Light Down-Converter Based on Luminescent Nanofibers from the Blending of Conjugated Rod-Coil Block Copolymers and Perovskite through Electrospinning

Abstract

1. Introduction

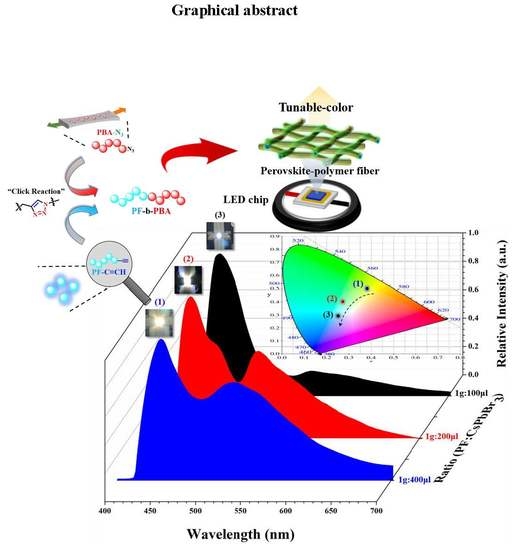

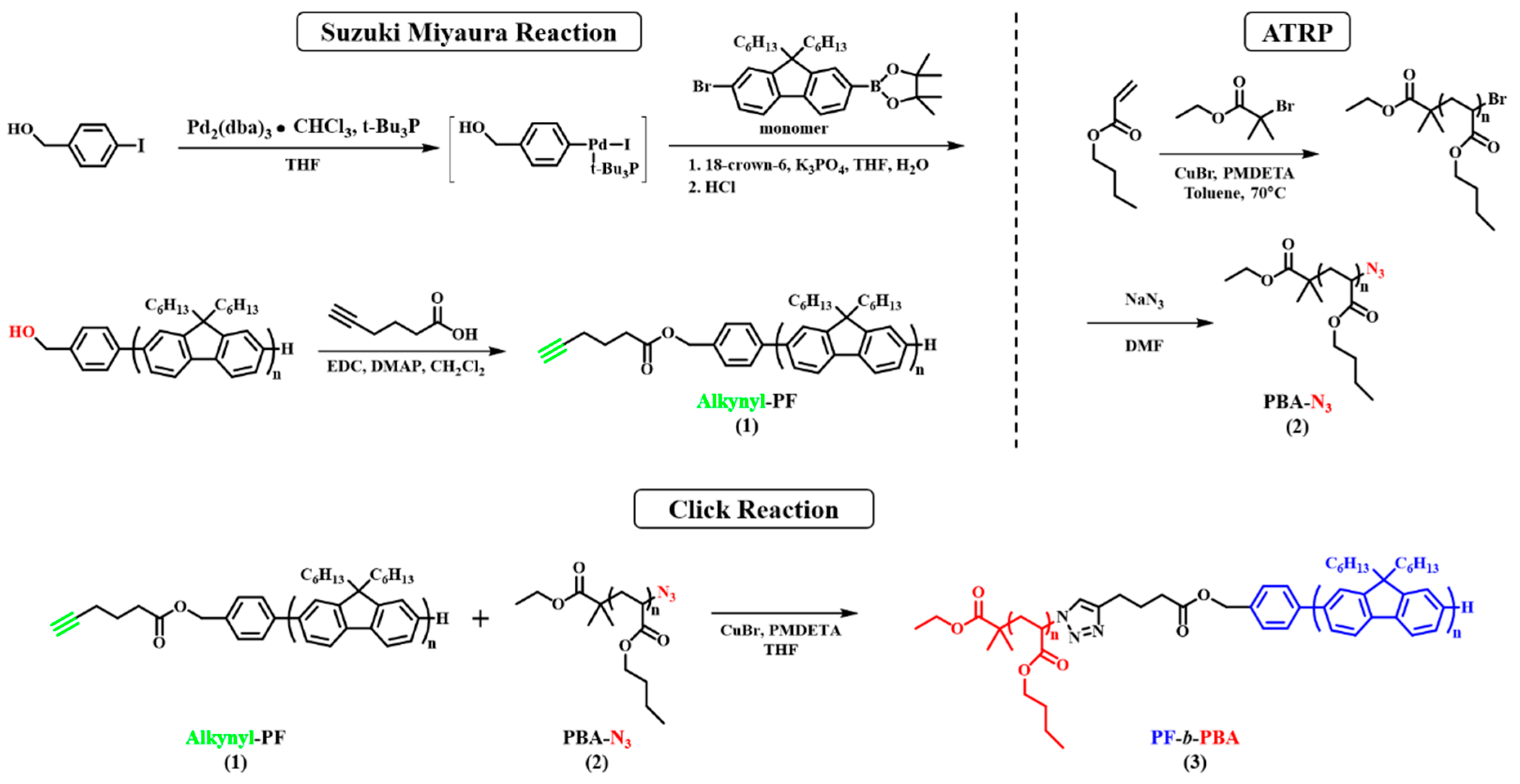

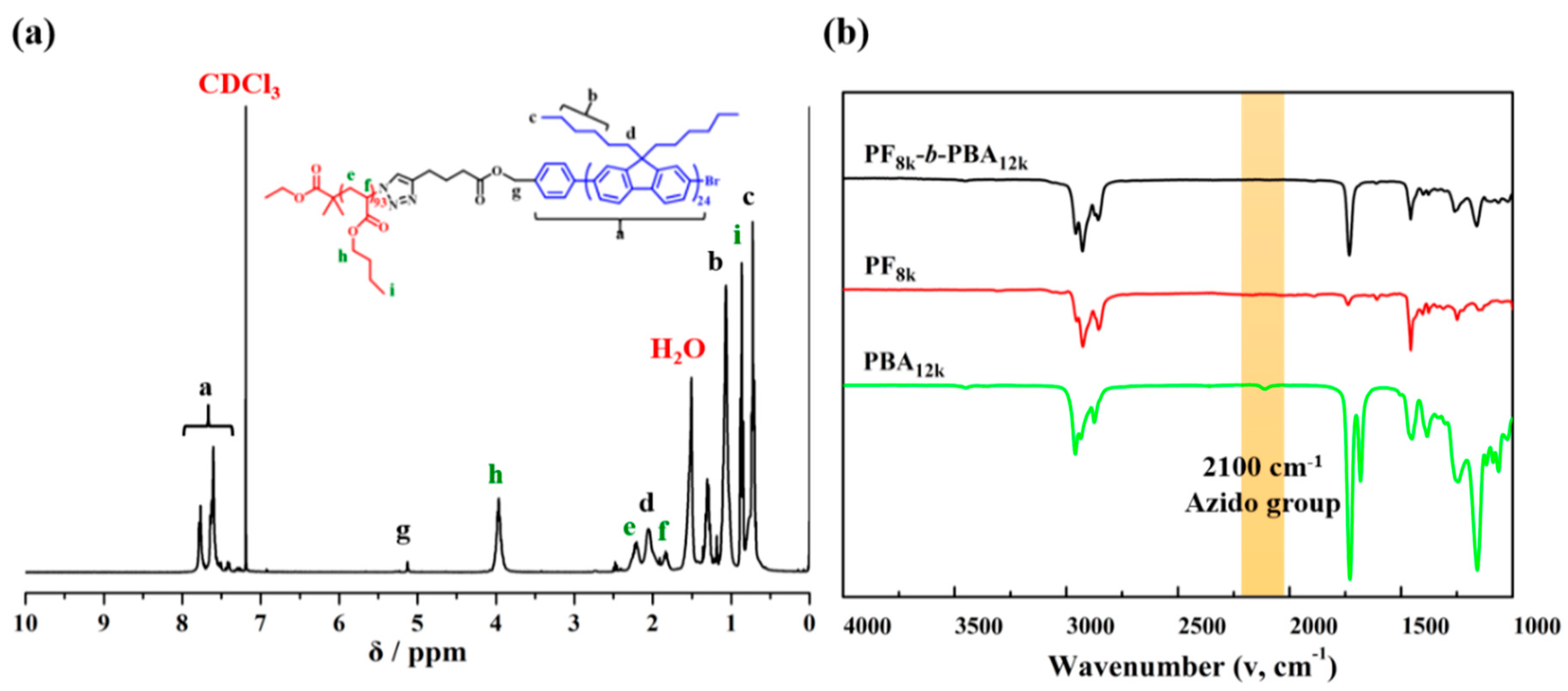

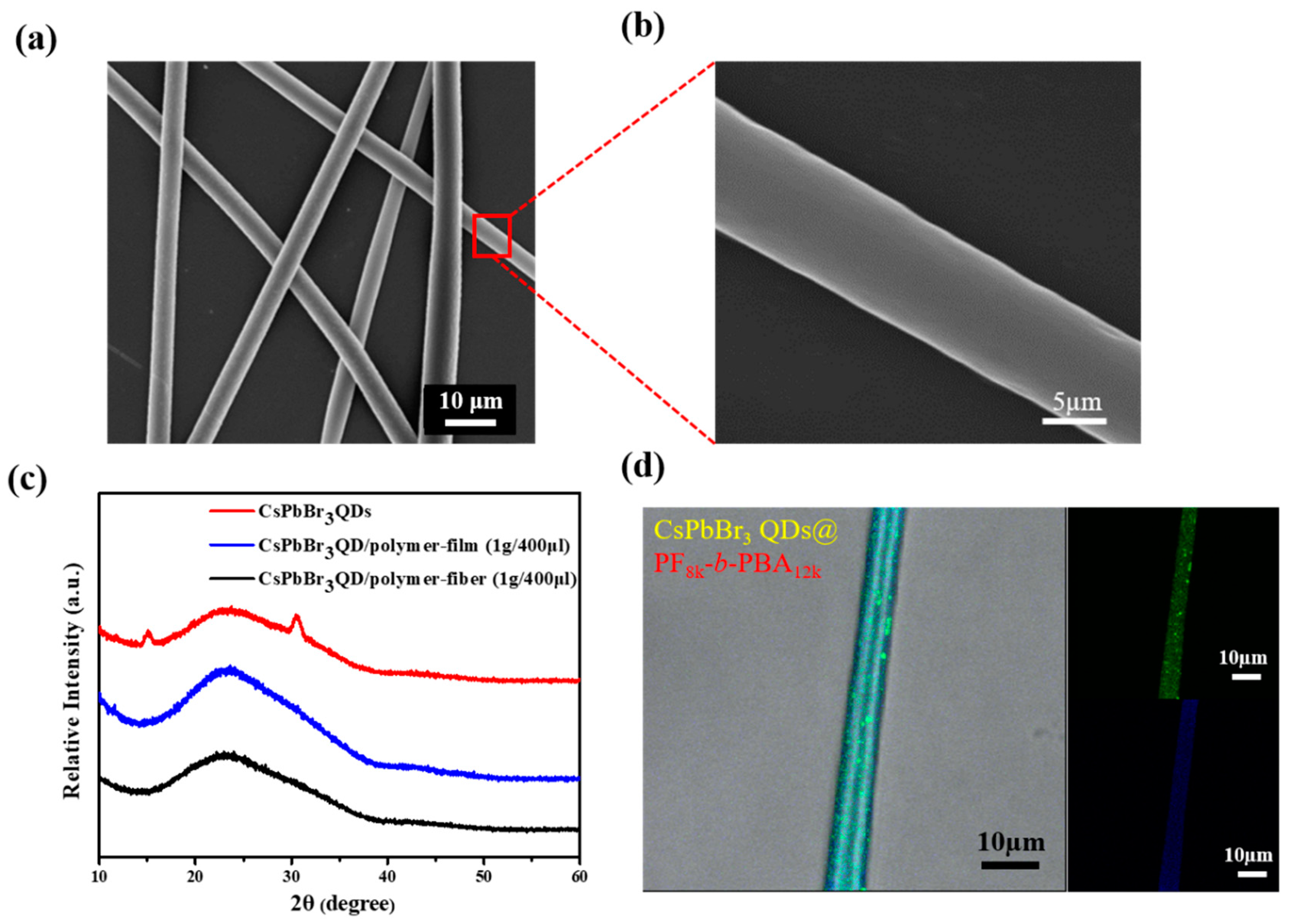

2. Results and Discussion

3. Conclusions

Supplementary Materials

Funding

Conflicts of Interest

References

- Chikamatsu, M.; Nagamatsu, S.; Yoshida, Y.; Saito, K.; Yase, K.; Kikuchi, K. Solution-processed n-type organic thin-film transistors with high field-effect mobility. Appl. Phys. Lett. 2005, 87, 203504. [Google Scholar] [CrossRef]

- Yu, X.; Rahmanudin, A.; Jeanbourquin, X.A.; Tsokkou, D.; Guijarro, N.S.; Banerji, N.; Sivula, K. Hybrid heterojunctions of solution-processed semiconducting 2D transition metal dichalcogenides. ACS Energy Lett. 2017, 2, 524–531. [Google Scholar] [CrossRef]

- Van de Wetering, K.; Brochon, C.; Ngov, C.; Hadziioannou, G. Design and Synthesis of a Low Band Gap Conjugated Macroinitiator: Toward Rod−Coil Donor−Acceptor Block Copolymers. Macromolecules 2006, 39, 4289–4297. [Google Scholar] [CrossRef]

- Yi, Z.; Wang, S.; Liu, Y. Design of high-mobility diketopyrrolopyrrole-based π-conjugated copolymers for organic thin-film transistors. Adv. Mater. 2015, 27, 3589–3606. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.-H.; Zhou, K.-G.; Xie, K.-F.; Zeng, J.; Zhang, H.-L.; Peng, Y. Tuning the electronic structure and transport properties of graphene by noncovalent functionalization: Effects of organic donor, acceptor and metal atoms. Nanotechnology 2010, 21, 065201. [Google Scholar] [CrossRef]

- An, B.-K.; Gierschner, J.; Park, S.Y. π-Conjugated cyanostilbene derivatives: A unique self-assembly motif for molecular nanostructures with enhanced emission and transport. Acc. Chem. Res. 2011, 45, 544–554. [Google Scholar] [CrossRef]

- Luo, C.; Kyaw, A.K.K.; Perez, L.A.; Patel, S.; Wang, M.; Grimm, B.; Bazan, G.C.; Kramer, E.J.; Heeger, A.J. General strategy for self-assembly of highly oriented nanocrystalline semiconducting polymers with high mobility. Nano Lett. 2014, 14, 2764–2771. [Google Scholar] [CrossRef]

- Choi, S.; Lee, H.; Ghaffari, R.; Hyeon, T.; Kim, D.H. Recent advances in flexible and stretchable bio-electronic devices integrated with nanomaterials. Adv. Mater. 2016, 28, 4203–4218. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lu, N.; Ma, R.; Kim, Y.-S.; Kim, R.-H.; Wang, S.; Wu, J.; Won, S.M.; Tao, H.; Islam, A. Epidermal electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef]

- Zhang, Y.; He, Z.; Jiang, S.; Gao, B.; Liu, Z.; Han, B.; Wang, H. Marine redox stratification during the early C ambrian (ca. 529-509 Ma) and its control on the development of organic-rich shales in Y angtze P latform. Geochem. Geophys. Geosyst. 2017, 18, 2354–2369. [Google Scholar]

- Choi, M.K.; Yang, J.; Kang, K.; Kim, D.C.; Choi, C.; Park, C.; Kim, S.J.; Chae, S.I.; Kim, T.-H.; Kim, J.H. Wearable red–green–blue quantum dot light-emitting diode array using high-resolution intaglio transfer printing. Nat. Commun. 2015, 6, 7149. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.-H.; Lee, C.-S.; Kim, S.; Hur, J.; Lee, S.; Shin, K.W.; Yoon, Y.-Z.; Choi, M.K.; Yang, J.; Kim, D.-H. Fully stretchable optoelectronic sensors based on colloidal quantum dots for sensing photoplethysmographic signals. ACS Nano 2017, 11, 5992–6003. [Google Scholar] [CrossRef]

- Son, D.; Chae, S.I.; Kim, M.; Choi, M.K.; Yang, J.; Park, K.; Kale, V.S.; Koo, J.H.; Choi, C.; Lee, M. Colloidal synthesis of uniform-sized molybdenum disulfide nanosheets for wafer-scale flexible nonvolatile memory. Adv. Mater. 2016, 28, 9326–9332. [Google Scholar] [CrossRef]

- Song, J.K.; Son, D.; Kim, J.; Yoo, Y.J.; Lee, G.J.; Wang, L.; Choi, M.K.; Yang, J.; Lee, M.; Do, K. Wearable force touch sensor array using a flexible and transparent electrode. Adv. Funct. Mater. 2017, 27, 1605286. [Google Scholar] [CrossRef]

- Choi, D.; Kim, H.; Persson, N.; Chu, P.-H.; Chang, M.; Kang, J.-H.; Graham, S.; Reichmanis, E. Elastomer–polymer semiconductor blends for high-performance stretchable charge transport networks. Chem. Mater. 2016, 28, 1196–1204. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Lin, C.-H.; Chen, W.-C. Morphology and photophysical properties of light-emitting electrospun nanofibers prepared from poly (fluorene) derivative/PMMA blends. Macromolecules 2007, 40, 6959–6966. [Google Scholar] [CrossRef]

- Lee, Y.; Zhou, H.; Lee, T.-W. One-dimensional conjugated polymer nanomaterials for flexible and stretchable electronics. J. Mater. Chem. C 2018, 6, 3538–3550. [Google Scholar] [CrossRef]

- Scott, J.I.; Xue, X.; Wang, M.; Kline, R.J.; Hoffman, B.C.; Dougherty, D.; Zhou, C.; Bazan, G.; O’Connor, B.T. Significantly increasing the ductility of high performance polymer semiconductors through polymer blending. ACS Appl. Mater. Interface 2016, 8, 14037–14045. [Google Scholar] [CrossRef]

- Shin, M.; Oh, J.Y.; Byun, K.E.; Lee, Y.J.; Kim, B.; Baik, H.K.; Park, J.J.; Jeong, U. Polythiophene nanofibril bundles surface-embedded in elastomer: A route to a highly stretchable active channel layer. Adv. Mater. 2015, 27, 1255–1261. [Google Scholar] [CrossRef]

- Song, E.; Kang, B.; Choi, H.H.; Sin, D.H.; Lee, H.; Lee, W.H.; Cho, K. Stretchable and transparent organic semiconducting thin film with conjugated polymer nanowires embedded in an elastomeric matrix. Adv. Electron. Mater. 2016, 2, 1500250. [Google Scholar] [CrossRef]

- Peng, R.; Pang, B.; Hu, D.; Chen, M.; Zhang, G.; Wang, X.; Lu, H.; Cho, K.; Qiu, L. An ABA triblock copolymer strategy for intrinsically stretchable semiconductors. J. Mater. Chem. C 2015, 3, 3599–3606. [Google Scholar] [CrossRef]

- Wu, H.-C.; Hung, C.-C.; Hong, C.-W.; Sun, H.-S.; Wang, J.-T.; Yamashita, G.; Higashihara, T.; Chen, W.-C. Isoindigo-based semiconducting polymers using carbosilane side chains for high performance stretchable field-effect transistors. Macromolecules 2016, 49, 8540–8548. [Google Scholar] [CrossRef]

- Oh, J.Y.; Rondeau-Gagné, S.; Chiu, Y.-C.; Chortos, A.; Lissel, F.; Wang, G.-J.N.; Schroeder, B.C.; Kurosawa, T.; Lopez, J.; Katsumata, T. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nat. Commun. 2016, 539, 411. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-T.; Saito, K.; Wu, H.-C.; Sun, H.-S.; Hung, C.-C.; Chen, Y.; Isono, T.; Kakuchi, T.; Satoh, T.; Chen, W.-C. High-performance stretchable resistive memories using donor–acceptor block copolymers with fluorene rods and pendent isoindigo coils. NPG Asia Mater. 2016, 8, e298. [Google Scholar] [CrossRef]

- Wang, J.-T.; Takshima, S.; Wu, H.-C.; Shih, C.-C.; Isono, T.; Kakuchi, T.; Satoh, T.; Chen, W.-C. Stretchable conjugated rod–coil poly (3-hexylthiophene)-block-poly (butyl acrylate) thin films for field effect transistor applications. Macromolecules 2017, 50, 1442–1452. [Google Scholar] [CrossRef]

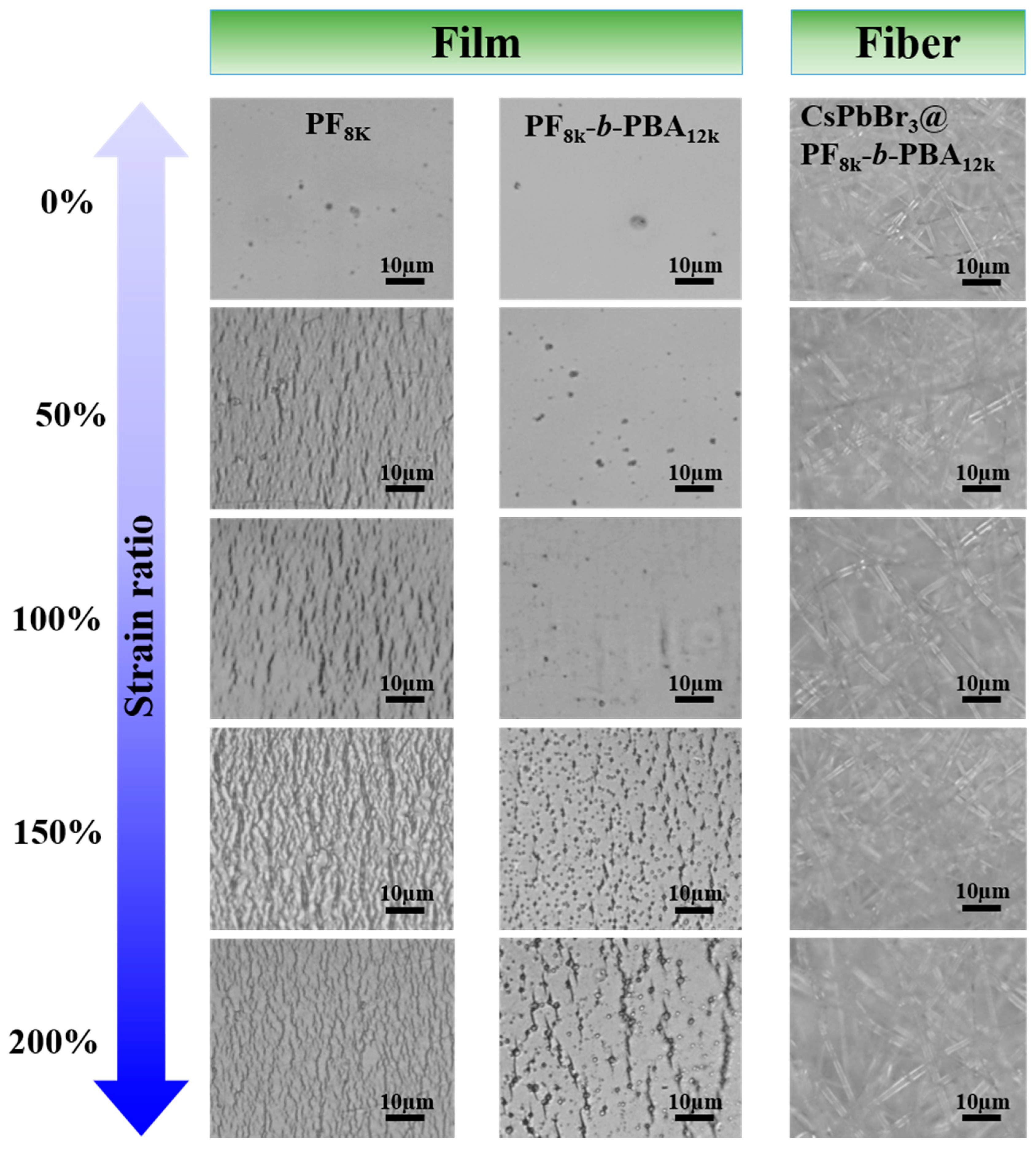

- Hsieh, H.-C.; Hung, C.-C.; Watanabe, K.; Chen, J.-Y.; Chiu, Y.-C.; Isono, T.; Chiang, Y.-C.; Reghu, R.R.; Satoh, T.; Chen, W.-C. Unraveling the stress effects on the optical properties of stretchable rod-coil polyfluorene-poly(n-butyl acrylate) block copolymer thin films. Polym. Chem. 2018, 9, 3820–3831. [Google Scholar] [CrossRef]

- Hung, C.C.; Nakahira, S.; Chiu, Y.C.; Isono, T.; Wu, H.C.; Watanabe, K.; Chiang, Y.C.; Takashima, S.; Borsali, R.; Tung, S.H.; et al. Control over Molecular Architectures of Carbohydrate-Based Block Copolymers for Stretchable Electrical Memory Devices. Macromolecules 2018, 51, 4966–4975. [Google Scholar] [CrossRef]

- Wen, H.-F.; Wu, H.-C.; Aimi, J.; Hung, C.-C.; Chiang, Y.-C.; Kuo, C.-C.; Chen, W.-C. Soft poly(butyl acrylate) side chains toward Intrinsically stretchable polymeric semiconductors for field-effect transistor applications. Macromolecules 2017, 50, 4982–4992. [Google Scholar] [CrossRef]

- Neher, D. Polyfluorene homopolymers: Conjugated liquid-crystalline polymers for bright blue emission and polarized electroluminescence. Macromol. Rapid Comm. 2001, 22, 1365–1385. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, L.; You, W. Rational design of high performance conjugated polymers for organic solar cells. Macromolecules 2012, 45, 607–632. [Google Scholar] [CrossRef]

- Lu, S.; Liu, T.; Ke, L.; Ma, D.-G.; Chua, S.-J.; Huang, W. Polyfluorene-based light-emitting rod− coil block copolymers. J. Macromol. 2005, 38, 8494–8502. [Google Scholar] [CrossRef]

- Saito, K.; Isono, T.; Sun, H.-S.; Kakuchi, T.; Chen, W.-C.; Satoh, T. Rod–coil type miktoarm star copolymers consisting of polyfluorene and polylactide: Precise synthesis and structure–morphology relationship. Polym. Chem. 2015, 6, 6959–6972. [Google Scholar] [CrossRef]

- Jin, G.; Xia, L.; Liu, Z.; Lin, H.; Ling, J.; Wu, H.; Hou, L.; Mo, Y. Highly efficient and stable blue polymer light emitting diodes based on polysilafluorenes with pendent hole transporting groups. J. Mater. Chem. C 2016, 4, 905–913. [Google Scholar] [CrossRef]

- Smith, K.A.; Lin, Y.-H.; Dement, D.B.; Strzalka, J.; Darling, S.B.; Pickel, D.L.; Verduzco, R. Synthesis and crystallinity of conjugated block copolymers prepared by click chemistry. Macromolecules 2013, 46, 2636–2645. [Google Scholar] [CrossRef]

- Bade, S.G.R.; Shan, X.; Hoang, P.T.; Li, J.; Geske, T.; Cai, L.; Pei, Q.; Wang, C.; Yu, Z. Stretchable Light-Emitting Diodes with Organometal-Halide-Perovskite–Polymer Composite Emitters. Adv. Mater. 2017, 29, 1607053. [Google Scholar] [CrossRef]

- Chou, S.-Y.; Ma, R.; Li, Y.; Zhao, F.; Tong, K.; Yu, Z.; Pei, Q. Transparent Perovskite Light-Emitting Touch-Responsive Device. ACS Nano 2017, 11, 11368–11375. [Google Scholar] [CrossRef]

- Lin, C.C.; Jiang, D.-H.; Kuo, C.-C.; Cho, C.-J.; Tsai, Y.-H.; Satoh, T.; Su, C. Water-resistant efficient stretchable perovskite-embedded fiber membranes for light-emitting diodes. ACS Appl. Mater. Interface 2018, 10, 2210–2215. [Google Scholar] [CrossRef]

- Sultana, A.; Alam, M.M.; Sadhukhan, P.; Ghorai, U.K.; Das, S.; Middya, T.R.; Mandal, D. Organo-lead halide perovskite regulated green light emitting poly(vinylidene fluoride) electrospun nanofiber mat and its potential utility for ambient mechanical energy harvesting application. Nano Energy 2018, 49, 380–392. [Google Scholar] [CrossRef]

- Hu, T.; Smith, M.D.; Dohner, E.R.; Sher, M.J.; Wu, X.; Trinh, M.T.; Fisher, A.; Corbett, J.; Zhu, X.Y.; Karunadasa, H.I.; et al. Mechanism for broadband white-light emission from two-dimensional (110) hybrid perovskites. J. Phys. Chem. Lett. 2016, 7, 2258–2263. [Google Scholar] [CrossRef]

- Mao, L.; Wu, Y.; Stoumpos, C.C.; Wasielewski, M.R.; Kanatzidis, M.G. White-light emission and structural distortion in new corrugated two-dimensional lead bromide perovskites. J. Am. Chem. Soc. 2017, 139, 5210–5215. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wu, Y.; Zhang, S.; Cai, B.; Gu, Y.; Song, J.; Zeng, H. CsPbX3 quantum dots for lighting and displays: Room-temperature synthesis, photoluminescence superiorities, underlying origins and white light-emitting diodes. Adv. Funct. Mater. 2016, 26, 2435–2445. [Google Scholar] [CrossRef]

- Wang, Y.; He, J.; Chen, H.; Chen, J.; Zhu, R.; Ma, P.; Towers, A.; Lin, Y.; Gesquiere, A.J.; Wu, S.T. Ultrastable, highly luminescent organic–inorganic perovskite–polymer composite films. Adv. Mater. 2016, 28, 10710–10717. [Google Scholar] [CrossRef]

- Zhou, Q.; Bai, Z.; Lu, W.g.; Wang, Y.; Zou, B.; Zhong, H. In situ fabrication of halide perovskite nanocrystal-embedded polymer composite films with enhanced photoluminescence for display backlights. Adv. Mater. 2016, 28, 9163–9168. [Google Scholar] [CrossRef]

- Jiang, D.-H.; Chiu, P.-C.; Cho, C.-J.; Veeramuthu, L.; Tung, S.-H.; Satoh, T.; Chiang, W.-H.; Cai, X.; Kuo, C.-C. Facile 3D Boron Nitride Integrated Electrospun Nanofibrous Membranes for Purging Organic Pollutants. Nanomaterials 2019, 9, 1383. [Google Scholar] [CrossRef]

- Jiang, D.-H.; Tsai, P.-C.; Kuo, C.-C.; Jhuang, F.-C.; Guo, H.-C.; Chen, S.-P.; Liao, Y.-C.; Satoh, T.; Tung, S.-H. Facile Preparation of Cu/Ag Core/Shell Electrospun Nanofibers as Highly Stable and Flexible Transparent Conductive Electrodes for Optoelectronic Devices. ACS Appl. Mater. Interface 2019, 11, 10118–10127. [Google Scholar] [CrossRef]

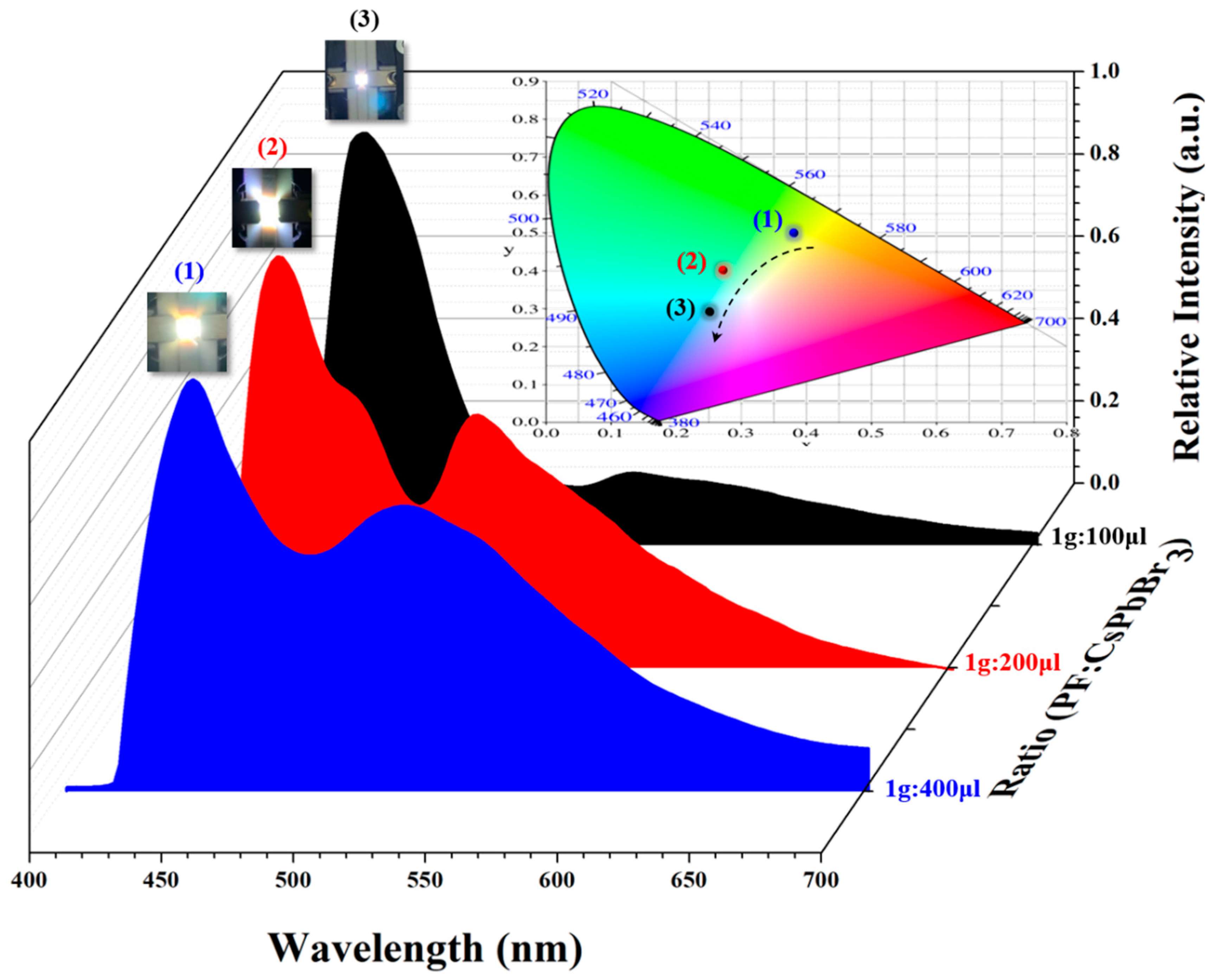

- Jiang, D.-H.; Tsai, Y.-H.; Veeramuthu, L.; Liang, F.-C.; Chen, L.-C.; Lin, C.C.; Satoh, T.; Tung, S.-H.; Kuo, C.-C. Novel ultra-stable and highly luminescent white light-emitting diodes from perovskite quantum dots—Polymer nanofibers through biaxial electrospinning. APL Mater. 2019, 7, 111105. [Google Scholar] [CrossRef]

- Veeramuthu, L.; Chen, B.-Y.; Tsai, C.-Y.; Liang, F.-C.; Venkatesan, M.; Jiang, D.-H.; Chen, C.-W.; Cai, X.; Kuo, C.-C. Novel stretchable thermochromic transparent heaters designed for smart window defroster applications by spray coating silver nanowire. RSC Adv. 2019, 9, 35786–35796. [Google Scholar] [CrossRef]

- Veeramuthu, L.; Li, W.-L.; Liang, F.-C.; Cho, C.-J.; Kuo, C.-C.; Chen, W.-C.; Lin, J.-H.; Lee, W.-Y.; Wang, C.-T.; Lin, W.-Y. Smart garment energy generators fabricated using stretchable electrospun nanofibers. React. Funct. Polym. 2019, 142, 96–103. [Google Scholar] [CrossRef]

- Cho, C.-J.; Lu, S.-T.; Kuo, C.-C.; Liang, F.-C.; Chen, B.-Y.; Chu, C.-C. Pyrene or rhodamine derivative–modified surfaces of electrospun nanofibrous chemosensors for colorimetric and fluorescent determination of Cu2+, Hg2+, and pH. React. Funct. Polym. 2016, 108, 137–147. [Google Scholar] [CrossRef]

- Liang, F.-C.; Chang, Y.-W.; Kuo, C.-C.; Cho, C.-J.; Jiang, D.-H.; Jhuang, F.-C.; Rwei, S.-P.; Borsali, R. A mechanically robust silver nanowire–polydimethylsiloxane electrode based on facile transfer printing techniques for wearable displays. Nanoscale 2019, 11, 1520–1530. [Google Scholar] [CrossRef] [PubMed]

- Sehaqui, H.; Morimune, S.; Nishino, T.; Berglund, L.A. Stretchable and strong cellulose nanopaper structures based on polymer-coated nanofiber networks: An alternative to nonwoven porous membranes from electrospinning. Biomacromolecules 2012, 13, 3661–3667. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, Y.; Zhang, X.; Huo, Z.; Li, X.; Que, M.; Peng, Z.; Wang, H.; Pan, C. A highly stretchable transparent self-powered triboelectric tactile sensor with metallized nanofibers for wearable electronics. Adv. Mater. 2018, 30, 1706738. [Google Scholar] [CrossRef] [PubMed]

| Sample | PBA a (wt%) | Mn,NMR a (g mol−1) | Mn,SEC b (g mol−1) | Mw/Mn b |

|---|---|---|---|---|

| PF8k | 0 | 8200 | 9400 | 1.38 |

| PBA12k-N3 | 100 | 11,700 | 12,500 | 1.10 |

| PF8k-b-PBA12k | 72 | 19,100 | 21,400 | 1.43 |

| Sample | Td (°C) | Tg (°C) | As-Cast Film | Nanofiber Membrane | |

|---|---|---|---|---|---|

| λabsmax (nm) | λPLmax (nm) | λPLmax (nm) | |||

| PF8k | 401 | 78 | 384 | 451,481 | -- |

| PBA12k | 340 | −54 | -- | -- | -- |

| PF8k-b-PBA12k | 350 | −78,110 | 386 | 445,466 | 446 |

| CsPbBr3@PF8k-b-PBA12k | -- | -- | 382 | 445,471,510 | 446,518 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, D.-H.; Kobayashi, S.; Jao, C.-C.; Mato, Y.; Isono, T.; Fang, Y.-H.; Lin, C.-C.; Satoh, T.; Tung, S.-H.; Kuo, C.-C. Light Down-Converter Based on Luminescent Nanofibers from the Blending of Conjugated Rod-Coil Block Copolymers and Perovskite through Electrospinning. Polymers 2020, 12, 84. https://doi.org/10.3390/polym12010084

Jiang D-H, Kobayashi S, Jao C-C, Mato Y, Isono T, Fang Y-H, Lin C-C, Satoh T, Tung S-H, Kuo C-C. Light Down-Converter Based on Luminescent Nanofibers from the Blending of Conjugated Rod-Coil Block Copolymers and Perovskite through Electrospinning. Polymers. 2020; 12(1):84. https://doi.org/10.3390/polym12010084

Chicago/Turabian StyleJiang, Dai-Hua, Saburo Kobayashi, Chih-Chun Jao, Yoshinobu Mato, Takuya Isono, Yu-Han Fang, Chun-Che Lin, Toshifumi Satoh, Shih-Huang Tung, and Chi-Ching Kuo. 2020. "Light Down-Converter Based on Luminescent Nanofibers from the Blending of Conjugated Rod-Coil Block Copolymers and Perovskite through Electrospinning" Polymers 12, no. 1: 84. https://doi.org/10.3390/polym12010084

APA StyleJiang, D.-H., Kobayashi, S., Jao, C.-C., Mato, Y., Isono, T., Fang, Y.-H., Lin, C.-C., Satoh, T., Tung, S.-H., & Kuo, C.-C. (2020). Light Down-Converter Based on Luminescent Nanofibers from the Blending of Conjugated Rod-Coil Block Copolymers and Perovskite through Electrospinning. Polymers, 12(1), 84. https://doi.org/10.3390/polym12010084