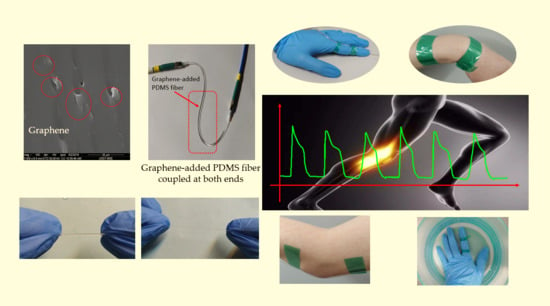

Flexible and Optical Fiber Sensors Composited by Graphene and PDMS for Motion Detection

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

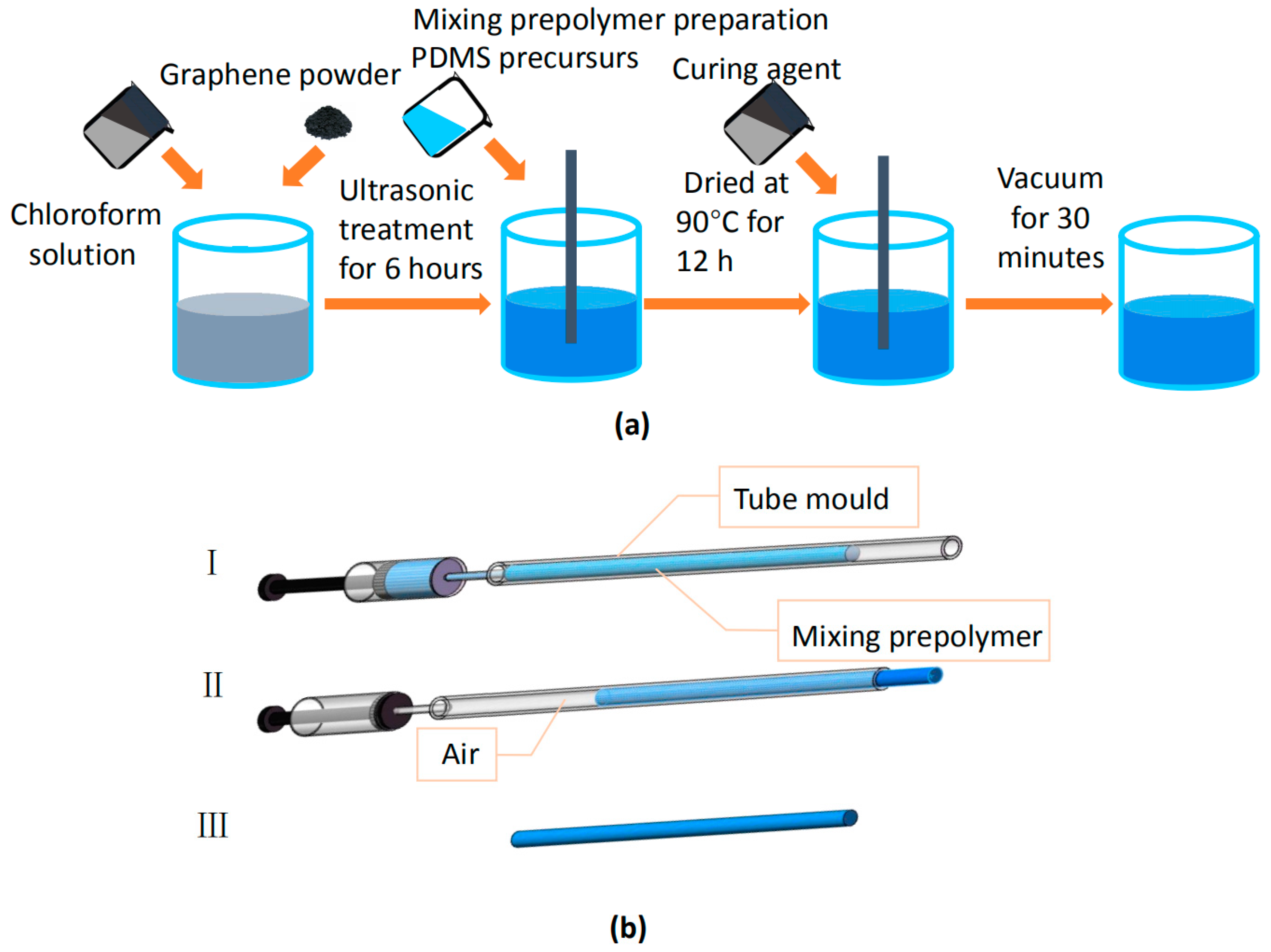

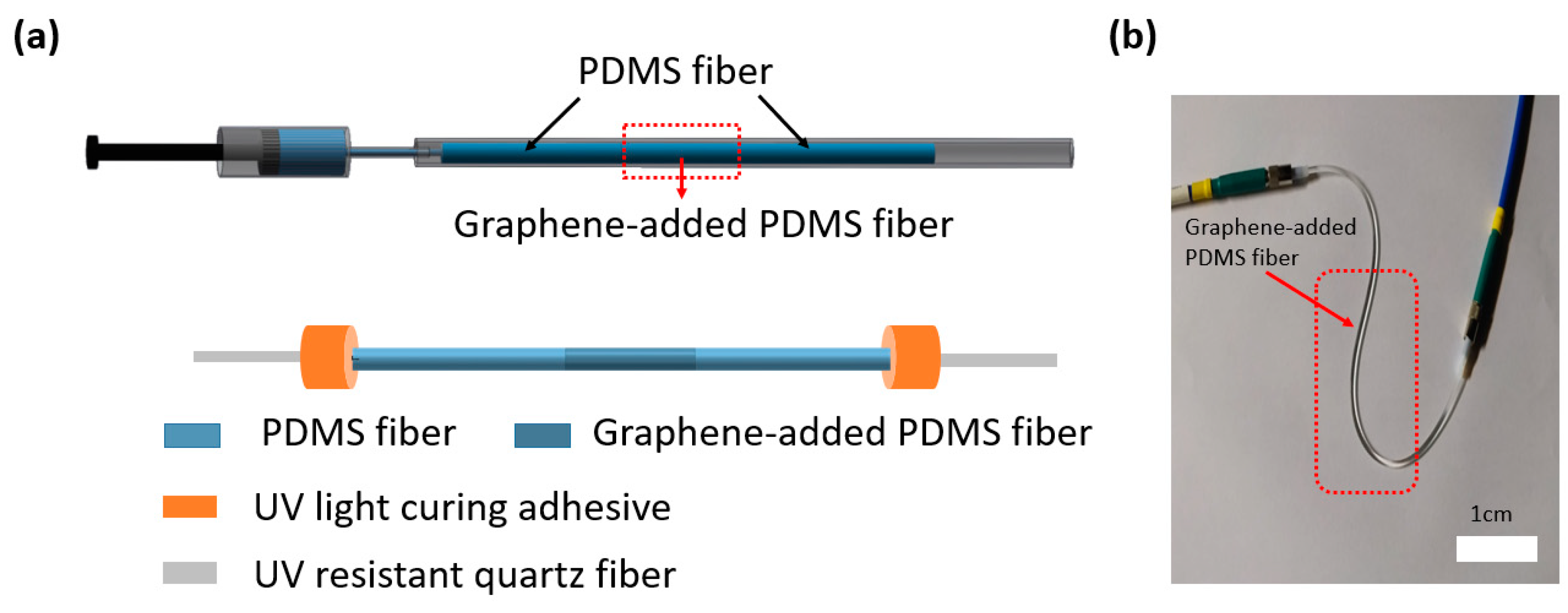

2.2. Fabrication Procedures of Optical Fiber

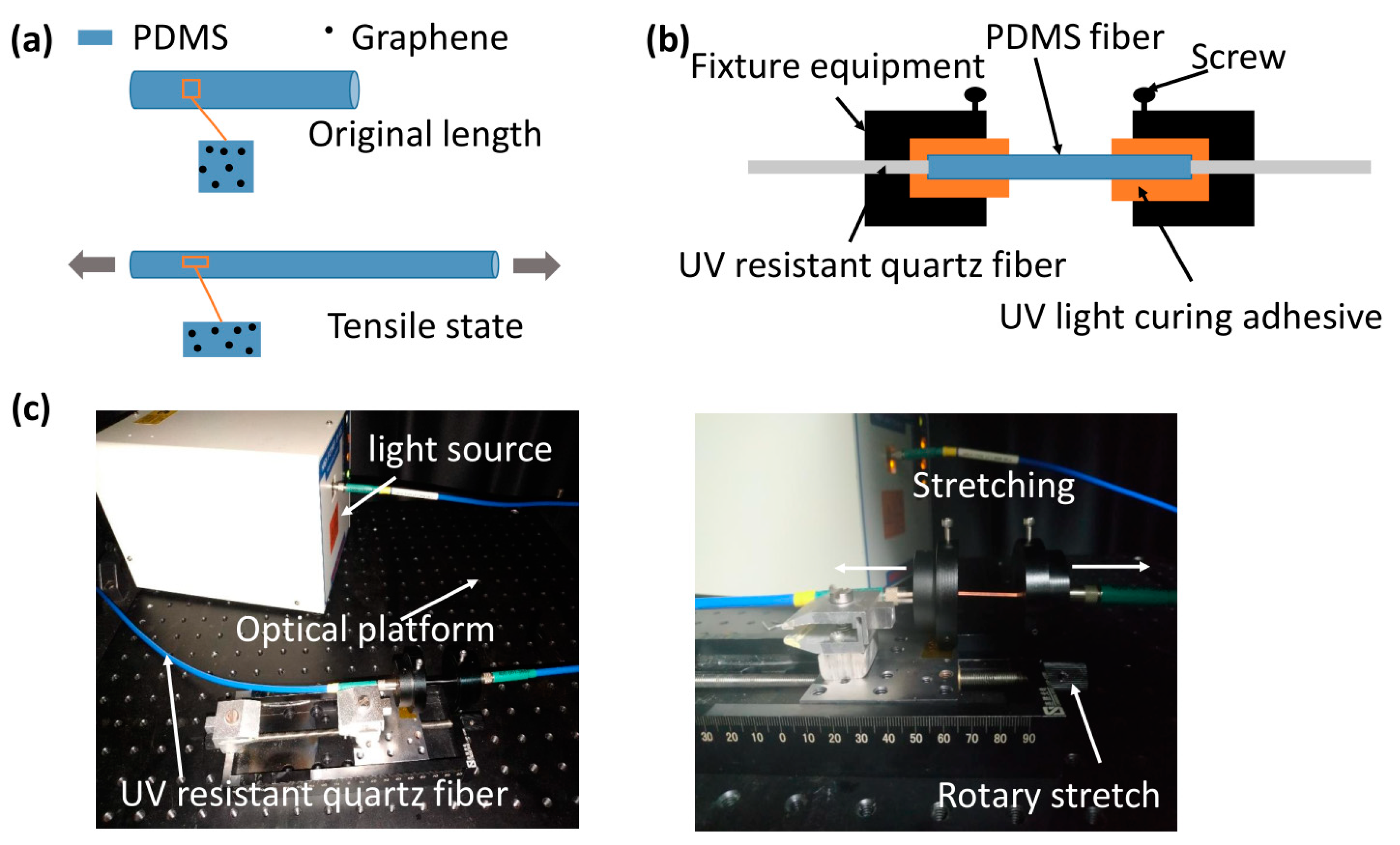

2.3. Optical Fiber Measurement

3. Results

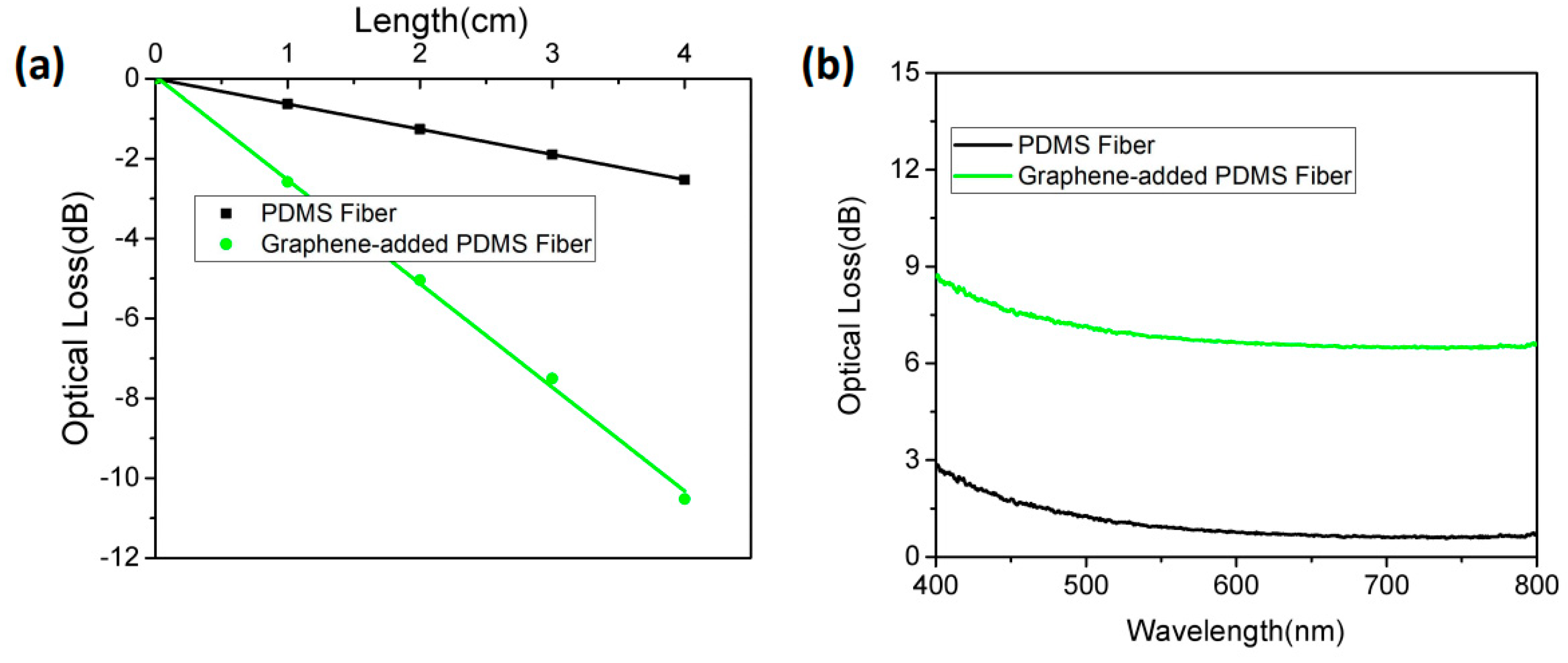

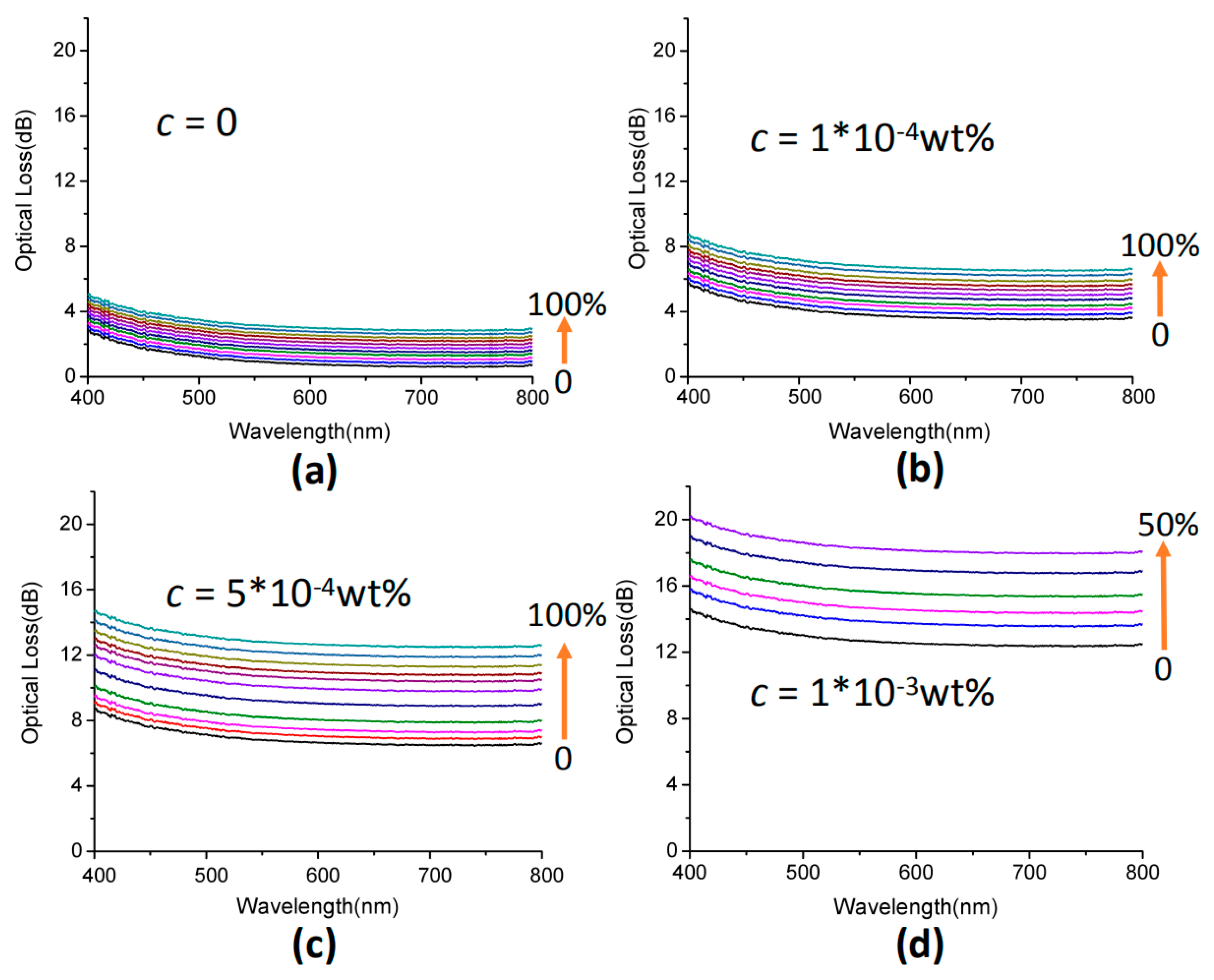

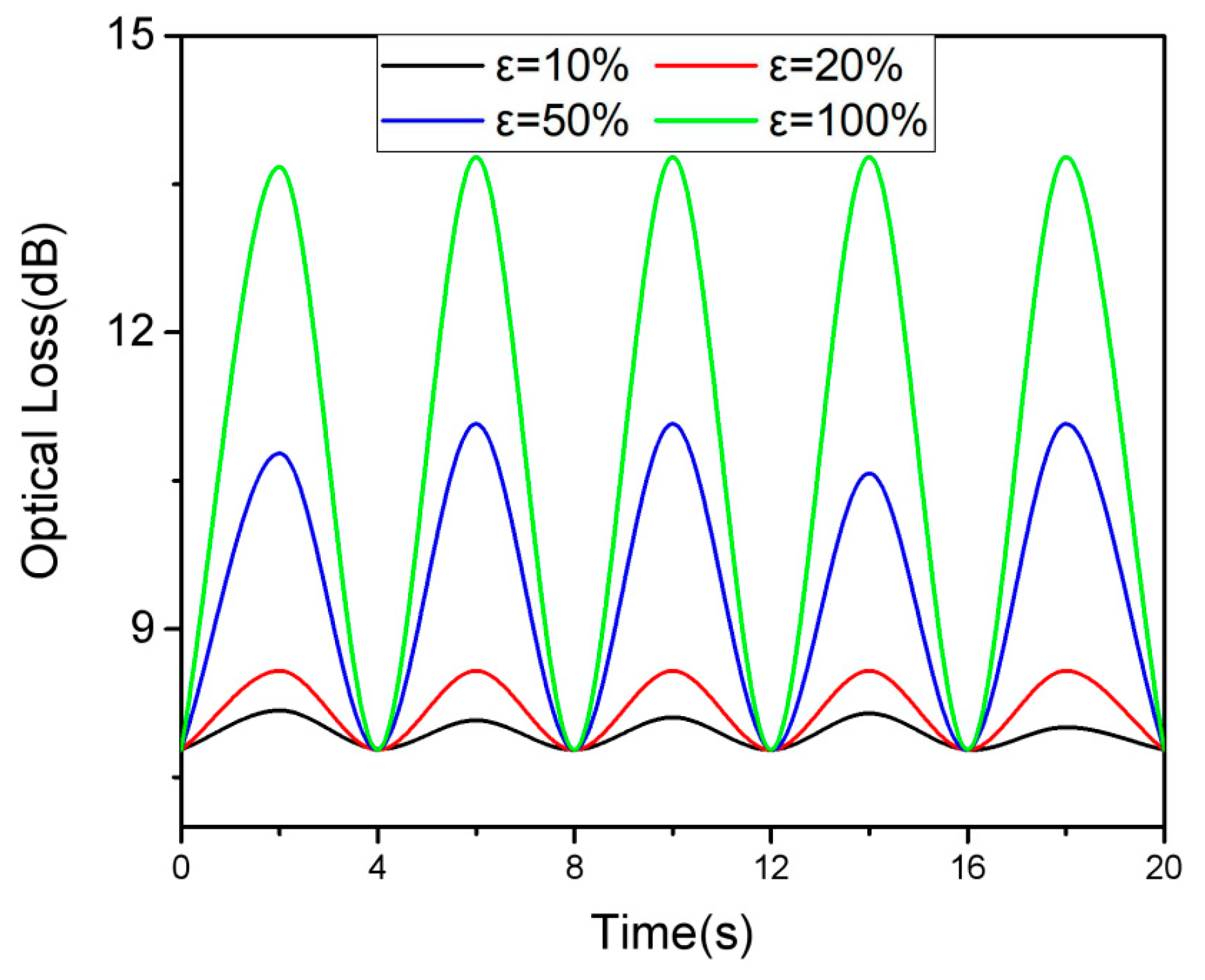

3.1. Characteristics of Fiber Optic Sensors

3.2. Sensing Mechanism of Fiber Optic Sensors

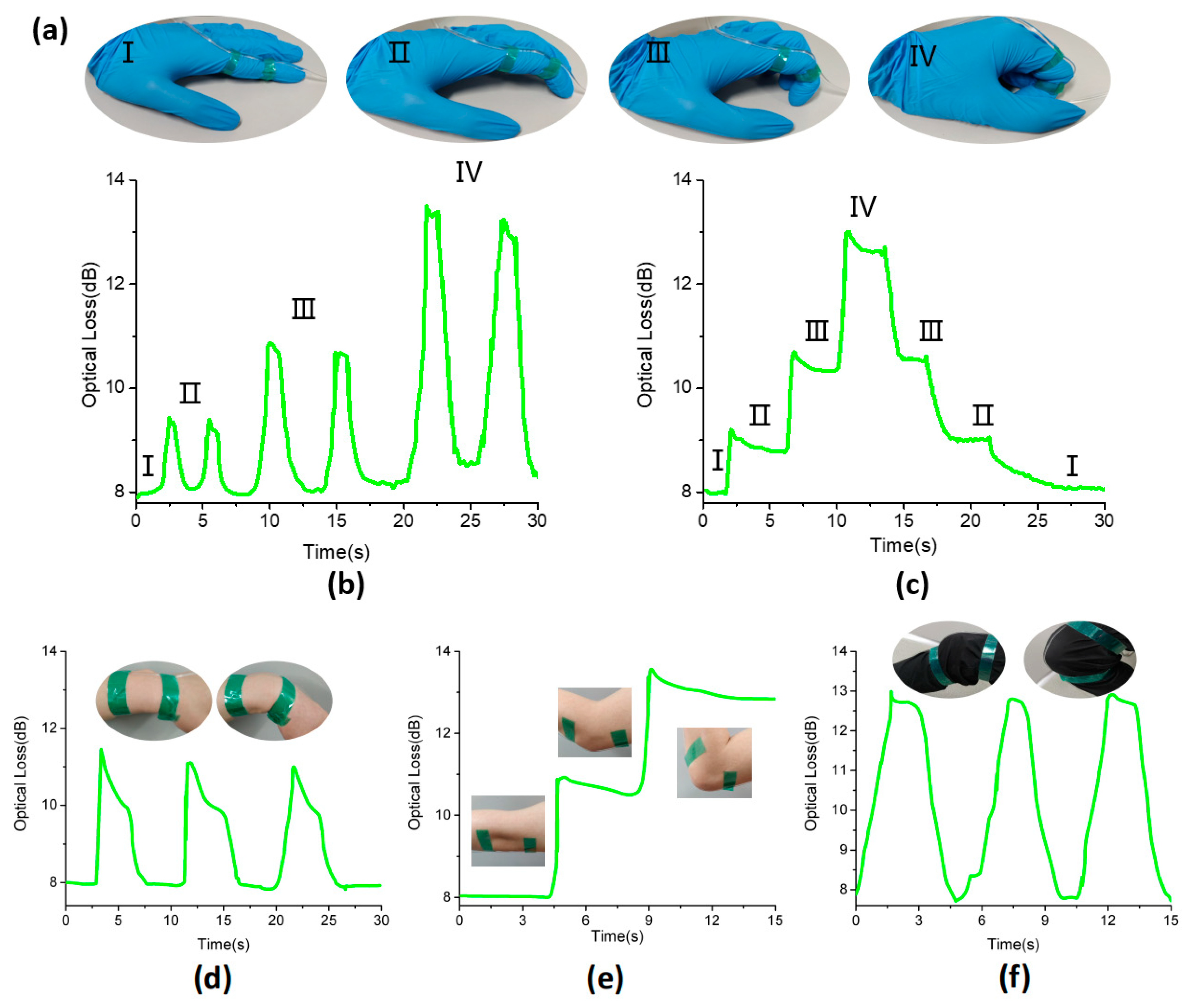

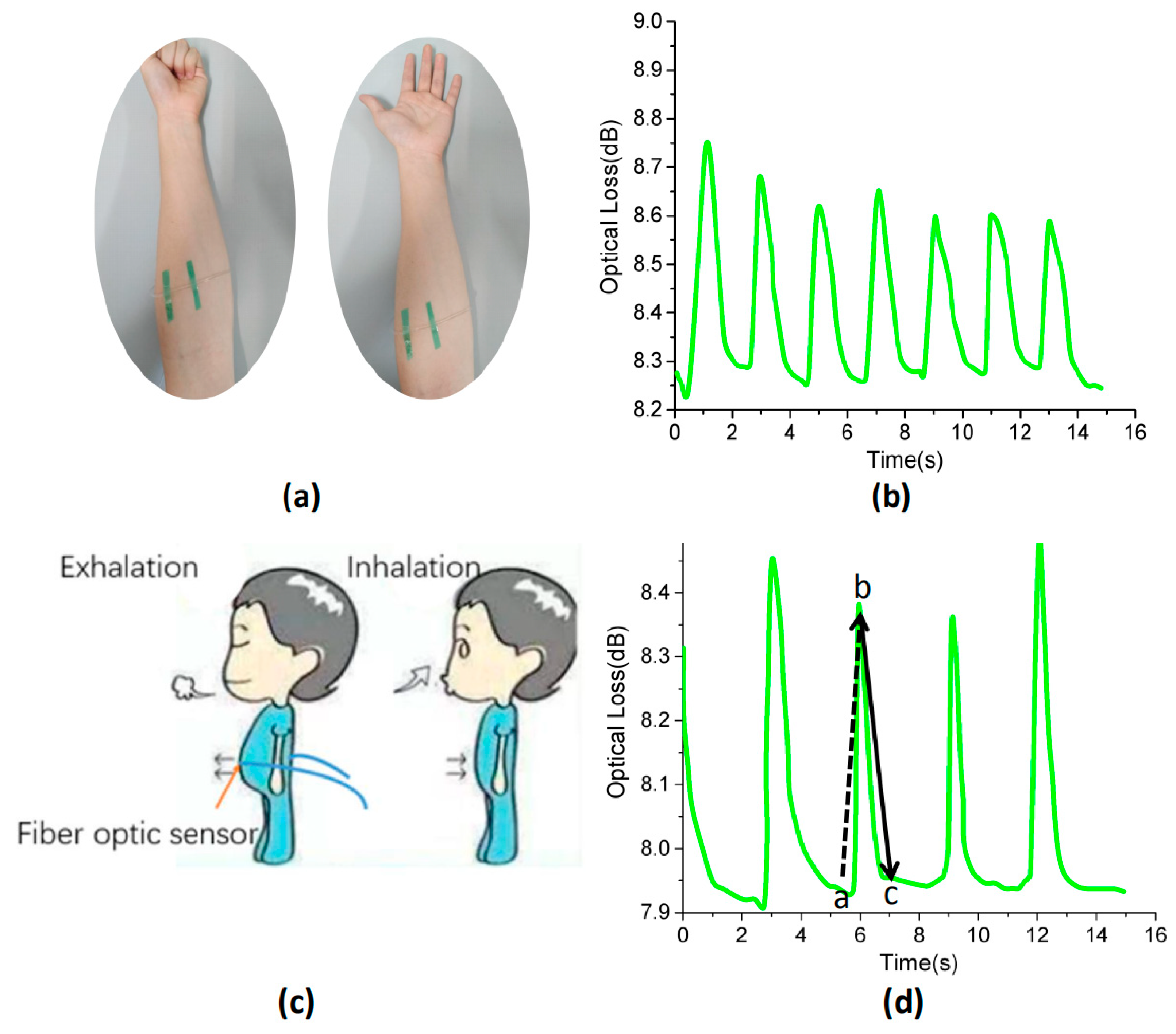

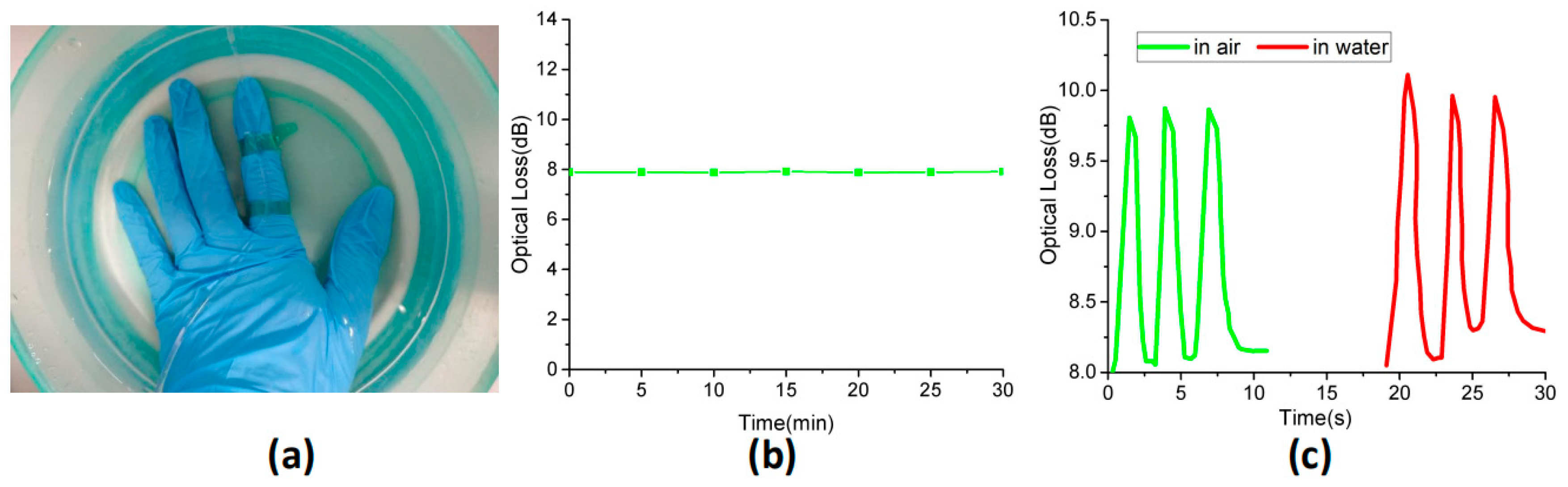

3.3. Motion-Detecting Applications

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sekitani, T.; Noguchi, Y.; Hata, K.; Fukushima, T.; Aida, T.; Someya, T. A rubberlike stretchable active matrix using elastic conductors. Science 2008, 321, 1468–1472. [Google Scholar] [CrossRef] [PubMed]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, C.K.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef] [PubMed]

- Mannsfeld, S.C.B.; Tee, C.K.; Stoltenberg, R.M.; Chen, H.H.; Barman, S.; Muir, B.V.O. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef] [PubMed]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Mcalpine, M.C.; Ahmad, H.; Wang, D.; Heath, J.R. Highly ordered nanowire arrays on plastic substrates for ultrasensitive flexible chemical sensors. Nat. Mater. 2007, 6, 379–384. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Sheng, B.; Wu, H.; Huang, Y.S.; Zhang, D.W.; Zhuang, S.L. Composite Films of Polydimethylsiloxane and Micro-Graphite with Tunable Optical Transmittance. Appl. Sci. 2019, 9, 2402. [Google Scholar] [CrossRef]

- Kim, D.H.; Ahn, J.H.; Choi, W.M.; Kim, H.S.; Kim, T.H.; Song, J. Stretchable and foldable silicon integrated circuits. Science 2008, 320, 507–511. [Google Scholar] [CrossRef]

- Someya, T.; Sekitani, T.; Iba, S.; Kato, Y.; Kawaguchi, H.; Sakurai, T. A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proc. Natl. Acad. Sci. USA 2013, 101, 9966–9970. [Google Scholar] [CrossRef]

- Someya, T.; Kato, Y.; Sekitani, T.; Iba, S.; Noguchi, Y.; Murase, Y. Conformable, flexible, large-area networks of pressure and thermal sensors with organic transistor active matrixes. Proc. Natl. Acad. Sci. USA 2005, 102, 12321–12325. [Google Scholar] [CrossRef]

- Hammock, M.L.; Chortos, A.; Tee, C.K.; Tok, B.H.; Bao, Z. 25th anniversary article: The evolution of electronic skin (e-skin): A brief history, design considerations, and recent progress. Adv. Mater. 2013, 25, 5997–6038. [Google Scholar] [CrossRef]

- Wang, X.; Gu, Y.; Xiong, Z.; Cui, Z.; Zhang, T. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv. Mater. 2014, 26, 1336–1342. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Qi, D.; Liu, Z.; Chandran, B.K.; Wang, T.; Yu, J. Soft thermal sensor with mechanical adaptability. Adv. Mater. 2016, 28, 9175–9181. [Google Scholar] [CrossRef]

- Wang, C.; Li, X.; Gao, E.; Jian, M.; Xia, K.; Wang, Q. Wearable strain sensors: Carbonized silk fabric for ultrastretchable, highly sensitive, and wearable strain sensors. Adv. Mater. 2016, 28, 6640–6648. [Google Scholar] [CrossRef]

- Pang, C.; Lee, G.Y.; Kim, T.I.; Kim, S.M.; Kim, H.N.; Ahn, S.H. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater. 2012, 11, 795–801. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef]

- Boland, C.S.; Khan, U.; Ryan, G.; Barwich, S.; Charifou, R.; Harvey, A. Sensitive electromechanical sensors using viscoelastic graphene-polymer nanocomposites. Science 2016, 354, 1257–1260. [Google Scholar] [CrossRef] [PubMed]

- Park, J.J.; Hyun, W.J.; Mun, S.C.; Park, Y.T.; Park, O.O. Highly stretchable and wearable graphene strain sensors with controllable sensitivity for human motion monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M. Wearable and highly sensitive graphene strain sensors for human motion monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, T.; Lao, J.; Zhang, R.; Zhang, Y. Ultra-sensitive graphene strain sensor for sound signal acquisition and recognition. Nano Res. 2015, 8, 1627–1636. [Google Scholar] [CrossRef]

- Tang, Z.; Jia, S.; Shi, S.; Wang, F.; Bo, L. Coaxial carbon nanotube/polymer fibers as wearable piezoresistive sensors. Sens. Actuators A Phys. 2018, 284, 85–95. [Google Scholar] [CrossRef]

- Kang, I.; Schulz, M.J.; Kim, J.H.; Shanov, V.; Shi, D. A carbon nanotube strain sensor for structural health monitoring. Smart Mater. Struct. 2006, 15, 737–748. [Google Scholar] [CrossRef]

- Tang, Z.H.; Jia, S.H.; Shi, X.S.; Li, B.; Zhou, C.H. Coaxial Printing of Silicone Elastomer Composite Fibers for Stretchable and Wearable Piezoresistive Sensors. Polymers 2019, 4, 666. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire–elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.Y.; Zhao, S.F.; Zhang, Z.; Zhang, R.L.; Li, J.H.; Leng, J.F.; Cao, D.X.; Zhang, G.P.; Sun, R. Nacre-inspired highly stretchable piezoresistive Cu-Ag nanowire/graphene synergistic conductive networks for strain sensors and beyond. J. Mater. Chem. C 2019, 7, 7061–7072. [Google Scholar] [CrossRef]

- Ren, W.C.; Ma, W.; Jin, X.; Zhang, S.F.; Tang, B.T. Polysulfide Trapping in Carbon Nanofiber Cloth/S Cathode with a Bifunctional Separator for High-Performance Li-S Batteries. ChemSusChem 2019, 12, 2447–2456. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Liu, X.; Jiang, N.; Yetisen, A.K.; Yuk, H.; Yang, C. Highly stretchable, strain sensing hydrogel optical fibers. Adv. Mater. 2016, 28, 10244–10249. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Mengxuan, N.; Changxi, Y. Highly flexible and stretchable optical strain sensing for human motion detection. Optica 2017, 4, 1285–1289. [Google Scholar] [CrossRef]

- Ju, Y.; Zhang, W.; Yang, C.; Zhang, S.L.; Ding, X.; Wang, S.T.; Zhou, H.; Feng, G.Y.; Zhou, S.H. Displacement and acoustic vibration sensor based on gold nanobipyramids doped PDMS micro-fiber. Opt. Express 2018, 26, 31889–31897. [Google Scholar] [CrossRef]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T. Fine structure constant defines visual transparency of graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef]

- Gray, G.T.; Maudlin, P.J.; Hull, L.M.; Zuo, Q.K.; Chen, S.R. Predicting material strength, damage, and fracture the synergy between experiment and modeling. J. Fail. Anal. Prev. 2005, 5, 7–17. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Sheng, B.; Peng, L.; Huang, Y.; Ni, Z. Flexible and Optical Fiber Sensors Composited by Graphene and PDMS for Motion Detection. Polymers 2019, 11, 1433. https://doi.org/10.3390/polym11091433

Wang D, Sheng B, Peng L, Huang Y, Ni Z. Flexible and Optical Fiber Sensors Composited by Graphene and PDMS for Motion Detection. Polymers. 2019; 11(9):1433. https://doi.org/10.3390/polym11091433

Chicago/Turabian StyleWang, Dong, Bin Sheng, Lina Peng, Yuanshen Huang, and Zhengji Ni. 2019. "Flexible and Optical Fiber Sensors Composited by Graphene and PDMS for Motion Detection" Polymers 11, no. 9: 1433. https://doi.org/10.3390/polym11091433

APA StyleWang, D., Sheng, B., Peng, L., Huang, Y., & Ni, Z. (2019). Flexible and Optical Fiber Sensors Composited by Graphene and PDMS for Motion Detection. Polymers, 11(9), 1433. https://doi.org/10.3390/polym11091433