An Experimental Study on Hydrodynamic Retention of Low and High Molecular Weight Sulfonated Polyacrylamide Polymer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polymer and Brine

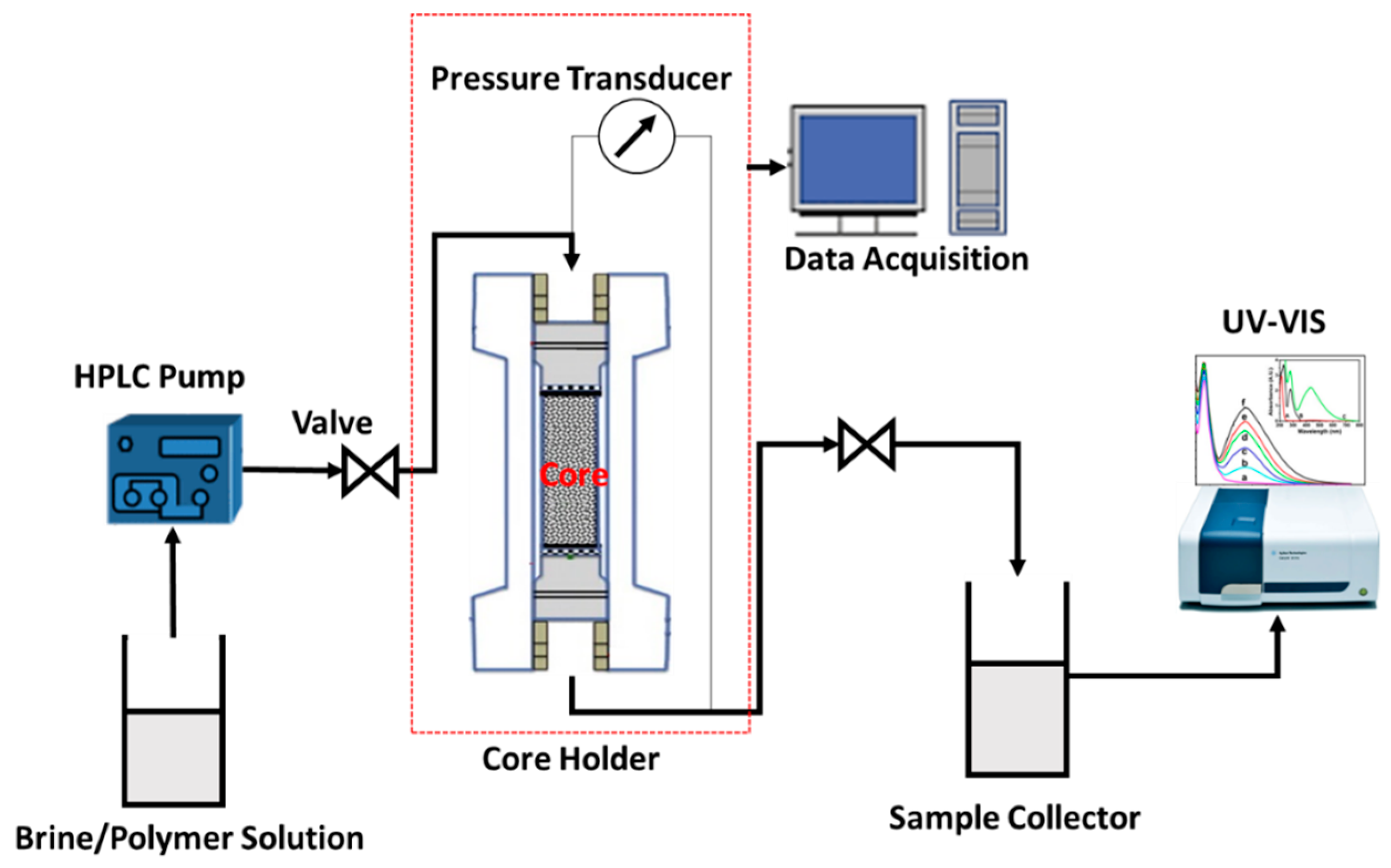

2.2. Dynamic Adsorption Measurement

2.3. Hydrodynamic Retention Measurement

2.4. Polymer Concentration Measurement

3. Results and Discussion

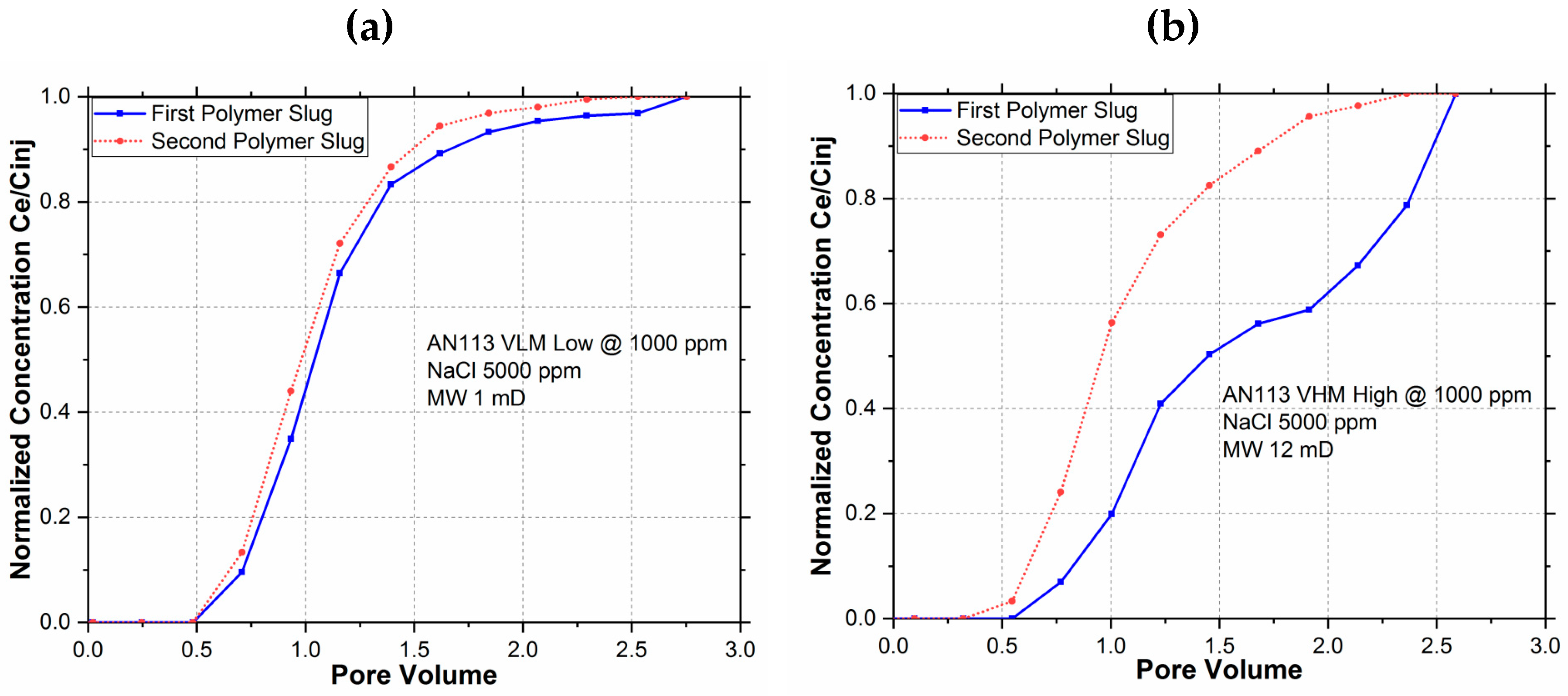

3.1. Retention Measurement

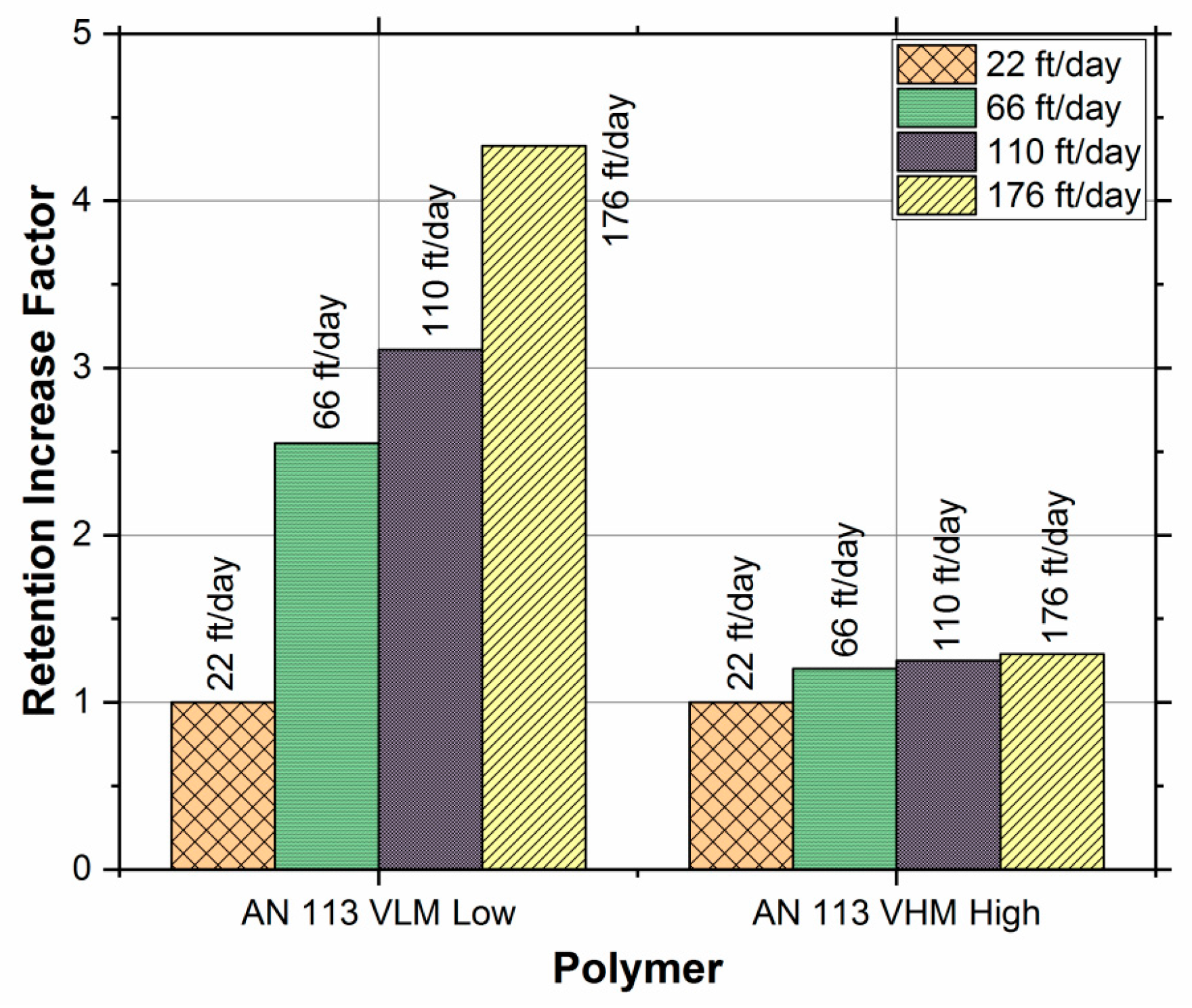

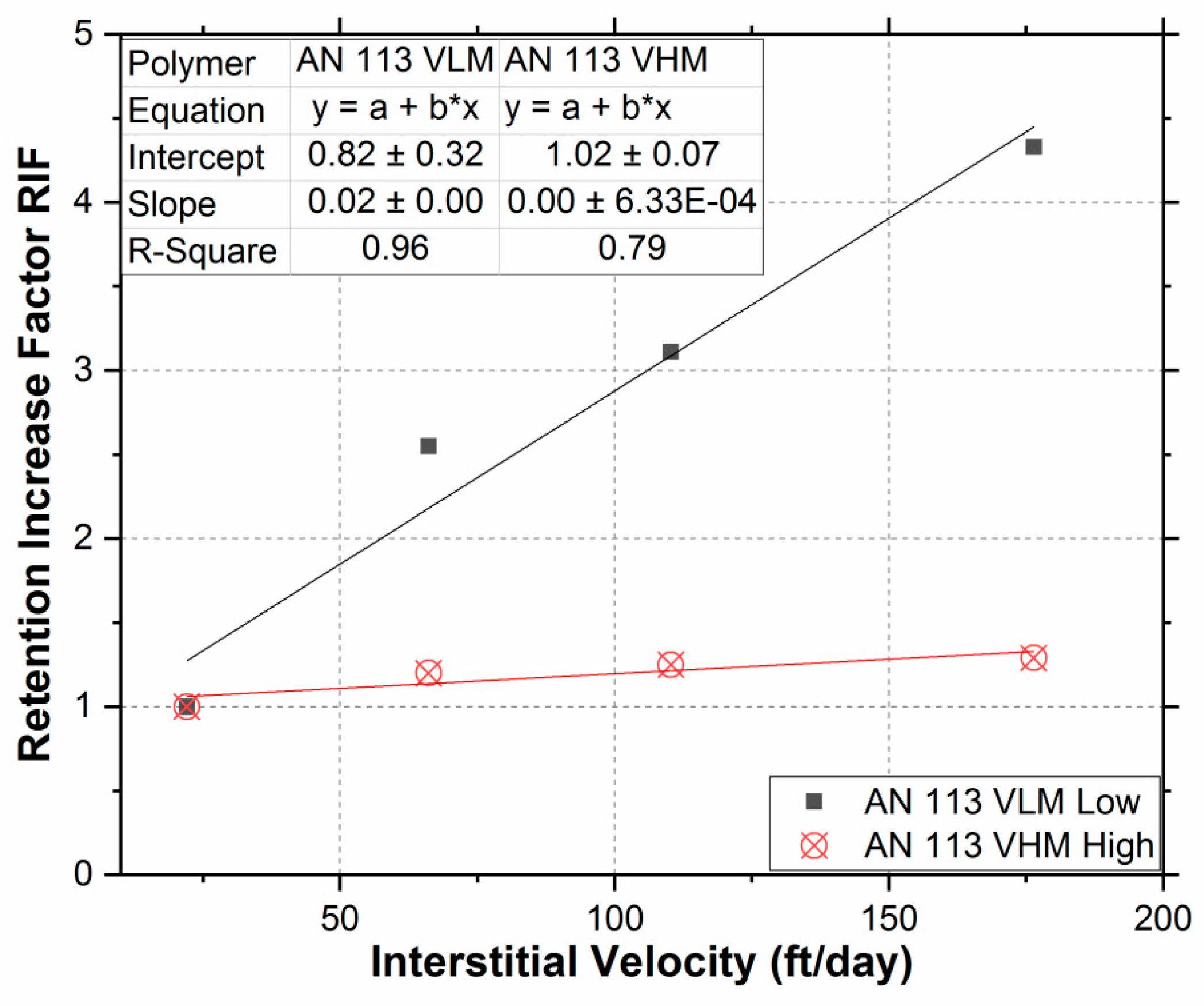

3.2. Effect of Rate on Polymer Retention

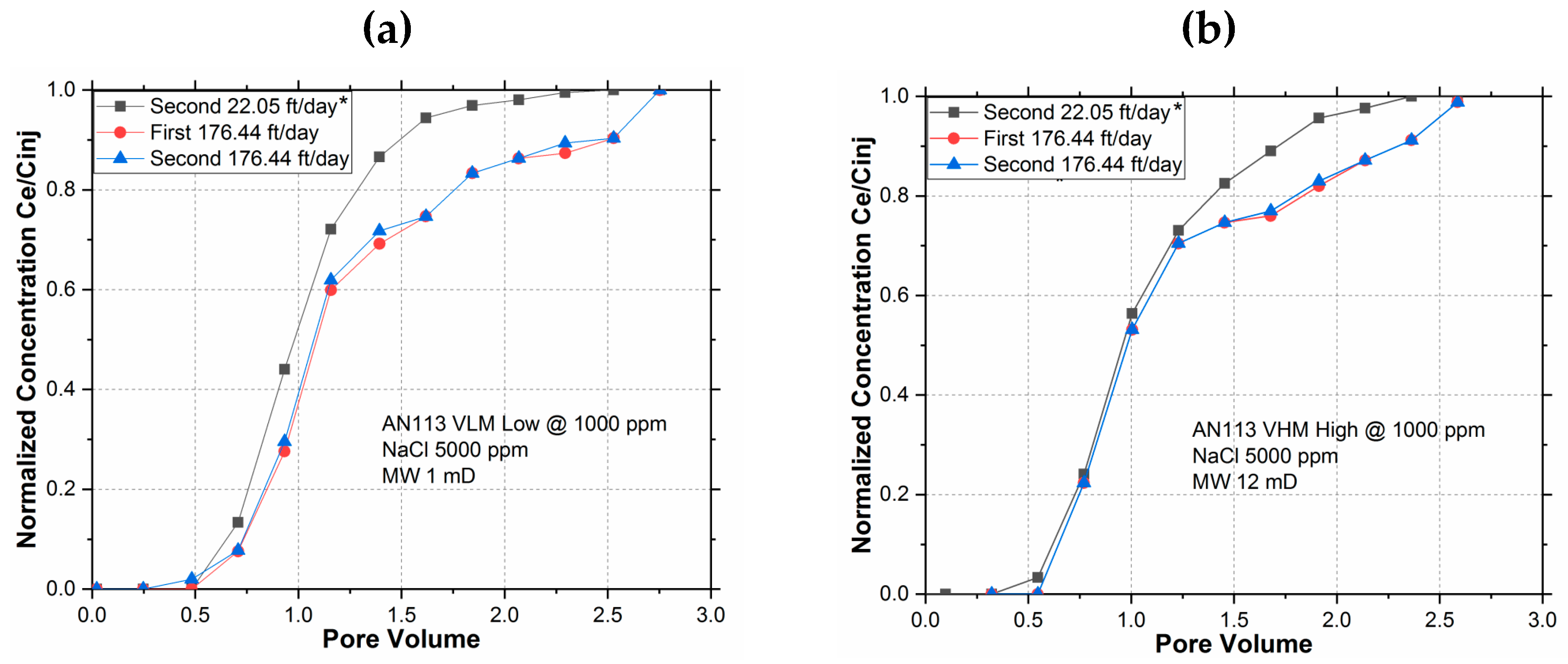

3.3. Reversibility of Hydrodynamic Retention

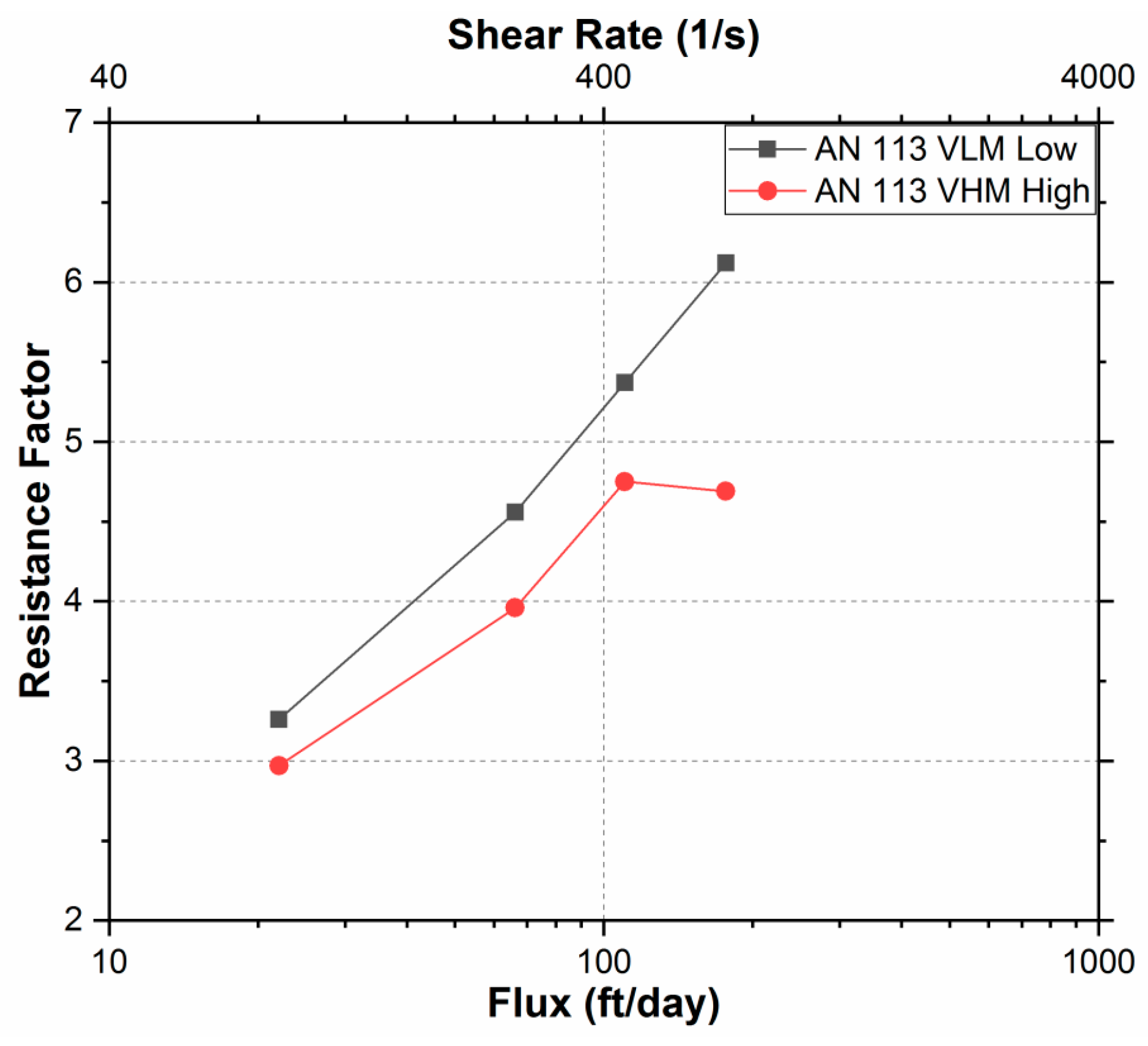

3.4. Permeability Reduction

3.5. Rheological Behaviour of AN 113 VLM and AN 113 VHM

3.5.1. Bulk Rheology Using Rheometer

3.5.2. In Situ Rheology Using Core Flood

4. Conclusions

- Polymer retention increased when the molecular weight of the AN 113 sulfonated polyacrylamide polymer also increased.

- The polymer retention (adsorption) of AN 113 VLM and AN 113 VHM caused irreversible permeability reduction, which increased the residual resistance factor of both (1.05 and 1.80).

- For unclear reasons, hydrodynamic retention was noticeably higher for lower molecular weight polymers.

- The polymer hydrodynamic retention was reversible and had no permanent effect on permeability reduction.

- Both AN 113 VLM and AN 113 VHM sulfonated polyacrylamide polymers showed shear thinning behavior in the bulk rheological study using Rheometer.

- The core flooding study showed that the resistance factor increased when the flow rate increased, which resulted in a shear thickening behavior for AN 113 VLM and AN 113 VHM. However, at very high flow rates, mechanical degradation may cause shear thinning behavior.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Al-Hajri, S.; Mahmood, S.M.; Akbari, S.; Abdulelah, H. Gelation behavior as a function of concentration of sodium thiosulfate for PAM gels cross-linked with chromium. J. Pet. Explor. Prod. Tech. 2019, 9, 1539–1546. [Google Scholar] [CrossRef]

- Chang, H.L. Polymer Flooding Technology Yesterday, Today, and Tomorrow. J. Pet. Technol. 1978, 30, 1–113. [Google Scholar] [CrossRef]

- Wang, D.; Cheng, J.; Xia, H.; Li, Q.; Shi, J. Viscous-elastic fluids can mobilize oil remaining after water-flood by force parallel to the oil-water interface. In Proceedings of the SPE Asia Pacific Improved Oil Recovery Conference, Kuala Lumpur, Malaysia, 6–9 October 2001. [Google Scholar]

- Wang, D.; Cheng, J.; Yang, Q.; Wenchao, G.; Qun, L.; Chen, F. Viscous-elastic polymer can increase microscale displacement efficiency in cores. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000. [Google Scholar]

- AlSofi, A.M.; Wang, J.; Leng, Z.; Abbad, M.; Kaidar, Z.F. Assessment of Polymer Interactions with Carbonate Rocks and Implications for EOR Applications. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 1 June 2017. [Google Scholar]

- Banerjee, S.; Abdulsattar, Z.R.; Agim, K.; Lane, R.H.; Hascakir, B. Mechanism of polymer adsorption on shale surfaces: Effect of polymer type and presence of monovalent and divalent salts. Petroleum 2017, 3, 384–390. [Google Scholar] [CrossRef]

- Cheraghian, G.; Khalili Nezhad, S.S.; Kamari, M.; Hemmati, M.; Masihi, M.; Bazgir, S. Adsorption polymer on reservoir rock and role of the nanoparticles, clay and SiO2. Int. Nano Lett. 2014, 4, 114. [Google Scholar] [CrossRef]

- Szabo, M. Some aspects of polymer retention in porous media using a C14-tagged hydrolyzed polyacrylamide. Soc. Pet. Eng. J. 1975, 15, 323–337. [Google Scholar] [CrossRef]

- Szabo, M.T. An evaluation of water-soluble polymers for secondary oil Recovery-Parts 1 and 2. J. Pet. Technol. 1979, 31, 553–570. [Google Scholar] [CrossRef]

- Al-Hajri, S.; Mahmood, S.; Abdulelah, H.; Akbari, S. An Overview on Polymer Retention in Porous Media. Energies 2018, 11, 2751. [Google Scholar] [CrossRef]

- Argillier, J.F.; Audibert, A.; Lecourtier, J.; Moan, M.; Rousseau, L. Solution and adsorption properties of hydrophobically associating water-soluble polyacrylamides. Colloids Surf. A Physicochem. Eng. Asp. 1996, 113, 247–257. [Google Scholar] [CrossRef]

- Aronofsky, J.; Ramey, H., Jr. Mobility Ratio-Its Influence on Injection or Production Histories in Five-Spot Water Flood. J. Pet. Technol. 1956, 8, 205–210. [Google Scholar] [CrossRef]

- Broseta, D.; Medjahed, F.; Lecourtier, J.; Robin, M. Polymer Adsorption/Retention in Porous Media: Effects of Core Wettability and Residual Oil. SPE Adv. Technol. Ser. 1995, 3, 103–112. [Google Scholar] [CrossRef]

- Chauveteau, G.; Denys, K.; Zaitoun, A. New Insight on Polymer Adsorption Under High Flow Rates. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 1 January 2002. [Google Scholar]

- Chiappa, L.; Mennella, A.; Lockhart, T.P.; Burrafato, G. Polymer adsorption at the brine/rock interface: The role of electrostatic interactions and wettability. J. Pet. Sci. Eng. 1999, 24, 113–122. [Google Scholar] [CrossRef]

- Choi, B.; Yu, K.; Lee, K.S. Modelling of polymer retention during low concentrated HPAM polymer flooding in the heterogeneous reservoirs. Int. J. OilGas Coal Technol. 2016, 11, 249–263. [Google Scholar] [CrossRef]

- Akbari, S.; Mahmood, S.M.; Nasr, N.H.; Al-Hajri, S.; Sabet, M. A critical review of concept and methods related to accessible pore volume during polymer-enhanced oil recovery. J. Pet. Sci. Eng. 2019, 182, 106263. [Google Scholar] [CrossRef]

- Sorbie, K.S. Polymer-Improved Oil Recovery; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Green, D.W.; Willhite, G.P. Enhanced Oil Recovery; Henry, L., Ed.; Doherty Memorial Fund of AIME, Society of Petroleum Engineers Richardson: Richardson, TX, USA, 1998; Volume 6. [Google Scholar]

- Chauveteau, G.; Kohler, N. Polymer flooding: The essential elements for laboratory evaluation. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 22–24 April 1974. [Google Scholar]

- Dominguez, J.; Willhite, G. Retention and flow characteristics of polymer solutions in porous media. Soc. Pet. Eng. J. 1977, 17, 111–121. [Google Scholar] [CrossRef]

- Huh, C.; Lange, E.; Cannella, W. Polymer retention in porous media. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 22–25 April 1990. [Google Scholar]

- Marker, J.M. Dependence of polymer retention on flow rate. J. Pet. Technol. 1973, 25, 1–307. [Google Scholar] [CrossRef]

- Lakatos, I.; Lakatos-Szabo, J.; Toth, J. Factors Influencing Polyacrylamide Adsorption in Porous Media and Their Effect on Flow Behavior. In Surface Phenomena in Enhanced Oil Recovery; Springer: Berlin/Heidelberg, Germany, 1981; pp. 821–842. [Google Scholar]

- Masoud, R.; Sigmund, S.; Marit, B.A.; Arne, S. Static and dynamic adsorption of salt tolerant polymers. In Proceedings of the European Symposium on Improved Oil Recovery, Paris, Frances, 27–29 April 2003. [Google Scholar]

- Rashidi, M.; Blokhus, A.M.; Skauge, A. Viscosity and retention of sulfonated polyacrylamide polymers at high temperature. J. Appl. Polym. Sci. 2011, 119, 3623–3629. [Google Scholar] [CrossRef]

- Chen, Z.; Du, C.; Kurnia, I.; Lou, J.; Zhang, G.; Yu, J.; Lee, R.L. A Study of Factors Influencing Polymer Hydrodynamic Retention in Porous Media. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11 April 2016; p. 10. [Google Scholar]

- Zhang, G.; Seright, R.S. Hydrodynamic Retention and Rheology of EOR Polymers in Porous Media. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 13 April 2015; p. 15. [Google Scholar]

- Lotsch, T.; Muller, T.; Pusch, G. The effect of inaccessible pore volume on polymer coreflood experiments. In Proceedings of the SPE Oilfield and Geothermal Chemistry Symposium, Phoenix, AZ, USA, 9–11 March 1985. [Google Scholar]

- Hunt, J.A.; Young, T.S.; Green, D.W.; Willhite, G.P. Size-Exclusion Chromatography in the Measurement of Concentration and Molecular Weight of Some EOR Polymers. SPE Reserv. Eng. 1988, 3, 835–841. [Google Scholar] [CrossRef]

- Wei, B.; Romero-Zerón, L.; Rodrigue, D. Mechanical Properties and Flow Behavior of Polymers for Enhanced Oil Recovery. J. Macromol. Sci. Part B 2014, 53, 625–644. [Google Scholar] [CrossRef]

- Hatzignatiou, D.G.; Norris, U.L.; Stavland, A. Core-scale simulation of polymer flow through porous media. J. Pet. Sci. Eng. 2013, 108, 137–150. [Google Scholar] [CrossRef]

- Lu, G.; Shao, N.; Cao, M.; Wang, B. Effect of Polymer Chain Structure on Rheological Behavior of Polyamide Imide Solution. Eng. Plastic. Appl 2016, 44, 90–92. [Google Scholar]

- Wei, B. Flow characteristics of three enhanced oil recovery polymers in porous media. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Akbari, S.; Mahmood, S.M.; Tan, I.M.; Bharadwaj, A.M.; Hematpour, H. Experimental investigation of the effect of different process variables on the viscosity of sulfonated polyacrylamide copolymers. J. Pet. Explor. Prod. Technol. 2017, 7, 87–101. [Google Scholar] [CrossRef]

- Akbari, S.; Mahmood, M.S.; Ghaedi, H.; Al-Hajri, S. A New Empirical Model for Viscosity of Sulfonated Polyacrylamide Polymers. Polymers 2019, 11, 1046. [Google Scholar] [CrossRef] [PubMed]

- Maerker, J.M. Shear Degradation of Partially Hydrolyzed Polyacrylamide Solutions. Soc. Pet. Eng. J. 1975, 15, 311–322. [Google Scholar] [CrossRef]

- Seright, R.S. The Effects of Mechanical Degradation and Viscoelastic Behavior on Injectivity of Polyacrylamide Solutions. Soc. Pet. Eng. J. 1983, 23, 475–485. [Google Scholar] [CrossRef]

- Durst, F.; Haas, R.; Interthal, W. Laminar and turbulent flows of dilute polymer solutions: A physical model. In Proceedings of the Progress and Trends in Rheology, Heidelberg, Germany, 14–16 April 1982; pp. 218–223. [Google Scholar]

| Core ID | Lithology | Length (cm) | Weight (g) | Porosity (%) | Permeability (md) | Pore Volume (cc) |

|---|---|---|---|---|---|---|

| B1 | Sandstone | 7.6 | 169 | 19.5 | 1991 | 17.2 |

| B2 | Sandstone | 7.6 | 170 | 19.2 | 1932 | 17.1 |

| Sample ID | Polymer Type | Concentration (ppm) | Molecular Weight (md) | Salinity (ppm) |

|---|---|---|---|---|

| P1 | AN113 VLM | 1000 | 0.5–1 | 5000 |

| P2 | AN113 VHM | 1000 | 11–12 | 5000 |

| Process | Injected PV * | Samples Collected |

|---|---|---|

| Pre-injection Brine | 3 | None |

| First Polymer slug | 2.5 | Every 4 cm3 |

| Post-injection Brine | 80 | None |

| Second Polymer slug | 2.5 | Every 4 cm3 |

| Polymer | Polymer Injection Rate (cm3/min) | Interstitial Velocity (ft/Day) | Retention at base velocity of 22 ft/Day (µg/g) | Total Retention (µg/g) | Retention Increase Factor |

|---|---|---|---|---|---|

| AN113 VLM | 1 | 22* | 9 | 9 | 1.00 |

| 3 | 66 | 23 | 2.55 | ||

| 5 | 110 | 28 | 3.11 | ||

| 8 | 176 | 39 | 4.33 | ||

| AN113 VHM | 1 | 22 * | 55 | 55 | 1.00 |

| 3 | 66 | 66 | 1.20 | ||

| 5 | 110 | 69 | 1.25 | ||

| 8 | 176 | 71 | 1.29 |

| Parameter | AN 113 VLM | AN 113 VHM |

|---|---|---|

| Interstitial velocity during post-polymer brine injection for each test, ft/D | 22 | 22 |

| Initial ΔP during brine injection prior to any polymer injection, psi | 0.018 | 0.020 |

| ΔP post-polymer injection, psi * | 0.019 | 0.032 |

| Calculated RRF (ΔPpost/ΔPpre) | 1.05 | 1.80 |

| Polymer | Flux (ft/Day) | Shear Rate (1/s) | ΔPpolymer (psi) | Calc ΔP * brine (psi) | Calc RF (ΔPpolymer/ΔPbrine) |

|---|---|---|---|---|---|

| AN 113 VLM | 22 | 87 | 0.062 | 0.019 | 3.26 |

| 66 | 262 | 0.260 | 0.057 | 4.56 | |

| 110 | 436 | 0.510 | 0.095 | 5.37 | |

| 176 | 698 | 0.930 | 0.152 | 6.12 | |

| AN 113 VHM | 22 | 87 | 0.095 | 0.032 | 2.97 |

| 66 | 262 | 0.380 | 0.096 | 3.96 | |

| 110 | 436 | 0.760 | 0.160 | 4.75 | |

| 176 | 698 | 1.200 | 0.256 | 4.69 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Hajri, S.; Mahmood, S.M.; Abdulrahman, A.; Abdulelah, H.; Akbari, S.; Saraih, N. An Experimental Study on Hydrodynamic Retention of Low and High Molecular Weight Sulfonated Polyacrylamide Polymer. Polymers 2019, 11, 1453. https://doi.org/10.3390/polym11091453

Al-Hajri S, Mahmood SM, Abdulrahman A, Abdulelah H, Akbari S, Saraih N. An Experimental Study on Hydrodynamic Retention of Low and High Molecular Weight Sulfonated Polyacrylamide Polymer. Polymers. 2019; 11(9):1453. https://doi.org/10.3390/polym11091453

Chicago/Turabian StyleAl-Hajri, Sameer, Syed M. Mahmood, Ahmed Abdulrahman, Hesham Abdulelah, Saeed Akbari, and Nabil Saraih. 2019. "An Experimental Study on Hydrodynamic Retention of Low and High Molecular Weight Sulfonated Polyacrylamide Polymer" Polymers 11, no. 9: 1453. https://doi.org/10.3390/polym11091453

APA StyleAl-Hajri, S., Mahmood, S. M., Abdulrahman, A., Abdulelah, H., Akbari, S., & Saraih, N. (2019). An Experimental Study on Hydrodynamic Retention of Low and High Molecular Weight Sulfonated Polyacrylamide Polymer. Polymers, 11(9), 1453. https://doi.org/10.3390/polym11091453