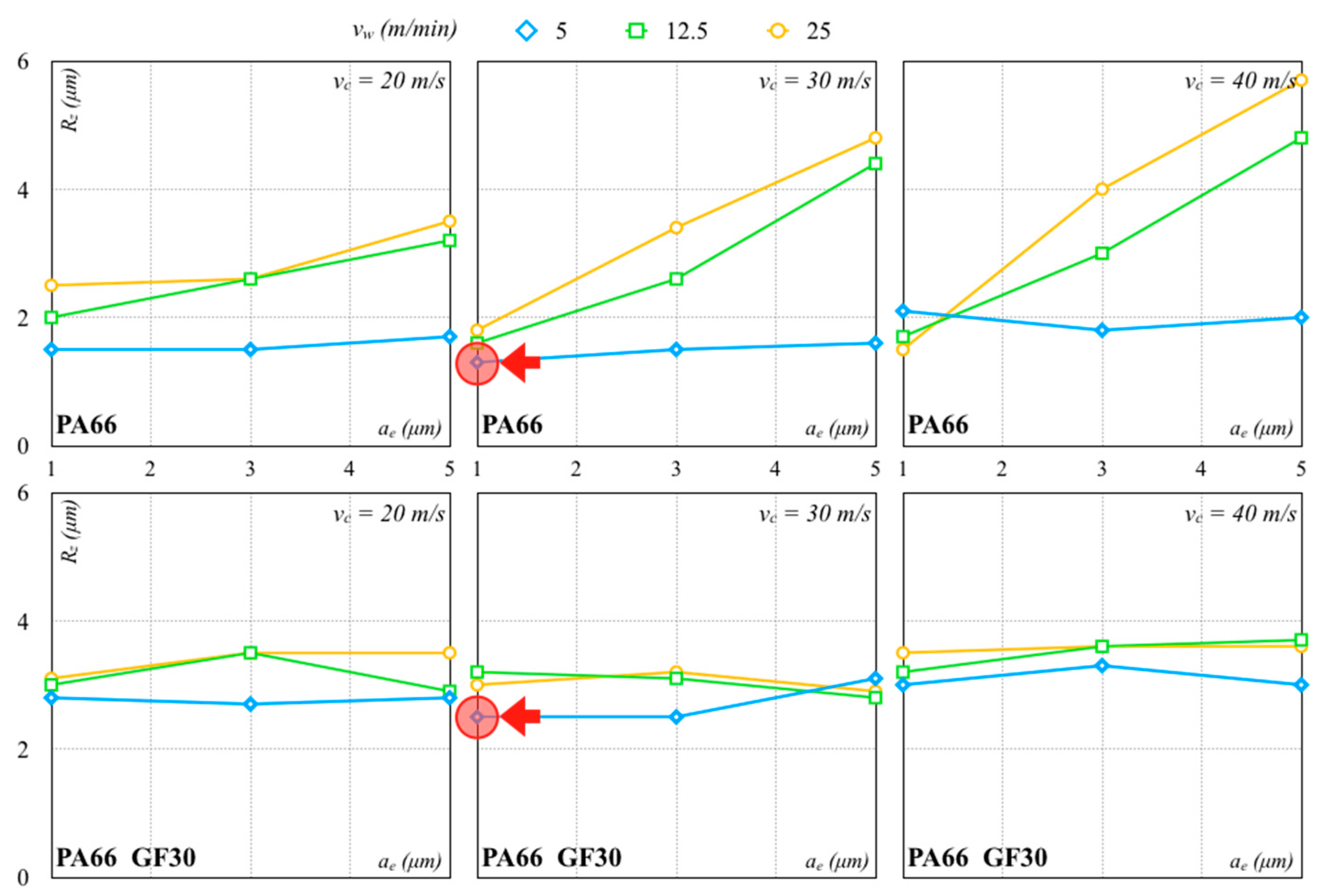

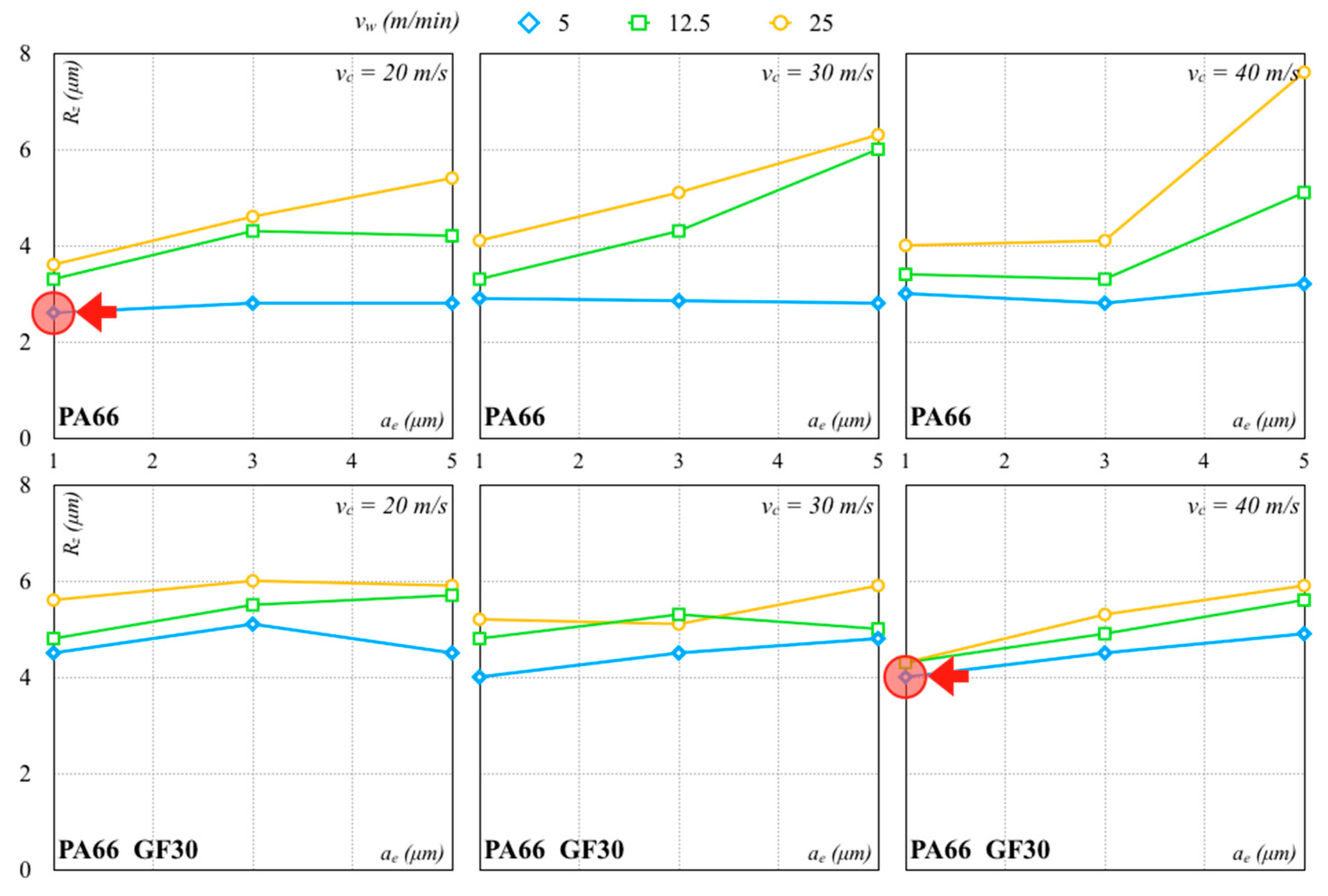

3.1. Preliminary Analysis with Air-Cooling

3.2. Liquid Coolant

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Patil, A.; Patel, A.; Purohit, R. An overview of Polymeric Materials for Automotive Applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Kobayashi, A. Ultra-Precision Machining of Plastics. Proc. SPIE 1984, 508, 31–36. [Google Scholar]

- Wegener, K.; Bleicher, F.; Krajnik, P.; Hoffmeister, H.-W.; Brecher, C. Recent developments in grinding machines. CIRP Ann. Manuf. Technol. 2017, 66, 779–802. [Google Scholar] [CrossRef]

- Silva, E.J.; Kirsch, B.; Bottene, A.; Simon, A.; Aurich, J.; Oliveira, J. Manufacturing of structured surfaces via grinding. J. Mater. Process. Technol. 2017, 243, 170–183. [Google Scholar] [CrossRef]

- Rudrapati, R.; Pal, P.K.; Bandyopadhyay, A. Modeling and optimization of machining parameters in cylindrical grinding process. Int. J. Adv. Manuf. Technol. 2016, 82, 2167–2182. [Google Scholar] [CrossRef]

- Spina, R.; Spekowius, M.; Hopmann, C. Simulation of crystallization of isotactic polypropylene with different shear regimes. Thermochim. Acta 2018, 659, 44–54. [Google Scholar] [CrossRef]

- El-Wakil, S.D. Grinding processes for polymer matrix composites. In Machining Technology for Composite Material; Woodhead Publishing Series; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Agarwal, S. On the mechanism and mechanics of wheel loading in grinding. J. Manuf. Process. 2019, 41, 36–47. [Google Scholar] [CrossRef]

- Spina, R.; Walach, P.; Schild, J.; Hopmann, C. Analysis of lens manufacturing with injection molding. Int. J. Precis. Eng. Manuf. 2012, 13, 2087–2095. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Polymers; ChemTec Publishing: Toronto, ON, Canada, 2012. [Google Scholar]

- Spina, R.; Cavalcante, B.M. Preliminary analysis of grinding of PA66 thermoplastics. AIP Conf. Proc. 2019, 2113, 130012. [Google Scholar]

- Davim, P.J.; Silva, L.R.; Festas, A.; Abrao, A.M. Machinability study on precision turning of PA66 polyamide with and without glass fiber reinforcing. Mater. Des. 2009, 30, 228–234. [Google Scholar] [CrossRef]

- Galantucci, L.M.; Tricarico, L.; Spina, R. A Quality Evaluation Method for Laser Welding of Al Alloys Through Neural Networks. CIRP Ann. Manuf. Technol. 2000, 49, 131–134. [Google Scholar] [CrossRef]

- Kopac, J.; Krajnik, P. High-performance grinding—A review. J. Mater. Process. Technol. 2006, 175, 278–284. [Google Scholar] [CrossRef]

- Bhowmik, S.; Naik, R. Selection of abrasive materials for manufacturing grinding wheels. Mater. Today Proc. 2018, 5, 2860–2864. [Google Scholar] [CrossRef]

- Guerrini, G.; Landi, E.; Peiffer, K.; Fortunato, A. Dry grinding of gears for sustainable automotive transmission production. J. Clean. Prod. 2018, 176, 76–88. [Google Scholar] [CrossRef]

- Drazumeric, R.; Roininen, R.; Badgera, J.; Krajnik, P. Temperature-based method for determination of feed increments in crankshaft grinding. J. Mater. Process. Technol. 2018, 259, 228–234. [Google Scholar] [CrossRef]

- Awale, A.S.; Vashista, M.; Yusufzai, M.Z.K. Multi-objective optimization of MQL mist parameters for eco-friendly T grinding. J. Manuf. Process. 2020, 56, 75–86. [Google Scholar] [CrossRef]

- Kim, J.W.; Jang, H.; Kim, J.W. Friction and wear of monolithic and glass-fiber reinforced PA66 in humid conditions. Wear 2014, 309, 82–88. [Google Scholar] [CrossRef]

- Aurich, J.C.; Herzenstiel, P.; Sudermann, H.; Magg, T. High-performance dry grinding using a grinding wheel with a defined grain pattern. CIRP Ann. Manuf. Technol. 2008, 57, 357–362. [Google Scholar] [CrossRef]

- Souza Ruzzi, R.; Da Silva, R.B.; Da Silva, L.; Machado, A.R.; Jackson, M.J.; Hassui, A. Influence of grinding parameters on Inconel 625 surface grinding. J. Manuf. Process. 2020, 55, 174–185. [Google Scholar] [CrossRef]

- Hu, N.S.; Zhang, L.C. Some observations in grinding unidirectional carbon fibre-reinforced plastics. J. Mater. Process. Technol. 2004, 152, 333–338. [Google Scholar] [CrossRef]

| PA66 | PA66 GF30 | ||

|---|---|---|---|

| Properties | Value | Unit | |

| Physical | |||

| Density | 1.15 | 1.34 | g/cm3 |

| Glass Transition Temperature | 47 | 48 | °C |

| Melting (Softening) Temperature | 258 | 254 | °C |

| Mechanical | |||

| Young’s Modulus | 3.5 | 5.5 | GPa |

| Yield Tensile Strength | 84 | 91 | MPa |

| Ultimate Tensile Strength | 85 | 91 | MPa |

| Elongation at break | 70 | 14 | % |

| Coefficient of Thermal Expansion | 120 | 50 | μm/m/°C |

| Process Parameters | Min | Avg | Max | Unit |

|---|---|---|---|---|

| Roughing | ||||

| cutting speed vc | 20.0 | 30.0 | 40.0 | m/s |

| infeed speed vw | 5.0 | 12.5 | 25.0 | m/min |

| depth of cut ae | 10.0 | 25.0 | 50.0 | μm |

| Finishing | ||||

| cutting speed vc | 20.0 | 30.0 | 40.0 | m/s |

| infeed speed vw | 5.0 | 12.5 | 25.0 | m/min |

| depth of cut ae | 1.0 | 3.0 | 5.0 | μm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spina, R.; Cavalcante, B. Evaluation of Grinding of Unfilled and Glass Fiber Reinforced Polyamide 6,6. Polymers 2020, 12, 2288. https://doi.org/10.3390/polym12102288

Spina R, Cavalcante B. Evaluation of Grinding of Unfilled and Glass Fiber Reinforced Polyamide 6,6. Polymers. 2020; 12(10):2288. https://doi.org/10.3390/polym12102288

Chicago/Turabian StyleSpina, Roberto, and Bruno Cavalcante. 2020. "Evaluation of Grinding of Unfilled and Glass Fiber Reinforced Polyamide 6,6" Polymers 12, no. 10: 2288. https://doi.org/10.3390/polym12102288

APA StyleSpina, R., & Cavalcante, B. (2020). Evaluation of Grinding of Unfilled and Glass Fiber Reinforced Polyamide 6,6. Polymers, 12(10), 2288. https://doi.org/10.3390/polym12102288